...

(a) For any flare that is used to reduce organic HAP emissions from a chemical manufacturing process unit, the owner or operator may elect to comply with the requirements in this section in lieu of the requirements of §63.11(b) and the requirements referenced therein. The owner or operator may also elect to comply with the requirements in this section pursuant to the overlap provisions provided in §63.110(j). However, for each source as defined in §63.101 and for each source as defined in §63.191, beginning no later than the compliance dates specified in §63.100(k)(10), the provisions specified in paragraphs (a)(1) through (22) of this section no longer apply. Instead, if an owner or operator reduces organic HAP emissions from a chemical manufacturing process unit by venting emissions through a closed-vent system to a steam-assisted, air-assisted, non-assisted, or pressure-assisted multi-point flare, then the owner or operator must meet the applicable requirements for flares as specified in §§63.670 and 63.671, including the provisions in tables 12 and 13 to subpart CC of this part, except as specified in paragraphs (b) through (o) of this section. This requirement also applies to any flare using fuel gas from a fuel gas system, of which 50 percent or more of the fuel gas is derived from a chemical manufacturing process unit, as determined on an annual average basis. For purposes of compliance with this paragraph, the following terms are defined in §63.641: Assist air, assist steam, center steam, combustion zone, combustion zone gas, flare, flare purge gas, flare supplemental gas, flare sweep gas, flare vent gas, lower steam, net heating value, perimeter assist air, pilot gas, premix assist air, total steam, and upper steam.

(1) Section 63.107(i) related to criteria in §63.11(b);

(2) Section 63.113(a)(1);

(3) Section 63.114(a)(2);

(4) Section 63.116(a)(1) through (3);

(5) Section 63.117(a)(5)(i) through (iii);

(6) Section 63.118(f)(5);

(7) The last sentence in §63.119(e)(1) related to flares;

(8) Section 63.120(e)(1) through (6);

(9) Section 63.122(c)(2) and (g)(3);

(10) Section 63.126(b)(2)(i);

(11) Section 63.127(a)(2);

(12) Section 63.128(b)(1) through (3);

(13) Section 63.129(a)(5)(i) through (iii);

(14) Section 63.130(a)(2)(i), (c), and (d)(5);

(15) Section 63.139(c)(3) and (d)(3);

(16) Section 63.145(j)(1) through (3);

(17) Section 63.146(b)(7)(i)(A) through (C);

(18) V63.147(d)(1);

(19) Section 63.172(d);

(20) Section 63.180(e)(1) through (3);

(21) Section 63.181(g)(1)(iii); and

(22) The phrase “including periods when a flare pilot light system does not have a flame” in §63.181(g)(2)(i) of subpart H of this part.

(b) When determining compliance with the pilot flame requirements specified in §63.670(b) and (g), substitute “pilot flame or flare flame” for each occurrence of “pilot flame.”

(c) When determining compliance with the flare tip velocity and combustion zone operating limits specified in §63.670(d) and (e), the requirement effectively applies starting with the 15-minute block that includes a full 15 minutes of the flaring event. The owner or operator is required to demonstrate compliance with the velocity and NHVcz requirements starting with the block that contains the fifteenth minute of a flaring event. The owner or operator is not required to demonstrate compliance for the previous 15-minute block in which the event started and contained only a fraction of flow.

(d) Instead of complying with §63.670(o)(2)(i), owners and operators must develop and implement the flare management plan no later than the compliance dates specified in §63.100(k)(10).

(e) Instead of complying with §63.670(o)(2)(iii), if required to develop a flare management plan and submit it to the Administrator, then owners and operators must also submit all versions of the plan in portable document format (PDF) to the EPA following the procedure specified in §63.9(k), except any medium submitted through mail must be sent to the attention of the Hazardous Organic Chemical Manufacturing Sector Lead.

(f) Section 63.670(o)(3)(ii) and all references to it do not apply. Instead, the owner or operator must comply with the maximum flare tip velocity operating limit at all times.

(g) Substitute “chemical manufacturing process unit” for each occurrence of “petroleum refinery.”

(h) Each occurrence of “refinery” does not apply.

