['Air Programs']

['Hazardous Air Pollutants']

01/20/2025

...

§63.640 Applicability and designation of affected source.

(a) This subpart applies to petroleum refining process units and to related emissions points that are specified in paragraphs (c)(1) through (9) of this section that are located at a plant site and that meet the criteria in paragraphs (a)(1) and (2) of this section:

(1) Are located at a plant site that is a major source as defined in section 112(a) of the Clean Air Act; and

(2) Emit or have equipment containing or contacting one or more of the hazardous air pollutants listed in table 1 of this subpart.

(b)(1) If the predominant use of the flexible operation unit, as described in paragraphs (b)(1)(i) and (ii) of this section, is as a petroleum refining process unit, as defined in §63.641, then the flexible operation unit shall be subject to the provisions of this subpart.

(i) Except as provided in paragraph (b)(1)(ii) of this section, the predominant use of the flexible operation unit shall be the use representing the greatest annual operating time.

(ii) If the flexible operation unit is used as a petroleum refining process unit and for another purpose equally based on operating time, then the predominant use of the flexible operation unit shall be the use that produces the greatest annual production on a mass basis.

(2) The determination of applicability of this subpart to petroleum refining process units that are designed and operated as flexible operation units shall be reported as specified in §63.655(h)(6)(i).

(c) For the purposes of this subpart, the affected source shall comprise all emissions points, in combination, listed in paragraphs (c)(1) through (9) of this section that are located at a single refinery plant site.

(1) All miscellaneous process vents from petroleum refining process units meeting the criteria in paragraph (a) of this section;

(2) All storage vessels associated with petroleum refining process units meeting the criteria in paragraph (a) of this section;

(3) All wastewater streams and treatment operations associated with petroleum refining process units meeting the criteria in paragraph (a) of this section;

(4) All equipment leaks from petroleum refining process units meeting the criteria in paragraph (a) of this section;

(5) All gasoline loading racks classified under Standard Industrial Classification code 2911 meeting the criteria in paragraph (a) of this section;

(6) All marine vessel loading operations located at a petroleum refinery meeting the criteria in paragraph (a) of this section and the applicability criteria of subpart Y, §63.560;

(7) All storage vessels and equipment leaks associated with a bulk gasoline terminal or pipeline breakout station classified under Standard Industrial Classification code 2911 located within a contiguous area and under common control with a refinery meeting the criteria in paragraph (a) of this section; and

(8) All heat exchange systems, as defined in this subpart.

(9) All releases associated with the decoking operations of a delayed coking unit, as defined in this subpart.

(d) The affected source subject to this subpart does not include the emission points listed in paragraphs (d)(1) through (d)(5) of this section.

(1) Stormwater from segregated stormwater sewers;

(2) Spills;

(3) Any pump, compressor, pressure relief device, sampling connection system, open-ended valve or line, valve, or instrumentation system that is intended to operate in organic hazardous air pollutant service, as defined in §63.641 of this subpart, for less than 300 hours during the calendar year;

(4) Catalytic cracking unit and catalytic reformer catalyst regeneration vents, and sulfur plant vents; and

(5) Emission points routed to a fuel gas system, as defined in §63.641, provided that on and after January 30, 2019, any flares receiving gas from that fuel gas system are subject to §63.670. No other testing, monitoring, recordkeeping, or reporting is required for refinery fuel gas systems or emission points routed to refinery fuel gas systems.

(e) The owner or operator of a storage vessel constructed on or before August 18, 1994, shall follow the procedures specified in paragraphs (e)(1) and (e)(2) of this section to determine whether a storage vessel is part of a source to which this subpart applies. The owner or operator of a storage vessel constructed after August 18, 1994, shall follow the procedures specified in paragraphs (e)(1), (e)(2)(i), and (e)(2)(ii) of this section to determine whether a storage vessel is part of a source to which this subpart applies.

(1) Where a storage vessel is used exclusively by a process unit, the storage vessel shall be considered part of that process unit.

(i) If the process unit is a petroleum refining process unit subject to this subpart, then the storage vessel is part of the affected source to which this subpart applies.

(ii) If the process unit is not subject to this subpart, then the storage vessel is not part of the affected source to which this subpart applies.

(2) If a storage vessel is not dedicated to a single process unit, then the applicability of this subpart shall be determined according to the provisions in paragraphs (e)(2)(i) through (e)(2)(iii) of this section.

(i) If a storage vessel is shared among process units and one of the process units has the predominant use, as determined by paragraphs (e)(2)(i)(A) and (e)(2)(i)(B) of this section, then the storage vessel is part of that process unit.

(A) If the greatest input on a volume basis into the storage vessel is from a process unit that is located on the same plant site, then that process unit has the predominant use.

(B) If the greatest input on a volume basis into the storage vessel is provided from a process unit that is not located on the same plant site, then the predominant use shall be the process unit that receives the greatest amount of material on a volume basis from the storage vessel at the same plant site.

(ii) If a storage vessel is shared among process units so that there is no single predominant use, and at least one of those process units is a petroleum refining process unit subject to this subpart, the storage vessel shall be considered to be part of the petroleum refining process unit that is subject to this subpart. If more than one petroleum refining process unit is subject to this subpart, the owner or operator may assign the storage vessel to any of the petroleum refining process units subject to this subpart.

(iii) If the predominant use of a storage vessel varies from year to year, then the applicability of this subpart shall be determined based on the utilization of that storage vessel during the year preceding August 18, 1995. This determination shall be reported as specified in §63.655(h)(6)(ii).

(f) The owner or operator of a distillation unit constructed on or before August 18, 1994, shall follow the procedures specified in paragraphs (f)(1) through (f)(4) of this section to determine whether a miscellaneous process vent from a distillation unit is part of a source to which this subpart applies. The owner or operator of a distillation unit constructed after August 18, 1994, shall follow the procedures specified in paragraphs (f)(1) through (f)(5) of this section to determine whether a miscellaneous process vent from a distillation unit is part of a source to which this subpart applies.

(1) If the greatest input to the distillation unit is from a process unit located on the same plant site, then the distillation unit shall be assigned to that process unit.

(2) If the greatest input to the distillation unit is provided from a process unit that is not located on the same plant site, then the distillation unit shall be assigned to the process unit located at the same plant site that receives the greatest amount of material from the distillation unit.

(3) If a distillation unit is shared among process units so that there is no single predominant use, as described in paragraphs (f)(1) and (f)(2) of this section, and at least one of those process units is a petroleum refining process unit subject to this subpart, the distillation unit shall be assigned to the petroleum refining process unit that is subject to this subpart. If more than one petroleum refining process unit is subject to this subpart, the owner or operator may assign the distillation unit to any of the petroleum refining process units subject to this rule.

(4) If the process unit to which the distillation unit is assigned is a petroleum refining process unit subject to this subpart and the vent stream contains greater than 20 parts per million by volume total organic hazardous air pollutants, then the vent from the distillation unit is considered a miscellaneous process vent (as defined in §63.641 of this subpart) and is part of the source to which this subpart applies.

(5) If the predominant use of a distillation unit varies from year to year, then the applicability of this subpart shall be determined based on the utilization of that distillation unit during the year preceding August 18, 1995. This determination shall be reported as specified in §63.655(h)(6)(iii).

(g) The provisions of this subpart do not apply to the processes specified in paragraphs (g)(1) through (g)(7) of this section.

(1) Research and development facilities, regardless of whether the facilities are located at the same plant site as a petroleum refining process unit that is subject to the provisions of this subpart;

(2) Equipment that does not contain any of the hazardous air pollutants listed in table 1 of this subpart that is located within a petroleum refining process unit that is subject to this subpart;

(3) Units processing natural gas liquids;

(4) Units that are used specifically for recycling discarded oil;

(5) Shale oil extraction units;

(6) Ethylene processes; and

(7) Process units and emission points subject to subparts F, G, H, and I of this part.

(h) Sources subject to this subpart are required to achieve compliance on or before the dates specified in table 11 of this subpart, except as provided in paragraphs (h)(1) through (3) of this section.

