['Air Programs']

['Air Emissions']

06/26/2024

...

§1066.801 Applicability and general provisions.

This subpart I specifies how to apply the test procedures of this part for light-duty vehicles, light-duty trucks, and heavy-duty vehicles at or below 14,000 pounds GVWR that are subject to chassis testing for exhaust emissions under 40 CFR part 86, subpart S. For these vehicles, references in this part 1066 to the standard-setting part include subpart H of this part and this subpart I.

(a) Use the procedures detailed in this subpart to measure vehicle emissions over a specified drive schedule in conjunction with subpart E of this part. Where the procedures of subpart E of this part differ from this subpart I, the provisions in this subpart I take precedence.

(b) Collect samples of every pollutant for which an emission standard applies, unless specified otherwise.

(c) This subpart covers the following test procedures:

(1) The Federal Test Procedure (FTP), which includes the general driving cycle. This procedure is also used for measuring evaporative emissions. This may be called the conventional test since it was adopted with the earliest emission standards.

(i) The FTP consists of one Urban Dynamometer Driving Schedule (UDDS) as specified in paragraph (a) of appendix I to 40 CFR part 86, followed by a 10-minute soak with the engine off and repeat driving through the first 505 seconds of the UDDS. Note that the UDDS represents about 7.5 miles of driving in an urban area. Engine startup (with all accessories turned off), operation over the initial UDDS, and engine shutdown make a complete cold-start test. The hot-start test consists of the first 505 seconds of the UDDS following the 10-minute soak and a hot-running portion of the UDDS after the first 505 seconds. The first 505 seconds of the UDDS is considered the transient portion; the remainder of the UDDS is considered the stabilized (or hot-stabilized) portion. The hot-stabilized portion for the hot-start test is generally measured during the cold-start test; however, in certain cases, the hot-start test may involve a second full UDDS following the 10-minute soak, rather than repeating only the first 505 seconds. See §§1066.815 and 1066.820.

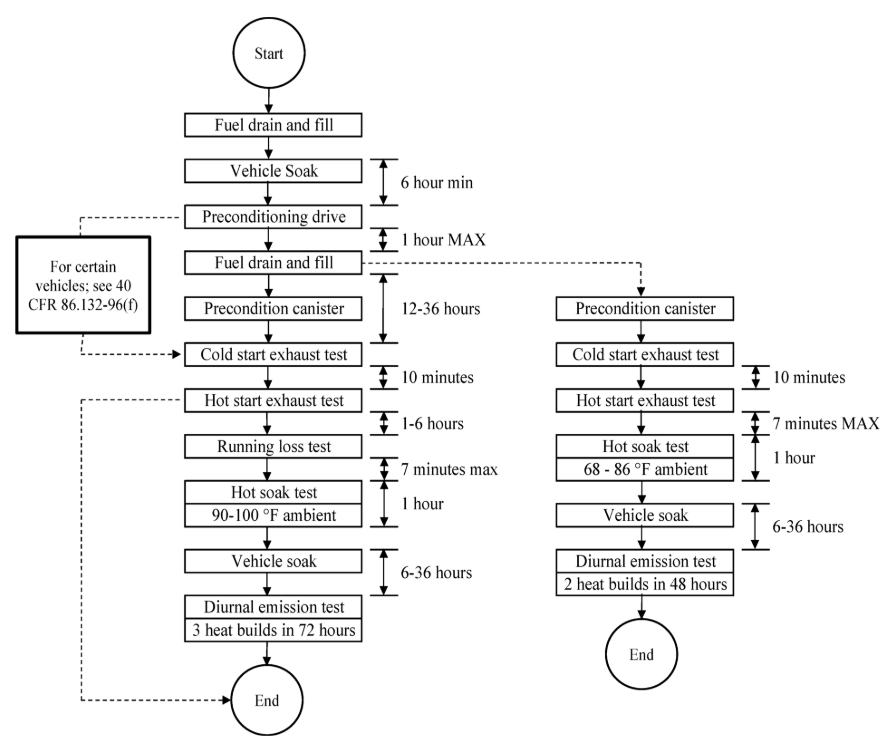

(ii) Evaporative emission testing includes a preconditioning drive with the UDDS and a full FTP cycle, including exhaust measurement, followed by evaporative emission measurements. In the three-day diurnal test sequence, the exhaust test is followed by a running loss test consisting of a UDDS, then two New York City Cycles as specified in paragraph (e) of appendix I to 40 CFR part 86, followed by another UDDS; see 40 CFR 86.134. Note that the New York City Cycle represents about 1.18 miles of driving in a city center. The running loss test is followed by a high-temperature hot soak test as described in 40 CFR 86.138 and a three-day diurnal emission test as described in 40 CFR 86.133. In the two-day diurnal test sequence, the exhaust test is followed by a low-temperature hot soak test as described in 40 CFR 86.138-96(k) and a two-day diurnal emission test as described in 40 CFR 86.133-96(p).

(iii) Refueling emission tests for vehicles that rely on integrated control of diurnal and refueling emissions includes vehicle operation over the full FTP test cycle corresponding to the three-day diurnal test sequence to precondition and purge the evaporative canister. For non-integrated systems, there is a preconditioning drive over the UDDS and a refuelingevent, followed by repeated UDDS driving to purge the evaporative canister. The refueling emission test procedures are described in 40 CFR 86.150 through 86.157.

(2) The US06 driving cycle is specified in paragraph (g) of appendix I to 40 CFR part 86. Note that the US06 driving cycle represents about 8.0 miles of relatively aggressive driving.

(3) The SC03 driving cycle is specified in paragraph (h) of appendix I to 40 CFR part 86. Note that the SC03 driving schedule represents about 3.6 miles of urban driving with the air conditioner operating.

