['Air Programs']

['Hazardous Air Pollutants']

01/20/2025

...

§63.1100 Applicability.

(a) General. This subpart applies to source categories and affected sources specified in §63.1103(a) through (h). The affected emission points, by source category, are summarized in table 1 of this section. This table also delineates the section and paragraph of the rule that directs an owner or operator of an affected source to source category-specific control, monitoring, recordkeeping, and reporting requirements.

| Source category | Storage vessels | Process vents | Transfer racks | Equipment leaks | Wastewater streams | Other | Source category MACT requirements |

|---|---|---|---|---|---|---|---|

| * * * * * * * | |||||||

| Carbon Black Production | No | Yes | No | No | No | No | §63.1103(f). |

| Cyanide Chemicals Manufacturing | Yes | Yes | Yes | Yes | Yes | No | §63.1103(g). |

| Ethylene Production | Yes | Yes | Yes | Yes | Yes | Yes c | §63.1103(e). |

| * * * * * * * | |||||||

| Spandex Production | Yes | Yes | No | No | No | Yes d | §63.1103(h). |

| a Maximum achievable control technology. | |||||||

| b Fiber spinning lines using spinning solution or suspension containing acrylonitrile. | |||||||

| c Heat exchange systems as defined in §63.1082(b). | |||||||

| d Fiber spinning lines. | |||||||

| Source category | Storage vessels | Process vents | Transfer racks | Equipment leaks | Wastewater streams | Other | Source category MACT requirements |

|---|---|---|---|---|---|---|---|

| Acetal Resins Production | Yes | Yes | No | Yes | Yes | No | §63.1103(a) |

| Acrylic and Modacrylic Fibers Production | Yes | Yes | No | Yes | Yes | Yes b | §63.1103(b) |

| Carbon Black Production | No | Yes | No | No | No | No | §63.1103(f). |

| Cyanide Chemicals Manufacturing | Yes | Yes | Yes | Yes | Yes | No | §63.1103(g). |

| Ethylene Production | Yes | Yes | Yes | Yes | Yes | Yes c | §63.1103(e). |

| Hydrogen Fluoride Production | Yes | Yes | Yes | Yes | No | No | §63.1103(c) |

| Polycarbonate Production | Yes | Yes | No | Yes | Yes | No | §63.1103(d) |

| Spandex Production | Yes | Yes | No | No | No | Yes d | §63.1103(h). |

| a Maximum achievable control technology. b Fiber spinning lines using spinning solution or suspension containing acrylonitrile. c Heat exchange systems as defined in §63.1082(b). d Fiber spinning lines. | |||||||

(b) Subpart A requirements. The following provisions of subpart A of this part (General Provisions), §§63.1 through 63.5, and §§63.12 through 63.15, apply to owners or operators of affected sources subject to this subpart. For sources that reclassify from major source to area source status, the applicable provisions of §63.9(j) and (k) apply. Beginning no later than the compliance dates specified in §63.1102(c), for ethylene production affected sources, §§63.7(a)(4), (c), (e)(4), and (g)(2), §63.9(k), and 63.10(b)(2)(vi) also apply.

(c) Research and development facilities. The provisions of this subpart do not apply to research and development facilities, consistent with section 112(b)(7) of the Act.

(d) Primary product determination and applicability. The primary product of a process unit shall be determined according to the procedures specified in paragraphs (d)(1) and (2) of this section. Paragraphs (d)(3), (4), and (5) of this section discuss compliance for those process units operated as flexible operation units.

(1) If a process unit only manufactures one product, then that product shall represent the primary product of the process unit.

(2) If a process unit is designed and operated as a flexible operation unit, the primary product shall be determined as specified in paragraphs (d)(2)(i) or (ii) of this section based on the anticipated operations for the 5 years following the promulgation date for existing affected sources and for the first 5 years after initial startup for new affected sources.

(i) If the flexible operation unit will manufacture one product for the greatest percentage of operating time over the five-year period, then that product shall represent the primary product of the flexible operation unit.

(ii) If the flexible operation unit will manufacture multiple products equally based on operating time, then the product with the greatest production on a mass basis over the five-year period shall represent the primary product of the flexible operation unit.

(3) Once the primary product of a process unit has been determined to be a product produced by a source category subject to this subpart, the owner or operator of the affected source shall comply with the standards for the primary product production process unit.

(4) The determination of the primary product for a process unit, including the assessment of applicability of this subpart to process units that are designed and operated as flexible operation units, shall be reported in the Notification of Compliance Status report required by §63.1110(a)(4) when the primary product is determined to be a product produced by a source category subject to requirements under this subpart. The Notification of Compliance Status shall include the information specified in either paragraph (d)(4)(i) or (ii) of this section. If the primary product is determined to be something other than a product produced by a source category subject to requirements under this subpart, the owner or operator shall retain information, data, and analyses used to document the basis for the determination that the primary product is not produced by a source category subject to requirements under this subpart.

(i) If the process unit manufactures only one product subject to requirements under this subpart, the identity of that product.

(ii) If the process unit is designed and operated as a flexible operation unit, the information specified in paragraphs (d)(4)(ii)(A) and (B) of this section, as appropriate.

(A) The identity of the primary product.

(B) Information concerning operating time and/or production mass for each product that was used to make the determination of the primary product under paragraph (d)(2)(i) or (ii) of this section.

(5) When a flexible operation unit that is subject to this subpart is producing a product other than a product subject to this subpart, or is producing a product subject to this subpart that is not the primary product, the owner or operator shall comply with either paragraph (d)(5) (i) or (ii) of this section for each emission point.

(i) The owner or operator shall control emissions during the production of all products in accordance with the requirements for the production of the primary product. As appropriate, the owner or operator shall demonstrate that the parameter monitoring level established for the primary product is also appropriate for those periods when products other than the primary product are being produced. Documentation of this demonstration shall be submitted in the Notification of Compliance Status report required by §63.1110(a)(4).

(ii) The owner or operator shall determine, for the production of each product, whether control is required in accordance with the applicable criteria for the primary product in §63.1103. If control is required, the owner or operator shall establish separate parameter monitoring levels, as appropriate, for the production of each product. The parameter monitoring levels developed shall be submitted in the Notification of Compliance Status report required by §63.1110(a)(4).

(e) Storage vessel ownership determination. To determine the process unit to which a storage vessel shall belong, the owner or operator shall sequentially follow the procedures specified in paragraphs (e)(1) through (8) of this section, stopping as soon as the determination is made.

(1) If a storage vessel is already subject to another subpart of this part on the date of promulgation for an affected source under the generic MACT, that storage vessel shall belong to the process unit subject to the other subpart.

(2) If a storage vessel is dedicated to a single process unit, the storage vessel shall belong to that process unit.

(3) If a storage vessel is shared among process units, then the storage vessel shall belong to that process unit located on the same plant site as the storage vessel that has the greatest input into or output from the storage vessel (i.e., the process unit has the predominant use of the storage vessel.)

(4) If predominant use cannot be determined for a storage vessel that is shared among process units and if only one of those process units is subject to this subpart, the storage vessel shall belong to that process unit.

(5) If predominant use cannot be determined for a storage vessel that is shared among process units and if more than one of the process units are subject to standards under this subpart that have different primary products, then the owner or operator shall assign the storage vessel to any one of the process units sharing the storage vessel.

(6) If the predominant use of a storage vessel varies from year to year, then predominant use shall be determined based on the utilization that occurred during the year preceding the date of promulgation of standards for an affected source under this subpart or based on the expected utilization for the 5 years following the promulgation date of standards for an affected source under this subpart for existing affected sources, whichever is more representative of the expected operations for that storage vessel, and based on the expected utilization for the 5 years after initial startup for new affected sources. The determination of predominant use shall be reported in the Notification of Compliance Status Report required by §63.1110(a)(4). If the predominant use changes, the redetermination of predominant use shall be reported in the next Periodic Report.