(1) Marine tank vessels at existing sources shall be in compliance with this subpart, except for §§63.657 through 63.660, no later than August 18, 1999, unless the vessels are included in an emissions average to generate emission credits. Marine tank vessels used to generate credits in an emissions average shall be in compliance with this subpart no later than August 18, 1998, unless an extension has been granted by the Administrator as provided in §63.6(i).

(2) Existing Group 1 floating roof storage vessels meeting the applicability criteria in item 1 of the definition of Group 1 storage vessel shall be in compliance with §63.646 at the first degassing and cleaning activity after August 18, 1998, or August 18, 2005, whichever is first.

(3) An owner or operator may elect to comply with the provisions of §63.648(c) through (i) as an alternative to the provisions of §63.648(a) and (b). In such cases, the owner or operator shall comply no later than the dates specified in paragraphs (h)(3)(i) through (iii) of this section.

(i) Phase I (see table 2 of this subpart), beginning on August 18, 1998;

(ii) Phase II (see table 2 of this subpart), beginning no later than August 18, 1999; and

(iii) Phase III (see table 2 of this subpart), beginning no later than February 18, 2001.

(i) If an additional petroleum refining process unit is added to a plant site that is a major source as defined in section 112(a) of the Clean Air Act, the addition shall be subject to the requirements for a new source if it meets the criteria specified in paragraphs (i)(1) through (i)(3) of this section:

(1) It is an addition that meets the definition of construction in §63.2 of subpart A of this part;

(2) Such construction commenced after July 14, 1994; and

(3) The addition has the potential to emit 10 tons per year or more of any hazardous air pollutant or 25 tons per year or more of any combination of hazardous air pollutants.

(j) If any change is made to a petroleum refining process unit subject to this subpart, the change shall be subject to the requirements for a new source if it meets the criteria specified in paragraphs (j)(1) and (j)(2) of this section:

(1) It is a change that meets the definition of reconstruction in §63.2 of subpart A of this part; and

(2) Such reconstruction commenced after July 14, 1994.

(k) If an additional petroleum refining process unit is added to a plant site or a change is made to a petroleum refining process unit and the addition or change is determined to be subject to the new source requirements according to paragraphs (i) or (j) of this section it must comply with the requirements specified in paragraphs (k)(1) and (k)(2) of this section:

(1) The reconstructed source, addition, or change shall be in compliance with the new source requirements in item (1), (2), or (3) of table 11 of this subpart, as applicable, upon initial startup of the reconstructed source or by August 18, 1995, whichever is later; and

(2) The owner or operator of the reconstructed source, addition, or change shall comply with the reporting and recordkeeping requirements that are applicable to new sources. The applicable reports include, but are not limited to:

(i) The application for approval of construction or reconstruction shall be submitted as soon as practical before the construction or reconstruction is planned to commence (but it need not be sooner than November 16, 1995);

(ii) The Notification of Compliance Status report as required by §63.655(f) for a new source, addition, or change;

(iii) Periodic Reports and other reports as required by §63.655(g) and (h);

(iv) Reports and notifications required by §60.487 of subpart VV of part 60 or §63.182 of subpart H of this part. The requirements for subpart H are summarized in table 3 of this subpart;

(v) Reports required by 40 CFR 61.357 of subpart FF;

(vi) Reports and notifications required by §63.428(b), (c), (g)(1), (h)(1) through (h)(3), and (k) of subpart R. These requirements are summarized in table 4 of this subpart; and

(vii) Reports and notifications required by §§63.565 and 63.567 of subpart Y of this part. These requirements are summarized in table 5 of this subpart.

(l) If an additional petroleum refining process unit is added to a plant site or if a miscellaneous process vent, storage vessel, gasoline loading rack, marine tank vessel loading operation, heat exchange system, or decoking operation that meets the criteria in paragraphs (c)(1) through (9) of this section is added to an existing petroleum refinery or if another deliberate operational process change creating an additional Group 1 emissions point(s) (as defined in §63.641) is made to an existing petroleum refining process unit, and if the addition or process change is not subject to the new source requirements as determined according to paragraph (i) or (j) of this section, the requirements in paragraphs (l)(1) through (4) of this section shall apply. Examples of process changes include, but are not limited to, changes in production capacity, or feed or raw material where the change requires construction or physical alteration of the existing equipment or catalyst type, or whenever there is replacement, removal, or addition of recovery equipment. For purposes of this paragraph (l) and paragraph (m) of this section, process changes do not include: Process upsets, unintentional temporary process changes, and changes that are within the equipment configuration and operating conditions documented in the Notification of Compliance Status report required by §63.655(f).

(1) The added emission point(s) and any emission point(s) within the added or changed petroleum refining process unit are subject to the requirements for an existing source.

(2) The added emission point(s) and any emission point(s) within the added or changed petroleum refining process unit shall be in compliance with the applicable requirements in item (4) of table 11 of this subpart by the dates specified in paragraph (l)(2)(i) or (ii) of this section.

(i) If a petroleum refining process unit is added to a plant site or an emission point(s) is added to any existing petroleum refining process unit, the added emission point(s) shall be in compliance upon initial startup of any added petroleum refining process unit or emission point(s) or by the applicable compliance date in item (4) of table 11 of this subpart, whichever is later.

(ii) If a deliberate operational process change to an existing petroleum refining process unit causes a Group 2 emission point to become a Group 1 emission point (as defined in §63.641), the owner or operator shall be in compliance upon initial startup or by August 18, 1998, whichever is later, unless the owner or operator demonstrates to the Administrator that achieving compliance will take longer than making the change. If this demonstration is made to the Administrator's satisfaction, the owner or operator shall follow the procedures in paragraphs (m)(1) through (m)(3) of this section to establish a compliance date.

(3) The owner or operator of a petroleum refining process unit or of a storage vessel, miscellaneous process vent, wastewater stream, gasoline loading rack, marine tank vessel loading operation, heat exchange system, or decoking operation meeting the criteria in paragraphs (c)(1) through (9) of this section that is added to a plant site and is subject to the requirements for existing sources shall comply with the reporting and recordkeeping requirements that are applicable to existing sources including, but not limited to, the reports listed in paragraphs (l)(3)(i) through (vii) of this section. A process change to an existing petroleum refining process unit shall be subject to the reporting requirements for existing sources including, but not limited to, the reports listed in paragraphs (l)(3)(i) through (vii) of this section. The applicable reports include, but are not limited to:

(i) The Notification of Compliance Status report as required by §63.655(f) for the emission points that were added or changed;

(ii) Periodic Reports and other reports as required by §63.655(g) and (h);

(iii) Reports and notifications required by sections of subpart A of this part that are applicable to this subpart, as identified in table 6 of this subpart.

(iv) Reports and notifications required by §63.182, or 40 CFR 60.487. The requirements of subpart H of this part are summarized in table 3 of this subpart;

(v) Reports required by §61.357 of subpart FF;

(vi) Reports and notifications required by §63.428(b), (c), (g)(1), (h)(1) through (h)(3), and (k) of subpart R. These requirements are summarized in table 4 of this subpart; and

(vii) Reports and notifications required by §§63.565 and 63.567 of subpart Y. These requirements are summarized in table 5 of this subpart.

(4) If pumps, compressors, pressure relief devices, sampling connection systems, open-ended valves or lines, valves, or instrumentation systems are added to an existing source, they are subject to the equipment leak standards for existing sources in §63.648. A notification of compliance status report shall not be required for such added equipment.

(m) If a change that does not meet the criteria in paragraph (l) of this section is made to a petroleum refining process unit subject to this subpart, and the change causes a Group 2 emission point to become a Group 1 emission point (as defined in §63.641), then the owner or operator shall comply with the applicable requirements of this subpart for existing sources, as specified in item (4) of table 11 of this subpart, for the Group 1 emission point as expeditiously as practicable, but in no event later than 3 years after the emission point becomes Group 1.

(1) The owner or operator shall submit to the Administrator for approval a compliance schedule, along with a justification for the schedule.

(2) The compliance schedule shall be submitted within 180 days after the change is made, unless the compliance schedule has been previously submitted to the permitting authority. If it is not possible to determine until after the change is implemented whether the emission point has become Group 1, the compliance schedule shall be submitted within 180 days of the date when the affect of the change is known to the source. The compliance schedule may be submitted in the next Periodic Report if the change is made after the date the Notification of Compliance Status report is due.

