['Air Programs']

['Hazardous Air Pollutants']

09/02/2024

...

(a) A performance test is required for determining compliance with the reduction of total organic HAP emissions in §63.126(b) of this subpart for all control devices except as specified in paragraph (c) of this section. Performance test procedures are as follows:

(1) For control devices shared between transfer racks and process vents, the performance test procedures in §63.116(c) of this subpart shall be followed.

(2) A performance test shall consist of three runs.

(3) All testing equipment shall be prepared and installed as specified in the appropriate test methods.

(4) For control devices shared between multiple arms that load simultaneously, the minimum sampling time for each run shall be 1 hour in which either an integrated sample or a minimum of four grab samples shall be taken. If grab sampling is used, then the samples shall be taken at approximately equal intervals in time, such as 15-minute intervals during the run.

(5) For control devices that are capable of continuous vapor processing but do not meet the conditions in (a)(7)(i)(B) of this section.

(A) Sampling sites shall be located at the inlet and outlet of the control device, except as provided in paragraph (a)(7)(i)(B) of this section.

(B) If a vent stream is introduced with the combustion air or as a secondary fuel into a boiler or process heater with a design capacity less than 44 megawatts, selection of paragraph (a)(1) or (a)(4) of this section, each run shall represent at least one complete filling period, during which liquid organic HAP's are loaded, and samples shall be collected using integrated sampling or grab samples taken at least four times per hour at approximately equal intervals of time, such as 15-minute intervals.

(6) For intermittent vapor processing systems that do not meet the conditions in paragraph (a)(1) or (a)(4) of this section, each run shall represent at least one complete control device cycle, and samples shall be collected using integrated sampling or grab samples taken at least four times per hour at approximately equal intervals of time, such as 15-minute intervals.

(7) Method 1 or 1A of 40 CFR part 60, appendix A, as appropriate, shall be used for selection of sampling sites.

(i) For an owner or operator complying with the 98-percent total organic HAP reduction requirements in §63.126(b)(1) of this subpart, sampling sites shall be located as specified in paragraph (a)(7)(i)(A) or (a)(7)(i)(B) of this section.

(A) Sampling sites shall be located at the inlet and outlet of the control device, except as provided in paragraph (a)(7)(i)(B) of this section.

(B) If a vent stream is introduced with the combustion air or as a secondary fuel into a boiler or process heater with a design capacity less than 44 megawatts, selection of the location of the inlet sampling sites shall ensure the measurement of total organic HAP or TOC (minus methane and ethane) concentrations in all vent streams and primary and secondary fuels introduced into the boiler or process heater. A sampling site shall also be located at the outlet of the boiler or process heater.

(ii) For an owner or operator complying with the 20 parts per million by volume limit in §63.126(b)(1) of this subpart, the sampling site shall be located at the outlet of the control device.

(8) The volumetric flow rate, in standard cubic meters per minute at 20°C, shall be determined using Method 2, 2A, 2C, or 2D of 40 CFR part 60, appendix A as appropriate.

(9) For the purpose of determining compliance with the 20 parts per million by volume limit in §63.126(b)(1), Method 18 or Method 25A of appendices A-6 and A-7 to part 60 of this chapter, respectively, shall be used to measure either organic compound concentration or organic HAP concentration, except as provided in paragraphs (a)(11) and (12) of this section.

(i) If Method 25A of appendix A-7 to part 60 of this chapter is used, the following procedures shall be used to calculate the concentration of organic compounds (C T):

(A) The principal organic HAP in the vent stream shall be used as the calibration gas.

(B) The span value for Method 25A of appendix A-7 to part 60 of this chapter shall be between 1.5 and 2.5 times the concentration being measured.

(C) Use of Method 25A of appendix A-7 to part 60 of this chapter is acceptable if the response from the high-level calibration gas is at least 20 times the standard deviation of the response from the zero calibration gas when the instrument is zeroed on the most sensitive scale.

