['Air Programs']

['Hazardous Air Pollutants']

01/20/2025

...

On or before January 30, 2019, the owner or operator of a flare used as a control device for an emission point subject to this subpart shall meet the applicable requirements for flares as specified in paragraphs (a) through (q) of this section and the applicable requirements in §63.671. The owner or operator may elect to comply with the requirements of paragraph (r) of this section in lieu of the requirements in paragraphs (d) through (f) of this section, as applicable.

(a) [Reserved]

(b) Pilot flame presence. The owner or operator shall operate each flare with a pilot flame present on an individual burner or stage of burners at all times when regulated material is routed to the flare. Each 15-minute block during which there is at least one minute where no pilot flame on an individual burner or stage of burners is present when regulated material is routed to the flare is a deviation of the standard. Deviations in different 15-minute blocks from the same event are considered separate deviations. The owner or operator shall monitor for the presence of a pilot flame on an individual burner or stage of burners as specified in paragraph (g) of this section. Beginning on April 4, 2024, pressure-assisted flares using stages of burners that cross-light must also comply with paragraphs (b)(1) and (2) of this section.

(1) Each stage of burners that cross-lights in the pressure-assisted flare must have at least two pilots with at least one continuously lit and capable of igniting all regulated material that is routed to that stage of burners.

(2) Unless the owner or operator of a pressure-assisted flare chooses to conduct a cross-light performance demonstration as specified in this paragraph, the owner or operator must ensure that if a stage of burners on the flare uses cross-lighting, that the distance between any two burners in series on that stage is no more than 6 feet when measured from the center of one burner to the next burner. A distance greater than 6 feet between any two burners in series may be used provided the owner or operator complies with the requirements in paragraphs (b)(2)(i) through (iii) of this section.

(i) You must conduct a performance demonstration that confirms the pressure-assisted flare will cross-light a minimum of three burners and the spacing between the burners and location of the pilot flame must be representative of the projected installation.

(ii) The compliance demonstration must be approved by the permitting authority and a copy of this approval must be maintained onsite.

(iii) The compliance demonstration report must include the information in paragraphs (b)(2)(iii)(A) through (K) of this section.

(A) A protocol describing the test methodology used, associated test method QA/QC parameters.

(B) The waste gas composition and NHVcz of the gas tested.

(C) The velocity of the waste gas tested.

(D) The pressure-assisted multi-point flare burner tip pressure.

(E) The time, length, and duration of the test.

(F) Records of whether a successful cross-light was observed over all of the burners and the length of time it took for the burners to cross-light.

(G) Records of maintaining a stable flame after a successful cross-light and the duration for which this was observed.

(H) Records of any smokingevents during the cross-light.

(I) Waste gas temperature.

(J) Meteorological conditions ( e.g., ambient temperature, barometric pressure, wind speed and direction, and relative humidity) during the demonstration.

(K) An indication whether there were any observed flare flameouts and if so, the number and duration of each flare flameout.

(c) Visible emissions. The owner or operator shall specify the smokeless design capacity of each flare and operate with no visible emissions, except for periods not to exceed a total of 5 minutes during any 2 consecutive hours, when regulated material is routed to the flare and the flare vent gas flow rate is less than the smokeless design capacity of the flare. The owner or operator shall monitor for visible emissions from the flare as specified in paragraph (h) of this section.

(d) Flare tip velocity. Except as provided in paragraph (d)(3) of this section for pressure-assisted flares, for each flare, the owner or operator shall comply with either paragraph (d)(1) or (2) of this section, provided the appropriate monitoring systems are in-place, whenever regulated material is routed to the flare for at least 15-minutes and the flare vent gas flow rate is less than the smokeless design capacity of the flare.

(1) Except as provided in paragraph (d)(2) of this section, the actual flare tip velocity (Vtip) must be less than 60 feet per second. The owner or operator shall monitor Vtipusing the procedures specified in paragraphs (i) and (k) of this section.

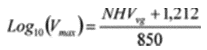

(2) Vtip must be less than 400 feet per second and also less than the maximum allowed flare tip velocity (Vmax) as calculated according to the following equation. The owner or operator shall monitor Vtip using the procedures specified in paragraphs (i) and (k) of this section and monitor gas composition and determine NHVvg using the procedures specified in paragraphs (j) and (l) of this section.

Where:

Vmax = Maximum allowed flare tip velocity, ft/sec.

NHVvg = Net heating value of flare vent gas, as determined by paragraph (k)(4) of this section, Btu/scf.

1,212 = Constant.

850 = Constant.

(3) Pressure-assisted flares are not subject to the flare tip velocity limits in either paragraph (d)(1) or (2) of this section. In lieu of the flare tip velocity limits, beginning on April 4, 2024, the owner or operator of a pressure-assisted flare must install and operate pressure monitor(s) on the main flare header, as well as a valve position indicator monitoring system for each staging valve to ensure that the flare operates within the proper range of conditions as specified by the manufacturer. The pressure monitor must meet the requirements in Table 13 of this subpart.

(e) Combustion zone operating limits. The owner or operator shall operate the flare to maintain the net heating value of flare combustion zone gas (NHV cz ) at or above the applicable limits in paragraphs (e)(1) and (2) of this section determined on a 15-minute block period basis when regulated material is routed to the flare for at least 15-minutes. The owner or operator shall monitor and calculate NHV cz as specified in paragraph (m) of this section.

(1) For all flares other than pressure-assisted flares, 270 British thermal units per standard cubic feet (Btu/scf).

(2) Beginning on April 4, 2024, for each pressure-assisted flare, 800 Btu/scf.

(f) Dilution operating limits for flares with perimeter assist air. Except as provided in paragraph (f)(1) of this section, for each flare actively receiving perimeter assist air, the owner or operator shall operate the flare to maintain the net heating value dilution parameter (NHVdil) at or above 22 British thermal units per square foot (Btu/ft 2) determined on a 15-minute block period basis when regulated material is being routed to the flare for at least 15-minutes. The owner or operator shall monitor and calculate NHVdil as specified in paragraph (n) of this section.

(1) If the only assist air provided to a specific flare is perimeter assist air intentionally entrained in lower and/or upper steam at the flare tip and the effective diameter is 9 inches or greater, the owner or operator shall comply only with the NHVcz operating limit in paragraph (e) of this section for that flare.