(7) If the storage vessel begins receiving material from (or sending material to) another process unit; ceases to receive material from (or send material to) a process unit; or if the applicability of this subpart to a storage vessel has been determined according to the provisions of paragraphs (e)(1) through (6) of this section and there is a significant change in the use of the storage vessel that could reasonably change the predominant use, the owner or operator shall reevaluate the applicability of this subpart to the storage vessel.

(8) Where a storage vessel is located at a major source that includes one or more process units that place material into, or receive materials from, the storage vessel, but the storage vessel is located in a tank farm, the applicability of this subpart shall be determined according to the provisions in paragraphs (e)(8)(i) through (iii) of this section.

(i) The storage vessel may only be assigned to a process unit that utilizes the storage vessel and does not have an intervening storage vessel for that product (or raw material, as appropriate). With respect to any process unit, an intervening storage vessel means a storage vessel connected by hard-piping to the process unit and to the storage vessel in the tank farm so that product or raw material entering or leaving the process unit flows into (or from) the intervening storage vessel and does not flow directly into (or from) the storage vessel in the tank farm.

(ii) If there is only one process unit at a major source that meets the criteria of paragraph (e)(8)(i) of this section with respect to a storage vessel, the storage vessel shall be assigned to that process unit.

(iii) If there are two or more process units at the major source that meet the criteria of paragraph (e)(8)(i) of this section with respect to a storage vessel, the storage vessel shall be assigned to one of those process units according to the provisions of paragraph (e)(6) of this section. The predominant use shall be determined among only those process units that meet the criteria of paragraph (e)(8)(i) of this section.

(f) Recovery operation equipment ownership determination. To determine the process unit to which recovery equipment shall belong, the owner or operator shall sequentially follow the procedures specified in paragraphs (f)(1) through (7) of this section, stopping as soon as the determination is made.

(1) If recovery operation equipment is already subject to another subpart of this part on the date standards are promulgated for an affected source, that recovery operation equipment shall belong to the process unit subject to the other subpart.

(2) If recovery operation equipment is used exclusively by a single process unit, the recovery operation shall belong to that process unit.

(3) If recovery operation equipment is shared among process units, then the recovery operation equipment shall belong to that process unit that has the greatest input into or output from the recovery operation equipment (i.e., that process unit has the predominant use of the recovery operation equipment).

(4) If predominant use cannot be determined for recovery operation equipment that is shared among process units and if one of those process units is a process unit subject to this subpart, the recovery operation equipment shall belong to the process unit subject to this subpart.

(5) If predominant use cannot be determined for recovery operation equipment that is shared among process units and if more than one of the process units are process units that have different primary products and that are subject to this subpart, then the owner or operator shall assign the recovery operation equipment to any one of those process units.

(6) If the predominant use of recovery operation equipment varies from year to year, then the predominant use shall be determined based on the utilization that occurred during the year preceding the promulgation date of standards for an affected source under this subpart or based on the expected utilization for the 5 years following the promulgation date for standards for an affected source under this subpart for existing affected sources, whichever is the more representative of the expected operations for the recovery operations equipment, and based on the expected utilization for the first 5 years after initial startup for new affected sources. This determination shall be reported in the Notification of Compliance Status Report required by §63.1110(a)(4). If the predominant use changes, the redetermination of predominant use shall be reported in the next Periodic Report.

(7) If there is an unexpected change in the utilization of recovery operation equipment that could reasonably change the predominant use, the owner or operator shall redetermine to which process unit the recovery operation belongs by reperforming the procedures specified in paragraphs (f)(2) through (6) of this section.

(g) Overlap with other regulations. Paragraphs (g)(1) through (7) of this section specify the applicability of this subpart YY emission point requirements when other rules may apply. Where this subpart YY allows an owner or operator an option to comply with one or another regulation to comply with this subpart YY, an owner or operator must report which regulation they choose to comply with in the Notification of Compliance Status report required by §63.1110(a)(4).

(1) Overlap of subpart YY with other regulations for storage vessels. (i) After the compliance dates specified in §63.1102, a storage vessel subject to this subpart YY that is also subject to subpart G or CC of this part is required to comply only with the provisions of this subpart YY.

(ii) After the compliance dates specified in §63.1102, a storage vessel that must be controlled according to the requirements of this subpart and subpart Ka or Kb of 40 CFR part 60 is required to comply only with the storage vessel requirements of this subpart.

(2) Overlap of subpart YY with other regulations for process vents. (i) After the compliance dates specified in §63.1102, a process vent that must be controlled according to the requirements of this subpart and subpart G of this part is in compliance with this subpart if it complies with either set of requirements. The owner or operator must specify the rule with which they will comply in the Notification of Compliance Status report required by §63.1110(a)(4).

(ii) After the compliance dates specified in §63.1102, a process vent that must be controlled according to the requirements of this subpart and subpart III, RRR or NNN of 40 CFR part 60 is required to comply only with the process vent requirements of this subpart.

(3) Overlap of this subpart YY with other regulations for transfer racks. After the compliance dates specified in §63.1102, a transfer rack that must be controlled according to the requirements of this subpart YY and either subpart G of this part or subpart BB of 40 CFR part 61 is required to comply only with the transfer rack requirements of this subpart YY.

(4) Overlap of subpart YY with other regulations for equipment leaks. (i) After the compliance dates specified in §63.1102, equipment that must be controlled according to this subpart and 40 CFR part 60, subpart VV, or 40 CFR part 61, subpart J or subpart V, is required only to comply with the equipment leak requirements of this subpart.

(ii) After the compliance dates specified in §63.1102, equipment that must be controlled according to this subpart YY and subpart H of this part is in compliance with the equipment leak requirements of this subpart YY if it complies with either set of requirements. For ethylene production affected sources, the requirement in §63.1103(e)(9)(i) also applies. The owner or operator must specify the rule with which they will comply in the Notification of Compliance Status report required by §63.1110(a)(4).

(iii) Beginning no later than the compliance dates specified in §63.1102(c), for ethylene production affected sources, equipment that must be controlled according to this subpart YY and subpart VVa of 40 CFR part 60 is required only to comply with the equipment leak requirements of this subpart, except the owner or operator must also comply with the calibration drift assessment requirements specified at 40 CFR 60.485a(b)(2) if they are required to do so in subpart VVa of 40 CFR part 60. When complying with the calibration drift assessment requirements at 40 CFR 60.485a(b)(2), the requirement at 40 CFR 60.486a(e)(8)(v) to record the instrument reading for each scale used applies.

(5) Overlap of this subpart YY with other regulations for wastewater for source categories other than ethylene production. (i) After the compliance dates specified in §63.1102 for an affected source subject to this subpart, a wastewater stream that is subject to the wastewater requirements of this subpart and the wastewater requirements of subparts F, G, and H of this part (collectively known as the “HON”) shall be deemed to be in compliance with the requirements of this subpart if it complies with either set of requirements. In any instance where a source subject to this subpart is collocated with a Synthetic Organic Chemical Manufacturing Industry (SOCMI) source, and a single wastewater treatment facility treats both Group 1 wastewaters and wastewater residuals from the source subject to this subpart and wastewaters from the SOCMI source, a certification by the treatment facility that they will manage and treat the waste in conformity with the specific control requirements set forth in §§63.133 through 63.147 will also be deemed sufficient to satisfy the certification requirements for wastewater treatment under this subpart.

(ii) After the compliance dates specified in §63.1102 for an affected source subject to this subpart, a wastewater stream that is subject to control requirements in the Benzene Waste NESHAP (subpart FF of part 61 of this chapter) and this subpart is required to comply with both rules.

(6) Overlap of subpart YY with other regulations for waste for the ethylene production source category. (i) After the compliance date specified in §63.1102, a waste stream that is conveyed, stored, or treated in a wastewater stream management unit, waste management unit, or wastewater treatment system that receives streams subject to both the control requirements of §63.1103(e)(3) for ethylene production sources and the provisions of §§63.133 through 63.147 shall comply as specified in paragraphs (g)(6)(i)(A) through (C) of this section. Compliance with the provisions of this paragraph (g)(6)(i) shall constitute compliance with the requirements of this subpart for that waste stream.