(D) The concentration of TOC shall be corrected to 3 percent oxygen using the procedures and equation in paragraph (a)(9)(v) of this section.

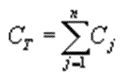

(ii) If Method 18 of appendix A-6 to 40 CFR part 60 is used to measure the concentration of organic compounds or ASTM D6420-18 (incorporated by reference, see §63.14), the organic compound concentration (CT) is the sum of the individual components and shall be computed for each run using the following equation:

Equation 1 to Paragraph (a)(9)(ii)

Where:

C T = Total concentration of organic compounds (minus methane and ethane), dry basis, parts per million by volume.

C j = Concentration of sample components j, dry basis, parts per million by volume.

n = Number of components in the sample.

(iii) If an owner or operator uses Method 18 of appendix A-6 to 40 CFR part 60 or ASTM D6420-18 (incorporated by reference, see §63.14) to compute total organic HAP concentration rather than organic compounds concentration, the equation in paragraph (a)(9)(ii) of this section shall be used except that only organic HAP species shall be summed. The list of organic HAP's is provided in table 2 to subpart F of this part.

(iv) Method 3A of appendix A-2 to 40 CFR part 60 or the manual method in ANSI/ASME PTC 19.10-1981 (incorporated by reference, see §63.14) shall be used to determine the oxygen concentration. The sampling site shall be the same as that of the organic hazardous air pollutants or organic compound samples, and the samples shall be taken during the same time that the organic hazardous air pollutants or organic compound samples are taken.

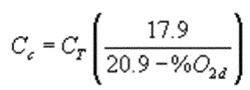

(v) The organic compound concentration corrected to 3 percent oxygen (Cc) shall be calculated using the following equation:

Equation 2 to Paragraph (a)(9)(v)

Where:

Cc = Concentration of organic compounds corrected to 3 percent oxygen, dry basis, parts per million by volume.

C T = Total concentration of organic compounds, dry basis, parts per million by volume.

%O2d = Concentration of oxygen, dry basis, percent by volume.

(10) For the purpose of determining compliance with the 98-percent reduction requirement in §63.126(b)(1), Method 18 or Method 25A of appendices A-6 and A-7 to part 60 of this chapter, respectively, shall be used, except as provided in paragraphs (a)(11) and (12) of this section.

(i) For the purpose of determining compliance with the reduction efficiency requirement, organic compound concentration may be measured in lieu of organic HAP concentration.

(ii) If Method 25A of appendix A-7 to part 60 of this chapter is used to measure the concentration of organic compounds (C T), the principal organic HAP in the vent stream shall be used as the calibration gas.

(A) An emission testing interval shall consist of each 15-minute period during the performance test. For each interval, a reading from each measurement shall be recorded.

(B) The average organic compound concentration and the volume measurement shall correspond to the same emissions testing interval.

(C) The mass at the inlet and outlet of the control device during each testing interval shall be calculated as follows:

Equation 3 to Paragraph (a)(10)(ii)(C)

Mj = FKVs C T

Where:

Mj = Mass of organic compounds emitted during testing interval j, kilograms.

Vs = Volume of air-vapor mixture exhausted at standard conditions, 20 °C and 760 millimeters mercury, standard cubic meters.

C T = Total concentration of organic compounds (as measured) at the exhaust vent, parts per million by volume, dry basis.

K = Density, kilograms per standard cubic meter organic HAP. 659 kilograms per standard cubic meter organic HAP. (Note: The density term cancels out when the percent reduction is calculated. Therefore, the density used has no effect. The density of hexane is given so that it can be used to maintain the units of Mj.)

F = 10 -6 = Conversion factor, (cubic meters organic HAP per cubic meters air) * (parts per million by volume) -1 .

