['Air Programs']

['Air Emissions']

10/12/2023

...

§1090.1300 General provisions.

(a) This subpart is organized as follows:

(1) Sections 1090.1310 through 1090.1330 specify the scope of required testing, including special provisions that apply in several unique circumstances.

(2) Sections 1090.1335 through 1090.1345 specify handling procedures for collecting and retaining samples. Sections 1090.1350 through 1090.1375 specify the procedures for measuring the specified parameters. These procedures apply to anyone who performs testing under this subpart.

(3) Section 1090.1390 specifies the requirements for calibrating automated detergent blending equipment.

(4) Section 1090.1395 specifies the procedures for testing related to gasoline deposit control test procedure.

(b) If you need to meet requirements for a quality assurance program at a minimum frequency, your first batch of product triggers the testing requirement. The specified frequency serves as a deadline for performing the required testing, and as a starting point for the next testing period. The following examples illustrate the requirements for testing based on sampling the more frequent of every 90 days or 500,000 gallons of certified butane you received from a supplier:

(1) If your testing period starts on March 1 and you use less than 500,000 gallons of butane from March 1 through May 29 (90 days), you must perform testing under a quality assurance program sometime between March 1 and May 29. Your next test period starts with the use of butane on May 30 and again ends after 90 days or after you use 500,000 gallons of butane, whichever occurs first.

(2) If your testing period starts on March 1 and you use 500,000 gallons of butane for the testing period on April 29 (60 days), you must perform testing under a quality assurance program sometime between March 1 and April 29. Your next testing period starts with the use of butane on April 30 and again ends after 90 days or after you use 500,000 gallons of butane, whichever occurs first.

(c) Anyone acting on behalf of a regulated party to demonstrate compliance with requirements under this part must meet the requirements of this subpart in the same way that the party needs to meet those requirements for its own testing. The regulated party and the third party will both be liable for any violations arising from the third party's failure to meet the requirements of this subpart.

(d) Anyone performing tests under this subpart must apply good laboratory practices for all sampling, measurement, and calculations related to testing required under this part. This requires performing these procedures in a way that is consistent with generally accepted scientific and engineering principles and properly accounting for all available relevant information.

(e) Subpart Q of this part has provisions related to importation, including additional provisions that specify how to meet the sampling and testing requirements of this subpart.

[85 FR 78469, Dec. 4, 2020]

§1090.1310 Testing to demonstrate compliance with standards.

(a) Perform testing as needed to certify fuel, fuel additive, or regulated blendstock as specified in subpart K of this part. This section specifies additional test requirements.

(b) A fuel manufacturer, fuel additive manufacturer, or regulated blendstock producer must perform the following measurements before fuel, fuel additive, or regulated blendstock from a given batch leaves the facility, except as specified in §1090.1315:

(1) Diesel fuel. Perform testing for each batch of ULSD, 500 ppm LM diesel fuel, and ECA marine fuel to demonstrate compliance with sulfur standards.

(2) Gasoline. Perform testing for each batch of gasoline to demonstrate compliance with sulfur standards and perform testing for each batch of summer gasoline to demonstrate compliance with RVP standards.

(c) The following testing provisions apply for gasoline, oxygenate, certified ethanol denaturant, certified butane, and certified pentane:

(1) A gasoline manufacturer producing BOB for which oxygenate added downstream is accounted for under §1090.710 must prepare a hand blend as specified in §1090.1340 and perform the following measurements:

(i) Measure the sulfur content of both the BOB and the hand blend.

(ii) Except as specified in §1090.1325(c), measure the benzene content of the hand blend.

(iii) For Summer CG, measure the RVP of the BOB.

(iv) For Summer RFG, measure the RVP of the hand blend.

(2) A gasoline manufacturer producing gasoline for which oxygenate added downstream is not accounted for under §1090.710 (e.g., E0 or so-called suboctane gasoline) must perform the following measurements:

(i) Measure the sulfur content of the gasoline.

(ii) Except as specified in §1090.1325(c), measure the benzene content of the gasoline.

(iii) For Summer CG and Summer RFG, measure the RVP of the gasoline.

(iv) For Summer RFG that is designated as “Intended for Oxygenate Blending” under §1090.1010(a)(4), create a hand blend as specified in §1090.1340 and measure the RVP of the hand blend.

(v) For gasoline blended with oxygenate, measure the oxygenate content of the gasoline.

(3) An oxygenate producer must measure the sulfur content of each batch of oxygenate, except that a DFE producer may meet the alternative requirements in §1090.1330.

(4) An ethanol denaturant producer that certifies denaturant under §1090.1330 must measure the sulfur content of each batch of denaturant.

(5) A certified butane or certified pentane producer must perform sampling and testing to demonstrate compliance with purity specifications and sulfur and benzene standards as specified in §1090.1320.

(6) A transmix processor producing gasoline from TGP must test each batch of gasoline for parameters required to demonstrate compliance with §1090.505 as specified in §1090.1325.

(d) A blending manufacturer producing gasoline by adding blendstock to PCG must comply with §1090.1320.

(e) For gasoline produced at a fuel blending facility or a transmix processing facility, a gasoline manufacturer must measure such gasoline for oxygenate and for distillation parameters (i.e., T10, T50, T90, final boiling point, and percent residue). However, a fuel manufacturer or transmix processor does not need to measure the oxygenate content of gasoline if PCG, transmix, TGP, and blendstocks used to produce the batch did not contain any oxygenates, based on the following documentation:

(1) For PCG, documentation consists of oxygenate content identified on PTDs.

(2) For transmix, TGP, and blendstocks, documentation consists of affidavits or oxygenate test results from the person providing the transmix or blendstock stating that these products do not contain oxygenate.

[85 FR 78469, Dec. 4, 2020]

§1090.1315 In-line blending.

A fuel manufacturer using in-line blending equipment may qualify for a waiver from the requirement in §1090.1310(b) to test every batch of fuel before the fuel leaves the fuel manufacturing facility as follows:

(a) Submit a request signed by the RCO to EPA with the following information:

(1) Describe the location of your in-line blending operation, how long it has been in operation, and how much of each type and grade of fuel you have blended over the preceding 3 years (or since starting the in-line blending operation if it is less than 3 years). Describe the physical layout of the blending operation and how you move the blended fuel into distribution. Also describe how your automated system monitors and controls blending proportions and the properties of the blended fuel. For new installations, describe these as a planned operation with projected volumes by type and grade. Describe clearly which portions of your blending operation are the subject of your waiver request.

(2) Describe how you collect and test composite fuel samples in a way that is equivalent to measuring the fuel properties of a batch of blended fuel as specified in this subpart. Also describe how your procedures conform to the sampling specifications in ASTM D4177 and the composite calculations in ASTM D5854 (both incorporated by reference in §1090.95).

(3) Describe any expectation or plan for you or another party to perform additional downstream testing for the same fuel parameters.

(4) Describe your quality assurance procedures. Explain how you will ensure that all fuel will meet all applicable per-gallon standards. Describe any experiences from the previous 3 years where these quality assurance procedures led you to make corrections to your in-line blending operation. Describe how you will deal with release of fuel that fails to meet a per-gallon standard.

(5) Describe any times from the previous 3 years that you modified fuel after it left your facility. Describe how you modified the fuel and why that was necessary.

(6) Describe how you will meet the auditing requirements specified in §1090.1850 and any additional, facility-specific considerations that relate to those auditing requirements.