(2) [Reserved]

(g) Pilot flame monitoring. The owner or operator shall continuously monitor the presence of the pilot flame(s) using a device (including, but not limited to, a thermocouple, ultraviolet beam sensor, or infrared sensor) capable of detecting that the pilot flame(s) is present.

(h) Visible emissions monitoring. The owner or operator shall conduct an initial visible emissions demonstration using an observation period of 2 hours using Method 22 at 40 CFR part 60, appendix A-7. The initial visible emissions demonstration should be conducted the first time regulated materials are routed to the flare. Subsequent visible emissions observations must be conducted using either the methods in paragraph (h)(1) of this section or, alternatively, the methods in paragraph (h)(2) of this section. The owner or operator must record and report any instances where visible emissions are observed for more than 5 minutes during any 2 consecutive hours as specified in §63.655(g)(11)(ii).

(1) At least once per day for each day regulated material is routed to the flare, conduct visible emissions observations using an observation period of 5 minutes using Method 22 at 40 CFR part 60, appendix A-7. If at any time the owner or operator sees visible emissions while regulated material is routed to the flare, even if the minimum required daily visible emission monitoring has already been performed, the owner or operator shall immediately begin an observation period of 5 minutes using Method 22 at 40 CFR part 60, appendix A-7. If visible emissions are observed for more than one continuous minute during any 5-minute observation period, the observation period using Method 22 at 40 CFR part 60, appendix A-7 must be extended to 2 hours or until 5-minutes of visible emissions are observed. Daily 5-minute Method 22 observations are not required to be conducted for days the flare does not receive any regulated material.

(2) Use a video surveillance camera to continuously record (at least one frame every 15 seconds with time and date stamps) images of the flare flame and a reasonable distance above the flare flame at an angle suitable for visual emissions observations. The owner or operator must provide real-time video surveillance camera output to the control room or other continuously manned location where the camera images may be viewed at any time.

(i) Flare vent gas, steam assist and air assist flow rate monitoring. The owner or operator shall install, operate, calibrate, and maintain a monitoring system capable of continuously measuring, calculating, and recording the volumetric flow rate in the flare header or headers that feed the flare as well as any flare supplemental gas used. Different flow monitoring methods may be used to measure different gaseous streams that make up the flare vent gas provided that the flow rates of all gas streams that contribute to the flare vent gas are determined. If assist air or assist steam is used, the owner or operator shall install, operate, calibrate, and maintain a monitoring system capable of continuously measuring, calculating, and recording the volumetric flow rate of assist air and/or assist steam used with the flare. If pre-mix assist air and perimeter assist are both used, the owner or operator shall install, operate, calibrate, and maintain a monitoring system capable of separately measuring, calculating, and recording the volumetric flow rate of premix assist air and perimeter assist air used with the flare. Flow monitoring system requirements and acceptable alternatives are provided in paragraphs (i)(1) through (6) of this section.

(1) The flow rate monitoring systems must be able to correct for the temperature and pressure of the system and output parameters in standard conditions (i.e., a temperature of 20°C (68°F) and a pressure of 1 atmosphere).

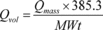

(2) Mass flow monitors may be used for determining volumetric flow rate of flare vent gas provided the molecular weight of the flare vent gas is determined using compositional analysis as specified in paragraph (j) of this section so that the mass flow rate can be converted to volumetric flow at standard conditions using the following equation.

Where:

Qvol = Volumetric flow rate, standard cubic feet per second.

Qmass = Mass flow rate, pounds per second.

385.3 = Conversion factor, standard cubic feet per pound-mole.

MWt = Molecular weight of the gas at the flow monitoring location, pounds per pound-mole.

(3) Mass flow monitors may be used for determining volumetric flow rate of assist air or assist steam. Use equation in paragraph (i)(2) of this section to convert mass flow rates to volumetric flow rates. Use a molecular weight of 18 pounds per pound-mole for assist steam and use a molecular weight of 29 pounds per pound-mole for assist air.

(4) Continuous pressure/temperature monitoring system(s) and appropriate engineering calculations may be used in lieu of a continuous volumetric flow monitoring systems provided the molecular weight of the gas is known. For assist steam, use a molecular weight of 18 pounds per pound-mole. For assist air, use a molecular weight of 29 pounds per pound-mole. For flare vent gas, molecular weight must be determined using compositional analysis as specified in paragraph (j) of this section.

(5) Continuously monitoring fan speed or power and using fan curves is an acceptable method for continuously monitoring assist air flow rates.

(6) For perimeter assist air intentionally entrained in lower and/or upper steam, the monitored steam flow rate and the maximum design air-to-steam volumetric flow ratio of the entrainment system may be used to determine the assist air flow rate.

(j) Flare vent gas composition monitoring. The owner or operator shall determine the concentration of individual components in the flare vent gas using either the methods provided in paragraph (j)(1) or (2) of this section, to assess compliance with the operating limits in paragraph (e) of this section and, if applicable, paragraphs (d) and (f) of this section. Alternatively, the owner or operator may elect to directly monitor the net heating value of the flare vent gas following the methods provided in paragraphs (j)(3) of this section and, if desired, may directly measure the hydrogen concentration in the flare vent gas following the methods provided in paragraphs (j)(4) of this section. The owner or operator may elect to use different monitoring methods for different gaseous streams that make up the flare vent gas using different methods provided the composition or net heating value of all gas streams that contribute to the flare vent gas are determined.

(1) Except as provided in paragraphs (j)(5) and (6) of this section, the owner or operator shall install, operate, calibrate, and maintain a monitoring system capable of continuously measuring (i.e., at least once every 15-minutes), calculating, and recording the individual component concentrations present in the flare vent gas.

(2) Except as provided in paragraphs (j)(5) and (6) of this section, the owner or operator shall install, operate, and maintain a grab sampling system capable of collecting an evacuated canister sample for subsequent compositional analysis at least once every eight hours while there is flow of regulated material to the flare. Subsequent compositional analysis of the samples must be performed according to Method 18 of 40 CFR part 60, appendix A-6, ASTM D6420-99 (Reapproved 2010), ASTM D1945-03 (Reapproved 2010), ASTM D1945-14 or ASTM UOP539-12 (all incorporated by reference - see §63.14).

