['Air Programs']

['Air Emissions']

10/12/2023

...

Authority:

42 U.S.C. 7414, 7521, 7522-7525, 7541, 7542, 7543, 7545, 7547, 7550, and 7601.

Subpart A - General Provisions

§1090.1 Applicability and relationship to other parts.

(a) This part specifies fuel quality standards for gasoline and diesel fuel introduced into commerce in the United States. Additional requirements apply for fuel used in certain marine applications, as specified in paragraph (b) of this section.

(1) The regulations include standards for fuel parameters that directly or indirectly affect vehicle, engine, and equipment emissions, air quality, and public health. The regulations also include standards and requirements for fuel additives and regulated blendstocks that are components of the fuels regulated under this part.

(2) This part also specifies requirements for any person that engages in activities associated with the production, distribution, storage, and sale of fuels, fuel additives, and regulated blendstocks, such as collecting and testing samples for regulated parameters, reporting information to EPA to demonstrate compliance with fuel quality requirements, and performing other compliance measures to implement the standards. A party that produces and distributes other related products, such as heating oil, may need to meet certain reporting, recordkeeping, labeling, or other requirements of this part.

(b)(1) The International Convention for the Prevention of Pollution from Ships, 1973 as modified by the Protocol of 1978 Annex VI (“MARPOL Annex VI”) is an international treaty that sets maximum sulfur content for fuel used in marine vessels, including separate standards for marine vessels navigating in a designated Emission Control Area (ECA). These standards and related requirements are specified in 40 CFR part 1043. This part also sets corresponding sulfur standards that apply to any person who produces or handles ECA marine fuel.

(2) This part also includes requirements for parties involved in the production and distribution of IMO marine fuel, such as collecting and testing samples of fuels for regulated parameters, reporting information to EPA to demonstrate compliance with fuel quality requirements, and performing other compliance measures to implement the standards.

(c) The requirements for the registration of fuel and fuel additives under 42 U.S.C. 7545(a), (b), and (e) are specified in 40 CFR part 79. A party that must meet the requirements of this part may also need to comply with the requirements for the registration of fuel and fuel additives under 40 CFR part 79.

(d) The requirements for the Renewable Fuel Standard (RFS) are specified in 40 CFR part 80, subpart M. A party that must meet the requirements of this part may also need to comply with the requirements for the RFS program under 40 CFR part 80, subpart M.

(e) Nothing in this part is intended to preempt the ability of state or local governments to control or prohibit any fuel or fuel additive for use in motor vehicles and motor vehicle engines that is not explicitly regulated by this part.

[85 FR 78469, Dec. 4, 2020]

§1090.5 Implementation dates.

(a) The provisions of this part apply beginning January 1, 2021, unless otherwise specified.

(b) The following provisions of 40 CFR part 80 are applicable after December 31, 2020:

(1) Gasoline sulfur and benzene credit balances and deficits from the 2020 compliance period carry forward for demonstrating compliance with requirements of this part. Any restrictions that apply to credits and deficits under 40 CFR part 80, such as a maximum credit life of 5 years, continue to apply under this part.

(2) Unless otherwise specified (e.g., in-line blending waivers for gasoline as specified in paragraph (b)(8) of this section), any approval granted under 40 CFR part 80 continues to be in effect under this part. For example, if EPA approved the use of an alternative label under 40 CFR part 80, that approval continues to be valid under this part, subject to any conditions specified for the approval.

(3) Unless otherwise specified, a regulated party must use the provisions of 40 CFR part 80 in 2021 to demonstrate compliance with regulatory requirements for the 2020 calendar year. This applies to calculating credits for the 2020 compliance period, and to any sampling, testing, reporting, and auditing related to fuels, fuel additives, and regulated blendstocks produced or imported in 2020.

(4) Any testing to establish the precision and accuracy of alternative test procedures under 40 CFR part 80 continues to be valid under this part.

(5) Requirements to keep records and retain fuel samples related to actions taken before January 1, 2021, continue to be in effect, as specified in 40 CFR part 80.

(6) A party may comply with the PTD requirements of 40 CFR part 80 instead of the requirements of subpart L of this part until May 1, 2021.

(7) A party may comply with the automatic sampling provisions of 40 CFR 80.8 instead of the requirements in §1090.1335(c) until January 1, 2022.

(8) A gasoline manufacturer may operate under an in-line blending waiver issued under 40 CFR part 80 until January 1, 2022, or until EPA approves a revised in-line blending waiver under §1090.1315, whichever is earlier. The following provisions apply:

(i) A gasoline manufacturer operating under an in-line blending waiver under 40 CFR 80.65 must monitor and test for sulfur content, benzene content, and for summer gasoline, RVP, and may discontinue monitoring and testing for other properties that are included in their in-line blending waiver.

(ii) The auditing requirements in §1090.1850 do not apply to an in-line blending waiver issued under 40 CFR part 80.

(c) The following requirements apply for the 2021 compliance period:

(1) The NSTOP specified in §1090.1450 must begin no later than June 1, 2021.

(2) A gasoline manufacturer that accounts for oxygenate added downstream under §1090.710 is deemed compliant with the requirement to participate in the NSTOP specified in §1090.710(a)(3) until June 1, 2021, if the gasoline manufacturer meets all other applicable requirements specified in §1090.710.

(3) The independent surveyor conducting the NSTOP must submit the proof of contract required under §1090.1400(b) no later than April 15, 2021.

(4) The independent surveyor may collect only one summer or winter gasoline sample for each participating fuel manufacturing facility instead of the minimum two samples required under §1090.1450(c)(2)(i).

[85 FR 78469, Dec. 4, 2020]

§1090.10 Contacting EPA.

A party must submit all reports, registrations, and documents for approval required under this part electronically to EPA using forms and procedures specified by EPA via the following website: https://www.epa.gov/fuels-registration-reporting-and-compliance-help.

[85 FR 78469, Dec. 4, 2020]

§1090.15 Confidential business information.

(a) Except as specified in paragraphs (b through (d) of this section, any information submitted under this part claimed as confidential remains subject to evaluation by EPA under 40 CFR part 2, subpart B.

(b) The following information contained in submissions under this part is not entitled to confidential treatment under 40 CFR part 2, subpart B or 5 U.S.C. 552(b)(4):

(1) Submitter's name.

(2) The name and location of the facility, if applicable.

(3) The general nature of a request.

(4) The relevant time period for a request, if applicable.

(c) The following information incorporated into EPA determinations on submissions under this part is not entitled to confidential treatment under 40 CFR part 2, subpart B or 5 U.S.C. 552(b)(4):

(1) Submitter's name.

(2) The name and location of the facility, if applicable.

(3) The general nature of a request.

(4) The relevant time period for a request, if applicable.

(5) The extent to which EPA either granted or denied the request and any relevant terms and conditions.

(d)(1) The following information contained in any enforcement action taken under this part is not entitled to confidential treatment under 40 CFR part 2, subpart B:

(i) The company's name.

(ii) The facility's name.

(iii) Any EPA-issued company and facility identification numbers.

(iv) The time or time period when any violation occurred.

(v) The quantity of fuel, fuel additive, or regulated blendstock affected by the violation.

(vi) Information relating to the exceedance of the fuel standard associated with the violation.

(vii) Information relating to the generation, transfer, or use of credits associated with the violation.

(viii) Any other information relevant to describing the violation.

(2) Enforcement actions within the scope of paragraph (d)(1) of this section include notices of violation, settlement agreements, administrative complaints, civil complaints, criminal information, and criminal indictments.

(e) EPA may disclose the information specified in paragraphs (b through (d) of this section on its website, or otherwise make it available to interested parties, without additional notice, notwithstanding any claims that the information is entitled to confidential treatment under 40 CFR part 2, subpart B and 5 U.S.C. 552(b)(4).

[85 FR 78469, Dec. 4, 2020; 87 FR 39677, July 1, 2022]

§1090.20 Approval of submissions under this part.

(a) EPA may approve any submission required or allowed under this part if the request for approval satisfies all specified requirements.

(b) EPA may impose terms and conditions on any approval of any submission required or allowed under this part.

(c) EPA will deny any request for approval if the submission is incomplete, contains inaccurate or misleading information, or does not meet all specified requirements.

(d) EPA may revoke any prior approval under this part for cause. For cause includes, but is not limited to, any of the following:

(1) The approval has proved inadequate in practice.

(2) The party fails to notify EPA if information that the approval was based on substantively changed after the approval was granted.

(e) EPA may also revoke and void any approval under this part effective from the approval date for cause. Cause for voiding an approval includes, but is not limited to, any of the following:

(1) The approval was not fully or diligently implemented.

(2) The approval was based on false, misleading, or inaccurate information.