(3) The Administrator shall approve or deny the compliance schedule or request changes within 120 calendar days of receipt of the compliance schedule and justification. Approval is automatic if not received from the Administrator within 120 calendar days of receipt.

(n) Overlap of this subpart with other regulations for storage vessels. As applicable, paragraphs (n)(1), (3), (4), (6), and (7) of this section apply for Group 2 storage vessels and paragraphs (n)(2) and (5) of this section apply for Group 1 storage vessels.

(1) After the compliance dates specified in paragraph (h) of this section, a Group 2 storage vessel that is subject to the provisions of 40 CFR part 60, subpart Kb, is required to comply only with the requirements of 40 CFR part 60, subpart Kb, except as provided in paragraph (n)(8) of this section. After the compliance dates specified in paragraph (h) of this section, a Group 2 storage vessel that is subject to the provisions of 40 CFR part 61, subpart Y, is required to comply only with the requirements of 40 CFR part 61, subpart Y, except as provided in paragraph (n)(10) of this section.

(2) After the compliance dates specified in paragraph (h) of this section, a Group 1 storage vessel that is also subject to 40 CFR part 60, subpart Kb, is required to comply only with either 40 CFR part 60, subpart Kb, except as provided in paragraph (n)(8) of this section or this subpart. After the compliance dates specified in paragraph (h) of this section, a Group 1 storage vessel that is also subject to 40 CFR part 61, subpart Y, is required to comply only with either 40 CFR part 61, subpart Y, except as provided in paragraph (n)(10) of this section or this subpart.

(3) After the compliance dates specified in paragraph (h) of this section, a Group 2 storage vessel that is part of a new source and is subject to 40 CFR 60.110b, but is not required to apply controls by 40 CFR 60.110b or 60.112b, is required to comply only with this subpart.

(4) After the compliance dates specified in paragraph (h) of this section, a Group 2 storage vessel that is part of a new source and is subject to 40 CFR 61.270, but is not required to apply controls by 40 CFR 61.271, is required to comply only with this subpart.

(5) After the compliance dates specified in paragraph (h) of this section, a Group 1 storage vessel that is also subject to the provisions of 40 CFR part 60, subpart K or Ka, is required to only comply with the provisions of this subpart.

(6) After compliance dates specified in paragraph (h) of this section, a Group 2 storage vessel that is subject to the control requirements of 40 CFR part 60, subparts K or Ka is required to comply only with the provisions of 40 CFR part 60, subparts K or Ka except as provided for in paragraph (n)(9) of this section.

(7) After the compliance dates specified in paragraph (h) of this section, a Group 2 storage vessel that is subject to 40 CFR part 60, subparts K or Ka, but not to the control requirements of 40 CFR part 60, subparts K or Ka, is required to comply only with this subpart.

(8) Storage vessels described by paragraph (n)(1) of this section are to comply with 40 CFR part 60, subpart Kb, except as provided in paragraphs (n)(8)(i) through (vi) of this section. Storage vessels described by paragraph (n)(2) electing to comply with part 60, subpart Kb of this chapter shall comply with subpart Kb except as provided in paragraphs (n)(8)(i) through (viii) of this section.

(i) Storage vessels that are to comply with §60.112b(a)(2) of subpart Kb are exempt from the secondary seal requirements of §60.112b(a)(2)(i)(B) during the gap measurements for the primary seal required by §60.113b(b) of subpart Kb.

(ii) If the owner or operator determines that it is unsafe to perform the seal gap measurements required in §60.113b(b) of this chapter or to inspect the vessel to determine compliance with §60.113b(a) of this chapter because the roof appears to be structurally unsound and poses an imminent danger to inspecting personnel, the owner or operator shall comply with the requirements in either §63.120(b)(7)(i) or (ii) of subpart G (only up to the compliance date specified in paragraph (h) of this section for compliance with §63.660, as applicable) or either §63.1063(c)(2)(iv)(A) or (B) of subpart WW.

(iii) If a failure is detected during the inspections required by §60.113b(a)(2) or during the seal gap measurements required by §60.113b(b)(1), and the vessel cannot be repaired within 45 days and the vessel cannot be emptied within 45 days, the owner or operator may utilize up to two extensions of up to 30 additional calendar days each. The owner or operator is not required to provide a request for the extension to the Administrator.

(iv) If an extension is utilized in accordance with paragraph (n)(8)(iii) of this section, the owner or operator shall, in the next periodic report, identify the vessel, provide the information listed in §60.113b(a)(2) or §60.113b(b)(4)(iii), and describe the nature and date of the repair made or provide the date the storage vessel was emptied.

(v) Owners and operators of storage vessels complying with subpart Kb of part 60 may submit the inspection reports required by §§60.115b(a)(3), (a)(4), and (b)(4) of subpart Kb as part of the periodic reports required by this subpart, rather than within the 30-day period specified in §§60.115b(a)(3), (a)(4), and (b)(4) of subpart Kb.

(vi) The reports of rim seal inspections specified in §60.115b(b)(2) are not required if none of the measured gaps or calculated gap areas exceed the limitations specified in §60.113b(b)(4). Documentation of the inspections shall be recorded as specified in §60.115b(b)(3).

(vii) To be in compliance with §60.112b(a)(1)(iv) or (a)(2)(ii) of this chapter, guidepoles in floating roof storage vessels must be equipped with covers and/or controls (e.g., pole float system, pole sleeve system, internal sleeve system or flexible enclosure system) as appropriate to comply with the “no visible gap” requirement.

(viii) If a flare is used as a control device for a storage vessel, on and after January 30, 2019, the owner or operator must meet the requirements of §63.670 instead of the requirements referenced from part 60, subpart Kb of this chapter for that flare.

(9) Storage vessels described by paragraph (n)(6) of this section that are to comply with 40 CFR part 60, subpart Ka, are to comply with only subpart Ka except as provided for in paragraphs (n)(9)(i) through (n)(9)(iv) of this section.

(i) If the owner or operator determines that it is unsafe to perform the seal gap measurements required in §60.113a(a)(1) of this chapter because the floating roof appears to be structurally unsound and poses an imminent danger to inspecting personnel, the owner or operator shall comply with the requirements in either §63.120(b)(7)(i) or (ii) of subpart G (only up to the compliance date specified in paragraph (h) of this section for compliance with §63.660, as applicable) or either §63.1063(c)(2)(iv)(A) or (B) of subpart WW.

(ii) If a failure is detected during the seal gap measurements required by §60.113a(a)(1) of subpart Ka, and the vessel cannot be repaired within 45 days and the vessel cannot be emptied within 45 days, the owner or operator may utilize up to 2 extensions of up to 30 additional calendar days each.

(iii) If an extension is utilized in accordance with paragraph (n)(9)(ii) of this section, the owner or operator shall, in the next periodic report, identify the vessel, describe the nature and date of the repair made or provide the date the storage vessel was emptied. The owner or operator shall also provide documentation of the decision to utilize an extension including a description of the failure, documentation that alternate storage capacity is unavailable, and a schedule of actions that will ensure that the control equipment will be repaired or the vessel emptied as soon as possible.

(iv) Owners and operators of storage vessels complying with subpart Ka of part 60 may submit the inspection reports required by §60.113a(a)(1)(i)(E) of subpart Ka as part of the periodic reports required by this subpart, rather than within the 60-day period specified in §60.113a(a)(1)(i)(E) of subpart Ka.

(10) Storage vessels described by paragraph (n)(1) of this section are to comply with 40 CFR part 61, subpart Y, except as provided in paragraphs (n)(10)(i) through (vi) of this section. Storage vessels described by paragraph (n)(2) electing to comply with 40 CFR part 61, subpart Y, shall comply with subpart Y except as provided for in paragraphs (n)(10)(i) through (viii) of this section.

(i) Storage vessels that are to comply with §61.271(b) of this chapter are exempt from the secondary seal requirements of §61.271(b)(2)(ii) of this chapter during the gap measurements for the primary seal required by §61.272(b) of this chapter.