(3) Except as provided in paragraphs (j)(5) and (6) of this section, the owner or operator shall install, operate, calibrate, and maintain a calorimeter capable of continuously measuring, calculating, and recording NHVvg at standard conditions.

(4) If the owner or operator uses a continuous net heating value monitor according to paragraph (j)(3) of this section, the owner or operator may, at their discretion, install, operate, calibrate, and maintain a monitoring system capable of continuously measuring, calculating, and recording the hydrogen concentration in the flare vent gas.

(5) Direct compositional or net heating value monitoring is not required for purchased (“pipeline quality”) natural gas streams. The net heating value of purchased natural gas streams may be determined using annual or more frequent grab sampling at any one representative location. Alternatively, the net heating value of any purchased natural gas stream can be assumed to be 920 Btu/scf.

(6) Direct compositional or net heating value monitoring is not required for gas streams that have been demonstrated to have consistent composition (or a fixed minimum net heating value) according to the methods in paragraphs (j)(6)(i) through (iii) of this section.

(i) The owner or operator shall submit to the Administrator a written application for an exemption from monitoring. The application must contain the following information:

(A) A description of the flare gas stream/system to be considered, including submission of a portion of the appropriate piping diagrams indicating the boundaries of the flare gas stream/system and the affected flare(s) to be considered;

(B) A statement that there are no crossover or entry points to be introduced into the flare gas stream/system (this should be shown in the piping diagrams) prior to the point where the flow rate of the gas streams is measured;

(C) An explanation of the conditions that ensure that the flare gas net heating value is consistent and, if flare gas net heating value is expected to vary (e.g., due to product loading of different material), the conditions expected to produce the flare gas with the lowest net heating value;

(D) The supporting test results from sampling the requested flare gas stream/system for the net heating value. Sampling data must include, at minimum, 2 weeks of daily measurement values (14 grab samples) for frequently operated flare gas streams/systems; for infrequently operated flare gas streams/systems, seven grab samples must be collected unless other additional information would support reduced sampling. If the flare gas stream composition can vary, samples must be taken during those conditions expected to result in lowest net heating value identified in paragraph (j)(6)(i)(C) of this section. The owner or operator shall determine net heating value for the gas stream using either gas composition analysis or net heating value monitor (with optional hydrogen concentration analyzer) according to the method provided in paragraph (l) of this section; and

(E) A description of how the 2 weeks (or seven samples for infrequently operated flare gas streams/systems) of monitoring results compares to the typical range of net heating values expected for the flare gas stream/system going to the affected flare (e.g., “the samples are representative of typical operating conditions of the flare gas stream going to the loading rack flare” or “the samples are representative of conditions expected to yield the lowest net heating value of the flare gas stream going to the loading rack flare”).

(F) The net heating value to be used for all flows of the flare vent gas from the flare gas stream/system covered in the application. A single net heating value must be assigned to the flare vent gas either by selecting the lowest net heating value measured in the sampling program or by determining the 95th percent confidence interval on the mean value of all samples collected using the t-distribution statistic (which is 1.943 for 7 grab samples or 1.771 for 14 grab samples).

(ii) The effective date of the exemption is the date of submission of the information required in paragraph (j)(6)(i) of this section.

(iii) No further action is required unless refinery operating conditions change in such a way that affects the exempt fuel gas stream/system (e.g., the stream composition changes). If such a change occurs, the owner or operator shall follow the procedures in paragraph (j)(6)(iii)(A), (B), or (C) of this section.

(A) If the operation change results in a flare vent gas net heating value that is still within the range of net heating values included in the original application, the owner or operator shall determine the net heating value on a grab sample and record the results as proof that the net heating value assigned to the vent gas stream in the original application is still appropriate.

(B) If the operation change results in a flare vent gas net heating value that is lower than the net heating value assigned to the vent gas stream in the original application, the owner or operator may submit new information following the procedures of paragraph (j)(6)(i) of this section within 60 days (or within 30 days after the seventh grab sample is tested for infrequently operated process units).

(C) If the operation change results in a flare vent gas net heating value has greater variability in the flare gas stream/system such the owner or operator chooses not to submit new information to support an exemption, the owner or operator must begin monitoring the composition or net heat content of the flare vent gas stream using the methods in this section (i.e., grab samples every 8 hours until such time a continuous monitor, if elected, is installed).

(k) Calculation methods for cumulative flow rates and determining compliance with Vtip operating limits. The owner or operator shall determine Vtip on a 15-minute block average basis according to the following requirements.

(1) The owner or operator shall use design and engineering principles to determine the unobstructed cross sectional area of the flare tip. The unobstructed cross sectional area of the flare tip is the total tip area that vent gas can pass through. This area does not include any stability tabs, stability rings, and upper steam or air tubes because flare vent gas does not exit through them.

(2) The owner or operator shall determine the cumulative volumetric flow of flare vent gas for each 15-minute block average period using the data from the continuous flow monitoring system required in paragraph (i) of this section according to the following requirements, as applicable. If desired, the cumulative flow rate for a 15-minute block period only needs to include flow during those periods when regulated material is sent to the flare, but owners or operators may elect to calculate the cumulative flow rates across the entire 15-minute block period for any 15-minute block period where there is regulated material flow to the flare.

(i) Use set 15-minute time periods starting at 12 midnight to 12:15 a.m., 12:15 a.m. to 12:30 a.m. and so on concluding at 11:45 p.m. to midnight when calculating 15-minute block average flow volumes.

(ii) If continuous pressure/temperature monitoring system(s) and engineering calculations are used as allowed under paragraph (i)(4) of this section, the owner or operator shall, at a minimum, determine the 15-minute block average temperature and pressure from the monitoring system and use those values to perform the engineering calculations to determine the cumulative flow over the 15-minute block average period. Alternatively, the owner or operator may divide the 15-minute block average period into equal duration subperiods(e.g., three 5-minute periods) and determine the average temperature and pressure for each subperiod, perform engineering calculations to determine the flow for each subperiod, then add the volumetric flows for the subperiods to determine the cumulative volumetric flow of vent gas for the 15-minute block average period.