(3) Failure of a party to fulfill or cause to be fulfilled any term or condition of an approval under this part.

(f) Any person that has an approval revoked or voided under this part is liable for any resulting violation of the requirements of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.50 Rounding.

(a) Unless otherwise specified, round values to the number of significant digits necessary to match the number of decimal places of the applicable standard or specification. Perform all rounding as specified in 40 CFR 1065.20(e)(1) through (6). This convention is consistent with ASTM E29 and NIST SP 811.

(b) Do not round intermediate values to transfer data unless the rounded number has at least 6 significant digits.

(c) When calculating a specified percentage of a given value, the specified percentage is understood to have infinite precision. For example, if an allowable limit is specified as a fuel volume representing 1 percent of total volume produced, calculate the allowable volume by multiplying total volume by exactly 0.01.

(d) Measurement devices that incorporate internal rounding may be used, consistent with the following provisions:

(1) Devices may use any rounding convention if they report 6 or more significant digits.

(2) Devices that report fewer than 6 significant digits may be used, consistent with the accuracy and repeatability specifications of the procedures specified in subpart N of this part.

(e) Use one of the following rounding conventions for all batch volumes in a given compliance period, and for all reporting under this part:

(1) Identify batch volume in gallons to the nearest whole gallon.

(2)(i) Round batch volumes between 1,000 and 11,000 gallons to the nearest 10 gallons.

(ii) Round batch volumes above 11,000 gallons to the nearest 100 gallons.

[85 FR 78469, Dec. 4, 2020]

§1090.55 Requirements for independent parties.

This section specifies how a third party demonstrates their independence from the regulated party that hires them and their technical ability to perform the specified services.

(a) Independence. The independent third party, their contractors, subcontractors, and their organizations must be independent of the regulated party. All the criteria listed in paragraphs (a)(1) and (2) of this section must be met by each person involved in the specified activities in this part that the independent third party is hired to perform for a regulated party, except that an internal auditor may instead meet the requirements in §1090.1800(b)(1)(i).

(1) Employment criteria. No person employed by an independent third party, including contractor and subcontractor personnel, who is involved in a specified activity performed by the independent third party under the provisions of this part, may be employed, currently or previously, by the regulated party for any duration within the 12 months preceding the date when the regulated party hired the independent third party to provide services under this part.

(2) Financial criteria. (i) The third-party's personnel, the third-party's organization, or any organization or individual that may be contracted or subcontracted by the third party must meet all the following requirements:

(A) Have received no more than one-quarter of their revenue from the regulated party during the year prior to the date of hire of the third party by the regulated party for any purpose.

(B) Have no interest in the regulated party's business. Income received from the third party to perform specified activities under this part is excepted.

(C) Not receive compensation for any specified activity in this part that is dependent on the outcome of the specified activity.

(ii) The regulated party must be free from any interest in the third-party's business.

(b) Technical ability. The third party must meet all the following requirements in order to demonstrate their technical capability to perform specified activities under this part:

(1) An independent surveyor that conducts a survey under subpart O of this part must have personnel familiar with petroleum marketing, the sampling and testing of gasoline and diesel fuel at retail stations, and the designing of surveys to estimate compliance rates for fuel parameters nationwide. The independent surveyor must demonstrate this technical ability in plans submitted under subpart O of this part.

(2) A laboratory attempting to qualify alternative procedures must contract with an independent third party to verify the accuracy and precision of measured values as specified in §1090.1365. The independent third party must demonstrate work experience and a good working knowledge of the VCSB methods specified in §§1090.1365 and 1090.1370, with training and expertise corresponding to a bachelor's degree in chemical engineering, or combined bachelor's degrees in chemistry and statistics.

(3) Any person auditing in-line blending operations must demonstrate work experience and be proficient in the VCSB methods specified in §§1090.1365 and 1090.1370.

(c) Suspension and disbarment. Any person suspended or disbarred under 2 CFR part 1532 or 48 CFR part 9, subpart 9.4, is not qualified to perform review functions under this part.

[85 FR 78469, Dec. 4, 2020; 88 FR 44593, July 12, 2023]

§1090.80 Definitions.

500 ppm LM diesel fuel means diesel fuel subject to the alternative sulfur standards in §1090.320 that is produced by a transmix processor under §1090.515.

Additization means the addition of detergent to gasoline to create detergent-additized gasoline.

Aggregated import facility means all import facilities within a PADD owned or operated by an importer and treated as a single fuel manufacturing facility in order to comply with the maximum benzene average standards under §1090.210(b).

Anhydrous ethanol means ethanol that contains no more than 1.0 volume percent water.

Auditor means any person that conducts audits under subpart S of this part.

Automated detergent blending facility means any facility (including, but not limited to, a truck or individual storage tank) at which detergents are blended with gasoline by means of an injector system calibrated to automatically deliver a specified amount of detergent.

Average standard means a fuel standard applicable over a compliance period.

Batch means a quantity of fuel, fuel additive, or regulated blendstock that has a homogeneous set of properties. This also includes fuel, fuel additive, or regulated blendstock for which homogeneity testing is not required under §1090.1337(a).

Biodiesel means a diesel fuel composed of mono-alkyl esters made from nonpetroleum feedstocks.

Blender pump means any fuel dispenser where PCG is blended with E85 (made only with PCG and DFE) or DFE to produce gasoline that has an ethanol content greater than that of the PCG. A fuel dispenser that produces gasoline with anything other than PCG and DFE (e.g., natural gas liquids) is a fuel blending facility.

Blending manufacturer means any person who owns, leases, operates, controls, or supervises a fuel blending facility in the United States.

Blendstock means any liquid compound or mixture of compounds (not including fuel or fuel additive) that is used or intended for use as a component of a fuel.

Business day means Monday through Friday, except the legal public holidays specified in 5 U.S.C. 6103 or any other day declared to be a holiday by federal statute or executive order.

Butane means an organic compound with the formula C4H10.

Butane blending facility means a fuel manufacturing facility where butane is blended into PCG.

California diesel means diesel fuel designated by a diesel fuel manufacturer as for use in California.

California gasoline means gasoline designated by a gasoline manufacturer as for use in California.

Carrier means any distributor who transports or stores or causes the transportation or storage of fuel, fuel additive, or regulated blendstock without taking title to or otherwise having any ownership of the fuel, fuel additive, or regulated blendstock, and without altering either the quality or quantity of the fuel, fuel additive, or regulated blendstock.

Category 1 (C1) marine vessel means a vessel that is propelled by an engine(s) that meets the definition of “Category 1” in 40 CFR part 1042.901.

Category 2 (C2) marine vessel means a vessel that is propelled by an engine(s) that meets the definition of “Category 2” in 40 CFR part 1042.901.

Category 3 (C3) marine vessel means a vessel that is propelled by an engine(s) that meets the definition of “Category 3” in 40 CFR part 1042.901.

CBOB means a BOB produced or imported for use outside of an RFG covered area.

Certified butane means butane that is certified to meet the requirements in §1090.250.

Certified butane blender means a blending manufacturer that produces gasoline by blending certified butane into PCG and that uses the provisions of §1090.1320(b) to meet the applicable sampling and testing requirements.

Certified butane producer means a regulated blendstock producer that certifies butane as meeting the requirements in §1090.250.

Certified ethanol denaturant means ethanol denaturant that is certified to meet the requirements in §1090.275.

Certified ethanol denaturant producer means any person that certifies ethanol denaturant as meeting the requirements in §1090.275.

Certified non-transportation 15 ppm distillate fuel or certified NTDF has the meaning given in 40 CFR 80.1401.

Certified pentane means pentane that is certified to meet the requirements in §1090.255.

Certified pentane blender means a blending manufacturer that produces gasoline by blending certified pentane into PCG and that uses the provisions of §1090.1320 to meet the applicable sampling and testing requirements.

Certified pentane producer means a regulated blendstock producer that certifies pentane as meeting the requirements in §1090.255.

Compliance period means the calendar year (January 1 through December 31).

Conventional gasoline (CG) means gasoline that is not certified to meet the requirements for RFG in §1090.220.

Crosscheck program means an arrangement for laboratories to perform measurements from test samples prepared from a single homogeneous fuel batch to establish an accepted reference value for evaluating accuracy of individual laboratories and measurement systems.

Days means calendar days, including weekends and holidays.

Denatured fuel ethanol (DFE) means anhydrous ethanol that contains a denaturant to make it unfit for human consumption, that is produced or imported for use in gasoline, and that meets the standards and requirements in §1090.270.

Detergent means any chemical compound or combination of chemical compounds that is added to gasoline to control deposit formation and meets the requirements in §1090.260. Detergent may be part of a detergent additive package.