(ii) If the owner or operator determines that it is unsafe to perform the seal gap measurements required in §61.272(b) of this chapter or to inspect the vessel to determine compliance with §61.272(a) of this chapter because the roof appears to be structurally unsound and poses an imminent danger to inspecting personnel, the owner or operator shall comply with the requirements in either §63.120(b)(7)(i) or (ii) of subpart G (only up to the compliance date specified in paragraph (h) of this section for compliance with §63.660, as applicable) or either §63.1063(c)(2)(iv)(A) or (B) of subpart WW.

(iii) If a failure is detected during the inspections required by §61.272(a)(2) of this chapter or during the seal gap measurements required by §61.272(b)(1) of this chapter, and the vessel cannot be repaired within 45 days and the vessel cannot be emptied within 45 days, the owner or operator may utilize up to two extensions of up to 30 additional calendar days each. The owner or operator is not required to provide a request for the extension to the Administrator.

(iv) If an extension is utilized in accordance with paragraph (n)(10)(iii) of this section, the owner or operator shall, in the next periodic report, identify the vessel, provide the information listed in §61.272(a)(2) or (b)(4)(iii) of this chapter, and describe the nature and date of the repair made or provide the date the storage vessel was emptied.

(v) Owners and operators of storage vessels complying with 40 CFR part 61, subpart Y, may submit the inspection reports required by §61.275(a), (b)(1), and (d) of this chapter as part of the periodic reports required by this subpart, rather than within the 60-day period specified in §61.275(a), (b)(1), and (d) of this chapter.

(vi) The reports of rim seal inspections specified in §61.275(d) of this chapter are not required if none of the measured gaps or calculated gap areas exceed the limitations specified in §61.272(b)(4) of this chapter. Documentation of the inspections shall be recorded as specified in §61.276(a) of this chapter.

(vii) To be in compliance with §61.271(a)(6) or (b)(3) of this chapter, guidepoles in floating roof storage vessels must be equipped with covers and/or controls (e.g., pole float system, pole sleeve system, internal sleeve system or flexible enclosure system) as appropriate to comply with the “no visible gap” requirement.

(viii) If a flare is used as a control device for a storage vessel, on and after January 30, 2019, the owner or operator must meet the requirements of §63.670 instead of the requirements referenced from part 61, subpart Y of this chapter for that flare.

(o) Overlap of this subpart CC with other regulations for wastewater.

(1) After the compliance dates specified in paragraph (h) of this section a Group 1 wastewater stream managed in a piece of equipment that is also subject to the provisions of 40 CFR part 60, subpart QQQ is required to comply only with this subpart.

(2) After the compliance dates specified in paragraph (h) of this section a Group 1 or Group 2 wastewater stream that is conveyed, stored, or treated in a wastewater stream management unit that also receives streams subject to the provisions of §§63.133 through 63.147 of subpart G wastewater provisions of this part shall comply as specified in paragraph (o)(2)(i) or (o)(2)(ii) of this section. Compliance with the provisions of paragraph (o)(2) of this section shall constitute compliance with the requirements of this subpart for that wastewater stream.

(i) Comply with paragraphs (o)(2)(i)(A) through (D) of this section.

(A) The provisions in §§63.133 through 63.140 of subpart G for all equipment used in the storage and conveyance of the Group 1 or Group 2 wastewater stream.

(B) The provisions in both 40 CFR part 61, subpart FF and in §§63.138 and 63.139 of subpart G for the treatment and control of the Group 1 or Group 2 wastewater stream.

(C) The provisions in §§63.143 through 63.148 of subpart G for monitoring and inspections of equipment and for recordkeeping and reporting requirements. The owner or operator is not required to comply with the monitoring, recordkeeping, and reporting requirements associated with the treatment and control requirements in 40 CFR part 61, subpart FF, §§61.355 through 61.357.

(D) If a flare is used as a control device, on and after January 30, 2019, the flare shall meet the requirements of §63.670. Prior to January 30, 2019, the flare shall meet the applicable requirements of 40 CFR part 61, subpart FF, and subpart G of this part, or the requirements of §63.670.

(ii) Comply with paragraphs (o)(2)(ii)(A) through (C) of this section.

(A) Comply with the provisions of §§63.133 through 63.148 and §§63.151 and 63.152 of subpart G.

(B) For any Group 2 wastewater stream or organic stream whose benzene emissions are subject to control through the use of one or more treatment processes or waste management units under the provisions of 40 CFR part 61, subpart FF on or after December 31, 1992, comply with the requirements of §63.133 through §63.147 of subpart G for Group 1 wastewater streams.

(C) If a flare is used as a control device, on and after January 30, 2019, the flare shall meet the requirements of §63.670. Prior to January 30, 2019, the flare shall meet the applicable requirements of 40 CFR part 61, subpart FF, and subpart G of this part, or the requirements of §63.670.

(p) Overlap of subpart CC with other regulations for equipment leaks.

(1) After the compliance dates specified in paragraph (h) of this section, equipment leaks that are also subject to the provisions of 40 CFR parts 60 and 61 standards promulgated before September 4, 2007, are required to comply only with the provisions specified in this subpart.

(2) Equipment leaks that are also subject to the provisions of 40 CFR part 60, subpart GGGa, are required to comply only with the provisions specified in 40 CFR part 60, subpart GGGa, except that pressure relief devices in organic HAP service must only comply with the requirements in §63.648(j).

(q) For overlap of subpart CC with local or State regulations, the permitting authority for the affected source may allow consolidation of the monitoring, recordkeeping, and reporting requirements under this subpart with the monitoring, recordkeeping, and reporting requirements under other applicable requirements in 40 CFR parts 60, 61, or 63, and in any 40 CFR part 52 approved State implementation plan provided the implementation plan allows for approval of alternative monitoring, reporting, or recordkeeping requirements and provided that the permit contains an equivalent degree of compliance and control.

(r) Overlap of subpart CC with other regulations for gasoline loading racks. After the compliance dates specified in paragraph (h) of this section, a Group 1 gasoline loading rack that is part of a source subject to subpart CC and also is subject to the provisions of 40 CFR part 60, subpart XX is required to comply only with this subpart.

(s) Overlap of this subpart with other regulation for flares. On January 30, 2019, flares that are subject to the provisions of 40 CFR 60.18 or 63.11 and subject to this subpart are required to comply only with the provisions specified in this subpart. Prior to January 30, 2019, flares that are subject to the provisions of 40 CFR 60.18 or 63.11 and elect to comply with the requirements in §§63.670 and 63.671 are required to comply only with the provisions specified in this subpart.

[60 FR 43260, Aug. 18, 1995; 61 FR 7051, Feb. 23, 1996, as amended at 61 FR 29878, June 12, 1996; 63 FR 44140, Aug. 18, 1998; 66 FR 28841, May 25, 2001; 74 FR 55683, Oct. 28, 2009; 78 FR 37145, June 20, 2013; 80 FR 75237, Dec. 1, 2015; 85 FR 6082, Feb. 4, 2020]

§63.641 Definitions.

All terms used in this subpart shall have the meaning given them in the Clean Air Act, subpart A of this part, and in this section. If the same term is defined in subpart A and in this section, it shall have the meaning given in this section for purposes of this subpart.

Affected source means the collection of emission points to which this subpart applies as determined by the criteria in §63.640.

Aliphatic means open-chained structure consisting of paraffin, olefin and acetylene hydrocarbons and derivatives.

Annual average true vapor pressure means the equilibrium partial pressure exerted by the stored liquid at the temperature equal to the annual average of the liquid storage temperature for liquids stored above or below the ambient temperature or at the local annual average temperature reported by the National Weather Service for liquids stored at the ambient temperature, as determined:

(1) In accordance with methods specified in §63.111 of subpart G of this part;

(2) From standard reference texts; or

(3) By any other method approved by the Administrator.

Assist air means all air that intentionally is introduced prior to or at a flare tip through nozzles or other hardware conveyance for the purposes including, but not limited to, protecting the design of the flare tip, promoting turbulence for mixing or inducing air into the flame. Assist air includes premix assist air and perimeter assist air. Assist air does not include the surrounding ambient air.