(3) The 15-minute block average Vtip shall be calculated using the following equation.

Where:

Vtip = Flare tip velocity, feet per second.

Qcum = Cumulative volumetric flow over 15-minute block average period, standard cubic feet.

Area = Unobstructed area of the flare tip, square feet.

900 = Conversion factor, seconds per 15-minute block average.

(4) If the owner or operator chooses to comply with paragraph (d)(2) of this section, the owner or operator shall also determine the net heating value of the flare vent gas following the requirements in paragraphs (j) and (l) of this section and calculate Vmax using the equation in paragraph (d)(2) of this section in order to compare Vtip to Vmax on a 15-minute block average basis.

(l) Calculation methods for determining flare vent gas net heating value. The owner or operator shall determine the net heating value of the flare vent gas (NHVvg) based on the composition monitoring data on a 15-minute block average basis according to the following requirements.

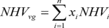

(1) If compositional analysis data are collected as provided in paragraph (j)(1) or (2) of this section, the owner or operator shall determine NHVvg of a specific sample by using the following equation.

Where:

NHVvg = Net heating value of flare vent gas, Btu/scf.

i = Individual component in flare vent gas.

n = Number of components in flare vent gas.

xi = Concentration of component i in flare vent gas, volume fraction.

NHVi = Net heating value of component i according to table 12 of this subpart, Btu/scf. If the component is not specified in table 12 of this subpart, the heats of combustion may be determined using any published values where the net enthalpy per mole of offgas is based on combustion at 25°C and 1 atmosphere (or constant pressure) with offgas water in the gaseous state, but the standard temperature for determining the volume corresponding to one mole of vent gas is 20°C.

(2) If direct net heating value monitoring data are collected as provided in paragraph (j)(3) of this section but a hydrogen concentration monitor is not used, the owner or operator shall use the direct output of the monitoring system(s) (in Btu/scf) to determine the NHVvg for the sample.

(3) If direct net heating value monitoring data are collected as provided in paragraph (j)(3) of this section and hydrogen concentration monitoring data are collected as provided in paragraph (j)(4) of this section, the owner or operator shall use the following equation to determine NHVvg for each sample measured via the net heating value monitoring system.

NHVvg = NHVmeasured + 938xH2

Where:

NHVvg = Net heating value of flare vent gas, Btu/scf.

NHVmeasured = Net heating value of flare vent gas stream as measured by the continuous net heating value monitoring system, Btu/scf.

xH2 = Concentration of hydrogen in flare vent gas at the time the sample was input into the net heating value monitoring system, volume fraction.

938 = Net correction for the measured heating value of hydrogen (1,212 − 274), Btu/scf.

(4) Use set 15-minute time periods starting at 12 midnight to 12:15 a.m., 12:15 a.m. to 12:30 a.m. and so on concluding at 11:45 p.m. to midnight when calculating 15-minute block averages.

(5) When a continuous monitoring system is used as provided in paragraph (j)(1) or (3) of this section and, if applicable, paragraph (j)(4) of this section, the owner or operator of a flare other than a pressure-assisted flare may elect to determine the 15-minute block average NHV vg using either the calculation methods in paragraph (l)(5)(i) of this section or the calculation methods in paragraph (l)(5)(ii) of this section. The owner or operator may choose to comply using the calculation methods in paragraph (l)(5)(i) of this section for some non-pressure-assisted flares at the petroleum refinery and comply using the calculation methods (l)(5)(ii) of this section for other flares. However, for each non-pressure-assisted flare, the owner or operator must elect one calculation method that will apply at all times, and use that method for all continuously monitored flare vent streams associated with that flare. If the owner or operator intends to change the calculation method that applies to a flare, the owner or operator must notify the Administrator 30 days in advance of such a change. For pressure-assisted flares, beginning on April 4, 2024, the owner or operator must use the calculation method in paragraph (l)(5)(ii) of this section.

(i) Feed-forward calculation method. When calculating NHVvg for a specific 15-minute block:

(A) Use the results from the first sample collected during an event, (for periodic flare vent gas flow events) for the first 15-minute block associated with that event.

(B) If the results from the first sample collected during an event (for periodic flare vent gas flow events) are not available until after the second 15-minute block starts, use the results from the first sample collected during an event for the second 15-minute block associated with that event.

(C) For all other cases, use the results that are available from the most recent sample prior to the 15-minute block period for that 15-minute block period for all flare vent gas steams. For the purpose of this requirement, use the time that the results become available rather than the time the sample was collected. For example, if a sample is collected at 12:25 a.m. and the analysis is completed at 12:38 a.m., the results are available at 12:38 a.m. and these results would be used to determine compliance during the 15-minute block period from 12:45 a.m. to 1:00 a.m.

(ii) Direct calculation method. When calculating NHVvg for a specific 15-minute block:

(A) If the results from the first sample collected during an event (for periodic flare vent gas flow events) are not available until after the second 15-minute block starts, use the results from the first sample collected during an event for the first 15-minute block associated with that event.

(B) For all other cases, use the arithmetic average of all NHVvg measurement data results that become available during a 15-minute block to calculate the 15-minute block average for that period. For the purpose of this requirement, use the time that the results become available rather than the time the sample was collected. For example, if a sample is collected at 12:25 a.m. and the analysis is completed at 12:38 a.m., the results are available at 12:38 a.m. and these results would be used to determine compliance during the 15-minute block period from 12:30 a.m. to 12:45 a.m.

(6) When grab samples are used to determine flare vent gas composition:

(i) Use the analytical results from the first grab sample collected for an event for all 15-minute periods from the start of the event through the 15-minute block prior to the 15-minute block in which a subsequent grab sample is collected.

(ii) Use the results from subsequent grab sampling events for all 15 minute periods starting with the 15-minute block in which the sample was collected and ending with the 15-minute block prior to the 15-minute block in which the next grab sample is collected. For the purpose of this requirement, use the time the sample was collected rather than the time the analytical results become available.

(7) If the owner or operator monitors separate gas streams that combine to comprise the total flare vent gas flow, the 15-minute block average net heating value shall be determined separately for each measurement location according to the methods in paragraphs (l)(1) through (6) of this section and a flow-weighted average of the gas stream net heating values shall be used to determine the 15-minute block average net heating value of the cumulative flare vent gas.