Detergent additive package means an additive package containing detergent and may also contain carrier oils and non-detergent-active components such as corrosion inhibitors, antioxidants, metal deactivators, and handling solvents.

Detergent blender means any person who owns, leases, operates, controls, or supervises the blending operation of a detergent blending facility, or imports detergent-additized gasoline.

Detergent blending facility means any facility (including, but not limited to, a truck or individual storage tank) at which detergent is blended with gasoline.

Detergent manufacturer means any person who owns, leases, operates, controls, or supervises a facility that produces detergent. A detergent manufacturer is a fuel additive manufacturer.

Detergent-additized gasoline or detergent gasoline means any gasoline that contains a detergent.

Diesel fuel means any of the following:

(1) Any fuel commonly or commercially known as diesel fuel.

(2) Any fuel (including NP diesel fuel or a fuel blend that contains NP diesel fuel) that is intended or used to power a vehicle or engine that is designed to operate using diesel fuel.

(3) Any fuel that conforms to the specifications of ASTM D975 (incorporated by reference in §1090.95) and is made available for use in a vehicle or engine designed to operate using diesel fuel.

Diesel fuel manufacturer means a fuel manufacturer that owns, leases, operates, controls, or supervises a fuel manufacturing facility where diesel fuel is produced or imported.

Distillate fuel means diesel fuel and other petroleum fuels with a T90 temperature below 700 °F that can be used in vehicles or engines that are designed to operate using diesel fuel. For example, diesel fuel, jet fuel, heating oil, No. 1 fuel (kerosene), No. 4 fuel, DMX, DMA, DMB, and DMC are distillate fuels. These specific fuel grades are identified in ASTM D975 and ISO 8217. Natural gas, LPG, and gasoline are not distillate fuels. T90 temperature is based on the distillation test method specified in §1090.1350.

Distributor means any person who transports, stores, or causes the transportation or storage of fuel, fuel additive, or regulated blendstock at any point between any fuel manufacturing facility, fuel additive manufacturing facility, or regulated blendstock production facility and any retail outlet or WPC facility.

Downstream location means any point in the fuel distribution system other than a fuel manufacturing facility through which the fuel passes after it leaves the fuel manufacturing facility gate at which it was certified (e.g., fuel at facilities of distributors, pipelines, terminals, carriers, retailers, oxygenate blenders, and WPCs).

E0 means gasoline that contains no ethanol. This is also known as neat gasoline.

E10 means gasoline that contains at least 9 and no more than 10 volume percent ethanol.

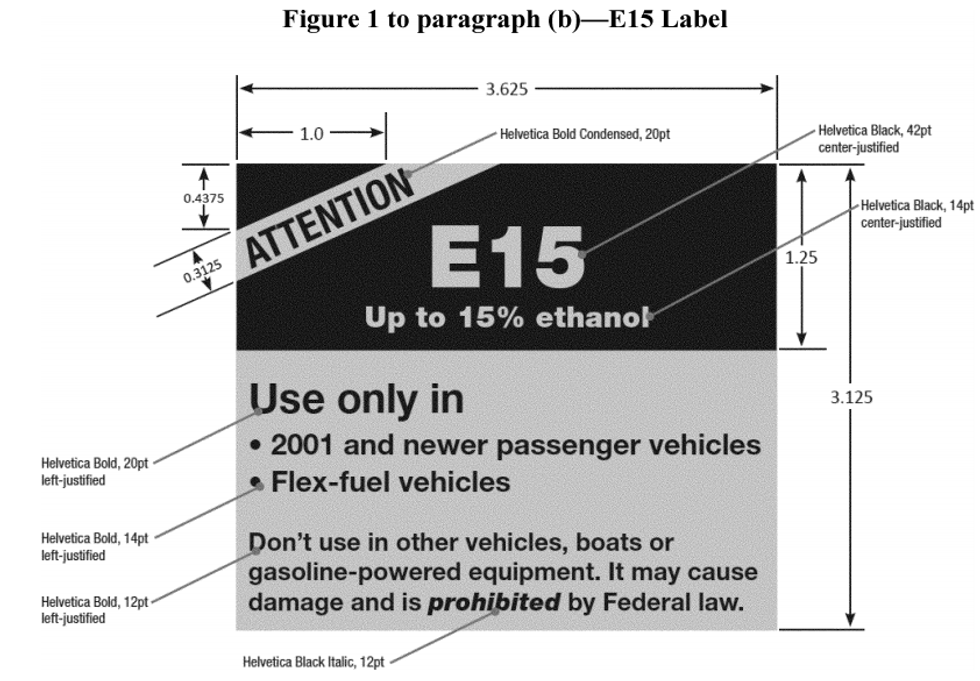

E15 means gasoline that contains more than 10 and no more than 15 volume percent ethanol.

E85 means a fuel that contains more than 50 volume percent but no more than 83 volume percent ethanol and is used, intended for use, or made available for use in flex-fuel vehicles or flex-fuel engines. E85 is not gasoline.

ECA marine fuel means diesel, distillate, or residual fuel used, intended for use, or made available for use in C3 marine vessels while the vessels are operating within an ECA, or an ECA associated area.

Ethanol means an alcohol of the chemical formula C2H5OH.

Ethanol denaturant means PCG, gasoline blendstocks, or natural gas liquids that are added to anhydrous ethanol to make the ethanol unfit for human consumption as required and defined in 27 CFR parts 19 through 21.

Facility means any place, or series of places, where any fuel, fuel additive, or regulated blendstock is produced, imported, blended, transported, distributed, stored, or sold.

Flex-fuel engine has the same meaning as flexible-fuel engine in 40 CFR 1054.801.

Flex-fuel vehicle has the same meaning as flexible-fuel vehicle in 40 CFR 86.1803-01.

Fuel means only the fuels regulated under this part.

Fuel additive means has the same meaning as additive in 40 CFR 79.2(e).

Fuel additive blender means any person who blends fuel additive into fuel in the United States, or any person who owns, leases, operates, controls, or supervises such an operation in the United States.

Fuel additive manufacturer means any person who owns, leases, operates, controls, or supervises a facility where fuel additives are produced or imported into the United States.

Fuel blending facility means any facility, other than a refinery or transmix processing facility, where fuel is produced by combining blendstocks or by combining blendstocks with fuel. Types of blending facilities include, but are not limited to, terminals, storage tanks, plants, tanker trucks, retail outlets, and marine vessels.

Fuel dispenser means any apparatus used to dispense fuel into motor vehicles, nonroad vehicles, engines, equipment, or portable fuel containers (as defined in 40 CFR 59.680).

Fuel manufacturer means any person who owns, leases, operates, controls, or supervises a fuel manufacturing facility. Fuel manufacturers include refiners, importers, blending manufacturers, and transmix processors.

Fuel manufacturing facility means any facility where fuels are produced, imported, or recertified. Fuel manufacturing facilities include refineries, fuel blending facilities, transmix processing facilities, import facilities, and any facility where fuel is recertified.

Fuel manufacturing facility gate means the point where the fuel leaves the fuel manufacturing facility at which the fuel manufacturer certified the fuel.

Gasoline means any of the following:

(1) Any fuel commonly or commercially known as gasoline, including BOB.

(2) Any fuel intended or used to power a vehicle or engine designed to operate on gasoline.

(3) Any fuel that conforms to the specifications of ASTM D4814 (incorporated by reference in §1090.95) and is made available for use in a vehicle or engine designed to operate on gasoline.

Gasoline before oxygenate blending (BOB) means gasoline for which a gasoline manufacturer has accounted for oxygenate added downstream under §1090.710. BOB is subject to all requirements and standards that apply to gasoline, unless subject to a specific alternative standard or requirement under this part.

Gasoline manufacturer means a fuel manufacturer that owns, leases, operates, controls, or supervises a fuel manufacturing facility where gasoline is produced, imported, or recertified.

Gasoline regulated blendstock means a regulated blendstock that is used or intended for use as a component of gasoline.

Gasoline treated as blendstock (GTAB) means a gasoline regulated blendstock that is imported and used to produce gasoline as specified in §1090.1615.

Global marine fuel means diesel fuel, distillate fuel, or residual fuel used, intended for use, or made available for use in steamships or Category 3 marine vessels while the vessels are operating in international waters or in any waters outside the boundaries of an ECA. Global marine fuel is subject to the provisions of MARPOL Annex VI. (Note: This part regulates global marine fuel only if it qualifies as a distillate fuel.)

Heating oil means a combustible product that is used, intended for use, or made available for use in furnaces, boilers, or similar applications. Kerosene and jet fuel are not heating oil.

IMO marine fuel means fuel that is ECA marine fuel or global marine fuel.

