EPA established chemical accident prevention requirements at 40 CFR 68 for businesses of all sizes that use certain listed regulated flammable and/or toxic substances. Owners and operators of a facility (considered a stationary source) that manufactures, uses, stores, or otherwise handles more than a threshold quantity of a listed regulated substance in a process must implement a set of hazard assessment, accident prevention, and emergency response elements and submit a single written risk management plan (RMP) to EPA or the state implementing agency for all covered processes at the facility. The submitted information helps local fire, police, and emergency response personnel (who must prepare for and respond to chemical accidents) and is useful to citizens in understanding the chemical hazards in communities.

Risk Management Plan (RMP)

Accidental chemical releases (including those of propane, ammonia, chlorine, and other substances) present hazards for companies large and small. With the right preparation and preventive efforts outlined in a Risk Management Plan (RMP), the risks posed to a business and its surrounding community can be mitigated. Compliance is crucial, as the submitted information helps local fire, police, and emergency response personnel in their preparation for and response to chemical accidents, and it is also useful for citizens who wish to understand the chemical hazards local to their communities.

The RMP rule, created by the Environmental Protection Agency (EPA) after passage of the Clean Air Act Amendments of 1990, requires owners and operators of a facility that manufactures, uses, stores, or otherwise handles more than a threshold quantity of a listed regulated substance in a process to implement a set of hazard assessment, accident prevention, and emergency response elements and submit a single written RMP to the EPA or the state implementing agency for all covered processes at the facility.

RMP applicability

- The EPA requires owners and operators to develop plans and procedures that result in the implementation of a risk management program.

- Many facilities covered under CAA are also regulated under the PSM standard.

Cited under 40 Code of Federal Regulations (CFR) 68 — Chemical accident prevention provisions, the Environmental Protection Agency’s (EPA’s) Risk Management Plan (RMP) regulation requires owners and operators to develop plans and procedures that result in the implementation of a risk management program for all covered facilities within the organization. Three of the most important requirements include the following:

- A hazard assessment of workplace activities.

- A prevention program that is based on the Occupational Safety and Health Administration’s (OSHA’s) Process Safety Management (PSM) standard.

- An emergency response program to train employees and contractors in emergency response procedures.

Overlap with PSM

Many facilities covered under the Clean Air Act (CAA) and by extension the RMP rule are already regulated under the PSM standard. Requirements of PSM that also apply to RMP are:

- Safety and compliance audits

- Pre-startup safety reviews

- Mechanical integrity

- Operating procedures

- Process safety information

- Management of change

- Incident investigation

- Emergency planning and response

- Process hazard analysis

- Training programs

- Employee participation

- Hot-work permits

- Contractor requirements

- Recordkeeping requirements

- Trade secrets clause

While the PSM standard centers on worker safety, the RMP rule focuses on releases that would pose a hazard to public health and the environment. Provisions of RMP that are in addition to requirements under PSM are:

- Management systems requirements

- Off-site analysis

- Five-year incident history

- Worst-case release scenarios

- Plan coordination with local emergency planning committee (LEPC)

- Information sharing to the public

- Facility registration

- Risk management plan requirement

- Reporting requirements

- Response drills and exercises

- Regulatory audit requirements

Who is subject to RMP?