(i) If a pressure-assisted multi-point flare is used as a control device, then owners and operators must meet the following conditions:

(1) The owner or operator is not required to comply with the flare tip velocity requirements in §63.670(d) and (k);

(2) The NHVcz for pressure-assisted mulit-point flares is 800 Btu/scf;

(3) Owners and operators must determine the 15-minute block average NHVvg using only the direct calculation method specified in §63.670(l)(5)(ii);

(4) Instead of complying with §63.670(b) and (g), if a pressure-assisted multi-point flare uses cross-lighting on a stage of burners rather than having an individual pilot flame on each burner, then owners and operators must operate each stage of the pressure-assisted multi-point flare with a flame present at all times when regulated material is routed to that stage of burners. Each stage of burners that cross-lights in the pressure-assisted multi-point flare must have at least two pilots with at least one continuously lit and capable of igniting all regulated material that is routed to that stage of burners. Each 15-minute block during which there is at least one minute where no pilot flame is present on a stage of burners when regulated material is routed to the flare is a violation of the standard. Violations in different 15-minute blocks from the same event are considered separate violations. The pilot flame(s) on each stage of burners that use cross-lighting must be continuously monitored by a thermocouple or any other equivalent device used to detect the presence of a flame;

(5) Unless the owner or operator chooses to conduct a cross-light performance demonstration as specified in this paragraph, owners and operators must ensure that if a stage of burners on the flare uses cross-lighting, that the distance between any two burners in series on that stage is no more than 6 feet when measured from the center of one burner to the next burner. A distance greater than 6 feet between any two burners in series may be used provided the owner or operator conducts a performance demonstration that confirms the pressure-assisted multi-point flare will cross-light a minimum of three burners and the spacing between the burners and location of the pilot flame must be representative of the projected installation. The compliance demonstration must be approved by the permitting authority and a copy of this approval must be maintained onsite. The compliance demonstration report must include: a protocol describing the test methodology used, associated test method QA/QC parameters, the waste gas composition and NHVcz of the gas tested, the velocity of the waste gas tested, the pressure-assisted multi-point flare burner tip pressure, the time, length, and duration of the test, records of whether a successful cross-light was observed over all of the burners and the length of time it took for the burners to cross-light, records of maintaining a stable flame after a successful cross-light and the duration for which this was observed, records of any smokingevents during the cross-light, waste gas temperature, meteorological conditions (e.g., ambient temperature, barometric pressure, wind speed and direction, and relative humidity), and whether there were any observed flare flameouts; and

(6) Owners and operators must install and operate pressure monitor(s) on the main flare header, as well as a valve position indicator monitoring system for each staging valve to ensure that the flare operates within the proper range of conditions as specified by the manufacturer. The pressure monitor must meet the requirements in table 13 to subpart CC of this part.

(7) If a pressure-assisted multi-point flare is operating under the requirements of an approved alternative means of emission limitations, owners and operators must either continue to comply with the terms of the alternative means of emission limitations or comply with the provisions in paragraphs (i)(1) through (6) of this section.

(j) If an owner or operator chooses to determine compositional analysis for net heating value with a continuous process mass spectrometer, then the owner or operator must comply with the requirements specified in paragraphs (j)(1) through (7) of this section.

(1) Owners and operators must meet the requirements in §63.671(e)(2). The owner or operator may augment the minimum list of calibration gas components found in §63.671(e)(2) with compounds found during a pre-survey or known to be in the gas through process knowledge.

(2) Calibration gas cylinders must be certified to an accuracy of 2 percent and traceable to National Institute of Standards and Technology (NIST) standards.

(3) For unknown gas components that have similar analytical mass fragments to calibration compounds, the owner or operator may report the unknowns as an increase in the overlapped calibration gas compound. For unknown compounds that produce mass fragments that do not overlap calibration compounds, the owner or operator may use the response factor for the nearest molecular weight hydrocarbon in the calibration mix to quantify the unknown component's NHVvg.

(4) The owner or operator may use the response factor for n-pentane to quantify any unknown components detected with a higher molecular weight than n-pentane.

(5) Owners and operators must perform an initial calibration to identify mass fragment overlap and response factors for the target compounds.

(6) Owners and operators must meet applicable requirements in Performance Specification 9 in appendix B to part 60 of this chapter for continuous monitoring system acceptance including, but not limited to, performing an initial multi-point calibration check at three concentrations following the procedure in section 10.1 and performing the periodic calibration requirements listed for gas chromatographs in table 13 to subpart CC of this part, for the process mass spectrometer. The owner or operator may use the alternative sampling line temperature allowed under Net Heating Value by Gas Chromatograph in table 13 to subpart CC of this part.

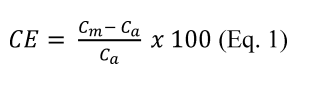

(7) The average instrument calibration error (CE) for each calibration compound at any calibration concentration must not differ by more than 10 percent from the certified cylinder gas value. The CE for each component in the calibration blend must be calculated using equation 1 to this paragraph.