(b) You must arrange for an audit of your blending operation each calendar year as specified in §1090.1850. The audit must review procedures and documents to determine whether measured and calculated values properly represent the aggregate fuel properties for the blended fuel.

(c) You must submit an updated in-line blending waiver request to EPA 60 days before making any material change to your in-line blending process. Examples of material changes include changing analyzer hardware or programming, changing the location of the analyzer, changing the piping configuration, changing the mixing control hardware or programming logic, changing sample compositors or compositor settings, or expanding fuel blending capacity. Changing the name of the company or business unit is an example of a change that is not material.

(d) If EPA approves your request for a waiver under this section, you may need to update your procedures for more effective control and documentation of measured fuel parameters based on audit results, development of improved practices, or other information.

[85 FR 78469, Dec. 4, 2020]

§1090.1320 Adding blendstock to PCG.

The requirements of this section apply for a refiner or blending manufacturer that adds blendstock to PCG to produce a new batch of gasoline. Paragraph (b) of this section specifies an alternative approach for a certified butane or certified pentane blender. Section 1090.1325 describes additional provisions that apply to a transmix processor.

(a) Sample and test using one of the following methods to exclude PCG from the compliance demonstration for sulfur and benzene:

(1) Compliance by subtraction. (i) Determine the sulfur content, benzene content, and oxygenate content of the PCG before blending blendstocks to produce a new batch of gasoline as follows:

(A) Sample and test the sulfur content, benzene content, and oxygenate content of each batch of PCG. The blending manufacturer does not need to test PCG for oxygenate content if they can demonstrate that the PCG does not contain oxygenates as specified in paragraph (a)(1)(i)(C) of this section or §1090.1310(e)(1).

(B) If the PCG is a BOB, prepare a hand blend under §1090.1340 and test the hand blend for sulfur content and benzene content.

(C) The blending manufacturer may use the PCG manufacturer's certification test results if the PCG was received directly from the PCG manufacturer by an in-tank transfer or tank-to-tank transfer within the same terminal as long as the results are from the PCG that is being transferred.

(ii) Determine the volume of PCG that was blended with blendstock to produce a new batch of gasoline. Report the PCG as a negative batch as specified in §1090.905(c)(3)(i).

(iii) After adding blendstock to PCG, sample and test the sulfur content, benzene content, and for summer gasoline, RVP, of the new batch of gasoline.

(iv) Determine the volume of the new batch of gasoline. Report the new batch of gasoline as a positive batch as specified in §1090.905(c)(3)(ii).

(v) Include the PCG batch and the new batch of gasoline in compliance calculations as specified in §1090.700(d)(4)(i).

(vi) The sample retention requirements in §1090.1345 apply for both the new batch of gasoline and the associated PCG.

(2) Compliance by addition. (i) Sample and test the sulfur content and benzene content of each batch of blendstock used to produce a new batch of gasoline from PCG using the procedures in §1090.1350. The homogeneity requirements for gasoline specified in §1090.1337 apply to blendstock and GTAB collected with manual sampling.

(ii) Determine the volume of each batch of blendstock used to produce the new batch of gasoline.

(iii) Determine the volume of each blended batch of gasoline, and measure the sulfur content and for summer gasoline, RVP, for each blended batch of gasoline using the procedures specified in §1090.1350. Testing the blended batch of gasoline for sulfur content, however, is not required if the fuel manufacturer tests the added blendstock and determines that both the blendstock and PCG meet the fuel manufacturing facility gate sulfur per-gallon standard in §1090.205(b).

(iv) Report each batch of blendstock as specified in §1090.905(c)(4).

(v) Include each batch of blendstock in compliance calculations as specified in §1090.700(d)(4)(ii).

(vi) The sample retention requirements in §1090.1345 apply for the new batch of gasoline and for each blendstock.

(b) A certified butane or certified pentane blender that blends certified butane or certified pentane into PCG to make a new batch of gasoline may comply with the following requirements instead of the requirements of paragraph (a) of this section:

(1) For summer gasoline, measure RVP of the blended fuel. The fuel manufacturer may rely on sulfur and benzene test results from the certified butane or certified pentane producer. Note that §1090.220(e) disallows adding certified butane or certified pentane to Summer RFG or Summer RBOB.

(2) Before blending the certified butane or certified pentane with PCG, obtain a copy of the producer's test results indicating that the certified butane or certified pentane meets the standards in §1090.250 or §1090.255, respectively.

(3) The certified pentane blender must enter into a contract with the certified pentane producer to verify that the certified pentane producer has an adequate quality assurance program to ensure that the certified pentane received will not be contaminated in transit.

(4) The certified butane or certified pentane blender must conduct a quality assurance program to demonstrate that the certified butane or certified pentane meets the standards specified in §1090.250 or §1090.255, respectively. The quality assurance program must be based on sampling the more frequent of every 90 days or 500,000 gallons of certified butane or certified pentane received from each distributor. The certified butane or certified pentane blender may rely on a third party to perform the testing.

(c) This paragraph describes provisions that apply in cases where PCG is a BOB for which the PCG manufacturer accounted for oxygenate added downstream under §1090.710 and the blending manufacturer makes a new batch that includes less oxygenate than was specified for the BOB by the PCG manufacturer. A blending manufacturer in this circumstance does not qualify for the small volume blender exemption for BOB recertification under §1090.740(a)(3) and must comply with all the following.

(1) Calculate and incur sulfur and benzene deficits under the BOB recertification provisions in §1090.740.

(2) Comply with either the compliance by subtraction requirements of paragraph (a)(1) of this section or the compliance by addition requirements of paragraph (a)(2) of this section. For compliance by subtraction, test the PCG without adding oxygenate (i.e., test the PCG “neat”), and report the PCG volume without adjusting for the volume of oxygenate that the PCG manufacturer specified under §1090.740.

[85 FR 78469, Dec. 4, 2020]

§1090.1325 Adding blendstock or PCG to TGP.

The following provisions apply to a transmix processor or blending manufacturer producing gasoline by adding blendstock or PCG to TGP:

(a) Determine the volume, sulfur content, and benzene content of each blendstock batch used to produce gasoline for reporting and compliance calculations by following the sampling and testing requirements in §1090.1320 and treating the TGP used to produce the gasoline as PCG.

(b) Sample and test the gasoline made from TGP and PCG or blendstock to demonstrate compliance with the fuel manufacturing facility gate sulfur per-gallon standard in §1090.205(b) and the applicable RVP standard in §1090.215.

(c) A transmix processor producing gasoline by only adding TGP to PCG does not have to measure the benzene content of the finished gasoline.

[85 FR 78469, Dec. 4, 2020]

§1090.1330 Preparing denatured fuel ethanol.

Instead of measuring every batch, a DFE producer or importer may calculate the sulfur content of a batch of DFE as follows:

(a) Determine the sulfur content of ethanol before adding denaturant by measuring it as specified in §1090.1310 or by estimating it based on your production quality control procedures.

(b) Use the ppm sulfur content of certified ethanol denaturant specified on the PTD for the batch. If the sulfur content is specified as a range, use the maximum specified value.

(c) Calculate the weighted sulfur content of the DFE using the values determined under paragraphs (a) and (b) of this section.

[85 FR 78469, Dec. 4, 2020]

§1090.1335 Collecting, preparing, and testing samples.