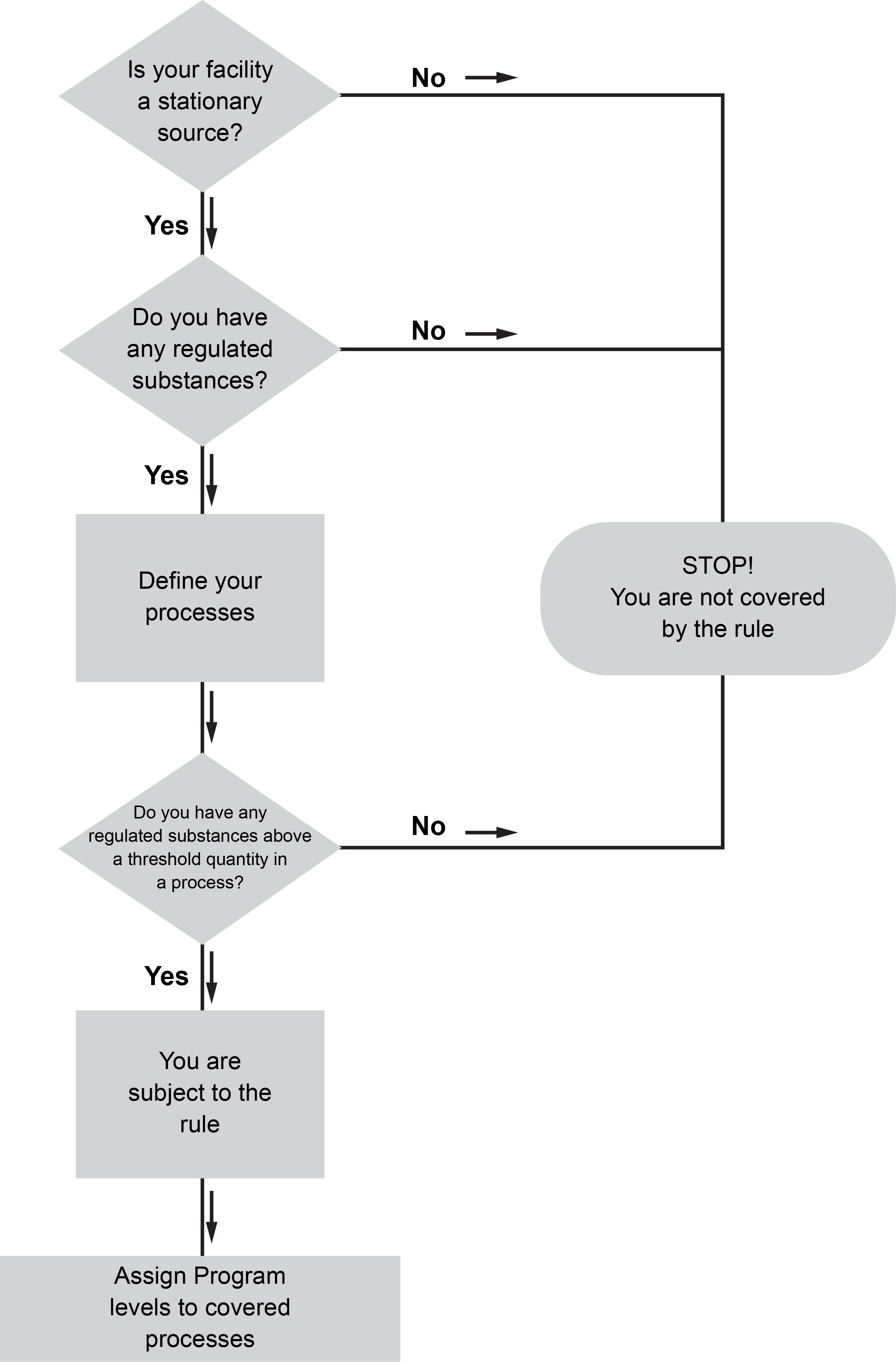

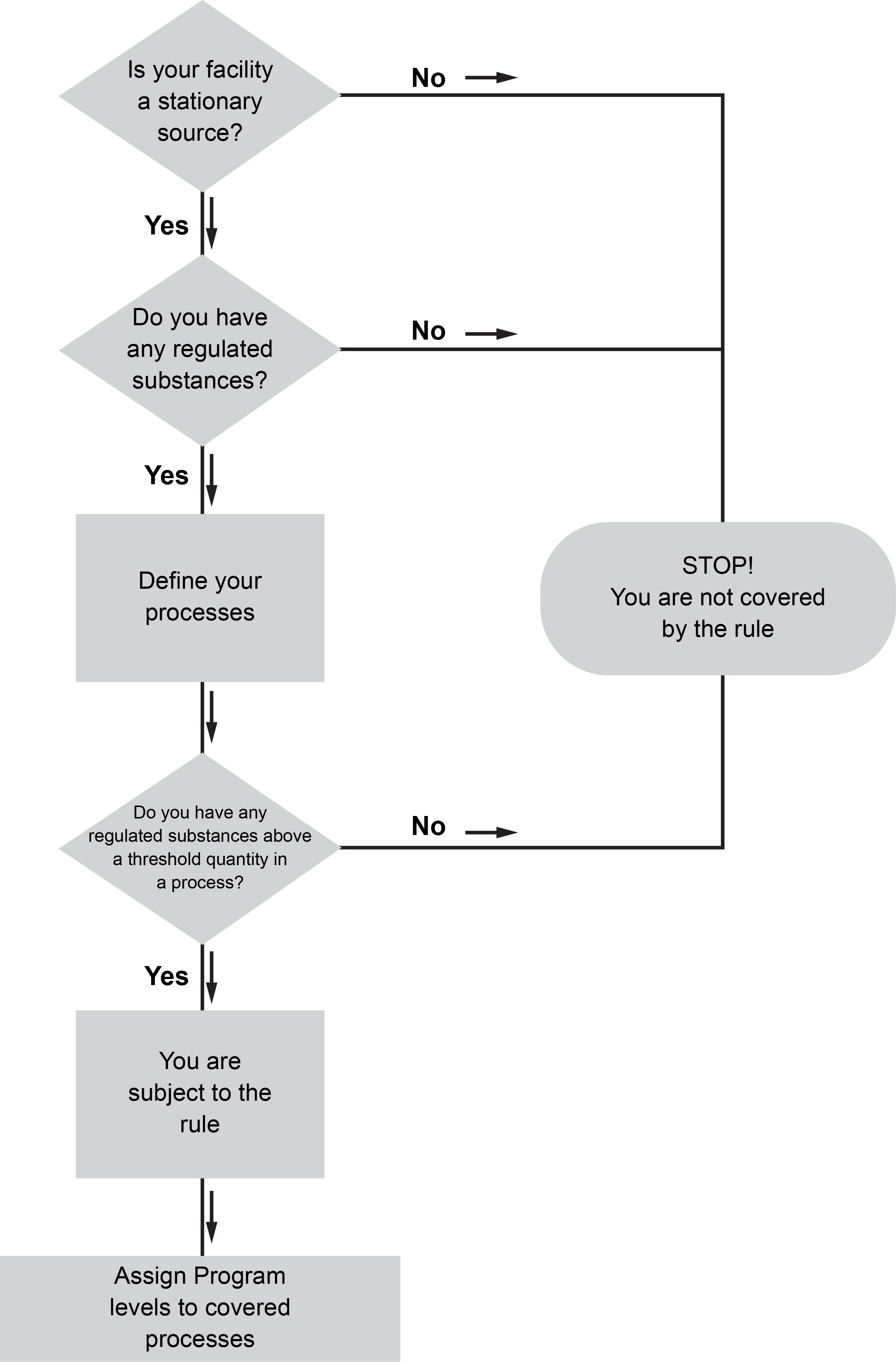

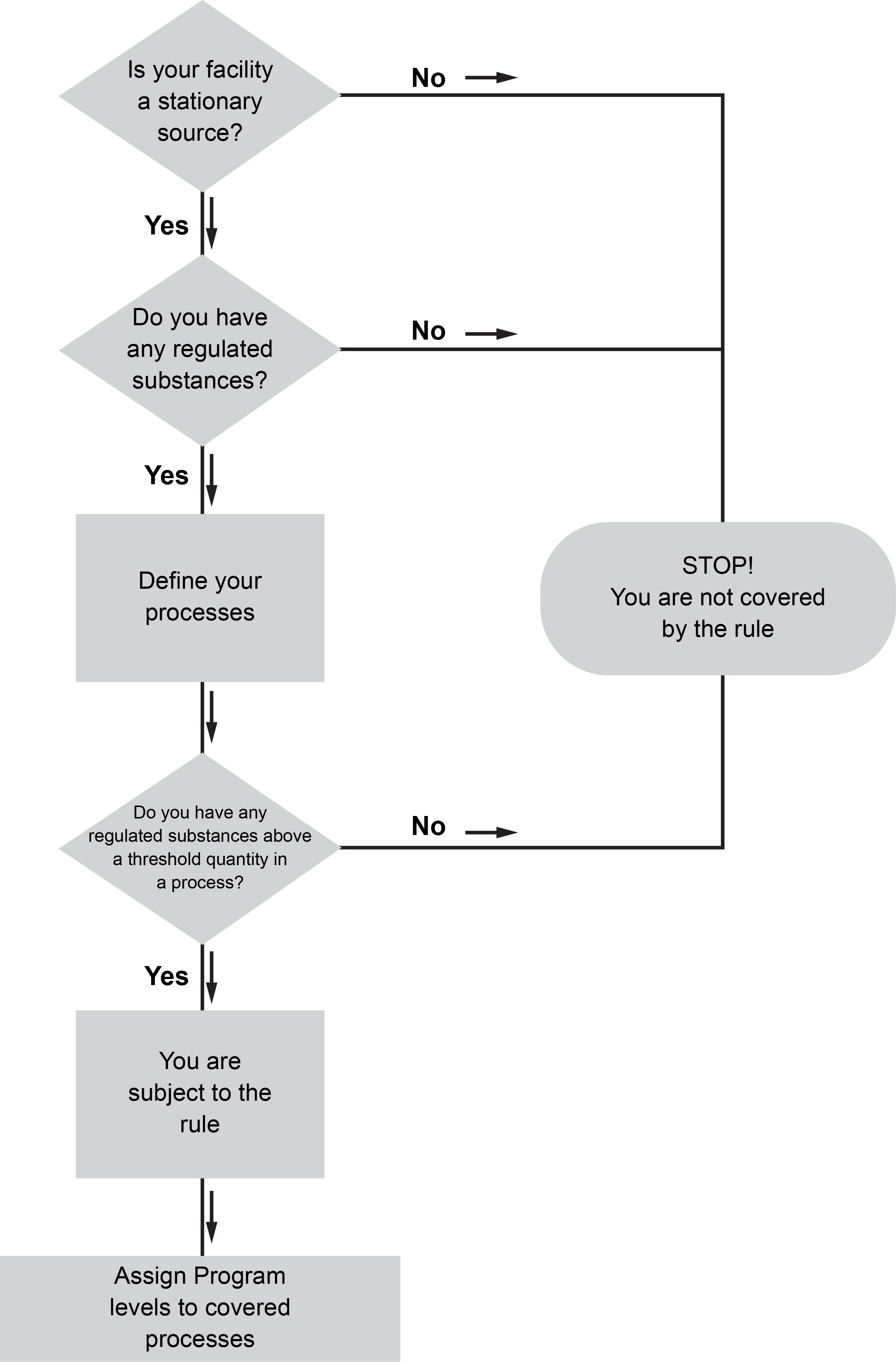

- Stationary sources that have more than a threshold quantity of a regulated substance in a process can use the included decision tree to determine if the company is subject to the Risk Management Plan (RMP) rule.

The requirements of 40 Code of Federal Regulations (CFR) 68 apply to stationary sources that have more than a threshold quantity of a regulated substance in a process, as determined under 68.115. A quick glance at this flow chart can help determine if the company’s facility is subject to the Risk Management Plan (RMP) rule.

Chemical lists

The RMP rule includes a List of Regulated Substances under 112(r) of the Clean Air Act (including common synonyms) to help assess if a particular chemical is subject to the rule. Where the Clean Air Act 112(r) program has been delegated to a state, that state may have additional requirements for the federally listed chemicals, and/or additional listed chemicals.

Thresholds

Threshold quantities of chemicals regulated under the RMP rule are included (in units of pounds) on the List of Regulated Substances under 112(r) of the Clean Air Act.

Process

The Environmental Protection Agency’s (EPA’s) definition of process is identical to the definition of process under the Occupational Safety and Health Administration (OSHA) Process Safety Management (PSM) standard. Under the RMP rule, a process is defined as “Any activity involving a regulated substance, including any use, storage, manufacturing, handling, or on-site movement of such substances, or combination of these activities.” For the purposes of this definition, any group of vessels that are interconnected, or separate vessels that are located such that a regulated substance could be involved in a potential release, shall be considered a single process.

Examples of “vessels” include:

- Reactors

- Tanks

- Drums

- Barrels

- Cylinders

- Vats

- Kettles

- Boilers

- Pipes

- Hoses

- Other containers

Who is exempt from RMP?

- Facilities that handle regulated substances in quantities below the specified threshold are exempt.

The Risk Management Plan (RMP) rule does not apply to facilities that handle regulated substances in quantities below the specified threshold limits outlined on the List of Regulated Substances under 112(r) of the Clean Air Act.

Other exemptions include:

- Flammable fuels used as fuel or held for sale as fuel at a retail facility (that is, a facility at which more than one-half of the income is obtained from direct sales to end users or at which more than one-half of the fuel sold, by volume, is sold through a cylinder exchange program). However, flammable fuels used as a feedstock or held for sale as fuel at a wholesale facility are still covered.