(A) Comply with the provisions in §§63.133 through 63.137 and 63.140 for all equipment used in the storage and conveyance of the waste stream.

(B) Comply with the provisions in §§63.1103(e), 63.138, and 63.139 for the treatment and control of the waste stream.

(C) Comply with the provisions in §§63.143 through 63.148 for monitoring and inspections of equipment and for recordkeeping and reporting requirements. The owner or operator is not required to comply with the monitoring, recordkeeping, and reporting requirements associated with the treatment and control requirements in §§61.355 through 61.357.

(ii) After the compliance date specified in §63.1102, compliance with §63.1103(e) shall constitute compliance with the Benzene Waste Operations NESHAP (subpart FF of 40 CFR part 61) for waste streams that are subject to both the control requirements of §63.1103(e)(3) for ethylene production sources and the control requirements of 40 CFR part 61, subpart FF.

(7) Overlap of this subpart YY with other regulations for flares for the ethylene production source category. (i) Beginning no later than the compliance dates specified in §63.1102(c), flares that are subject to 40 CFR 63.18 or §63.11 and used as a control device for an emission point subject to the requirements in Table 7 to §63.1103(e) are required to comply only with §63.1103(e)(4). At any time before the compliance dates specified in §63.1102(c), flares that are subject to 40 CFR 63.18 or §63.11 and elect to comply with §63.1103(e)(4) are required to comply only with §63.1103(e)(4).

(ii) Beginning no later than the compliance dates specified in §63.1102(c), flares subject to §63.987 and used as a control device for an emission point subject to the requirements in Table 7 to §63.1103(e) are only required to comply with §63.1103(e)(4).

(iii) Beginning no later than the compliance dates specified in §63.1102(c), flares subject to the requirements in 40 CFR part 63, subpart CC and used as a control device for an emission point subject to the requirements in Table 7 to §63.1103(e) are only required to comply with the flare requirements in 40 CFR part 63, subpart CC.

[64 FR 34921, June 29, 1999, as amended at 64 FR 63698, 63706, Nov. 22, 1999; 67 FR 46279, July 12, 2002; 70 FR 19272, Apr. 13, 2005; 79 FR 60922, Oct. 8, 2014; 85 FR 40423, July 6, 2020; 85 FR 73896, Nov. 19, 2020]

§63.1101 Definitions.

All terms used in this subpart shall have the meaning given them in the Act, in 40 CFR 63.2 (General Provisions), and in this section. The definitions in this section do not apply to waste requirements for ethylene production sources.

Annual average concentration, as used in the wastewater provisions, means the flow-weighted annual average concentration, as determined according to the procedures specified in §63.144(b).

Annual average flow rate, as used in the wastewater provisions, means the annual average flow rate, as determined according to the procedures specified in §63.144(c).

Batch cycle refers to manufacturing a product from start to finish in a batch unit operation.

Batch emission episode means a discrete venting episode that may be associated with a single unit operation. A unit operation may have more than one batch emission episode per batch cycle. For example, a displacement of vapor resulting from the charging of a vessel with organic HAP will result in a discrete emission episode. If the vessel is then heated, there may also be another discrete emission episode resulting from the expulsion of expanded vapor. Both emission episodes may occur during the same batch cycle in the same vessel or unit operation. There are possibly other emission episodes that may occur from the vessel or other process equipment, depending on process operations.

Batch unit operation means a unit operation involving intermittent or discontinuous feed into equipment and, in general, involves the emptying of equipment after the batch cycle ceases and prior to beginning a new batch cycle. Mass, temperature, concentration and other properties of the process may vary with time. Addition of raw material and withdrawal of product do not simultaneously occur in a batch unit operation.

Bottoms receiver means a tank that collects distillation bottoms before the stream is sent for storage or for further downstream processing.

By compound means by individual stream components, not carbon equivalents.

Capacity means the volume of liquid that is capable of being stored in a storage vessel, determined by multiplying the vessel's internal cross-sectional area by the internal height of the shell.

Closed vent system means a system that is not open to the atmosphere and is composed of piping, ductwork, connections, and, if necessary, flow inducing devices that transport gas or vapor from an emission point to a control device. A closed vent system does not include the vapor collection system that is part of any tank truck or railcar or the loading arm or hose that is used for vapor return. For transfer racks, the closed vent system begins at, and includes, the first block valve on the downstream side of the loading arm or hose used to convey displaced vapors.

Combined vent stream means a process vent that is comprised of at least one gas stream from a batch unit operation manifolded with at least one gas stream from a continuous unit operation.

Compliance equipment means monitoring equipment used by an owner or operator of an affected source under this subpart to demonstrate compliance with an operation or emission limit standard.

Continuous parameter monitoring system or CPMS means the total equipment that may be required to meet the data acquisition and availability requirements of this subpart, and that is used to sample, condition (if applicable), analyze, and provide a record of process or control system parameters.

Continuous unit operation means a unit operation where the inputs and outputs flow continuously. Continuous unit operations typically approach steady-state conditions. Continuous unit operations typically involve the simultaneous addition of raw material and withdrawal of the product.

Control device means, with the exceptions noted below, a combustion device, recovery device, recapture device, or any combination of these devices used to comply with this subpart or a referencing subpart. For process vents from continuous unit operations at affected sources in source categories where the applicability criteria includes a TRE index value, recovery devices are not considered to be control devices. Primary condensers on steam strippers or fuel gas systems are not considered to be control devices.

Day means a calendar day.

Distillate receiver means overhead receivers, overhead accumulators, reflux drums, and condenser(s) including ejector condenser(s) associated with a distillation unit.

Distillation unit means a device or vessel in which one or more feed streams are separated into two or more exit streams, each exit stream having component concentrations different from those in the feed stream(s). The separation is achieved by the redistribution of the components between the liquid and the vapor phases by vaporization and condensation as they approach equilibrium within the distillation unit. Distillation unit includes the distillate receiver, reboiler, and any associated vacuum pump or steam jet.

Emission point means an individual process vent, storage vessel, transfer rack, wastewater stream, kiln, fiber spinning line, equipment leak, or other point where a gaseous stream is released.

Equipment means each of the following that is subject to control under this subpart: pump, compressor, agitator, pressure relief device, sampling collection system, open-ended valve or line, valve, connector, instrumentation system in organic hazardous air pollutant service as defined in §63.1103 for the applicable process unit, whose primary product is a product produced by a source category subject to this subpart.

Equivalent method means any method of sampling and analysis for an air pollutant that has been demonstrated to the Administrator's satisfaction to have a consistent and quantitatively known relationship to the reference method, under specified conditions.

Excess emissions means emissions in excess of those that would have occurred if there were no start-up, shutdown, or malfunction and the owner or operator complied with the relevant provisions of this subpart.

Final recovery device means the last recovery device on a process vent stream from a continuous unit operation at an affected source in a source category where the applicability criteria includes a TRE index value. The final recovery device usually discharges to a combustion device, recapture device, or directly to the atmosphere.

Flexible operation unit means a process unit that manufactures different chemical products periodically by alternating raw materials or operating conditions.

Fuel gas means gases that are combusted to derive useful work or heat.

Fuel gas system means the offsite and onsite piping and flow and pressure control system that gathers gaseous stream(s) generated by onsite operations, may blend them with other sources of gas, and transports the gaseous stream for use as a fuel gas in combustion devices or in-process combustion equipment, such as furnaces and gas turbines, either singly or in combination.

Group 1 wastewater stream means a process wastewater stream at an existing or new source that meets the criteria for Group 1 status in §63.132(c).

Group 2 wastewater stream means a process wastewater stream that does not meet the definition of a Group 1 wastewater stream.

Halogens and hydrogen halides means hydrogen chloride (HCl), chlorine (Cl2), hydrogen bromide (HBr), bromine (Br2), and hydrogen fluoride (HF).

