['Air Programs']

['Hazardous Air Pollutants']

02/25/2022

...

Authority: 42 U.S.C. 7401, 7412, 7414, 7416, 7601.

§61.140 Applicability.

The provisions of this subpart are applicable to those sources specified in §§61.142 through 61.151, 61.154, and 61.155.

[55 FR 48414, Nov. 20, 1990]

§61.141 Definitions.

All terms that are used in this subpart and are not defined below are given the same meaning as in the Act and in subpart A of this part.

Active waste disposal site means any disposal site other than an inactive site.

Adequately wet means sufficiently mix or penetrate with liquid to prevent the release of particulates. If visible emissions are observed coming from asbestos-containing material, then that material has not been adequately wetted. However, the absence of visible emissions is not sufficient evidence of being adequately wet.

Asbestos means the asbestiform varieties of serpentinite (chrysotile), riebeckite (crocidolite), cummingtonite-grunerite, anthophyllite, and actinolite-tremolite.

Asbestos-containing waste materials means mill tailings or any waste that contains commercial asbestos and is generated by a source subject to the provisions of this subpart. This term includes filters from control devices, friable asbestos waste material, and bags or other similar packaging contaminated with commercial asbestos. As applied to demolition and renovation operations, this term also includes regulated asbestos-containing material waste and materials contaminated with asbestos including disposable equipment and clothing.

Asbestos mill means any facility engaged in converting, or in any intermediate step in converting, asbestos ore into commercial asbestos. Outside storage of asbestos material is not considered a part of the asbestos mill.

Asbestos tailings means any solid waste that contains asbestos and is a product of asbestos mining or milling operations.

Asbestos waste from control devices means any waste material that contains asbestos and is collected by a pollution control device.

Category I nonfriable asbestos-containing material (ACM) means asbestos-containing packings, gaskets, resilient floor covering, and asphalt roofing products containing more than 1 percent asbestos as determined using the method specified in appendix E, subpart E, 40 CFR part 763, section 1, Polarized Light Microscopy.

Category II nonfriable ACM means any material, excluding Category I nonfriable ACM, containing more than 1 percent asbestos as determined using the methods specified in appendix E, subpart E, 40 CFR part 763, section 1, Polarized Light Microscopy that, when dry, cannot be crumbled, pulverized, or reduced to powder by hand pressure.

Commercial asbestos means any material containing asbestos that is extracted from ore and has value because of its asbestos content.

Cutting means to penetrate with a sharp-edged instrument and includes sawing, but does not include shearing, slicing, or punching.

Demolition means the wrecking or taking out of any load-supporting structural member of a facility together with any related handling operations or the intentional burning of any facility.

Emergency renovation operation means a renovation operation that was not planned but results from a sudden, unexpected event that, if not immediately attended to, presents a safety or public health hazard, is necessary to protect equipment from damage, or is necessary to avoid imposing an unreasonable financial burden. This term includes operations necessitated by nonroutine failures of equipment.

Fabricating means any processing (e.g., cutting, sawing, drilling) of a manufactured product that contains commercial asbestos, with the exception of processing at temporary sites (field fabricating) for the construction or restoration of facilities. In the case of friction products, fabricating includes bonding, debonding, grinding, sawing, drilling, or other similar operations performed as part of fabricating.

Facility means any institutional, commercial, public, industrial, or residential structure, installation, or building (including any structure, installation, or building containing condominiums or individual dwelling units operated as a residential cooperative, but excluding residential buildings having four or fewer dwelling units); any ship; and any active or inactive waste disposal site. For purposes of this definition, any building, structure, or installation that contains a loft used as a dwelling is not considered a residential structure, installation, or building. Any structure, installation or building that was previously subject to this subpart is not excluded, regardless of its current use or function.

Facility component means any part of a facility including equipment.

Friable asbestos material means any material containing more than 1 percent asbestos as determined using the method specified in appendix E, subpart E, 40 CFR part 763, section 1, Polarized Light Microscopy, that, when dry, can be crumbled, pulverized, or reduced to powder by hand pressure. If the asbestos content is less than 10 percent as determined by a method other than point counting by polarized light microscopy (PLM), verify the asbestos content by point counting using PLM.

Fugitive source means any source of emissions not controlled by an air pollution control device.

Glove bag means a sealed compartment with attached inner gloves used for the handling of asbestos-containing materials. Properly installed and used, glove bags provide a small work area enclosure typically used for small-scale asbestos stripping operations. Information on glove-bag installation, equipment and supplies, and work practices is contained in the Occupational Safety and Health Administration's (OSHA's) final rule on occupational exposure to asbestos (appendix G to 29 CFR 1926.58).

Grinding means to reduce to powder or small fragments and includes mechanical chipping or drilling.

In poor condition means the binding of the material is losing its integrity as indicated by peeling, cracking, or crumbling of the material.

Inactive waste disposal site means any disposal site or portion of it where additional asbestos-containing waste material has not been deposited within the past year.

Installation means any building or structure or any group of buildings or structures at a single demolition or renovation site that are under the control of the same owner or operator (or owner or operator under common control).

Leak-tight means that solids or liquids cannot escape or spill out. It also means dust-tight.

Malfunction means any sudden and unavoidable failure of air pollution control equipment or process equipment or of a process to operate in a normal or usual manner so that emissions of asbestos are increased. Failures of equipment shall not be considered malfunctions if they are caused in any way by poor maintenance, careless operation, or any other preventable upset conditions, equipment breakdown, or process failure.

Manufacturing means the combining of commercial asbestos - or, in the case of woven friction products, the combining of textiles containing commercial asbestos - with any other material(s), including commercial asbestos, and the processing of this combination into a product. Chlorine production is considered a part of manufacturing.

Natural barrier means a natural object that effectively precludes or deters access. Natural barriers include physical obstacles such as cliffs, lakes or other large bodies of water, deep and wide ravines, and mountains. Remoteness by itself is not a natural barrier.

Nonfriable asbestos-containing material means any material containing more than 1 percent asbestos as determined using the method specified in appendix E, subpart E, 40 CFR part 763, section 1, Polarized Light Microscopy, that, when dry, cannot be crumbled, pulverized, or reduced to powder by hand pressure.

Nonscheduled renovation operation means a renovation operation necessitated by the routine failure of equipment, which is expected to occur within a given period based on past operating experience, but for which an exact date cannot be predicted.

Outside air means the air outside buildings and structures, including, but not limited to, the air under a bridge or in an open air ferry dock.

Owner or operator of a demolition or renovation activity means any person who owns, leases, operates, controls, or supervises the facility being demolished or renovated or any person who owns, leases, operates, controls, or supervises the demolition or renovation operation, or both.

Particulate asbestos material means finely divided particles of asbestos or material containing asbestos.

Planned renovation operations means a renovation operation, or a number of such operations, in which some RACM will be removed or stripped within a given period of time and that can be predicted. Individual nonscheduled operations are included if a number of such operations can be predicted to occur during a given period of time based on operating experience.

Regulated asbestos-containing material (RACM) means (a) Friable asbestos material, (b) Category I nonfriable ACM that has become friable, (c) Category I nonfriable ACM that will be or has been subjected to sanding, grinding, cutting, or abrading, or (d) Category II nonfriable ACM that has a high probability of becoming or has become crumbled, pulverized, or reduced to powder by the forces expected to act on the material in the course of demolition or renovation operations regulated by this subpart.

Remove means to take out RACM or facility components that contain or are covered with RACM from any facility.

Renovation means altering a facility or one or more facility components in any way, including the stripping or removal of RACM from a facility component. Operations in which load-supporting structural members are wrecked or taken out are demolitions.

Resilient floor covering means asbestos-containing floor tile, including asphalt and vinyl floor tile, and sheet vinyl floor covering containing more than 1 percent asbestos as determined using polarized light microscopy according to the method specified in appendix E, subpart E, 40 CFR part 763, section 1, Polarized Light Microscopy.

Roadways means surfaces on which vehicles travel. This term includes public and private highways, roads, streets, parking areas, and driveways.

Strip means to take off RACM from any part of a facility or facility components.

Structural member means any load-supporting member of a facility, such as beams and load supporting walls; or any nonload-supporting member, such as ceilings and nonload-supporting walls.

Visible emissions means any emissions, which are visually detectable without the aid of instruments, coming from RACM or asbestos-containing waste material, or from any asbestos milling, manufacturing, or fabricating operation. This does not include condensed, uncombined water vapor.

Waste generator means any owner or operator of a source covered by this subpart whose act or process produces asbestos-containing waste material.

Waste shipment record means the shipping document, required to be originated and signed by the waste generator, used to track and substantiate the disposition of asbestos-containing waste material.

Working day means Monday through Friday and includes holidays that fall on any of the days Monday through Friday.

[49 FR 13661, Apr. 5, 1984; 49 FR 25453, June 21, 1984, as amended by 55 FR 48414, Nov. 20, 1990; 56 FR 1669, Jan. 16, 1991; 60 FR 31920, June 19, 1995]

§61.142 Standard for asbestos mills.

(a) Each owner or operator of an asbestos mill shall either discharge no visible emissions to the outside air from that asbestos mill, including fugitive sources, or use the methods specified by §61.152 to clean emissions containing particulate asbestos material before they escape to, or are vented to, the outside air.

(b) Each owner or operator of an asbestos mill shall meet the following requirements:

(1) Monitor each potential source of asbestos emissions from any part of the mill facility, including air cleaning devices, process equipment, and buildings that house equipment for material processing and handling, at least once each day, during daylight hours, for visible emissions to the outside air during periods of operation. The monitoring shall be by visual observation of at least 15 seconds duration per source of emissions.