Assist steam means all steam that intentionally is introduced prior to or at a flare tip through nozzles or other hardware conveyance for the purposes including, but not limited to, protecting the design of the flare tip, promoting turbulence for mixing or inducing air into the flame. Assist steam includes, but is not necessarily limited to, center steam, lower steam and upper steam.

Boiler means any enclosed combustion device that extracts useful energy in the form of steam and is not an incinerator.

By compound means by individual stream components, not by carbon equivalents.

Car-seal means a seal that is placed on a device that is used to change the position of a valve (e.g., from opened to closed) in such a way that the position of the valve cannot be changed without breaking the seal.

Center steam means the portion of assist steam introduced into the stack of a flare to reduce burnback.

Closed blowdown system means a system used for depressuring process vessels that is not open to the atmosphere and is configured of piping, ductwork, connections, accumulators/knockout drums, and, if necessary, flow inducing devices that transport gas or vapor from a process vessel to a control device or back into the process.

Closed vent system means a system that is not open to the atmosphere and is configured of piping, ductwork, connections, and, if necessary, flow inducing devices that transport gas or vapor from an emission point to a control device or back into the process. If gas or vapor from regulated equipment is routed to a process (e.g., to a petroleum refinery fuel gas system), the process shall not be considered a closed vent system and is not subject to closed vent system standards.

Combustion device means an individual unit of equipment such as a flare, incinerator, process heater, or boiler used for the combustion of organic hazardous air pollutant vapors.

Combustion zone means the area of the flare flame where the combustion zone gas combines for combustion.

Combustion zone gas means all gases and vapors found just after a flare tip. This gas includes all flare vent gas, total steam, and premix air.

Connector means flanged, screwed, or other joined fittings used to connect two pipe lines or a pipe line and a piece of equipment. A common connector is a flange. Joined fittings welded completely around the circumference of the interface are not considered connectors for the purpose of this regulation. For the purpose of reporting and recordkeeping, connector means joined fittings that are accessible.

Continuous record means documentation, either in hard copy or computer readable form, of data values measured at least once every hour and recorded at the frequency specified in §63.655(i).

Continuous recorder means a data recording device recording an instantaneous data value or an average data value at least once every hour.

Control device means any equipment used for recovering, removing, or oxidizing organic hazardous air pollutants. Such equipment includes, but is not limited to, absorbers, carbon adsorbers, condensers, incinerators, flares, boilers, and process heaters. For miscellaneous process vents (as defined in this section), recovery devices (as defined in this section) are not considered control devices.

Cooling tower means a heat removal device used to remove the heat absorbed in circulating cooling water systems by transferring the heat to the atmosphere using natural or mechanical draft.

Cooling tower return line means the main water trunk lines at the inlet to the cooling tower before exposure to the atmosphere.

Decoking operations means the sequence of steps conducted at the end of the delayed coking unit's cooling cycle to open the coke drum to the atmosphere in order to remove coke from the coke drum. Decoking operations begin at the end of the cooling cycle when steam released from the coke drum is no longer discharged via the unit's blowdown system but instead is vented directly to the atmosphere. Decoking operations include atmospheric depressuring (venting), deheading, draining, and decoking (coke cutting).

Delayed coking unit means a refinery process unit in which high molecular weight petroleum derivatives are thermally cracked and petroleum coke is produced in a series of closed, batch system reactors. A delayed coking unit includes, but is not limited to, all of the coke drums associated with a single fractionator; the fractionator, including the bottoms receiver and the overhead condenser; the coke drum cutting water and quench system, including the jet pump and coker quench water tank; and the coke drum blowdown recovery compressor system.

Delayed coker vent means a miscellaneous process vent that contains uncondensed vapors from the delayed coking unit's blowdown system. Venting from the delayed coker vent is typically intermittent in nature, and occurs primarily during the cooling cycle of a delayed coking unit coke drum when vapor from the coke drums cannot be sent to the fractionator column for product recovery. The emissions from the decoking operations, which include direct atmospheric venting, deheading, draining, or decoking (coke cutting), are not considered to be delayed coker vents.

Distillate receiver means overhead receivers, overhead accumulators, reflux drums, and condenser(s) including ejector-condenser(s) associated with a distillation unit.

Distillation unit means a device or vessel in which one or more feed streams are separated into two or more exit streams, each exit stream having component concentrations different from those in the feed stream(s). The separation is achieved by the redistribution of the components between the liquid and the vapor phases by vaporization and condensation as they approach equilibrium within the distillation unit. Distillation unit includes the distillate receiver, reboiler, and any associated vacuum pump or steam jet.

Emission point means an individual miscellaneous process vent, storage vessel, wastewater stream, equipment leak, decoking operation or heat exchange system associated with a petroleum refining process unit; an individual storage vessel or equipment leak associated with a bulk gasoline terminal or pipeline breakout station classified under Standard Industrial Classification code 2911; a gasoline loading rack classified under Standard Industrial Classification code 2911; or a marine tank vessel loading operation located at a petroleum refinery.

Equipment leak means emissions of organic hazardous air pollutants from a pump, compressor, pressure relief device, sampling connection system, open-ended valve or line, valve, or instrumentation system “in organic hazardous air pollutant service” as defined in this section. Vents from wastewater collection and conveyance systems (including, but not limited to wastewater drains, sewer vents, and sump drains), tank mixers, and sample valves on storage tanks are not equipment leaks.

Flame zone means the portion of a combustion chamber of a boiler or process heater occupied by the flame envelope created by the primary fuel.

Flare means a combustion device lacking an enclosed combustion chamber that uses an uncontrolled volume of ambient air to burn gases. For the purposes of this rule, the definition of flare includes, but is not necessarily limited to, pressure-assisted flares, air-assisted flares, steam-assisted flares, and non-assisted flares.

Flare purge gas means gas introduced between a flare header's water seal and the flare tip to prevent oxygen infiltration (backflow) into the flare tip or for other safety reasons. For a flare with no water seal, the function of flare purge gas is performed by flare sweep gas and, therefore, by definition, such a flare has no flare purge gas.

Flare supplemental gas means all gas introduced to the flare to improve the heat content of combustion zone gas. Flare supplemental gas does not include assist air or assist steam.

Flare sweep gas means, for a flare with a flare gas recovery system, the gas intentionally introduced into the flare header system to maintain a constant flow of gas through the flare header in order to prevent oxygen buildup in the flare header; flare sweep gas in these flares is introduced prior to and recovered by the flare gas recovery system. For a flare without a flare gas recovery system, flare sweep gas means the gas intentionally introduced into the flare header system to maintain a constant flow of gas through the flare header and out the flare tip in order to prevent oxygen buildup in the flare header and to prevent oxygen infiltration (backflow) into the flare tip.

Flare vent gas means all gas found just prior to the flare tip. This gas includes all flare waste gas (i.e., gas from facility operations that is directed to a flare for the purpose of disposing of the gas), that portion of flare sweep gas that is not recovered, flare purge gas and flare supplemental gas, but does not include pilot gas, total steam or assist air.

Flexible enclosure device means a seal made of an elastomeric fabric (or other material) which completely encloses a slotted guidepole or ladder and eliminates the vapor emission pathway from inside the storage vessel through the guidepole slots or ladder slots to the outside air.

Flexible operation unit means a process unit that manufactures different products periodically by alternating raw materials or operating conditions. These units are also referred to as campaign plants or blocked operations.

Flow indicator means a device that indicates whether gas is flowing, or whether the valve position would allow gas to flow, in a line.

Force majeure event means a release of HAP, either directly to the atmosphere from a pressure relief device or discharged via a flare, that is demonstrated to the satisfaction of the Administrator to result from an event beyond the refinery owner or operator's control, such as natural disasters; acts of war or terrorism; loss of a utility external to the refinery (e.g., external power curtailment), excluding power curtailment due to an interruptible service agreement; and fire or explosion originating at a near or adjoining facility outside of the refinery that impacts the refinery's ability to operate.

Fuel gas system means the offsite and onsite piping and control system that gathers gaseous streams generated by refinery operations, may blend them with sources of gas, if available, and transports the blended gaseous fuel at suitable pressures for use as fuel in heaters, furnaces, boilers, incinerators, gas turbines, and other combustion devices located within or outside of the refinery. The fuel is piped directly to each individual combustion device, and the system typically operates at pressures over atmospheric. The gaseous streams can contain a mixture of methane, light hydrocarbons, hydrogen and other miscellaneous species.

