['Air Programs']

['Hazardous Air Pollutants']

02/25/2022

...

(a) Applicability. To determine which requirements of paragraphs (a), (b), and (c) of this section apply to the owner or operator of a demolition or renovation activity and prior to the commencement of the demolition or renovation, thoroughly inspect the affected facility or part of the facility where the demolition or renovation operation will occur for the presence of asbestos, including Category I and Category II nonfriable ACM. The requirements of paragraphs (b) and (c) of this section apply to each owner or operator of a demolition or renovation activity, including the removal of RACM as follows:

(1) In a facility being demolished, all the requirements of paragraphs (b) and (c) of this section apply, except as provided in paragraph (a)(3) of this section, if the combined amount of RACM is

(i) At least 80 linear meters (260 linear feet) on pipes or at least 15 square meters (160 square feet) on other facility components, or

(ii) At least 1 cubic meter (35 cubic feet) off facility components where the length or area could not be measured previously.

(2) In a facility being demolished, only the notification requirements of paragraphs (b)(1), (2), (3)(i) and (iv), and (4)(i) through (vii) and (4)(ix) and (xvi) of this section apply, if the combined amount of RACM is

(i) Less than 80 linear meters (260 linear feet) on pipes and less than 15 square meters (160 square feet) on other facility components, and

(ii) Less than one cubic meter (35 cubic feet) off facility components where the length or area could not be measured previously or there is no asbestos.

(3) If the facility is being demolished under an order of a State or local government agency, issued because the facility is structurally unsound and in danger of imminent collapse, only the requirements of paragraphs (b)(1), (b)(2), (b)(3)(iii), (b)(4) (except (b)(4)(viii)), (b)(5), and (c)(4) through (c)(9) of this section apply.

(4) In a facility being renovated, including any individual nonscheduled renovation operation, all the requirements of paragraphs (b) and (c) of this section apply if the combined amount of RACM to be stripped, removed, dislodged, cut, drilled, or similarly disturbed is

(i) At least 80 linear meters (260 linear feet) on pipes or at least 15 square meters (160 square feet) on other facility components, or

(ii) At least 1 cubic meter (35 cubic feet) off facility components where the length or area could not be measured previously.

(iii) To determine whether paragraph (a)(4) of this section applies to planned renovation operations involving individual nonscheduled operations, predict the combined additive amount of RACM to be removed or stripped during a calendar year of January 1 through December 31.

(iv) To determine whether paragraph (a)(4) of this section applies to emergency renovation operations, estimate the combined amount of RACM to be removed or stripped as a result of the sudden, unexpected event that necessitated the renovation.

(5) Owners or operators of demolition and renovation operations are exempt from the requirements of §§61.05(a), 61.07, and 61.09.

(b) Notification requirements. Each owner or operator of a demolition or renovation activity to which this section applies shall:

(1) Provide the Administrator with written notice of intention to demolish or renovate. Delivery of the notice by U.S. Postal Service, commercial delivery service, or hand delivery is acceptable.

(2) Update notice, as necessary, including when the amount of asbestos affected changes by at least 20 percent.

(3) Postmark or deliver the notice as follows:

(i) At least 10 working days before asbestos stripping or removal work or any other activity begins (such as site preparation that would break up, dislodge or similarly disturb asbestos material), if the operation is described in paragraphs (a) (1) and (4) (except (a)(4)(iii) and (a)(4)(iv)) of this section. If the operation is as described in paragraph (a)(2) of this section, notification is required 10 working days before demolition begins.

(ii) At least 10 working days before the end of the calendar year preceding the year for which notice is being given for renovations described in paragraph (a)(4)(iii) of this section.

(iii) As early as possible before, but not later than, the following working day if the operation is a demolition ordered according to paragraph (a)(3) of this section or, if the operation is a renovation described in paragraph (a)(4)(iv) of this section.

(iv) For asbestos stripping or removal work in a demolition or renovation operation, described in paragraphs (a) (1) and (4) (except (a)(4)(iii) and (a)(4)(iv)) of this section, and for a demolition described in paragraph (a)(2) of this section, that will begin on a date other than the one contained in the original notice, notice of the new start date must be provided to the Administrator as follows:

(A) When the asbestos stripping or removal operation or demolition operation covered by this paragraph will begin after the date contained in the notice,

(1) Notify the Administrator of the new start date by telephone as soon as possible before the original start date, and

(2) Provide the Administrator with a written notice of the new start date as soon as possible before, and no later than, the original start date. Delivery of the updated notice by the U.S. Postal Service, commercial delivery service, or hand delivery is acceptable.

