['Air Programs']

['Hazardous Air Pollutants']

02/27/2022

...

§63.541 Applicability.

(a) You are subject to this subpart if you own or operate any of the following affected sources at a secondary lead smelter: Blast, reverberatory, rotary, and electric furnaces; refining kettles; agglomerating furnaces; dryers; process fugitive emissions sources; buildings containing lead bearing materials; and fugitive dust sources. The provisions of this subpart do not apply to primary lead processors, lead refiners, or lead remelters.

(b) Table 1 to this subpart specifies the provisions of subpart A of this part that apply to owners and operators of secondary lead smelters subject to this subpart.

(c) If you are subject to the provisions of this subpart, you are also subject to title V permitting requirements under 40 CFR parts 70 or 71, as applicable.

(d) Emissions standards in this subpart apply at all times.

§63.542 Definitions.

Terms used in this subpart are defined in the Clean Air Act, in subpart A of this part, or in this section as follows:

Affected source means any of the following sources at a secondary lead smelter: Blast, reverberatory, rotary, and electric furnaces; refining kettles; agglomerating furnaces; dryers; process fugitive emissions sources; buildings containing lead bearing materials; and fugitive dust sources.

Affirmative defense means, in the context of an enforcement proceeding, a response or defense put forward by a defendant, regarding which the defendant has the burden of proof, and the merits of which are independently and objectively evaluated in a judicial or administrative proceeding.

Agglomerating furnace means a furnace used to melt into a solid mass flue dust that is collected from a baghouse.

Bag leak detection system means an instrument that is capable of monitoring particulate matter (dust) loadings in the exhaust of a baghouse in order to detect bag failures. A bag leak detection system includes, but is not limited to, an instrument that operates on triboelectric, light scattering, transmittance or other effect to monitor relative particulate matter loadings.

Battery breaking area means the plant location at which lead-acid batteries are broken, crushed, or disassembled and separated into components.

Blast furnace means a smelting furnace consisting of a vertical cylinder atop a crucible, into which lead-bearing charge materials are introduced at the top of the furnace and combustion air is introduced through tuyeres at the bottom of the cylinder, and that uses coke as a fuel source and that is operated at such a temperature in the combustion zone (greater than 980 Celsius) that lead compounds are chemically reduced to elemental lead metal.

Blast furnace charging location means the physical opening through which raw materials are introduced into a blast furnace.

Collocated blast furnace and reverberatory furnace means operation at the same location of a blast furnace and a reverberatory furnace where the vent streams of the furnaces are mixed before cooling, with the volumetric flow rate discharged from the blast furnace being equal to or less than that discharged from the reverberatory furnace.

Dryer means a chamber that is heated and that is used to remove moisture from lead-bearing materials before they are charged to a smelting furnace.

Dryer transition equipment means the junction between a dryer and the charge hopper or conveyor, or the junction between the dryer and the smelting furnace feed chute or hopper located at the ends of the dryer.

Electric furnace means a smelting furnace consisting of a vessel into which reverberatory furnace slag is introduced and that uses electrical energy to heat the reverberatory furnace slag to such a temperature (greater than 980 Celsius) that lead compounds are reduced to elemental lead metal.

Fugitive dust source means a stationary source of hazardous air pollutant emissions at a secondary lead smelter that is not associated with a specific process or process fugitive vent or stack. Fugitive dust sources include, but are not limited to, roadways, storage piles, lead bearing material handling transfer points, lead bearing material transport areas, lead bearing material storage areas, other lead bearing material process areas, and buildings.

Furnace and refining/casting area means any area of a secondary lead smelter in which:

(1) Smelting furnaces are located;

(2) Refining operations occur; or

(3) Casting operations occur.

Lead alloy means an alloy in which the predominant component is lead.

Lead bearing material means material with a lead content equal to or greater than 5 mg/l as measured by EPA Method 1311 (Under Method 1311, only materials with at least 100 ppm lead will be considered to be lead bearing).

Leeward wall means the furthest exterior wall of a total enclosure that is opposite the windward wall.

Maintenance activity means any of the following routine maintenance and repair activities that could generate fugitive lead dust:

(1) Replacement or repair of refractory, or any internal or external part of equipment used to process, handle or control lead-containing materials.

(2) Replacement of any duct section used to convey lead-containing exhaust.

(3) Metal cutting or welding that penetrates the metal structure of any equipment, and its associated components, used to process lead-containing material such that lead dust within the internal structure or its components can become fugitive lead dust.

(4) Resurfacing, repair or removal of ground, pavement, concrete, or asphalt.

Materials storage and handling area means any area of a secondary lead smelter in which lead-bearing materials (including, but not limited to, broken battery components, reverberatory furnace slag, flue dust, and dross) are stored or handled between process steps including, but not limited to, areas in which materials are stored in open piles, bins, or tubs, and areas in which material is prepared for charging to a smelting furnace.

Natural draft opening means any permanent opening in an enclosure that remains open during operation of the facility and is not connected to a duct in which a fan is installed.

New source means any affected source at a secondary lead smelting facility the construction or reconstruction of which is commenced after May 19, 2011. A building that is constructed for the purpose of controlling fugitive emissions from an existing source is not considered to be a new source.

Partial enclosure means a structure comprised of walls or partitions on at least three sides or three-quarters of the perimeter surrounding stored materials or process equipment to prevent the entrainment of particulate matter into the air.

Pavement cleaning means the use of vacuum equipment, water sprays, or a combination thereof to remove dust or other accumulated material from the paved areas of a secondary lead smelter.

Plant roadway means any area of a secondary lead smelter outside of a total enclosure that is subject to vehicle traffic, including traffic by forklifts, front-end loaders, or vehicles carrying whole batteries or cast lead ingots. Excluded from this definition are employee and visitor parking areas, provided they are not subject to traffic by vehicles carrying lead-bearing materials.

Pressurized dryer breaching seal means a seal system connecting the dryer transition pieces which is maintained at a higher pressure than the inside of the dryer.

Process fugitive emissions source means a source of hazardous air pollutant emissions at a secondary lead smelter that is associated with lead smelting or refining, but is not the primary exhaust stream from a smelting furnace, and is not a fugitive dust source. Process fugitive emissions sources include, but are not limited to, smelting furnace charging points, smelting furnace lead and slag taps, refining kettles, agglomerating furnaces, and drying kiln transition pieces.

Process vent means furnace vents, dryer vents, agglomeration furnace vents, vents from battery breakers, vents from buildings containing lead bearing material, and any ventilation system controlling lead emissions.

Refining kettle means an open-top vessel that is constructed of cast iron or steel and is indirectly heated from below and contains molten lead for the purpose of refining and alloying the lead. Included are pot furnaces, receiving kettles, and holding kettles.

Reverberatory furnace means a refractory-lined furnace that uses one or more flames to heat the walls and roof of the furnace and lead-bearing scrap to such a temperature (greater than 980 Celsius) that lead compounds are chemically reduced to elemental lead metal.

Rotary furnace (also known as a rotary reverberatory furnace) means a furnace consisting of a refractory-lined chamber that rotates about a horizontal axis and that uses one or more flames to heat the walls of the furnace and lead-bearing scrap to such a temperature (greater than 980 Celsius) that lead compounds are chemically reduced to elemental lead metal.

Secondary lead smelter means any facility at which lead-bearing scrap material, primarily, but not limited to, lead-acid batteries, is recycled into elemental lead or lead alloys by smelting.

Shutdown means the period when no lead bearing materials are being fed to the furnace and smelting operations have ceased during which the furnace is cooled from steady-state operating temperature to ambient temperature.

Smelting means the chemical reduction of lead compounds to elemental lead or lead alloys through processing in high-temperature (greater than 980 Celsius) furnaces including, but not limited to, blast furnaces, reverberatory furnaces, rotary furnaces, and electric furnaces.