Gasoline means any petroleum distillate or petroleum distillate/alcohol blend having a Reid vapor pressure of 27.6 kilopascals or greater that is used as a fuel for internal combustion engines.

Gasoline loading rack means the loading arms, pumps, meters, shutoff valves, relief valves, and other piping and valves necessary to fill gasoline cargo tanks.

Group 1 gasoline loading rack means any gasoline loading rack classified under Standard Industrial Classification code 2911 that is located within a bulk gasoline terminal that has a gasoline throughput greater than 75,700 liters per day. Gasoline throughput shall be the maximum calculated design throughput for the terminal as may be limited by compliance with enforceable conditions under Federal, State, or local law and discovered by the Administrator and any other person.

Group 1 marine tank vessel means a vessel at an existing source loaded at any land- or sea-based terminal or structure that loads liquid commodities with vapor pressures greater than or equal to 10.3 kilopascals in bulk onto marine tank vessels, that emits greater than 9.1 megagrams of any individual HAP or 22.7 megagrams of any combination of HAP annually after August 18, 1999, or a vessel at a new source loaded at any land- or sea-based terminal or structure that loads liquid commodities with vapor pressures greater than or equal to 10.3 kilopascals onto marine tank vessels.

Group 1 miscellaneous process vent means a miscellaneous process vent for which the total organic HAP concentration is greater than or equal to 20 parts per million by volume, and the total volatile organic compound emissions are greater than or equal to 33 kilograms per day for existing sources and 6.8 kilograms per day for new sources at the outlet of the final recovery device (if any) and prior to any control device and prior to discharge to the atmosphere.

Group 1 storage vessel means:

(1) Prior to February 1, 2016:

(i) A storage vessel at an existing source that has a design capacity greater than or equal to 177 cubic meters and stored-liquid maximum true vapor pressure greater than or equal to 10.4 kilopascals and stored-liquid annual average true vapor pressure greater than or equal to 8.3 kilopascals and annual average HAP liquid concentration greater than 4 percent by weight total organic HAP;

(ii) A storage vessel at a new source that has a design storage capacity greater than or equal to 151 cubic meters and stored-liquid maximum true vapor pressure greater than or equal to 3.4 kilopascals and annual average HAP liquid concentration greater than 2 percent by weight total organic HAP; or

(iii) A storage vessel at a new source that has a design storage capacity greater than or equal to 76 cubic meters and less than 151 cubic meters and stored-liquid maximum true vapor pressure greater than or equal to 77 kilopascals and annual average HAP liquid concentration greater than 2 percent by weight total organic HAP.

(2) On and after February 1, 2016:

(i) A storage vessel at an existing source that has a design capacity greater than or equal to 151 cubic meters (40,000 gallons) and stored-liquid maximum true vapor pressure greater than or equal to 5.2 kilopascals (0.75 pounds per square inch) and annual average HAP liquid concentration greater than 4 percent by weight total organic HAP;

(ii) A storage vessel at an existing source that has a design storage capacity greater than or equal to 76 cubic meters (20,000 gallons) and less than 151 cubic meters (40,000 gallons) and stored-liquid maximum true vapor pressure greater than or equal to 13.1 kilopascals (1.9 pounds per square inch) and annual average HAP liquid concentration greater than 4 percent by weight total organic HAP;

(iii) A storage vessel at a new source that has a design storage capacity greater than or equal to 151 cubic meters (40,000 gallons) and stored-liquid maximum true vapor pressure greater than or equal to 3.4 kilopascals (0.5 pounds per square inch) and annual average HAP liquid concentration greater than 2 percent by weight total organic HAP; or

(iv) A storage vessel at a new source that has a design storage capacity greater than or equal to 76 cubic meters (20,000 gallons) and less than 151 cubic meters (40,000 gallons) and stored-liquid maximum true vapor pressure greater than or equal to 13.1 kilopascals (1.9 pounds per square inch) and annual average HAP liquid concentration greater than 2 percent by weight total organic HAP.

Group 1 wastewater stream means a wastewater stream at a petroleum refinery with a total annual benzene loading of 10 megagrams per year or greater as calculated according to the procedures in 40 CFR 61.342 of subpart FF of part 61 that has a flow rate of 0.02 liters per minute or greater, a benzene concentration of 10 parts per million by weight or greater, and is not exempt from control requirements under the provisions of 40 CFR part 61, subpart FF.

Group 2 gasoline loading rack means a gasoline loading rack classified under Standard Industrial Classification code 2911 that does not meet the definition of a Group 1 gasoline loading rack.

Group 2 marine tank vessel means a marine tank vessel that does not meet the definition of a Group 1 marine tank vessel.

Group 2 miscellaneous process vent means a miscellaneous process vent that does not meet the definition of a Group 1 miscellaneous process vent.

Group 2 storage vessel means a storage vessel that does not meet the definition of a Group 1 storage vessel.

Group 2 wastewater stream means a wastewater stream that does not meet the definition of Group 1 wastewater stream.

Hazardous air pollutant or HAP means one of the chemicals listed in section 112(b) of the Clean Air Act.

Heat exchange system means a device or collection of devices used to transfer heat from process fluids to water without intentional direct contact of the process fluid with the water (i.e., non-contact heat exchanger) and to transport and/or cool the water in a closed-loop recirculation system (cooling tower system) or a once-through system (e.g., river or pond water). For closed-loop recirculation systems, the heat exchange system consists of a cooling tower, all petroleum refinery process unit heat exchangers that are in organic HAP service, as defined in this subpart, serviced by that cooling tower, and all water lines to and from these petroleum refinery process unit heat exchangers. For once-through systems, the heat exchange system consists of all heat exchangers that are in organic HAP service, as defined in this subpart, servicing an individual petroleum refinery process unit and all water lines to and from these heat exchangers. Sample coolers or pump seal coolers are not considered heat exchangers for the purpose of this definition and are not part of the heat exchange system. Intentional direct contact with process fluids results in the formation of a wastewater.

Heat exchanger exit line means the cooling water line from the exit of one or more heat exchangers (where cooling water leaves the heat exchangers) to either the entrance of the cooling tower return line or prior to exposure to the atmosphere, in, as an example, a once-through cooling system, whichever occurs first.

Incinerator means an enclosed combustion device that is used for destroying organic compounds. Auxiliary fuel may be used to heat waste gas to combustion temperatures. Any energy recovery section present is not physically formed into one manufactured or assembled unit with the combustion section; rather, the energy recovery section is a separate section following the combustion section and the two are joined by ducts or connections carrying flue gas.

In heavy liquid service means that the piece of equipment is not in gas/vapor service or in light liquid service.

In light liquid service means that the piece of equipment contains a liquid that meets the conditions specified in §60.593(d) of part 60, subpart GGG.

In organic hazardous air pollutant service or in organic HAP service means that a piece of equipment either contains or contacts a fluid (liquid or gas) that is at least 5 percent by weight of total organic HAP as determined according to the provisions of §63.180(d) of this part and table 1 of this subpart. The provisions of §63.180(d) also specify how to determine that a piece of equipment is not in organic HAP service.

Leakless valve means a valve that has no external actuating mechanism.

Lower steam means the portion of assist steam piped to an exterior annular ring near the lower part of a flare tip, which then flows through tubes to the flare tip, and ultimately exits the tubes at the flare tip.

Maximum true vapor pressure means the equilibrium partial pressure exerted by the stored liquid at the temperature equal to the highest calendar-month average of the liquid storage temperature for liquids stored above or below the ambient temperature or at the local maximum monthly average temperature as reported by the National Weather Service for liquids stored at the ambient temperature, as determined:

(1) In accordance with methods specified in §63.111 of subpart G of this part;

(2) From standard reference texts; or

(3) By any other method approved by the Administrator.