(B) When the asbestos stripping or removal operation or demolition operation covered by this paragraph will begin on a date earlier than the original start date,

(1) Provide the Administrator with a written notice of the new start date at least 10 working days before asbestos stripping or removal work begins.

(2) For demolitions covered by paragraph (a)(2) of this section, provide the Administrator written notice of a new start date at least 10 working days before commencement of demolition. Delivery of updated notice by U.S. Postal Service, commercial delivery service, or hand delivery is acceptable.

(C) In no event shall an operation covered by this paragraph begin on a date other than the date contained in the written notice of the new start date.

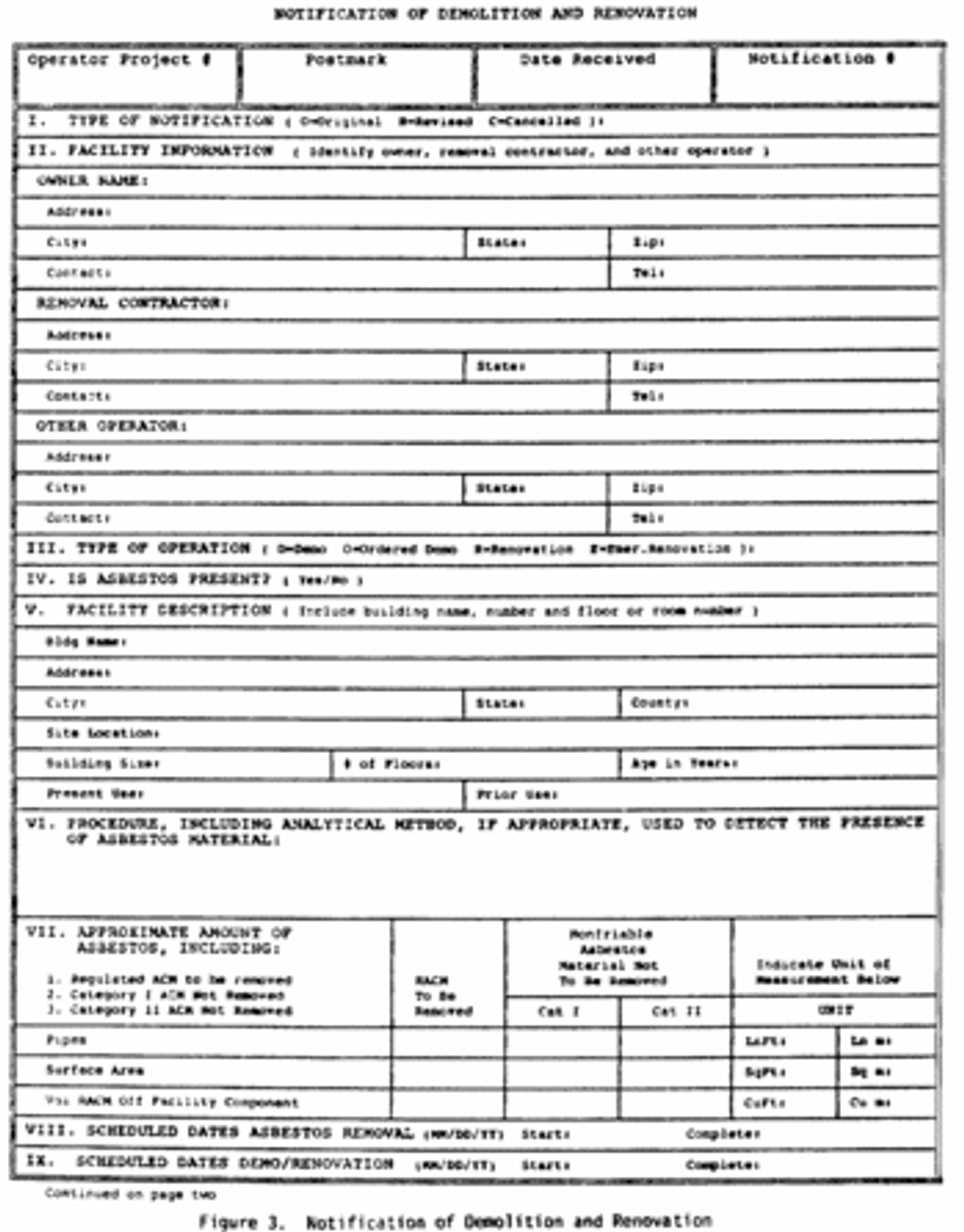

(4) Include the following in the notice:

(i) An indication of whether the notice is the original or a revised notification.