Startup means the period when no led bearing materials have been fed to the furnace and smelting operations have not yet commenced during which the furnace is heated from ambient temperature to steady-state operating temperature.

Total enclosure means a containment building that is completely enclosed with a floor, walls, and a roof to prevent exposure to the elements and to assure containment of lead bearing material with limited openings to allow access and egress for people and vehicles. The total enclosure must provide an effective barrier against fugitive dust emissions such that the direction of air flow through any openings is inward and the enclosure is maintained under constant negative pressure.

Vehicle wash means a device for removing dust and other accumulated material from the wheels, body, and underside of a vehicle to prevent the inadvertent transfer of lead contaminated material to another area of a secondary lead smelter or to public roadways.

Wet suppression means the use of water, water combined with a chemical surfactant, or a chemical binding agent to prevent the entrainment of dust into the air from fugitive dust sources.

Windward wall means the exterior wall of a total enclosure that is most impacted by the wind in its most prevailing direction determined by a wind rose using available data from the closest representative meteorological station. When openings into enclosures are not impacted by ambient wind due to the enclosure being part of a larger structure, the owner or operator may designate which wall of the enclosure to define as the windward wall.

[77 FR 580, Jan. 5, 2012, as amended at 79 FR 371, Jan. 3, 2014]

§63.543 What are my standards for process vents?

(a) For existing sources, you must maintain the concentration of lead compounds in any process vent gas at or below 1.0 milligrams of lead per dry standard cubic meter (0.00043 grains of lead per dry standard cubic foot). You must maintain the flow-weighted average concentration of lead compounds in vent gases from a secondary lead smelting facility at or below 0.20 milligrams of lead per dry standard cubic meter (0.000087 grains of lead per dry standard cubic foot).

(1) You must demonstrate compliance with the flow weighted average emissions limit on a 12-month rolling average basis, calculated monthly using the most recent test data available.

(2) Until 12 monthly weighted average emissions rates have been accumulated, calculate only the monthly average weighted emissions rate.

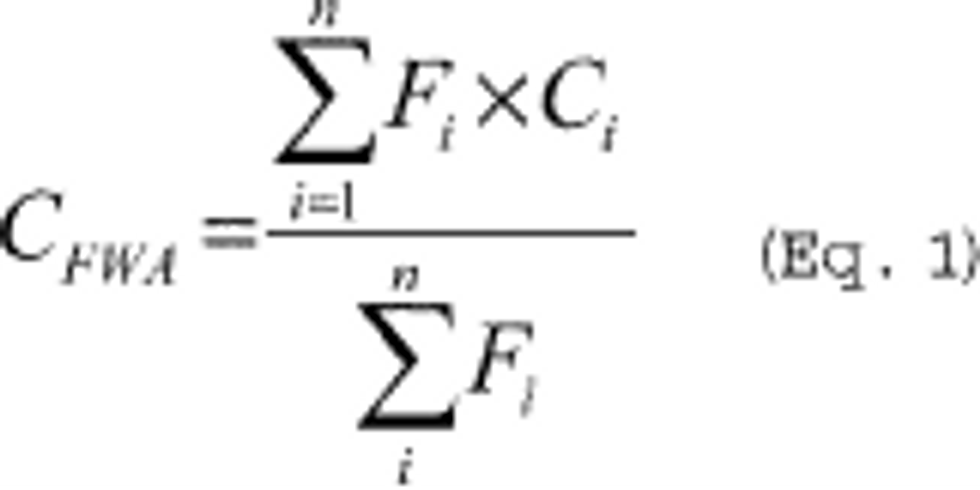

(3) You must use Equation 1 of this section to calculate the flow-weighted average concentration of lead compounds from process vents:

Where:

CFWA = Flow-weighted average concentration of all process vents.

n = Number of process vents.

Fi = Flow rate from process vent i in dry standard cubic feet per minute, as measured during the most recent compliance test.

Ci = Concentration of lead in process vent i, as measured during the most recent compliance test.

(4) Each month, you must use the concentration of lead and flow rate obtained during the most recent compliance test performed prior to or during that month to perform the calculation using Equation 1 of this section.

(5) If a continuous emissions monitoring system (CEMS) is used to measure the concentration of lead in a vent, the monthly average lead concentration and monthly average flow rate must be used rather than the most recent compliance test data.

(b) For new sources that begin construction or reconstruction after May 19, 2011 you must maintain the concentration of lead compounds in any process vent gas at or below 0.20 milligrams of lead per dry standard cubic meter (0.000087 grains of lead per dry standard cubic foot).

(c) You must meet the applicable emissions limits for total hydrocarbons and dioxins and furans from furnace sources specified in Table 2 of this subpart. There are no standards for dioxins and furans during periods of startup and shutdown.

(d) If you combine furnace emissions from multiple types of furnaces and these furnaces do not meet the definition of collocated blast and reverberatory furnaces, you must calculate your emissions limit for the combined furnace stream using Equation 2 of this section.

Where:

CEL = Flow-weighted average emissions limit (concentration) of combined furnace vents.

n = Number of furnace vents.

Fi = Flow rate from furnace vent i in dry standard cubic feet per minute.

CEli = Emissions limit (concentration) of pollutant in furnace vent i as specified in Table 2 of this subpart.

(e) If you combine furnace emissions with the furnace charging process fugitive emissions and discharge them to the atmosphere through a common emissions point, you must demonstrate compliance with the applicable total hydrocarbons concentration limit specified in paragraph (c) of this section at a location downstream from the point at which the two emissions streams are combined.

(f) If you do not combine the furnace charging process fugitive emissions with the furnace process emissions, and discharge such emissions to the atmosphere through separate emissions points, you must maintain the total hydrocarbons concentration in the exhaust gas at or below 20 parts per million by volume, expressed as propane.

(g) Following the initial performance or compliance test to demonstrate compliance with the lead emissions limits specified in paragraph (a) or (b) of this section, you must conduct performance tests according to the schedule in paragraph (g)(1) or (2) of this section.

(1) Conduct an annual performance test for lead compounds from each process vent (no later than 12 calendar months following the previous compliance test), unless you install and operate a CEMS meeting the requirements of §63.8.

(2) If an annual compliance test demonstrates that a process vent emitted lead compounds at 0.10 milligram of lead per dry standard cubic meter or less during the time of the annual compliance test, you may submit a written request to the Administrator applying for an extension of up to 24 calendar months from the previous compliance test to conduct the next compliance test for lead compounds.

(h) Following the initial performance or compliance test to demonstrate compliance with the total hydrocarbons emissions limits in paragraphs (c) and (f) of this section, you must conduct an annual performance test for total hydrocarbons emissions from each process vent that has established limits for total hydrocarbons (no later than 12 calendar months following the previous compliance test), unless you install and operate a CEMS meeting the requirements of §63.8. If an annual compliance test demonstrates that a process vent emitted total hydrocarbons at less than 50 percent of the allowable limit during the time of the annual compliance test, you may submit a written request to the Administrator applying for an extension of up to 24 calendar months from the previous compliance test to conduct the next compliance test for total hydrocarbons.

(i) Following the initial performance or compliance test to demonstrate compliance with the dioxins and furans emissions limits specified in paragraph (c) of this section, you must conduct a performance test for dioxins and furans emissions from each process vent that has established limits for dioxins and furans at least once every 6 years following the previous compliance test.

(j) You must conduct the performance tests specified in paragraphs (g) through (i) of this section under maximum representative operating conditions for the process. During the performance test, you may operate the control device at maximum or minimum representative operating conditions for monitored control device parameters, whichever results in lower emission reduction. Upon request, you must make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

(k) At all times, you must operate and maintain any affected source, including associated air pollution control equipment and monitoring equipment, in a manner consistent with safety and good air pollution control practices for minimizing emissions. Determination of whether such operation and maintenance procedures are being used will be based on information available to the Administrator that may include, but is not limited to, monitoring results, review of operation and maintenance procedures, review of operation and maintenance records, and inspection of the source.