(m) Calculation methods for determining combustion zone net heating value. The owner or operator shall determine the net heating value of the combustion zone gas (NHVcz) as specified in paragraph (m)(1) or (2) of this section, as applicable.

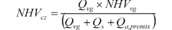

(1) Except as specified in paragraph (m)(2) of this section, determine the 15-minute block average NHVcz based on the 15-minute block average vent gas and assist gas flow rates using the following equation. For periods when there is no assist steam flow or premix assist air flow, NHVcz = NHVvg.

Where:

NHVcz = Net heating value of combustion zone gas, Btu/scf.

NHVvg = Net heating value of flare vent gas for the 15-minute block period, Btu/scf.

Qvg = Cumulative volumetric flow of flare vent gas during the 15-minute block period, scf.

Qs = Cumulative volumetric flow of total steam during the 15-minute block period, scf.

Qa,premix = Cumulative volumetric flow of premix assist air during the 15-minute block period, scf.

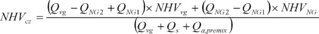

(2) Owners or operators of flares that use the feed-forward calculation methodology in paragraph (l)(5)(i) of this section and that monitor gas composition or net heating value in a location representative of the cumulative vent gas stream and that directly monitor flare supplemental gas flow additions to the flare must determine the 15-minute block average NHVcz using the following equation.

Where:

NHVcz = Net heating value of combustion zone gas, Btu/scf.

NHVvg = Net heating value of flare vent gas for the 15-minute block period, Btu/scf.

Qvg = Cumulative volumetric flow of flare vent gas during the 15-minute block period, scf.

QNG2 = Cumulative volumetric flow of flare supplemental gas during the 15-minute block period, scf.

QNG1 = Cumulative volumetric flow of flare supplemental gas during the previous 15-minute block period, scf. For the first 15-minute block period of an event, use the volumetric flow value for the current 15-minute block period, i.e., QNG1 = QNG2.

NHVNG = Net heating value of flare supplemental gas for the 15-minute block period determined according to the requirements in paragraph (j)(5) of this section, Btu/scf.

Qs = Cumulative volumetric flow of total steam during the 15-minute block period, scf.

Qa,premix = Cumulative volumetric flow of premix assist air during the 15-minute block period, scf.

(n) Calculation methods for determining the net heating value dilution parameter. The owner or operator shall determine the net heating value dilution parameter (NHVdil) as specified in paragraph (n)(1) or (2) of this section, as applicable.

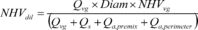

(1) Except as specified in paragraph (n)(2) of this section, determine the 15-minute block average NHVdil based on the 15-minute block average vent gas and perimeter assist air flow rates using the following equation only during periods when perimeter assist air is used. For 15-minute block periods when there is no cumulative volumetric flow of perimeter assist air, the 15-minute block average NHVdil parameter does not need to be calculated.

Where:

NHVdil = Net heating value dilution parameter, Btu/ft 2.

NHVvg = Net heating value of flare vent gas determined for the 15-minute block period, Btu/scf.

Qvg = Cumulative volumetric flow of flare vent gas during the 15-minute block period, scf.

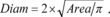

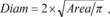

Diam = Effective diameter of the unobstructed area of the flare tip for flare vent gas flow, ft. Use the area as determined in paragraph (k)(1) of this section and determine the diameter as

Qs = Cumulative volumetric flow of total steam during the 15-minute block period, scf.

Qa,premix = Cumulative volumetric flow of premix assist air during the 15-minute block period, scf.

Qa,perimeter = Cumulative volumetric flow of perimeter assist air during the 15-minute block period, scf.

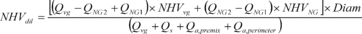

(2) Owners or operators of flares that use the feed-forward calculation methodology in paragraph (l)(5)(i) of this section and that monitor gas composition or net heating value in a location representative of the cumulative vent gas stream and that directly monitor flare supplemental gas flow additions to the flare must determine the 15-minute block average NHVdil using the following equation only during periods when perimeter assist air is used. For 15-minute block periods when there is no cumulative volumetric flow of perimeter assist air, the 15-minute block average NHVdil parameter does not need to be calculated.

Where:

NHVdil = Net heating value dilution parameter, Btu/ft 2.

NHVvg = Net heating value of flare vent gas determined for the 15-minute block period, Btu/scf.

Qvg = Cumulative volumetric flow of flare vent gas during the 15-minute block period, scf.

QNG2 = Cumulative volumetric flow of flare supplemental gas during the 15-minute block period, scf.

QNG1 = Cumulative volumetric flow of flare supplemental gas during the previous 15-minute block period, scf. For the first 15-minute block period of an event, use the volumetric flow value for the current 15-minute block period, i.e., QNG1 = QNG2.

NHVNG = Net heating value of flare supplemental gas for the 15-minute block period determined according to the requirements in paragraph (j)(5) of this section, Btu/scf.

Diam = Effective diameter of the unobstructed area of the flare tip for flare vent gas flow, ft. Use the area as determined in paragraph (k)(1) of this section and determine the diameter as

Qs = Cumulative volumetric flow of total steam during the 15-minute block period, scf.

Qa,premix = Cumulative volumetric flow of premix assist air during the 15-minute block period, scf.

Qa,perimeter = Cumulative volumetric flow of perimeter assist air during the 15-minute block period, scf.

(o) Emergency flaring provisions. The owner or operator of a flare that has the potential to operate above its smokeless capacity under any circumstance shall comply with the provisions in paragraphs (o)(1) through (7) of this section.

(1) Develop a flare management plan to minimize flaring during periods of startup, shutdown, or emergency releases. The flare management plan must include the information described in paragraphs (o)(1)(i) through (vii) of this section.

(i) A listing of all refinery process units, ancillary equipment, and fuel gas systems connected to the flare for each affected flare.