(4) The hot portion of the LA-92 driving cycle is specified in paragraph (c) of appendix I to 40 CFR part 86. Note that the hot portion of the LA-92 driving cycle represents about 9.8 miles of relatively aggressive driving for commercial trucks. This driving cycle applies for heavy-duty vehicles above 10,000 pounds GVWR and at or below 14,000 pounds GVWR only for vehicles subject to Tier 3 standards.

(5) The Highway Fuel Economy Test (HFET) is specified in appendix I to 40 CFR part 600. Note that the HFET represents about 10.2 miles of rural and freeway driving with an average speed of 48.6 mi/hr and a maximum speed of 60.0 mi/hr. See §1066.840.

(6) Cold temperature standards apply for NMOG+NO X (or NMHC), PM, and CO emissions when vehicles operate over the FTP at a nominal temperature of −7 °C. See subpart H of this part.

(7) Emission measurement to determine air conditioning credits forgreenhouse gas standards. In this optional procedure, manufacturers operate vehicles over repeat runs of the AC17 test sequence to allow for calculating credits as part of demonstrating compliance with CO 2 emission standards. The AC17 test sequence consists of a UDDS preconditioning drive, followed by emission measurements over the SC03 and HFET driving cycles. See §1066.845.

(8) The mid-temperature intermediate soak FTP is specified as the procedure for Partial Soak Emission Testing in Section E4.4 of California ARB's PHEV Test Procedures for plug-in hybrid electric vehicles, in Part II Section I.7 of California ARB's LMDV Test Procedures for other hybrid electric vehicles, and in Part II, Section B.9.1 and B.9.3 of California ARB's LMDV Test Procedures for other vehicles (both incorporated by reference, see §1066.1010).

(9) The early driveaway FTP is specified as the procedure for Quick Drive-Away Emission Testing in Section E4.5 of California ARB's PHEV Test Procedures for plug-in hybrid electric vehicles, in Part II Section I.8 of California ARB's LMDV Test Procedures for other hybrid electric vehicles, and in Part II, Section B.9.2 and B.9.4 of California ARB's LMDV Test Procedures for other vehicles (both incorporated by reference, see §1066.1010). Additionally, vehicle speed may not exceed 0.0 mi/hr until 7.0 seconds into the driving schedule and vehicle speed may not exceed 2.0 mi/hr from 7.1 through 7.9 seconds.

(10) The high-load PHEV engine starts US06 is specified in Section E7.2 of California ARB's PHEV Test Procedures using the cold-start US06 Charge-Depleting Emission Test (incorporated by reference, see §1066.1010).

(d) The following provisions apply for all testing:

(1) Ambient temperatures encountered by the test vehicle must be (20 to 30) °C, unless otherwise specified. Where ambient temperature specifications apply before or between test measurements, the vehicle may be exposed to temperatures outside of the specified range for up to 10 minutes to account for vehicle transport or other actions to prepare for testing. The temperatures monitored during testing must be representative of those experienced by the test vehicle. For example, do not measure ambient temperatures near a heat source.

(2) Do not operate or store the vehicle at an incline if good engineering judgment indicates that it would affect emissions.

(3) If a test is void after collecting emission data from previous test segments, the test may be repeated to collect only those data points needed to complete emission measurements. You may combine emission measurements from different test runs to demonstrate compliance with emission standards.

(4) Prepare vehicles for testing as described in §1066.810.

(e) The following figure illustrates the FTP test sequence for measuring exhaust and evaporative emissions:

Figure 1 to Paragraph (e)—FTP Test Sequence

[79 FR 23823, Apr. 28, 2014, as amended at 80 FR 9123, Feb. 19, 2015; 81 FR 74213, Oct. 25, 2016; 86 FR 34583, Jun. 29, 2021; 89 FR 28213, Apr. 18, 2024]

§1066.805 Road-load power, test weight, and inertia weight class determination.

(a) Simulate a vehicle's test weight on the dynamometer using the appropriate equivalent test weight shown in Table 1 of this section. Equivalent test weights are established according to each vehicle's test weight basis, as described in paragraph (b) of this section. Table 1 also specifies the inertia weight class corresponding to each equivalent test weight; the inertia weight class allows for grouping vehicles with a range of equivalent test weights. Table 1 follows:

| Test weight | Equivalent test | Inertia weight |

|---|---|---|

| Up to 1062 | 1000 | 1000 |

| 1063 to 1187 | 1125 | 1000 |

| 1188 to 1312 | 1250 | 1250 |

| 1313 to 1437 | 1375 | 1250 |

| 1438 to 1562 | 1500 | 1500 |

| 1563 to 1687 | 1625 | 1500 |

| 1688 to 1812 | 1750 | 1750 |

| 1813 to 1937 | 1875 | 1750 |

| 1938 to 2062 | 2000 | 2000 |

| 2063 to 2187 | 2125 | 2000 |

| 2188 to 2312 | 2250 | 2250 |

| 2313 to 2437 | 2375 | 2250 |

| 2438 to 2562 | 2500 | 2500 |

| 2563 to 2687 | 2625 | 2500 |

| 2688 to 2812 | 2750 | 2750 |

| 2813 to 2937 | 2875 | 2750 |

| 2938 to 3062 | 3000 | 3000 |

| 3063 to 3187 | 3125 | 3000 |

| 3188 to 3312 | 3250 | 3000 |

| 3313 to 3437 | 3375 | 3500 |

| 3438 to 3562 | 3500 | 3500 |

| 3563 to 3687 | 3625 | 3500 |

| 3688 to 3812 | 3750 | 3500 |

| 3813 to 3937 | 3875 | 4000 |

| 3938 to 4125 | 4000 | 4000 |

| 4126 to 4375 | 4250 | 4000 |

| 4376 to 4625 | 4500 | 4500 |

| 4626 to 4875 | 4750 | 4500 |

| 4876 to 5125 | 5000 | 5000 |

| 5126 to 5375 | 5250 | 5000 |

| 5376 to 5750 | 5500 | 5500 |

| 5751 to 6250 | 6000 | 6000 |

| 6251 to 6750 | 6500 | 6500 |

| 6751 to 7250 | 7000 | 7000 |

| 7251 to 7750 | 7500 | 7500 |

| 7751 to 8250 | 8000 | 8000 |

| 8251 to 8750 | 8500 | 8500 |

| 8751 to 9250 | 9000 | 9000 |

| 9251 to 9750 | 9500 | 9500 |

| 9751 to 10250 | 10000 | 10000 |

| 10251 to 10750 | 10500 | 10500 |

| 10751 to 11250 | 11000 | 11000 |

| 11251 to 11750 | 11500 | 11500 |

| 11751 to 12250 | 12000 | 12000 |

| 12251 to 12750 | 12500 | 12500 |

| 12751 to 13250 | 13000 | 13000 |

| 13251 to 13750 | 13500 | 13500 |

| 13751 to 14000 | 14000 | 14000 |

(b) The test weight basis for non-MDPV heavy-duty vehicles is “adjusted loaded vehicle weight”. For all other vehicles, the test weight basis for establishing equivalent test weight is “loaded vehicle weight”. These load terms are defined in 40 CFR 86.1803.

(c) For FTP, US06, SC03, New York City Cycle, HFET, and LA-92 testing, determine road-load forces for each test vehicle at speeds between 9.3 and 71.5 miles per hour. The road-load force must represent vehicle operation on a smooth, level road with no wind or calm winds, no precipitation, an ambient temperature of approximately 20 °C, and atmospheric pressure of 98.21 kPa. You may extrapolate road-load force for speeds below 9.3 mi/hr.

[79 FR 23823, Apr. 28, 2016, as amended at 81 FR 74213, Oct. 25, 2016; 89 FR 28214, Apr. 18, 2024]

§1066.810 Vehicle preparation.

(a) Include additional fittings and adapters as required to accommodate a fuel drain at the lowest point possible in the tank(s) as installed on the vehicle.

(b) For preconditioning that involves loading an evaporative emission canister with butane, provide valving or other means to allow for purging and loading the canister.

(c) For vehicles to be tested for running loss emissions (40 CFR 86.134), prepare the fuel tank for measuring temperature and pressure as specified in 40 CFR 86.107-98(e) and (f) and 40 CFR 86.134. Vapor temperature measurement is optional during the running loss test.

(d) For vehicles to be tested for running loss emissions, prepare the exhaust system by sealing or plugging all detectable sources of exhaust gas leaks. Inspect or test the exhaust system to ensure that there are no leaks that would cause exhaust hydrocarbon emissions to be detected as running losses.

(e) The following provisions apply for preconditioning steps to reduce nonfuel emissions to normal vehicle background levels for vehicles subject to Tier 3 evaporative emission standards under 40 CFR 86.1813:

(1) You must notify us in advance if you plan to perform such preconditioning. This notice must include a detailed description of the intended procedures and any measurements or thresholds for determining when stabilization is complete. You need not repeat this notification for additional vehicle testing in the same or later model years as long as your preconditioning practice conforms to these procedures.

(2) You may precondition a vehicle as described in paragraph (e)(1) of this section only within 12 months after the vehicle's original date of manufacture, except that you may ask us to approve further preconditioning steps for any testing to address identifiable sources of nonfuel emissions beyond what would generally occur with an appropriately aged in-use vehicle. For example, you may clean up fluid leaks and you may perform further off-vehicle preconditioning for tires or other replacement parts that are less than 12 months old. You may also replace the spare tire with an aged spare tire, and you may replace the windshield washer fluid with water.

§1066.815 Exhaust emission test procedures for FTP testing.

(a) General. The FTP exhaust emission test sequence consists of a cold-start test and a hot-start test as described in §1066.801.

(b) PM sampling options. Collect PM using any of the procedures specified in paragraphs (b)(1) through (5) of this section and use the corresponding equation in §1066.820 to calculate FTP composite emissions. Testing must meet the requirements related to filter face velocity as described in §1066.110(b)(2)(iii)(C), except as specified in paragraphs (b)(4) and (5) of this section. For procedures involving flow weighting, set the filter face velocity to a weighting target of 1.0 to meet the requirements of §1066.110(b)(2)(iii)(C). Allow filter face velocity to decrease as a percentage of the weighting factor if the weighting factor is less than 1.0 and do not change the nominal CVS flowrates or secondary dilution ratios between FTP or UDDS test intervals. Use the appropriate equations in §1066.610 to show that you meet the dilution factor requirements of §1066.110(b)(2)(iii)(B). If you collect PM using the procedures specified in paragraph (b)(4) or (5) of this section, the residence time requirements in 40 CFR 1065.140(e)(3) apply, except that you may exceed an overall residence time of 5.5 s for sample flow rates below the highest expected sample flow rate.

(1) You may collect a separate PM sample for transient and stabilized portions of the cold-start UDDS and the hot-start UDDS. This may either be done by sampling with three bags or four bags. You may omit the stabilized portion of the hot-start test (bag 4) and use the stabilized portion of the cold-start test (bag 2) in its place.

(2) You may collect PM on one filter over the cold-start UDDS and on a separate filter over the hot-start UDDS.

(3) You may collect PM on one filter over the cold-start UDDS (bag 1 and bag 2) and on a separate filter over the 867 seconds of the stabilized portion of the cold-start UDDS and the first 505 seconds of the hot-start UDDS (bag 2 and bag 3). Note that this option involves duplicate measurements during the stabilized portion of the cold-start UDDS.