(a) General provisions. Use good laboratory practice to collect samples to represent the batch you are testing. For example, take steps to ensure that a batch is always well mixed before sampling. Also, always take steps to prevent sample contamination, such as completely flushing sampling taps and piping and pre-rinsing sample containers with the product being sampled. Follow the procedures in paragraph (b) of this section for manual sampling. Follow the procedures paragraph (c) of this section for automatic sampling. Additional requirements for measuring RVP are specified in paragraph (d) of this section. A description of how to determine compliance based on single or multiple tests on single or multiple samples is specified in paragraph (e) of this section.

(b) Manual sampling. Perform manual sampling using one of the methods specified in ASTM D4057 (incorporated by reference in §1090.95) to demonstrate compliance with standards as follows:

(1) Collect a “running” or “all-levels” sample from the top of the tank. Drawing a sample from a standpipe is acceptable only if it is slotted or perforated to ensure that the drawn sample properly represents the whole batch of fuel.

(2)(i) Use tap sampling or spot sampling to collect upper, middle, and lower samples if a running or all-levels sample is impractical for a given storage configuration. Collect samples that most closely match the recommendations in Table 5 of ASTM D4057. Adjust spot sampling for partially filled tanks as shown in Table 1 or Table 5 of ASTM D4057, as applicable.

(ii) Spot sampling must not be used for certification testing unless the tank contains less than 10 feet of product.

(3) If the procedures in paragraphs (b)(1) and (2) of this section are impractical for a given storage configuration, you may use alternative sampling procedures as specified in ASTM D4057. This applies primarily for sampling with trucks, railcars, retail stations, and other downstream locations.

(4) Test results with manual sampling are valid only after you demonstrate homogeneity as specified in §1090.1337.

(5) Except as specified for marine vessels in §1090.1605, you must not do certification testing with a composite sample from manual sampling.

(c) Automatic sampling. (1) For in-line blending waivers under §1090.1315, follow all specifications for automatic sampling as specified in EPA's approval letter instead of or in addition to the specifications in paragraph (c)(2) of this section. Automatic sampling is also appropriate for a configuration involving a pipeline filling a tank that will be certified as compliant before it leaves the fuel manufacturing facility gate.

(2) Perform automatic sampling as specified in ASTM D4177 (incorporated by reference in §1090.95), with the following additional specifications:

(i) Configure the system to ensure a well-mixed stream at the sampling point. Align the start and end of sampling with the start and end of creating the batch.

(ii) The default sampling frequency must follow the recommended approach of at least 9,604 samples to represent a batch. Less frequent sampling is acceptable as long as the interval between samples does not exceed 20 seconds throughout the batch.

(iii) Collect three samples for individual measurements in addition to the composite sample. Draw head, middle, and tail samples after flowing 15, 50, and 85 percent of the estimated batch volume, respectively.

(iv) EPA may approve a different sampling strategy under an approved in-line blending waiver under §1090.1315 if it is appropriate for a given facility or for a small-volume batch.

(d) Sampling provisions related to measuring RVP of summer gasoline. The following additional provisions apply for preparing samples to measure RVP of summer gasoline:

(1) Meet the additional specifications for manual and automatic sampling in ASTM D5842 (incorporated by reference in §1090.95).

(2) If you measure other fuel parameters for a given sample in addition to RVP testing, always measure RVP first.

(e) Testing to demonstrate compliance with standards. (1) Perform testing as specified in this subpart.

(2) For parameters subject to per-gallon standards, report the highest measured value (or the lowest measured value for testing related to cetane index or other parameters that are subject to a standard representing a minimum value). This applies for repeat tests on a given sample and for testing multiple samples (including head, middle, and tail samples from automatic sampling). A batch is noncompliant if any tested sample does not meet all applicable per-gallon standards.

(3) In the case of automatic sampling for parameters subject to average standards, report the result from the composite sample to represent the batch for demonstrating compliance with the average standard. For any repeat testing with the composite sample, calculate the arithmetic average from all tests to represent the batch.

(4) In the case of manual sampling for parameters subject to average standards, determine the value representing the batch as follows:

(i) For testing with only a single sample, report that value to represent the batch. If there are repeat tests with that sample, report the arithmetic average from all tests to represent the sample.

(ii) For testing with more than one sample, report the arithmetic average from all tested samples to represent the batch. If there are repeat tests for any sample, calculate the arithmetic average of those repeat tests to determine a single value to represent that sample before calculating the average value to represent the batch.

[85 FR 78469, Dec. 4, 2020]

§1090.1337 Demonstrating homogeneity.

(a) Certification test results corresponding to manual sampling as specified in §1090.1335(b) are valid only if collected samples meet the homogeneity specifications in this section, except that the homogeneity testing requirement does not apply in the following cases:

(1) There is only a single sample using the procedure specified in §1090.1335(b)(2).

(2) Upright cylindrical tanks that have a liquid depth of less than 10 feet.

(3) You draw spot or tap samples as specified in paragraph (c) of this section, test each sample for every parameter subject to a testing requirement, and use the worst-case test result for each parameter for purposes of reporting, meeting per-gallon and average standards, and all other aspects of compliance.

(4) Sampling at a downstream location where it is not possible to collect separate samples and steps are taken to ensure that the batch is well mixed.

(b)(1) Testing performed to establish homogeneity is not considered certification testing, except as specified in paragraph (b)(2) of this section.

(2) Homogeneity testing may be used as certification testing if any of the following criteria are met:

(i) All tested samples meet all applicable per-gallon standards.

(ii) The testing meets the requirement in §1090.1335(b)(2)(ii).

(iii) The testing follows the procedures specified in paragraph (a)(3) of this section.

(c) Use spot sampling as specified in §1090.1335(b)(2) for homogeneity testing. Tap sampling is acceptable if spot sampling is impractical for a given facility.

(d) Demonstrate homogeneity for gasoline using two of the procedures specified in this paragraph (d) with each sample. For summer gasoline, the homogeneity demonstration must include RVP measurement.

(1) Measure API gravity using ASTM D287, ASTM D1298, ASTM D4052, or ASTM D7777 (incorporated by reference in §1090.95).

(2) Measure the sulfur content as specified in §1090.1360.

(3) Measure the benzene content as specified §1090.1360.

(4) Measure the RVP as specified in §1090.1360.

(e) For testing to meet the diesel fuel standards in subpart D of this part, demonstrate homogeneity using one of the procedures specified in paragraph (d)(1) or (2) of this section.

(f) Consider the batch to be homogeneous for a given parameter if the measured values for all tested samples vary by less than the published reproducibility of the test method multiplied by 0.75 (R × 0.75). If reproducibility is a function of measured values, calculate reproducibility using the average value of the measured parameter representing all tested samples. Calculate using all meaningful significant figures as specified for the test method, even if §1090.1350(c) describes a different precision. For cases that do not require a homogeneity demonstration under paragraph (a) of this section, the lack of homogeneity demonstration does not prevent a quantity of fuel, fuel additive, or regulated blendstock from being considered a batch for demonstrating compliance with the requirements of this part.

[85 FR 78469, Dec. 4, 2020]

§1090.1340 Preparing a hand blend from BOB.

(a) If you produce or import BOB and instruct downstream blenders to add oxygenate, you must meet the requirements of this subpart by blending oxygenate that reflects the anticipated sulfur content and benzene content of the oxygenate for blending into a BOB sample. To do this, prepare each hand blend by adding oxygenate to the BOB sample in a way that corresponds to your instructions to downstream blenders for the sampled batch of fuel. Prepare a hand blend as follows:

(1) Take steps to avoid introducing high or low bias in sulfur content when selecting from available samples to prepare the hand blend. For example, if there are three samples with discrete sulfur measurements, select the sample with the mid-range sulfur content. In other cases, randomly select the sample.