Importer means any person who imports fuel, fuel additive, or regulated blendstock into the United States.

Import facility means any facility where an importer imports fuel, fuel additive, or regulated blendstock.

Independent surveyor means any person who meets the independence requirements in §1090.55 and conducts a survey under subpart O of this part.

Intake valve deposits (IVD) means the deposits formed on the intake valve(s) of a gasoline-fueled engine during operation.

Jet fuel means any distillate fuel used, intended for use, or made available for use in aircraft.

Kerosene means any No. 1 distillate fuel that is used, intended for use, or made available for use as kerosene.

Liquefied petroleum gas (LPG) means a liquid hydrocarbon fuel that is stored under pressure and is composed primarily of compounds that are gases at atmospheric conditions (temperature = 25 °C and pressure = 1 atm), excluding natural gas.

Locomotive engine means an engine used in a locomotive as defined in 40 CFR 92.2.

Marine engine has the meaning given under 40 CFR 1042.901.

Methanol means any fuel sold for use in motor vehicles and engines and commonly known or commercially sold as methanol or MXX, where XX represents the percent methanol (CH3OH) by volume.

Natural gas means a fuel that is primarily composed of methane.

Natural gas liquids (NGLs) means natural gasoline or other mixtures of hydrocarbons (primarily but not limited to propane, butane, pentane, hexane, and heptane) that are separated from the gaseous state of natural gas in the form of liquids at a facility, such as a natural gas production facility, gas processing plant, natural gas pipeline, refinery, or similar facility.

Non-automated detergent blending facility means any facility (including a truck or individual storage tank) at which detergent additive is blended using a hand blending technique or any other non-automated method.

Nonpetroleum (NP) diesel fuel means renewable diesel fuel or biodiesel. NP diesel fuel also includes other renewable fuel under 40 CFR part 80, subpart M, that is used or intended for use to power a vehicle or engine that is designed to operate using diesel fuel or that is made available for use in a vehicle or engine designed to operate using diesel fuel.

Oxygenate means a liquid compound that consists of one or more oxygenated compounds. Examples include DFE and isobutanol.

Oxygenate blender means any person who adds oxygenate to gasoline in the United States, or any person who owns, leases, operates, controls, or supervises such an operation in the United States.

Oxygenate blending facility means any facility (including but not limited to a truck) at which oxygenate is added to gasoline (including BOB), and at which the quality or quantity of gasoline is not altered in any other manner except for the addition of deposit control additives.

Oxygenate import facility means any facility where oxygenate, including DFE, is imported into the United States.

Oxygenate producer means any person who produces or imports oxygenate for gasoline in the United States, or any person who owns, leases, operates, controls, or supervises an oxygenate production or import facility in the United States.

Oxygenate production facility means any facility where oxygenate is produced, including DFE.

Oxygenated compound means an oxygen-containing, ashless organic compound, such as an alcohol or ether, which may be used as a fuel or fuel additive.

PADD means Petroleum Administration for Defense District. These districts are the same as the PADDs used by other federal agencies, except for the addition of PADDs VI and VII. The individual PADDs are identified by region, state, and territory as follows:

| PADD | Regional description | State or territory |

|---|---|---|

| I | East Coast | Connecticut, Delaware, District of Columbia, Florida, Georgia, Maine, Maryland, Massachusetts, New Hampshire, New Jersey, New York, North Carolina, Pennsylvania, Rhode Island, South Carolina, Vermont, Virginia, West Virginia. |

| II | Midwest | Illinois, Indiana, Iowa, Kansas, Kentucky, Michigan, Minnesota, Missouri, Nebraska, North Dakota, Ohio, Oklahoma, South Dakota, Tennessee, Wisconsin |

| III | Gulf Coast | Alabama, Arkansas, Louisiana, Mississippi, New Mexico, Texas. |

| IV | Rocky Mountain | Colorado, Idaho, Montana, Utah, Wyoming. |

| V | West Coast | Alaska, Arizona, California, Hawaii, Nevada, Oregon, Washington. |

| VI | Antilles | Puerto Rico, U.S. Virgin Islands. |

| VII | Pacific Territories | American Samoa, Guam, Northern Mariana Islands. |

Pentane means an organic compound with the formula C5H12.

Pentane blending facility means a fuel manufacturing facility where pentane is blended into PCG.

Per-gallon standard means the maximum or minimum value for any parameter that applies to every volume unit of a specified fuel, fuel additive, or regulated blendstock.

Person has the meaning given in 42 U.S.C. 7602(e).

Pipeline interface means the mixture between different fuels and products that abut each other during shipment by a refined petroleum products pipeline system.

Pipeline operator means any person who owns, leases, operates, controls, or supervises a pipeline that transports fuel, fuel additive, or regulated blendstock in the United States.

Previously certified gasoline (PCG) means CG, RFG, or BOB that has been certified as a batch by a gasoline manufacturer.

Product transfer documents (PTDs) mean documents that reflect the transfer of title or physical custody of fuel, fuel additive, or regulated blendstock (e.g., invoices, receipts, bills of lading, manifests, pipeline tickets) between a transferor and a transferee.

RBOB means a BOB produced or imported for use in an RFG covered area.

Refiner means any person who owns, leases, operates, controls, or supervises a refinery in the United States.

Refinery means a facility where fuels are produced from feedstocks, including crude oil or renewable feedstocks, through physical or chemical processing equipment.

Reformulated gasoline (RFG) means gasoline that is certified under §1090.1000(b) and that meets each of the standards and requirements in §1090.220.

Regulated blendstock means certified butane, certified pentane, TGP, TDP, and GTAB.

Regulated blendstock producer means any person who owns, leases, operates, controls, or supervises a facility where regulated blendstocks are produced or imported.

Renewable diesel fuel means diesel fuel that is made from renewable (nonpetroleum) feedstocks and is not a mono-alkyl ester.

Reseller means any person who purchases fuel identified by the corporate, trade, or brand name of a fuel manufacturer from such manufacturer or a distributor and resells or transfers it to a retailer or WPC, and whose assets or facilities are not substantially owned, leased, or controlled by such manufacturer.

Residual fuel means a petroleum fuel with a T90 temperature at or above 700 °F. For example, No. 5 fuels and No. 6 fuels are residual fuels. Residual fuel grades are specified in ASTM D396 and ISO 8217. T90 temperature is based on the distillation test method specified in §1090.1350.

Responsible corporate officer (RCO) means a person who is authorized by the regulated party to make representations on behalf of, or obligate the company as ultimately responsible for, any activity regulated under this part (e.g., refining, importing, blending). An example is an officer of a corporation under the laws of incorporation of the state in which the company is incorporated. Examples of positions in non-corporate business structures that qualify are owner, chief executive officer, president, or operations manager.

Retail outlet means any establishment at which fuel is sold or offered for sale for use in motor vehicles, nonroad engines, nonroad vehicles, or nonroad equipment, including locomotive or marine engines.

Retailer means any person who owns, leases, operates, controls, or supervises a retail outlet.

RFG covered area means the geographic areas specified in §1090.285 in which only RFG may be sold or dispensed to ultimate consumers.

RFG opt-in area means an area that becomes a covered area under 42 U.S.C. 7545(k)(6) as listed in §1090.285.

Round (rounded, rounding) has the meaning given in §1090.50.

Sampling strata means the three types of areas sampled during a survey, which include the following:

(1) Densely populated areas.

(2) Transportation corridors.

(3) Rural areas.

State Implementation Plan (SIP) means a plan approved or promulgated under 42 U.S.C. 7410 or 7502.

Summer gasoline means gasoline that is subject to the RVP standards in §1090.215.

Summer season or high ozone season means the period from June 1 through September 15 for retailers and WPCs, and May 1 through September 15 for all other persons, or an RVP control period specified in a SIP if it is longer.

Tank truck means a truck used for transporting fuel, fuel additive, or regulated blendstock.

Transmix means any of the following mixtures of fuels, which no longer meet the specifications for a fuel that can be used or sold as a fuel without further processing:

(1) Pipeline interface that is not cut into the adjacent products.

(2) Mixtures produced by unintentionally combining gasoline and distillate fuels.

(3) Mixtures of gasoline and distillate fuel produced from normal business operations at terminals or pipelines, such as gasoline or distillate fuel drained from a tank or drained from piping or hoses used to transfer gasoline or distillate fuel to tanks or trucks, or gasoline or distillate fuel discharged from a safety relief valve that are segregated for further processing.

Transmix blender means any person who owns, leases, operates, controls, or supervises a transmix blending facility.

Transmix blending facility means any facility that produces gasoline by blending transmix into PCG under §1090.500.