Impurity means a substance that is produced coincidentally with the primary product, or is present in a raw material. An impurity does not serve a useful purpose in the production or use of the primary product and is not isolated.

Initial startup means, for new sources, the first time the source begins production. For additions or changes not defined as a new source by this subpart, initial startup means the first time additional or changed equipment is put into operation. Initial startup does not include operation solely for testing equipment. Initial startup does not include subsequent startup (as defined in this section) of process units following malfunctions or process unit shutdowns. Except for equipment leaks, initial startup also does not include subsequent startups (as defined in this section) of process units following changes in product for flexible operation units or following recharging of equipment in batch unit operations.

Low throughput transfer rack means a transfer rack that transfers less than a total of 11.8 million liters per year of liquid containing regulated HAP.

Maintenance wastewater means wastewater generated by the draining of process fluid from components in the process unit, whose primary product is a product produced by a source category subject to this subpart, into an individual drain system prior to or during maintenance activities. Maintenance wastewater can be generated during planned and unplanned shutdowns and during periods not associated with a shutdown. Examples of activities that can generate maintenance wastewaters include descaling of heat exchanger tubing bundles, cleaning of distillation column traps, draining of low legs and high point bleeds, draining of pumps into an individual drain system, and draining of portions of the process unit, whose primary product is a product produced by a source category subject to this subpart, for repair.

Malfunction means any sudden, infrequent, and not reasonably preventable failure of air pollution control equipment, process equipment, or a process to operate in a normal or usual manner which causes, or has the potential to cause, the emission limitations in an applicable standard to be exceeded. Failures that are caused in part by poor maintenance or careless operation are not malfunctions.

Maximum true vapor pressure means the equilibrium partial pressure exerted by the total organic HAP in the stored or transferred liquid at the temperature equal to the highest calendar-month average of the liquid storage or transfer temperature for liquids stored or transferred above or below the ambient temperature or at the local maximum monthly average temperature as reported by the National Weather Service for liquids stored or transferred at the ambient temperature, as determined:

(1) In accordance with methods described in American Petroleum Institute Publication 2517, Evaporation Loss From External Floating-Roof Tanks (incorporated by reference as specified in §63.14 of subpart A of this part); or

(2) As obtained from standard reference texts; or

(3) As determined by the American Society for Testing and Materials Method D2879-83 (incorporated by reference as specified in §63.14 of subpart A of this part); or

(4) Any other method approved by the Administrator.

Oil-water separator or organic-water separator means a waste management unit, generally a tank used to separate oil or organics from water. An oil-water or organic-water separator consists of not only the separation unit but also the forebay and other separator basins, skimmers, weirs, grit chambers, sludge hoppers, and bar screens that are located directly after the individual drain system and prior to additional waste management units such as an air flotation unit, clarifier, or biological treatment unit. Examples of an oil-water or organic-water separator include, but are not limited to, an American Petroleum Institute separator, parallel-plate interceptor, and corrugated-plate interceptor with the associated ancillary equipment.

On-site means, with respect to records required to be maintained by this subpart, a location within a plant site that encompasses the affected source. On-site includes, but is not limited to, the affected source to which the records pertain, or central files elsewhere at the plant site.

Organic hazardous air pollutant or organic HAP means any organic chemicals that are also HAP.

Permitting authority means one of the following:

(1) The State air pollution control agency, local agency, other State agency, or other agency authorized by the Administrator to carry out a permit program under part 70 of this chapter; or

(2) The Administrator, in the case of EPA-implemented permit programs under title V of the Act (42 U.S.C. 7661) and part 71 of this chapter.

Plant site means all contiguous or adjoining property that is under common control, including properties that are separated only by a road or other public right-of-way. Common control includes properties that are owned, leased, or operated by the same entity, parent entity, subsidiary, or any combination thereof.

Point of determination means each point where process wastewater exits the process unit, whose primary product is a product produced by a source category subject to this subpart.

Note to definition for point of determination:

The regulation allows determination of the characteristics of a wastewater stream at the point of determination or downstream of the point of determination if corrections are made for changes in flow rate and annual average concentration of Table 9 compounds (as defined under this subpart) as determined in §63.144. Such changes include losses by air emissions, reduction of annual average concentration or changes in flow rate by mixing with other water or wastewater streams, and reduction in flow rate or annual average concentration by treating or otherwise handling the wastewater stream to remove or destroy hazardous air pollutants.

Pressure release means the emission of materials resulting from the system pressure being greater than the set pressure of the pressure relief device. This release can be one release or a series of releases over a short time period.

Pressure relief device or valve means a safety device used to prevent operating pressures from exceeding the maximum allowable working pressure of the process equipment. A common pressure relief device is a spring-loaded pressure relief valve. Devices that are actuated either by a pressure of less than or equal to 2.5 pounds per square inch gauge or by a vacuum are not pressure relief devices. This definition does not apply to ethylene production affected sources.

Process condenser means a condenser whose primary purpose is to recover material as an integral part of a process. The condenser must support a vapor-to-liquid phase change for periods of source equipment operation that are above the boiling or bubble point of substance(s). Examples of process condensers include distillation condensers, reflux condensers, process condensers in line prior to the vacuum source, and process condensers used in stripping or flashing operations.

Process unit means the equipment assembled and connected by pipes or ducts to process raw and/or intermediate materials and to manufacture an intended product. A process unit includes more than one unit operation.

Process unit shutdown means a work practice or operational procedure that stops production from a process unit, or part of a process unit during which practice or procedure it is technically feasible to clear process material from the process unit, or part of the process unit, consistent with safety constraints and during which repairs can be effected. The following are not considered process unit shutdowns:

(1) An unscheduled work practice or operational procedure that stops production from a process unit, or part of a process unit, for less than 24 hours.

(2) An unscheduled work practice or operational procedure that would stop production from a process unit, or part of a process unit, for a shorter period of time than would be required to clear the process unit, or part of the process unit, of materials and start up the unit and result in greater emissions than delay of repair of leaking components until the next scheduled process unit shutdown.

(3) The use of spare equipment and technically feasible bypassing of equipment without stopping production.

Process vent means the point of discharge to the atmosphere (or the point of entry into a control device, if any) of a gas stream from a unit operation within a source category subject to this subpart. Process vent excludes the following gas stream discharges:

(1) Relief valve discharges;

(2) Leaks from equipment subject to this subpart;

(3) Gas streams exiting a control device complying with this subpart;

(4) Gas streams transferred to other processes (on-site or off-site) for reaction or other use in another process ( i.e., for chemical value as a product, isolated intermediate, byproduct, or co-product for heat value);

(5) Gas streams transferred for fuel value ( i.e., net positive heating value), use, reuse, or sale for fuel value, use, or reuse. On or after November 19, 2021 this exclusion no longer applies to the Carbon Black Production source category;

(6) Gas streams from storage vessels or transfer racks subject to this subpart;

(7) Gas streams from waste management units subject to this subpart;

(8) Gas streams from wastewater streams subject to this subpart;

(9) Gas streams exiting process analyzers; and

(10) Gas stream discharges that contain less than or equal to 0.005 weight-percent total organic HAP.

Process wastewater means wastewater which, during manufacturing or processing, comes into direct contact with or results from the production or use of any raw material, intermediate product, finished product, by-product, or waste product. Examples are product tank drawdown or feed tank drawdown, water formed during a chemical reaction or used as a reactant, water used to wash impurities from organic products or reactants, equipment washes between batches in a batch process, water used to cool or quench organic vapor streams through direct contact, and condensed steam from jet ejector systems pulling vacuum on vessels containing organics.

Process wastewater stream means a stream that contains process wastewater.

Product means a compound or chemical which is manufactured as the intended product of the applicable production process unit as defined in §63.1103. By-products, isolated intermediates, impurities, wastes, and trace contaminants are not considered products.

Recapture device means an individual unit of equipment capable of and used for the purpose of recovering chemicals, but not normally for use, reuse, or sale. For example, a recapture device may recover chemicals primarily for disposal. Recapture devices include, but are not limited to, absorbers, carbon adsorbers, and condensers. For purposes of the monitoring, recordkeeping, and reporting requirements of this subpart, recapture devices are considered recovery devices.