(2) If your instructions allow for a downstream blender to add more than one type or concentration of oxygenate, prepare the hand blend as follows:

(i) For summer gasoline intended for blending with ethanol, use the lowest specified ethanol blend.

(ii) For all winter gasoline and for summer gasoline intended for blending only with oxygenate other than ethanol, use the lowest specified oxygenate concentration, regardless of the type of oxygenate.

(iii) As an example, if you give instructions for a given batch of BOB to perform downstream blending to make E10, E15, and an 8 percent blend with butanol, prepare a hand blend for testing winter gasoline with 8 percent butanol, and prepare an E10 hand blend for testing summer gasoline.

(b) Prepare the hand blend using the procedures specified in ASTM D7717 (incorporated by reference in §1090.95). The hand blend must have an amount of oxygenate that does not exceed the oxygenate concentration specified on the PTD for the BOB under §1090.1110(b)(1).

[85 FR 78469, Dec. 4, 2020]

§1090.1345 Retaining samples.

(a) Retain samples as follows:

(1) A fuel manufacturer, regulated blendstock producer, or independent surveyor must keep representative samples of gasoline, diesel fuel, or oxygenate that is subject to certification testing requirements under this subpart for at least 30 days after testing is complete, except that a longer sample retention of 90 days applies for a blending manufacturer that produces gasoline.

(2) A certified pentane producer must keep representative samples of certified pentane for at least 30 days after testing is complete.

(3) A blending manufacturer required to test blendstock under §1090.1320(a)(2) must keep representative samples of the blendstock and the new batch of gasoline for at least 90 days after testing is complete.

(4) An oxygenate producer or importer must keep oxygenate samples as follows:

(i) Keep a representative sample of any tested oxygenate. Also keep a representative sample of DFE if you used the provisions of §1090.1330 to calculate its sulfur content.

(ii) Keep all the samples you collect over the previous 21 days. If you have fewer than 20 samples from the previous 21 days, continue keeping the most recent 20 samples collected up to a maximum of 90 days for any given sample.

(5) The nominal volume of retained liquid samples must be at least 330 ml. If you have only a single sample for testing, keep that sample after testing is complete. If you collect multiple samples from a single batch or you create a hand blend, select a representative sample as follows:

(i) If you are required to test a hand blend under §1090.1340, keep a sample of the BOB and a sample representative of the oxygenate used to prepare the hand blend.

(ii) For summer gasoline, keep an untested (or less tested) sample that is most like the tested sample, as applicable. In all other cases, keep the tested (or most tested) sample.

(c) Keep records of all calculations, test results, and test methods for the batch associated with each stored sample.

(d) If EPA requests a test sample, you must follow EPA's instructions and send it to EPA by a courier service (or equivalent). The instructions will describe where and when to send the sample. For each test sample, you must identify the test results and test methods used.

(e) You are responsible for meeting the requirements of this section even if a third party performs testing and stores the fuel samples for you.

[85 FR 78469, Dec. 4, 2020]

§1090.1350 Overview of test procedures.

A fuel manufacturer, fuel additive manufacturer, regulated blendstock producer, or independent surveyor meets the requirements of this subpart based on laboratory measurements of the specified fuel parameters. Test procedures for these measurements apply as follows:

(a) Except as specified in paragraph (b) of this section, the Performance-based Measurement System specified in §§1090.1360 through 1090.1375 applies for all testing specified in this subpart for the following fuels and fuel parameters:

(1) Sulfur content of diesel fuel.

(2) Sulfur content of ECA marine fuel.

(3) RVP, sulfur content, benzene content, and oxygenate content of gasoline. The procedures for measuring sulfur in gasoline in this subpart also apply for testing sulfur in certified ethanol denaturant; however, demonstrating compliance for alternative procedures in §1090.1365 and statistical quality control in §1090.1375 do not apply for sulfur concentration above 80 ppm.

(4) Sulfur content of butane.

(b) Specific test procedures apply for measuring other fuel parameters, as follows:

(1) Determine the cetane index of diesel fuel as specified in ASTM D976 or ASTM D4737 (incorporated by reference in §1090.95). There is no cetane-related test requirement for biodiesel that meets ASTM D6751 (incorporated by reference in §1090.95).

(2) Measure aromatic content of diesel fuel as specified in ASTM D1319 or ASTM D5186 (incorporated by reference in §1090.95). You may use an alternative procedure if you correlate your test results with ASTM D1319 or ASTM D5186. There is no aromatics-related test requirement for biodiesel that meets ASTM D6751.

(3) Measure the purity of butane as specified in ASTM D2163 (incorporated by reference in §1090.95). Measure the purity of pentane as specified in ASTM D2163 or ASTM D5134 (incorporated by reference in §1090.95).

(4) Measure the benzene content of butane and pentane as specified in ASTM D2163, ASTM D5134, ASTM D6729, or ASTM D6730 (incorporated by reference in §1090.95).

(5) Measure the sulfur content of pentane as specified in ASTM D5453 (incorporated by reference in §1090.95).

(6) Measure distillation parameters as specified in ASTM D86 (incorporated by reference in §1090.95). You may use an alternative procedure if you correlate your test results with ASTM D86.

(7) Measure the sulfur content of neat ethanol as specified in ASTM D5453. You may use an alternative procedure if you adequately correlate your test results with ASTM D5453.

(8) Measure the phosphorus content of gasoline as specified in ASTM D3231 (incorporated by reference in §1090.95).

(9) Measure the lead content of gasoline as specified in ASTM D3237 (incorporated by reference in §1090.95).

(10) Measure the sulfur content of gasoline additives and diesel fuel additives as specified in ASTM D2622 (incorporated by reference in §1090.95).

(11) Use referee procedures specified in §1090.1360(d) and the following additional methods to measure gasoline fuel parameters to meet the survey requirements of subpart O of this part:

| Fuel parameter | Units | Test method 1 |

|---|---|---|

| 1 ASTM specifications are incorporated by reference, see §1090.95. | ||

| Distillation | °C | ASTM D86. |

| Aromatic content | volume percent | ASTM D5769. |

| Olefin content | volume percent | ASTM D6550. |

(12) Updated versions of the test procedures specified in this section are acceptable as alternative procedures if both repeatability and reproducibility are the same or better than the values specified in the earlier version.

(c) Record measured values with the following precision, with rounding in accordance with §1090.50:

(1) Record sulfur content to the nearest whole ppm.

(2) Record benzene to the nearest 0.01 volume percent.

(3) Record RVP to the nearest 0.01 psi.

(4) Record oxygenate content to the nearest 0.01 mass percent for each calibrated oxygenate.

(5) Record diesel aromatic content to the nearest 0.1 volume percent, or record cetane index to the nearest whole number.

(6) Record gasoline aromatic and olefin content to the nearest 0.1 volume percent.

(7) Record distillation parameters to the nearest whole degree.

(d) For any measurement or calculation that depends on the volume of the test sample, correct the volume of the sample to a reference temperature of 15.56 °C. Use a correction equation that is appropriate for each tested compound. This applies for all fuels, blendstocks, and additives, except butane.

[85 FR 78469, Dec. 4, 2020]

§1090.1355 Calculation adjustments and corrections.