(4) You may collect PM on a single filter over the cold-start UDDS and the first 505 seconds of the hot-start UDDS using one of the following methods:

(i) Adjust your sampling system flow rate over the filter to weight the filter face velocity over the three intervals of the FTP based on weighting targets of 0.43 for bag 1, 1.0 for bag 2, and 0.57 for bag 3.

(ii) Maintain a constant sampling system flow rate over the filter for all three intervals of the FTP by increasing overall dilution ratios for bag 1 and bag 3. To do this, reduce the sample flow rate from the exhaust (or diluted exhaust) such that the value is reduced to 43% and 57%, respectively, of the bag 2 values. For constant-volume samplers, this requires that you decrease the dilute exhaust sampling rate from the CVS and compensate for that by increasing the amount of secondary dilution air.

(5) You may collect PM on a single filter over the cold-start UDDS and the full hot-start UDDS using one of the following methods:

(i) Adjust your sampling system flow rate over the filter to weight the filter face velocity based on weighting targets of 0.75 for the cold-start UDDS and 1.0 for the hot-start UDDS.

(ii) Maintain a constant sampling system flow rate over the filter for both the cold-start and hot-start UDDS by increasing the overall dilution ratio for the cold-start UDDS. To do this, reduce the sample flow rate from the exhaust (or diluted exhaust) such that the value is reduced to 75% of the hot-start UDDS value. For constant-volume samplers, this requires that you decrease the dilute exhaust sampling rate from the CVS and compensate for that by increasing the amount of secondary dilution air.

(c) Gaseous sampling options. Collect gaseous samples using any of the following procedures:

(1) You may collect a single sample for a full UDDS (cold-start or hot-start).

(2) You may sample emissions separately for transient and stabilized portions of any UDDS.

(3) You may omit the stabilized portion of the hot-start test (bag 4) and use the stabilized portion of the cold-start test (bag 2) in its place.

(d) Test sequence. Follow the exhaust emission measurement procedures specified in §§1066.410 through 1066.425, subject to the following exceptions and additional provisions:

(1) Take the following steps for the cold-start test:

(i) Precondition the vehicle as described in §1066.816. Initiate the cold-start test following the 12 to 36 hour soak period.

(ii) Simultaneously start any electronic integrating devices, continuous data recording, and batch sampling before attempting to start the engine. Initiate the sequence of points in the test cycle when the engine starts. Place the vehicle in gear 15 seconds after engine starting, which is 5 seconds before the first acceleration.

(iii) At the end of the deceleration scheduled to occur 505 seconds into the cold-start UDDS, simultaneously switch all the sample flows from the cold-start transient interval to the stabilized interval, stopping all cold-start transient interval sampling and recording, including background sampling. Reset integrating devices for the stabilized interval and indicate the end of the cold-start interval in the recorded data. Operate the vehicle over the remainder of the UDDS. Turn the engine off 2 seconds after the end of the last deceleration in the stabilized interval (1,369 seconds after the start of the driving schedule).

(iv) Five seconds after the engine stops running, stop all stabilized interval sampling and recording, including background sampling. Stop any integrating devices for the stabilized interval and indicate the end of the stabilized interval in the recorded data. Note that the 5 second delay is intended to account for sampling system transport.

(2) Take the following steps for the hot-start test:

(i) Initiate the hot-start test (9 to 11) minutes after the end of the sample period for the cold-start UDDS.

(ii) Repeat the steps in paragraph (d)(1)(ii) of this section. Operate the vehicle over the first 505 seconds of the UDDS. For tests that do not include bag 4 operation, turn off the engine and simultaneously stop all hot-start sampling and recording, including background sampling, and any integrating devices at the end of the deceleration scheduled to occur 505 seconds into the hot-start UDDS.

(iii) To include bag 4 measurement, operate the vehicles over the remainder of the UDDS and conclude the testing as described in paragraphs (d)(1)(iii) and (iv) of this section.

(3) This completes the procedure for measuring FTP exhaust emissions. See §1066.801 and subpart J of this part for continuing the test sequence to measure evaporative or refueling emissions.

[79 FR 23823, Apr. 28, 2014, as amended at 80 FR 9124, Feb. 19, 2015; 81 FR 74213, Oct. 25, 2016; 88 FR 4709, Jan. 24, 2023]

§1066.816 Vehicle preconditioning for FTP testing.

Precondition the test vehicle before the FTP exhaust measurement as described in 40 CFR 86.132.

§1066.820 Composite calculations for FTP exhaust emissions.

(a) Determine the mass of exhaust emissions of each pollutant for each FTP test interval as described in §1066.605.

(b) Calculate the final composite gaseous test results as a mass-weighted value, e[emission]-FTPcomp, in grams per mile using the following equation:

Where:

mc = the combined mass emissions determined from the cold-start UDDS test interval (generally known as bag 1 and bag 2), in grams.

Dct = the measured driving distance from the transient portion of the cold-start test (bag 1), in miles.

Dcs = the measured driving distance from the stabilized portion of the cold-start test (bag 2), in miles.

mh = the combined mass emissions determined from the hot-start UDDS test interval in grams. This is the hot-stabilized portion from either the first or second UDDS (bag 2, unless you measure bag 4), in addition to the hot transient portion (bag 3).

Dht = the measured driving distance from the transient portion of the hot-start test (bag 3), in miles.

Dhs = the measured driving distance from the stabilized portion of the hot-start test (bag 4), in miles. Set Dhs = Dcs for testing where the hot-stabilized portion of the UDDS is not run.

(c) Calculate the final composite PM test results as a mass-weighted value, ePM-FTPcomp, in grams per mile as follows:

(1) Use the following equation for PM measured as described in §1066.815(b)(1), (2), or (3):

Where:

mPM-cUDDS = the combined PM mass emissions determined from the cold-start UDDS test interval (bag 1 and bag 2), in grams, as calculated using Eq. 1066.605-3.

mPM-hUDDS = the combined PM mass emissions determined from the hot-start UDDS test interval (bag 3 and bag 4), in grams, as calculated using Eq. 1066.605-3. This is the hot-stabilized portion from either the first or second UDDS (bag 2, unless you measure bag 4), in addition to the hot transient portion (bag 3).