- Ammonia used as an agricultural nutrient, when held by farmers.

- Gasoline (which includes some of the regulated chemicals) that is used for internal combustion engines.

- Regulated substances in naturally occurring hydrocarbon mixtures (e.g., natural gas condensate, crude oil, field gas, and produced water) prior to initial processing in a petroleum refining process unit or a natural gas processing plant.

- Any source located on the outer continental shelf (e.g. oil rigs or production platforms).

- Regulated substances contained in articles. Articles are manufactured items that are formed to a specific shape or design during manufacture, that have end use functions dependent in whole or in part upon the shape or design during end use, and that do not release or otherwise result in exposure to a regulated substance under normal conditions of processing and use.

- A regulated flammable substance that is present in a mixture if it comprises less than one percent by weight of the mixture. If the regulated substance comprises more than one percent by weight of the mixture and the mixture has a flash point greater than 22.8 degrees C and a boiling point above 37.8 degrees C or the mixture does not meet the National Fire Protection Association (NFPA) flammability rating of 4 or higher, then the mixture is exempt.

- A regulated toxic substance that is present in a mixture if it comprises less than one percent by weight of the mixture. If the regulated substance comprises more than one percent by weight of the mixture and if the partial pressure of the regulated toxic substance in the mixture is less than 10mm mercury, then the mixture is exempt. This, however, does not apply to Oleum; toluene 2,4- diisocyanate; toluene 2,6-diisocyanate; toluene diisocyanate.

- Four aqueous solutions already have specified concentrations that make them subject to RMP and therefore should not be considered in this mixture exemption. These four solutions are ammonia (20%), hydrochloric acid (37%), hydrofluoric acid (50%), and nitric acid (80%).

- Regulated substances used for the following purposes are exempt from the RMP rule:

- Use as a structural component of the stationary source,

- Use of products for routine janitorial maintenance,

- Foods, drugs, cosmetics, or other personal items containing the regulated substance used by employees,

- Use of regulated substances present in process water or non-contact cooling water as drawn from the environment or municipal sources or use of regulated substances present in air used either as compressed air or as part of combustion.

- Regulated substances used in laboratories at a stationary source under the supervision of a technically qualified individual. This exemption does not apply to:

- Specialty chemical production,

- Manufacture, processing, or use of substances in pilot plant scale operations, and

- Activities conducted outside the laboratory.

The General Duty Clause

- In addition to specific RMP requirements, stationary sources are obligated to meet the Clean Air Act General Duty Clause.

- The General Duty Clause gives stationary sources responsibility for knowing hazards posed by chemicals and assessing impacts, safely preventing releases, and minimizing consequences if accidental releases occur.

Under the Clean Air Act 112(r)(1), the General Duty Clause states: “The owners and operators of stationary sources producing, processing, handling or storing such substances [i.e., a chemical in 40 Code of Federal Regulations (CFR) part 68 or any other extremely hazardous substance] have a general duty [in the same manner and to the same extent as the general duty clause in the Occupational Safety and Health Act (OSHA)] to identify hazards which may result from (such) releases using appropriate hazard assessment techniques, to design and maintain a safe facility taking such steps as are necessary to prevent releases, and to minimize the consequences of accidental releases which do occur.”

The General Duty Clause applies to any stationary source producing, processing, handling, or storing regulated substances or other extremely hazardous substances covered under the Risk Management Plan (RMP) rule. “Other extremely hazardous substances” are any chemicals listed in 40 CFR part 68, or any other chemicals which may be considered extremely hazardous.

Facilities subject to the General Duty Clause are, among other things, responsible for the following:

- Knowing the hazards posed by the chemicals and assessing the impacts of possible releases,

- Designing and maintaining a safe facility to prevent accidental releases, and

- Minimizing the consequences of accidental releases that do occur.

It is important to understand that the General Duty Clause is not a regulation and compliance cannot be checked against a regulation or submission of data. Generally, the business should:

- Adopt or follow any relevant industry codes, practices, or consensus standards (for the process or facility as a whole as well as for particular chemicals or pieces of equipment),

- Be aware of unique circumstances of the facility which may require a tailored accident prevention program, and

- Be aware of accidents and other incidents in the industry that indicates potential hazards.

What must RMP facilities do?

- For each RMP covered process, there are categories of requirements across the three different levels of programs.

Based on the operations and situation of a given facility, the owner or operator of a process covered under the Risk Management Plan (RMP) rule must:

- Prepare and submit a single RMP, including registration that covers all affected processes and chemicals.

- Conduct a worst-case release scenario, review accident history, ensure emergency response procedures are coordinated with community response organizations to determine eligibility for Program 1, and, if eligible, document the worst-case scenario and complete a Program 1 certification for the RMP.

- Conduct a hazard assessment, document a management system, implement a more extensive, but streamlined prevention program, and implement an emergency response program for Program 2 processes.

- Conduct a hazard assessment, document a management system, implement a prevention program that is fundamentally identical to the Occupational Safety and Health Administration (OSHA) Process Safety Management (PSM) standard, and implement an emergency response program for Program 3 processes.

Comparison of program requirements

The table below describes what the RMP requires of various facilities based on six categories of requirements across the three different levels of programs classified by the Environmental Protection Agency (EPA).

| Requirement | Program 1 | Program 2 | Program 3 |

|---|---|---|---|

| Hazard assessment | Worst-case analysis | Worst-case analysis Alternative releases | Worst-case analysis Alternative releases |

| Five-year accident history | Five-year accident history | Five-year accident history | Five-year accident history |

| Management program | Document management system | Document management system | |

| Prevention program | Certify no additional steps needed | Safety information Hazard review Operating procedures Training Maintenance Incident investigation Compliance audit | Process safety information Process hazard analysis Operating procedures Training Mechanical integrity Incident investigation Compliance audit Management of change Pre-startup review Contractors Employee participation Hot work permits |

| Emergency response program | Coordinate with local responders | Develop plan and program | Develop plan and program |

| RMP contents | Confidential business information (CBI) Document(s) supporting any CBI Executive summary Registration Worst-case data Five-year accident history Certification | Confidential business information (CBI) Document(s) supporting any CBI Executive summary Registration Worst-case data Alternative release data Five-year accident history Prevention program data Emergency response data Certification | Confidential business information (CBI) Document(s) supporting any CBI Executive summary Registration Worst-case data Alternative release data Five-year accident history Prevention program data Emergency response data Certification |

What are the final changes to the Safer Communities by Chemical Accident Prevention - Risk Management Program Rule?

On February 27, 2024 the EPA signed the Safer Communities by Chemical Accident Prevention (SCCAPP) rule, which finalizes revisions to the Risk Management Program.

Below are a number of changes included in the final rule:

Prevention Program (Subparts C and D)

- Natural hazards and power loss: (1) Adding amplifying regulatory text to emphasize that natural hazards (including those that result from climate change) and loss of power are among the hazards that must be addressed in Program 2 hazard reviews and Program 3 process hazard analyses. (2) Requiring back-up power for release monitoring equipment. (3) Requiring a justification in the Risk Management Plan when hazard evaluation recommendations are not adopted.

- Facility siting: (1) Emphasizing that facility siting should be addressed in hazard reviews and explicitly defining the facility siting requirement for Program 2 hazard reviews and Program 3 process hazard analyses. (2) Requiring a justification in the Risk Management Plan when facility siting hazard recommendations are not adopted.

- Safer technologies and alternatives analysis: Requiring (1) A STAA evaluation for all Program 3 NAICS 324 and 325 processes; (2) A Practicability assessment of inherently safer technologies and designs (IST/ISD) considered for processes (a) in Program 3 NAICS code 324 and 325 within one mile of another Program 3 NAICS code 324 or 325 process, (b) with hydrofluoric acid alkylation processes classified under NAICS 324, (c) having one RMP accident since the facility’s most recent process hazard analysis; (3) Implementation of at least one passive measure at the facility, or IST/ISD, or a combination of active and procedural measures equivalent to or greater than the risk reduction of a passive measure for the same facilities required to conduct the practicability assessment and (4) A justification in the Risk Management Plan when STAA recommendations are not adopted.

- Root cause analysis: Requiring a formal root cause analysis incident investigation when facilities have had an RMP-reportable accident.

- Third-party compliance audits: (1) Requiring the next scheduled compliance audit be a third-party audit when facilities have had an RMP-reportable accident. (2) Requiring a justification in the Risk Management Plan when third-party compliance audit recommendations are not adopted.