(l) If you own or operate a unit subject to emission limits in Table 2 of this subpart, you must minimize the unit's startup and shutdown periods following the manufacturer's recommended procedures, if available. You must develop and follow standard operating procedures designed to minimize emissions of total hydrocarbon for each startup or shutdown scenario anticipated. You must submit a signed statement in the Notification of Compliance Status report that indicates that you conducted startups and shutdowns according to the manufacturer's recommended procedures, if available, and the standard operating procedures designed to minimize emissions of total hydrocarbons.

(m) In addition to complying with the applicable emissions limits for dioxins and furans listed in Table 2 to this subpart, you must operate a process to separate plastic battery casing materials from all automotive batteries prior to introducing feed into a furnace.

[77 FR 580, Jan. 5, 2012, as amended at 79 FR 371, Jan. 3, 2014]

§63.544 What are my total enclosure standards?

(a) You must operate the process fugitive emissions sources and fugitive dust sources listed in paragraphs (a)(1) through (9) of this section in a total enclosure that is maintained at negative pressure at all times and vented to a control device designed to capture lead particulate. The total enclosure must meet the requirements specified in paragraph (c) of this section.

(1) Smelting furnaces.

(2) Smelting furnace charging areas.

(3) Lead taps, slag taps, and molds during tapping.

(4) Battery breakers.

(5) Refining kettles, casting areas.

(6) Dryers.

(7) Agglomerating furnaces and agglomerating furnace product taps.

(8) Material handling areas for any lead bearing materials except those listed in paragraph (b) of this section.

(9) Areas where dust from fabric filters, sweepings or used fabric filters are processed.

(b) Total enclosures are not required in the following areas: lead ingot product handling areas, stormwater and wastewater treatment areas, intact battery storage areas, areas where lead bearing material is stored in closed containers or enclosed mechanical conveyors, and areas where clean battery casing material is handled.

(c) You must construct and operate total enclosures for the sources listed in paragraph (a) of this section as specified in paragraphs (c)(1) through (3) of this section. The total enclosure must be free of significant cracks, gaps, corrosion or other deterioration that could cause lead bearing material to be released from the primary barrier. Measures must be in place to prevent the tracking of lead bearing material out of the unit by personnel or by equipment used in handling the material. An area must be designated to decontaminate equipment and any rinsate must be collected and properly managed.

(1) You must ventilate the total enclosure continuously to ensure negative pressure values of at least 0.013 mm of mercury (0.007 inches of water).

(2) You must maintain an inward flow of air through all natural draft openings.

(3) If areas that contain one or more sources listed in paragraphs (a)(1) through (9) of this section are enclosed within a larger building that also meets the definition of a total enclosure under §63.542, the requirements of paragraphs (c)(1) and (2) shall be monitored pursuant to §63.548(k) at only one leeward, one windward and one additional wall of the outermost portion of the larger totally enclosed building rather than each individual area within the building.

(d) You must inspect enclosures and facility structures that contain any lead-bearing materials at least once per month. You must repair any gaps, breaks, separations, leak points or other possible routes for emissions of lead to the atmosphere within one week of identification unless you obtain approval for an extension from the Administrator before the repair period is exceeded.

[77 FR 580, Jan. 5, 2012, as amended at 79 FR 371, Jan. 3, 2014]

§63.545 What are my standards for fugitive dust sources?

(a) You must prepare, and at all times operate according to, a standard operating procedures manual that describes in detail the measures that will be put in place and implemented to control the fugitive dust emissions from the sources listed in paragraphs (a)(1) through (7) of this section.

(1) Plant roadways.

(2) Plant buildings.

(3) Accidental releases.

(4) Battery storage area.

(5) Equipment maintenance.

(6) Material storage areas.

(7) Material handling areas.

(b) You must submit the standard operating procedures manual to the Administrator or delegated authority for review and approval when initially developed and any time changes are made.

(c) The controls specified in the standard operating procedures manual must at a minimum include the requirements specified in paragraphs (c)(1) through (7) of this section.

(1) Cleaning. Where a cleaning practice is specified, you must clean by wet wash or a vacuum equipped with a filter rated by the manufacturer to achieve 99.97 percent capture efficiency for 0.3 micron particles in a manner that does not generate fugitive lead dust.

(2) Plant roadways and paved areas. You must pave all areas subject to vehicle traffic and you must clean the pavement twice per day, except on days when natural precipitation makes cleaning unnecessary or when sand or a similar material has been spread on plant roadways to provide traction on ice or snow. Limited access and limited use roadways such as unpaved roads to remote locations on the property may be exempt from this requirement if they are used infrequently (no more than one round trip per day).

(3) Accidental releases. You must initiate cleaning of all affected areas within one hour after detection of any accidental release of lead dust that exceeds 10 pounds (the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) reportable quantity for lead at 40 CFR 302.4).

(4) Battery storage areas. You must inspect any batteries that are not stored in a total enclosure once each week and move any broken batteries to an enclosure within 72 hours of identification. You must clean residue from broken batteries within 72 hours of identification.

(5) Materials storage and handling areas. You must wash each vehicle at each exit of the material storage and handling areas. The vehicle wash must include washing of tires, undercarriage and exterior surface of the vehicle followed by vehicle inspection.

(6) Equipment maintenance. You must perform all maintenance activities that could generate lead dust in a manner that minimizes emissions of fugitive dust. This must include one or more of the following:

(i) Performing maintenance inside a total permanent enclosure maintained at negative pressure.

(ii) Performing maintenance inside a temporary enclosure and use a vacuum system either equipped with a filter rated by the manufacturer to achieve a capture efficiency of 99.97 percent for 0.3 micron particles or routed to an existing control device permitted for this activity.

(iii) Performing maintenance inside a partial enclosure and use of wet suppression sufficient to prevent dust formation.

(iv) Decontamination of equipment prior to removal from an enclosure.

(v) Immediate repair of ductwork or structure leaks without an enclosure if the time to construct a temporary enclosure would exceed the time to make a temporary or permanent repair, or if construction of an enclosure would cause a higher level of emissions than if an enclosure were not constructed.

(vi) Activities required for inspection of fabric filters and maintenance of filters that are in need of removal and replacement are not required to be conducted inside of total enclosures. Used fabric filters must be placed in sealed plastic bags or containers prior to removal from a baghouse.

(7) Material transport. You must collect and transport all lead bearing dust (i.e. lead bearing material which is a dust) within closed conveyor systems or in sealed, leak-proof containers unless the collection and transport activities are contained within a total enclosure. All other lead bearing material must be contained and covered for transport outside of a total enclosure in a manner that prevents spillage or dust formation. Intact batteries and lead ingot product are exempt from the requirement to be covered for transport.

(d) Your standard operating procedures manual must specify that records be maintained of all pavement cleaning, vehicle washing, and battery storage inspection activities performed to control fugitive dust emissions.

(e) You must pave all grounds on the facility or plant groundcover sufficient to prevent wind-blown dust. You may use dust suppressants on unpaved areas that will not support a groundcover (e.g., roadway shoulders, steep slopes, limited access and limited use roadways).

(f) As provided in §63.6(g), as an alternative to the requirements specified in this section, you can demonstrate to the Administrator (or delegated State, local, or Tribal authority) that an alternative measure(s) is equivalent or better than a practice(s) described in this section.

§63.546 Compliance dates.

(a) For affected sources that commenced construction or reconstruction on or before May 19, 2011, you must demonstrate compliance with the requirements of this subpart no later than January 6, 2014.

(b) For affected sources that commenced construction or reconstruction after May 19, 2011, you must demonstrate compliance with the requirements of this subpart by January 5, 2012 or upon startup of operations, whichever is later.