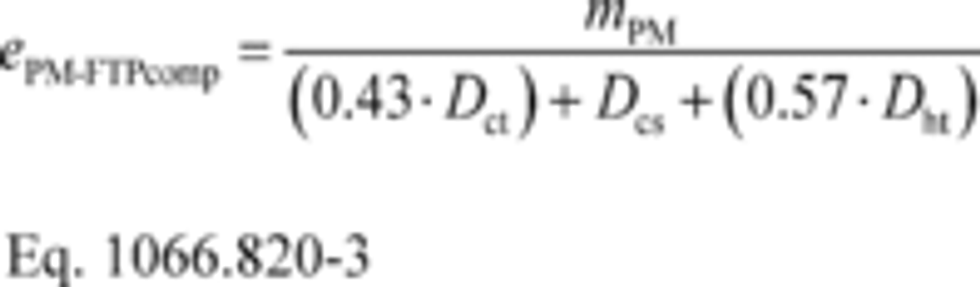

(2) Use the following equation for PM measured as described in §1066.815(b)(4):

Where:

mPM = the combined PM mass emissions determined from the cold-start UDDS test interval and the first 505 seconds of the hot-start UDDS test interval (bag 1, bag 2, and bag 3), in grams, as calculated using Eqs. 1066.605-4 and 1066.605-5.

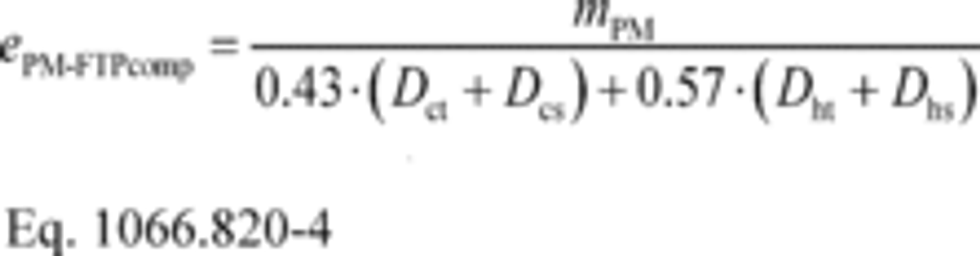

(3) Use the following equation for PM measured as described in §1066.815(b)(5):

Where:

mPM = the combined PM mass emissions determined from the cold-start UDDS test interval and the hot-start UDDS test interval (bag 1, bag 2, bag 3, and bag 4), in grams, as calculated using Eqs. 1066.605-6 and 1066.605-7.

[79 FR 23823, Apr. 28, 2016, as amended at 81 FR 74214, Oct. 25, 2016]

§1066.830 Supplemental Federal Test Procedures; overview.

Sections 1066.831 and 1066.835 describe the detailed procedures for the Supplemental Federal Test Procedure (SFTP). This testing applies for Tier 3 vehicles subject to the SFTP standards in 40 CFR 86.1811-17 or 86.1816-18. The SFTP test procedure consists of FTP testing and two additional test elements—a sequence of vehicle operation with more aggressive driving and a sequence of vehicle operation that accounts for the impact of the vehicle's air conditioner. Tier 4 vehicles subject to 40 CFR 86.1811-27 must meet standards for each individual driving cycle.

(a) The SFTP standard applies as a composite representing the three test elements. The emission results from the aggressive driving test element (§1066.831), the air conditioning test element (§1066.835), and the FTP test element (§1066.820) are analyzed according to the calculation methodology and compared to the applicable SFTP emission standards as described in 40 CFR part 86, subpart S.

(b) The test elements of the SFTP may be run in any sequence that includes the specified preconditioning steps.

[89 FR 28215, Apr. 18, 2024]

§1066.831 Exhaust emission test procedures for aggressive driving.

(a) This section describes how to test using the US06 or LA-92 driving schedule. The US06 driving schedule can be divided into two test intervals - the US06 City cycle comprises the combined portions of the cycle from 1 to 130 seconds and from 495 to 596 seconds, and the US06 Highway cycle comprises the portion of the cycle between 130 and 495 seconds. See §1066.801 for further information on the driving schedules.

(b) Take the following steps to precondition vehicles for testing under this section:

(1) Drain and refill the vehicle's fuel tank(s) in any of the following cases:

(i) For aggressive-driving tests that do not follow FTP or HFET testing.

(ii) For a test element that starts more than 72 hours after the most recent FTP or HFET measurement (with or without evaporative emission measurements).

(iii) For testing in which the test vehicle has not remained in an area where ambient temperatures were within the range specified for testing since the previous FTP or HFET.

(2) Keep ambient temperatures within the ranges specified for test measurements throughout the preconditioning sequence.

(3) Warm up the vehicle to a stabilized condition as follows:

(i) Push or drive the vehicle onto the dynamometer.

(ii) Operate the vehicle one time over one of the driving schedules specified in this paragraph (b)(3)(ii). You may ask us to use a particular preconditioning driving schedule if that is related to fuel effects on adaptive memory systems. For our testing, we will generally operate the vehicle over the same preconditioning cycle that will be used for testing in this section. You may exercise your sampling equipment, but you may not determine emissions results during preconditioning. Choose from the following driving schedules:

(A) The first 505 seconds of the UDDS (bag 1).

(B) The last 867 seconds of the UDDS (bag 2).

(C) The HFET driving schedule.

(D) US06 driving schedule or, for heavy-duty vehicles at or below 10,000 pounds GVWR with a power-to-weight ratio at or below 0.024 hp/lbm, just the highway portion of the US06 driving schedule.