(ii) An assessment of whether discharges to affected flares from these process units, ancillary equipment and fuel gas systems can be minimized or prevented during periods of startup, shutdown, or emergency releases. The flare minimization assessment must (at a minimum) consider the items in paragraphs (o)(1)(ii)(A) through (C) of this section. The assessment must provide clear rationale in terms of costs (capital and annual operating), natural gas offset credits (if applicable), technical feasibility, secondary environmental impacts and safety considerations for the selected minimization alternative(s) or a statement, with justifications, that flow reduction could not be achieved. Based upon the assessment, each owner or operator of an affected flare shall identify the minimization alternatives that it has implemented by the due date of the flare management plan and shall include a schedule for the prompt implementation of any selected measures that cannot reasonably be completed as of that date.

(A) Modification in startup and shutdown procedures to reduce the quantity of process gas discharge to the flare.

(B) Implementation of prevention measures listed for pressure relief devices in §63.648(j)(3)(ii)(A) through (E) for each pressure relief device that can discharge to the flare.

(C) Installation of a flare gas recovery system or, for facilities that are fuel gas rich, a flare gas recovery system and a co-generation unit or combined heat and power unit.

(iii) A description of each affected flare containing the information in paragraphs (o)(1)(iii)(A) through (G) of this section.

(A) A general description of the flare, including whether it is a ground flare or elevated (including height), the type of assist system (e.g., air, steam, pressure, non-assisted), whether the flare is used on a routine basis or if it is only used during periods of startup, shutdown or emergency release, and whether the flare is equipped with a flare gas recovery system.

(B) The smokeless capacity of the flare based on a 15-minute block average and design conditions. Note: A single value must be provided for the smokeless capacity of the flare.

(C) The maximum vent gas flow rate (hydraulic load capacity).

(D) The maximum supplemental gas flow rate.

(E) For flares that receive assist steam, the minimum total steam rate and the maximum total steam rate.

(F) For flares that receive assist air, an indication of whether the fan/blower is single speed, multi-fixed speed (e.g., high, medium, and low speeds), or variable speeds. For fans/blowers with fixed speeds, provide the estimated assist air flow rate at each fixed speed. For variable speeds, provide the design fan curve (e.g., air flow rate as a function of power input).

(G) Simple process flow diagram showing the locations of the flare following components of the flare: Flare tip (date installed, manufacturer, nominal and effective tip diameter, tip drawing); knockout or surge drum(s) or pot(s) (including dimensions and design capacities); flare header(s) and subheader(s); assist system; and ignition system.

(iv) Description and simple process flow diagram showing all gas lines (including flare waste gas, purge or sweep gas (as applicable), supplemental gas) that are associated with the flare. For purge, sweep, supplemental gas, identify the type of gas used. Designate which lines are exempt from composition or net heating value monitoring and why (e.g., natural gas, gas streams that have been demonstrated to have consistent composition, pilot gas). Designate which lines are monitored and identify on the process flow diagram the location and type of each monitor. Designate the pressure relief devices that are vented to the flare.

(v) For each flow rate, gas composition, net heating value or hydrogen concentration monitor identified in paragraph (o)(1)(iv) of this section, provide a detailed description of the manufacturer's specifications, including, but not limited to, make, model, type, range, precision, accuracy, calibration, maintenance and quality assurance procedures.

(vi) For each pressure relief device vented to the flare identified in paragraph (o)(1)(iv) of this section, provide a detailed description of each pressure release device, including type of relief device (rupture disc, valve type) diameter of the relief device opening, set pressure of the relief device and listing of the prevention measures implemented. This information may be maintained in an electronic database on-site and does not need to be submitted as part of the flare management plan unless requested to do so by the Administrator.

(vii) Procedures to minimize or eliminate discharges to the flare during the planned startup and shutdown of the refinery process units and ancillary equipment that are connected to the affected flare, together with a schedule for the prompt implementation of any procedures that cannot reasonably be implemented as of the date of the submission of the flare management plan.

(2) Each owner or operator required to develop and implement a written flare management plan as described in paragraph (o)(1) of this section must submit the plan to the Administrator as described in paragraphs (o)(2)(i) through (iii) of this section.

(i) The owner or operator must develop and implement the flare management plan no later than January 30, 2019 or at startup for a new flare that commenced construction on or after February 1, 2016.

(ii) The owner or operator must comply with the plan as submitted by the date specified in paragraph (o)(2)(i) of this section. The plan should be updated periodically to account for changes in the operation of the flare, such as new connections to the flare or the installation of a flare gas recovery system, but the plan need be re-submitted to the Administrator only if the owner or operator alters the design smokeless capacity of the flare. The owner or operator must comply with the updated plan as submitted.

(iii) All versions of the plan submitted to the Administrator shall also be submitted to the following address: U.S. Environmental Protection Agency, Office of Air Quality Planning and Standards, Sector Policies and Programs Division, U.S. EPA Mailroom (E143-01), Attention: Refinery Sector Lead, 109 T.W. Alexander Drive, Research Triangle Park, NC 27711. Electronic copies in lieu of hard copies may also be submitted to refineryRTR@epa.gov.

(3) The owner or operator of a flare subject to this subpart shall conduct a root cause analysis and a corrective action analysis for each flow event that contains regulated material and that meets either the criteria in paragraph (o)(3)(i) or (ii) of this section.

(i) The vent gas flow rate exceeds the smokeless capacity of the flare based on a 15-minute block average and visible emissions are present from the flare for more than 5 minutes during any 2 consecutive hours during the release event.

(ii) The vent gas flow rate exceeds the smokeless capacity of the flare and the 15-minute block average flare tip velocity exceeds the maximum flare tip velocity determined using the methods in paragraph (d)(2) of this section.

(4) A root cause analysis and corrective action analysis must be completed as soon as possible, but no later than 45 days after a flare flow event meeting the criteria in paragraph (o)(3)(i) or (ii) of this section. Special circumstances affecting the number of root cause analyses and/or corrective action analyses are provided in paragraphs (o)(4)(i) through (v) of this section.

(i) You may conduct a single root cause analysis and corrective action analysis for a single continuous flare flow event that meets both of the criteria in paragraphs (o)(3)(i) and (ii) of this section.

(ii) You may conduct a single root cause analysis and corrective action analysis for a single continuous flare flow event regardless of the number of 15-minute block periods in which the flare tip velocity was exceeded or the number of 2 hour periods that contain more the 5 minutes of visible emissions.