Transmix distillate product (TDP) means the diesel fuel blendstock that is produced when transmix is separated into blendstocks at a transmix processing facility.

Transmix gasoline product (TGP) means the gasoline blendstock that is produced when transmix is separated into blendstocks at a transmix processing facility.

Transmix processing facility means any facility that produces TGP or TDP from transmix by distillation or other refining processes, but does not produce gasoline or diesel fuel by processing crude oil or other products.

Transmix processor means any person who owns, leases, operates, controls, or supervises a transmix processing facility. A transmix processor is a fuel manufacturer.

Ultra low-sulfur diesel (ULSD) means diesel fuel that is certified to meet the standards in §1090.305.

United States means the 50 states, the District of Columbia, the Commonwealth of Puerto Rico, the Commonwealth of the Northern Mariana Islands, Guam, American Samoa, and the U.S. Virgin Islands.

Volume Additive Reconciliation (VAR) Period means the following:

(1) For an automated detergent blending facility, the VAR period is a time period lasting no more than 31 days or until an adjustment to a detergent concentration rate that increases the initial rate by more than 10 percent, whichever occurs first. The concentration setting for a detergent injector may be adjusted by more than 10 percent above the initial rate without terminating the VAR Period, provided the purpose of the change is to correct a batch misadditization prior to the transfer of the batch to another party, or to correct an equipment malfunction and the concentration is immediately returned to no more than 10 percent above the initial rate of concentration after the correction.

(2) For a non-automated detergent blending facility, the VAR Period constitutes the blending of one batch of gasoline.

Voluntary consensus standards body (VCSB) means an organization that follows consistent protocols to adopt standards reflecting a wide range of input from interested parties. ASTM International and the International Organization for Standardization are examples of VCSB organizations.

Wholesale purchaser-consumer (WPC) means any person that is an ultimate consumer of fuels and who purchases or obtains fuels for use in motor vehicles, nonroad vehicles, nonroad engines, or nonroad equipment, including locomotive or marine engines, and, in the case of liquid fuels, receives delivery of that product into a storage tank of at least 550-gallon capacity substantially under the control of that person.

Winter gasoline means gasoline that is not subject to the RVP standards in §1090.215.

Winter season means any duration outside of the summer season or high ozone season.

[85 FR 78469, Dec. 4, 202; 88 FR 44593, July 12, 20230]

§1090.85 Explanatory terms.

This section explains how certain phrases and terms are used in this part, especially those used to clarify and explain regulatory provisions. They do not, however, constitute specific regulatory requirements and as such do not impose any compliance obligation on regulated parties.

(a) Types of provisions. The term “provision” includes all aspects of the regulations in this part. As specified in this section, regulatory provisions include standards, requirements, and prohibitions, along with a variety of other types of provisions.

(1) A standard is a limit on the formulation, components, or characteristics of any fuel, fuel additive, or regulated blendstock, established by regulation under this part. Compliance with or conformance to a standard is a specific type of requirement. Thus, a statement about the requirements of a part or section also applies with respect to the standards in the part or section. Examples of standards include the sulfur per-gallon standards for gasoline and diesel fuel.

(2) While requirements state what someone must do, prohibitions state what someone must not do. Failing to meet any requirement that applies to a person under this part is a prohibited act.

(3) The regulations in this part include provisions that are not standards, requirements, or prohibitions, such as definitions.

(b) Subject to. A fuel is considered “subject to” a specific provision if that provision applies, even if it falls within an exemption authorized under a different part of this regulation. For example, gasoline is subject to the provisions of this part even if it is exempt from the standards under subpart G of this part.

(c) Singular and plural. Unless stated otherwise or unless it is clear from the regulatory context, provisions written in singular form include the plural form and provisions written in plural form include the singular form.

(d) Inclusive lists. Lists in the regulations in this part prefaced by “including” or “this includes” are not exhaustive. The terms “including” and “this includes” should be read to mean “including but not limited to” and “this includes but is not limited to.”

(e) Notes. Statements that begin with “Note:” or “Note that” are intended to clarify specific regulatory provisions stated elsewhere in the regulations in this part. By themselves, such statements are not intended to specify regulatory requirements.

(f) Examples. Examples provided in the regulations in this part are typically introduced by either “for example” or “such as.” Specific examples given in the regulations do not necessarily represent the most common examples. The regulations may specify examples conditionally (that is, specifying that they are applicable only if certain criteria or conditions are met). Lists of examples are not exhaustive.

[85 FR 78469, Dec. 4, 2020]

§1090.90 Acronyms and abbreviations.

| 500 ppm LM diesel fuel | As defined in §1090.80. |

| ABT | averaging, banking, and trading. |

| ARV | accepted reference value. |

| BOB | gasoline before oxygenate blending. |

| CARB | California Air Resources Board. |

| CFR | Code of Federal Regulations. |

| CG | conventional gasoline. |

| DFE | denatured fuel ethanol. |

| E0 | As defined in §1090.80. |

| E10 | As defined in §1090.80. |

| E15 | As defined in §1090.80. |

| ECA marine fuel | As defined in §1090.80. |

| EPA | Environmental Protection Agency. |

| GTAB | gasoline treated as blendstock. |

| IMO marine fuel | As defined in §1090.80. |

| LAC | lowest additive concentration. |

| LLOQ | laboratory limit of quantitation. |

| MARPOL Annex VI | The International Convention for the Prevention of Pollution from Ships, 1973 as modified by the Protocol of 1978 Annex VI. |

| NAAQS | National Ambient Air Quality Standard. |

| NARA | National Archives and Records Administration. |

| NFSP | national fuels survey program. |

| NGL | natural gas liquids. |

| NIST | National Institute for Standards and Technology. |

| NSTOP | national sampling and testing oversight program. |

| PCG | previously certified gasoline. |

| PLOQ | published limit of quantitation. |

| ppm (mg/kg) | parts per million (or milligram per kilogram). |

| PTD | product transfer document. |

| R&D | research and development. |

| RCO | responsible corporate officer. |

| RFG | reformulated gasoline. |

| RFS | Renewable Fuel Standard. |

| RVP | Reid vapor pressure. |

| SIP | state implementation plan. |

| SQC | statistical quality control. |

| T10, T50, T90 | temperatures representing the points in a distillation process where 10, 50, and 90 percent of the sample evaporates, respectively. |

| TDP | transmix distillate product. |

| TGP | transmix gasoline product. |

| U.S | United States. |

| U.S.C | United States Code. |

| ULSD | ultra-low-sulfur diesel fuel. |

| VCSB | voluntary consensus standards body. |

[85 FR 78469, Dec. 4, 2020]

§1090.95 Incorporation by reference.

(a) Certain material is incorporated by reference into this part with the approval of the Director of the Federal Register under 5 U.S.C. 552(a) and 1 CFR part 51. All approved material is available for inspection at U.S. EPA, Air and Radiation Docket and Information Center, WJC West Building, Room 3334, 1301 Constitution Ave. NW, Washington, DC 20460, (202) 566-1742, and is also available from the sources listed in this section. This material is also available for inspection at the National Archives and Records Administration (NARA). For information on the availability of this material at NARA, email fedreg.legal@nara.gov, or go to www.archives.gov/federal-register/cfr/ibr-locations.html.

(b) American Institute of Certified Public Accountants, 220 Leigh Farm Rd., Durham, NC 27707-8110, (888) 777-7077, or www.aicpa.org.

(1) AICPA Code of Professional Conduct, updated through June 2020; IBR approved for §1090.1800(b).

(2) Statements on Quality Control Standards (SQCS) No. 8, QC Section 10: A Firm's System of Quality Control, current as of July 1, 2019; IBR approved for §1090.1800(b).

(3) Statement on Standards for Attestation Engagements No. 18, Attestation Standards: Clarification and Recodification, Issued April 2016; IBR approved for §1090.1800(b).

(c) ASTM International, 100 Barr Harbor Dr., P.O. Box C700, West Conshohocken, PA 19428-2959, (877) 909-2786, or www.astm.org.

(1) ASTM D86-20a, Standard Test Method for Distillation of Petroleum Products and Liquid Fuels at Atmospheric Pressure, approved July 1, 2020 (“ASTM D86”); IBR approved for §1090.1350(b).

(2) ASTM D287-12b (Reapproved 2019), Standard Test Method for API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method), approved December 1, 2019 (“ASTM D287”); IBR approved for §1090.1337(d).

(3) ASTM D975-20a, Standard Specification for Diesel Fuel, approved June 1, 2020 (“ASTM D975”); IBR approved for §1090.80.

(4) ASTM D976-06 (Reapproved 2016), Standard Test Method for Calculated Cetane Index of Distillate Fuels, approved April 1, 2016 (“ASTM D976”); IBR approved for §1090.1350(b).