- Employee participation: (1) Requiring employee participation in resolving process hazard analyses, compliance audit and incident investigation recommendations and findings. (2) Outlining stop work procedures in Program 3 employee participation plans. (3) Requiring Program 2 and Program 3 employee participation plans to include opportunities for employees to anonymously report RMP-reportable accidents or other related RMP non-compliance issues. (4) Requiring training on employee participation plans.

Emergency Response (Subpart E)

- Community notification of RMP accidents: (1) Requiring non-responding RMP facilities to develop procedures for informing the public about accidental releases. (2) Requiring release notification data be provided to local responders. (3) Partnering with local responders to ensure a community notification system is in place for notification of RMP-reportable accidents.

- Emergency response exercises: (1) Requiring a 10-year frequency for field exercises unless local responders indicate that frequency is infeasible. (2) Requiring mandatory scope and reporting requirements for emergency response exercises.

Information Availability (Subpart H, § 68.210)

- Enhanced Information Availability: New requirements for the facility to provide chemical hazard information upon request to the public living, working or spending significant time within six miles of the facility, in at least two most common languages in the community. Under the previous regulation, facilities were not required to provide this information.

Other Areas of Technical Clarification (Subparts A, C, D)

Minor regulatory edits to clarify:

- Program 3 process safety information should be kept up to date,

- Program 2 and Program 3 requirements consistent for recognized and generally accepted good engineering practices (RAGAGEP),

- Hot work permits should be retained for three years,

- Fiscal or calendar prior year sales should be used to qualify for the retail facility exemption,

- RAGAGEP should be reviewed in process hazard analyses to determine gaps in safety.

Determine program level

- Program 1 requirements apply to processes for which a worst-case release, as evaluated in the hazard assessment, would not affect the public.

- Program 2 requirements apply to less complex operations that do not involve chemical processing.

- Program 3 requirements apply to higher risk complex chemical processing operations and processes subject to OSHA’s PSM Standard.

The Risk Management Plan (RMP) rule defines the activities sources must undertake to address the risks posed by regulated substances in covered processes. To ensure that individual processes are subject to appropriate requirements that match their size and the risks they may pose, the Environmental Protection Agency (EPA) has classified them into three categories of programs, each of which has specific requirements to fulfill depending on a facility’s processes.

Program 1

Program 1 requirements under the RMP rule apply to processes for which a worst-case release, as evaluated in the hazard assessment, would not affect the public. Remotely located facilities using listed flammables are primarily those sources eligible for this.

Program 2

Program 2 requirements under the RMP rule apply to less complex operations that do not involve chemical processing (e.g., retailers, propane users, non-chemical manufacturers, and other processes not regulated under the Occupational Safety and Health Administration’s (OSHA’s) Process Safety Management (PSM) Standard).

Program 3

Program 3 requirements under the RMP rule apply to higher risk complex chemical processing operations and processes subject to OSHA’s PSM Standard.

Determine applicable process(es)

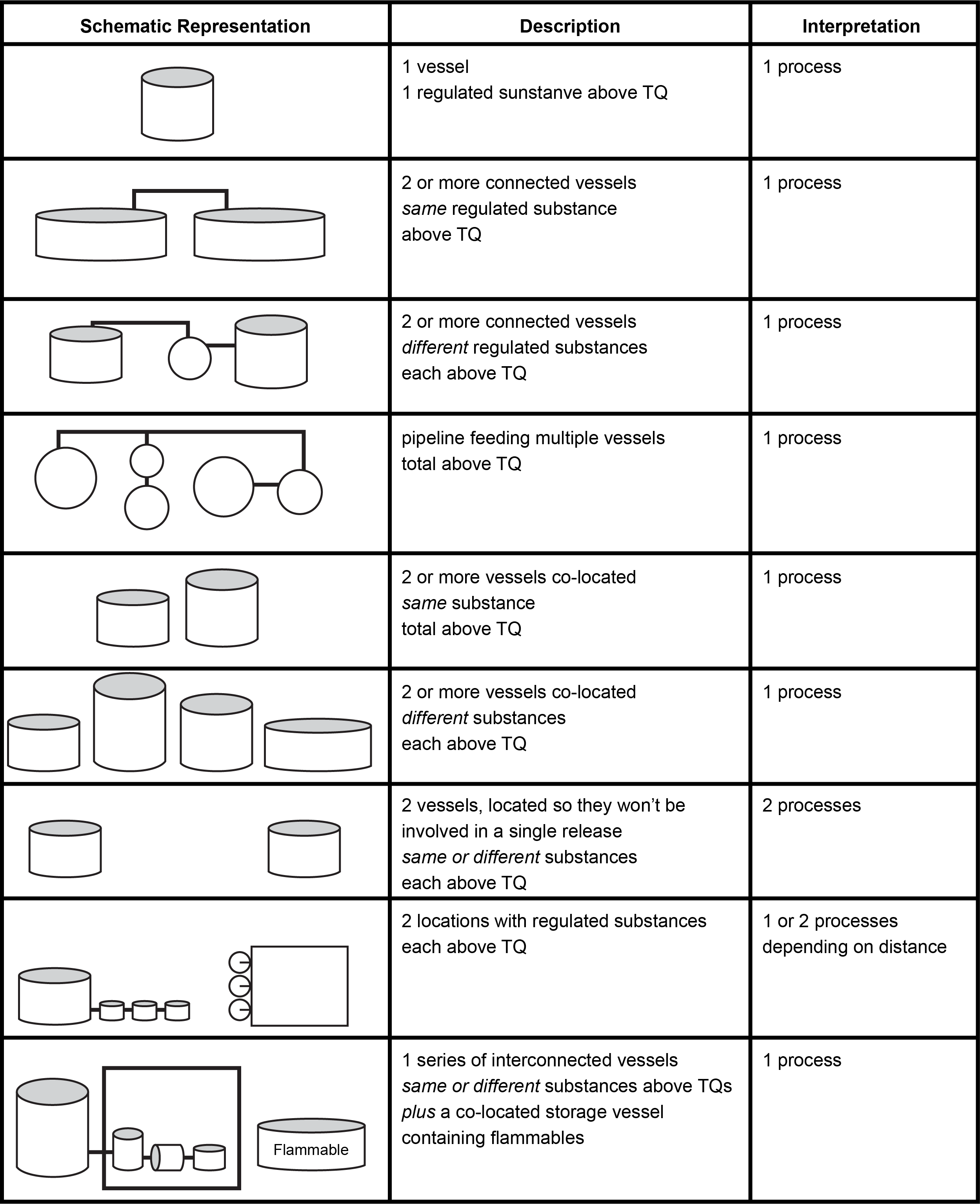

A process covered under the Risk Management Plan (RMP) rule can be as simple as a single storage vessel (or a group of vessels) in one location, or as complicated as a system of interconnected reactor vessels, distillation columns, receivers, pumps, piping, and storage vessels. The company’s facility is covered under the RMP rule if any of the following processes apply:

- The company stores a regulated substance in a single vessel in quantities above the threshold quantity.

- The company has interconnected vessels that together hold more than a threshold quantity of a regulated substance. These connections need not be permanent, and if two or more vessels are connected occasionally, they are considered a single process for the purposes of determining whether a threshold quantity is present.

- The company has multiple unconnected vessels containing the same substance, if they have determined that they are co-located and thus considered a single process for purposes of the rule.