(E) The SC03 driving schedule.

(F) The LA-92 driving schedule.

(G) The Hot LA-92 driving schedule.

(4) Allow the vehicle to idle for (1 to 2) minutes. This leads directly into the test measurements described in paragraph (c) of this section.

(c) For testing involving the full US06 driving schedule, you may collect emissions from separate city and highway test intervals (see 40 CFR part 600), or you may collect emissions over the full US06 driving schedule as a single test interval. Take the following steps to measure emissions over separate city and highway test intervals:

(1) At 130 seconds, simultaneously stop all US06 City, and start all US06 Highway sampling, recording, and integrating (including background sampling). At 136 seconds (before the acceleration), record the measured dynamometer roll revolutions.

(2) At 495 seconds, simultaneously stop all US06 Highway, and start all US06 City sampling, recording, and integrating (including background sampling). At 500 seconds (before the acceleration), record the measured dynamometer roll revolutions.

(3) Except as specified in paragraph (c)(4) of this section, treat the emissions from the first and second portions of the US06 City test interval as a single sample.

(4) If you collect gaseous emissions over separate city and highway test intervals, you may still collect PM over the full US06 driving schedule as a single test interval. If you do this, calculate a composite dilution factor based on city and highway emissions using Eq. 1066.610-4 to show that you meet the dilution factor requirements of §1066.110(b)(2)(iii)(B).

(d) For diesel-fueled vehicles, measure THC emissions on a continuous basis. For separate measurement of the city and highway test intervals as described in paragraph (c) of this section, perform separate calculations for each portion of the test cycle.

(e) Follow the exhaust emission measurement procedures specified in §§1066.410 through 1066.425, subject to the following exceptions and additional provisions:

(1) Following the preconditioning specified in paragraph (b) of this section, place the vehicle in gear and simultaneously start sampling and recording. Begin the first acceleration 5 seconds after placing the vehicle in gear.

(2) Operate the vehicle over the full US06 driving schedule, with the following exceptions that apply only for Tier 3 vehicles:

(i) For heavy-duty vehicles above 10,000 pounds GVWR, operate the vehicle over the Hot LA-92 driving schedule.

(ii) Heavy-duty vehicles at or below 10,000 pounds GVWR with a power-to-weight ratio at or below 0.024 hp/pound may be certified using only the highway portion of the US06 driving schedule as described in 40 CFR 86.1816.

(3) Turn the engine off 2 seconds after the end of the last deceleration. Five seconds after the engine stops running, stop all sampling and recording, including background sampling. Stop any integrating devices and indicate the end of the test cycle in the recorded data. Note that the 5 second delay is intended to account for sampling system transport.

(4) Correct calculated NOX emissions as described in §1066.615(a)(1).

[79 FR 23823, Apr. 28, 2014, as amended at 80 FR 9124, Feb. 19, 2015; 88 FR 4709, Jan. 24, 2023; 89 FR 28215, Apr. 18, 2024]

§1066.835 Exhaust emission test procedure for SC03 emissions.

This section describes how to test using the SC03 driving schedule (see §1066.801). This procedure is designed to determine gaseous exhaust emissions while simulating an urban trip on a hot summer day. The provisions of 40 CFR part 86 and 40 CFR part 600 waive SC03 testing for some vehicles; in those cases, calculate SFTP composite emissions by adjusting the weighting calculation as specified in 40 CFR part 86, subpart S.

(a) Drain and refill the vehicle's fuel tank(s) if testing starts more than 72 hours after the most recent FTP or HFET measurement (with or without evaporative emission measurements).

(b) Keep the vehicle in an environment meeting the conditions described in paragraph (f) of this section throughout the preconditioning sequence.

(c) Warm up the vehicle to a stabilized condition as follows:

(1) Push or drive the test vehicle onto the dynamometer.

(2) Close the vehicle's windows before testing.

(3) The test cell and equipment must meet the specifications in paragraph (e) of this section. Measure and control ambient conditions as specified in paragraph (f) of this section.

(4) Set the vehicle's air conditioning controls by selecting A/C mode and “maximum”, setting airflow to “recirculate” (if so equipped), selecting the highest fan setting, and turning the A/C temperature to full cold (or 72°F for automatic systems). Turn the control to the “on” position before testing so the air conditioning system is active whenever the engine is running.

(5) Perform a preconditioning drive by operating the test vehicle one time over the first 505 seconds of the UDDS (bag 1), the last 867 seconds of the UDDS (bag 2), or the SC03 driving schedule. If the air conditioning test sequence starts more than 2 hours after a different exhaust emission test, you may instead operate the vehicle one time over the full UDDS.

(6) Following the preconditioning drive, turn off the test vehicle and the vehicle cooling fan(s) and allow the vehicle to soak for (9 to 11) minutes.

(d) Follow the exhaust emission measurement procedures specified in §§1066.410 through 1066.425, subject to the following exceptions and additional provisions:

(1) Place the vehicle in gear 15 seconds after engine starting, which is 3 seconds before the first acceleration. Follow the SC03 driving schedule.

(2) Turn the engine off 2 seconds after the end of the last deceleration. Five seconds after the engine stops running, stop all sampling and recording, including background sampling. Stop any integrating devices any indicate the end of the test cycle in the recorded data. Note that the 5 second delay is intended to account for sampling system transport.

(3) Correct calculated NOX emissions as described in §1066.615(a)(2).

(e) The following requirements apply for the test cell and cooling fan configuration:

(1) Minimum test cell size. The test cell must be at least 20 feet wide, 40 feet long, and 10 feet high, unless we approve the use of a smaller test cell. We will approve this only if you demonstrate that the smaller test cell is capable of meeting all the requirements of this section.

(2) Vehicle frontal air flow. Verify that the fan configuration meets the requirements of §1066.105(c)(5).