(c) Until the date specified in 63.546(a), secondary lead smelters that commenced construction or reconstruction on or before May 19, 2011, must continue to demonstrate compliance with the requirements of this subpart, codified in 40 CFR 63.541 through 40 CFR 63.550, that were in effect prior to the January 5, 2012, amendments. This means that secondary lead smelters that commenced construction or reconstruction on or before June 9, 1994, must continue to demonstrate compliance with existing source requirements of this subpart that were in effect prior to the January 5, 2012, amendments until the date specified in §63.546(a). Secondary lead smelters that commenced construction or reconstruction after June 9, 1994, and on or before May 19, 2011, must continue to demonstrate compliance with new source requirements of this subpart that were in effect prior to the January 5, 2012, amendments until the date specified in §63.546(a).

[77 FR 580, Jan. 5, 2012, as amended at 79 FR 371, Jan. 3, 2014]

§63.547 Test methods.

(a) You must use the test methods from appendix A of part 60 as listed in paragraphs (a)(1) through (5) of this section to determine compliance with the emissions standards for lead compounds specified in §63.543(a) and (b).

(1) EPA Method 1 at 40 CFR part 60, appendix A-1 to select the sampling port location and the number of traverse points.

(2) EPA Method 2 at 40 CFR part 60, appendix A-1 or EPA Method 5D at 40 CFR part 60, appendix A-3, section 8.3 for positive pressure fabric filters, to measure volumetric flow rate.

(3) EPA Method 3, 3A, or 3B at 40 CFR part 60, appendix A-2 to determine the dry molecular weight of the stack gas.

(4) EPA Method 4 at 40 CFR part 60, appendix A-3 to determine moisture content of the stack gas.

(5) EPA Method 12 or Method 29 at 40 CFR part 60, appendix A-8 to determine compliance with the lead compound emissions standards. The minimum sample volume must be 2.0 dry standard cubic meters (70 dry standard cubic feet) for each run. You must perform three test runs and you must determine compliance using the average of the three runs.

(b) You must use the following test methods in appendix A of part 60 listed in paragraphs (b)(1) through (4) of this section, as specified, to determine compliance with the emissions standards for total hydrocarbons specified in §63.543(c) through (f).

(1) EPA Method 1 at 40 CFR part 60, appendix A-1 to select the sampling port location and number of traverse points.

(2) The Single Point Integrated Sampling and Analytical Procedure of Method 3B to measure the carbon dioxide content of the stack gases when using either EPA Method 3A or 3B at 40 CFR part 60, appendix A-2.

(3) EPA Method 4 at 40 CFR part 60, appendix A-3 to measure moisture content of the stack gases.

(4) EPA Method 25A at 40 CFR part 60, appendix A-7 to measure total hydrocarbons emissions. The minimum sampling time must be 1 hour for each run. You must perform a minimum of three test runs. You must calculate a 1-hour average total hydrocarbons concentration for each run and use the average of the three 1-hour averages to determine compliance.

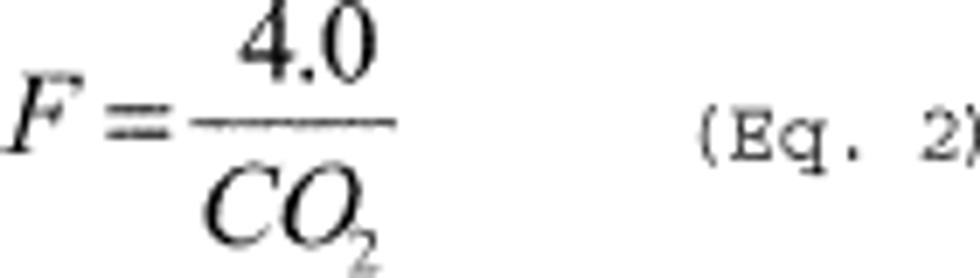

(c) You must correct the measured total hydrocarbons concentrations to 4 percent carbon dioxide as specified in paragraphs (c)(1) through (3) of this section.

(1) If the measured percent carbon dioxide is greater than 0.4 percent in each compliance test, you must determine the correction factor using Equation 2 of this section.

Where:

F = Correction factor (no units).

CO2 = Percent carbon dioxide measured using EPA Method 3A or 3B at 40 CFR part 60, appendix A-2, where the measured carbon dioxide is greater than 0.4 percent.

(2) If the measured percent carbon dioxide is equal to or less than 0.4 percent, you must use a correction factor (F) of 10.

(3) You must determine the corrected total hydrocarbons concentration by multiplying the measured total hydrocarbons concentration by the correction factor (F) determined for each compliance test.

(d) You must use the following test methods in appendix A of part 60 listed in paragraphs (d)(1) through (5) of this section, as specified, to determine compliance with the emissions standards for dioxins and furans specified in §63.543(c).

(1) EPA Method 1 at 40 CFR part 60, appendix A-1 to select the sampling port location and the number of traverse points.

(2) EPA Method 2 at 40 CFR part 60, appendix A-1 or EPA Method 5D at 40 CFR part 60, appendix A-3, section 8.3 for positive pressure fabric filters to measure volumetric flow rate.

(3) EPA Method 3A or 3B at 40 CFR part 60, appendix A-2 to determine the oxygen and carbon dioxide concentrations of the stack gas.

(4) EPA Method 4 at 40 CFR part 60, appendix A-3 to determine moisture content of the stack gas.

(5) EPA Method 23 at 40 CFR part 60, appendix A-7 to determine the dioxins and furans concentration.

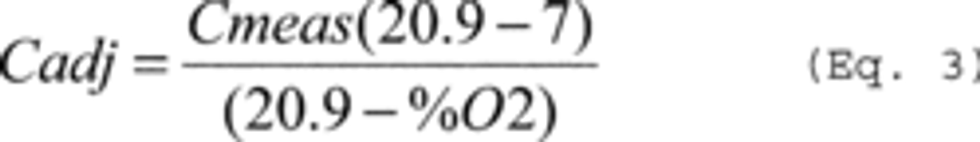

(e) You must determine the dioxins and furans toxic equivalency by following the procedures in paragraphs (e)(1) through (3) of this section.

(1) Measure the concentration of each dioxins and furans congener shown in Table 3 of this subpart using EPA Method 23 at 40 CFR part 60, appendix A-7. You must correct the concentration of dioxins and furans in terms of toxic equivalency to 7 percent O2 using Equation 3 of this section.

Where:

Cadj = Dioxins and furans concentration adjusted to 7 percent oxygen.

Cmeas = Dioxins and furans concentration measured in nanograms per dry standard cubic meter.

(20.9-7) = 20.9 percent oxygen - 7 percent oxygen (defined oxygen correction basis).

20.9 = Oxygen concentration in air, percent.

%O2 = Oxygen concentration measured on a dry basis, percent.

(2) For each dioxins and furans congener measured as specified in paragraph (e)(1) of this section, multiply the congener concentration by its corresponding toxic equivalency factor specified in Table 3 to this subpart.

(3) Sum the values calculated as specified in paragraph (e)(2) of this section to obtain the total concentration of dioxins and furans emitted in terms of toxic equivalency.

§63.548 Monitoring requirements.

(a) You must prepare, and at all times operate according to, a standard operating procedures manual that describes in detail procedures for inspection, maintenance, and bag leak detection and corrective action plans for all baghouses (fabric filters or cartridge filters) that are used to control process vents, process fugitive, or fugitive dust emissions from any source subject to the lead emissions standards in §§63.543, 63.544, and 63.545, including those used to control emissions from building ventilation.

(b) You must submit the standard operating procedures manual for baghouses required by paragraph (a) of this section to the Administrator or delegated authority for review and approval.

