['Air Programs']

['Air Emissions']

06/26/2024

...

(a) Overview. This section describes a voluntary procedure for measuring the net impact of air conditioner operation on CO2 emissions. See 40 CFR 86.1868 for provisions describing how to use these procedures to calculate credits and otherwise comply with emission standards.

(b) Test cell. Operate the vehicle in a test cell meeting the specifications described in §1066.835(e). You may add airflow up to a maximum of 4 miles per hour during engine idling and when the engine is off if that is needed to meet ambient temperature or humidity requirements.

c) Ambient conditions. Measure and control ambient conditions as specified in §1066.835(f), except that you must control ambient temperature during emission sampling to (22.0 to 28.0)°C throughout the test and (23.5 to 26.5)°C on average. These tolerances apply to the combined SC03 and HFET drive cycles during emission sampling. Note that you must set the same ambient temperature target for both the air conditioning on and off portions of emission sampling. Control ambient temperature during the preconditioning cycle and 30 minute soak to (25.0 ± 5.0)°C. For these same modes with no emission sampling, target the specified ambient humidity levels, but you do not need to meet the humidity tolerances. Note that solar heating is disabled for certain test intervals as described in this section.

(d) Interior air temperature measurement. Measure and record the vehicle's interior air temperature at least once every 5 seconds during the sampling period. Measure temperature at the outlet of the center-most duct on the dashboard, and approximately 30 mm behind the driver's headrest and passenger's headrest.

(e) Air conditioning system settings. For testing that requires the air conditioning to be operating, set the vehicle's air conditioning controls as follows:

(1) For automatic systems, set the temperature control to 72°F (22°C).

(2) For manual systems, select A/C mode, set the temperature to full cold and “maximum”, set airflow to “recirculate” (if so equipped), and select the highest fan setting. During the first idle period of the SC03 driving schedule (between 186 and 204 seconds), reduce the fan speed setting to nominally 50% of maximum fan speed, set airflow to “fresh air” (if so equipped), and adjust the temperature setting to target a temperature of 55°F (13°C) at the dashboard air outlet. Maintain these settings for the remainder of the test. You may rely on prior temperature measurements to determine the temperature setting; however, if the system is unable to meet the 55°F (13°C) target, you may instead set airflow to “fresh air” and temperature to full cold. If the vehicle is equipped with technology that defaults to recirculated air at ambient temperatures above 75°F (22°C), that technology should remain enabled throughout the test; this may mean not setting the airflow to “recirculate” at the start and not setting the airflow to “fresh air” during the first idle period of the SC03 driving schedule. Except as specified in paragraph (e)(3) of this section, use good engineering judgment to apply the settings described in this paragraph (e)(2) equally throughout the vehicle if there are separate controls for different zones (such as rear air conditioning).

(3) If the air conditioning system is designed with parameters that switch back to a default setting at key-off, perform testing in that default condition. If the air conditioning system includes any optional equipment or user controls not addressed in this paragraph (e), the manufacturer should ask us for preliminary approval to determine the appropriate settings for testing.

(f) Test procedure. Follow the exhaust emission measurement procedures specified in §§1066.410 through 1066.425, subject to the following exceptions and additional provisions:

(1) Prepare each test vehicle for a series of tests according to 40 CFR 86.132-00(a) through (g). If the vehicle has been tested within the last 36 hours concluding with a 12 to 36 hour soak, continue to paragraph (f)(2) of this section; otherwise perform an additional UDDS preconditioning cycle that concludes with a 12 to 36 hour soak. You may use a forced cooldown system to bring critical vehicle temperatures to within soak temperature limits. Critical temperatures include transmission oil, engine oil, engine coolant, and cabin air temperatures.

(2) Open the vehicle's windows and operate the vehicle over a preconditioning UDDS with no solar heating and with the air conditioning off. At the end of the preconditioning drive, turn off the test vehicle and all cooling fans.

(3) Turn on solar heating within one minute after turning off the engine. Once the solar energy intensity reaches 805 W/m 2 , let the vehicle soak for (30 ± 1) minutes. You may alternatively rely on prior measurements to start the soak period after a defined period of warming up to the specified solar heat load. Close the vehicle's windows at the start of the soak period; ensure that the windows are adequately closed where instrumentation and wiring pass through to the interior.

(4) Turn the air conditioning control to the “on” position before testing so the air conditioning system is active whenever the engine is running. Place the vehicle in gear 15 seconds after engine starting, which is 3 seconds before the first acceleration. At the end of the driving schedule, simultaneously switch all the sampling, recording, and integrating from SC03 to HFET, including background sampling. Indicate the end of the test cycle in the recorded data. Record the measured dynamometer roll revolutions corresponding to the SC03 driving schedule.

(5) Directly following the SC03 driving schedule, operate the vehicle over the HFET driving schedule. Turn the vehicle off at the end of the driving schedule and simultaneously stop all sampling, recording, and integrating, including background sampling. Indicate the end of the test cycle in the recorded data. Record the measured dynamometer roll revolutions corresponding to the HFET drive schedule. Turn off the solar heating.

(6) Allow the vehicle to remain on the dynamometer for (10 to 15) minutes after emission sampling has concluded. Repeat the testing described in paragraphs (f)(1) through (5) of this section and turn off the vehicle's air conditioner and the solar heating throughout the test run. The windows may be open or closed.

(g) Calculations. (1) Determine the mass of CO 2 emissions for each of the two test intervals as described in §1066.605.

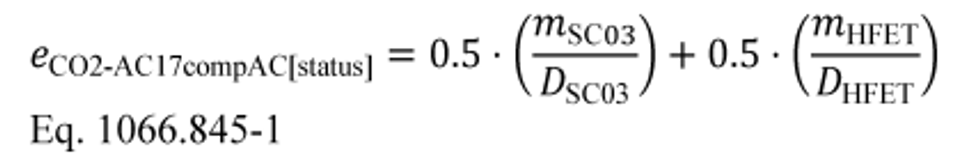

(2) Calculate separate composite mass-weighted emissions of CO 2 , CO2-AC17compAC[status] , representing the average of the SC03 and HFET emissions, in grams per mile for operation with the vehicle's air conditioner and the solar heating on and off using the following equation:

Where:

mSC03 = mass emissions from the SC03 test interval, in grams.

DSC03 = measured driving distance during the SC03 test interval, in miles.

mHFET = mass emissions from the HFET test interval, in grams.

DHFET = measured driving distance during the HFET test interval, in miles.

(3) Calculate the incremental CO 2 emissions due to air conditioning operation by subtracting the composite mass-weighted emissions of CO 2 with the vehicle's air conditioner and the solar heating on, eCO2-AC17compACon, from the composite mass-weighted emissions of CO 2 with the vehicle's air conditioner and the solar heating off, eCO2-AC17compACoff.

(h) Record information for each test as specified in §1066.695. Emission results and the results of all calculations must be reported for each phase of the test. The manufacturer must also report the following information for each vehicle tested: interior volume, climate control system type and characteristics, refrigerant used, compressor type, and evaporator/condenser characteristics.

[79 FR 23823,Apr. 28, 2014, as amended at 79 FR 36658, June 30, 2014; 80 FR 9124, Feb. 19, 2015; 88 FR 4710, Jan. 24, 2023]

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.