Adjust measured values as follows:

(a) Adjust measured values for total vapor pressure as follows:

RVP (psi) = 0.956 · Ptotal − 0.347

Where:

Ptotal = Measured total vapor pressure, in psi.

(b) For measuring the sulfur content and benzene content of gasoline, adjust a given test result upward in certain circumstances, as follows:

(1) If your measurement method involves a published procedure with a Pooled Limit of Quantitation (PLOQ), treat the PLOQ as your final result if your measured result is below the PLOQ.

(2) If your measurement method involves a published procedure with a limited scope but no PLOQ, treat the lower bound of the scope as your final result if your measured result is less than that value.

(3) If you establish a Laboratory Limit of Quantitation (LLOQ) below the lower bound of the scope of the procedure as specified in ASTM D6259 (incorporated by reference in §1090.95), treat the LLOQ as your final result if your measured result is less than the LLOQ. Note that this option is meaningful only if the LLOQ is less than a published PLOQ, or if there is no published PLOQ.

(c) For measuring the sulfur content of ULSD at a downstream location, subtract 2 ppm from the result.

(d) For measuring the benzene content of butane and pentane, report a zero value if the test result is at or below the PLOQ or Limit of Detection (LOD) that applies for the test method.

(e) If measured content of any oxygenate compound is less than 0.20 percent by mass, record the result as “None detected.”

[85 FR 78469, Dec. 4, 2020]

§1090.1360 Performance-based Measurement System.

(a) The Performance-based Measurement System (PBMS) is an approach that allows for laboratory testing with any procedure that meets specified performance criteria. This subpart specifies the performance criteria for measuring certain fuel parameters to demonstrate compliance with the standards and other specifications of this part. These provisions do not apply to process stream analyzers used with in-line blending.

(b) Different requirements apply for absolute fuel parameters and method-defined fuel parameters.

(1) Absolute fuel parameters are those for which it is possible to evaluate measurement accuracy by comparing measured values of a test sample to a reference sample with a known value for the measured parameter. The following are absolute fuel parameters:

(i) Sulfur. This applies for measuring sulfur in any fuel, fuel additive, or regulated blendstock.

(ii) [Reserved]

(2) Method-defined fuel parameters are all those that are not absolute fuel parameters. Additional test provisions apply for method-defined fuel parameters under this section because there is no reference sample for evaluating measurement accuracy.

(c) The performance criteria of this section apply as follows:

(1) Section 1090.1365 specifies the initial qualifying criteria for all measurement procedures. You may use an alternative procedure only if testing shows that you meet the initial qualifying criteria.

(2) Section 1090.1375 specifies ongoing quality testing requirements that apply for a laboratory that uses either referee procedures or alternative procedures.

(3) Streamlined requirements for alternative procedures apply for procedures adopted by a voluntary consensus standards body (VCSB). Certification testing with non-VCSB procedures requires advance approval by EPA. Procedures are considered non-VCSB testing as follows:

(i) Procedures developed by individual companies or other parties are considered non-VCSB procedures.

(ii) Draft procedures under development by a VCSB organization are considered non-VCSB procedures until they are approved for publication.

(iii) A published procedure is considered non-VCSB for testing with fuel parameters that fall outside the range of values covered in the research report of the ASTM D6708 (incorporated by reference in §1090.95) assessment comparing candidate alternative procedures to the referee procedure specified in paragraph (d) of this section.

(4) You may use updated versions of the referee procedures as alternative procedures subject to the limitations of §1090.1365(a)(2). You may ask EPA for approval to use an updated version of the referee procedure for qualifying other alternative procedures if the updated referee procedure has the same or better repeatability and reproducibility compared to the version specified in §1090.95. If the updated procedure has worse repeatability or reproducibility compared to the earlier version, you must complete the required testing specified in §1090.1365 using the older, referenced version of the referee procedure.

(5) Any laboratory may use the specified referee procedure without qualification testing. To use alternative procedures at a given laboratory, you must perform the specified testing to demonstrate compliance with precision and accuracy requirements, with the following exceptions:

(i) Testing you performed to qualify alternative procedures under 40 CFR part 80 continues to be valid for making the demonstrations required in this part.

(ii) Qualification testing is not required for a laboratory that measures the benzene content of gasoline using Procedure B of ASTM D3606 (incorporated by reference in §1090.95). However, qualification testing may be necessary for updated versions of this procedure as specified in §1090.1365(a)(2).

(d) Referee procedures are presumed to meet the initial qualifying criteria in this section. You may use alternative procedures if you qualify them using the referee procedures as a benchmark as specified in §1090.1365. The following are the referee procedures:

| Tested product | Parameter | Referee procedure 1 |

|---|---|---|

| 1 ASTM specifications are incorporated by reference, see §1090.95. | ||

| ULSD, 500 ppm diesel fuel, ECA marine fuel, gasoline | Sulfur | ASTM D2622. |

| Butane | Sulfur | ASTM D6667. |

| Gasoline | oxygenate content | ASTM D5599. |

| Gasoline | RVP | ASTM D5191, except as specified in §1090.1355(a). |

| Gasoline | benzene | ASTM D5769. |

[85 FR 78469, Dec. 4, 2020]

§1090.1365 Qualifying criteria for alternative measurement procedures.

This section specifies how to qualify alternative procedures for measuring absolute and method-defined fuel parameters under the Performance-based Analytical Test Method specified in §1090.1360.

(a) The following general provisions apply for qualifying alternative procedures:

(1) Alternative procedures must have appropriate precision to allow for reporting to the number of decimal places specified in §1090.1350(c).

(2) Testing to qualify an alternative procedure applies for the specified version of the procedure you use for making the necessary measurements. For referee procedures and for alternative procedures for method-defined fuel parameters that you have qualified for your laboratory, updated versions of those same procedures are qualified without further testing, as long as the specified reproducibility is the same as or better than the values specified in the earlier version. For absolute fuel parameters, updated versions are qualified without testing if both repeatability and reproducibility are the same as or better than the values specified in the earlier version.

(3) Except as specified in paragraph (d) of this section, testing to demonstrate compliance with the precision and accuracy specifications in this section apply only for the laboratory where the testing occurred.

(4) If a procedure for measuring benzene or sulfur in gasoline has no specified PLOQ and no specified scope with a lower bound, you must establish a LLOQ for your laboratory.

(5) Testing for method-defined fuel parameters must take place at a reference installation as specified in §1090.1370.

(b) All alternative procedures must meet precision criteria based on a calculated maximum allowable standard deviation for a given fuel parameter as specified in this paragraph (b). The precision criteria apply for measuring the parameters and fuels specified in paragraph (b)(3) of this section. Take the following steps to qualify the measurement procedure for measuring a given fuel parameter:

(1) The fuel must meet the parameter specifications in Table 1 to paragraph (b)(3) of this section. This may require that you modify the fuel you typically produce to be within the specified range. Absent a specification (maximum or minimum), select a fuel representing values that are typical for your testing. Store and mix the fuel to maintain a homogenous mixture throughout the measurement period to ensure that each fuel sample drawn from the batch has the same properties.

(2) Measure the fuel parameter from a homogeneous fuel batch at least 20 times. Record each result in sequence. Do not omit any valid results unless you use good engineering judgment to determine that the omission is necessary and you document those results and the reason for excluding them. Perform this analysis over a 20-day period. You may make up to 4 separate measurements in a 24-hour period, as long as the interval between measurements is at least 4 hours. Do not measure RVP more than once from a single sample.