(c) The procedures that you specify in the standard operating procedures manual for inspections and routine maintenance must, at a minimum, include the requirements of paragraphs (c)(1) through (9) of this section.

(1) Daily monitoring of pressure drop across each baghouse cell.

(2) Weekly confirmation that dust is being removed from hoppers through visual inspection, or equivalent means of ensuring the proper functioning of removal mechanisms.

(3) Daily check of compressed air supply for pulse-jet baghouses.

(4) An appropriate methodology for monitoring cleaning cycles to ensure proper operation.

(5) Monthly check of bag cleaning mechanisms for proper functioning through visual inspection or equivalent means.

(6) Monthly check of bag tension on reverse air and shaker-type baghouses. Such checks are not required for shaker-type baghouses using self-tensioning (spring loaded) devices.

(7) Quarterly confirmation of the physical integrity of the baghouse through visual inspection of the baghouse interior for air leaks.

(8) Quarterly inspection of fans for wear, material buildup, and corrosion through visual inspection, vibration detectors, or equivalent means.

(9) Except as provided in paragraphs (g) and (h) of this section, continuous operation of a bag leak detection system, unless a system meeting the requirements of paragraph (m) of this section for a continuous emissions monitoring system is installed for monitoring the concentration of lead.

(d) The procedures you specify in the standard operating procedures manual for baghouse maintenance must include, at a minimum, a preventative maintenance schedule that is consistent with the baghouse manufacturer's instructions for routine and long-term maintenance.

(e) The bag leak detection system required by paragraph (c)(9) of this section, must meet the specification and requirements of paragraphs (e)(1) through (8) of this section.

(1) The bag leak detection system must be certified by the manufacturer to be capable of detecting particulate matter emissions at concentrations of 1.0 milligram per actual cubic meter (0.00044 grains per actual cubic foot) or less.

(2) The bag leak detection system sensor must provide output of relative particulate matter loadings.

(3) The bag leak detection system must be equipped with an alarm system that will alarm when an increase in relative particulate loadings is detected over a preset level.

(4) You must install and operate the bag leak detection system in a manner consistent with the guidance provided in “Office of Air quality Planning and Standards (OAQPS) Fabric Filter Bag Leak Detection Guidance” EPA-454/R-98-015, September 1997 (incorporated by reference, see §63.14) and the manufacturer's written specifications and recommendations for installation, operation, and adjustment of the system.

(5) The initial adjustment of the system must, at a minimum, consist of establishing the baseline output by adjusting the sensitivity (range) and the averaging period of the device, and establishing the alarm set points and the alarm delay time.

(6) Following initial adjustment, you must not adjust the sensitivity or range, averaging period, alarm set points, or alarm delay time, except as detailed in the approved standard operating procedures manual required under paragraph (a) of this section. You cannot increase the sensitivity by more than 100 percent or decrease the sensitivity by more than 50 percent over a 365 day period unless such adjustment follows a complete baghouse inspection that demonstrates that the baghouse is in good operating condition.

(7) For negative pressure, induced air baghouses, and positive pressure baghouses that are discharged to the atmosphere through a stack, you must install the bag leak detector downstream of the baghouse and upstream of any wet acid gas scrubber.

(8) Where multiple detectors are required, the system's instrumentation and alarm may be shared among detectors.

(f) You must include in the standard operating procedures manual required by paragraph (a) of this section a corrective action plan that specifies the procedures to be followed in the case of a bag leak detection system alarm. The corrective action plan must include, at a minimum, the procedures that you will use to determine and record the time and cause of the alarm as well as the corrective actions taken to minimize emissions as specified in paragraphs (f)(1) and (f)(2) of this section.

(1) The procedures used to determine the cause of the alarm must be initiated within 30 minutes of the alarm.

(2) The cause of the alarm must be alleviated by taking the necessary corrective action(s) that may include, but not be limited to, those listed in paragraphs (f)(2)(i) through (vi) of this section.

(i) Inspecting the baghouse for air leaks, torn or broken filter elements, or any other malfunction that may cause an increase in emissions.

(ii) Sealing off defective bags or filter media.

(iii) Replacing defective bags or filter media, or otherwise repairing the control device.

(iv) Sealing off a defective baghouse compartment.

(v) Cleaning the bag leak detection system probe, or otherwise repairing the bag leak detection system.

(vi) Shutting down the process producing the particulate emissions.

(g) Baghouses equipped with high efficiency particulate air (or HEPA) filters as a secondary filter used to control emissions from any source subject to the lead emission standards in §65.543(a) or (b), are exempt from the requirement to be equipped with a bag leak detection system. You must monitor and record the pressure drop across each HEPA filter system daily. If the pressure drop is outside the limit(s) specified by the filter manufacturer, you must take appropriate corrective measures, which may include but not be limited to those given in paragraphs (g)(1) through (4) of this section.

(1) Inspecting the filter and filter housing for air leaks and torn or broken filters.

(2) Replacing defective filter media, or otherwise repairing the control device.

(3) Sealing off a defective control device by routing air to other control devices

(4) Shutting down the process producing the particulate emissions.

(h) Baghouses followed by a wet electrostatic precipitator used as a secondary control device for any source subject to the lead emission standards in §63.543(a) or (b), are exempt from the requirement to be equipped with a bag leak detection system.

(i) If you use a wet scrubber to control particulate matter and metal hazardous air pollutant emissions from a process vent to demonstrate continuous compliance with the emissions standards, you must monitor and record the pressure drop and water flow rate of the wet scrubber during the initial performance or compliance test conducted to demonstrate compliance with the lead emissions limit under §63.543(a) or (b). Thereafter, you must monitor and record the pressure drop and water flow rate values at least once every hour and you must maintain the pressure drop and water flow rate at levels no lower than 30 percent below the pressure drop and water flow rate measured during the initial performance or compliance test.

(j) You must comply with the requirements specified in paragraphs (j)(1) through (4) of this section to demonstrate continuous compliance with the total hydrocarbons and dioxins and furans emissions standards. During periods of startup and shutdown, the requirements of paragraph (j)(4) of this section do not apply. Instead, you must demonstrate compliance with the standard for total hydrocarbon by meeting the requirements of §63.543(l).

(1) Continuous temperature monitoring. You must install, calibrate, maintain, and continuously operate a device to monitor and record the temperature of the afterburner or furnace exhaust streams consistent with the requirements for continuous monitoring systems in §63.8.

(2) Prior to or in conjunction with the initial performance or compliance test to determine compliance with §63.543(c), you must conduct a performance evaluation for the temperature monitoring device according to §63.8(e). The definitions, installation specifications, test procedures, and data reduction procedures for determining calibration drift, relative accuracy, and reporting described in Performance Specification 2, 40 CFR part 60, appendix B, sections 2, 3, 5, 7, 8, 9, and 10 must be used to conduct the evaluation. The temperature monitoring device must meet the following performance and equipment specifications:

(i) The recorder response range must include zero and 1.5 times the average temperature identified in paragraph (j)(3) of this section.

(ii) The monitoring system calibration drift must not exceed 2 percent of 1.5 times the average temperature identified in paragraph (j)(3) of this section.

(iii) The monitoring system relative accuracy must not exceed 20 percent.

(iv) The reference method must be a National Institute of Standards and Technology calibrated reference thermocouple-potentiometer system or an alternate reference, subject to the approval of the Administrator.

(3) You must monitor and record the temperature of the afterburner or the furnace exhaust streams every 15 minutes during the initial performance or compliance test for total hydrocarbons and dioxins and furans and determine an arithmetic average for the recorded temperature measurements.

(4) To demonstrate continuous compliance with the standards for total hydrocarbons and dioxins and furans, you must maintain an afterburner or exhaust temperature such that the average temperature in any 3-hour period does not fall more than 28°Celsius (50°Fahrenheit) below the average established in paragraph (j)(3) of this section.

