['Air Programs']

['Air Emissions']

05/20/2024

...

This section specifies how to qualify alternative procedures for measuring absolute and method-defined fuel parameters under the Performance-based Analytical Test Method specified in §1090.1360.

(a) The following general provisions apply for qualifying alternative procedures:

(1) Alternative procedures must have appropriate precision to allow for reporting to the number of decimal places specified in §1090.1350(c).

(2) Testing to qualify an alternative procedure applies for the specified version of the procedure you use for making the necessary measurements. For referee procedures and for alternative procedures for method-defined fuel parameters that you have qualified for your laboratory, updated versions of those same procedures are qualified without further testing, as long as the specified reproducibility is the same as or better than the values specified in the earlier version. For absolute fuel parameters, updated versions are qualified without testing if both repeatability and reproducibility are the same as or better than the values specified in the earlier version.

(3) Except as specified in paragraph (d) of this section, testing to demonstrate compliance with the precision and accuracy specifications in this section apply only for the laboratory where the testing occurred.

(4) If a procedure for measuring benzene or sulfur in gasoline has no specified PLOQ and no specified scope with a lower bound, you must establish a LLOQ for your laboratory.

(5) Testing for method-defined fuel parameters must take place at a reference installation as specified in §1090.1370.

(b) All alternative procedures must meet precision criteria based on a calculated maximum allowable standard deviation for a given fuel parameter as specified in this paragraph (b). The precision criteria apply for measuring the parameters and fuels specified in paragraph (b)(3) of this section. Take the following steps to qualify the measurement procedure for measuring a given fuel parameter:

(1) The fuel must meet the parameter specifications in Table 1 to paragraph (b)(3) of this section. This may require that you modify the fuel you typically produce to be within the specified range. Absent a specification (maximum or minimum), select a fuel representing values that are typical for your testing. Store and mix the fuel to maintain a homogenous mixture throughout the measurement period to ensure that each fuel sample drawn from the batch has the same properties.

(2) Measure the fuel parameter from a homogeneous fuel batch at least 20 times. Record each result in sequence. Do not omit any valid results unless you use good engineering judgment to determine that the omission is necessary and you document those results and the reason for excluding them. Perform this analysis over a 20-day period. You may make up to 4 separate measurements in a 24-hour period, as long as the interval between measurements is at least 4 hours. Do not measure RVP more than once from a single sample.

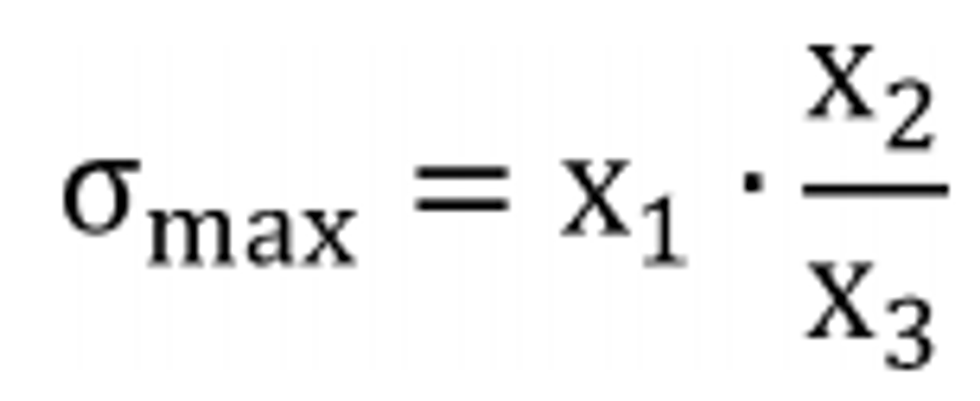

(3) Calculate the maximum allowable standard deviation as follows:

Where:

σmax = Maximum allowable standard deviation.