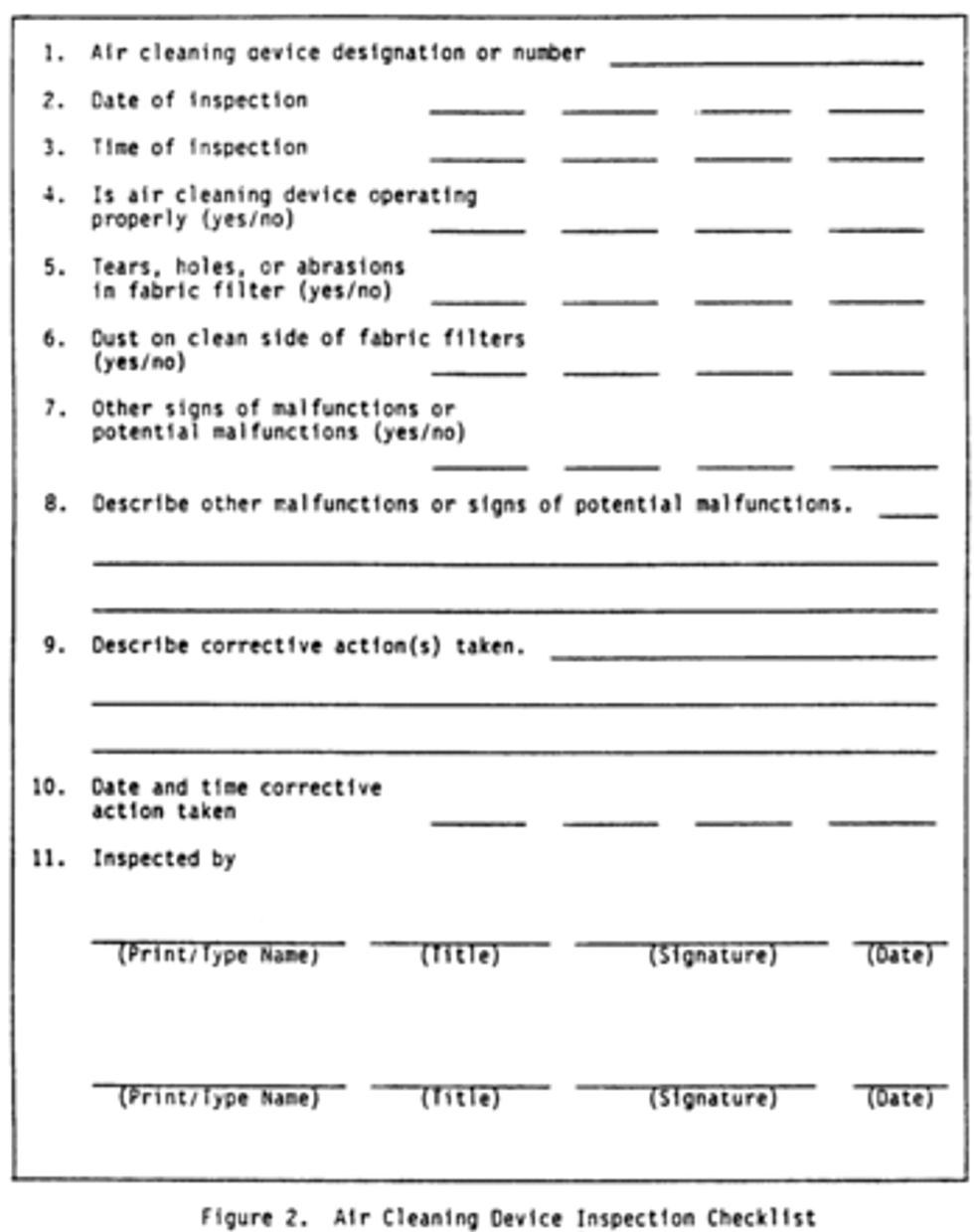

(2) Inspect each air cleaning device at least once each week for proper operation and for changes that signal the potential for malfunction, including, to the maximum extent possible without dismantling other than opening the device, the presence of tears, holes, and abrasions in filter bags and for dust deposits on the clean side of bags. For air cleaning devices that cannot be inspected on a weekly basis according to this paragraph, submit to the Administrator, and revise as necessary, a written maintenance plan to include, at a minimum, the following:

(i) Maintenance schedule.

(ii) Recordkeeping plan.

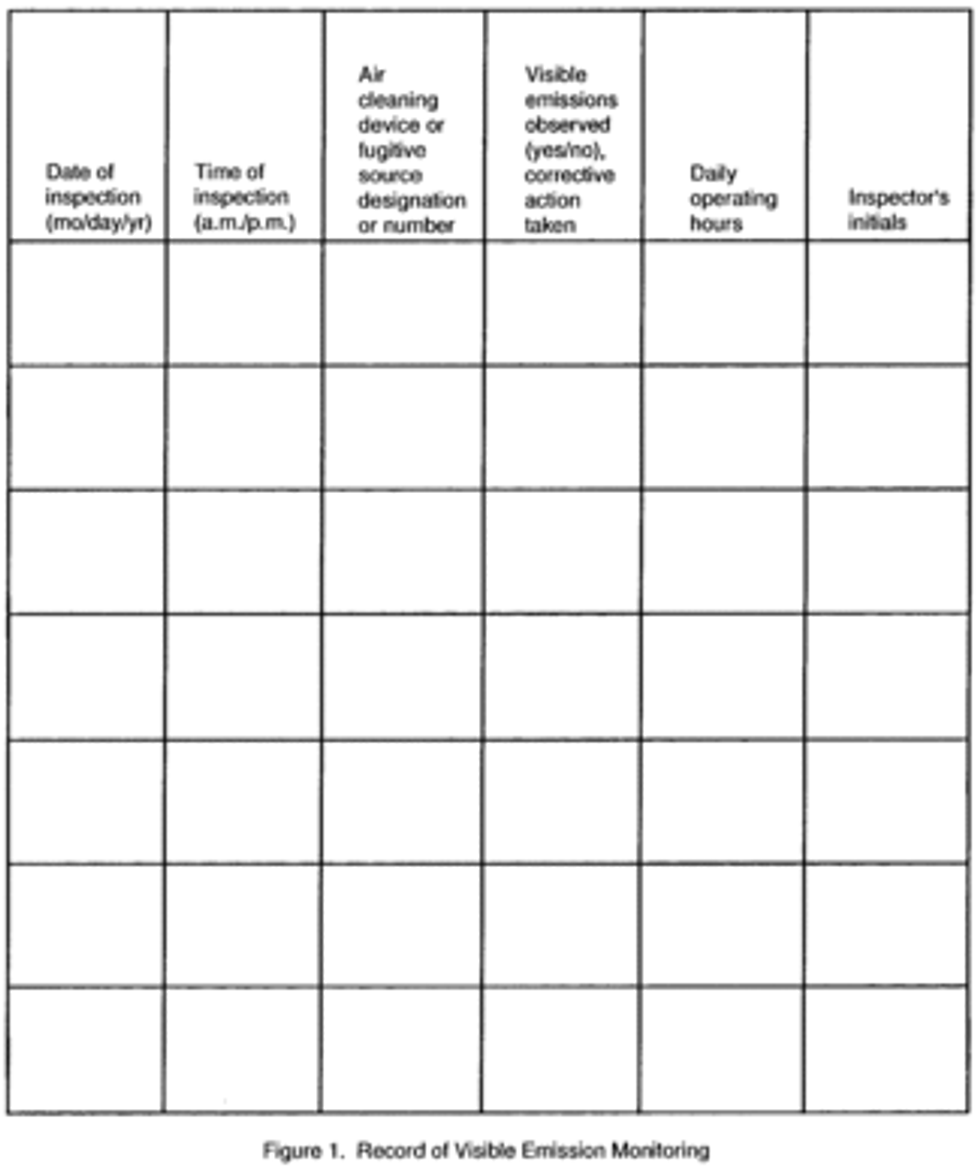

(3) Maintain records of the results of visible emissions monitoring and air cleaning device inspections using a format similar to that shown in Figures 1 and 2 and include the following:

(i) Date and time of each inspection.

(ii) Presence or absence of visible emissions.

(iii) Condition of fabric filters, including presence of any tears, holes, and abrasions.

(iv) Presence of dust deposits on clean side of fabric filters.

(v) Brief description of corrective actions taken, including date and time.

(vi) Daily hours of operation for each air cleaning device.

(4) Furnish upon request, and make available at the affected facility during normal business hours for inspection by the Administrator, all records required under this section.

(5) Retain a copy of all monitoring and inspection records for at least 2 years.

(6) Submit semiannually a copy of visible emission monitoring records to the Administrator if visible emissions occurred during the report period. Semiannual reports shall be postmarked by the 30th day following the end of the six-month period.

[55 FR 48416, Nov. 20, 1990, as amended at 64 FR 7467, Feb. 12, 1999]

§61.143 Standard for roadways.

No person may construct or maintain a roadway with asbestos tailings or asbestos-containing waste material on that roadway, unless, for asbestos tailings.

(a) It is a temporary roadway on an area of asbestos ore deposits (asbestos mine): or

(b) It is a temporary roadway at an active asbestos mill site and is encapsulated with a resinous or bituminous binder. The encapsulated road surface must be maintained at a minimum frequency of once per year to prevent dust emissions; or

(c) It is encapsulated in asphalt concrete meeting the specifications contained in section 401 of Standard Specifications for Construction of Roads and Bridges on Federal Highway Projects, FP-85, 1985, or their equivalent.

[55 FR 48419, Nov. 20, 1990; 56 FR 1669, Jan. 16, 1991]

§61.144 Standard for manufacturing.

(a) Applicability. This section applies to the following manufacturing operations using commercial asbestos.

(1) The manufacture of cloth, cord, wicks, tubing, tape, twine, rope, thread, yarn, roving, lap, or other textile materials.

(2) The manufacture of cement products.

(3) The manufacture of fireproofing and insulating materials.

(4) The manufacture of friction products.

(5) The manufacture of paper, millboard, and felt.

(6) The manufacture of floor tile.

(7) The manufacture of paints, coatings, caulks, adhesives, and sealants.

(8) The manufacture of plastics and rubber materials.

(9) The manufacture of chlorine utilizing asbestos diaphragm technology.

(10) The manufacture of shotgun shell wads.

(11) The manufacture of asphalt concrete.

(b) Standard. Each owner or operator of any of the manufacturing operations to which this section applies shall either:

(1) Discharge no visible emissions to the outside air from these operations or from any building or structure in which they are conducted or from any other fugitive sources; or

(2) Use the methods specified by §61.152 to clean emissions from these operations containing particulate asbestos material before they escape to, or are vented to, the outside air.

(3) Monitor each potential source of asbestos emissions from any part of the manufacturing facility, including air cleaning devices, process equipment, and buildings housing material processing and handling equipment, at least once each day during daylight hours for visible emissions to the outside air during periods of operation. The monitoring shall be by visual observation of at least 15 seconds duration per source of emissions.

(4) Inspect each air cleaning device at least once each week for proper operation and for changes that signal the potential for malfunctions, including, to the maximum extent possible without dismantling other than opening the device, the presence of tears, holes, and abrasions in filter bags and for dust deposits on the clean side of bags. For air cleaning devices that cannot be inspected on a weekly basis according to this paragraph, submit to the Administrator, and revise as necessary, a written maintenance plan to include, at a minimum, the following:

(i) Maintenance schedule.

(ii) Recordkeeping plan.

(5) Maintain records of the results of visible emission monitoring and air cleaning device inspections using a format similar to that shown in Figures 1 and 2 and include the following.

(i) Date and time of each inspection.

(ii) Presence or absence of visible emissions.

(iii) Condition of fabric filters, including presence of any tears, holes and abrasions.

(iv) Presence of dust deposits on clean side of fabric filters.

(v) Brief description of corrective actions taken, including date and time.

(vi) Daily hours of operation for each air cleaning device.

(6) Furnish upon request, and make available at the affected facility during normal business hours for inspection by the Administrator, all records required under this section.

(7) Retain a copy of all monitoring and inspection records for at least 2 years.