(D) The organic compound mass emission rates at the inlet and outlet of the control device shall be calculated as follows:

Equations 4 and 5 to Paragraph (a)(10)(ii)(D)

Where:

E i , E o = Mass flow rate of organic compounds at the inlet (i) and outlet (o) of the combustion or recovery device, kilograms per hour.

M ij , M oj = Mass of organic compounds at the inlet (i) or outlet (o) during testing interval j, kilograms.

T = Total time of all testing intervals, hours.

n = Number of testing intervals.

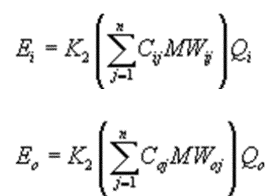

(iii) If Method 18 of appendix A-6 to 40 CFR part 60 or ASTM D6420-18 (incorporated by reference, see §63.14) is used to measure organic compounds, the mass rates of organic compounds (Ei, Eo) shall be computed using the following equations:

Equations 6 and 7 to Paragraph (a)(10)(iii)

Where:

C ij , C oj = Concentration of sample component j of the gas stream at the inlet and outlet of the control device, respectively, dry basis, parts per million by volume.

MW ij , MW oj = Molecular weight of sample component j of the gas stream at the inlet and outlet of the control device, respectively, gram/gram-mole.

Q i , Q o = Flow rate of gas stream at the inlet and outlet of the control device, respectively, dry standard cubic meter per minute.

K 2 = Constant, 2.494 × 10 -6 (parts per million) -1 (gram-mole per standard cubic meter) (kilogram/gram) (minute/hour), where standard temperature for (gram-mole per standard cubic meter) is 20 °C.

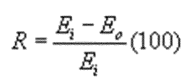

(iv) Where Method 18 or 25A of appendices A-6 and A-7 to part 60 of this chapter, respectively, or ASTM D6420-18 (incorporated by reference, see §63.14) is used to measure the percent reduction in organic compounds, the percent reduction across the control device shall be calculated as follows:

Equation 8 to Paragraph (a)(10)(iv)

Where:

R = Control efficiency of control device, percent.

E i = Mass emitted or mass flow rate of organic compounds at the inlet to the combustion or recovery device as calculated under paragraph (a)(10)(ii)(D) or (a)(10)(iii) of this section, kilogram per hour.

E o = Mass emitted or mass flow rate of organic compounds at the outlet of the combustion or recovery device, as calculated under paragraph (a)(10)(ii)(D) or (a)(10)(iii) of this section, kilogram per hour.

(11) The owner or operator may use any methods or data other than Method 18 or Method 25A of 40 CFR part 60, appendix A, if the method or data has been validated according to Method 301 of appendix A of this part.

(12) ASTM D6420-18 (incorporated by reference, see §63.14) may also be used in lieu of Method 18 of appendix A-6 to part 60 of this chapter, if the target compounds are all known and are all listed in section 1.1 of ASTM D6420-18 as measurable; ASTM D6420-18 must not be used for methane and ethane; and ASTM D6420-18 may not be used as a total VOC method.

(b) Except as specified in §63.108(a), when a flare is used to comply with §63.126(b)(2), the owner or operator shall comply with paragraphs (b)(1) through (3) of this section. The owner or operator is not required to conduct a performance test to determine percent emission reduction or outlet organic HAP or TOC concentration.

(1) Conduct a visible emission test using the techniques specified in §63.11(b)(4). The observation period shall be as specified in paragraph (b)(1)(i) or (ii) of this section instead of the 2-hour period specified in §63.11(b)(4).

(i) If the loading cycle is less than 2 hours, then the observation period for that run shall be for the entire loading cycle.

(ii) If additional loading cycles are initiated within the 2-hour period, then visible emission observations shall be conducted for the additional cycles.

(2) Determine the net heating value of the gas being combusted, using the techniques specified in §63.11(b)(6).

(3) Determine the exit velocity using the techniques specified in either §63.11(b)(7)(i) (and §63.11(b)(7)(iii), where applicable) or §63.11(b)(8), as appropriate.