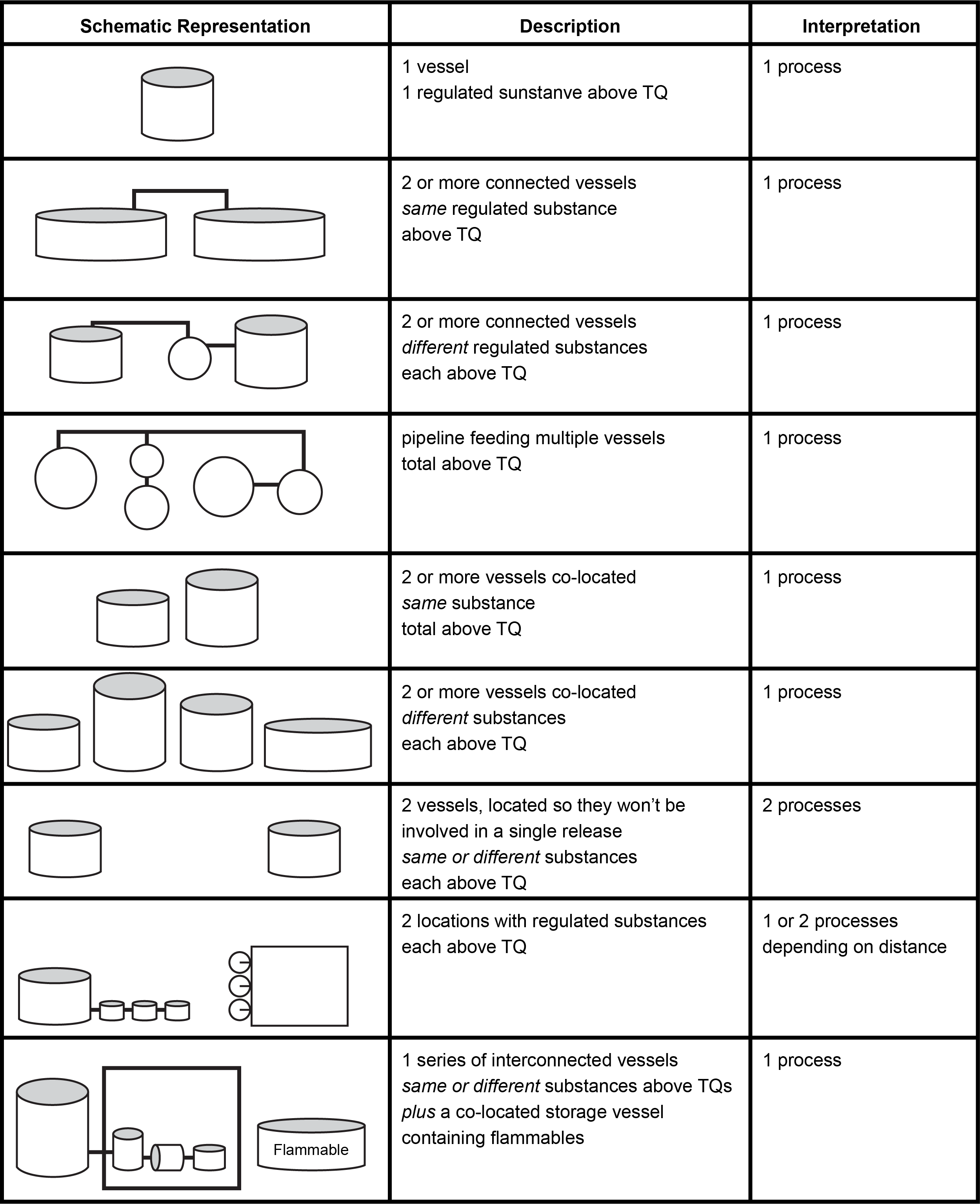

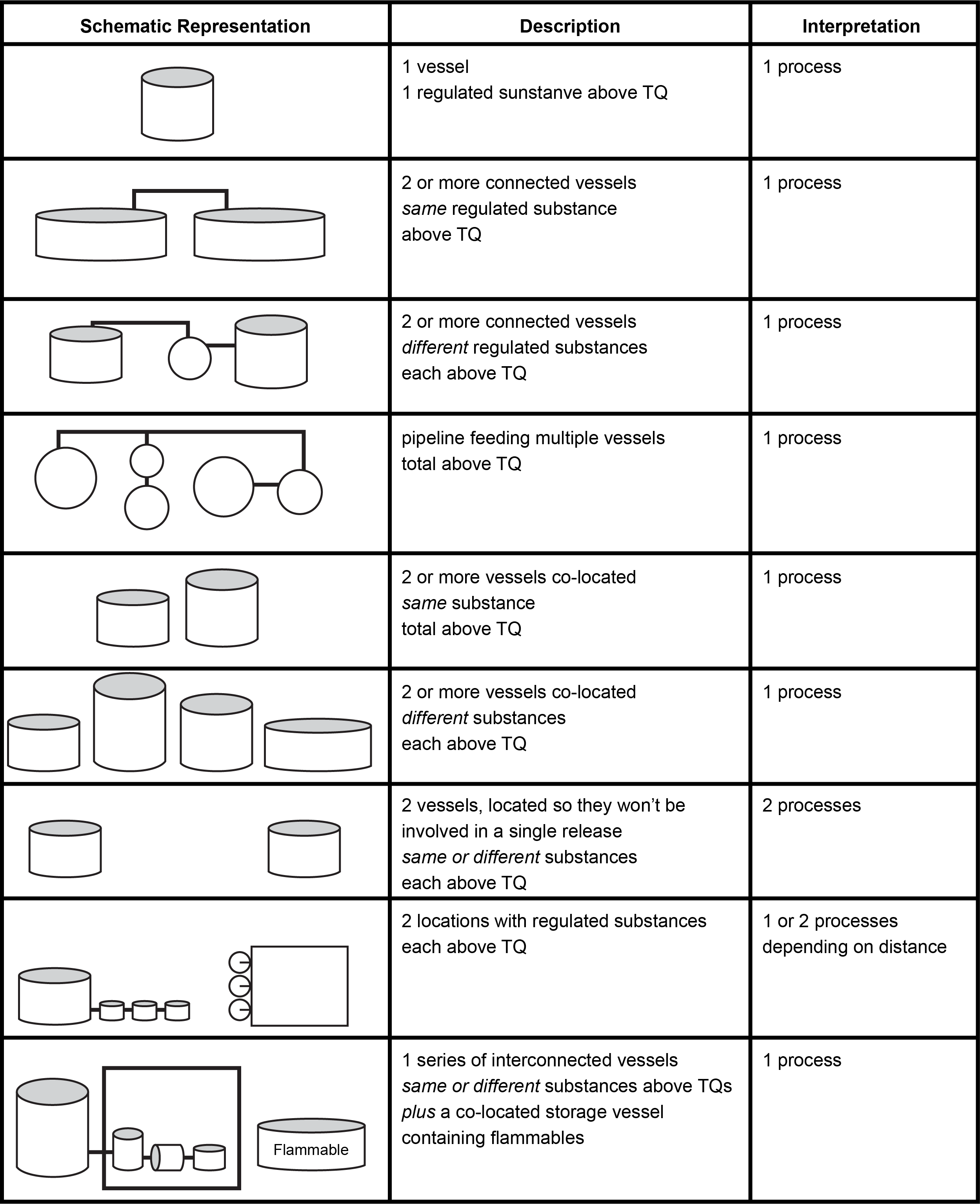

The following table summarizes processes across schematic representation, description, and interpretation.

Create a risk management plan

- Once the company has determined the program level and applicable process, a RMP must be created and then submitted to the EPA.

Once the company has determined the program level and applicable process for the facility, a Risk Management Plan (RMP) must be created and then submitted to the Environmental Protection Agency (EPA) via the RMP*eSubmit software.

Required plan elements

- Program 1 processes must only perform some risk planning actions; a prevention program, an emergency response program, or a management system are not required.

Under the Risk Management Plan (RMP) rule, sources with a regulated substance above a threshold quantity will be required to conduct the following elements of risk management planning:

- An off-site consequence analysis that evaluates specific potential release scenarios, including worst-case and alternate scenarios.

- A Five-year history of accidental releases of regulated substances.

- An emergency response program.

- An integrated prevention program to manage risk.

- An overall management system to supervise the implementation of these program elements.

- An RMP, revised at least once every five years, that summarizes and documents these activities for all covered processes.

Based on their limited potential for serious offset consequences, Program 1 processes are not required to implement a prevention program, an emergency response program, or a management system. Sources with processes in Program 2 and Program 3, however, must address each of these elements.

RMP e-reporting to the EPA

Software called RMP*eSubmit is the only way to submit Risk Management Plans (RMPs) to the Environmental Protection Agency (EPA). RMP*eSubmit improves data quality and to enables facilities to access their RMP 24 hours day, seven days a week. For more on RMP*eSubmit, go to www.epa.gov/rmp/rmpesubmit.

RMP*Comp (www.epa.gov/rmp/rmpcomp) is an electronic tool that performs the off-site consequence analysis required under the Risk Management Program.

After the company has prepared the plan using RMP*eSubmit, they may also resubmit, correct, or withdraw an RMP.

RMP applicability

- The EPA requires owners and operators to develop plans and procedures that result in the implementation of a risk management program.

- Many facilities covered under CAA are also regulated under the PSM standard.

Cited under 40 Code of Federal Regulations (CFR) 68 — Chemical accident prevention provisions, the Environmental Protection Agency’s (EPA’s) Risk Management Plan (RMP) regulation requires owners and operators to develop plans and procedures that result in the implementation of a risk management program for all covered facilities within the organization. Three of the most important requirements include the following:

- A hazard assessment of workplace activities.