(8) Submit semiannually a copy of the visible emission monitoring records to the Administrator if visible emission occurred during the report period. Semiannual reports shall be postmarked by the 30th day following the end of the six-month period.

[49 FR 13661, Apr. 5, 1984, as amended at 55 FR 48419, Nov. 20, 1990; 56 FR 1669, Jan. 16, 1991; 64 FR 7467, Feb. 12, 1999]

§61.145 Standard for demolition and renovation.

(a) Applicability. To determine which requirements of paragraphs (a), (b), and (c) of this section apply to the owner or operator of a demolition or renovation activity and prior to the commencement of the demolition or renovation, thoroughly inspect the affected facility or part of the facility where the demolition or renovation operation will occur for the presence of asbestos, including Category I and Category II nonfriable ACM. The requirements of paragraphs (b) and (c) of this section apply to each owner or operator of a demolition or renovation activity, including the removal of RACM as follows:

(1) In a facility being demolished, all the requirements of paragraphs (b) and (c) of this section apply, except as provided in paragraph (a)(3) of this section, if the combined amount of RACM is

(i) At least 80 linear meters (260 linear feet) on pipes or at least 15 square meters (160 square feet) on other facility components, or

(ii) At least 1 cubic meter (35 cubic feet) off facility components where the length or area could not be measured previously.

(2) In a facility being demolished, only the notification requirements of paragraphs (b)(1), (2), (3)(i) and (iv), and (4)(i) through (vii) and (4)(ix) and (xvi) of this section apply, if the combined amount of RACM is

(i) Less than 80 linear meters (260 linear feet) on pipes and less than 15 square meters (160 square feet) on other facility components, and

(ii) Less than one cubic meter (35 cubic feet) off facility components where the length or area could not be measured previously or there is no asbestos.

(3) If the facility is being demolished under an order of a State or local government agency, issued because the facility is structurally unsound and in danger of imminent collapse, only the requirements of paragraphs (b)(1), (b)(2), (b)(3)(iii), (b)(4) (except (b)(4)(viii)), (b)(5), and (c)(4) through (c)(9) of this section apply.

(4) In a facility being renovated, including any individual nonscheduled renovation operation, all the requirements of paragraphs (b) and (c) of this section apply if the combined amount of RACM to be stripped, removed, dislodged, cut, drilled, or similarly disturbed is

(i) At least 80 linear meters (260 linear feet) on pipes or at least 15 square meters (160 square feet) on other facility components, or

(ii) At least 1 cubic meter (35 cubic feet) off facility components where the length or area could not be measured previously.

(iii) To determine whether paragraph (a)(4) of this section applies to planned renovation operations involving individual nonscheduled operations, predict the combined additive amount of RACM to be removed or stripped during a calendar year of January 1 through December 31.

(iv) To determine whether paragraph (a)(4) of this section applies to emergency renovation operations, estimate the combined amount of RACM to be removed or stripped as a result of the sudden, unexpected event that necessitated the renovation.

(5) Owners or operators of demolition and renovation operations are exempt from the requirements of §§61.05(a), 61.07, and 61.09.

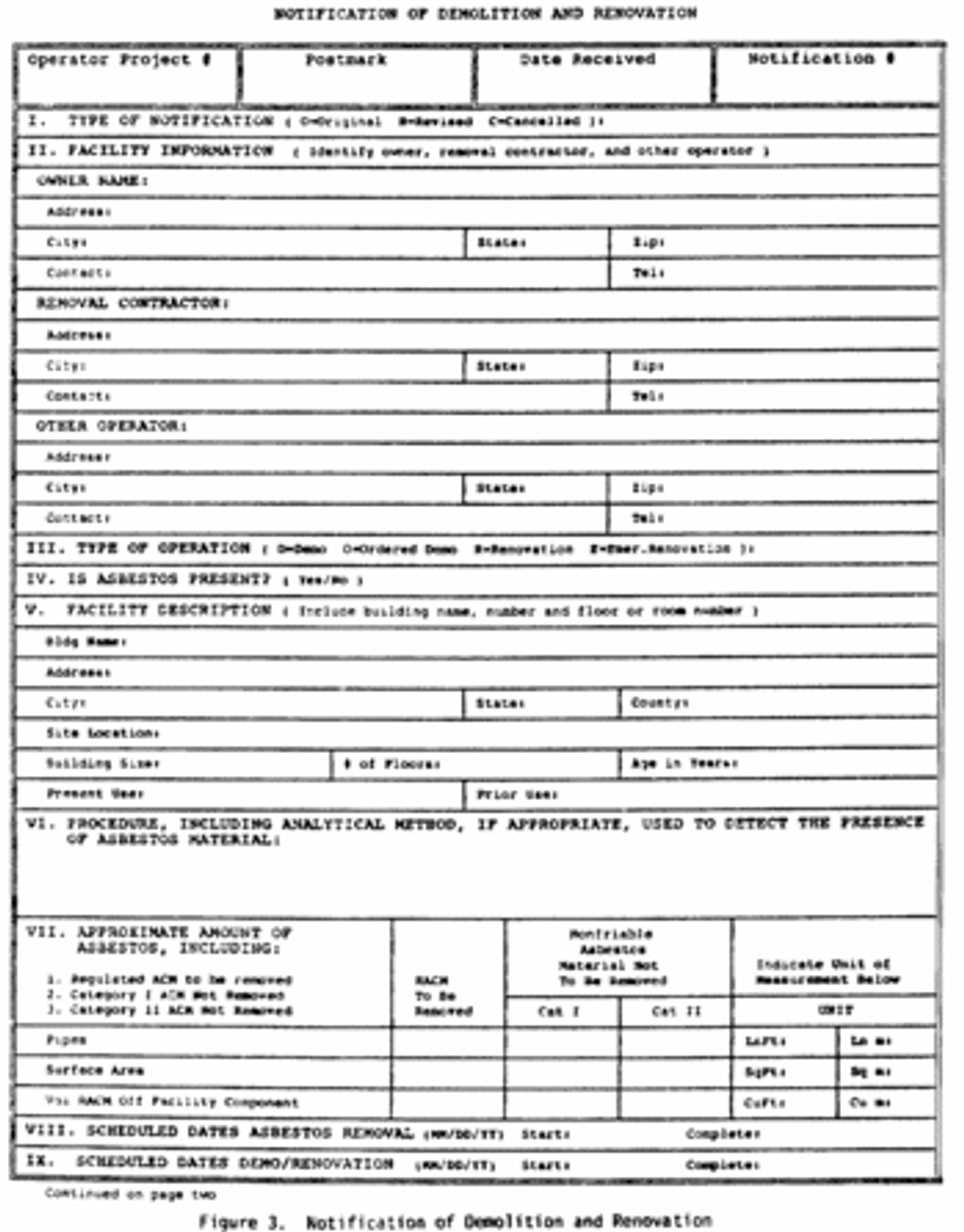

(b) Notification requirements. Each owner or operator of a demolition or renovation activity to which this section applies shall:

(1) Provide the Administrator with written notice of intention to demolish or renovate. Delivery of the notice by U.S. Postal Service, commercial delivery service, or hand delivery is acceptable.

(2) Update notice, as necessary, including when the amount of asbestos affected changes by at least 20 percent.

(3) Postmark or deliver the notice as follows:

(i) At least 10 working days before asbestos stripping or removal work or any other activity begins (such as site preparation that would break up, dislodge or similarly disturb asbestos material), if the operation is described in paragraphs (a) (1) and (4) (except (a)(4)(iii) and (a)(4)(iv)) of this section. If the operation is as described in paragraph (a)(2) of this section, notification is required 10 working days before demolition begins.

(ii) At least 10 working days before the end of the calendar year preceding the year for which notice is being given for renovations described in paragraph (a)(4)(iii) of this section.

(iii) As early as possible before, but not later than, the following working day if the operation is a demolition ordered according to paragraph (a)(3) of this section or, if the operation is a renovation described in paragraph (a)(4)(iv) of this section.

(iv) For asbestos stripping or removal work in a demolition or renovation operation, described in paragraphs (a) (1) and (4) (except (a)(4)(iii) and (a)(4)(iv)) of this section, and for a demolition described in paragraph (a)(2) of this section, that will begin on a date other than the one contained in the original notice, notice of the new start date must be provided to the Administrator as follows:

(A) When the asbestos stripping or removal operation or demolition operation covered by this paragraph will begin after the date contained in the notice,

(1) Notify the Administrator of the new start date by telephone as soon as possible before the original start date, and

(2) Provide the Administrator with a written notice of the new start date as soon as possible before, and no later than, the original start date. Delivery of the updated notice by the U.S. Postal Service, commercial delivery service, or hand delivery is acceptable.

(B) When the asbestos stripping or removal operation or demolition operation covered by this paragraph will begin on a date earlier than the original start date,

(1) Provide the Administrator with a written notice of the new start date at least 10 working days before asbestos stripping or removal work begins.

(2) For demolitions covered by paragraph (a)(2) of this section, provide the Administrator written notice of a new start date at least 10 working days before commencement of demolition. Delivery of updated notice by U.S. Postal Service, commercial delivery service, or hand delivery is acceptable.

(C) In no event shall an operation covered by this paragraph begin on a date other than the date contained in the written notice of the new start date.

(4) Include the following in the notice:

(i) An indication of whether the notice is the original or a revised notification.

(ii) Name, address, and telephone number of both the facility owner and operator and the asbestos removal contractor owner or operator.

(iii) Type of operation: demolition or renovation.

(iv) Description of the facility or affected part of the facility including the size (square meters [square feet] and number of floors), age, and present and prior use of the facility.

(v) Procedure, including analytical methods, employed to detect the presence of RACM and Category I and Category II nonfriable ACM.

(vi) Estimate of the approximate amount of RACM to be removed from the facility in terms of length of pipe in linear meters (linear feet), surface area in square meters (square feet) on other facility components, or volume in cubic meters (cubic feet) if off the facility components. Also, estimate the approximate amount of Category I and Category II nonfriable ACM in the affected part of the facility that will not be removed before demolition.

(vii) Location and street address (including building number or name and floor or room number, if appropriate), city, county, and state, of the facility being demolished or renovated.

(viii) Scheduled starting and completion dates of asbestos removal work (or any other activity, such as site preparation that would break up, dislodge, or similarly disturb asbestos material) in a demolition or renovation; planned renovation operations involving individual nonscheduled operations shall only include the beginning and ending dates of the report period as described in paragraph (a)(4)(iii) of this section.

(ix) Scheduled starting and completion dates of demolition or renovation.