(ii) Name, address, and telephone number of both the facility owner and operator and the asbestos removal contractor owner or operator.

(iii) Type of operation: demolition or renovation.

(iv) Description of the facility or affected part of the facility including the size (square meters [square feet] and number of floors), age, and present and prior use of the facility.

(v) Procedure, including analytical methods, employed to detect the presence of RACM and Category I and Category II nonfriable ACM.

(vi) Estimate of the approximate amount of RACM to be removed from the facility in terms of length of pipe in linear meters (linear feet), surface area in square meters (square feet) on other facility components, or volume in cubic meters (cubic feet) if off the facility components. Also, estimate the approximate amount of Category I and Category II nonfriable ACM in the affected part of the facility that will not be removed before demolition.

(vii) Location and street address (including building number or name and floor or room number, if appropriate), city, county, and state, of the facility being demolished or renovated.

(viii) Scheduled starting and completion dates of asbestos removal work (or any other activity, such as site preparation that would break up, dislodge, or similarly disturb asbestos material) in a demolition or renovation; planned renovation operations involving individual nonscheduled operations shall only include the beginning and ending dates of the report period as described in paragraph (a)(4)(iii) of this section.

(ix) Scheduled starting and completion dates of demolition or renovation.

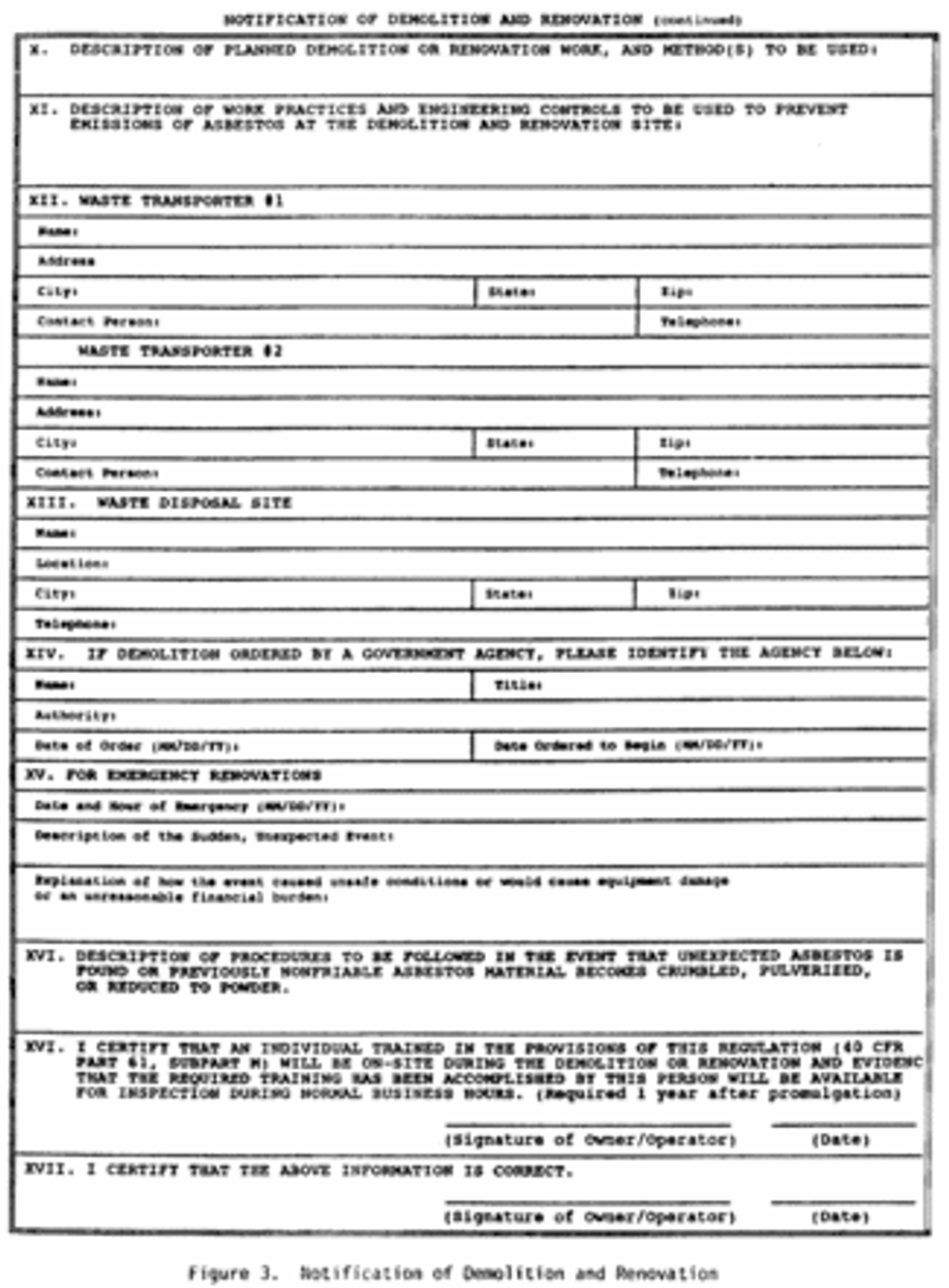

(x) Description of planned demolition or renovation work to be performed and method(s) to be employed, including demolition or renovation techniques to be used and description of affected facility components.

(xi) Description of work practices and engineering controls to be used to comply with the requirements of this subpart, including asbestos removal and waste-handling emission control procedures.

(xii) Name and location of the waste disposal site where the asbestos-containing waste material will be deposited.

(xiii) A certification that at least one person trained as required by paragraph (c)(8) of this section will supervise the stripping and removal described by this notification. This requirement shall become effective 1 year after promulgation of this regulation.

(xiv) For facilities described in paragraph (a)(3) of this section, the name, title, and authority of the State or local government representative who has ordered the demolition, the date that the order was issued, and the date on which the demolition was ordered to begin. A copy of the order shall be attached to the notification.

(xv) For emergency renovations described in paragraph (a)(4)(iv) of this section, the date and hour that the emergency occurred, a description of the sudden, unexpected event, and an explanation of how the event caused an unsafe condition, or would cause equipment damage or an unreasonable financial burden.