Recovery device means an individual unit of equipment capable of and normally used for the purpose of recovering chemicals for fuel value (i.e., net positive heating value), use, reuse, or for sale for fuel value. Examples of equipment that may be recovery devices include absorbers, carbon adsorbers, condensers, oil-water separators or organic-water separators, or organic removal devices such as decanters, strippers, or thin-film evaporation units. For purposes of the monitoring, recordkeeping, and reporting requirements of this subpart, recapture devices are considered recovery devices.

Research and development facility means laboratory and pilot plant operations whose primary purpose is to conduct research and development into new processes and products, where the operations are under the close supervision of technically trained personnel, and is not engaged in the manufacture of products for commercial sale, except in a de minimis manner.

Shutdown means the cessation of operation of an affected source or equipment that is used to comply with this subpart, or the emptying and degassing of a storage vessel. For the purposes of this subpart, shutdown includes, but is not limited to, periodic maintenance, replacement of equipment, or repair. Shutdown does not include the routine rinsing or washing of equipment in batch operation between batches. Shutdown includes the decoking of ethylene cracking furnaces.

Startup means the setting into operation of a regulated source and/or equipment required or used to comply with this subpart. Startup includes initial startup, operation solely for testing equipment, the recharging of equipment in batch operation, and transitional conditions due to changes in product for flexible operation units.

Storage vessel or tank, for the purposes of regulation under the storage vessel provisions of this subpart, means a stationary unit that is constructed primarily of nonearthen materials (such as wood, concrete, steel, fiberglass, or plastic) that provides structural support and is designed to hold an accumulation of liquids or other materials. Storage vessel includes surge control vessels and bottoms receiver vessels. For the purposes of regulation under the storage vessel provisions of this subpart, storage vessel does not include vessels permanently attached to motor vehicles such as trucks, railcars, barges, or ships; pressure vessels designed to operate in excess of 204.9 kilopascals and without emissions to the atmosphere; or wastewater storage vessels. Wastewater storage vessels are covered under the wastewater provisions of §63.1106.

Subsequent startup means any setting into operation of a regulated source and/or equipment required or used to comply with this subpart following the initial startup.

Surge control vessel means a feed drum, recycle drum, or intermediate vessel. Surge control vessels are used within a process unit (as defined in this subpart) when in-process storage, mixing, or management of flow rates or volumes is needed to assist in production of a product.

Table 9 compounds means compounds listed in Table 9 of subpart G of this part.

Total organic compounds or (TOC) means the total gaseous organic compounds (minus methane and ethane) in a vent stream, with the concentrations expressed on a carbon basis.

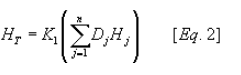

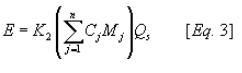

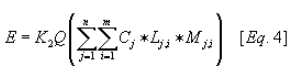

Total resource effectiveness index value or TRE index value means a measure of the supplemental total resource requirement per unit reduction of organic HAP associated with a process vent stream, based on vent stream flow rate, emission rate of organic HAP, net heating value, and corrosion properties (whether or not the vent stream contains halogenated compounds), as quantified by the equations given under §63.1104(j).

Transfer rack means a single system used to fill bulk cargo tanks mounted on or in a truck or railcar. A transfer rack includes all loading arms, pumps, meters, shutoff valves, relief valves, and other piping and equipment necessary for the transfer operation. Transfer equipment and operations that are physically separate (i.e., do not share common piping, valves, and other equipment) are considered to be separate transfer racks.

Unit operation means distinct equipment used in processing, among other things, to prepare reactants, facilitate reactions, separate and purify products, and recycle materials. Equipment used for these purposes includes, but is not limited to, reactors, distillation columns, extraction columns, absorbers, decanters, dryers, condensers, and filtration equipment.

Vapor balancing system means a piping system that is designed to collect organic HAP vapors displaced from tank trucks or railcars during loading; and to route the collected organic HAP vapors to the storage vessel from which the liquid being loaded originated, or to compress collected organic HAP vapors and commingle with the raw feed of a production process unit.

Wastewater is either a process wastewater or a maintenance wastewater and means water that:

(1) Contains either:

(i) An annual average concentration of Table 9 compounds (as defined under this subpart) of at least 5 parts per million by weight at the point of determination and has an annual average flow rate of 0.02 liter per minute or greater, or

(ii) An annual average concentration of Table 9 compounds (as defined under this subpart) of at least 10,000 parts per million by weight at the point of determination at any flow rate, and that

(2) Is discarded from a process unit, whose primary product is a product produced by a source category subject to this subpart.

Wastewater stream means a stream that contains wastewater.

[64 FR 34921, June 29, 1999, as amended at 64 FR 63699, 63706, Nov. 22, 1999; 66 FR 55847, Nov. 2, 2001; 67 FR 39305, June 7, 2002; 67 FR 46280, July 12, 2002; 71 FR 20458, Apr. 20, 2006; 79 FR 60922, Oct. 8, 2014; 85 FR 40424, July 6, 2020; 86 FR 66122, Nov. 19, 2021]

§63.1102 Compliance schedule.

(a) General requirements. Affected sources, as defined in §63.1103(a)(1)(i) for acetyl resins production, §63.1103(b)(1)(i) for acrylic and modacrylic fiber production, §63.1103(c)(1)(i) for hydrogen fluoride production, §63.1103(d)(1)(i) for polycarbonate production, §63.1103(e)(1)(i) for ethylene production, §63.1103(f)(1)(i) for carbon black production, §63.1103(g)(1)(i) for cyanide chemicals manufacturing, or §63.1103(h)(1)(i) for spandex production shall comply with the appropriate provisions of this subpart and the subparts referenced by this subpart YY according to the schedule in paragraph (a)(1) or (2) of this section, as appropriate, except as provided in paragraph (b) of this section. Affected sources in ethylene production also must comply according to paragraph (c) of this section. Affected sources in cyanide chemicals manufacturing also must comply according to paragraph (d) of this section. Affected sources in carbon black production also must comply according to paragraph (e) of this section. Proposal and effective dates are specified in table 1 to this section and in paragraph (d) for cyanide chemicals manufacturing affected sources and paragraph (e) for carbon black production affected sources of this section.

(1) Compliance dates for new and reconstructed sources. (i) The owner or operator of a new or reconstructed affected source that commences construction or reconstruction after the proposal date, and that has an initial startup before the effective date of standards for an affected source, shall comply with this subpart no later than the applicable effective date in Table 1 to §63.1102 of this section.

(ii) The owner or operator of a new or reconstructed affected source that has an initial startup after the applicable effective date in Table 1 to §63.1102 of this section shall comply with this subpart upon startup of the source.

(iii) The owner or operator of an affected source that commences construction or reconstruction after the proposal date, but before the effective date in Table 1 to this section, shall comply with this subpart no later than the date 3 years after the effective date if the conditions in paragraphs (a)(1)(iii) (A) and (B) of this section are met.

(A) The promulgated standards are more stringent than the proposed standards.

(B) The owner or operator complies with this subpart as proposed during the 3-year period immediately after the effective date of standards for the affected source.

(2) Compliance dates for existing sources. (i) The owner or operator of an existing affected source shall comply with the requirements of this subpart within 3 years after the effective date of standards for the affected source.

(ii) The owner or operator of an area source that increases its emissions of (or its potential to emit) HAP such that the source becomes a major source shall be subject to the relevant standards for existing sources under this subpart. Such sources shall comply with the relevant standards within 3 years of becoming a major source.