Miscellaneous process vent means a gas stream containing greater than 20 parts per million by volume organic HAP that is continuously or periodically discharged from a petroleum refining process unit meeting the criteria specified in §63.640(a). Miscellaneous process vents include gas streams that are discharged directly to the atmosphere, gas streams that are routed to a control device prior to discharge to the atmosphere, or gas streams that are diverted through a product recovery device prior to control or discharge to the atmosphere. Miscellaneous process vents include vent streams from: Caustic wash accumulators, distillation tower condensers/accumulators, flash/knockout drums, reactor vessels, scrubber overheads, stripper overheads, vacuum pumps, steam ejectors, hot wells, high point bleeds, wash tower overheads, water wash accumulators, blowdown condensers/accumulators, and delayed coker vents. Miscellaneous process vents do not include:

(1) Gaseous streams routed to a fuel gas system, provided that on and after January 30, 2019, any flares receiving gas from the fuel gas system are in compliance with §63.670;

(2) Pressure relief device discharges;

(3) Leaks from equipment regulated under §63.648;

(4) [Reserved]

(5) In situ sampling systems (onstream analyzers) until February 1, 2016. After this date, these sampling systems will be included in the definition of miscellaneous process vents and sampling systems determined to be Group 1 miscellaneous process vents must comply with the requirements in §§63.643 and 63.644 no later than January 30, 2019;

(6) Catalytic cracking unit catalyst regeneration vents;

(7) Catalytic reformer regeneration vents;

(8) Sulfur plant vents;

(9) Vents from control devices such as scrubbers, boilers, incinerators, and electrostatic precipitators applied to catalytic cracking unit catalyst regeneration vents, catalytic reformer regeneration vents, and sulfur plant vents;

(10) Vents from any stripping operations applied to comply with the wastewater provisions of this subpart, subpart G of this part, or 40 CFR part 61, subpart FF;

(11) Emissions associated with delayed coking unit decoking operations;

(12) Vents from storage vessels;

(13) Emissions from wastewater collection and conveyance systems including, but not limited to, wastewater drains, sewer vents, and sump drains; and

(14) Hydrogen production plant vents through which carbon dioxide is removed from process streams or through which steam condensate produced or treated within the hydrogen plant is degassed or deaerated.

Net heating value means the energy released as heat when a compound undergoes complete combustion with oxygen to form gaseous carbon dioxide and gaseous water (also referred to as lower heating value).

Operating permit means a permit required by 40 CFR parts 70 or 71.

Organic hazardous air pollutant or organic HAP in this subpart, means any of the organic chemicals listed in table 1 of this subpart.

Perimeter assist air means the portion of assist air introduced at the perimeter of the flare tip or above the flare tip. Perimeter assist air includes air intentionally entrained in lower and upper steam. Perimeter assist air includes all assist air except premix assist air.

Periodically discharged means discharges that are intermittent and associated with routine operations, maintenance activities, startups, shutdowns, malfunctions, or process upsets.

Petroleum-based solvents means mixtures of aliphatic hydrocarbons or mixtures of one and two ring aromatic hydrocarbons.

Petroleum refining process unit means a process unit used in an establishment primarily engaged in petroleum refining as defined in the Standard Industrial Classification code for petroleum refining (2911), and used primarily for the following:

(1) Producing transportation fuels (such as gasoline, diesel fuels, and jet fuels), heating fuels (such as kerosene, fuel gas distillate, and fuel oils), or lubricants;

(2) Separating petroleum; or

(3) Separating, cracking, reacting, or reforming intermediate petroleum streams.

(4) Examples of such units include, but are not limited to, petroleum-based solvent units, alkylation units, catalytic hydrotreating, catalytic hydrorefining, catalytic hydrocracking, catalytic reforming, catalytic cracking, crude distillation, lube oil processing, hydrogen production, isomerization, polymerization, thermal processes, and blending, sweetening, and treating processes. Petroleum refining process units also include sulfur plants.

Pilot gas means gas introduced into a flare tip that provides a flame to ignite the flare vent gas.

Plant site means all contiguous or adjoining property that is under common control including properties that are separated only by a road or other public right-of-way. Common control includes properties that are owned, leased, or operated by the same entity, parent entity, subsidiary, or any combination thereof.

Premix assist air means the portion of assist air that is introduced to the flare vent gas, whether injected or induced, prior to the flare tip. Premix assist air also includes any air intentionally entrained in center steam.

Pressure relief device means a valve, rupture disk, or similar device used only to release an unplanned, nonroutine discharge of gas from process equipment in order to avoid safety hazards or equipment damage. A pressure relief device discharge can result from an operator error, a malfunction such as a power failure or equipment failure, or other unexpected cause. Such devices include conventional, spring-actuated relief valves, balanced bellows relief valves, pilot-operated relief valves, rupture disks, and breaking, buckling, or shearing pin devices.

Primary fuel means the fuel that provides the principal heat input (i.e., more than 50 percent) to the device. To be considered primary, the fuel must be able to sustain operation without the addition of other fuels.

Process heater means an enclosed combustion device that primarily transfers heat liberated by burning fuel directly to process streams or to heat transfer liquids other than water.

Process unit means the equipment assembled and connected by pipes or ducts to process raw and/or intermediate materials and to manufacture an intended product. A process unit includes any associated storage vessels. For the purpose of this subpart, process unit includes, but is not limited to, chemical manufacturing process units and petroleum refining process units.

Process unit shutdown means a work practice or operational procedure that stops production from a process unit or part of a process unit during which it is technically feasible to clear process material from a process unit or part of a process unit consistent with safety constraints and during which repairs can be accomplished. An unscheduled work practice or operational procedure that stops production from a process unit or part of a process unit for less than 24 hours is not considered a process unit shutdown. An unscheduled work practice or operational procedure that would stop production from a process unit or part of a process unit for a shorter period of time than would be required to clear the process unit or part of the process unit of materials and start up the unit, or would result in greater emissions than delay of repair of leaking components until the next scheduled process unit shutdown is not considered a process unit shutdown. The use of spare equipment and technically feasible bypassing of equipment without stopping production are not considered process unit shutdowns.

Recovery device means an individual unit of equipment capable of and used for the purpose of recovering chemicals for use, reuse, or sale. Recovery devices include, but are not limited to, absorbers, carbon adsorbers, and condensers.

Reference control technology for gasoline loading racks means a vapor collection and processing system used to reduce emissions due to the loading of gasoline cargo tanks to 10 milligrams of total organic compounds per liter of gasoline loaded or less.

Reference control technology for marine vessels means a vapor collection system and a control device that reduces captured HAP emissions by 97 percent.

Reference control technology for miscellaneous process vents means a combustion device used to reduce organic HAP emissions by 98 percent, or to an outlet concentration of 20 parts per million by volume.

Reference control technology for storage vessels means either:

(1) For Group 1 storage vessels complying with §63.660:

(i) An internal floating roof, including an external floating roof converted to an internal floating roof, meeting the specifications of §§63.1063(a)(1)(i), (a)(2), and (b) and 63.660(b)(2);

(ii) An external floating roof meeting the specifications of §§63.1063(a)(1)(ii), (a)(2), and (b) and 63.660(b)(2); or

(iii) [Reserved]

(iv) A closed-vent system to a control device that reduces organic HAP emissions by 95 percent, or to an outlet concentration of 20 parts per million by volume (ppmv).

(v) For purposes of emissions averaging, these four technologies are considered equivalent.

(2) For all other storage vessels:

(i) An internal floating roof meeting the specifications of §63.119(b) of subpart G except for §63.119(b)(5) and (6);

(ii) An external floating roof meeting the specifications of §63.119(c) of subpart G except for §63.119(c)(2);

(iii) An external floating roof converted to an internal floating roof meeting the specifications of §63.119(d) of subpart G except for §63.119(d)(2); or

(iv) A closed-vent system to a control device that reduces organic HAP emissions by 95 percent, or to an outlet concentration of 20 parts per million by volume.

(v) For purposes of emissions averaging, these four technologies are considered equivalent.

Reference control technology for wastewater means the use of:

(1) Controls specified in §§61.343 through 61.347 of subpart FF of part 61;

(2) A treatment process that achieves the emission reductions specified in table 7 of this subpart for each individual HAP present in the wastewater stream or is a steam stripper that meets the specifications in §63.138(g) of subpart G of this part; and

(3) A control device to reduce by 95 percent (or to an outlet concentration of 20 parts per million by volume for combustion devices) the organic HAP emissions in the vapor streams vented from treatment processes (including the steam stripper described in paragraph (2) of this definition) managing wastewater.