x1, x2, and x3 have the values from the following table:

| Fuel, fuel additive, or regulated blendstock | Fuel parameter | Range | x1 | x2 = Repeatability (r) or reproducibility (R) 1 | x3 | Fixed values of σmax | Source 2 |

|---|---|---|---|---|---|---|---|

| 1 Calculate repeatability and reproducibility using the average value determined from testing. Use units as specified in §1090.1350(c). | |||||||

| 2 ASTM publications are incorporated by reference, see §1090.95. Note that the listed procedure may be different than the referee procedure identified in §1090.1360(d), or it may be an older version of the referee procedure. | |||||||

| 3 Use only 1-liter containers for testing to qualify alternative methods. | |||||||

| ULSD | Sulfur | 5 ppm minimum | 1.5 | r = 1.33 | 2.77 | 0.72 | ASTM D3120-08 (R2019). |

| 500 ppm LM diesel fuel | Sulfur | 350 ppm minimum | 1.5 | r = 21.3 | 2.77 | 11.5 | ASTM D2622-16. |

| ECA marine fuel | Sulfur | 700 ppm minimum | 1.5 | 37.1 | 2.77 | 20.1 | ASTM D2622-16. |

| Butane | Sulfur | 1.5 | r = 0.1152.x | 2.77 | ASTM D6667-14 (R2019). | ||

| Gasoline | Sulfur | 1.5 | r = 0.4998.x 0.54 | 2.77 | ASTM D7039-15a (R2020). | ||

| Gasoline | oxygenate | 0.3 | R = 0.13.x 0.83 | 1 | ASTM D5599-18. | ||

| Gasoline | RVP 3 | 0.3 | R = 0.40 | 1 | 0.12 | ASTM D5191-20. | |

| Gasoline | Benzene | 0.15 | R = 0.221.x 0.67 | 1 | ASTM D5769-20. | ||

(c) Alternative VCSB procedures for measuring absolute fuel parameters (sulfur) must meet accuracy criteria based on the following measurement procedure:

(1) Obtain gravimetric sulfur standards to serve as representative reference samples. The samples must have known sulfur content within the ranges specified in paragraph (c)(3) of this section. The known sulfur content is the accepted reference value (ARV) for the fuel sample.

(2) Measure the sulfur content of the fuel sample at your laboratory at least 10 times, without interruption. Use good laboratory practice to compensate for any known chemical interferences; however, you must apply that same compensation for all tests to measure the sulfur content of a test fuel. Calculate the arithmetic average of all the measured values, including any compensation.

(3) The measurement procedure meets the accuracy requirement as follows:

(i) Demonstrate accuracy for measuring sulfur in gasoline, gasoline regulated blendstock, and gasoline additive using test fuels to represent sulfur values from 1 to 10 ppm, 11 to 20 ppm, and 21 to 95 ppm. You may omit any of these ranges if you do not perform testing with fuel in that range. Calculate the maximum allowable difference between the average measured value and ARV for each applicable range as follows:

Δmax = 0.75 · σmax

Where:

Δmax = Maximum allowable difference.

σmax = the maximum allowable standard deviation from paragraph (b)(3) of this section using the sulfur content represented by ARV.

(ii) Demonstrate accuracy for measuring sulfur in diesel fuel using test fuels meeting the specifications in Table 2 to this section. For testing diesel-related blendstocks and additives, use representative test samples meeting the appropriate sulfur specification. Table 2 to this paragraph also identifies the maximum allowable difference between average measured values and ARV corresponding to ARV at the upper end of the specified ranges. These values are based on calculations with the equation in paragraph (c)(3)(i) of this section, with parameter values set to be equal to the standard.

| Fuel | Sulfur content (ppm) | Illustrated maximum allowable differences |

|---|---|---|

| ULSD | 10-20 | 0.54 |

| 500 ppm LM diesel fuel | 450-500 | 8.65 |

| ECA marine fuel | 900-1,000 | 15.1 |

(d) Alternative VCSB procedures for measuring method-defined fuel parameters must meet accuracy criteria as follows:

(1) You may use the alternative procedure only if you follow all the statistical protocols and meet all the criteria specified in Section 6 of ASTM D6708 (incorporated by reference in §1090.95) when comparing your measurements using the alternative procedure to measurements at a reference installation using the appropriate referee procedure identified in §1090.1360(d).