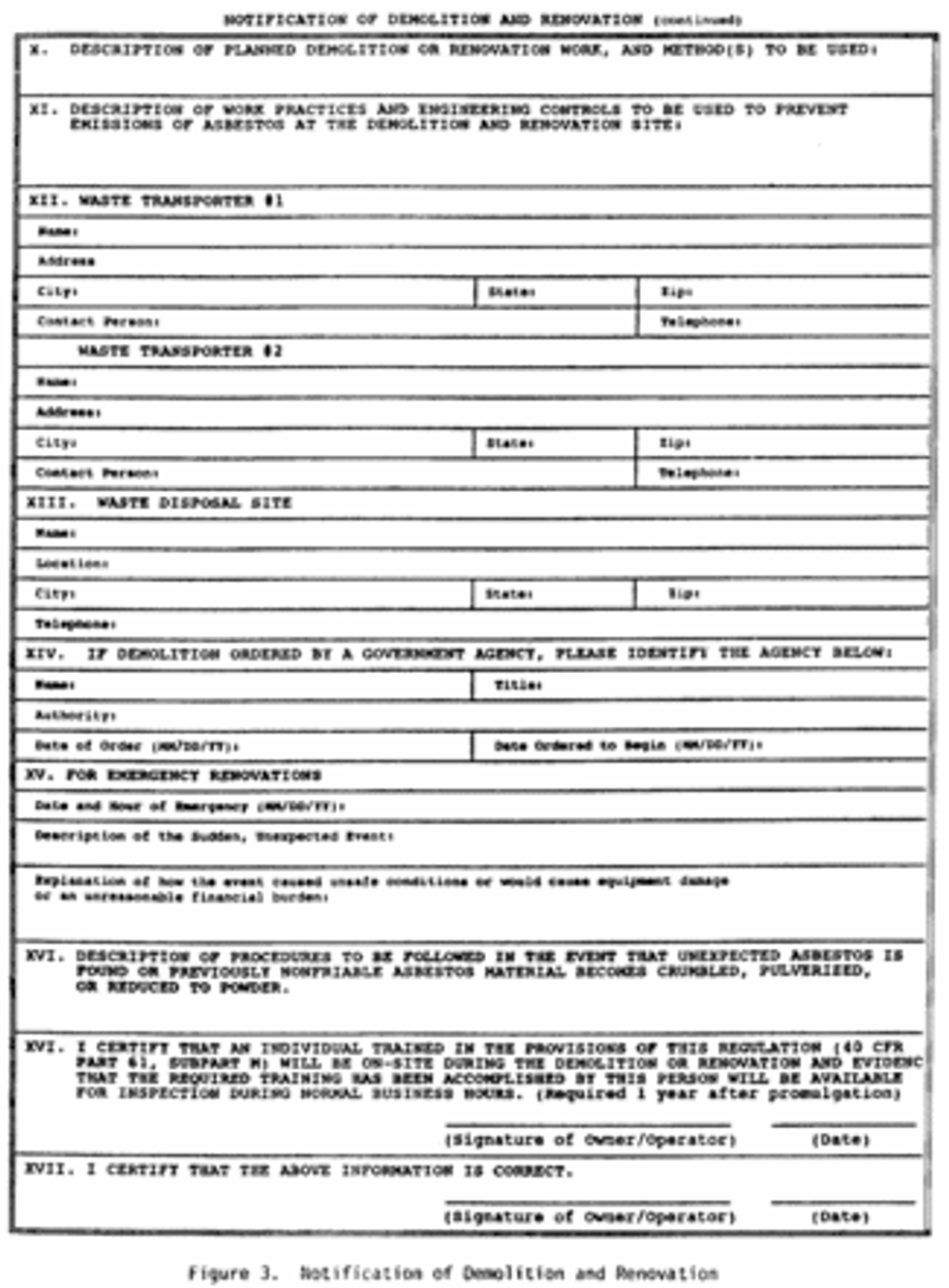

(x) Description of planned demolition or renovation work to be performed and method(s) to be employed, including demolition or renovation techniques to be used and description of affected facility components.

(xi) Description of work practices and engineering controls to be used to comply with the requirements of this subpart, including asbestos removal and waste-handling emission control procedures.

(xii) Name and location of the waste disposal site where the asbestos-containing waste material will be deposited.

(xiii) A certification that at least one person trained as required by paragraph (c)(8) of this section will supervise the stripping and removal described by this notification. This requirement shall become effective 1 year after promulgation of this regulation.

(xiv) For facilities described in paragraph (a)(3) of this section, the name, title, and authority of the State or local government representative who has ordered the demolition, the date that the order was issued, and the date on which the demolition was ordered to begin. A copy of the order shall be attached to the notification.

(xv) For emergency renovations described in paragraph (a)(4)(iv) of this section, the date and hour that the emergency occurred, a description of the sudden, unexpected event, and an explanation of how the event caused an unsafe condition, or would cause equipment damage or an unreasonable financial burden.

(xvi) Description of procedures to be followed in the event that unexpected RACM is found or Category II nonfriable ACM becomes crumbled, pulverized, or reduced to powder.

(xvii) Name, address, and telephone number of the waste transporter.

(5) The information required in paragraph (b)(4) of this section must be reported using a form similiar to that shown in Figure 3.

(c) Procedures for asbestos emission control. Each owner or operator of a demolition or renovation activity to whom this paragraph applies, according to paragraph (a) of this section, shall comply with the following procedures:

(1) Remove all RACM from a facility being demolished or renovated before any activity begins that would break up, dislodge, or similarly disturb the material or preclude access to the material for subsequent removal. RACM need not be removed before demolition if:

(i) It is Category I nonfriable ACM that is not in poor condition and is not friable.

(ii) It is on a facility component that is encased in concrete or other similarly hard material and is adequately wet whenever exposed during demolition; or

(iii) It was not accessible for testing and was, therefore, not discovered until after demolition began and, as a result of the demolition, the material cannot be safely removed. If not removed for safety reasons, the exposed RACM and any asbestos-contaminated debris must be treated as asbestos-containing waste material and adequately wet at all times until disposed of.

(iv) They are Category II nonfriable ACM and the probability is low that the materials will become crumbled, pulverized, or reduced to powder during demolition.

(2) When a facility component that contains, is covered with, or is coated with RACM is being taken out of the facility as a unit or in sections:

(i) Adequately wet all RACM exposed during cutting or disjoining operations; and

(ii) Carefully lower each unit or section to the floor and to ground level, not dropping, throwing, sliding, or otherwise damaging or disturbing the RACM.

(3) When RACM is stripped from a facility component while it remains in place in the facility, adequately wet the RACM during the stripping operation.

(i) In renovation operations, wetting is not required if:

(A) The owner or operator has obtained prior written approval from the Administrator based on a written application that wetting to comply with this paragraph would unavoidably damage equipment or present a safety hazard; and

(B) The owner or operator uses of the following emission control methods:

(1) A local exhaust ventilation and collection system designed and operated to capture the particulate asbestos material produced by the stripping and removal of the asbestos materials. The system must exhibit no visible emissions to the outside air or be designed and operated in accordance with the requirements in §61.152.

(2) A glove-bag system designed and operated to contain the particulate asbestos material produced by the stripping of the asbestos materials.

(3) Leak-tight wrapping to contain all RACM prior to dismantlement.

(ii) In renovation operations where wetting would result in equipment damage or a safety hazard, and the methods allowed in paragraph (c)(3)(i) of this section cannot be used, another method may be used after obtaining written approval from the Administrator based upon a determination that it is equivalent to wetting in controlling emissions or to the methods allowed in paragraph (c)(3)(i) of this section.

(iii) A copy of the Administrator's written approval shall be kept at the worksite and made available for inspection.

(4) After a facility component covered with, coated with, or containing RACM has been taken out of the facility as a unit or in sections pursuant to paragraph (c)(2) of this section, it shall be stripped or contained in leak-tight wrapping, except as described in paragraph (c)(5) of this section. If stripped, either:

(i) Adequately wet the RACM during stripping; or

(ii) Use a local exhaust ventilation and collection system designed and operated to capture the particulate asbestos material produced by the stripping. The system must exhibit no visible emissions to the outside air or be designed and operated in accordance with the requirements in §61.152.

(5) For large facility components such as reactor vessels, large tanks, and steam generators, but not beams (which must be handled in accordance with paragraphs (c)(2), (3), and (4) of this section), the RACM is not required to be stripped if the following requirements are met:

(i) The component is removed, transported, stored, disposed of, or reused without disturbing or damaging the RACM.

(ii) The component is encased in a leak-tight wrapping.

(iii) The leak-tight wrapping is labeled according to §61.149(d)(1)(i), (ii), and (iii) during all loading and unloading operations and during storage.

(6) For all RACM, including material that has been removed or stripped:

(i) Adequately wet the material and ensure that it remains wet until collected and contained or treated in preparation for disposal in accordance with §61.150; and

(ii) Carefully lower the material to the ground and floor, not dropping, throwing, sliding, or otherwise damaging or disturbing the material.

(iii) Transport the material to the ground via leak-tight chutes or containers if it has been removed or stripped more than 50 feet above ground level and was not removed as units or in sections.

(iv) RACM contained in leak-tight wrapping that has been removed in accordance with paragraphs (c)(4) and (c)(3)(i)(B)(3) of this section need not be wetted.

(7) When the temperature at the point of wetting is below 0°C (32°F):

(i) The owner or operator need not comply with paragraph (c)(2)(i) and the wetting provisions of paragraph (c)(3) of this section.

(ii) The owner or operator shall remove facility components containing, coated with, or covered with RACM as units or in sections to the maximum extent possible.

(iii) During periods when wetting operations are suspended due to freezing temperatures, the owner or operator must record the temperature in the area containing the facility components at the beginning, middle, and end of each workday and keep daily temperature records available for inspection by the Administrator during normal business hours at the demolition or renovation site. The owner or operator shall retain the temperature records for at least 2 years.

(8) Effective 1 year after promulgation of this regulation, no RACM shall be stripped, removed, or otherwise handled or disturbed at a facility regulated by this section unless at least one on-site representative, such as a foreman or management-level person or other authorized representative, trained in the provisions of this regulation and the means of complying with them, is present. Every 2 years, the trained on-site individual shall receive refresher training in the provisions of this regulation. The required training shall include as a minimum: applicability; notifications; material identification; control procedures for removals including, at least, wetting, local exhaust ventilation, negative pressure enclosures, glove-bag procedures, and High Efficiency Particulate Air (HEPA) filters; waste disposal work practices; reporting and recordkeeping; and asbestos hazards and worker protection. Evidence that the required training has been completed shall be posted and made available for inspection by the Administrator at the demolition or renovation site.

(9) For facilities described in paragraph (a)(3) of this section, adequately wet the portion of the facility that contains RACM during the wrecking operation.

(10) If a facility is demolished by intentional burning, all RACM including Category I and Category II nonfriable ACM must be removed in accordance with the NESHAP before burning.

[55 FR 48419, Nov. 20, 1990; 56 FR 1669, Jan. 16, 1991]

§61.146 Standard for spraying.