(k) You must install, operate, and maintain a digital differential pressure monitoring system to continuously monitor each total enclosure as described in paragraphs (k)(1) through (5) of this section.

(1) You must install and maintain a minimum of one building digital differential pressure monitoring system at each of the following three walls in each total enclosure that has a total ground surface area of 10,000 square feet or more:

(i) The leeward wall.

(ii) The windward wall.

(iii) An exterior wall that connects the leeward and windward wall at a location defined by the intersection of a perpendicular line between a point on the connecting wall and a point on its furthest opposite exterior wall, and intersecting within plus or minus 10 meters of the midpoint of a straight line between the two other monitors specified. The midpoint monitor must not be located on the same wall as either of the other two monitors. If approved by the permitting authority, this third monitor may be placed in an alternative location on the midpoint wall or an exterior wall that is not the windward wall, leeward wall or midpoint wall.

(2) You must install and maintain a minimum of one building digital differential pressure monitoring system at the leeward wall of each total enclosure that has a total ground surface area of less than 10,000 square feet.

(3) The digital differential pressure monitoring systems must be certified by the manufacturer to be capable of measuring and displaying negative pressure containing values in the range of 0.01 to 0.2 millimeters mercury (0.005 to 0.11 inches of water) and capable of recording data in increments of 0.002 millimeters of mercury (0.001 inches of water).

(4) You must equip each digital differential pressure monitoring system with a continuous recorder. To demonstrate compliance with the standard for differential pressure, you must maintain the pressure in total enclosures such that the average pressure in any 15-minute period does not fall below the level specified in §63.544(c)(1). The 15-minute averages must include at least one reading per minute.

(5) You must calibrate each digital differential pressure monitoring system in accordance with manufacturer's specifications.

(l) Except as provided in paragraphs (l)(2) or (3) of this section, all new or reconstructed sources subject to the requirements under §63.543 must install, calibrate, maintain, and operate a CEMS for measuring lead emissions. In addition to the General Provisions requirements for CEMS in §63.8(c) that are referenced in Table 1 to this subpart, you must comply with the requirements for CEMS specified in paragraph (m) of this section.

(1) Sources subject to the emissions limits for lead compounds under §63.543(b) must install a CEMS for measuring lead emissions within 180 days of promulgation by the EPA of performance specifications for lead CEMS.

(2) Prior to 180 days after the EPA promulgates performance specifications for CEMS used to measure lead concentrations, you must use the procedure described in §63.543(g)(1) to determine compliance.

(3) Vents from control devices that serve only to control emissions from buildings containing lead bearing materials are exempt from the requirement to install a CEMS for measuring lead emissions.

(m) If a CEMS is used to measure lead emissions, you must install a continuous emissions monitoring system with a sensor in a location that provides representative measurement of the exhaust gas flow rate at the sampling location of the CEMS used to measure lead emissions, taking into account the manufacturer's recommendations. The flow rate sensor is that portion of the system that senses the volumetric flow rate and generates an output proportional to that flow rate.

(1) The continuous emissions monitoring system must be designed to measure the exhaust gas flow rate over a range that extends from a value of at least 20 percent less than the lowest expected exhaust flow rate to a value of at least 20 percent greater than the highest expected exhaust gas flow rate.

(2) The continuous emissions monitoring system must be equipped with a data acquisition and recording system that is capable of recording values over the entire range specified in paragraph (m)(1) of this section.

(3) You must perform an initial relative accuracy test of the continuous emissions monitoring system in accordance with the applicable Performance Specification in appendix B to part 60 of this chapter.

(4) You must operate the continuous emissions monitoring system and record data during all periods of operation of the affected facility including periods of startup, shutdown, and malfunction, except for periods of monitoring system malfunctions, repairs associated with monitoring system malfunctions, and required monitoring system quality assurance or quality control activities including, as applicable, calibration checks and required zero and span adjustments.

(5) If you have a CEMS to measure lead emissions, you must calculate the average lead concentration and flow rate monthly to determine compliance with §63.543(a).

(6) When the continuous emissions monitoring system is unable to provide quality assured data, the following apply:

(i) When data are not available for periods of up to 48 hours, the highest recorded hourly emissions rate from the previous 24 hours must be used.

(ii) When data are not available for 48 or more hours, the maximum daily emissions rate based on the previous 30 days must be used.

[77 FR 580, Jan. 5, 2012, as amended at 79 FR 371, Jan. 3, 2014]

§63.549 Notification requirements.

(a) You must comply with all of the notification requirements of §63.9. Electronic notifications are encouraged if suitable for the specific case (e.g., by electronic media such as Excel spreadsheet, on CD or hard copy), and when required by this subpart.

(b) You must submit the fugitive dust control standard operating procedures manual required under §63.545(a) and the standard operating procedures manual for baghouses required under §63.548(a) to the Administrator or delegated authority along with a notification that the smelter is seeking review and approval of these plans and procedures. You must submit this notification no later than January 7, 2013. For sources that commenced construction or reconstruction after January 5, 2012, you must submit this notification no later than 180 days before startup of the constructed or reconstructed secondary lead smelter, but no sooner than January 5, 2012. For an affected source that has received a construction permit from the Administrator or delegated authority on or before January 5, 2012, you must submit this notification no later than January 7, 2014.

§63.550 Recordkeeping and reporting requirements.

(a) You must comply with all of the recordkeeping and reporting requirements specified in §63.10 that are referenced in Table 1 to this subpart.

(1) Records must be maintained in a form suitable and readily available for expeditious review, according to §63.10(b)(1). However, electronic recordkeeping and reporting if suitable for the specific case (e.g., by electronic media such as Excel spreadsheet, on CD or hard copy), and when required by this subpart.

(2) Records must be kept on site for at least 2 years after the date of occurrence, measurement, maintenance, corrective action, report, or record, according to §63.10(b)(1).

(b) The standard operating procedures manuals required in §§63.545(a) and 63.548(a) must be submitted to the Administrator in electronic format for review and approval of the initial submittal and whenever an update is made to the procedure.

(c) You must maintain for a period of 5 years, records of the information listed in paragraphs (c)(1) through (13) of this section.

(1) Electronic records of the bag leak detection system output.

(2) An identification of the date and time of all bag leak detection system alarms, the time that procedures to determine the cause of the alarm were initiated, the cause of the alarm, an explanation of the corrective actions taken, and the date and time the cause of the alarm was corrected.

(3) All records of inspections and maintenance activities required under §63.548(c) as part of the practices described in the standard operating procedures manual for baghouses required under §63.548(a).

(4) Electronic records of the pressure drop and water flow rate values for wet scrubbers used to control metal hazardous air pollutant emissions from process fugitive sources as required in §63.548(i).

(5) Electronic records of the output from the continuous temperature monitor required in §63.548(j)(1), and an identification of periods when the 3-hour average temperature fell below the minimum established under §63.548(j)(4), and an explanation of the corrective actions taken.

(6) Electronic records of the continuous pressure monitors for total enclosures required in §63.548(k), and an identification of periods when the pressure was not maintained as required in §63.544(c)(1).

(7) Records of any time periods power was lost to the continuous pressure monitors for total enclosures required in §63.548(k) and records of loss of power to the air handling system maintaining negative pressure on total enclosures.

(8) Records of the inspections of facility enclosures required in §63.544(d).

(9) Records of all cleaning and inspections required as part of the practices described in the standard operating procedures manual required under §63.545(a) for the control of fugitive dust emissions.

(10) Electronic records of the output of any CEMS installed to monitor lead emissions meeting the requirements of §63.548(m).

(11) Records of the occurrence and duration of each malfunction of operation (i.e., process equipment) or the air pollution control equipment and monitoring equipment.

(12) Records of actions taken during periods of malfunction to minimize emissions in accordance with §63.543(k), including corrective actions to restore malfunctioning process and air pollution control and monitoring equipment to its normal or usual manner of operation.