Equation 1 to Paragraph (j)(7)

Where:

C m = Average instrument response (ppm)

C a = Certified cylinder gas value (ppm)

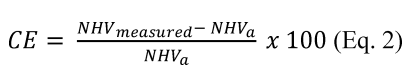

(k) If an owner or operator use a gas chromatograph or mass spectrometer for compositional analysis for net heating value, then the owner or operator may choose to use the CE of NHV measured versus the cylinder tag value NHV as the measure of agreement for daily calibration and quarterly audits in lieu of determining the compound-specific CE. The CE for NHV at any calibration level must not differ by more than 10 percent from the certified cylinder gas value. The CE for must be calculated using equation 2 to this paragraph.

Equation 2 to Paragraph (k)

Where:

NHV measured = Average instrument response (Btu/scf)

NHV a = Certified cylinder gas value (Btu/scf)

(l) Instead of complying with §63.670(q), owners and operators must comply with the reporting requirements specified in paragraphs (l)(1) and (2) of this section.

(1) The initial notification requirements specified in §63.152(b)(7).

(2) The Periodic Report required by §63.152(c) must include the items specified in paragraphs (l)(2)(i) through (vi) of this section.

(i) Records as specified in paragraph (m)(1) of this section for each 15-minute block during which there was at least one minute when regulated material is routed to a flare and no pilot flame or flare flame is present. Include the start and stop time and date of each 15-minute block.

(ii) Visible emission records as specified in paragraph (m)(2)(iv) of this section for each period of 2 consecutive hours during which visible emissions exceeded a total of 5 minutes. Indicate the date and start and end times for each period.

(iii) The periods specified in paragraph (m)(6) of this section. Indicate the date and start and end times for each period, and the net heating value operating parameter(s) determined following the methods in §63.670(k) through (n) as applicable.

(iv) For flaring events meeting the criteria in §63.670(o)(3) and paragraph (f) of this section:

(A) The start and stop time and date of the flaring event.

(B) The length of time in minutes for which emissions were visible from the flare during the event.

(C) For steam-assisted, air-assisted, and non-assisted flares, the start date, start time, and duration in minutes for periods of time that the flare tip velocity exceeds the maximum flare tip velocity determined using the methods in §63.670(d)(2) and the maximum 15-minute block average flare tip velocity in ft/sec recorded during the event.

(D) Results of the root cause and corrective actions analysis completed during the reporting period, including the corrective actions implemented during the reporting period and, if applicable, the implementation schedule for planned corrective actions to be implemented subsequent to the reporting period.

(v) For pressure-assisted multi-point flares, the periods of time when the pressure monitor(s) on the main flare header show the burners operating outside the range of the manufacturer's specifications. Indicate the date and start and end times for each period.

(vi) For pressure-assisted multi-point flares, the periods of time when the staging valve position indicator monitoring system indicates a stage should not be in operation and is or when a stage should be in operation and is not. Indicate the date and start and end times for each period.

(m) Instead of complying with §63.670(p), owners and operators must keep the flare monitoring records specified in paragraphs (m)(1) through (14) of this section.

(1) Retain records of the output of the monitoring device used to detect the presence of a pilot flame or flare flame as required in §63.670(b) and the presence of a pilot flame as required in paragraph (i)(4) of this section for a minimum of 2 years. Retain records of each 15-minute block during which there was at least one minute that no pilot flame or flare flame is present when regulated material is routed to a flare for a minimum of 5 years. For a pressure-assisted multi-point flare that uses cross-lighting, retain records of each 15-minute block during which there was at least one minute that no pilot flame is present on each stage when regulated material is routed to a flare for a minimum of 5 years. The owner or operator may reduce the collected minute-by-minute data to a 15-minute block basis with an indication of whether there was at least one minute where no pilot flame or flare flame was present.

(2) Retain records of daily visible emissions observations as specified in paragraphs (m)(2)(i) through (iv) of this section, as applicable, for a minimum of 3 years.

(i) To determine when visible emissions observations are required, the record must identify all periods when regulated material is vented to the flare.

(ii) If visible emissions observations are performed using Method 22 in appendix A-7 to part 60 of this chapter, then the record must identify whether the visible emissions observation was performed, the results of each observation, total duration in minutes of observed visible emissions, and whether it was a 5-minute or 2-hour observation. Record the date and start time of each visible emissions observation.