(c) An owner or operator is not required to conduct a performance test when any of the conditions specified in paragraphs (c)(1) through (c)(7) of this section are met.

(1) When a boiler or process heater with a design heat input capacity of 44 megawatts or greater is used.

(2) When a boiler or process heater burning hazardous waste is used for which the owner or operator:

(i) Has been issued a final permit under part 270 of this chapter and complies with the requirements of part 266, subpart H, of this chapter;

(ii) Has certified compliance with the interim status requirements of part 266, subpart H, of this chapter;

(iii) Has submitted a Notification of Compliance under §63.1207(j) and complies with the requirements of subpart EEE of this part; or

(iv) Complies with subpart EEE of this part and will submit a Notification of Compliance under §63.1207(j) by the date the owner or operator would have been required to submit the initial performance test report for this subpart.

(3) When emissions are routed to a fuel gas system or when a boiler or process heater is used and the vent stream is introduced with the primary fuel.

(4) When a vapor balancing system is used.

(5) When emissions are recycled to a chemical manufacturing process unit.

(6) When a transfer rack transfers less than 11.8 million liters per year and the owner or operator complies with the requirements in paragraph (h) of this section or uses a flare to comply with §63.126(b)(2) of this subpart.

(7) When a hazardous waste incinerator is used for which the owner or operator:

(i) Has been issued a final permit under part 270 of this chapter and complies with the requirements of part 264, subpart O, of this chapter;

(ii) Has certified compliance with the interim status requirements of part 265, subpart O, of this chapter;

(iii) Has submitted a Notification of Compliance under §63.1207(j) and complies with the requirements subpart EEE of this part; or

(iv) Complies with the requirements subpart EEE of this part and will submit a Notification of Compliance under §63.1207(j) by the date the owner or operator would have been required to submit the initial performance test report for this subpart.

(d) An owner or operator using a combustion device followed by a scrubber or other halogen reduction device to control a halogenated transfer vent stream in compliance with §63.126(d) of this subpart shall conduct a performance test to determine compliance with the control efficiency or emission limits for hydrogen halides and halogens.

(1) For an owner or operator determining compliance with the percent reduction of total hydrogen halides and halogens, sampling sites shall be located at the inlet and outlet of the scrubber or other halogen reduction device used to reduce halogen emissions. For an owner or operator complying with the 0.45 kilogram per hour outlet mass emission rate limit for total hydrogen halides and halogens, the sampling site shall be located at the outlet of the scrubber or other halogen reduction device and prior to release to the atmosphere.

(2) Except as provided in paragraph (d)(5) of this section, Method 26 or 26A of 40 CFR part 60, appendix A, shall be used to determine the concentration in milligrams per dry standard cubic meter of the hydrogen halides and halogens that may be present in the stream. The mass emission rate of each hydrogen halide and halogen compound shall be calculated from the concentrations and the gas stream flow rate.

(3) To determine compliance with the percent emissions reduction limit, the mass emission rate for any hydrogen halides and halogens present at the scrubber inlet shall be summed together. The mass emission rate of the compounds present at the scrubber outlet shall be summed together. Percent reduction shall be determined by comparison of the summed inlet and outlet measurements.

(4) To demonstrate compliance with the 0.45 kilograms per hour mass emission rate limit, the test results must show that the mass emission rate of the total hydrogen halides and halogens measured at the scrubber outlet is below 0.45 kilograms per hour.

(5) The owner or operator may use any other method or data to demonstrate compliance if the method or data has been validated according to the protocol of Method 301 of appendix A of this part.

(e) The owner or operator shall inspect the vapor collection system and vapor balancing system, according to the requirements for vapor collection systems in §63.148 of this subpart.

(1) Inspections shall be performed only while a tank truck or railcar is being loaded.

(2) For vapor collection systems only, an inspection shall be performed prior to each performance test required to demonstrate compliance with §63.126(b)(1) of this subpart.