(5) ASTM D1298-12b (Reapproved 2017), Standard Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method, approved July 15, 2017 (“ASTM D1298”); IBR approved for §1090.1337(d).

(6) ASTM D1319-19, Standard Test Method for Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator Adsorption, approved August 1, 2019 (“ASTM D1319”); IBR approved for §1090.1350(b).

(7) ASTM D2163-14 (Reapproved 2019), Standard Test Method for Determination of Hydrocarbons in Liquefied Petroleum (LP) Gases and Propane/Propene Mixtures by Gas Chromatography, approved May 1, 2019 (“ASTM D2163”); IBR approved for §1090.1350(b).

(8) ASTM D2622-16, Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry, approved January 1, 2016 (“ASTM D2622”); IBR approved for §§1090.1350(b), 1090.1360(d), 1090.1365(b), and 1090.1375(c).

(9) ASTM D3120-08 (Reapproved 2019), Standard Test Method for Trace Quantities of Sulfur in Light Liquid Petroleum Hydrocarbons by Oxidative Microcoulometry, approved May 1, 2019 (“ASTM D3120”); IBR approved for §1090.1365(b).

(10) ASTM D3231-18, Standard Test Method for Phosphorus in Gasoline, approved April 1, 2018 (“ASTM D3231”); IBR approved for §1090.1350(b).

(11) ASTM D3237-17, Standard Test Method for Lead in Gasoline by Atomic Absorption Spectroscopy, approved June 1, 2017 (“ASTM D3237”); IBR approved for §1090.1350(b).

(12) ASTM D3606-20e1, Standard Test Method for Determination of Benzene and Toluene in Spark Ignition Fuels by Gas Chromatography, approved July 1, 2020 (“ASTM D3606”); IBR approved for §1090.1360(c).

(13) ASTM D4052-18a, Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter, approved December 15, 2018 (“ASTM D4052”); IBR approved for §1090.1337(d).

(14) ASTM D4057-19, Standard Practice for Manual Sampling of Petroleum and Petroleum Products, approved July 1, 2019 (“ASTM D4057”); IBR approved for §§1090.1335(b) and 1090.1605(b).

(15) ASTM D4177-16e1, Standard Practice for Automatic Sampling of Petroleum and Petroleum Products, approved October 1, 2016 (“ASTM D4177”); IBR approved for §§1090.1315(a) and 1090.1335(c).

(16) ASTM D4737-10 (Reapproved 2016), Standard Test Method for Calculated Cetane Index by Four Variable Equation, approved July 1, 2016 (“ASTM D4737”); IBR approved for §1090.1350(b).

(17) ASTM D4806-20, Standard Specification for Denatured Fuel Ethanol for Blending with Gasolines for Use as Automotive Spark-Ignition Engine Fuel, approved May 1, 2020 (“ASTM D4806”); IBR approved for §1090.1395(a).

(18) ASTM D4814-20a, Standard Specification for Automotive Spark-Ignition Engine Fuel, approved April 1, 2020 (“ASTM D4814”); IBR approved for §§1090.80 and 1090.1395(a).

(19) ASTM D5134-13 (Reapproved 2017), Standard Test Method for Detailed Analysis of Petroleum Naphthas through n-Nonane by Capillary Gas Chromatography, approved October 1, 2017 (“ASTM D5134”); IBR approved for §1090.1350(b).

(20) ASTM D5186-20, Standard Test Method for Determination of the Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels By Supercritical Fluid Chromatography, approved July 1, 2020 (“ASTM D5186”); IBR approved for §1090.1350(b).

(21) ASTM D5191-20, Standard Test Method for Vapor Pressure of Petroleum Products and Liquid Fuels (Mini Method), approved May 1, 2020 (“ASTM D5191”); IBR approved for §§1090.1360(d) and 1090.1365(b).

(22) ASTM D5453-19a, Standard Test Method for Determination of Total Sulfur in Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel Engine Fuel, and Engine Oil by Ultraviolet Fluorescence, approved July 1, 2019 (“ASTM D5453”); IBR approved for §1090.1350(b).

(23) ASTM D5500-20a, Standard Test Method for Vehicle Evaluation of Unleaded Automotive Spark-Ignition Engine Fuel for Intake Deposit Formation, approved June 1, 2020 (“ASTM D5500”); IBR approved for §1090.1395(c).

(24) ASTM D5599-18, Standard Test Method for Determination of Oxygenates in Gasoline by Gas Chromatography and Oxygen Selective Flame Ionization Detection, approved June 1, 2018 (“ASTM D5599”); IBR approved for §§1090.1360(d) and 1090.1365(b).

(25) ASTM D5769-20, Standard Test Method for Determination of Benzene, Toluene, and Total Aromatics in Finished Gasolines by Gas Chromatography/Mass Spectrometry, approved June 1, 2020 (“ASTM D5769”); IBR approved for §§1090.1350(b), 1090.1360(d), and 1090.1365(b).

(26) ASTM D5842-19, Standard Practice for Sampling and Handling of Fuels for Volatility Measurement, approved November 1, 2019 (“ASTM D5842”); IBR approved for §1090.1335(d).

(27) ASTM D5854-19a, Standard Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products, approved May 1, 2019 (“ASTM D5854”); IBR approved for §1090.1315(a).

(28) ASTM D6201-19a, Standard Test Method for Dynamometer Evaluation of Unleaded Spark-Ignition Engine Fuel for Intake Valve Deposit Formation, approved December 1, 2019 (“ASTM D6201”); IBR approved for §1090.1395(a).

(29) ASTM D6259-15 (Reapproved 2019), Standard Practice for Determination of a Pooled Limit of Quantitation for a Test Method, approved May 1, 2019 (“ASTM D6259”); IBR approved for §1090.1355(b).

(30) ASTM D6299-20, Standard Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measurement System Performance, approved May 1, 2020 (“ASTM D6299”); IBR approved for §§1090.1370(c), 1090.1375(a), (b), and (c), and 1090.1450(c).

(31) ASTM D6550-20, Standard Test Method for Determination of Olefin Content of Gasolines by Supercritical-Fluid Chromatography, approved July 1, 2020 (“ASTM D6550”); IBR approved for §1090.1350(b).

(32) ASTM D6667-14 (Reapproved 2019), Standard Test Method for Determination of Total Volatile Sulfur in Gaseous Hydrocarbons and Liquefied Petroleum Gases by Ultraviolet Fluorescence, approved May 1, 2019 (“ASTM D6667”); IBR approved for §§1090.1360(d), 1090.1365(b), and 1090.1375(c).

(33) ASTM D6708-19a, Standard Practice for Statistical Assessment and Improvement of Expected Agreement Between Two Test Methods that Purport to Measure the Same Property of a Material, approved November 1, 2019 (“ASTM D6708”); IBR approved for §§1090.1360(c), 1090.1365(d) and (f), and 1090.1375(c).

(34) ASTM D6729-14, Standard Test Method for Determination of Individual Components in Spark Ignition Engine Fuels by 100 Metre Capillary High Resolution Gas Chromatography, approved October 1, 2014 (“ASTM D6729”); IBR approved for §1090.1350(b).

(35) ASTM D6730-19, Standard Test Method for Determination of Individual Components in Spark Ignition Engine Fuels by 100-Metre Capillary (with Precolumn) High-Resolution Gas Chromatography, approved July 1, 2019 (“ASTM D6730”); IBR approved for §1090.1350(b).

(36) ASTM D6751-20, Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels, approved January 1, 2020 (“ASTM D6751”); IBR approved for §1090.1350(b).

(37) ASTM D6792-17, Standard Practice for Quality Management Systems in Petroleum Products, Liquid Fuels, and Lubricants Testing Laboratories, approved May 1, 2017 (“ASTM D6792”); IBR approved for §1090.1450(c).

(38) ASTM D7039-15a (Reapproved 2020), Standard Test Method for Sulfur in Gasoline, Diesel Fuel, Jet Fuel, Kerosine, Biodiesel, Biodiesel Blends, and Gasoline-Ethanol Blends by Monochromatic Wavelength Dispersive X-ray Fluorescence Spectrometry, approved May 1, 2020 (“ASTM D7039”); IBR approved for §1090.1365(b).

(39) ASTM D7717-11 (Reapproved 2017), Standard Practice for Preparing Volumetric Blends of Denatured Fuel Ethanol and Gasoline Blendstocks for Laboratory Analysis, approved May 1, 2017 (“ASTM D7717”); IBR approved for §1090.1340(b).

(40) ASTM D7777-13 (Reapproved 2018)e1, Standard Test Method for Density, Relative Density, or API Gravity of Liquid Petroleum by Portable Digital Density Meter, approved October 1, 2018 (“ASTM D7777”); IBR approved for §1090.1337(d).