(xvi) Description of procedures to be followed in the event that unexpected RACM is found or Category II nonfriable ACM becomes crumbled, pulverized, or reduced to powder.

(xvii) Name, address, and telephone number of the waste transporter.

(5) The information required in paragraph (b)(4) of this section must be reported using a form similiar to that shown in Figure 3.

(c) Procedures for asbestos emission control. Each owner or operator of a demolition or renovation activity to whom this paragraph applies, according to paragraph (a) of this section, shall comply with the following procedures:

(1) Remove all RACM from a facility being demolished or renovated before any activity begins that would break up, dislodge, or similarly disturb the material or preclude access to the material for subsequent removal. RACM need not be removed before demolition if:

(i) It is Category I nonfriable ACM that is not in poor condition and is not friable.

(ii) It is on a facility component that is encased in concrete or other similarly hard material and is adequately wet whenever exposed during demolition; or

(iii) It was not accessible for testing and was, therefore, not discovered until after demolition began and, as a result of the demolition, the material cannot be safely removed. If not removed for safety reasons, the exposed RACM and any asbestos-contaminated debris must be treated as asbestos-containing waste material and adequately wet at all times until disposed of.

(iv) They are Category II nonfriable ACM and the probability is low that the materials will become crumbled, pulverized, or reduced to powder during demolition.

(2) When a facility component that contains, is covered with, or is coated with RACM is being taken out of the facility as a unit or in sections:

(i) Adequately wet all RACM exposed during cutting or disjoining operations; and

(ii) Carefully lower each unit or section to the floor and to ground level, not dropping, throwing, sliding, or otherwise damaging or disturbing the RACM.

(3) When RACM is stripped from a facility component while it remains in place in the facility, adequately wet the RACM during the stripping operation.

(i) In renovation operations, wetting is not required if:

(A) The owner or operator has obtained prior written approval from the Administrator based on a written application that wetting to comply with this paragraph would unavoidably damage equipment or present a safety hazard; and

(B) The owner or operator uses of the following emission control methods:

(1) A local exhaust ventilation and collection system designed and operated to capture the particulate asbestos material produced by the stripping and removal of the asbestos materials. The system must exhibit no visible emissions to the outside air or be designed and operated in accordance with the requirements in §61.152.