(13) Records of any periods of startup or shutdown of a furnace and actions taken to minimize emissions during that period in accordance with §63.543(l).

(d) You must comply with all of the reporting requirements specified in §63.10 of the General Provisions that are referenced in Table 1 to this subpart.

(1) You must submit reports no less frequent than specified under §63.10(e)(3) of the General Provisions.

(2) Once a source reports a violation of the standard or excess emissions, you must follow the reporting format required under §63.10(e)(3) until a request to reduce reporting frequency is approved by the Administrator.

(e) In addition to the information required under the applicable sections of §63.10, you must include in the reports required under paragraph (d) of this section the information specified in paragraphs (e)(1) through (14) of this section.

(1) Records of the concentration of lead in each process vent, and records of the rolling 12-month flow-weighted average concentration of lead compounds in vent gases calculated monthly as required in §63.543(a), except during the first year when the concentration is calculated using the method described in §63.543(a)(2).

(2) Records of the concentration of total hydrocarbon and dioxins and furans in each process vent that has established limits for total hydrocarbon and dioxins and furans as required in §63.543(c).

(3) Records of all periods when monitoring using a CEMS for lead or total hydrocarbon was not in compliance with applicable limits.

(4) Records of all alarms from the bag leak detection system specified in §63.548.

(5) A description of the procedures taken following each bag leak detection system alarm pursuant to §63.548(f)(1) and (2).

(6) A summary of the records maintained as part of the practices described in the standard operating procedures manual for baghouses required under §63.548(a), including an explanation of the periods when the procedures were not followed and the corrective actions taken.

(7) An identification of the periods when the pressure drop and water flow rate of wet scrubbers used to control process fugitive sources dropped below the levels established in §63.548(i), and an explanation of the corrective actions taken.

(8) Records of the temperature monitor output, in 3-hour block averages, for those periods when the temperature monitored pursuant to §63.548(j) fell below the level established in §63.548(j)(4).

(9) Certification that the plastic separation process for battery breakers required in §63.543(m) was operated at all times the battery breaker was in service.

(10) Records of 15-minute periods when the pressure was not maintained as required in §63.544(c) or power was lost to the continuous pressure monitoring system as required in §63.548(k). Records of which wall is chosen as the windward wall must be included in the records required by §63.10(c) if a total enclosure located within a larger structure is not impacted by ambient wind.

(11) If a malfunction occurred during the reporting period, the report must include the number, duration, and a brief description for each type of malfunction that occurred during the reporting period and caused or may have caused any applicable emissions limitation to be exceeded. The report must also include a description of actions taken during a malfunction of an affected source to minimize emissions in accordance with §63.543(k), including actions taken to correct a malfunction.

(12) A summary of the fugitive dust control measures performed during the required reporting period, including an explanation of the periods when the procedures outlined in the standard operating procedures manual pursuant to §63.545(a) were not followed and the corrective actions taken. The reports must not contain copies of the daily records required to demonstrate compliance with the requirements of the standard operating procedures manuals required under §63.545(a).

(13) Records of any periods of startup or shutdown of a furnace including an explanation of the periods when the procedures required in §63.543(l) were not followed and the corrective actions taken.

(14) You must submit records pursuant to paragraphs (e)(14)(i) through (iii) of this section.

(i) As of January 1, 2012 and within 60 days after the date of completing each performance test, as defined in §63.2 and as required in this subpart, you must submit performance test data, except opacity data, electronically to EPA's Central Data Exchange by using the Electronic Reporting Tool (see http://www.epa.gov/ttn/chief/ert/ert_tool.html/). Only data collected using test methods compatible with the Electronic Reporting Tool are subject to this requirement to be submitted electronically into EPA's WebFIRE database.

(ii) Within 60 days after the date of completing each CEMS performance evaluation test, as defined in §63.2 and required by this subpart, you must submit the relative accuracy test audit data electronically into EPA's Central Data Exchange by using the Electronic Reporting Tool as mentioned in paragraph (e)(14)(i) of this section. Only data collected using test methods compatible with the Electronic Reporting Tool are subject to this requirement to be submitted electronically into EPA's WebFIRE database.

(iii) All reports required by this subpart not subject to the requirements in paragraph (e)(14)(i) and (ii) of this section must be sent to the Administrator at the appropriate address listed in §63.13. The Administrator or the delegated authority may request a report in any form suitable for the specific case (e.g., by electronic media such as Excel spreadsheet, on CD or hard copy). The Administrator retains the right to require submittal of reports subject to paragraph (e)(14)(i) and (ii) of this section in paper format.

[77 FR 580, Jan. 5, 2012, as amended at 79 FR 372, Jan. 3, 2014]

§63.551 Implementation and enforcement.

(a) This subpart can be implemented and enforced by the U.S. EPA, or a delegated authority such as the applicable State, local, or tribal agency. If the U.S. EPA Administrator has delegated authority to a State, local, or tribal agency, then that agency, in addition to the U.S. EPA, has the authority to implement and enforce this subpart. Contact the applicable U.S. EPA Regional Office to find out if this subpart is delegated to a State, local, or tribal agency.

(b) In delegating implementation and enforcement authority of this subpart to a State, local, or tribal agency under subpart E of this part, the authorities contained in paragraph (c) of this section are retained by the Administrator of U.S. EPA and cannot be transferred to the State, local, or tribal agency.

(c) The authorities that cannot be delegated to State, local, or tribal agencies are as specified in paragraphs (c)(1) through (4) of this section.

(1) Approval of alternatives to the requirements in §§63.541, 63.543 through 63.544, §63.545, and §63.546.

(2) Approval of major alternatives to test methods under §63.7(e)(2)(ii) and (f), as defined in §63.90, and as required in this subpart.

(3) Approval of major alternatives to monitoring under §63.8(f), as defined in §63.90, and as required in this subpart.

(4) Approval of major alternatives to recordkeeping and reporting under §63.10(f), as defined in §63.90, and as required in this subpart.

§63.552 Affirmative defense to civil penalties for exceedance of emissions limit during malfunction.

In response to an action to enforce the standards set forth in this subpart, you may assert an affirmative defense to a claim for civil penalties for exceedances of such standards that are caused by malfunction, as defined at §63.2. Appropriate penalties may be assessed, however, if you fail to meet your burden of proving all of the requirements in the affirmative defense. The affirmative defense shall not be available for claims for injunctive relief.

(a) Affirmative defense. To establish the affirmative defense in any action to enforce such a limit, you must timely meet the notification requirements in paragraph (b) of this section, and must prove by a preponderance of evidence that:

(1) The excess emissions:

(i) Were caused by a sudden, infrequent, and unavoidable failure of air pollution control and monitoring equipment, process equipment, or a process to operate in a normal or usual manner.

(ii) Could not have been prevented through careful planning, proper design or better operation and maintenance practices.

(iii) Did not stem from any activity orevent that could have been foreseen and avoided, or planned for.

(iv) Were not part of a recurring pattern indicative of inadequate design, operation, or maintenance.

(2) Repairs were made as expeditiously as possible when the applicable emissions limitations were being exceeded. Off-shift and overtime labor were used, to the extent practicable to make these repairs.

(3) The frequency, amount and duration of the excess emissions (including any bypass) were minimized to the maximum extent practicable during periods of such emissions.

(4) If the excess emissions resulted from a bypass of control equipment or a process, then the bypass was unavoidable to prevent loss of life, personal injury, or severe property damage.

(5) All possible steps were taken to minimize the impact of the excess emissions on ambient air quality, the environment and human health.

(6) All emissions monitoring and control systems were kept in operation if at all possible, consistent with safety and good air pollution control practices.

(7) All of the actions in response to the excess emissions were documented by properly signed, contemporaneous operating logs.