(iii) You may conduct a single root cause analysis and corrective action analysis for a single event that causes two or more flares that are operated in series (i.e., cascaded flare systems) to have a flow event meeting the criteria in paragraph (o)(3)(i) or (ii) of this section.

(iv) Prior to June 3, 2024, you may conduct a single root cause analysis and corrective action analysis for a single event that causes two or more flares to have a flow event meeting the criteria in paragraph (o)(3)(i) or (ii) of this section, regardless of the configuration of the flares, if the root cause is reasonably expected to be a force majeure event, as defined in this subpart.

(v) Except as provided in paragraphs (o)(4)(iii) and (iv) of this section, if more than one flare has a flow event that meets the criteria in paragraph (o)(3)(i) or (ii) of this section during the same time period, an initial root cause analysis shall be conducted separately for each flare that has a flow event meeting the criteria in paragraph (o)(3)(i) or (ii) of this section. If the initial root cause analysis indicates that the flow events have the same root cause(s), the initially separate root cause analyses may be recorded as a single root cause analysis and a single corrective action analysis may be conducted.

(5) Each owner or operator of a flare required to conduct a root cause analysis and corrective action analysis as specified in paragraphs (o)(3) and (4) of this section shall implement the corrective action(s) identified in the corrective action analysis in accordance with the applicable requirements in paragraphs (o)(5)(i) through (iii) of this section.

(i) All corrective action(s) must be implemented within 45 days of the event for which the root cause and corrective action analyses were required or as soon thereafter as practicable. If an owner or operator concludes that no corrective action should be implemented, the owner or operator shall record and explain the basis for that conclusion no later than 45 days following the event.

(ii) For corrective actions that cannot be fully implemented within 45 days following the event for which the root cause and corrective action analyses were required, the owner or operator shall develop an implementation schedule to complete the corrective action(s) as soon as practicable.

(iii) No later than 45 days following the event for which a root cause and corrective action analyses were required, the owner or operator shall record the corrective action(s) completed to date, and, for action(s) not already completed, a schedule for implementation, including proposed commencement and completion dates.

(6) The owner or operator shall determine the total number of events for which a root cause and corrective action analyses was required during the calendar year for each affected flare separately for events meeting the criteria in paragraph (o)(3)(i) of this section and those meeting the criteria in paragraph (o)(3)(ii) of this section. For the purpose of this requirement, a single root cause analysis conducted for an event that met both of the criteria in paragraphs (o)(3)(i) and (ii) of this section would be counted as an event under each of the separate criteria counts for that flare. Additionally, if a single root cause analysis was conducted for an event that caused multiple flares to meet the criteria in paragraph (o)(3)(i) or (ii) of this section, that event would count as an event for each of the flares for each criteria in paragraph (o)(3) of this section that was met during that event. Prior to June 3, 2024, the owner or operator shall also determine the total number of events for which a root cause and correct action analyses was required and the analyses concluded that the root cause was a force majeure event, as defined in this subpart.

(7) The following events would be a violation of this emergency flaring work practice standard.

(i) Any flow event for which a root cause analysis was required and the root cause was determined to be operator error or poor maintenance.

(ii) Prior to June 3, 2024, two visible emissions exceedance events meeting the criteria in paragraph (o)(3)(i) of this section that were not caused by a force majeure event from a single flare in a 3 calendar year period for the same root cause for the same equipment. On and after June 3, 2024, two visible emissions exceedance events meeting the criteria in paragraph (o)(3)(i) of this section from a single flare in a 3 calendar year period for the same root cause for the same equipment.

(iii) Prior to June 3, 2024, two flare tip velocity exceedance events meeting the criteria in paragraph (o)(3)(ii) of this section that were not caused by a force majeure event from a single flare in a 3 calendar year period for the same root cause for the same equipment. On and after June 3, 2024, two flare tip velocity exceedance events meeting the criteria in paragraph (o)(3)(ii) of this section from a single flare in a 3 calendar year period for the same root cause for the same equipment.

(iv) Prior to June 3, 2024, three visible emissions exceedance events meeting the criteria in paragraph (o)(3)(i) of this section that were not caused by a force majeure event from a single flare in a 3 calendar year period for any reason. On and after June 3, 2024, three visible emissions exceedance events meeting the criteria in paragraph (o)(3)(i) of this section from a single flare in a 3 calendar year period for any reason.

(v) Prior to June 3, 2024, three flare tip velocity exceedance events meeting the criteria in paragraph (o)(3)(ii) of this section that were not caused by a force majeure event from a single flare in a 3 calendar year period for any reason. On and after June 3, 2024, three flare tip velocity exceedance events meeting the criteria in paragraph (o)(3)(ii) of this section from a single flare in a 3 calendar year period for any reason.

(p) Flare monitoring records. The owner or operator shall keep the records specified in §63.655(i)(9).

(q) Reporting. The owner or operator shall comply with the reporting requirements specified in §63.655(g)(11).

(r) Alternative means of emissions limitation. An owner or operator may request approval from the Administrator for site-specific operating limits that shall apply specifically to a selected flare. Site-specific operating limits include alternative threshold values for the parameters specified in paragraphs (d) through (f) of this section as well as threshold values for operating parameters other than those specified in paragraphs (d) through (f) of this section. The owner or operator must demonstrate that the flare achieves 96.5 percent combustion efficiency (or 98 percent destruction efficiency) using the site-specific operating limits based on a performance evaluation as described in paragraph (r)(1) of this section. The request shall include information as described in paragraph (r)(2) of this section. The request shall be submitted and followed as described in paragraph (r)(3) of this section.

(1) The owner or operator shall prepare and submit a site-specific test plan and receive approval of the site-specific performance evaluation plan prior to conducting any flare performance evaluation test runs intended for use in developing site-specific operating limits. The site-specific performance evaluation plan shall include, at a minimum, the elements specified in paragraphs (r)(1)(i) through (ix) of this section. Upon approval of the site-specific performance evaluation plan, the owner or operator shall conduct performance evaluation test runs for the flare following the procedures described in the site-specific performance evaluation plan.