The owner or operator of an operation in which asbestos-containing materials are spray applied shall comply with the following requirements:

(a) For spray-on application on buildings, structures, pipes, and conduits, do not use material containing more than 1 percent asbestos as determined using the method specified in appendix E, subpart E, 40 CFR part 763, section 1, Polarized Light Microscopy, except as provided in paragraph (c) of this section.

(b) For spray-on application of materials that contain more than 1 percent asbestos as determined using the method specified in appendix E, subpart E, 40 CFR part 763, section 1, Polarized Light Microscopy, on equipment and machinery, except as provided in paragraph (c) of this section:

(1) Notify the Administrator at least 20 days before beginning the spraying operation. Include the following information in the notice:

(i) Name and address of owner or operator.

(ii) Location of spraying operation.

(iii) Procedures to be followed to meet the requirements of this paragraph.

(2) Discharge no visible emissions to the outside air from spray-on application of the asbestos-containing material or use the methods specified by §61.152 to clean emissions containing particulate asbestos material before they escape to, or are vented to, the outside air.

(c) The requirements of paragraphs (a) and (b) of this section do not apply to the spray-on application of materials where the asbestos fibers in the materials are encapsulated with a bituminous or resinous binder during spraying and the materials are not friable after drying.

(d) Owners or operators of sources subject to this paragraph are exempt from the requirements of §§61.05(a), 61.07 and 61.09.

[49 FR 13661, Apr. 5, 1984. Redesignated and amended at 55 FR 48424, Nov. 20, 1990; 60 FR 31920, June 19, 1995]

§61.147 Standard for fabricating.

(a) Applicability. This section applies to the following fabricating operations using commercial asbestos:

(1) The fabrication of cement building products.

(2) The fabrication of friction products, except those operations that primarily install asbestos friction materials on motor vehicles.

(3) The fabrication of cement or silicate board for ventilation hoods; ovens; electrical panels; laboratory furniture, bulkheads, partitions, and ceilings for marine construction; and flow control devices for the molten metal industry.

(b) Standard. Each owner or operator of any of the fabricating operations to which this section applies shall either:

(1) Discharge no visible emissions to the outside air from any of the operations or from any building or structure in which they are conducted or from any other fugitive sources; or

(2) Use the methods specified by §61.152 to clean emissions containing particulate asbestos material before they escape to, or are vented to, the outside air.

(3) Monitor each potential source of asbestos emissions from any part of the fabricating facility, including air cleaning devices, process equipment, and buildings that house equipment for material processing and handling, at least once each day, during daylight hours, for visible emissions to the outside air during periods of operation. The monitoring shall be by visual observation of at least 15 seconds duration per source of emissions.

(4) Inspect each air cleaning device at least once each week for proper operation and for changes that signal the potential for malfunctions, including, to the maximum extent possible without dismantling other than opening the device, the presence of tears, holes, and abrasions in filter bags and for dust deposits on the clean side of bags. For air cleaning devices that cannot be inspected on a weekly basis according to this paragraph, submit to the Administrator, and revise as necessary, a written maintenance plan to include, at a minimum, the following:

(i) Maintenance schedule.

(ii) Recordkeeping plan.

(5) Maintain records of the results of visible emission monitoring and air cleaning device inspections using a format similar to that shown in Figures 1 and 2 and include the following:

(i) Date and time of each inspection.

(ii) Presence or absence of visible emissions.

(iii) Condition of fabric filters, including presence of any tears, holes, and abrasions.

(iv) Presence of dust deposits on clean side of fabric filters.

(v) Brief description of corrective actions taken, including date and time.

(vi) Daily hours of operation for each air cleaning device.

(6) Furnish upon request and make available at the affected facility during normal business hours for inspection by the Administrator, all records required under this section.

(7) Retain a copy of all monitoring and inspection records for at least 2 years.

(8) Submit semiannually a copy of the visible emission monitoring records to the Administrator if visible emission occurred during the report period. Semiannual reports shall be postmarked by the 30th day following the end of the six-month period.

[49 FR 13661, Apr. 5, 1984. Redesignated and amended at 55 FR 48424, Nov. 20, 1991; 64 FR 7467, Feb. 12, 1999]

§61.148 Standard for insulating materials.

No owner or operator of a facility may install or reinstall on a facility component any insulating materials that contain commercial asbestos if the materials are either molded and friable or wet-applied and friable after drying. The provisions of this section do not apply to spray-applied insulating materials regulated under §61.146.

[55 FR 48424, Nov. 20, 1990]

§61.149 Standard for waste disposal for asbestos mills.

Each owner or operator of any source covered under the provisions of §61.142 shall:

(a) Deposit all asbestos-containing waste material at a waste disposal site operated in accordance with the provisions of §61.154; and

(b) Discharge no visible emissions to the outside air from the transfer of control device asbestos waste to the tailings conveyor, or use the methods specified by §61.152 to clean emissions containing particulate asbestos material before they escape to, or are vented to, the outside air. Dispose of the asbestos waste from control devices in accordance with §61.150(a) or paragraph (c) of this section; and

(c) Discharge no visible emissions to the outside air during the collection, processing, packaging, or on-site transporting of any asbestos-containing waste material, or use one of the disposal methods specified in paragraphs (c) (1) or (2) of this section, as follows:

(1) Use a wetting agent as follows:

(i) Adequately mix all asbestos-containing waste material with a wetting agent recommended by the manufacturer of the agent to effectively wet dust and tailings, before depositing the material at a waste disposal site. Use the agent as recommended for the particular dust by the manufacturer of the agent.

(ii) Discharge no visible emissions to the outside air from the wetting operation or use the methods specified by §61.152 to clean emissions containing particulate asbestos material before they escape to, or are vented to, the outside air.

(iii) Wetting may be suspended when the ambient temperature at the waste disposal site is less than ?9.5°C (15°F), as determined by an appropriate measurement method with an accuracy of ±1°C (±2°F). During periods when wetting operations are suspended, the temperature must be recorded at least at hourly intervals, and records must be retained for at least 2 years in a form suitable for inspection.

(2) Use an alternative emission control and waste treatment method that has received prior written approval by the Administrator. To obtain approval for an alternative method, a written application must be submitted to the Administrator demonstrating that the following criteria are met:

(i) The alternative method will control asbestos emissions equivalent to currently required methods.

(ii) The suitability of the alternative method for the intended application.

(iii) The alternative method will not violate other regulations.

(iv) The alternative method will not result in increased water pollution, land pollution, or occupational hazards.

(d) When waste is transported by vehicle to a disposal site:

(1) Mark vehicles used to transport asbestos-containing waste material during the loading and unloading of the waste so that the signs are visible. The markings must:

(i) Be displayed in such a manner and location that a person can easily read the legend.

(ii) Conform to the requirements for 51 cm × 36 cm (20 in × 14 in) upright format signs specified in 29 CFR 1910.145(d)(4) and this paragraph; and

(iii) Display the following legend in the lower panel with letter sizes and styles of a visibility at least equal to those specified in this paragraph.

Legend

DANGER

ASBESTOS DUST HAZARD

CANCER AND LUNG DISEASE HAZARD

Authorized Personnel Only

Notation

2.5 cm (1 inch) Sans Serif, Gothic or Block

2.5 cm (1 inch) Sans Serif, Gothic or Block

1.9 cm ( 3/4 inch) Sans Serif, Gothic or Block

14 Point Gothic

Spacing between any two lines must be a least equal to the height of the upper of the two lines.

(2) For off-site disposal, provide a copy of the waste shipment record, described in paragraph (e)(1) of this section, to the disposal site owner or operator at the same time as the asbestos-containing waste material is delivered to the disposal site.

(e) For all asbestos-containing waste material transported off the facility site:

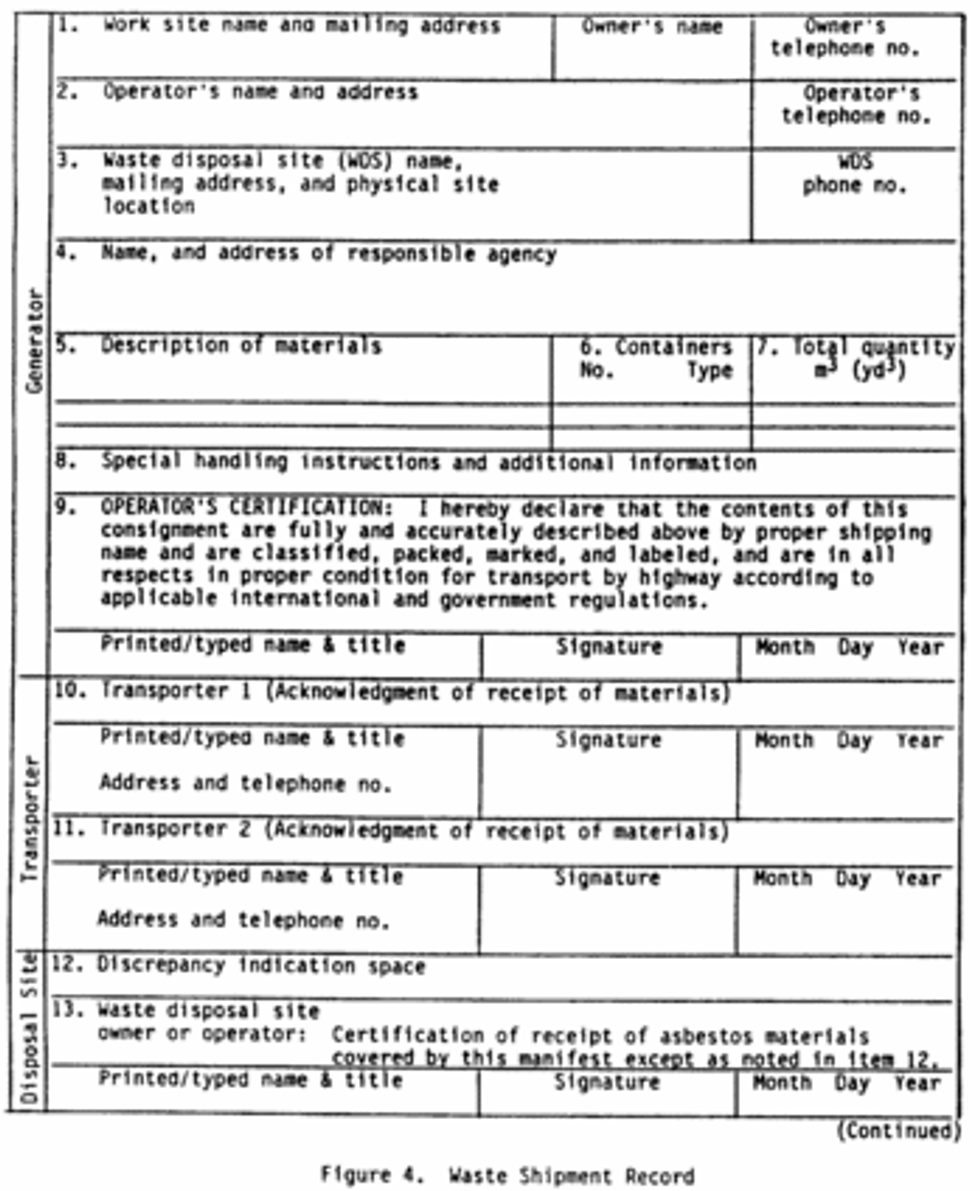

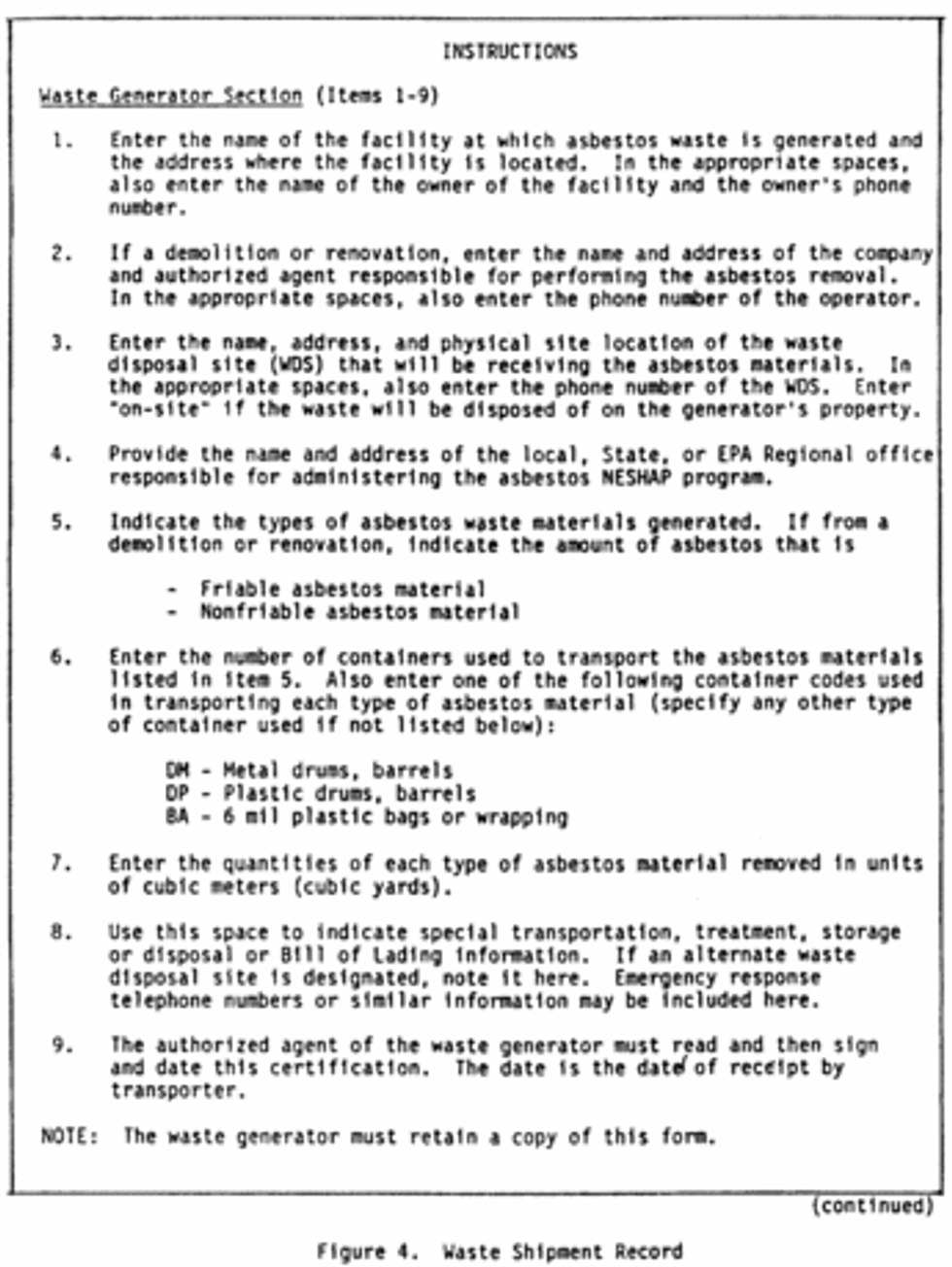

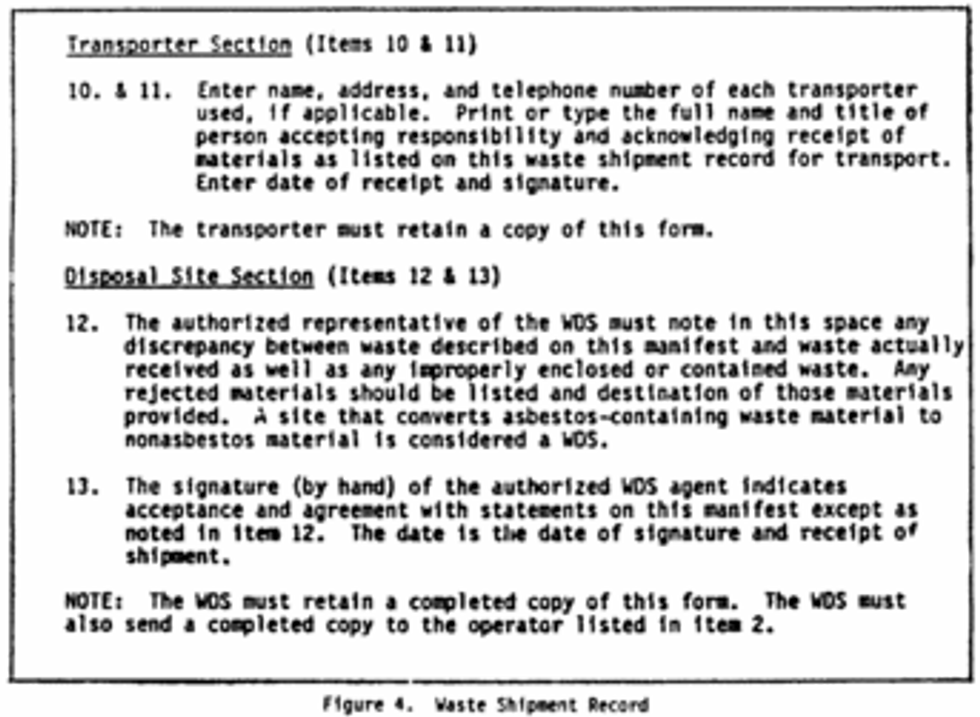

(1) Maintain asbestos waste shipment records, using a form similar to that shown in Figure 4, and include the following information:

(i) The name, address, and telephone number of the waste generator.

(ii) The name and address of the local, State, or EPA Regional agency responsible for administering the asbestos NESHAP program.

(iii) The quantity of the asbestos-containing waste material in cubic meters (cubic yards).

(iv) The name and telephone number of the disposal site operator.

(v) The name and physical site location of the disposal site.

(vi) The date transported.

(vii) The name, address, and telephone number of the transporter(s).

(viii) A certification that the contents of this consignment are fully and accurately described by proper shipping name and are classified, packed, marked, and labeled, and are in all respects in proper condition for transport by highway according to applicable international and government regulations.

(2) For waste shipments where a copy of the waste shipment record, signed by the owner or operator of the designated disposal site, is not received by the waste generator within 35 days of the date the waste was accepted by the initial transporter, contact the transporter and/or the owner or operator of the designated disposal site to determine the status of the waste shipment.

(3) Report in writing to the local, State, or EPA Regional office responsible for administering the asbestos NESHAP program for the waste generator if a copy of the waste shipment record, signed by the owner or operator of the designated waste disposal site, is not received by the waste generator within 45 days of the date the waste was accepted by the initial transporter. Include in the report the following information:

(i) A copy of the waste shipment record for which a confirmation of delivery was not received, and

(ii) A cover letter signed by the waste generator explaining the efforts taken to locate the asbestos waste shipment and the results of those efforts.

(4) Retain a copy of all waste shipment records, including a copy of the waste shipment record signed by the owner or operator of the designated waste disposal site, for at least 2 years.

(f) Furnish upon request, and make available for inspection by the Administrator, all records required under this section.

§61.150 Standard for waste disposal for manufacturing, fabricating, demolition, renovation, and spraying operations.

Each owner or operator of any source covered under the provisions of §§61.144, 61.145, 61.146, and 61.147 shall comply with the following provisions:

(a) Discharge no visible emissions to the outside air during the collection, processing (including incineration), packaging, or transporting of any asbestos-containing waste material generated by the source, or use one of the emission control and waste treatment methods specified in paragraphs (a) (1) through (4) of this section.

(1) Adequately wet asbestos-containing waste material as follows:

(i) Mix control device asbestos waste to form a slurry; adequately wet other asbestos-containing waste material; and

(ii) Discharge no visible emissions to the outside air from collection, mixing, wetting, and handling operations, or use the methods specified by §61.152 to clean emissions containing particulate asbestos material before they escape to, or are vented to, the outside air; and

(iii) After wetting, seal all asbestos-containing waste material in leak-tight containers while wet; or, for materials that will not fit into containers without additional breaking, put materials into leak-tight wrapping; and

(iv) Label the containers or wrapped materials specified in paragraph (a)(1)(iii) of this section using warning labels specified by Occupational Safety and Health Standards of the Department of Labor, Occupational Safety and Health Administration (OSHA) under 29 CFR 1910.1001(j)(4) or 1926.1101(k)(8). The labels shall be printed in letters of sufficient size and contrast so as to be readily visible and legible.

(v) For asbestos-containing waste material to be transported off the facility site, label containers or wrapped materials with the name of the waste generator and the location at which the waste was generated.

(2) Process asbestos-containing waste material into nonfriable forms as follows:

(i) Form all asbestos-containing waste material into nonfriable pellets or other shapes;

(ii) Discharge no visible emissions to the outside air from collection and processing operations, including incineration, or use the method specified by §61.152 to clean emissions containing particulate asbestos material before they escape to, or are vented to, the outside air.

(3) For facilities demolished where the RACM is not removed prior to demolition according to §§61.145(c)(1) (i), (ii), (iii), and (iv) or for facilities demolished according to §61.145(c)(9), adequately wet asbestos-containing waste material at all times after demolition and keep wet during handling and loading for transport to a disposal site. Asbestos-containing waste materials covered by this paragraph do not have to be sealed in leak-tight containers or wrapping but may be transported and disposed of in bulk.

(4) Use an alternative emission control and waste treatment method that has received prior approval by the Administrator according to the procedure described in §61.149(c)(2).

(5) As applied to demolition and renovation, the requirements of paragraph (a) of this section do not apply to Category I nonfriable ACM waste and Category II nonfriable ACM waste that did not become crumbled, pulverized, or reduced to powder.