- A prevention program that is based on the Occupational Safety and Health Administration’s (OSHA’s) Process Safety Management (PSM) standard.

- An emergency response program to train employees and contractors in emergency response procedures.

Overlap with PSM

Many facilities covered under the Clean Air Act (CAA) and by extension the RMP rule are already regulated under the PSM standard. Requirements of PSM that also apply to RMP are:

- Safety and compliance audits

- Pre-startup safety reviews

- Mechanical integrity

- Operating procedures

- Process safety information

- Management of change

- Incident investigation

- Emergency planning and response

- Process hazard analysis

- Training programs

- Employee participation

- Hot-work permits

- Contractor requirements

- Recordkeeping requirements

- Trade secrets clause

While the PSM standard centers on worker safety, the RMP rule focuses on releases that would pose a hazard to public health and the environment. Provisions of RMP that are in addition to requirements under PSM are:

- Management systems requirements

- Off-site analysis

- Five-year incident history

- Worst-case release scenarios

- Plan coordination with local emergency planning committee (LEPC)

- Information sharing to the public

- Facility registration

- Risk management plan requirement

- Reporting requirements

- Response drills and exercises

- Regulatory audit requirements

Who is subject to RMP?

- Stationary sources that have more than a threshold quantity of a regulated substance in a process can use the included decision tree to determine if the company is subject to the Risk Management Plan (RMP) rule.

The requirements of 40 Code of Federal Regulations (CFR) 68 apply to stationary sources that have more than a threshold quantity of a regulated substance in a process, as determined under 68.115. A quick glance at this flow chart can help determine if the company’s facility is subject to the Risk Management Plan (RMP) rule.

Chemical lists

The RMP rule includes a List of Regulated Substances under 112(r) of the Clean Air Act (including common synonyms) to help assess if a particular chemical is subject to the rule. Where the Clean Air Act 112(r) program has been delegated to a state, that state may have additional requirements for the federally listed chemicals, and/or additional listed chemicals.

Thresholds

Threshold quantities of chemicals regulated under the RMP rule are included (in units of pounds) on the List of Regulated Substances under 112(r) of the Clean Air Act.

Process

The Environmental Protection Agency’s (EPA’s) definition of process is identical to the definition of process under the Occupational Safety and Health Administration (OSHA) Process Safety Management (PSM) standard. Under the RMP rule, a process is defined as “Any activity involving a regulated substance, including any use, storage, manufacturing, handling, or on-site movement of such substances, or combination of these activities.” For the purposes of this definition, any group of vessels that are interconnected, or separate vessels that are located such that a regulated substance could be involved in a potential release, shall be considered a single process.

Examples of “vessels” include:

- Reactors

- Tanks

- Drums

- Barrels

- Cylinders

- Vats

- Kettles

- Boilers

- Pipes

- Hoses

- Other containers

Who is exempt from RMP?

- Facilities that handle regulated substances in quantities below the specified threshold are exempt.

The Risk Management Plan (RMP) rule does not apply to facilities that handle regulated substances in quantities below the specified threshold limits outlined on the List of Regulated Substances under 112(r) of the Clean Air Act.

Other exemptions include:

- Flammable fuels used as fuel or held for sale as fuel at a retail facility (that is, a facility at which more than one-half of the income is obtained from direct sales to end users or at which more than one-half of the fuel sold, by volume, is sold through a cylinder exchange program). However, flammable fuels used as a feedstock or held for sale as fuel at a wholesale facility are still covered.

- Ammonia used as an agricultural nutrient, when held by farmers.

- Gasoline (which includes some of the regulated chemicals) that is used for internal combustion engines.

- Regulated substances in naturally occurring hydrocarbon mixtures (e.g., natural gas condensate, crude oil, field gas, and produced water) prior to initial processing in a petroleum refining process unit or a natural gas processing plant.

- Any source located on the outer continental shelf (e.g. oil rigs or production platforms).

- Regulated substances contained in articles. Articles are manufactured items that are formed to a specific shape or design during manufacture, that have end use functions dependent in whole or in part upon the shape or design during end use, and that do not release or otherwise result in exposure to a regulated substance under normal conditions of processing and use.

- A regulated flammable substance that is present in a mixture if it comprises less than one percent by weight of the mixture. If the regulated substance comprises more than one percent by weight of the mixture and the mixture has a flash point greater than 22.8 degrees C and a boiling point above 37.8 degrees C or the mixture does not meet the National Fire Protection Association (NFPA) flammability rating of 4 or higher, then the mixture is exempt.

- A regulated toxic substance that is present in a mixture if it comprises less than one percent by weight of the mixture. If the regulated substance comprises more than one percent by weight of the mixture and if the partial pressure of the regulated toxic substance in the mixture is less than 10mm mercury, then the mixture is exempt. This, however, does not apply to Oleum; toluene 2,4- diisocyanate; toluene 2,6-diisocyanate; toluene diisocyanate.

- Four aqueous solutions already have specified concentrations that make them subject to RMP and therefore should not be considered in this mixture exemption. These four solutions are ammonia (20%), hydrochloric acid (37%), hydrofluoric acid (50%), and nitric acid (80%).

- Regulated substances used for the following purposes are exempt from the RMP rule:

- Use as a structural component of the stationary source,

- Use of products for routine janitorial maintenance,

- Foods, drugs, cosmetics, or other personal items containing the regulated substance used by employees,

- Use of regulated substances present in process water or non-contact cooling water as drawn from the environment or municipal sources or use of regulated substances present in air used either as compressed air or as part of combustion.

- Regulated substances used in laboratories at a stationary source under the supervision of a technically qualified individual. This exemption does not apply to:

- Specialty chemical production,

- Manufacture, processing, or use of substances in pilot plant scale operations, and

- Activities conducted outside the laboratory.

Who is subject to RMP?

- Stationary sources that have more than a threshold quantity of a regulated substance in a process can use the included decision tree to determine if the company is subject to the Risk Management Plan (RMP) rule.

The requirements of 40 Code of Federal Regulations (CFR) 68 apply to stationary sources that have more than a threshold quantity of a regulated substance in a process, as determined under 68.115. A quick glance at this flow chart can help determine if the company’s facility is subject to the Risk Management Plan (RMP) rule.

Chemical lists

The RMP rule includes a List of Regulated Substances under 112(r) of the Clean Air Act (including common synonyms) to help assess if a particular chemical is subject to the rule. Where the Clean Air Act 112(r) program has been delegated to a state, that state may have additional requirements for the federally listed chemicals, and/or additional listed chemicals.

Thresholds

Threshold quantities of chemicals regulated under the RMP rule are included (in units of pounds) on the List of Regulated Substances under 112(r) of the Clean Air Act.

Process

The Environmental Protection Agency’s (EPA’s) definition of process is identical to the definition of process under the Occupational Safety and Health Administration (OSHA) Process Safety Management (PSM) standard. Under the RMP rule, a process is defined as “Any activity involving a regulated substance, including any use, storage, manufacturing, handling, or on-site movement of such substances, or combination of these activities.” For the purposes of this definition, any group of vessels that are interconnected, or separate vessels that are located such that a regulated substance could be involved in a potential release, shall be considered a single process.

Examples of “vessels” include:

- Reactors

- Tanks

- Drums

- Barrels

- Cylinders

- Vats

- Kettles

- Boilers

- Pipes

- Hoses

- Other containers

Who is exempt from RMP?

- Facilities that handle regulated substances in quantities below the specified threshold are exempt.

The Risk Management Plan (RMP) rule does not apply to facilities that handle regulated substances in quantities below the specified threshold limits outlined on the List of Regulated Substances under 112(r) of the Clean Air Act.

Other exemptions include:

- Flammable fuels used as fuel or held for sale as fuel at a retail facility (that is, a facility at which more than one-half of the income is obtained from direct sales to end users or at which more than one-half of the fuel sold, by volume, is sold through a cylinder exchange program). However, flammable fuels used as a feedstock or held for sale as fuel at a wholesale facility are still covered.

- Ammonia used as an agricultural nutrient, when held by farmers.

- Gasoline (which includes some of the regulated chemicals) that is used for internal combustion engines.

- Regulated substances in naturally occurring hydrocarbon mixtures (e.g., natural gas condensate, crude oil, field gas, and produced water) prior to initial processing in a petroleum refining process unit or a natural gas processing plant.

- Any source located on the outer continental shelf (e.g. oil rigs or production platforms).