(8) At all times, the affected source was operated in a manner consistent with good practices for minimizing emissions.

(9) A written root cause analysis has been prepared, the purpose of which is to determine, correct, and eliminate the primary causes of the malfunction and the excess emissions resulting from the malfunction event at issue. The analysis shall also specify, using best monitoring methods and engineering judgment, the amount of excess emissions that were the result of the malfunction.

(b) Notification. The owner or operator of the affected source experiencing an exceedance of its emissions limit(s) during a malfunction, shall notify the Administrator by telephone or facsimile transmission as soon as possible, but no later than two business days after the initial occurrence of the malfunction, it wishes to avail itself of an affirmative defense to civil penalties for that malfunction. The owner or operator seeking to assert an affirmative defense, shall also submit a written report to the Administrator within 45 days of the initial occurrence of the exceedance of the standard in this subpart to demonstrate, with all necessary supporting documentation, that it has met the requirements set forth in paragraph (a) of this section. The owner or operator may seek an extension of this deadline for up to 30 additional days by submitting a written request to the Administrator before the expiration of the 45-day period. Until a request for an extension has been approved by the Administrator, the owner or operator is subject to the requirement to submit such report within 45 days of the initial occurrence of the exceedance.

Table 1 to Subpart X of Part 63 - General Provisions Applicability to Subpart X

| Reference | Applies to subpart X | Comment |

|---|---|---|

| 63.1 | Yes. | |

| 63.2 | Yes. | |

| 63.3 | Yes. | |

| 63.4 | Yes. | |

| 63.5 | Yes. | |

| 63.6(a), (b), (c) | Yes. | |

| 63.6(d) | No. | Section reserved. |

| 63.6(e)(1)(i) | No. | See 63.543(k) for general duty requirement. |

| 63.6(e)(1)(ii) | No. | |

| 63.6(e)(1)(iii) | Yes. | |

| 63.6(e)(2) | No. | Section reserved. |

| 63.6(e)(3) | No. | |

| 63.6(f)(1) | No. | |

| 63.6(g) | Yes. | |

| 63.6(h) | No. | No opacity limits in rule. |

| 63.6(i) | Yes. | |

| 63.6(j) | Yes. | |

| 63.7(a)-(d) | Yes. | |

| 63.7(e)(1) | No. | See 63.543(j). |

| 63.7(e)(2)-(e)(4) | Yes. | |

| 63.7(f), (g), (h) | Yes. | |

| 63.8(a)-(b) | Yes. | |

| 63.8(c)(1)(i) | No. | See 63.543(k) for general duty requirement. |

| 63.8(c)(1)(ii) | Yes. | |

| 63.8(c)(1)(iii) | No. | |

| 63.8(c)(2)-(d)(2) | Yes. | |

| 63.8(d)(3) | Yes, except for last sentence. | |

| 63.8(e)-(g) | Yes. | |

| 63.9(a), (b), (c), (e), (g), (h)(1)through (3), (h)(5) and (6), (i) and (j) | Yes. | |

| 63.9(f) | No. | |

| 63.9(h)(4) | No. | Reserved. |

| 63.9(k) | Yes | Only as specified in 63.9(j). |

| 63.10 (a) | Yes. | |

| 63.10 (b)(1) | Yes. | |

| 63.10(b)(2)(i) | No. | |

| 63.10(b)(2)(ii) | No. | See 63.550 for recordkeeping of occurrence and duration of malfunctions and recordkeeping of actions taken during malfunction. |

| 63.10(b)(2)(iii) | Yes. | |

| 63.10(b)(2)(iv)-(b)(2)(v) | No. | |

| 63.10(b)(2)(vi)-(b)(2)(xiv) | Yes. | |

| 63.(10)(b)(3) | Yes. | |

| 63.10(c)(1)-(9) | Yes. | |

| 63.10(c)(10)-(11) | No. | See 63.550 for recordkeeping of malfunctions. |

| 63.10(c)(12)-(c)(14) | Yes. | |

| 63.10(c)(15) | No. | |

| 63.10(d)(1)-(4) | Yes. | |

| 63.10(d)(5) | No. | See 63.550(e)(11) for reporting of malfunctions. |

| 63.10(e)-(f) | Yes. | |

| 63.11 | No. | Flares will not be used to comply with the emission limits. |

| 63.12 to 63.15 | Yes. |

[85 FR 73892, Nov. 19, 2020]

Table 2 to Subpart X of Part 63 - Emissions Limits for Secondary Lead Smelting Furnaces

| For vents from these processes . . . | You must meet the following emissions limits . . . a | |

|---|---|---|

| Total hydrocarbon ppm by volume expressed as propane corrected to 4 percent carbon dioxide | Dioxin and furan (dioxins and furans) nanograms/dscm expressed as TEQ corrected to 7 percent O2 | |

| a There are no standards for dioxins and furans during periods of startup and shutdown. | ||

| Collocated blast and reverberatory furnaces (new and existing) | 20 ppmv | 0.50 ng/dscm. |

| Collocated blast and reverberatory furnaces when the reverberatory furnace is not operating for units that comments construction or reconstruction before June 9, 1994 | 360 ppmv | 170 ng/dscm. |

| Collocated blast and reverberatory furnaces when the reverberatory furnace is not operating for units that commence construction or reconstruction after June 9, 1994 | 70 ppmv | 170 ng/dscm. |

| Blast furnaces that commence construction or reconstruction before June 9, 1994 | 360 ppmv | 170 ng/dscm. |

| Blast furnaces that commence construction or reconstruction after June 9, 1994 | 70 ppmv | 170 ng/dscm. |

| Blast furnaces that commence construction or reconstruction after May 19, 2011 | 70 ppmv | 10 ng/dscm. |

| Reverberatory and electric furnaces that commence construction or reconstruction before May 19, 2011 | 12 ppmv | 0.20 ng/dscm. |

| Reverberatory and electric furnaces that commence construction or reconstruction after May 19, 2011 | 12 ppmv | 0.10 ng/dscm. |

Table 3 to Subpart X of Part 63 - Toxic Equivalency Factors

| Dioxin/furan congener | Toxic equivalency factor |

|---|---|

| 2,3,7,8-tetrachlorinated dibenzo-p-dioxin | 1 |

| 1,2,3,7,8-pentachlorinated dibenzo-p-dioxin | 1 |

| 1,2,3,4,7,8-hexachlorinated dibenzo-p-dioxin | 0.1 |

| 1,2,3,7,8,9-hexachlorinated dibenzo-p-dioxin | 0.1 |

| 1,2,3,6,7,8-hexachlorinated dibenzo-p-dioxin | 0.1 |

| 1,2,3,4,6,7,8-heptachlorinated dibenzo-p-dioxin | 0.01 |

| octachlorinated dibenzo-p-dioxin | 0.0003 |

| 2,3,7,8-tetrachlorinated dibenzofuran | 0.1 |

| 2,3,4,7,8-pentachlorinated dibenzofuran | 0.3 |

| 1,2,3,7,8-pentachlorinated dibenzofuran | 0.03 |

| 1,2,3,4,7,8-hexachlorinated dibenzofuran | 0.1 |

| 1,2,3,6,7,8-hexachlorinated dibenzofuran | 0.1 |

| 1,2,3,7,8,9-hexachlorinated dibenzofuran | 0.1 |

| 2,3,4,6,7,8-hexachlorinated dibenzofuran | 0.1 |

| 1,2,3,4,6,7,8-heptachlorinated dibenzofuran | 0.01 |

| 1,2,3,4,7,8,9-heptachlorinated dibenzofuran | 0.01 |

| octachlorinated dibenzofuran | 0.0003 |

[79 FR 372, Jan. 3, 2014]

Source: 77 FR 580, Jan. 5, 2012, unless otherwise noted.

['Air Programs']

['Hazardous Air Pollutants']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.