(b) All asbestos-containing waste material shall be deposited as soon as is practical by the waste generator at:

(1) A waste disposal site operated in accordance with the provisions of §61.154, or

(2) An EPA-approved site that converts RACM and asbestos-containing waste material into nonasbestos (asbestos-free) material according to the provisions of §61.155.

(3) The requirements of paragraph (b) of this section do not apply to Category I nonfriable ACM that is not RACM.

(c) Mark vehicles used to transport asbestos-containing waste material during the loading and unloading of waste so that the signs are visible. The markings must conform to the requirements of §§61.149(d)(1) (i), (ii), and (iii).

(d) For all asbestos-containing waste material transported off the facility site:

(1) Maintain waste shipment records, using a form similar to that shown in Figure 4, and include the following information:

(i) The name, address, and telephone number of the waste generator.

(ii) The name and address of the local, State, or EPA Regional office responsible for administering the asbestos NESHAP program.

(iii) The approximate quantity in cubic meters (cubic yards).

(iv) The name and telephone number of the disposal site operator.

(v) The name and physical site location of the disposal site.

(vi) The date transported.

(vii) The name, address, and telephone number of the transporter(s).

(viii) A certification that the contents of this consignment are fully and accurately described by proper shipping name and are classified, packed, marked, and labeled, and are in all respects in proper condition for transport by highway according to applicable international and government regulations.

(2) Provide a copy of the waste shipment record, described in paragraph (d)(1) of this section, to the disposal site owners or operators at the same time as the asbestos-containing waste material is delivered to the disposal site.

(3) For waste shipments where a copy of the waste shipment record, signed by the owner or operator of the designated disposal site, is not received by the waste generator within 35 days of the date the waste was accepted by the initial transporter, contact the transporter and/or the owner or operator of the designated disposal site to determine the status of the waste shipment.

(4) Report in writing to the local, State, or EPA Regional office responsible for administering the asbestos NESHAP program for the waste generator if a copy of the waste shipment record, signed by the owner or operator of the designated waste disposal site, is not received by the waste generator within 45 days of the date the waste was accepted by the initial transporter. Include in the report the following information:

(i) A copy of the waste shipment record for which a confirmation of delivery was not received, and

(ii) A cover letter signed by the waste generator explaining the efforts taken to locate the asbestos waste shipment and the results of those efforts.

(5) Retain a copy of all waste shipment records, including a copy of the waste shipment record signed by the owner or operator of the designated waste disposal site, for at least 2 years.

(e) Furnish upon request, and make available for inspection by the Administrator, all records required under this section.

[55 FR 48429, Nov. 20, 1990; 56 FR 1669, Jan. 16, 1991, as amended at 68 FR 54793, Sept. 18, 2003]

§61.151 Standard for inactive waste disposal sites for asbestos mills and manufacturing and fabricating operations.

Each owner or operator of any inactive waste disposal site that was operated by sources covered under §61.142, 61.144, or 61.147 and received deposits of asbestos-containing waste material generated by the sources, shall:

(a) Comply with one of the following:

(1) Either discharge no visible emissions to the outside air from an inactive waste disposal site subject to this paragraph; or

(2) Cover the asbestos-containing waste material with at least 15 centimeters (6 inches) of compacted nonasbestos-containing material, and grow and maintain a cover of vegetation on the area adequate to prevent exposure of the asbestos-containing waste material. In desert areas where vegetation would be difficult to maintain, at least 8 additional centimeters (3 inches) of well-graded, nonasbestos crushed rock may be placed on top of the final cover instead of vegetation and maintained to prevent emissions; or

(3) Cover the asbestos-containing waste material with at least 60 centimeters (2 feet) of compacted nonasbestos-containing material, and maintain it to prevent exposure of the asbestos-containing waste; or

(4) For inactive waste disposal sites for asbestos tailings, a resinous or petroleum-based dust suppression agent that effectively binds dust to control surfaceair emissions may be used instead of the methods in paragraphs (a) (1), (2), and (3) of this section. Use the agent in the manner and frequency recommended for the particular asbestos tailings by the manufacturer of the dust suppression agent to achieve and maintain dust control. Obtain prior written approval of the Administrator to use other equally effective dust suppression agents. For purposes of this paragraph, any used, spent, or other waste oil is not considered a dust suppression agent.

(b) Unless a natural barrier adequately deters access by the general public, install and maintain warning signs and fencing as follows, or comply with paragraph (a)(2) or (a)(3) of this section.

(1) Display warning signs at all entrances and at intervals of 100 m (328 ft) or less along the property line of the site or along the perimeter of the sections of the site where asbestos-containing waste material was deposited. The warning signs must:

(i) Be posted in such a manner and location that a person can easily read the legend; and

(ii) Conform to the requirements for 51 cm × 36 cm (20? × 14?) upright format signs specified in 29 CFR 1910.145(d)(4) and this paragraph; and

(iii) Display the following legend in the lower panel with letter sizes and styles of a visibility at least equal to those specified in this paragraph.

| Legend | Notation |

|---|---|

| Asbestos Waste Disposal Site | 2.5 cm (1 inch) Sans Serif, Gothic or Block |

| Do Not Create Dust | 1.9 cm ( 3/4 inch) Sans Serif, Gothic or Block |

| Breathing Asbestos is Hazardous to Your Health | 14 Point Gothic. |

Spacing between any two lines must be at least equal to the height of the upper of the two lines.

(2) Fence the perimeter of the site in a manner adequate to deter access by the general public.

(3) When requesting a determination on whether a natural barrier adequately deters public access, supply information enabling the Administrator to determine whether a fence or a natural barrier adequately deters access by the general public.

(c) The owner or operator may use an alternative control method that has received prior approval of the Administrator rather than comply with the requirements of paragraph (a) or (b) of this section.

(d) Notify the Administrator in writing at least 45 days prior to excavating or otherwise disturbing any asbestos-containing waste material that has been deposited at a waste disposal site under this section, and follow the procedures specified in the notification. If the excavation will begin on a date other than the one contained in the original notice, notice of the new start date must be provided to the Administrator at least 10 working days before excavation begins and in no event shall excavation begin earlier than the date specified in the original notification. Include the following information in the notice:

(1) Scheduled starting and completion dates.

(2) Reason for disturbing the waste.

(3) Procedures to be used to control emissions during the excavation, storage, transport, and ultimate disposal of the excavated asbestos-containing waste material. If deemed necessary, the Administrator may require changes in the emission control procedures to be used.

(4) Location of any temporary storage site and the final disposal site.

(e) Within 60 days of a site becoming inactive and after the effective date of this subpart, record, in accordance with State law, a notation on the deed to the facility property and on any other instrument that would normally be examined during a title search; this notation will in perpetuity notify any potential purchaser of the property that:

(1) The land has been used for the disposal of asbestos-containing waste material;

(2) The survey plot and record of the location and quantity of asbestos-containing waste disposed of within the disposal site required in §61.154(f) have been filed with the Administrator; and

(3) The site is subject to 40 CFR part 61, subpart M.

[49 FR 13661, Apr. 5, 1984, as amended at 53 FR 36972, Sept. 23, 1988. Redesignated and amended at 55 FR 48429, Nov. 20, 1990]

§61.152 Air-cleaning.

(a) The owner or operator who uses air cleaning, as specified in §§61.142(a), 61.144(b)(2), 61.145(c)(3)(i)(B)(1), 61.145(c)(4)(ii), 61.145(c)(11)(i), 61.146(b)(2), 61.147(b)(2), 61.149(b), 61.149(c)(1)(ii), 61.150(a)(1)(ii), 61.150(a)(2)(ii), and 61.155(e) shall:

(1) Use fabric filter collection devices, except as noted in paragraph (b) of this section, doing all of the following:

(i) Ensuring that the airflow permeability, as determined by ASTM Method D737-75, does not exceed 9 m 3/min/m 2 (30 ft 3/min/ft 2) for woven fabrics or 11 3/min/m 2(35 ft 3/min/ft 2) for felted fabrics, except that 12 m 3/min/m 2 (40 ft 3min/ft 2) for woven and 14 m 3/min/m 2 (45 ft 3min/ft 2) for felted fabrics is allowed for filtering air from asbestos ore dryers; and

(ii) Ensuring that felted fabric weighs at least 475 grams per square meter (14 ounces per square yard) and is at least 1.6 millimeters (one-sixteenth inch) thick throughout; and

(iii) Avoiding the use of synthetic fabrics that contain fill yarn other than that which is spun.

(2) Properly install, use, operate, and maintain all air-cleaning equipment authorized by this section. Bypass devices may be used only during upset or emergency conditions and then only for so long as it takes to shut down the operation generating the particulate asbestos material.

(3) For fabric filter collection devices installed after January 10, 1989, provide for easy inspection for faulty bags.

(b) There are the following exceptions to paragraph (a)(1):

(1) After January 10, 1989, if the use of fabric creates a fire or explosion hazard, or the Administrator determines that a fabric filter is not feasible, the Administrator may authorize as a substitute the use of wet collectors designed to operate with a unit contacting energy of at least 9.95 kilopascals (40 inches water gage pressure).

(2) Use a HEPA filter that is certified to be at least 99.97 percent efficient for 0.3 micron particles.

(3) The Administrator may authorize the use of filtering equipment other than described in paragraphs (a)(1) and (b)(1) and (2) of this section if the owner or operator demonstrates to the Administrator's satisfaction that it is equivalent to the described equipment in filtering particulate asbestos material.

[49 FR 13661, Apr. 5, 1984; 49 FR 25453, June 21, 1984, as amended at 51 FR 8199, Mar. 10, 1986. Redesignated and amended at 55 FR 48430, Nov. 20, 1990]

§61.153 Reporting.

(a) Any new source to which this subpart applies (with the exception of sources subject to §§61.143, 61.145, 61.146, and 61.148), which has an initial startup date preceding the effective date of this revision, shall provide the following information to the Administrator postmarked or delivered within 90 days of the effective date. In the case of a new source that does not have an initial startup date preceding the effective date, the information shall be provided, postmarked or delivered, within 90 days of the initial startup date. Any owner or operator of an existing source shall provide the following information to the Administrator within 90 days of the effective date of this subpart unless the owner or operator of the existing source has previously provided this information to the Administrator. Any changes in the information provided by any existing source shall be provided to the Administrator, postmarked or delivered, within 30 days after the change.

(1) A description of the emission control equipment used for each process; and

(i) If the fabric device uses a woven fabric, the airflow permeability in m 3/min/m 2 and; if the fabric is synthetic, whether the fill yarn is spun or not spun; and

(ii) If the fabric filter device uses a felted fabric, the density in g/m 2, the minimum thickness in inches, and the airflow permeability in m 3/min/m 2.