- Regulated substances contained in articles. Articles are manufactured items that are formed to a specific shape or design during manufacture, that have end use functions dependent in whole or in part upon the shape or design during end use, and that do not release or otherwise result in exposure to a regulated substance under normal conditions of processing and use.

- A regulated flammable substance that is present in a mixture if it comprises less than one percent by weight of the mixture. If the regulated substance comprises more than one percent by weight of the mixture and the mixture has a flash point greater than 22.8 degrees C and a boiling point above 37.8 degrees C or the mixture does not meet the National Fire Protection Association (NFPA) flammability rating of 4 or higher, then the mixture is exempt.

- A regulated toxic substance that is present in a mixture if it comprises less than one percent by weight of the mixture. If the regulated substance comprises more than one percent by weight of the mixture and if the partial pressure of the regulated toxic substance in the mixture is less than 10mm mercury, then the mixture is exempt. This, however, does not apply to Oleum; toluene 2,4- diisocyanate; toluene 2,6-diisocyanate; toluene diisocyanate.

- Four aqueous solutions already have specified concentrations that make them subject to RMP and therefore should not be considered in this mixture exemption. These four solutions are ammonia (20%), hydrochloric acid (37%), hydrofluoric acid (50%), and nitric acid (80%).

- Regulated substances used for the following purposes are exempt from the RMP rule:

- Use as a structural component of the stationary source,

- Use of products for routine janitorial maintenance,

- Foods, drugs, cosmetics, or other personal items containing the regulated substance used by employees,

- Use of regulated substances present in process water or non-contact cooling water as drawn from the environment or municipal sources or use of regulated substances present in air used either as compressed air or as part of combustion.

- Regulated substances used in laboratories at a stationary source under the supervision of a technically qualified individual. This exemption does not apply to:

- Specialty chemical production,

- Manufacture, processing, or use of substances in pilot plant scale operations, and

- Activities conducted outside the laboratory.

The General Duty Clause

- In addition to specific RMP requirements, stationary sources are obligated to meet the Clean Air Act General Duty Clause.

- The General Duty Clause gives stationary sources responsibility for knowing hazards posed by chemicals and assessing impacts, safely preventing releases, and minimizing consequences if accidental releases occur.

Under the Clean Air Act 112(r)(1), the General Duty Clause states: “The owners and operators of stationary sources producing, processing, handling or storing such substances [i.e., a chemical in 40 Code of Federal Regulations (CFR) part 68 or any other extremely hazardous substance] have a general duty [in the same manner and to the same extent as the general duty clause in the Occupational Safety and Health Act (OSHA)] to identify hazards which may result from (such) releases using appropriate hazard assessment techniques, to design and maintain a safe facility taking such steps as are necessary to prevent releases, and to minimize the consequences of accidental releases which do occur.”

The General Duty Clause applies to any stationary source producing, processing, handling, or storing regulated substances or other extremely hazardous substances covered under the Risk Management Plan (RMP) rule. “Other extremely hazardous substances” are any chemicals listed in 40 CFR part 68, or any other chemicals which may be considered extremely hazardous.

Facilities subject to the General Duty Clause are, among other things, responsible for the following:

- Knowing the hazards posed by the chemicals and assessing the impacts of possible releases,

- Designing and maintaining a safe facility to prevent accidental releases, and

- Minimizing the consequences of accidental releases that do occur.

It is important to understand that the General Duty Clause is not a regulation and compliance cannot be checked against a regulation or submission of data. Generally, the business should:

- Adopt or follow any relevant industry codes, practices, or consensus standards (for the process or facility as a whole as well as for particular chemicals or pieces of equipment),

- Be aware of unique circumstances of the facility which may require a tailored accident prevention program, and

- Be aware of accidents and other incidents in the industry that indicates potential hazards.

What must RMP facilities do?

- For each RMP covered process, there are categories of requirements across the three different levels of programs.

Based on the operations and situation of a given facility, the owner or operator of a process covered under the Risk Management Plan (RMP) rule must:

- Prepare and submit a single RMP, including registration that covers all affected processes and chemicals.

- Conduct a worst-case release scenario, review accident history, ensure emergency response procedures are coordinated with community response organizations to determine eligibility for Program 1, and, if eligible, document the worst-case scenario and complete a Program 1 certification for the RMP.

- Conduct a hazard assessment, document a management system, implement a more extensive, but streamlined prevention program, and implement an emergency response program for Program 2 processes.

- Conduct a hazard assessment, document a management system, implement a prevention program that is fundamentally identical to the Occupational Safety and Health Administration (OSHA) Process Safety Management (PSM) standard, and implement an emergency response program for Program 3 processes.

Comparison of program requirements

The table below describes what the RMP requires of various facilities based on six categories of requirements across the three different levels of programs classified by the Environmental Protection Agency (EPA).

| Requirement | Program 1 | Program 2 | Program 3 |

|---|---|---|---|

| Hazard assessment | Worst-case analysis | Worst-case analysis Alternative releases | Worst-case analysis Alternative releases |

| Five-year accident history | Five-year accident history | Five-year accident history | Five-year accident history |

| Management program | Document management system | Document management system | |

| Prevention program | Certify no additional steps needed | Safety information Hazard review Operating procedures Training Maintenance Incident investigation Compliance audit | Process safety information Process hazard analysis Operating procedures Training Mechanical integrity Incident investigation Compliance audit Management of change Pre-startup review Contractors Employee participation Hot work permits |

| Emergency response program | Coordinate with local responders | Develop plan and program | Develop plan and program |

| RMP contents | Confidential business information (CBI) Document(s) supporting any CBI Executive summary Registration Worst-case data Five-year accident history Certification | Confidential business information (CBI) Document(s) supporting any CBI Executive summary Registration Worst-case data Alternative release data Five-year accident history Prevention program data Emergency response data Certification | Confidential business information (CBI) Document(s) supporting any CBI Executive summary Registration Worst-case data Alternative release data Five-year accident history Prevention program data Emergency response data Certification |

What are the final changes to the Safer Communities by Chemical Accident Prevention - Risk Management Program Rule?

On February 27, 2024 the EPA signed the Safer Communities by Chemical Accident Prevention (SCCAPP) rule, which finalizes revisions to the Risk Management Program.

Below are a number of changes included in the final rule:

Prevention Program (Subparts C and D)

- Natural hazards and power loss: (1) Adding amplifying regulatory text to emphasize that natural hazards (including those that result from climate change) and loss of power are among the hazards that must be addressed in Program 2 hazard reviews and Program 3 process hazard analyses. (2) Requiring back-up power for release monitoring equipment. (3) Requiring a justification in the Risk Management Plan when hazard evaluation recommendations are not adopted.

- Facility siting: (1) Emphasizing that facility siting should be addressed in hazard reviews and explicitly defining the facility siting requirement for Program 2 hazard reviews and Program 3 process hazard analyses. (2) Requiring a justification in the Risk Management Plan when facility siting hazard recommendations are not adopted.

- Safer technologies and alternatives analysis: Requiring (1) A STAA evaluation for all Program 3 NAICS 324 and 325 processes; (2) A Practicability assessment of inherently safer technologies and designs (IST/ISD) considered for processes (a) in Program 3 NAICS code 324 and 325 within one mile of another Program 3 NAICS code 324 or 325 process, (b) with hydrofluoric acid alkylation processes classified under NAICS 324, (c) having one RMP accident since the facility’s most recent process hazard analysis; (3) Implementation of at least one passive measure at the facility, or IST/ISD, or a combination of active and procedural measures equivalent to or greater than the risk reduction of a passive measure for the same facilities required to conduct the practicability assessment and (4) A justification in the Risk Management Plan when STAA recommendations are not adopted.

- Root cause analysis: Requiring a formal root cause analysis incident investigation when facilities have had an RMP-reportable accident.

- Third-party compliance audits: (1) Requiring the next scheduled compliance audit be a third-party audit when facilities have had an RMP-reportable accident. (2) Requiring a justification in the Risk Management Plan when third-party compliance audit recommendations are not adopted.

- Employee participation: (1) Requiring employee participation in resolving process hazard analyses, compliance audit and incident investigation recommendations and findings. (2) Outlining stop work procedures in Program 3 employee participation plans. (3) Requiring Program 2 and Program 3 employee participation plans to include opportunities for employees to anonymously report RMP-reportable accidents or other related RMP non-compliance issues. (4) Requiring training on employee participation plans.

Emergency Response (Subpart E)

- Community notification of RMP accidents: (1) Requiring non-responding RMP facilities to develop procedures for informing the public about accidental releases. (2) Requiring release notification data be provided to local responders. (3) Partnering with local responders to ensure a community notification system is in place for notification of RMP-reportable accidents.