(f) Maintain ambient conditions as follows:

(1) Ambient temperature and humidity. Measure and record ambient temperature and humidity in the test cell at least once every 30 seconds during the sampling period. Alternatively, if you collect data of at least once every 12 seconds, you may use a moving average of up to 30 second intervals to measure and record ambient temperature and humidity. Control ambient temperature throughout the test sequence to (35.0 ± 3.0)°C. Control ambient temperature during emission sampling to (33.6 to 36.4)°C on average. Control ambient humidity during emission sampling as described in §1066.420(d).

(2) Conditions before testing. Use good engineering judgment to demonstrate that you meet the specified temperature and humidity tolerances in paragraph (f)(1) of this section during the preconditioning cycle and during the vehicle soak period in paragraph (c)(6) of this section.

(3) Solar heat load. Simulate solar heating as follows:

(i) You may use a metal halide lamp, a sodium lamp, or a quartz halogen lamp with dichroic mirrors as a radiant energy emitter. We may also approve the use of a different type of radiant energy emitter if you demonstrate that it meets the requirements of this section.

(ii) We recommend achieving radiant heating with spectral distribution characteristics as described in the following table:

| Band width (nm) | Percent of total spectrum | |

|---|---|---|

| Lower limit (%) | Upper limit (%) | |

| a Note that you may need to filter the UV region between 280 and 320 nm. | ||

| <320 a | 0 | |

| 320-400 | 0 | 7 |

| 400-780 | 45 | 55 |

| >780 | 35 | 53 |

(iii) Determine radiant energy intensity experienced by the vehicle as the average value between two measurements along the vehicle's centerline, one at the base of the windshield and the other at the bottom of the rear window (or equivalent location for vehicles without a rear window). This value must be (850 ± 45) W/m 2 . Instruments for measuring radiant energy intensity must meet the following minimum specifications:

(A) Sensitivity of 9 microvolts per W/m 2.

(B) Response time of 5 seconds. For purposes of this requirement, “response time” means the time for the instrument to reach 95 percent of its equilibrium response after a step change in radiant intensity.

(C) Cosine response error of no more than ±1% for 0-70 degree zenith angles. The cosine response error is the percentage difference between the intensity measured at a given angle and a reference value, where the reference value is the intensity predicted from the zero-degree intensity and the cosine of the incident angle.

(D) When comparing measured values for radiant energy to reference values, each measured value over the full range of measurement may not deviate from the corresponding reference value by more than ±0.5% of the analyzer range's maximum value.

(iv) Check the uniformity of radiant energy intensity at least every 500 hours of emitter usage or every 6 months, whichever is sooner, and after any major modifications affecting the solar simulation. Determine uniformity by measuring radiant energy intensity using instruments that meet the specifications described in paragraph (f)(3)(iii) of this section at each point of a 0.5 m grid over the vehicle's full footprint, including the edges of the footprint, at an elevation 1 m above the floor. Measured values of radiant energy intensity must be between (722 and 978) W/m 2 at all points.

[79 FR 23823, Apr. 28, 2014, as amended at 80 FR 9124, Feb. 19, 2015; 81 FR 74214, Oct. 25, 2016; 86 FR 34585, Jun. 29, 2021; 88 FR 4709, Jan. 24, 2023]

§1066.840 Highway fuel economy test procedure.

This section describes the procedure for the highway fuel economy test (HFET). This test involves emission sampling and fuel economy measurement for certain vehicles as described in 40 CFR part 86, subpart S, and in 40 CFR part 600. See §1066.801 for further information on the driving schedules. Follow the exhaust emission measurement procedures specified in §§1066.410 through 1066.425, subject to the following exceptions and additional provisions:

(a) Perform the HFET immediately following the FTP when this is practical. If the HFET procedure starts more than 3 hours after an FTP (including evaporative emission measurements, if applicable), operate it over one UDDS to precondition the vehicle. We may approve additional preconditioning in unusual circumstances.

(b) Operate the vehicle over the HFET driving schedule for preconditioning. Allow the vehicle to idle for 15 seconds (with the vehicle in gear), then start a repeat run of the HFET driving schedule and simultaneously start sampling and recording.

(c) Turn the engine off at the end of the HFET driving schedule and stop all sampling and recording, including background. Stop any integrating devices and indicate the end of the test cycle in the recorded data.

§1066.845 AC17 air conditioning efficiency test procedure.

(a) Overview. This section describes a voluntary procedure for measuring the net impact of air conditioner operation on CO2 emissions. See 40 CFR 86.1868 for provisions describing how to use these procedures to calculate credits and otherwise comply with emission standards.

(b) Test cell. Operate the vehicle in a test cell meeting the specifications described in §1066.835(e). You may add airflow up to a maximum of 4 miles per hour during engine idling and when the engine is off if that is needed to meet ambient temperature or humidity requirements.

c) Ambient conditions. Measure and control ambient conditions as specified in §1066.835(f), except that you must control ambient temperature during emission sampling to (22.0 to 28.0)°C throughout the test and (23.5 to 26.5)°C on average. These tolerances apply to the combined SC03 and HFET drive cycles during emission sampling. Note that you must set the same ambient temperature target for both the air conditioning on and off portions of emission sampling. Control ambient temperature during the preconditioning cycle and 30 minute soak to (25.0 ± 5.0)°C. For these same modes with no emission sampling, target the specified ambient humidity levels, but you do not need to meet the humidity tolerances. Note that solar heating is disabled for certain test intervals as described in this section.

(d) Interior air temperature measurement. Measure and record the vehicle's interior air temperature at least once every 5 seconds during the sampling period. Measure temperature at the outlet of the center-most duct on the dashboard, and approximately 30 mm behind the driver's headrest and passenger's headrest.

