Flammable liquids and liquified petroleum gases

- Since flammable liquids are used in many workplaces for a variety of reasons, OSHA’s requirements vary depending on exposure and other related factors.

- LPG is used in many workplaces for a variety of reasons and can pose a great hazard if not handled, used, and stored properly.

- Regulatory information for flammable liquids and LPGs can be found under 29 CFR 1910.

Flammable liquids

Flammable liquids are used in many workplaces for a variety of reasons. As their name implies, these liquids pose serious fire hazards if not handled, used, and stored properly. Flammable liquids are any liquid having a flashpoint at or below 199.4 °F (93 °C).

The Occupational Safety and Health Administration’s (OSHA’s) flammable liquids requirements apply to employers with employees who use or are exposed to flammable liquids. Depending on the type of work yielding the exposure, the quantities, and other factors, there are varying requirements. OSHA’s regulatory information for flammable liquids can be found under 29 CFR 1910.106.

What is required in the workplace?

In general, covered employers are required to:

- Properly design and install flammable liquid storage tanks;

- Properly design and install drainage, dikes, and walls for aboveground tanks;

- Use only approved containers for flammable liquids;

- Use only approved flammable storage cabinets (and do not exceed storage amount limitations);

- Follow the construction requirements for inside storage rooms;

- Follow flammable liquid storage amount limitations for warehouses or storage buildings;

- Follow flammable liquid storage amount limitations outside of buildings;

- Follow precautions to prevent the ignition of flammable vapors;

- Follow the requirements for providing appropriate firefighting equipment in areas where flammable liquids are stored and used; and

Employ the required maintenance and operating practices to control leakage and prevent the accidental escape of flammable liquids.

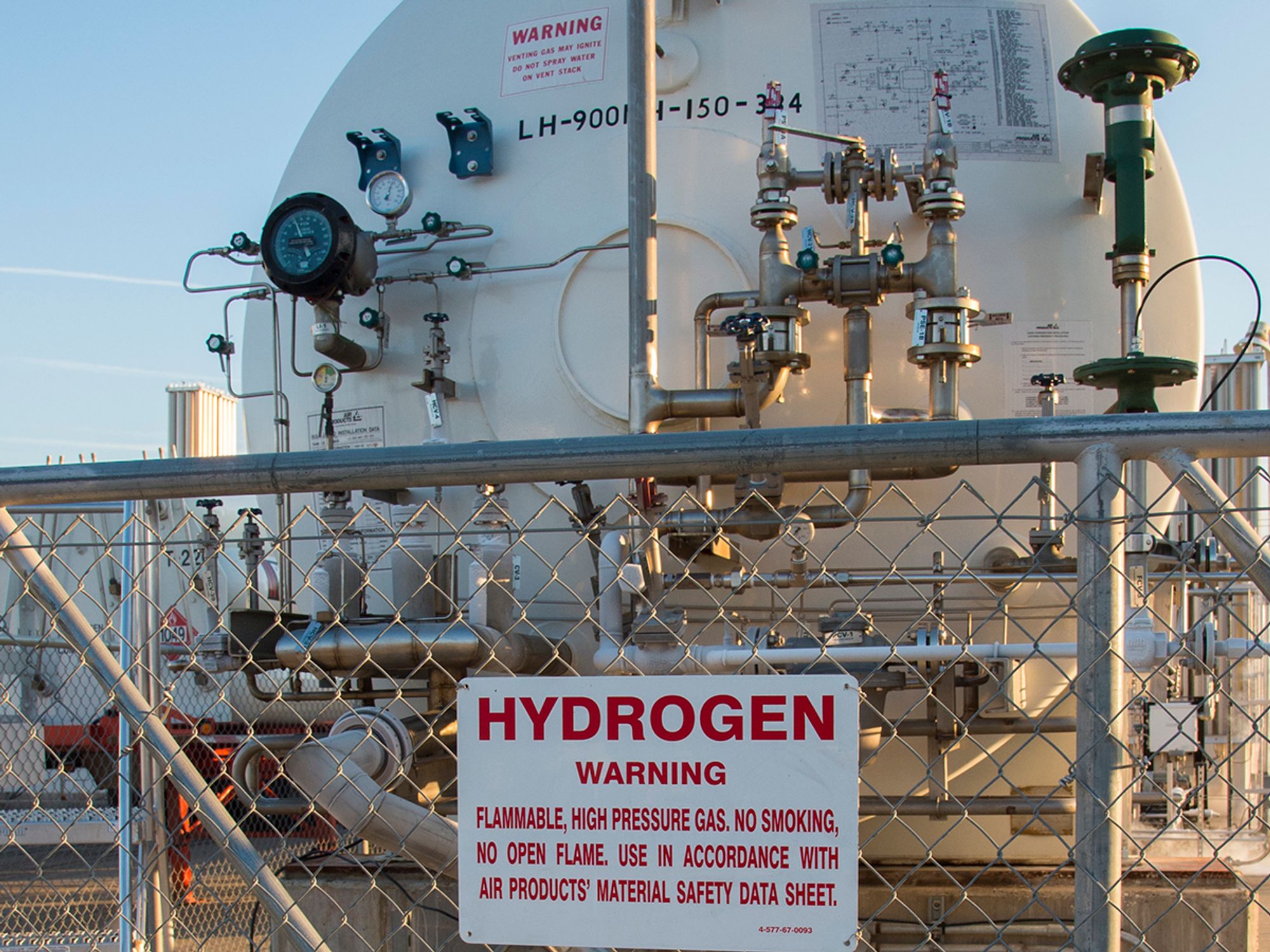

Liquified Petroleum Gases

Liquified Petroleum Gas (LPG) is used in many workplaces for a variety of reasons. LPGs are any material which is composed predominantly of (or a mixture of) propane, propylene, butanes (normal butane or iso-butane), and butylene. LPG poses a great hazard if not handled, used, and stored properly.

OSHA’s LPG requirements apply to employers who have employees who use or are exposed to LPG. Depending on the type of work yielding the exposure, the quantities, and other factors, there are varying requirements. OSHA’s regulatory information for LPGs can be found under 29 CFR 1910.110.

Exemptions from the regulation

This regulation does not apply to:

- Marine and pipeline terminals, natural gas processing plants, refineries, or tank farms other than those at industrial sites;

- LPG refrigerated storage systems;

- LPG when used with oxygen (The requirements of 1910.253 apply to such use);

- LPG when used in utility gas plants (For this usage, the National Fire Protection Association Standard for the Storage and Handling of Liquefied Petroleum Gases at Utility Gas Plants, (NFPA) No. 59-1968, will apply); or

- Low-pressure LPG piping systems (not in excess of one-half pound per square inch or 14 inches water column), and the installation and operation of residential and commercial appliances, including their inlet connections supplied through such systems. (For these systems, the National Fire Protection Association Standard for the Installation of Gas Appliances and Gas Piping, (NFPA) 54-1969 will apply).

What is required in the workplace?

In general, covered employers are required to:

- Properly design and install LPG tanks and containers;

- Properly design and install drainage, dikes, and walls for aboveground tanks;

- Use only approved containers for LPG;

- Follow the construction requirements for LPG tanks and containers;

- Follow LPG storage amount limitations for warehouses or storage buildings;

- Follow LPG storage amount limitations outside of buildings;

- Follow precautions to prevent the ignition of flammable vapors;

- Follow the requirements for providing appropriate firefighting equipment in areas where LPG is stored and used; and

- Employ the required maintenance and operating practices to control leakage and prevent the accidental escape of LPG.