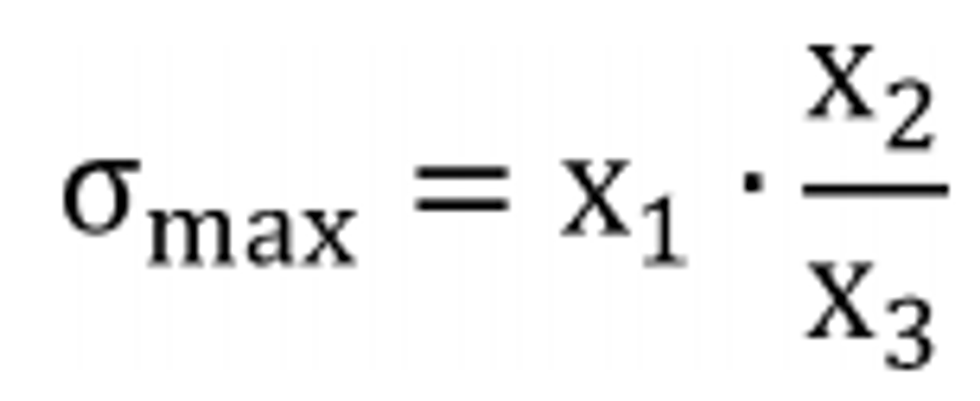

(3) Calculate the maximum allowable standard deviation as follows:

Where:

σmax = Maximum allowable standard deviation.

x1, x2, and x3 have the values from the following table:

| Fuel, fuel additive, or regulated blendstock | Fuel parameter | Range | x1 | x 2 = Repeatability (r) or reproducibility (R) 1 | x3 | Fixed values of σmax | Source 2 |

|---|---|---|---|---|---|---|---|

| 1 Calculate repeatability and reproducibility using the average value determined from testing. Use units as specified in §1090.1350(c). | |||||||

| 2 ASTM publications are incorporated by reference, see §1090.95. Note that the listed procedure may be different than the referee procedure identified in §1090.1360(d), or it may be an older version of the referee procedure. | |||||||

| 3 Use only 1-liter containers for testing to qualify alternative methods. | |||||||

| ULSD | Sulfur | 5 ppm minimum | 1.5 | r = 1.33 | 2.77 | 0.72 | ASTM D3120-08 (R2019). |

| 500 ppm LM diesel fuel | Sulfur | 350 ppm minimum | 1.5 | r = 21.3 | 2.77 | 11.5 | ASTM D2622-16. |

| ECA marine fuel | Sulfur | 700 ppm minimum | 1.5 | 37.1 | 2.77 | 20.1 | ASTM D2622-16. |

| Butane | Sulfur | 1.5 | r = 0.1152.x | 2.77 | ASTM D6667-14 (R2019). | ||

| Gasoline | Sulfur | 1.5 | r = 0.4998.x 0.54 | 2.77 | ASTM D7039-15a (R2020). | ||

| Gasoline | oxygenate | 0.3 | R = 0.13.x 0.83 | 1 | ASTM D5599-18. | ||

| Gasoline | RVP 3 | 0.3 | R = 0.40 | 1 | 0.12 | ASTM D5191-20. | |

| Gasoline | Benzene | 0.15 | R = 0.221.x 0.67 | 1 | ASTM D5769-20. | ||

(c) Alternative VCSB procedures for measuring absolute fuel parameters (sulfur) must meet accuracy criteria based on the following measurement procedure:

(1) Obtain gravimetric sulfur standards to serve as representative reference samples. The samples must have known sulfur content within the ranges specified in paragraph (c)(3) of this section. The known sulfur content is the accepted reference value (ARV) for the fuel sample.

(2) Measure the sulfur content of the fuel sample at your laboratory at least 10 times, without interruption. Use good laboratory practice to compensate for any known chemical interferences; however, you must apply that same compensation for all tests to measure the sulfur content of a test fuel. Calculate the arithmetic average of all the measured values, including any compensation.

(3) The measurement procedure meets the accuracy requirement as follows:

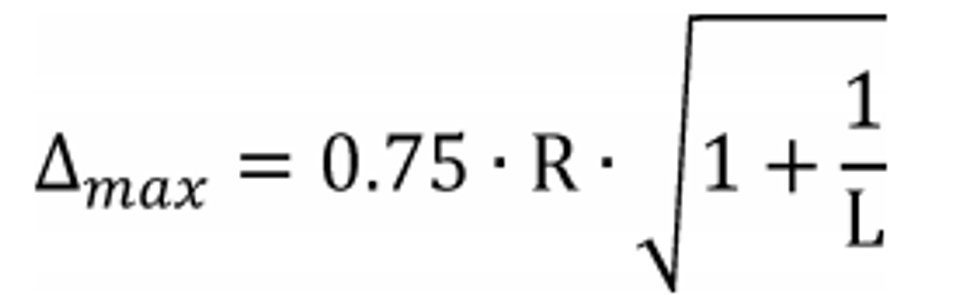

(i) Demonstrate accuracy for measuring sulfur in gasoline, gasoline regulated blendstock, and gasoline additive using test fuels to represent sulfur values from 1 to 10 ppm, 11 to 20 ppm, and 21 to 95 ppm. You may omit any of these ranges if you do not perform testing with fuel in that range. Calculate the maximum allowable difference between the average measured value and ARV for each applicable range as follows:

Δmax = 0.75 · σmax

Where:

Δmax = Maximum allowable difference.

σmax = the maximum allowable standard deviation from paragraph (b)(3) of this section using the sulfur content represented by ARV.

(ii) Demonstrate accuracy for measuring sulfur in diesel fuel using test fuels meeting the specifications in Table 2 to this section. For testing diesel-related blendstocks and additives, use representative test samples meeting the appropriate sulfur specification. Table 2 to this paragraph also identifies the maximum allowable difference between average measured values and ARV corresponding to ARV at the upper end of the specified ranges. These values are based on calculations with the equation in paragraph (c)(3)(i) of this section, with parameter values set to be equal to the standard.

| Fuel | Sulfur content (ppm) | Illustrated maximum allowable differences |

|---|---|---|

| ULSD | 10-20 | 0.54 |

| 500 ppm LM diesel fuel | 450-500 | 8.65 |

| ECA marine fuel | 900-1,000 | 15.1 |

(d) Alternative VCSB procedures for measuring method-defined fuel parameters must meet accuracy criteria as follows:

(1) You may use the alternative procedure only if you follow all the statistical protocols and meet all the criteria specified in Section 6 of ASTM D6708 (incorporated by reference in §1090.95) when comparing your measurements using the alternative procedure to measurements at a reference installation using the appropriate referee procedure identified in §1090.1360(d).

(2) For qualifying alternative procedures, determine whether the alternative procedure needs a correlation equation to correct bias relative to the reference test method. Create such a correlation equation as specified in Section 7 of ASTM D6708. For all testing, apply the correlation equation to adjust measured values to be statistically consistent to measuring with the reference test method.

(3) If an alternative VCSB procedure states that the procedure has a successful assessment relative to the referee procedures in this section under ASTM D6708, that finding applies for all laboratories using that procedure.

(e) Alternative non-VCSB procedures for measuring absolute fuel parameters (sulfur) must meet accuracy criteria as follows:

(1) Demonstrate whether the procedure meets statistical criteria and whether it needs a correlation equation as specified in paragraphs (d)(1) and (2) of this section. Apply the correlation equation for all testing with the alternative procedure.