(e) Air conditioning system settings. For testing that requires the air conditioning to be operating, set the vehicle's air conditioning controls as follows:

(1) For automatic systems, set the temperature control to 72°F (22°C).

(2) For manual systems, select A/C mode, set the temperature to full cold and “maximum”, set airflow to “recirculate” (if so equipped), and select the highest fan setting. During the first idle period of the SC03 driving schedule (between 186 and 204 seconds), reduce the fan speed setting to nominally 50% of maximum fan speed, set airflow to “fresh air” (if so equipped), and adjust the temperature setting to target a temperature of 55°F (13°C) at the dashboard air outlet. Maintain these settings for the remainder of the test. You may rely on prior temperature measurements to determine the temperature setting; however, if the system is unable to meet the 55°F (13°C) target, you may instead set airflow to “fresh air” and temperature to full cold. If the vehicle is equipped with technology that defaults to recirculated air at ambient temperatures above 75°F (22°C), that technology should remain enabled throughout the test; this may mean not setting the airflow to “recirculate” at the start and not setting the airflow to “fresh air” during the first idle period of the SC03 driving schedule. Except as specified in paragraph (e)(3) of this section, use good engineering judgment to apply the settings described in this paragraph (e)(2) equally throughout the vehicle if there are separate controls for different zones (such as rear air conditioning).

(3) If the air conditioning system is designed with parameters that switch back to a default setting at key-off, perform testing in that default condition. If the air conditioning system includes any optional equipment or user controls not addressed in this paragraph (e), the manufacturer should ask us for preliminary approval to determine the appropriate settings for testing.

(f) Test procedure. Follow the exhaust emission measurement procedures specified in §§1066.410 through 1066.425, subject to the following exceptions and additional provisions:

(1) Prepare each test vehicle for a series of tests according to 40 CFR 86.132-00(a) through (g). If the vehicle has been tested within the last 36 hours concluding with a 12 to 36 hour soak, continue to paragraph (f)(2) of this section; otherwise perform an additional UDDS preconditioning cycle that concludes with a 12 to 36 hour soak. You may use a forced cooldown system to bring critical vehicle temperatures to within soak temperature limits. Critical temperatures include transmission oil, engine oil, engine coolant, and cabin air temperatures.

(2) Open the vehicle's windows and operate the vehicle over a preconditioning UDDS with no solar heating and with the air conditioning off. At the end of the preconditioning drive, turn off the test vehicle and all cooling fans.

(3) Turn on solar heating within one minute after turning off the engine. Once the solar energy intensity reaches 805 W/m 2 , let the vehicle soak for (30 ± 1) minutes. You may alternatively rely on prior measurements to start the soak period after a defined period of warming up to the specified solar heat load. Close the vehicle's windows at the start of the soak period; ensure that the windows are adequately closed where instrumentation and wiring pass through to the interior.

(4) Turn the air conditioning control to the “on” position before testing so the air conditioning system is active whenever the engine is running. Place the vehicle in gear 15 seconds after engine starting, which is 3 seconds before the first acceleration. At the end of the driving schedule, simultaneously switch all the sampling, recording, and integrating from SC03 to HFET, including background sampling. Indicate the end of the test cycle in the recorded data. Record the measured dynamometer roll revolutions corresponding to the SC03 driving schedule.

(5) Directly following the SC03 driving schedule, operate the vehicle over the HFET driving schedule. Turn the vehicle off at the end of the driving schedule and simultaneously stop all sampling, recording, and integrating, including background sampling. Indicate the end of the test cycle in the recorded data. Record the measured dynamometer roll revolutions corresponding to the HFET drive schedule. Turn off the solar heating.

(6) Allow the vehicle to remain on the dynamometer for (10 to 15) minutes after emission sampling has concluded. Repeat the testing described in paragraphs (f)(1) through (5) of this section and turn off the vehicle's air conditioner and the solar heating throughout the test run. The windows may be open or closed.

(g) Calculations. (1) Determine the mass of CO 2 emissions for each of the two test intervals as described in §1066.605.

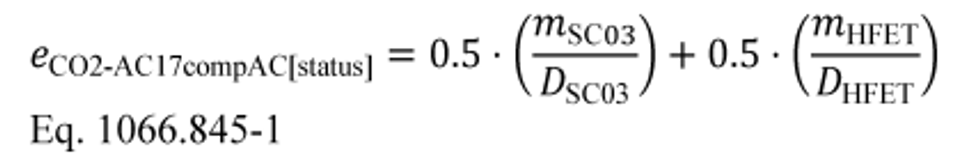

(2) Calculate separate composite mass-weighted emissions of CO 2 , CO2-AC17compAC[status] , representing the average of the SC03 and HFET emissions, in grams per mile for operation with the vehicle's air conditioner and the solar heating on and off using the following equation:

Where:

mSC03 = mass emissions from the SC03 test interval, in grams.

DSC03 = measured driving distance during the SC03 test interval, in miles.

mHFET = mass emissions from the HFET test interval, in grams.

DHFET = measured driving distance during the HFET test interval, in miles.

(3) Calculate the incremental CO 2 emissions due to air conditioning operation by subtracting the composite mass-weighted emissions of CO 2 with the vehicle's air conditioner and the solar heating on, eCO2-AC17compACon, from the composite mass-weighted emissions of CO 2 with the vehicle's air conditioner and the solar heating off, eCO2-AC17compACoff.

(h) Record information for each test as specified in §1066.695. Emission results and the results of all calculations must be reported for each phase of the test. The manufacturer must also report the following information for each vehicle tested: interior volume, climate control system type and characteristics, refrigerant used, compressor type, and evaporator/condenser characteristics.

[79 FR 23823,Apr. 28, 2014, as amended at 79 FR 36658, June 30, 2014; 80 FR 9124, Feb. 19, 2015; 88 FR 4710, Jan. 24, 2023]

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.