(2) For qualifying alternative procedures, determine whether the alternative procedure needs a correlation equation to correct bias relative to the reference test method. Create such a correlation equation as specified in Section 7 of ASTM D6708. For all testing, apply the correlation equation to adjust measured values to be statistically consistent to measuring with the reference test method.

(3) If an alternative VCSB procedure states that the procedure has a successful assessment relative to the referee procedures in this section under ASTM D6708, that finding applies for all laboratories using that procedure.

(e) Alternative non-VCSB procedures for measuring absolute fuel parameters (sulfur) must meet accuracy criteria as follows:

(1) Demonstrate whether the procedure meets statistical criteria and whether it needs a correlation equation as specified in paragraphs (d)(1) and (2) of this section. Apply the correlation equation for all testing with the alternative procedure.

(2) Demonstrate at your laboratory that the alternative procedure meets the accuracy criteria specified in paragraph (c) of this section.

(3) Send EPA a written request to use the alternative procedure. In your request, fully describe the procedure to show how it functions for achieving accurate measurements and include detailed information related to your assessment under paragraph (e)(1) and (2) of this section.

(f) Alternative non-VCSB procedures for measuring method-defined fuel parameters must meet accuracy and precision criteria as follows:

(1) Demonstrate whether the procedure meets statistical criteria and whether it needs a correlation equation as specified in paragraphs (e)(1) and (2) of this section. Apply the correlation equation for all testing with the alternative procedure.

(2) Test with a range of fuels that are typical of those you will analyze at your laboratory. Use either consensus-named fuels or locally-named reference materials. Consensus-named fuels are homogeneous fuel quantities sent around to different laboratories for analysis, which results in a “consensus name” representing the average value of the parameter for all participating laboratories. Locally named reference materials are fuel samples analyzed using the reference test method, either at your laboratory or at a reference installation, to establish an estimated value for the fuel parameter; locally named reference materials usually come from the fuel you produce.

(3) You may qualify your procedure as meeting the requirements of paragraph (f)(1) of this section only for a narrower, defined range of fuels. If this is the case, identify the appropriate range of fuels in your request for approval and describe how you will screen fuel samples accordingly.

(4) Qualify the precision of the alternative procedure by comparing results to testing with the referee procedure based on “between methods reproducibility,” Rxy, as specified in ASTM D6708. The Rxy must be at or below 75 percent of the reproducibility of the referee procedure in §1090.1360(d).

(5) Perform testing at your laboratory as specified in paragraph (b) of this section to establish the repeatability of the alternative procedure. The repeatability must be as good as or better than that specified in paragraph (b)(3) of this section.

(6) Fully describe the procedure to show how it functions for achieving accurate measurements. Describe the technology, test instruments, and testing method so a competent person lacking experience with the procedure and test instruments would be able to replicate the results.

(7) Engage a third-party auditor to review and verify your information as follows:

(i) The auditor must qualify as an independent third party and meet the specifications for technical ability as specified in §1090.55.

(ii) The auditor must send you a report describing their inspection of your laboratories and their review of the information supporting your request to use the alternative procedure. The report must describe how the auditor performed the review, identify any errors or discrepancies, and state whether the information supports a conclusion that the alternative procedure should be approved.

(iii) The auditor must keep records related to the review for at least 5 years after sending you the report and provide those records to EPA upon request.

(8) Send EPA a written request to use the alternative procedure. Include the specified information and any additional information EPA needs to evaluate your request.

(g) Keep fuel samples from any qualification testing under this section for at least 180 days after you have taken all steps to qualify an alternative procedure under this section. This applies for testing at your laboratory and at any reference installation you use for demonstrating the accuracy of an alternative procedure.

[85 FR 78469, Dec. 4, 2020]

READ MORESHOW LESS

['Air Programs']

['Air Emissions']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.