(b) All acrylic and modacrylic fiber production affected sources and polycarbonate production affected sources that commenced construction or reconstruction on or before January 9, 2014, shall be in compliance with the pressure relief device monitoring requirements of §63.1107(e)(3) upon initial startup or October 9, 2017, whichever is later, and the equipment leaks requirements of 40 CFR part 63, subpart UU upon initial startup or October 8, 2015, whichever is later. New acrylic and modacrylic fiber production affected sources and polycarbonate production affected sources that commence construction or reconstruction after January 9, 2014, shall be in compliance with the pressure relief device monitoring requirements of §63.1107(e)(3) upon initial startup or by October 8, 2014, whichever is later.

| Source category | Proposal date | Effective date |

|---|---|---|

| (a) Acetal Resins Production | October 14, 1998 | June 29, 1999. |

| (b) Acrylic and Modacrylic Fibers Production | October 14, 1998 | June 29, 1999. |

| (c) Hydrogen Fluoride Production | October 14, 1998 | June 29, 1999. |

| (d) Polycarbonate Production | October 14, 1998 | June 29, 1999. |

| (e) Ethylene Production | December 6, 2000 | July 12, 2002. |

| (f) Carbon Black Production | December 6, 2000 | July 12, 2002. |

| (g) Cyanide Chemicals Manufacturing | December 6, 2000 | July 12, 2002. |

| (h) Spandex Production | December 6, 2000 | July 12, 2002. |

(c) All ethylene production affected sources that commenced construction or reconstruction on or before October 9, 2019, must be in compliance with the requirements listed in paragraphs (c)(1) through (13) of this section upon initial startup or July 6, 2023, whichever is later. All ethylene production affected sources that commenced construction or reconstruction after October 9, 2019, must be in compliance with the requirements listed in paragraphs (c)(1) through (13) of this section upon initial startup, or July 6, 2020, whichever is later.

(1) Overlap requirements specified in §63.1100(g)(4)(iii) and (7), if applicable.

(2) The storage vessel requirements specified in paragraphs (b)(1)(iii) and (c)(1)(ii) of Table 7 to §63.1103(e), and the degassing requirements specified in §63.1103(e)(10).

(3) The ethylene process vent requirements specified in paragraph (d)(1)(ii) of Table 7 to §63.1103(e).

(4) The transfer rack requirements specified in §63.1105(a)(5).

(5) The equipment requirements specified in paragraph (f)(1)(ii) of Table 7 to §63.1103(e) and §63.1107(h).

(6) The bypass line requirements specified in paragraph (i) of Table 7 to §63.1103(e), and §63.1103(e)(6).

(7) The decoking requirements for ethylene cracking furnaces specified in paragraph (j) of Table 7 to §63.1103(e), and §63.1103(e)(7) and (8).

(8) The flare requirements specified in §63.1103(e)(4).

(9) The maintenance vent requirements specified in §63.1103(e)(5).

(10) The requirements specified in §63.1103(e)(9).

(11) The requirements in §63.1108(a)(4), (b)(1)(ii), (b)(2), and (b)(4)(ii)(B).

(12) The recordkeeping requirements specified in §63.1109(e) through (i).

(13) The reporting requirements specified in §63.1110(a)(10), (d)(1)(iv) and (v), and (e)(4) through (8).

(d) Cyanide chemicals manufacturing. (1) If applicable, all cyanide chemicals manufacturing affected sources that commenced construction or reconstruction on or before January 15, 2021, must be in compliance with the requirements listed in paragraphs (d)(1)(i) and (ii) of this section upon initial startup or November 20, 2022, whichever is later. If applicable, all cyanide chemicals manufacturing affected sources that commenced construction or reconstruction after January 15, 2021, must be in compliance with the requirements listed in paragraphs (d)(1)(i) and (ii) of this section upon initial startup, or November 19, 2021, whichever is later.

(i) Requirements specified in Table 9 to §63.1103(g), table entry (f)(1)(ii), for new cyanide chemicals manufacturing process units that generate process wastewater.

(ii) Requirements specified in Table 9 to §63.1103(g), table entry (g), for existing cyanide chemicals manufacturing process units that generate process wastewater.

(2) All cyanide chemicals manufacturing affected sources that commenced construction or reconstruction on or before January 15, 2021, must be in compliance with the requirements listed in paragraphs (d)(2)(i) through (iii) of this section upon initial startup or May 18, 2022, whichever is later. All cyanide chemicals manufacturing affected sources that commenced construction or reconstruction after January 15, 2021, must be in compliance with the requirements listed in paragraphs (d)(2)(i) through (iii) of this section upon initial startup, or November 19, 2021, whichever is later.

(i) The exceptions specified in §63.1103(g)(6) related to 40 part 63, subparts SS, TT, and UU startup, shutdown, and malfunction requirements.

(ii) The compliance requirements specified in §63.1108(a)(4), (b)(1)(ii), (b)(2), and (b)(4)(ii)(B).

(iii) The electronic reporting requirements specified in §63.1110(a)(10).

(e) Carbon black production. (1) If applicable, all carbon black production affected sources that commenced construction or reconstruction on or before January 14, 2021, must be in compliance with the requirements listed in paragraphs (e)(1)(i) through (iii) of this section upon initial startup or November 20, 2022, whichever is later. If applicable, all carbon black production affected sources that commenced construction or reconstruction after January 14, 2021, must be in compliance with the requirements listed in paragraphs (e)(1)(i) through (iii) of this section upon initial startup, or November 19, 2021, whichever is later.

(i) The process vent applicability determination requirements specified in §63.1103(f)(3)(iv).

(ii) The performance test frequency requirements specified in §63.1108(b)(4)(ii).

(iii) The boiler and process heater tune up requirements specified in §63.1103(f)(3)(iii).

(2) All carbon black production affected sources that commenced construction or reconstruction on or before January 14, 2021, must be in compliance with the requirements listed in paragraphs (e)(2)(i) through (iv) of this section upon initial startup or May 18, 2022, whichever is later. All carbon black production affected sources that commenced construction or reconstruction after January 14, 2021, must be in compliance with the requirements listed in paragraphs (e)(2)(i) through (iv) of this section upon initial startup, or November 19, 2021, whichever is later.

(i) The exceptions specified in §63.1103(f)(4) related to 40 part 63, subpart SS, startup, shutdown, and malfunction requirements.

(ii) The exception specified in §63.1103(f)(5) related to the requirement that a closed vent system route the collected vapors to a control device when demonstrating compliance.

(iii) The compliance requirements specified in §63.1108(a)(4), (b)(1)(ii), (b)(2), and (b)(4)(ii)(B).

(iv) The electronic reporting requirements specified in §63.1110(a)(10).

(3) All carbon black production affected sources that commenced construction or reconstruction on or before January 14, 2021, must be in compliance with the requirements specified in line entry (b) in Table 8 to §63.1103(f) on or before November 19, 2024. All carbon black production affected sources that commenced construction or reconstruction after January 14, 2021, must be in compliance with the requirements specified in line entries (b) and (c) in Table 8 to §63.1103(f) upon initial startup or November 19, 2021, whichever is later.

[67 FR 46280, July 12, 2002, as amended at 79 FR 60922, Oct. 8, 2014; 85 FR 40425, July 6, 2020; 86 FR 66122, Nov. 19, 2021; 89 FR 23864, April 4, 2024]

§63.1103 Source category-specific applicability, definitions, and requirements.

(a) Acetal resins production applicability, definitions, and requirements - (1) Applicability XX

(A) All storage vessels that store liquids containing organic HAP. For purposes of regulation, surge control vessels and bottoms receivers that are located as part of the process train prior to the polymer reactor are to be regulated under the front-end process vent provisions.

(B) All process vents from continuous unit operations (front end process vents and back end process vents).

(C) All wastewater streams associated with the acetal resins production process unit as defined in (a)(2) of this section.

(D) Equipment (as defined in §63.1101 of this subpart) that contains or contacts organic HAP.

(ii) Compliance schedule. The compliance schedule for affected sources as defined in paragraph (a)(1)(i) of this section is specified in §63.1102(a).

(2) Definitions.