(2) Demonstrate at your laboratory that the alternative procedure meets the accuracy criteria specified in paragraph (c) of this section.

(3) Send EPA a written request to use the alternative procedure. In your request, fully describe the procedure to show how it functions for achieving accurate measurements and include detailed information related to your assessment under paragraph (e)(1) and (2) of this section.

(f) Alternative non-VCSB procedures for measuring method-defined fuel parameters must meet accuracy and precision criteria as follows:

(1) Demonstrate whether the procedure meets statistical criteria and whether it needs a correlation equation as specified in paragraphs (e)(1) and (2) of this section. Apply the correlation equation for all testing with the alternative procedure.

(2) Test with a range of fuels that are typical of those you will analyze at your laboratory. Use either consensus-named fuels or locally-named reference materials. Consensus-named fuels are homogeneous fuel quantities sent around to different laboratories for analysis, which results in a “consensus name” representing the average value of the parameter for all participating laboratories. Locally named reference materials are fuel samples analyzed using the reference test method, either at your laboratory or at a reference installation, to establish an estimated value for the fuel parameter; locally named reference materials usually come from the fuel you produce.

(3) You may qualify your procedure as meeting the requirements of paragraph (f)(1) of this section only for a narrower, defined range of fuels. If this is the case, identify the appropriate range of fuels in your request for approval and describe how you will screen fuel samples accordingly.

(4) Qualify the precision of the alternative procedure by comparing results to testing with the referee procedure based on “between methods reproducibility,” Rxy, as specified in ASTM D6708. The Rxy must be at or below 75 percent of the reproducibility of the referee procedure in §1090.1360(d).

(5) Perform testing at your laboratory as specified in paragraph (b) of this section to establish the repeatability of the alternative procedure. The repeatability must be as good as or better than that specified in paragraph (b)(3) of this section.

(6) Fully describe the procedure to show how it functions for achieving accurate measurements. Describe the technology, test instruments, and testing method so a competent person lacking experience with the procedure and test instruments would be able to replicate the results.

(7) Engage a third-party auditor to review and verify your information as follows:

(i) The auditor must qualify as an independent third party and meet the specifications for technical ability as specified in §1090.55.

(ii) The auditor must send you a report describing their inspection of your laboratories and their review of the information supporting your request to use the alternative procedure. The report must describe how the auditor performed the review, identify any errors or discrepancies, and state whether the information supports a conclusion that the alternative procedure should be approved.

(iii) The auditor must keep records related to the review for at least 5 years after sending you the report and provide those records to EPA upon request.

(8) Send EPA a written request to use the alternative procedure. Include the specified information and any additional information EPA needs to evaluate your request.

(g) Keep fuel samples from any qualification testing under this section for at least 180 days after you have taken all steps to qualify an alternative procedure under this section. This applies for testing at your laboratory and at any reference installation you use for demonstrating the accuracy of an alternative procedure.

[85 FR 78469, Dec. 4, 2020]

§1090.1370 Qualifying criteria for reference installations.

(a) A reference installation refers to a laboratory that uses the referee procedure specified in §1090.1360(d) to evaluate the accuracy of alternative procedures for method-defined parameters, by comparing measured values to companion tests using one of the referee procedures in §1090.1360(d). This evaluation may result in an equation to correlate results between the two procedures. Once a laboratory qualifies as a reference installation, that qualification is valid for five years from the qualifying date, consistent with good laboratory practices.

(b) You may qualify a reference installation for VCSB procedures by participating in an interlaboratory crosscheck program with at least 16 separate measurements that are not identified as outliers. This presumes that the results for the candidate reference installation are not outliers.

(c) You may qualify a reference installation for VCSB or non-VCSB procedures based on the following measurement protocol:

(1) Use the precision testing procedure specified in §1090.1365(b) to show that your standard deviation for tests using the reference test method is at or below 0.3 times the reproducibility for a given fuel parameter.

(2) You must correlate your test results for a given fuel parameter against the accepted reference values from a monthly crosscheck program based on Section 6.2.2.1 and Note 7 of ASTM D6299 (incorporated by reference in §1090.95) as follows:

(i) If there are multiple fuels available from the crosscheck program, select the fuel that has the closest value to the standard. If there is no standard for a given fuel parameter, select the fuel with values for the fuel parameter that best represent typical values for fuels you test.

(ii) Measure the fuel parameter for the crosscheck fuel at your laboratory using the appropriate referee procedure. Calculate a mean value that includes all your repeat measurements.

(iii) Determine the mean value from the crosscheck program and calculate the difference between this value and the mean value from your testing. Express this difference as a certain number of standard deviations relative to the data set from the crosscheck program.

(iv) The calculated monthly difference between the mean values from §1090.1365(c)(3)(ii) for 5 consecutive months must fall within the central 50 percent of the distribution of data at least 3 times. The central 50 percent of the distribution corresponds to 0.68 standard deviations.

(v) Calculate the mean value of the differences from §1090.1365(c)(3)(ii) for all 5 months. This mean value must fall within the central 50 percent of the distribution of data from the crosscheck program. For example, if the difference was 0.5 standard deviations for two months, 0.6 for one month, and 0.7 for two months, the mean value of the difference is 0.6 standards deviations, and the reference installation meets the requirements of this paragraph.

(3) You must demonstrate that the reference installation is in statistical quality control for at least 5 months with the designated procedure as specified in ASTM D6299. If at any point the reference installation is not in statistical quality control, you must make any necessary changes and restart testing toward meeting the requirement to achieve statistical quality control for at least 5 months, except as follows:

(i) Do not consider measurements you perform as part of regular maintenance or recalibration for evaluating statistical quality control.

(ii) If you find that the reference installation is not in statistical quality control during an initial 5-month period and you are able to identify the problem and make the necessary changes to again achieve statistical quality control before the end of the 5-month demonstration period, you may consider the reference installation as meeting the requirement to be in statistical quality control for at least 5 months.

[85 FR 78469, Dec. 4, 2020]

§1090.1375 Quality control procedures.

This section specifies ongoing quality testing requirements as part of the Performance-based Measurement System specified in §1090.1360.

(a) General provisions. You must perform testing to show that your laboratory meets specified precision and accuracy criteria as follows:

(1) The testing requirement applies for the referee procedures in §1090.1360(d) and for alternate procedures that are qualified or approved under §1090.1365. The testing requirements apply separately for each test instrument at each laboratory.

(2) If you fail to conduct specified testing, your test instrument is not qualified for measuring fuel parameters to demonstrate compliance with the standards and other specifications of this part until you perform this testing. Similarly, if your test instrument fails to meet the specified criteria, it is not qualified for measuring fuel parameters to demonstrate compliance with the standards and other specifications of this part until you make the necessary changes to your test instrument and perform testing to show that the test instrument again meets the specified criteria.

(3) If you perform major maintenance such as overhauling an instrument, confirm that the instrument still meets precision and accuracy criteria before you start testing again based on the procedures specified in ASTM D6299 (incorporated by reference in §1090.95).

(4) Keep records to document your testing under this section for 5 years.

(b) Precision demonstration. Show that you meet precision criteria as follows:

(1) Meeting the precision criteria of this paragraph (b) qualifies your test instrument for performing up to 20 tests or 7 days, whichever is less. Include all tests except for testing to meet precision or accuracy requirements.