(2) A glove-bag system designed and operated to contain the particulate asbestos material produced by the stripping of the asbestos materials.

(3) Leak-tight wrapping to contain all RACM prior to dismantlement.

(ii) In renovation operations where wetting would result in equipment damage or a safety hazard, and the methods allowed in paragraph (c)(3)(i) of this section cannot be used, another method may be used after obtaining written approval from the Administrator based upon a determination that it is equivalent to wetting in controlling emissions or to the methods allowed in paragraph (c)(3)(i) of this section.

(iii) A copy of the Administrator's written approval shall be kept at the worksite and made available for inspection.

(4) After a facility component covered with, coated with, or containing RACM has been taken out of the facility as a unit or in sections pursuant to paragraph (c)(2) of this section, it shall be stripped or contained in leak-tight wrapping, except as described in paragraph (c)(5) of this section. If stripped, either:

(i) Adequately wet the RACM during stripping; or

(ii) Use a local exhaust ventilation and collection system designed and operated to capture the particulate asbestos material produced by the stripping. The system must exhibit no visible emissions to the outside air or be designed and operated in accordance with the requirements in §61.152.

(5) For large facility components such as reactor vessels, large tanks, and steam generators, but not beams (which must be handled in accordance with paragraphs (c)(2), (3), and (4) of this section), the RACM is not required to be stripped if the following requirements are met:

(i) The component is removed, transported, stored, disposed of, or reused without disturbing or damaging the RACM.

(ii) The component is encased in a leak-tight wrapping.

(iii) The leak-tight wrapping is labeled according to §61.149(d)(1)(i), (ii), and (iii) during all loading and unloading operations and during storage.

(6) For all RACM, including material that has been removed or stripped:

(i) Adequately wet the material and ensure that it remains wet until collected and contained or treated in preparation for disposal in accordance with §61.150; and

(ii) Carefully lower the material to the ground and floor, not dropping, throwing, sliding, or otherwise damaging or disturbing the material.

(iii) Transport the material to the ground via leak-tight chutes or containers if it has been removed or stripped more than 50 feet above ground level and was not removed as units or in sections.

(iv) RACM contained in leak-tight wrapping that has been removed in accordance with paragraphs (c)(4) and (c)(3)(i)(B)(3) of this section need not be wetted.

(7) When the temperature at the point of wetting is below 0°C (32°F):

(i) The owner or operator need not comply with paragraph (c)(2)(i) and the wetting provisions of paragraph (c)(3) of this section.

(ii) The owner or operator shall remove facility components containing, coated with, or covered with RACM as units or in sections to the maximum extent possible.

(iii) During periods when wetting operations are suspended due to freezing temperatures, the owner or operator must record the temperature in the area containing the facility components at the beginning, middle, and end of each workday and keep daily temperature records available for inspection by the Administrator during normal business hours at the demolition or renovation site. The owner or operator shall retain the temperature records for at least 2 years.

(8) Effective 1 year after promulgation of this regulation, no RACM shall be stripped, removed, or otherwise handled or disturbed at a facility regulated by this section unless at least one on-site representative, such as a foreman or management-level person or other authorized representative, trained in the provisions of this regulation and the means of complying with them, is present. Every 2 years, the trained on-site individual shall receive refresher training in the provisions of this regulation. The required training shall include as a minimum: applicability; notifications; material identification; control procedures for removals including, at least, wetting, local exhaust ventilation, negative pressure enclosures, glove-bag procedures, and High Efficiency Particulate Air (HEPA) filters; waste disposal work practices; reporting and recordkeeping; and asbestos hazards and worker protection. Evidence that the required training has been completed shall be posted and made available for inspection by the Administrator at the demolition or renovation site.

(9) For facilities described in paragraph (a)(3) of this section, adequately wet the portion of the facility that contains RACM during the wrecking operation.

(10) If a facility is demolished by intentional burning, all RACM including Category I and Category II nonfriable ACM must be removed in accordance with the NESHAP before burning.

[55 FR 48419, Nov. 20, 1990; 56 FR 1669, Jan. 16, 1991]

READ MORESHOW LESS

['Air Programs']

['Hazardous Air Pollutants']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.