- Emergency response exercises: (1) Requiring a 10-year frequency for field exercises unless local responders indicate that frequency is infeasible. (2) Requiring mandatory scope and reporting requirements for emergency response exercises.

Information Availability (Subpart H, § 68.210)

- Enhanced Information Availability: New requirements for the facility to provide chemical hazard information upon request to the public living, working or spending significant time within six miles of the facility, in at least two most common languages in the community. Under the previous regulation, facilities were not required to provide this information.

Other Areas of Technical Clarification (Subparts A, C, D)

Minor regulatory edits to clarify:

- Program 3 process safety information should be kept up to date,

- Program 2 and Program 3 requirements consistent for recognized and generally accepted good engineering practices (RAGAGEP),

- Hot work permits should be retained for three years,

- Fiscal or calendar prior year sales should be used to qualify for the retail facility exemption,

- RAGAGEP should be reviewed in process hazard analyses to determine gaps in safety.

Determine program level

- Program 1 requirements apply to processes for which a worst-case release, as evaluated in the hazard assessment, would not affect the public.

- Program 2 requirements apply to less complex operations that do not involve chemical processing.

- Program 3 requirements apply to higher risk complex chemical processing operations and processes subject to OSHA’s PSM Standard.

The Risk Management Plan (RMP) rule defines the activities sources must undertake to address the risks posed by regulated substances in covered processes. To ensure that individual processes are subject to appropriate requirements that match their size and the risks they may pose, the Environmental Protection Agency (EPA) has classified them into three categories of programs, each of which has specific requirements to fulfill depending on a facility’s processes.

Program 1

Program 1 requirements under the RMP rule apply to processes for which a worst-case release, as evaluated in the hazard assessment, would not affect the public. Remotely located facilities using listed flammables are primarily those sources eligible for this.

Program 2

Program 2 requirements under the RMP rule apply to less complex operations that do not involve chemical processing (e.g., retailers, propane users, non-chemical manufacturers, and other processes not regulated under the Occupational Safety and Health Administration’s (OSHA’s) Process Safety Management (PSM) Standard).

Program 3

Program 3 requirements under the RMP rule apply to higher risk complex chemical processing operations and processes subject to OSHA’s PSM Standard.

Determine applicable process(es)

A process covered under the Risk Management Plan (RMP) rule can be as simple as a single storage vessel (or a group of vessels) in one location, or as complicated as a system of interconnected reactor vessels, distillation columns, receivers, pumps, piping, and storage vessels. The company’s facility is covered under the RMP rule if any of the following processes apply:

- The company stores a regulated substance in a single vessel in quantities above the threshold quantity.

- The company has interconnected vessels that together hold more than a threshold quantity of a regulated substance. These connections need not be permanent, and if two or more vessels are connected occasionally, they are considered a single process for the purposes of determining whether a threshold quantity is present.

- The company has multiple unconnected vessels containing the same substance, if they have determined that they are co-located and thus considered a single process for purposes of the rule.

The following table summarizes processes across schematic representation, description, and interpretation.

Create a risk management plan

- Once the company has determined the program level and applicable process, a RMP must be created and then submitted to the EPA.

Once the company has determined the program level and applicable process for the facility, a Risk Management Plan (RMP) must be created and then submitted to the Environmental Protection Agency (EPA) via the RMP*eSubmit software.

Required plan elements

- Program 1 processes must only perform some risk planning actions; a prevention program, an emergency response program, or a management system are not required.

Under the Risk Management Plan (RMP) rule, sources with a regulated substance above a threshold quantity will be required to conduct the following elements of risk management planning:

- An off-site consequence analysis that evaluates specific potential release scenarios, including worst-case and alternate scenarios.

- A Five-year history of accidental releases of regulated substances.

- An emergency response program.

- An integrated prevention program to manage risk.

- An overall management system to supervise the implementation of these program elements.

- An RMP, revised at least once every five years, that summarizes and documents these activities for all covered processes.

Based on their limited potential for serious offset consequences, Program 1 processes are not required to implement a prevention program, an emergency response program, or a management system. Sources with processes in Program 2 and Program 3, however, must address each of these elements.

RMP e-reporting to the EPA

Software called RMP*eSubmit is the only way to submit Risk Management Plans (RMPs) to the Environmental Protection Agency (EPA). RMP*eSubmit improves data quality and to enables facilities to access their RMP 24 hours day, seven days a week. For more on RMP*eSubmit, go to www.epa.gov/rmp/rmpesubmit.

RMP*Comp (www.epa.gov/rmp/rmpcomp) is an electronic tool that performs the off-site consequence analysis required under the Risk Management Program.

After the company has prepared the plan using RMP*eSubmit, they may also resubmit, correct, or withdraw an RMP.

Determine program level

- Program 1 requirements apply to processes for which a worst-case release, as evaluated in the hazard assessment, would not affect the public.

- Program 2 requirements apply to less complex operations that do not involve chemical processing.

- Program 3 requirements apply to higher risk complex chemical processing operations and processes subject to OSHA’s PSM Standard.

The Risk Management Plan (RMP) rule defines the activities sources must undertake to address the risks posed by regulated substances in covered processes. To ensure that individual processes are subject to appropriate requirements that match their size and the risks they may pose, the Environmental Protection Agency (EPA) has classified them into three categories of programs, each of which has specific requirements to fulfill depending on a facility’s processes.

Program 1

Program 1 requirements under the RMP rule apply to processes for which a worst-case release, as evaluated in the hazard assessment, would not affect the public. Remotely located facilities using listed flammables are primarily those sources eligible for this.

Program 2

Program 2 requirements under the RMP rule apply to less complex operations that do not involve chemical processing (e.g., retailers, propane users, non-chemical manufacturers, and other processes not regulated under the Occupational Safety and Health Administration’s (OSHA’s) Process Safety Management (PSM) Standard).

Program 3

Program 3 requirements under the RMP rule apply to higher risk complex chemical processing operations and processes subject to OSHA’s PSM Standard.

Determine applicable process(es)

A process covered under the Risk Management Plan (RMP) rule can be as simple as a single storage vessel (or a group of vessels) in one location, or as complicated as a system of interconnected reactor vessels, distillation columns, receivers, pumps, piping, and storage vessels. The company’s facility is covered under the RMP rule if any of the following processes apply:

- The company stores a regulated substance in a single vessel in quantities above the threshold quantity.

- The company has interconnected vessels that together hold more than a threshold quantity of a regulated substance. These connections need not be permanent, and if two or more vessels are connected occasionally, they are considered a single process for the purposes of determining whether a threshold quantity is present.

- The company has multiple unconnected vessels containing the same substance, if they have determined that they are co-located and thus considered a single process for purposes of the rule.

The following table summarizes processes across schematic representation, description, and interpretation.

Create a risk management plan

- Once the company has determined the program level and applicable process, a RMP must be created and then submitted to the EPA.

Once the company has determined the program level and applicable process for the facility, a Risk Management Plan (RMP) must be created and then submitted to the Environmental Protection Agency (EPA) via the RMP*eSubmit software.

Required plan elements

- Program 1 processes must only perform some risk planning actions; a prevention program, an emergency response program, or a management system are not required.

Under the Risk Management Plan (RMP) rule, sources with a regulated substance above a threshold quantity will be required to conduct the following elements of risk management planning:

- An off-site consequence analysis that evaluates specific potential release scenarios, including worst-case and alternate scenarios.

- A Five-year history of accidental releases of regulated substances.

- An emergency response program.

- An integrated prevention program to manage risk.

- An overall management system to supervise the implementation of these program elements.

- An RMP, revised at least once every five years, that summarizes and documents these activities for all covered processes.

Based on their limited potential for serious offset consequences, Program 1 processes are not required to implement a prevention program, an emergency response program, or a management system. Sources with processes in Program 2 and Program 3, however, must address each of these elements.

RMP e-reporting to the EPA

Software called RMP*eSubmit is the only way to submit Risk Management Plans (RMPs) to the Environmental Protection Agency (EPA). RMP*eSubmit improves data quality and to enables facilities to access their RMP 24 hours day, seven days a week. For more on RMP*eSubmit, go to www.epa.gov/rmp/rmpesubmit.

RMP*Comp (www.epa.gov/rmp/rmpcomp) is an electronic tool that performs the off-site consequence analysis required under the Risk Management Program.

After the company has prepared the plan using RMP*eSubmit, they may also resubmit, correct, or withdraw an RMP.