(3) For each vapor collection system that is operated and maintained under negative pressure, the owner or operator is not required to comply with the requirements specified in §63.148 of this subpart.

(f) For the purposes of demonstrating vapor tightness to determine compliance with §63.126(e)(2) of this subpart, the following procedures and equipment shall be used:

(1) The pressure test procedures specified in Method 27 of 40 CFR part 60, appendix A; and

(2) A pressure measurement device which has a precision of ±2.5 millimeters of mercury or better and which is capable of measuring above the pressure at which the tank truck or railcar is to be tested for vapor tightness.

(g) An owner or operator using a scrubber or other halogen reduction device to reduce the vent stream halogen atom mass emission rate to less than 0.45 kilograms per hour prior to a combustion device used to comply with §63.126(d)(2) shall determine the halogen atom mass emission rate prior to the combustor according to the procedures in paragraph (d)(3) of this section.

(h) For transfer racks that transfer less than 11.8 million liters per year of liquid organic HAP's, the owner or operator may comply with the requirements in paragraphs (h)(1) through (h)(3) of this section instead of the requirements in paragraph (a) or (b) of this section.

(1) The owner or operator shall prepare, as part of the Notification of Compliance Status required by §63.152(b) of this subpart, a design evaluation that shall document that the control device being used achieves the required control efficiency during reasonably expected maximum loading conditions. This documentation is to include a description of the gas stream which enters the control device, including flow and organic HAP content, and the information specified in paragraphs (h)(1)(i) through (h)(1)(v) of this section, as applicable.

(i) If the control device receives vapors, gases, or liquids, other than fuels, from emission points other than transfer racks subject to this subpart, the efficiency demonstration is to include consideration of all vapors, gases, and liquids, other than fuels, received by the control device.

(ii) If an enclosed combustion device with a minimum residence time of 0.5 seconds and a minimum temperature of 760 degrees Celsius is used to meet the 98-percent emission reduction requirement, documentation that those conditions exist is sufficient to meet the requirements of paragraph (h)(1) of this section.

(iii) Except as provided in paragraph (h)(1)(ii) of this section, for thermal incinerators, the design evaluation shall include the autoignition temperature of the organic HAP, the flow rate of the organic HAP emission stream, the combustion temperature, and the residence time at the combustion temperature.

(iv) Except as provided in §63.127(b)(4), for carbon adsorbers, the design evaluation shall include the affinity of the organic HAP vapors for carbon, the amount of carbon in each bed, the number of beds, the humidity of the feed gases, the temperature of the feed gases, the flow rate of the organic HAP emission stream, the desorption schedule, the regeneration stream pressure or temperature, and the flow rate of the regeneration stream. For vacuum desorption, pressure drop shall be included.

(v) For condensers, the design evaluation shall include the final temperature of the organic HAP vapors, the type of condenser, and the design flow rate of the organic HAP emission stream.

(2) The owner or operator shall submit, as part of the Notification of Compliance Status required by §63.152(b) of this subpart, the operating range for each monitoring parameter identified for each control device. The specified operating range shall represent the conditions for which the control device can achieve the 98-percent-or-greater emission reduction required by §63.126(b)(1) of this subpart.

(3) The owner or operator shall monitor the parameters specified in the Notification of Compliance Status required in §63.152(b) of this subpart or operating permit and shall operate and maintain the control device such that the monitored parameters remain within the ranges specified in the Notification of Compliance Status, except as provided in §§63.152(c) and 63.152(f) of this subpart.

[59 FR 19468, Apr. 22, 1994, as amended at 61 FR 64576, Dec. 5, 1996; 62 FR 2750, Jan. 17, 1997; 66 FR 6932, Jan. 22, 2001; 89 FR 43067, May 16, 2024]

READ MORESHOW LESS

['Air Programs']

['Hazardous Air Pollutants']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.