(iii) If a video surveillance camera is used pursuant to §63.670(h)(2), then the record must include all video surveillance images recorded, with time and date stamps.

(iv) For each 2-hour period for which visible emissions are observed for more than 5 minutes in 2 consecutive hours, then the record must include the date and start and end time of the 2-hour period and an estimate of the cumulative number of minutes in the 2-hour period for which emissions were visible.

(3) The 15-minute block average cumulative flows for flare vent gas and, if applicable, total steam, perimeter assist air, and premix assist air specified to be monitored under §63.670(i), along with the date and time interval for the 15-minute block. If multiple monitoring locations are used to determine cumulative vent gas flow, total steam, perimeter assist air, and premix assist air, then retain records of the 15-minute block average flows for each monitoring location for a minimum of 2 years and retain the 15-minute block average cumulative flows that are used in subsequent calculations for a minimum of 5 years. If pressure and temperature monitoring is used, then retain records of the 15-minute block average temperature, pressure, and molecular weight of the flare vent gas or assist gas stream for each measurement location used to determine the 15-minute block average cumulative flows for a minimum of 2 years, and retain the 15-minute block average cumulative flows that are used in subsequent calculations for a minimum of 5 years.

(4) The flare vent gas compositions specified to be monitored under §63.670(j). Retain records of individual component concentrations from each compositional analysis for a minimum of 2 years. If an NHVvg analyzer is used, retain records of the 15-minute block average values for a minimum of 5 years.

(5) Each 15-minute block average operating parameter calculated following the methods specified in §63.670(k) through (n) as applicable.

(6) All periods during which operating values are outside of the applicable operating limits specified in §63.670(d) through (f) and paragraph (i) of this section when regulated material is being routed to the flare.

(7) All periods during which the owner or operator does not perform flare monitoring according to the procedures in §63.670(g) through (j).

(8) For pressure-assisted multi-point flares, if a stage of burners on the flare uses cross-lighting, then a record of any changes made to the distance between burners.

(9) For pressure-assisted multi-point flares, all periods when the pressure monitor(s) on the main flare header show burners are operating outside the range of the manufacturer's specifications. Indicate the date and time for each period, the pressure measurement, the stage(s) and number of burners affected, and the range of manufacturer's specifications.

(10) For pressure-assisted multi-point flares, all periods when the staging valve position indicator monitoring system indicates a stage of the pressure-assisted multi-point flare should not be in operation and when a stage of the pressure-assisted multi-point flare should be in operation and is not. Indicate the date and time for each period, whether the stage was supposed to be open, but was closed or vice versa, and the stage(s) and number of burners affected.

(11) Records of periods when there is flow of vent gas to the flare, but when there is no flow of regulated material to the flare, including the start and stop time and dates of periods of no regulated material flow.

(12) Records when the flow of vent gas exceeds the smokeless capacity of the flare, including start and stop time and dates of the flaring event.

(13) Records of the root cause analysis and corrective action analysis conducted as required in §63.670(o)(3) and paragraph (f) of this section, including an identification of the affected flare, the date and duration of the event, a statement noting whether the event resulted from the same root cause(s) identified in a previous analysis and either a description of the recommended corrective action(s) or an explanation of why corrective action is not necessary under §63.670(o)(5)(i).

(14) For any corrective action analysis for which implementation of corrective actions are required in §63.670(o)(5), a description of the corrective action(s) completed within the first 45 days following the discharge and, for action(s) not already completed, a schedule for implementation, including proposed commencement and completion dates.

(n) The owner or operator may elect to comply with the alternative means of emissions limitation requirements specified in §63.670(r) in lieu of the requirements in §63.670(d) through (f), as applicable. However, instead of complying with §63.670(r)(3)(iii), owners and operators must also submit the alternative means of emissions limitation request to the following address: U.S. Environmental Protection Agency, Office of Air Quality Planning and Standards, Sector Policies and Programs Division, U.S. EPA Mailroom (C404-02), Attention: Hazardous Organic Chemical Manufacturing Sector Lead, 4930 Old Page Rd., Durham, NC 27703.

(o) The referenced provisions specified in paragraphs (o)(1) through (4) of this section do not apply when demonstrating compliance with this section.

(1) Section 63.670(o)(4)(iv) of subpart CC of this part.

(2) The last sentence of §63.670(o)(6).

(3) The phrase “that were not caused by a force majeure event” in §63.670(o)(7)(ii).

(4) The phrase “that were not caused by a force majeure event” in §63.670(o)(7)(iv).

[ 89 FR 43067, May 16, 2024]