(i) The design and dimensions of the flare, flare type (air-assisted only, steam-assisted only, air- and steam-assisted, pressure-assisted, or non-assisted), and description of gas being flared, including quantity of gas flared, frequency of flaring events (if periodic), expected net heating value of flare vent gas, minimum total steam assist rate.

(ii) The operating conditions (vent gas compositions, vent gas flow rates and assist flow rates, if applicable) likely to be encountered by the flare during normal operations and the operating conditions for the test period.

(iii) A description of (including sample calculations illustrating) the planned data reduction and calculations to determine the flare combustion or destruction efficiency.

(iv) Site-specific operating parameters to be monitored continuously during the flare performance evaluation. These parameters may include but are not limited to vent gas flow rate, steam and/or air assist flow rates, and flare vent gas composition. If new operating parameters are proposed for use other than those specified in paragraphs (d) through (f) of this section, an explanation of the relevance of the proposed operating parameter(s) as an indicator of flare combustion performance and why the alternative operating parameter(s) can adequately ensure that the flare achieves the required combustion efficiency.

(v) A detailed description of the measurement methods, monitored pollutant(s), measurement locations, measurement frequency, and recording frequency proposed for both emission measurements and flare operating parameters.

(vi) A description of (including sample calculations illustrating) the planned data reduction and calculations to determine the flare operating parameters.

(vii) The minimum number and length of test runs and range of operating values to be evaluated during the performance evaluation. A sufficient number of test runs shall be conducted to identify the point at which the combustion/destruction efficiency of the flare deteriorates.

(viii) [Reserved]

(ix) Test schedule.

(2) The request for flare-specific operating limits shall include sufficient and appropriate data, as determined by the Administrator, to allow the Administrator to confirm that the selected site-specific operating limit(s) adequately ensures that the flare destruction efficiency is 98 percent or greater or that the flare combustion efficiency is 96.5 percent or greater at all times. At a minimum, the request shall contain the information described in paragraphs (r)(2)(i) through (iv) of this section.

(i) The design and dimensions of the flare, flare type (air-assisted only, steam-assisted only, air- and steam-assisted, pressure-assisted, or non-assisted), and description of gas being flared, including quantity of gas flared, frequency of flaring events (if periodic), expected net heating value of flare vent gas, minimum total steam assist rate.

(ii) Results of each performance evaluation test run conducted, including, at a minimum:

(A) The measured combustion/destruction efficiency.

(B) The measured or calculated operating parameters for each test run. If operating parameters are calculated, the raw data from which the parameters are calculated must be included in the test report.

(C) Measurement location descriptions for both emission measurements and flare operating parameters.

(D) Description of sampling and analysis procedures (including number and length of test runs) and any modifications to standard procedures. If there were deviations from the approved test plan, a detailed description of the deviations and rationale why the test results or calculation procedures used are appropriate.

(E) Operating conditions (e.g., vent gas composition, assist rates, etc.) that occurred during the test.

(F) Quality assurance procedures.

(G) Records of calibrations.

(H) Raw data sheets for field sampling.

(I) Raw data sheets for field and laboratory analyses.

(J) Documentation of calculations.

(iii) The selected flare-specific operating limit values based on the performance evaluation test results, including the averaging time for the operating limit(s), and rationale why the selected values and averaging times are sufficiently stringent to ensure proper flare performance. If new operating parameters or averaging times are proposed for use other than those specified in paragraphs (d) through (f) of this section, an explanation of why the alternative operating parameter(s) or averaging time(s) adequately ensures the flare achieves the required combustion efficiency.

(iv) The means by which the owner or operator will document on-going, continuous compliance with the selected flare-specific operating limit(s), including the specific measurement location and frequencies, calculation procedures, and records to be maintained.

(3) The request shall be submitted as described in paragraphs (r)(3)(i) through (iv) of this section.

(i) The owner or operator may request approval from the Administrator at any time upon completion of a performance evaluation conducted following the methods in an approved site-specific performance evaluation plan for an operating limit(s) that shall apply specifically to that flare.

(ii) The request must be submitted to the Administrator for approval. The owner or operator must continue to comply with the applicable standards for flares in this subpart until the requirements in §63.6(g)(1) are met and a notice is published in the Federal Register allowing use of such an alternative means of emission limitation.

(iii) The request shall also be submitted to the following address: U.S. Environmental Protection Agency, Office of Air Quality Planning and Standards, Sector Policies and Programs Division, U.S. EPA Mailroom (E143-01), Attention: Refinery Sector Lead, 109 T.W. Alexander Drive, Research Triangle Park, NC 27711. Electronic copies in lieu of hard copies may also be submitted to refineryrtr@epa.gov.

(iv) If the Administrator finds any deficiencies in the request, the request must be revised to address the deficiencies and be re-submitted for approval within 45 days of receipt of the notice of deficiencies. The owner or operator must comply with the revised request as submitted until it is approved.

(4) The approval process for a request for a flare-specific operating limit(s) is described in paragraphs (r)(4)(i) through (iii) of this section.

(i) Approval by the Administrator of a flare-specific operating limit(s) request will be based on the completeness, accuracy and reasonableness of the request. Factors that the EPA will consider in reviewing the request for approval include, but are not limited to, those described in paragraphs (r)(4)(i)(A) through (C) of this section.

(A) The description of the flare design and operating characteristics.

(B) If a new operating parameter(s) other than those specified in paragraphs (d) through (f) of this section is proposed, the explanation of how the proposed operating parameter(s) serves a good indicator(s) of flare combustion performance.

(C) The results of the flare performance evaluation test runs and the establishment of operating limits that ensures that the flare destruction efficiency is 98 percent or greater or that the flare combustion efficiency is 96.5 percent or greater at all times.

(D) The completeness of the flare performance evaluation test report.

(ii) If the request is approved by the Administrator, a flare-specific operating limit(s) will be established at the level(s) demonstrated in the approved request.

(iii) If the Administrator finds any deficiencies in the request, the request must be revised to address the deficiencies and be re-submitted for approval.

[80 FR 75258, Dec. 1, 2015, as amended at 81 FR 45241, July 13, 2016; 83 FR 60720, Nov. 26, 2018; 85 FR 6083, Feb. 4, 2020; 89 FR 23860 April 4, 2024 ]

['Air Programs']

['Hazardous Air Pollutants']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.