Refinery fuel gas means a gaseous mixture of methane, light hydrocarbons, hydrogen, and other miscellaneous species (nitrogen, carbon dioxide, hydrogen sulfide, etc.) that is produced in the refining of crude oil and/or petrochemical processes and that is separated for use as a fuel in boilers and process heaters throughout the refinery.

Regulated material means any stream associated with emission sources listed in §63.640(c) required to meet control requirements under this subpart as well as any stream for which this subpart or a cross-referencing subpart specifies that the requirements for flare control devices in §63.670 must be met.

Relief valve means a type of pressure relief device that is designed to re-close after the pressure relief.

Research and development facility means laboratory and pilot plant operations whose primary purpose is to conduct research and development into new processes and products, where the operations are under the close supervision of technically trained personnel, and is not engaged in the manufacture of products for commercial sale, except in a de minimis manner.

Shutdown means the cessation of a petroleum refining process unit or a unit operation (including, but not limited to, a distillation unit or reactor) within a petroleum refining process unit for purposes including, but not limited to, periodic maintenance, replacement of equipment, or repair.

Startup means the setting into operation of a petroleum refining process unit for purposes of production. Startup does not include operation solely for purposes of testing equipment. Startup does not include changes in product for flexible operation units.

Storage vessel means a tank or other vessel that is used to store organic liquids. Storage vessel does not include:

(1) Vessels permanently attached to motor vehicles such as trucks, railcars, barges, or ships;

(2) Pressure vessels designed to operate in excess of 204.9 kilopascals and without emissions to the atmosphere;

(3) Vessels with capacities smaller than 40 cubic meters;

(4) Bottoms receiver tanks; or

(5) Wastewater storage tanks. Wastewater storage tanks are covered under the wastewater provisions.

Temperature monitoring device means a unit of equipment used to monitor temperature and having an accuracy of ±1 percent of the temperature being monitored expressed in degrees Celsius or ±0.5°C, whichever is greater.

Thermal expansion relief valve means a pressure relief valve designed to protect equipment from excess pressure due to thermal expansion of blocked liquid-filled equipment or piping due to ambient heating or heat from a heat tracing system. Pressure relief valves designed to protect equipment from excess pressure due to blockage against a pump or compressor or due to fire contingency are not thermal expansion relief valves.

Total annual benzene means the total amount of benzene in waste streams at a facility on an annual basis as determined in §61.342 of 40 CFR part 61, subpart FF.

Total organic compounds or TOC, as used in this subpart, means those compounds excluding methane and ethane measured according to the procedures of Method 18 of 40 CFR part 60, appendix A. Method 25A may be used alone or in combination with Method 18 to measure TOC as provided in §63.645 of this subpart.

Total steam means the total of all steam that is supplied to a flare and includes, but is not limited to, lower steam, center steam and upper steam.

Upper steam means the portion of assist steam introduced via nozzles located on the exterior perimeter of the upper end of the flare tip.

Wastewater means water or wastewater that, during production or processing, comes into direct contact with or results from the production or use of any raw material, intermediate product, finished product, byproduct, or waste product and is discharged into any individual drain system. Examples are feed tank drawdown; water formed during a chemical reaction or used as a reactant; water used to wash impurities from organic products or reactants; water used to cool or quench organic vapor streams through direct contact; and condensed steam from jet ejector systems pulling vacuum on vessels containing organics.

Editorial Note: At 83 FR 60713, Nov. 26, 2018, §63.641 was amended by adding paragraphs (1)(i) and (ii) to the definition of “Reference control technology for storage vessels,” however due to an inaccurate amendatory instruction, these amendments could not be incorporated.

[60 FR 43260, Aug. 18, 1995, as amended at 61 FR 29879, June 12, 1996; 62 FR 7938, Feb. 21, 1997; 63 FR 31361, June 9, 1998; 63 FR 44141, Aug. 18, 1998; 74 FR 55685, Oct. 28, 2008; 78 FR 37146, June 20, 2013; 80 FR 75239, Dec. 1, 2015; 81 FR 45241, July 13, 2016; 83 FR 60713, Nov. 26, 2018; 85 FR 6082, Feb. 4, 2020; 89 FR 23858, April 4, 2024]

§63.642 General standards.

(a) Each owner or operator of a source subject to this subpart is required to apply for a part 70 or part 71 operating permit from the appropriate permitting authority. If the EPA has approved a State operating permit program under part 70, the permit shall be obtained from the State authority. If the State operating permit program has not been approved, the source shall apply to the EPA Regional Office pursuant to part 71.

(b) The emission standards set forth in this subpart shall apply at all times.

(c) Table 6 of this subpart specifies the provisions of subpart A of this part that apply and those that do not apply to owners and operators of sources subject to this subpart.

(d) Initial performance tests and initial compliance determinations shall be required only as specified in this subpart.

(1) Performance tests and compliance determinations shall be conducted according to the schedule and procedures specified in this subpart.

(2) The owner or operator shall notify the Administrator of the intention to conduct a performance test at least 30 days before the performance test is scheduled.

(3) Performance tests shall be conducted according to the provisions of §63.7(e) except that performance tests shall be conducted at maximum representative operating capacity for the process. During the performance test, an owner or operator shall operate the control device at either maximum or minimum representative operating conditions for monitored control device parameters, whichever results in lower emission reduction. An owner or operator shall not conduct a performance test during startup, shutdown, periods when the control device is bypassed or periods when the process, monitoring equipment or control device is not operating properly. The owner/operator may not conduct performance tests during periods of malfunction. The owner or operator must record the process information that is necessary to document operating conditions during the test and include in such record an explanation to support that the test was conducted at maximum representative operating capacity. Upon request, the owner or operator shall make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

(4) Data shall be reduced in accordance with the EPA-approved methods specified in the applicable section or, if other test methods are used, the data and methods shall be validated according to the protocol in Method 301 of appendix A of this part.

(e) All applicable records shall be maintained as specified in §63.655(i).

(f) All reports required under this subpart shall be sent to the Administrator at the addresses listed in §63.13 of subpart A of this part. If acceptable to both the Administrator and the owner or operator of a source, reports may be submitted on electronic media.

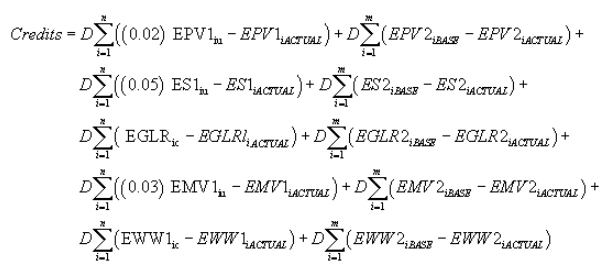

(g) The owner or operator of an existing source subject to the requirements of this subpart shall control emissions of organic HAP's to the level represented by the following equation:

EA = 0.02Σ EPV1 + Σ EPV2 + 0.05Σ ES1 + Σ ES2 + Σ EGLR1C + Σ EGLR2 + (R) Σ EMV1 + Σ EMV2 + Σ EWW1C + Σ EWW2

where:

EA = Emission rate, megagrams per year, allowed for the source.

0.02Σ EPV1 = Sum of the residual emissions, megagrams per year, from all Group 1 miscellaneous process vents, as defined in §63.641.

Σ EPV2 = Sum of the emissions, megagrams per year, from all Group 2 process vents, as defined in §63.641.

0.05Σ ES1 = Sum of the residual emissions, megagrams per year, from all Group 1 storage vessels, as defined in §63.641.

Σ ES2 = Sum of the emissions, megagrams per year, from all Group 2 storage vessels, as defined in §63.641.

Σ EGLR1C = Sum of the residual emissions, megagrams per year, from all Group 1 gasoline loading racks, as defined in §63.641.

Σ EGLR2 = Sum of the emissions, megagrams per year, from all Group 2 gasoline loading racks, as defined in §63.641.