(2) Perform precision testing using the control-chart procedures in ASTM D6299. If you opt to use procedure 2A (Q-Procedure) or 2B (dynamically updated exponentially weighted moving average), validate the first run on the new QC batch by either an overlap in-control result of the old batch, or by a single execution of an accompanying standard reference material. The new QC material result would be considered validated if the single result of the standard reference material is within the established site precision (R') of the ARV of the standard reference material.

(3) Use I charts and MR charts as specified in ASTM D6299 to show that the standard deviation for the test instrument meets the precision criteria specified in §1090.1365(b).

(c) Accuracy demonstration. For absolute fuel parameters (VCSB and non-VCSB) and for method-defined fuel parameters using non-VCSB methods, you must show that you meet accuracy criteria as specified in this paragraph (c). For method-defined VCSB procedures, you may meet accuracy requirements as specified in this paragraph (c) or by comparing your results to the accepted reference value in an inter-laboratory crosscheck program sponsored by ASTM International or another VCSB at least 3 times per year.

(1) Meeting the accuracy criteria of this paragraph (c) qualifies your test instrument for 130 days.

(2) Except as specified in paragraph (c)(3) of this section, test every instrument using a check standard meeting the specifications of ASTM D6299. Select a fuel sample with an ARV that is at or slightly below the standard that applies. If there are both average and batch standards, use the average standard. If there is no standard, select a fuel sample representing fuel that is typical for your testing.

(3) The following provisions apply for method-defined non-VCSB alternative procedures with high sensitivity to sample-specific bias:

(i) Procedures have high sensitivity if the closeness sum of squares (CSS) statistic exceeds the 95th percentile value, as specified in ASTM D6708 (incorporated by reference in §1090.95).

(ii) Create a check standard from production fuel representing the fuel you will routinely analyze. Determine the ARV of your check standard using the protocol in ASTM D6299 at a reference installation as specified in §1090.1370.

(iii) You must send EPA a fuel sample from every twentieth batch of gasoline or diesel fuel and identify the procedures and corresponding test results from your testing. EPA may return one of your samples to you for further testing; if this occurs, you must repeat your measurement and report your results within 180 days of receiving the fuel sample.

(4) You meet accuracy requirements under this section if the difference between your measured value for the check standard and the ARV is less than the value from the following equation:

Where:

Δmax = Maximum allowable difference.

R = Reproducibility of the referee procedure identified in §1090.1360(d), as noted in Table 1 to paragraph (b)(3) of §1090.1365 or in the following table:

| Tested product | Referee procedure 1 | Reproducibility (R) 2 |

|---|---|---|

| 1 ASTM specifications are incorporated by reference, see §1090.95. | ||

| 2 Calculate reproducibility using the average value determined from testing. Use units as specified in §1090.1350(c). | ||

| ULSD, 500 ppm diesel fuel, ECA marine fuel, diesel fuel additive, gasoline, gasoline regulated blendstock, and gasoline additive | ASTM D2622 | R = 0.4273 · x 0.8015 |

| Butane | ASTM D6667 | R = 0.3130 · x |

L = the total number of test results used to determine the ARV of a consensus-named fuel. For testing locally named fuels for which no consensus-based ARV applies, use L = ∞.

[85 FR 78469, Dec. 4, 2020]

§1090.1390 Requirement for Automated Detergent Blending Equipment Calibration.

(a) An automated detergent blending facility must calibrate their automated detergent blending equipment once in each calendar half-year, with the acceptable calibrations being no less than 120 days apart.

(b) Equipment recalibration is also required each time the detergent package is changed, unless written documentation indicates that the new detergent package has the same viscosity as the previous detergent package. Calibrating after changing the detergent package may be used to satisfy the semiannual recalibration requirement in paragraph (a) of this section, provided that the calibrations occur in the appropriate calendar half-year and are no less than 120 days apart.

[85 FR 78469, Dec. 4, 2020]

§1090.1395 Gasoline deposit control test procedures.

A gasoline detergent manufacturer must perform testing using one of the methods specified in this section to establish the lowest additive concentration (LAC) for the detergent.

(a) Top Tier-Based Test Method. Use the procedures specified in ASTM D6201 (incorporated by reference in §1090.95), as follows:

(1) Use a base fuel that conforms to the specifications for gasoline-alcohol blends in ASTM D4814 (incorporated by reference in §1090.95). Blendstocks used to formulate the test fuel must be derived from conversion units downstream of distillation, with all processes representing normal fuel manufacturing facility operations. Blendstocks must not come from chemical grade streams. Butane and pentane may be added to adjust vapor pressure. The base fuel should include any nondetergent additives typical of commercially available fuel if they may positively or negatively affect deposit formation. In addition, the base fuel must have the following properties:

(i) 8.0-10.0 volume percent DFE that meets the requirements in §1090.270 and conforms to the specifications of ASTM D4806 (incorporated by reference in §1090.95).

(ii) At least 8.0 volume percent olefins.

(iii) At least 15 volume percent aromatics.

(iv) No more than 80 ppm sulfur.

(v) T90 distillation temperature at or above 143 °C.

(vi) No detergent-active substance. A base fuel with typical nondetergent additives, such as antioxidants, corrosion inhibitors, and metal deactivators, may be used.

(2) Perform the 100-hour test for intake valve deposits with the base fuel to demonstrate that the intake valves accumulate at least 500 mg on average. If the test engine fails to accumulate enough deposits, make any necessary adjustments and repeat the test. This demonstration is valid for any further detergent testing with the same base fuel.

(3) Repeat the test on the same engine with a specific concentration of detergent added to the base fuel. If the test results in less than 50 mg average per intake valve, the tested detergent concentration is the LAC for the detergent.

(b) CARB Test Method. Use the procedures specified by CARB in Title 13, California Code of Regulations, section 2257 (incorporated by reference in §1090.95).

(1) A detergent tested under this option or certified under 40 CFR 80.163(d) prior to January 21, 2021, may be used at the LAC specified for use in the state of California in any gasoline in the United States.

(2) The gasoline detergent manufacturer must cease selling a detergent immediately upon being notified by CARB that the CARB certification for this detergent has been invalidated and must notify EPA under 40 CFR 79.21.

(c) EPA BMW method. Use the procedures specified in ASTM D5500 (incorporated by reference in §1090.95), as follows:

(1) Prepare the test fuel with the following specification:

(i) Sulfur—minimum 340 ppm.

(ii) T90—minimum 171 °C.

(iii) Olefins—minimum 11.4 volume percent.

(iv) Aromatics—minimum 31.1 volume percent.

(v) Ethanol—minimum 10 volume percent.

(vi) Sulfur, T90, olefins, and aromatics specifications must be met before adding ethanol.

(vii) Di-tert-butyl disulfide may be added to the test fuel.

(2) The duration of testing may be less than 10,000 miles. Measured deposits must meet the following specified values to qualify the test fuel and establish a detergent's LAC:

(i) Measured deposits for the fuel without detergent must be at least 290 mg per valve on average.

(ii) Measured deposits for the fuel with detergent must be less than 100 mg per valve on average.

(d) Alternative test methods. (1) An EPA-approved alternative test method may be used if the alternative test method can be correlated to any of the methods specified in paragraphs (a) through (c) of this section.

(2) Information describing the alternative test method and analysis demonstrating correlation must be submitted for EPA approval as specified in §1090.10.

[85 FR 78469, Dec. 4, 2020]

[85 FR 78469, Dec. 4, 2020]

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.