(d) Environmental Protection Agency, Air and Radiation Docket and Information Center, WJC West Building, Room 3334, 1301 Constitution Ave. NW, Washington, DC 20460, (202) 566-1742.

(1) CARB Test Method, 13 CA ADC §2257; California Code of Regulations Title 13. Motor Vehicles, Division 3. Air Resources Board, Chapter 5. Standards for Motor Vehicle Fuels, Article 1. Standards for Gasoline, Subarticle 1. Gasoline Standards that Became Applicable Before 1996, §2257. Required Additives in Gasoline; amendment filed May 17, 1999.

(2) [Reserved]

(e) The Institute of Internal Auditors, 1035 Greenwood Blvd., Suite 401, Lake Mary, FL 32746, (407) 937-1111, or www.theiia.org.

(1) International Standards for the Professional Practice of Internal Auditing (Standards), Revised October 2016; IBR approved for §1090.1800(b).

(2) [Reserved]

(f) National Institute of Standards and Technology, 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, (301) 975-6478, or www.nist.gov.

(1) NIST Handbook 158, Field Sampling Procedures for Fuel and Motor Oil Quality Testing—A Handbook for Use by Fuel and Oil Quality Regulatory Officials, 2016 Edition, April 2016; IBR approved for §1090.1410(b).

(2) [Reserved]

[85 FR 78469, Dec. 4, 2020]

[85 FR 78469, Dec. 4, 2020]

Subpart B - General Requirements and Provisions for Regulated Parties

§1090.100 General provisions.

This subpart provides an overview of the general requirements and provisions applicable to any regulated party under this part. A person who meets the definition of more than one type of regulated party must comply with the requirements applicable to each of those types of regulated parties. For example, a fuel manufacturer that also transports fuel must meet the requirements applicable to a fuel manufacturer and a distributor. A regulated party is required to comply with all applicable requirements of this part, regardless of whether they are identified in this subpart. Any person that produces, sells, transfers, supplies, dispenses, or distributes fuel, fuel additive, or regulated blendstock must comply with all applicable requirements.

(a) Recordkeeping. Any party that engages in activities that are regulated under this part must comply with recordkeeping requirements under subpart M of this part.

(b) Compliance and enforcement. Any party that engages in activities that are regulated under this part is subject to compliance and enforcement provisions under subpart R of this part.

(c) Hardships and exemptions. Some regulated parties under this part may be eligible, or eligible to petition, for a hardship or exemption under subpart G of this part.

(d) In addition to the requirements of paragraphs (a) through (c) of this section and §1090.105, an importer must also comply with subpart Q of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.105 Fuel manufacturers.

This section provides an overview of general requirements applicable to a fuel manufacturer. A gasoline manufacturer must comply with the requirements of paragraph (a) of this section. A diesel fuel or IMO marine fuel manufacturer must comply with the requirements of paragraph (b) of this section.

(a) Gasoline manufacturers. Except as specified otherwise in this subpart, a gasoline manufacturer must comply with the following requirements:

(1) Producing compliant gasoline. A gasoline manufacturer must produce or import gasoline that meets the standards of subpart C of this part and must comply with the ABT requirements in subpart H of this part.

(2) Registration. A gasoline manufacturer must register with EPA under subpart I of this part.

(3) Reporting. A gasoline manufacturer must submit reports to EPA under subpart J of this part.

(4) Certification and designation. A gasoline manufacturer must certify and designate the gasoline they produce under subpart K of this part.

(5) PTDs. On each occasion when a gasoline manufacturer transfers custody of or title to any gasoline, the transferor must provide to the transferee PTDs under subpart L of this part.

(6) Sampling, testing, and sample retention. A gasoline manufacturer must conduct sampling, testing, and sample retention in accordance with subpart N of this part.

(7) Surveys. A gasoline manufacturer may participate in applicable fuel surveys under subpart O of this part.

(8) Annual attest engagement. A gasoline manufacturer must submit annual attest engagement reports to EPA under subpart S of this part.

(b) Diesel fuel and IMO marine fuel manufacturers. A diesel fuel or IMO marine fuel manufacturer must comply with the following requirements, as applicable:

(1) Producing compliant diesel fuel and ECA marine fuel. A diesel fuel or ECA marine fuel manufacturer must produce or import diesel fuel or ECA marine fuel that meets the requirements of subpart D of this part.

(2) Registration. A diesel fuel or ECA marine fuel manufacturer must register with EPA under subpart I of this part.

(3) Reporting. A diesel fuel manufacturer must submit reports to EPA under subpart J of this part.

(4) Certification and designation. A diesel fuel or ECA marine fuel manufacturer must certify and designate the diesel fuel or ECA marine fuel they produce under subpart K of this part. A distillate global marine fuel manufacturer must designate the distillate global marine fuel they produce under subpart K of this part.

(5) PTDs. On each occasion when a diesel fuel or IMO marine fuel manufacturer transfers custody or title to any diesel fuel or IMO marine fuel, the transferor must provide to the transferee PTDs under subpart L of this part.

(6) Sampling, testing, and retention requirements. A diesel fuel or ECA marine fuel manufacturer must conduct sampling, testing, and sample retention in accordance with subpart N of this part.

(7) Surveys. A diesel fuel manufacturer may participate in applicable fuel surveys under subpart O of this part.

(8) Distillate global marine fuel manufacturers. A distillate global marine fuel manufacturer does not need to comply with the requirements of paragraphs (b)(1) through (3), and (6) of this section for global marine fuel that is exempt from the standards in subpart D of this part, as specified in §1090.650.

[85 FR 78469, Dec. 4, 2020]

§1090.110 Detergent blenders.

A detergent blender must comply with the requirements of this section.

(a) Gasoline standards. A detergent blender must comply with the applicable requirements of subpart C of this part.

(b) PTDs. On each occasion when a detergent blender transfers custody of or title to any fuel, fuel additive, or regulated blendstock, the transferor must provide to the transferee PTDs under subpart L of this part.

(c) Recordkeeping. A detergent blender must demonstrate compliance with the requirements in §1090.260(a) as specified in §1090.1240.

(d) Equipment calibration. A detergent blender at an automated detergent blending facility must calibrate their detergent blending equipment in accordance with subpart N of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.115 Oxygenate blenders.

An oxygenate blender must comply with the requirements of this section.

(a) Gasoline standards. An oxygenate blender must comply with the applicable requirements of subpart C of this part.

(b) Registration. An oxygenate blender must register with EPA under subpart I of this part.

(c) PTDs. On each occasion when an oxygenate blender transfers custody or title to any fuel, fuel additive, or regulated blendstock, the transferor must provide to the transferee PTDs under subpart L of this part.

(d) Oxygenate blending requirements. An oxygenate blender must follow the blending instructions specified by the gasoline manufacturer under §1090.710(a)(5) unless the oxygenate blender recertifies BOBs under §1090.740.

[85 FR 78469, Dec. 4, 2020]

§1090.120 Oxygenate producers.

This section provides an overview of general requirements applicable to an oxygenate producer (e.g., a DFE or isobutanol producer). A DFE producer must comply with the requirements for an oxygenate producer in paragraph (a) of this section and the additional requirements specified in paragraph (b) of this section.

(a) Oxygenate producers. An oxygenate producer must comply with the following requirements:

(1) Gasoline standards. An oxygenate producer must comply with the applicable requirements of subpart C of this part.

(2) Registration. An oxygenate producer must register with EPA under subpart I of this part.

(3) Reporting. An oxygenate producer must submit reports to EPA under subpart J of this part.

(4) Certification and designation. An oxygenate producer must certify and designate the oxygenate they produce under subpart K of this part.

(5) PTDs. On each occasion when an oxygenate producer transfers custody or title to any fuel, fuel additive, or regulated blendstock, the transferor must provide to the transferee PTDs under subpart L of this part.

(6) Sampling, testing, and retention requirements. An oxygenate producer must conduct sampling, testing, and sample retention in accordance with subpart N of this part.

(b) DFE producers. In addition to the requirements specified in paragraph (a) of this section, a DFE producer must meet all the following requirements:

(1) Use denaturant that complies with the requirements specified in §§1090.270(b) and 1090.275.

(2) Participate in a survey program conducted by an independent surveyor under subpart O of this part if the DFE producer produces DFE made available for use in the production of E15.

[85 FR 78469, Dec. 4, 2020]

§1090.125 Certified butane producers.

A certified butane producer must comply with the requirements of this section.

(a) Gasoline standards. A certified butane producer must comply with the applicable requirements of subpart C of this part.

(b) Certification and designation. A certified butane producer must certify and designate the certified butane they produce under subpart K of this part.