Acetal resins production means the production of homopolymers and/or copolymers of alternating oxymethylene units. Acetal resins are also known as polyoxymethylenes, polyacetals, and aldehyde resins. Acetal resins are generally produced by polymerizing formaldehyde (HCHO) with the methylene functional group (CH2) and are characterized by repeating oxymethylene units (CH2O) in the polymer backbone.

Back end process vent means any process vent from a continuous unit operation that is not a front end process vent up to the final separation of raw materials and by-products from the stabilized polymer.

Front end process vent means any process vent from a continuous unit operation involved in the purification of formaldehyde feedstock for use in the acetal homopolymer process. All front end process vents are restricted to those vents that occur prior to the polymer reactor.

(3) Requirements. Table 1 of this section specifies the acetal resins production standards applicability for existing and new sources. Applicability assessment procedures and methods are specified in §§63.1104 through 63.1107. An owner or operator of an affected source is not required to perform tests, TRE calculations or other applicability assessment procedures if they opt to comply with the most stringent requirements for an applicable emission point pursuant to this subpart. General compliance, recordkeeping, and reporting requirements are specified in §§63.1108 through 63.1112. Procedures for approval of alternative means of emission limitations are specified in §63.1113. The owner or operator must control organic HAP emissions from each affected source emission point by meeting the applicable requirements specified in table 1 of this section.

| If you own or operate. . . | And if. . . | Then you must. . . |

|---|---|---|

| 1. A storage vessel with: 34 cubic meters <capacity | The maximum true vapor pressure of organic HAP >17.1 kilopascals (for existing sources) or >11.7 kilopascals (for new sources) | a. Reduce emissions of total organic HAP by 95 weight-percent by venting emissions through a closed vent system to any combination of control devices meeting the requirements of subpart SS (national emission standards for closed vent systems, control devices, recovery devices, and routing to a fuel gas system or a process), as specified in §63.982(a)(1) (storage vessel requirements) of this part; or |

| b. Comply with the requirements of subpart WW (national emission standards for storage vessels (control level 2)) of this part. | ||

| 2. A front end process vent from continuous unit operations | a. Reduce emissions of total organic HAP by using a flare meeting the requirements of subpart SS of this part; or | |

| b. Reduce emissions of total organic HAP by 60 weight-percent, or reduce TOC to a concentration of 20 parts per million by volume, whichever is less stringent, by venting emissions through a closed vent system to any combination of control devices meeting the requirements of subpart SS, as specified in §63.982(a)(2) (process vent requirements) of this part. | ||

| 3. A back end process vent from continuous unit operations | The vent stream has a TRE a <1.0 | a. Reduce emissions of total organic HAP by using a flare meeting the requirements of subpart SS of this part; or |

| b. Reduce emissions of total organic HAP by 98 weight-percent, or reduce TOC to a concentration of 20 parts per million by volume, whichever is less stringent, by venting emissions through a closed vent system to any combination of control devices meeting the requirements of subpart SS, as specified in §63.982(a)(2) (process vent requirements) of this part; or | ||

| c. Achieve and maintain a TRE index value greater than 1.0. | ||

| 4. A back end process vent from continuous unit operations | 1.0 ≤TRE a ≤4.0 | Monitor and keep records of equipment operating parameters specified to be monitored under subpart SS, §§63.990(c)(absorber, condenser, and carbon adsorber monitoring) or 63.995(c) (other noncombustion systems used as a control device monitoring) of this part. |

| 5. Equipment as defined under §63.1101 | The equipment contains or contacts ≥10 weight-percent organic HAP b, and operates ≤300 hours per year | Comply with the requirements of subpart TT (national emission standards for equipment leaks (control level 1)) or subpart UU (national emission standards for equipment leaks (control level 2)) of this part. |

| 6. An acetal resins production process unit that generates process wastewater | The process wastewater stream is a Group 1 or Group 2 wastewater stream | Comply with the requirements of §63.1106(a). |

| 7. An acetal resins production process unit that generates maintenance wastewater | The maintenance wastewater contains organic HAP | Comply with the requirements of §63.1106(b). |

| 8. An item of equipment listed in §63.1106(c)(1) | The item of equipment meets the criteria specified in §63.1106(c)(1) through (3) and either (c)(4)(i) or (ii) | Comply with the requirements in Table 35 of subpart G of this part. |

| a The TRE is determined according to the procedures specified in §63.1104(j). b The weight-percent organic HAP is determined for equipment according to procedures specified in §63.1107. | ||

(b) Acrylic and modacrylic fiber production applicability, definitions, and requirements - (1) Applicability - (i) Affected source. For the acrylic fibers and modacrylic fibers production (as defined in paragraph (b)(2) of this section) source category, the affected source shall comprise all emission points, in combination, listed in paragraphs (b)(1)(i)(A) through (E) of this section, that are associated with a suspension or solution polymerization process unit that produces acrylic and modacrylic fiber located at a major source as defined in section 112(a) of the Act.

(A) All storage vessels that store liquid containing acrylonitrile or organic HAP.

(B) All process vents from continuous unit operations.

(C) All wastewater streams associated with the acrylic and modacrylic fibers production process unit as defined in (b)(2) of this section.

(D) Equipment (as defined in §63.1101 of this subpart) that contains or contacts acrylonitrile or organic HAP.

(E) All acrylic and modacrylic fiber spinning lines using a spinning solution or suspension having organic acrylonitrile or organic HAP. For the purposes of implementing this paragraph, a spinning line includes the spinning solution filters, spin bath, and the equipment used downstream of the spin bath to wash, dry, or draw the spun fiber.

(ii) Compliance schedule. The compliance schedule, for affected sources as defined in paragraph (b)(1)(i) of this section, is specified in §63.1102.

(2) Definitions.

Acrylic fiber means a manufactured synthetic fiber in which the fiber-forming substance is any long-chain synthetic polymer composed of at least 85 percent by weight of acrylonitrile units.

Acrylic and modacrylic fibers production means the production of either of the following synthetic fibers composed of acrylonitrile units:

(i) Acrylic fiber.

(ii) Modacrylic fiber.

Acrylonitrile solution polymerization means a process where acrylonitrile and comonomers are dissolved in a solvent to form a polymer solution (typically polyacrylonitrile). The polyacrylonitrile is soluble in the solvent. In contrast to suspension polymerization, the resulting reactor polymer solution (spin dope) is filtered and pumped directly to the fiber spinning process.

Acrylonitrile suspension polymerization means a polymerization process where small drops of acrylonitrile and comonomers are suspended in water in the presence of a catalyst where they polymerize under agitation. Solid beads of polymer are formed in this suspension reaction which are subsequently filtered, washed, refiltered, and dried. The beads must be subsequently redissolved in a solvent to create a spin dope prior to introduction to the fiber spinning process.

Fiber spinning line means the group of equipment and process vents associated with acrylic or modacrylic fiber spinning operations. The fiber spinning line includes (as applicable to the type of spinning process used) the blending and dissolving tanks, spinning solution filters, wet spinning units, spin bath tanks, and the equipment used downstream of the spin bath to wash, dry, or draw the spun fiber.

In organic hazardous air pollutant or in organic HAP service means, for acrylic and modacrylic fiber production affected sources, that a piece of equipment either contains or contacts a fluid (liquid or gas) that is at least 10 percent by weight of total organic HAP as determined according to the provisions of §63.180(d). The provisions of §63.180(d) also specify how to determine that a piece of equipment is not in organic HAP service.

Modacrylic fiber means a manufactured synthetic fiber in which the fiber-forming substance is any long-chain synthetic polymer composed of at least 35 percent by weight of acrylonitrile units but less than 85 percent by weight of acrylonitrile units.

Seal means, for acrylic and modacrylic fiber production affected sources complying with the requirements of §63.1033(b) or §63.167(a) on or after October 8, 2014, that instrument monitoring of the open-ended valve or line conducted according to the method specified in §63.1023(b) and, as applicable, §63.1023(c), or §63.180(b) and, as applicable, §63.180(c), indicates no readings of 500 parts per million or greater.