(2) If a fabric filter device is used to control emissions,

(i) The airflow permeability in m 3/min/m 2 (ft 3/min/ft 2) if the fabric filter device uses a woven fabric, and, if the fabric is synthetic, whether the fill yarn is spun or not spun; and

(ii) If the fabric filter device uses a felted fabric, the density in g/m 2 (oz/yd 2), the minimum thickness in millimeters (inches), and the airflow permeability in m 3/min/m 2 (ft 3/min/ft 2).

(3) If a HEPA filter is used to control emissions, the certified efficiency.

(4) For sources subject to §§61.149 and 61.150:

(i) A brief description of each process that generates asbestos-containing waste material; and

(ii) The average volume of asbestos-containing waste material disposed of, measured in m 3/day (yd 3/day); and

(iii) The emission control methods used in all stages of waste disposal; and

(iv) The type of disposal site or incineration site used for ultimate disposal, the name of the site operator, and the name and location of the disposal site.

(5) For sources subject to §§61.151 and 61.154:

(i) A brief description of the site; and

(ii) The method or methods used to comply with the standard, or alternative procedures to be used.

(b) The information required by paragraph (a) of this section must accompany the information required by §61.10. Active waste disposal sites subject to §61.154 shall also comply with this provision. Roadways, demolition and renovation, spraying, and insulating materials are exempted from the requirements of §61.10(a). The information described in this section must be reported using the format of appendix A of this part as a guide.

(Sec. 114. Clean Air Act as amended (42 U.S.C. 7414))

[49 FR 13661, Apr. 5, 1984. Redesignated and amended at 55 FR 48430, Nov. 20, 1990; 56 FR 1669, Jan. 16, 1991]

§61.154 Standard for active waste disposal sites.

Each owner or operator of an active waste disposal site that receives asbestos-containing waste material from a source covered under §61.149, 61.150, or 61.155 shall meet the requirements of this section:

(a) Either there must be no visible emissions to the outside air from any active waste disposal site where asbestos-containing waste material has been deposited, or the requirements of paragraph (c) or (d) of this section must be met.

(b) Unless a natural barrier adequately deters access by the general public, either warning signs and fencing must be installed and maintained as follows, or the requirements of paragraph (c)(1) of this section must be met.

(1) Warning signs must be displayed at all entrances and at intervals of 100 m (330 ft) or less along the property line of the site or along the perimeter of the sections of the site where asbestos-containing waste material is deposited. The warning signs must:

(i) Be posted in such a manner and location that a person can easily read the legend; and

(ii) Conform to the requirements of 51 cm × 36 cm (20? × 14?) upright format signs specified in 29 CFR 1910.145(d)(4) and this paragraph; and

(iii) Display the following legend in the lower panel with letter sizes and styles of a visibility at least equal to those specified in this paragraph.

| Legend | Notation |

|---|---|

| Asbestos Waste Disposal Site | 2.5 cm (1 inch) Sans Serif, Gothic or Block. |

| Do Not Create Dust | 1.9 cm ( 3/4 inch) Sans Serif, Gothic or Block. |

| Breathing Asbestos is Hazardous to Your Health | 14 Point Gothic. |

Spacing between any two lines must be at least equal to the height of the upper of the two lines.

(2) The perimeter of the disposal site must be fenced in a manner adequate to deter access by the general public.

(3) Upon request and supply of appropriate information, the Administrator will determine whether a fence or a natural barrier adequately deters access by the general public.

(c) Rather than meet the no visible emission requirement of paragraph (a) of this section, at the end of each operating day, or at least once every 24-hour period while the site is in continuous operation, the asbestos-containing waste material that has been deposited at the site during the operating day or previous 24-hour period shall:

(1) Be covered with at least 15 centimeters (6 inches) of compacted nonasbestos-containing material, or

(2) Be covered with a resinous or petroleum-based dust suppression agent that effectively binds dust and controls wind erosion. Such an agent shall be used in the manner and frequency recommended for the particular dust by the dust suppression agent manufacturer to achieve and maintain dust control. Other equally effective dust suppression agents may be used upon prior approval by the Administrator. For purposes of this paragraph, any used, spent, or other waste oil is not considered a dust suppression agent.

(d) Rather than meet the no visible emission requirement of paragraph (a) of this section, use an alternative emissions control method that has received prior written approval by the Administrator according to the procedures described in §61.149(c)(2).

(e) For all asbestos-containing waste material received, the owner or operator of the active waste disposal site shall:

(1) Maintain waste shipment records, using a form similar to that shown in Figure 4, and include the following information:

(i) The name, address, and telephone number of the waste generator.

(ii) The name, address, and telephone number of the transporter(s).

(iii) The quantity of the asbestos-containing waste material in cubic meters (cubic yards).

(iv) The presence of improperly enclosed or uncovered waste, or any asbestos-containing waste material not sealed in leak-tight containers. Report in writing to the local, State, or EPA Regional office responsible for administering the asbestos NESHAP program for the waste generator (identified in the waste shipment record), and, if different, the local, State, or EPA Regional office responsible for administering the asbestos NESHAP program for the disposal site, by the following working day, the presence of a significant amount of improperly enclosed or uncovered waste. Submit a copy of the waste shipment record along with the report.

(v) The date of the receipt.

(2) As soon as possible and no longer than 30 days after receipt of the waste, send a copy of the signed waste shipment record to the waste generator.

(3) Upon discovering a discrepancy between the quantity of waste designated on the waste shipment records and the quantity actually received, attempt to reconcile the discrepancy with the waste generator. If the discrepancy is not resolved within 15 days after receiving the waste, immediately report in writing to the local, State, or EPA Regional office responsible for administering the asbestos NESHAP program for the waste generator (identified in the waste shipment record), and, if different, the local, State, or EPA Regional office responsible for administering the asbestos NESHAP program for the disposal site. Describe the discrepancy and attempts to reconcile it, and submit a copy of the waste shipment record along with the report.

(4) Retain a copy of all records and reports required by this paragraph for at least 2 years.

(f) Maintain, until closure, records of the location, depth and area, and quantity in cubic meters (cubic yards) of asbestos-containing waste material within the disposal site on a map or diagram of the disposal area.

(g) Upon closure, comply with all the provisions of §61.151.

(h) Submit to the Administrator, upon closure of the facility, a copy of records of asbestos waste disposal locations and quantities.

(i) Furnish upon request, and make available during normal business hours for inspection by the Administrator, all records required under this section.

(j) Notify the Administrator in writing at least 45 days prior to excavating or otherwise disturbing any asbestos-containing waste material that has been deposited at a waste disposal site and is covered. If the excavation will begin on a date other than the one contained in the original notice, notice of the new start date must be provided to the Administrator at least 10 working days before excavation begins and in no event shall excavation begin earlier than the date specified in the original notification. Include the following information in the notice:

(1) Scheduled starting and completion dates.

(2) Reason for disturbing the waste.

(3) Procedures to be used to control emissions during the excavation, storage, transport, and ultimate disposal of the excavated asbestos-containing waste material. If deemed necessary, the Administrator may require changes in the emission control procedures to be used.

(4) Location of any temporary storage site and the final disposal site.

(Secs. 112 and 301(a) of the Clean Air Act as amended (42 U.S.C. 7412, 7601(a))

[49 FR 13661, Apr. 5, 1990. Redesignated and amended at 55 FR 48431, Nov. 20, 1990; 56 FR 1669, Jan. 16, 1991]

§61.155 Standard for operations that convert asbestos-containing waste material into nonasbestos (asbestos-free) material.

Each owner or operator of an operation that converts RACM and asbestos-containing waste material into nonasbestos (asbestos-free) material shall:

(a) Obtain the prior written approval of the Administrator to construct the facility. To obtain approval, the owner or operator shall provide the Administrator with the following information:

(1) Application to construct pursuant to §61.07.

(2) In addition to the information requirements of §61.07(b)(3), a

(i) Description of waste feed handling and temporary storage.

(ii) Description of process operating conditions.

(iii) Description of the handling and temporary storage of the end product.

(iv) Description of the protocol to be followed when analyzing output materials by transmission electron microscopy.

(3) Performance test protocol, including provisions for obtaining information required under paragraph (b) of this section.

(4) The Administrator may require that a demonstration of the process be performed prior to approval of the application to construct.

(b) Conduct a start-up performance test. Test results shall include:

(1) A detailed description of the types and quantities of nonasbestos material, RACM, and asbestos-containing waste material processed, e.g., asbestos cement products, friable asbestos insulation, plaster, wood, plastic, wire, etc. Test feed is to include the full range of materials that will be encountered in actual operation of the process.

(2) Results of analyses, using polarized light microscopy, that document the asbestos content of the wastes processed.

(3) Results of analyses, using transmission electron microscopy, that document that the output materials are free of asbestos. Samples for analysis are to be collected as 8-hour composite samples (one 200-gram (7-ounce) sample per hour), beginning with the initial introduction of RACM or asbestos-containing waste material and continuing until the end of the performance test.

(4) A description of operating parameters, such as temperature and residence time, defining the full range over which the process is expected to operate to produce nonasbestos (asbestos-free) materials. Specify the limits for each operating parameter within which the process will produce nonasbestos (asbestos-free) materials.

(5) The length of the test.

(c) During the initial 90 days of operation,

(1) Continuously monitor and log the operating parameters identified during start-up performance tests that are intended to ensure the production of nonasbestos (asbestos-free) output material.

(2) Monitor input materials to ensure that they are consistent with the test feed materials described during start-up performance tests in paragraph (b)(1) of this section.

(3) Collect and analyze samples, taken as 10-day composite samples (one 200-gram (7-ounce) sample collected every 8 hours of operation) of all output material for the presence of asbestos. Composite samples may be for fewer than 10 days. Transmission electron microscopy (TEM) shall be used to analyze the output material for the presence of asbestos. During the initial 90-day period, all output materials must be stored on-site until analysis shows the material to be asbestos-free or disposed of as asbestos-containing waste material according to §61.150.

(d) After the initial 90 days of operation,

(1) Continuously monitor and record the operating parameters identified during start-up performance testing and any subsequent performance testing. Any output produced during a period of deviation from the range of operating conditions established to ensure the production of nonasbestos (asbestos-free) output materials shall be:

(i) Disposed of as asbestos-containing waste material according to §61.150, or

(ii) Recycled as waste feed during process operation within the established range of operating conditions, or

(iii) Stored temporarily on-site in a leak-tight container until analyzed for asbestos content. Any product material that is not asbestos-free shall be either disposed of as asbestos-containing waste material or recycled as waste feed to the process.

(2) Collect and analyze monthly composite samples (one 200-gram (7-ounce) sample collected every 8 hours of operation) of the output material. Transmission electron microscopy shall be used to analyze the output material for the presence of asbestos.

(e) Discharge no visible emissions to the outside air from any part of the operation, or use the methods specified by §61.152 to clean emissions containing particulate asbestos material before they escape to, or are vented to, the outside air.

(f) Maintain records on-site and include the following information:

(1) Results of start-up performance testing and all subsequent performance testing, including operating parameters, feed characteristic, and analyses of output materials.