(c) PTDs. On each occasion when a certified butane producer transfers custody of or title to any certified butane, the transferor must provide to the transferee PTDs under subpart L of this part.

(d) Sampling, testing, and retention requirements. A certified butane producer must conduct sampling, testing, and sample retention in accordance with subpart N of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.130 Certified butane blenders.

A certified butane blender that blends certified butane into PCG is a gasoline manufacturer that may comply with the requirements of this section in lieu of the requirements in §1090.105.

(a) Gasoline standards. A certified butane blender must comply with the applicable requirements of subpart C of this part.

(b) Registration. A certified butane blender must register with EPA under subpart I of this part.

(c) Reporting. A certified butane blender must submit reports to EPA under subpart J of this part.

(d) PTDs. When certified butane is blended with PCG, PTDs that accompany the gasoline blended with certified butane must comply with subpart L of this part.

(e) Sampling and testing requirements. A certified butane blender must comply with the alternative sampling and testing approach in §1090.1320(b).

(f) Survey. A certified butane blender may participate in the applicable fuel surveys of subpart O of this part.

(g) Annual attest engagement. A certified butane blender must submit annual attest engagement reports to EPA under subpart S of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.135 Certified pentane producers.

A certified pentane producer must comply with the requirements of this section.

(a) Gasoline standards. A certified pentane producer must comply with the applicable requirements of subpart C of this part.

(b) Registration. A certified pentane producer must register with EPA under subpart I of this part.

(c) Reporting. A certified pentane producer must submit reports to EPA under subpart J of this part.

(d) Certification and designation. A certified pentane producer must certify and designate the certified pentane they produce under subpart K of this part.

(e) PTDs. On each occasion when a certified pentane producer transfers custody of or title to any certified pentane, the transferor must provide to the transferee PTDs under subpart L of this part.

(f) Sampling, testing, and retention requirements. A certified pentane producer must conduct sampling, testing, and sample retention in accordance with subpart N of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.140 Certified pentane blenders.

A certified pentane blender that blends certified pentane into PCG is a gasoline manufacturer that may comply with the requirements of this section in lieu of the requirements in §1090.105.

(a) Gasoline standards. A certified pentane blender must comply with the applicable requirements of subpart C of this part.

(b) Registration. A certified pentane blender must register with EPA under subpart I of this part.

(c) Reporting. A certified pentane blender must submit reports to EPA under subpart J of this part.

(d) PTDs. When certified pentane is blended with PCG, PTDs that accompany the gasoline blended with pentane must comply with subpart L of this part.

(e) Sampling, testing, and retention requirements. A certified pentane blender must comply with the alternative sampling and testing approach in §1090.1320(b).

(f) Survey. A certified pentane blender may participate in the applicable fuel surveys of subpart O of this part.

(g) Annual attest engagement. A certified pentane blender must submit annual attest engagement reports to EPA under subpart S of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.145 Transmix processors.

A transmix processor must comply with the requirements of this section.

(a) Transmix requirements. A transmix processor must comply with the transmix requirements of subpart F of this part.

(b) Registration. A transmix processor must register with EPA under subpart I of this part.

(c) Certification and designation. A transmix processor must certify and designate the fuel they produce under subpart K of this part.

(d) PTDs. On each occasion when a transmix processor produces a batch of fuel or transfers custody of or title to any fuel, fuel additive, or regulated blendstock, the transferor must provide to the transferee PTDs under subpart L of this part.

(e) Sampling, testing, and retention requirements. A transmix processor must conduct sampling, testing, and sample retention in accordance with subparts F and N of this part.

(f) Reporting. A transmix processor must submit reports to EPA under subpart J of this part.

(g) Annual attest engagement. A transmix processor must submit annual attest engagement reports to EPA under subpart S of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.150 Transmix blenders.

A transmix blender must comply with the requirements of this section.

(a) Transmix requirements. A transmix blender must comply with the transmix requirements of subpart F of this part.

(b) PTDs. On each occasion when a transmix blender produces a batch of fuel or transfers custody or title to any fuel, fuel additive, or regulated blendstock, the transferor must provide to the transferee PTDs under subpart L of this part.

(c) Sampling, testing, and retention requirements. A transmix blender must conduct sampling, testing, and sample retention in accordance with subparts F and N of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.155 Fuel additive manufacturers.

This section provides an overview of general requirements applicable to a fuel additive manufacturer. A gasoline additive manufacturer must comply with the requirements of paragraph (a) of this section. A diesel fuel additive manufacturer must comply with the requirements of paragraph (b) of this section. A certified ethanol denaturant producer must comply with the requirements of paragraph (c) of this section.

(a) Gasoline additive manufacturers. A gasoline additive manufacturer must meet the following requirements:

(1) Gasoline additive standards. A gasoline additive manufacturer must produce gasoline additives that comply with subpart C of this part.

(2) Certification. A gasoline additive manufacturer must certify the gasoline additives they produce under subpart K of this part.

(3) PTDs. On each occasion when a gasoline additive manufacturer transfers custody of or title to any gasoline additive, the transferor must provide to the transferee PTDs under subpart L of this part.

(4) Gasoline detergent manufacturers. A gasoline detergent manufacturer must comply with the following requirements:

(i) Part 79 registration and LAC determination. A gasoline detergent manufacturer must register gasoline detergent(s) under 40 CFR 79.21 at a concentration that is greater than or equal to the LAC reported by the gasoline detergent manufacturer under 40 CFR 79.21(j). Note: EPA provides a list on EPA's website of detergents that have been certified by the gasoline detergent manufacturer as meeting the deposit control requirement (Search for “List of Certified Detergent Additives”).

(ii) Gasoline detergent standards. Report the LAC determined under §1090.260(b) and provide specific composition information as part of the gasoline detergent manufacturer's registration of the detergent under 40 CFR 79.21(j).

(iii) PTDs. On each occasion when a gasoline detergent manufacturer transfers custody of or title to any gasoline detergent, the transferor must provide to the transferee PTDs under subpart L of this part.

(iv) Sampling, testing, and retention requirements. A gasoline detergent manufacturer that registers detergents must conduct sampling, testing, and sample retention in accordance with subpart N of this part.

(b) Diesel fuel additive manufacturers. A diesel fuel additive manufacturer must meet the following requirements:

(1) Diesel fuel additive standards. A diesel fuel additive manufacturer must produce diesel fuel additives that comply with subpart D of this part.

(2) Certification. A diesel fuel additive manufacturer must certify the diesel fuel additives they produce under subpart K of this part.

(3) PTDs. On each occasion when a diesel fuel additive manufacturer transfers custody of or title to any diesel additive, the transferor must provide to the transferee PTDs under subpart L of this part.

(c) Certified ethanol denaturant producers and importers. A certified ethanol denaturant producer or importer must meet the following requirements:

(1) Certification. A certified ethanol denaturant producer or importer must certify that certified ethanol denaturant meets the requirements in §1090.275 using the procedures specified at §1090.1000(g).

(2) Registration. A certified ethanol denaturant producer or importer must register with EPA under subpart I of this part.

(3) PTDs. On each occasion when a certified ethanol denaturant producer transfers custody or title to any fuel, fuel additive, or regulated blendstock, the transferor must provide to the transferee PTDs under subpart L of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.160 Distributors, carriers, and resellers.

A distributor, carrier, or reseller must comply with the requirements of this section.

(a) Gasoline and diesel standards. A distributor, carrier, or reseller must comply with the applicable requirements of subparts C and D of this part.

(b) Registration. A distributor or carrier must register with EPA under subpart I of this part if they are part of the 500 ppm LM diesel fuel distribution chain under a compliance plan submitted under §1090.515(g).

(c) PTDs. On each occasion when a distributor, carrier, or reseller transfers custody or title to any fuel, fuel additive, or regulated blendstock, the transferor must provide to the transferee PTDs under subpart L of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.165 Retailers and WPCs.

A retailer or WPC must comply with the requirements of this section.

(a) Gasoline and diesel standards. A retailer or WPC must comply with the applicable requirements of subparts C and D of this part.

(b) Labeling. A retailer or WPC that dispenses fuels requiring a label under this part must display fuel labels under subpart P of this part.

(c) Fuels made through fuel dispensers. A retailer or WPC that produces gasoline (e.g., E15) through a fuel dispenser with anything other than PCG and DFE is also a blending manufacturer and must comply with the applicable requirements in §1090.105.

[85 FR 78469, Dec. 4, 2020]

§1090.170 Independent surveyors.

An independent surveyor that conducts fuel surveys must comply with the requirements of this section.

(a) Survey provisions. An independent surveyor must conduct fuel surveys under subpart O of this part.