Spin dope means the liquid mixture of polymer and solvent that is fed to the spinneret to form the acrylic and modacrylic fibers.

(3) Requirements. An owner or operator of an affected source must comply with the requirements of paragraph (b)(3)(i) or (ii) of this section.

(i) Table 2 of this section specifies the acrylic and modacrylic fiber production source category control requirement applicability for both existing and new sources. Applicability assessment procedures and methods are specified in §§63.1104 through 63.1107. An owner or operator of an affected source is not required to perform tests, or other applicability assessment procedures if they opt to comply with the most stringent requirements for an applicable emission point pursuant to this subpart. General compliance, recordkeeping, and reporting requirements are specified in §§63.1108 through 63.1112. Procedures for approval of alternative means of emission limitations are specified in §63.1113. The owner or operator must control organic HAP emissions from each affected source emission point by meeting the applicable requirements specified in table 2 of this section.

| If you own or operate. . . | And if. . . | Then you must. . . |

|---|---|---|

| 1. A storage vessel | The stored material contains organic HAP | a. Reduce emissions of organic HAP by 98 weight-percent by venting emissions through a closed vent system to any combination of control device meeting the requirements of subpart SS of this part, as specified in §63.982(a)(1) (storage vessel requirements), or 95 weight-percent or greater by venting through a closed vent system to a recovery device meeting the requirements of subpart SS, §63.993 (recovery device requirements); or |

| b. Comply with the requirements of subpart WW of this part. | ||

| 2. A process vent from continuous unit operations (halogenated) | The vent steam has a mass emission rate of halogen atoms contained in organic compounds ≥0.45 kilograms per hour, a and an organic HAP concentration ≥50 parts per million by volume b and an average flow rate ≥0.005 cubic meters per minute | a. Reduce emissions of organic HAP or TOC as specified for nonhalogenated process vents from continuous unit operations (other than by using a flare) by venting emissions through a closed vent system to a halogen reduction device meeting the requirements of subpart SS of this part, §63.994 (halogen reduction devices requirements) that reduces hydrogen halides and halogens by 99 weight-percent or to less than 0.45 kilograms per year, whichever is less stringent; or |

| b. Reduce the process vent halogen atom mass emission rate to less than 0.45 kilograms per hour by venting emissions through a closed vent system to a halogen reduction device meeting the requirements of subpart SS of this part, §63.994 (halogen reduction devices requirements) and then complying with the requirements specified for process vents from continuous unit operations (nonhalogenated). | ||

| 3. A process vent from continuous unit operations (nonhalogenated) | The vent steam has a mass emission rate of halogen atoms contained in organic compounds <0.45 kilograms per hour, a and an organic HAP concentration ≥50 parts per million by volume b and an average flow rate ≥0.005 cubic meters per minute | a. Reduce emissions of organic HAP by using a flare meeting the requirements of subpart SS of this part, §63.987 (flare requirements); or b. Reduce emissions of organic HAP by 98 weight-percent, or reduce TOC to a concentration of 20 parts per million by volume, whichever is less stringent, by venting emissions through a closed vent system to any combination of control devices meeting the requirements of subpart SS of this part, as specified in §63.982(a)(2) (process vent requirements). |

| 4. A fiber spinning line that is a new or reconstructed source | The lines use a spin dope produced from either a suspension polymerization process or solution polymerization process | a. Reduce organic HAP emissions by 85 weight-percent or more. (For example, you may enclose the spinning and washing areas of the spinning line (as specified in paragraph (b)(4) of this section) and vent through a closed vent system and use any combination of control devices meeting the requirements of subpart SS of this part, as specified in §63.982(a).); or |

| b. Reduce organic HAP emissions from the spinning line to less than or equal to 0.25 kilograms of organic HAP per megagram (0.5 pounds of organic HAP per ton) of acrylic and modacrylic fiber produced; or | ||

| c. Reduce the organic HAP concentration of the spin dope to less than 100 ppmw. | ||

| 5. A fiber spinning line that is an existing source | The spinning line uses a spin dope produced from a solution polymerization process | Reduce organic HAP emissions from the spinning line to less than or equal to 20 kilograms of organic HAP per megagram (40 pounds of organic HAP per ton) of acrylic and modacrylic fiber produced. |

| 6. A fiber spinning line that is an existing source | The spinning line uses a spin dope produced from a suspension polymerization process | a. Reduce the organic HAP concentration of the spin dope to less than 100 ppmw; b or b. Reduce organic HAP emissions from the spinning line to less than or equal to 0.25 kilograms of organic HAP per megagram of acrylic and modacrylic fiber produced. |

| 7. Equipment as defined under §63.1101 (with the differences for pressure relief devices described in item 11 below) | It contains or contacts ≥10 weight-percent organic HAP, c and operates ≥300 hours per year | a. Comply with either §63.1008 or §63.1027 for connectors in gas and vapor service and in light liquid service, and comply with the requirements of subpart UU of this part, except §63.1030, for all other applicable equipment; or |

| b. Comply with the requirements in subpart H of this part, except §63.165, as provided by the regulatory overlap provisions in §63.1100(g)(4)(ii). | ||

| 8. An acrylic and modacrylic fiber production process unit that generates process wastewater | The process wastewater stream is a Group 1 or Group 2 wastewater stream | Comply with the requirements of §63.1106(a). |

| 9. An acrylic and modacrylic fiber production process unit that generates maintenance wastewater | The maintenance wastewater contains organic HAP | Comply with the requirements of §63.1106(b). |

| 10. An item of equipment listed in §63.1106(c)(1) | The item of equipment meets the criteria specified in §63.1106(c)(1) through (3) and either (c)(4)(i) or (ii) | Comply with the requirements in Table 35 of subpart G of this part. |

| 11. Pressure relief devices | The pressure relief device is in organic HAP service | Comply with §63.1107(e). |

| a The mass emission rate of halogen atoms contained in organic compounds is determined according to the procedures specified in §63.1104(i). b The percent by weight organic HAP is determined according to the procedures specified in §63.1107. c The weight-percent organic HAP is determined for equipment according to procedures specified in §63.1107. | ||

(ii) The owner or operator must control organic HAP emissions from the acrylic and modacrylic fibers production facility by meeting the applicable requirements specified in table 3 of this section. The owner or operator must determine the facility organic HAP emission rate using the procedures specified in paragraph (b)(5) of this section. Applicability assessment procedures and methods are specified in §§63.1104 through 63.1107. An owner or operator of an affected source does not have to perform tests, TRE calculations or other applicability assessment procedures if they opt to comply with the most stringent requirements for an applicable emission point pursuant to this subpart. General compliance, recordkeeping, and reporting requirements are specified in §§63.1108 through 63.1112. Procedures for approval of alternative means of emission limitations are specified in §63.1113.

| If you own or operate . . . | Then you must control total organic HAP emissions from the affected source by . . . |

|---|---|

| 1. An acrylic and modacrylic fibers production affected source and your facility is an existing source | Meeting all of following requirements: a. Reduce total organic HAP emissions from all affected storage vessels, process vents, wastewater streams associated with the acrylic and modacrylic fibers production process unit as defined in paragraph (b)(2) of this section, and fiber spinning lines operated in your acrylic and modacrylic fibers production facility to less than or equal to 0.5 kilograms (kg) of organic HAP per megagram (Mg) of fiber produced. |

| b. Determine the facility organic HAP emission rate in accordance with the requirements specified in paragraph (b)(5) of this section. | |

| 2. An acrylic and modacrylic fibers production affected source and your facility is a new source | Meeting all of following requirements: a. Reduce total organic HAP emissions from all affected storage vessels, process vents, wastewater streams associated with the acrylic and modacrylic fibers production process unit as defined in paragraph (b)(2) of this section, and fiber spinning lines operated in your acrylic and modacrylic fibers production facility to less than or equal to 0.25 kilograms (kg) of organic HAP per megagram (Mg) of fiber produced. |

| b. Determine the facility organic HAP emission rate in accordance with the requirements specified in paragraph (b)(5) of this section. | |