['Air Programs']

['Air Emissions']

07/08/2024

...

§1037.301 Overview of measurements related to GEM inputs in a selective enforcement audit.

(a) We may require you to perform selective enforcement audits under 40 CFR part 1068, subpart E, with respect to any GEM inputs in your application for certification. Sections 1037.305 through 1037.315 describe how this applies uniquely in certain circumstances.

(b) A selective enforcement audit for this part consists of performing measurements with production vehicles relative to one or more declared values for GEM inputs, and using those measured values in place of your declared values to run GEM. Except as specified in this subpart, the vehicle is considered passing if the new modeled emission result is at or below the modeled emission result corresponding to the declared GEM inputs. If you report an FEL for the vehicle configuration before the audit, we will instead consider the vehicle passing if the new cycle-weighted emission result is at or below the FEL.

(c) We may audit your production components and your records to confirm that physical parameters are correct, such as dimensional accuracy and material selection. We may also audit your records to confirm that you are properly documenting the certified configurations of production vehicles.

(d) Selective enforcement audit provisions for fuel maps apply to engine manufacturers as specified in 40 CFR 1036.301. See §1037.315 for selective enforcement audit provisions applicable to powertrain fuel maps.

(e) We may suspend or revoke certificates based on the outcome of a selective enforcement audit for any appropriate configurations within one or more vehicle families.

(f) We may apply selective enforcement audit provisions with respect to off-cycle technologies, with any necessary modifications, consistent with good engineering judgment.

[86 FR 34463, Jun. 29, 2021]

§1037.305 Audit procedures for tractors - aerodynamic testing.

To perform a selective enforcement audit with respect to drag area for tractors, use the reference method specified in §1037.525; we may instead require you to use the same method you used for certification. The following provisions apply instead of 40 CFR 1068.415 through 1068.425 for a selective enforcement audit with respect to drag area:

(a) Determine whether a tractor meets standards as follows:

(1) We will select a vehicle configuration for testing. Perform a coastdown measurement according to §1037.528 with the vehicle in its production configuration. If the production configuration cannot be connected to a standard trailer, you may ask us to approve trailer specifications different than §1037.501(g)(1) based on good engineering judgment. Instead of the process described in §1037.528(h)(12), determine your test result as described in this paragraph (a). You must have an equal number of runs in each direction.

(2) Measure a yaw curve for your test vehicle using your alternate method according to §1037.525(b)(3). You do not need to test at the coastdown effective yaw angle. You may use a previously established yaw curve from your certification testing if it is available.

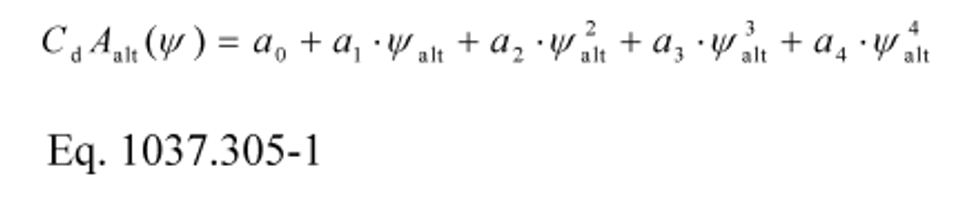

(3) Using the yaw curve, perform a regression using values of drag area, CdAalt, and yaw angle, ψalt, to determine the air-direction correction coefficients, a0, a1, a2, a3, and a4, for the following equation:

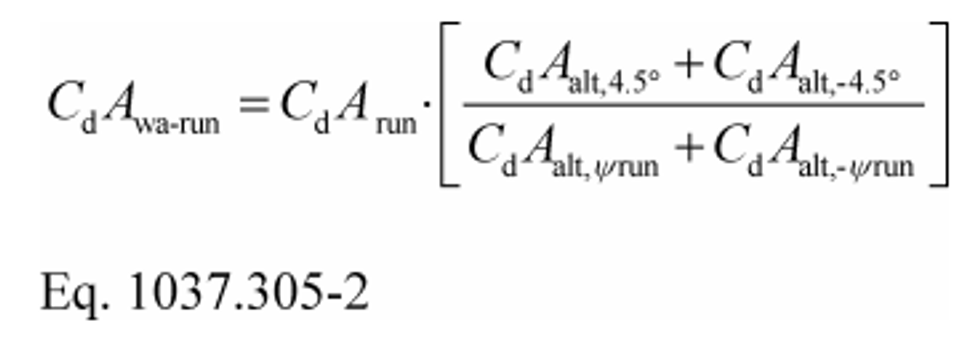

(4) Adjust the drag area value from each coastdown run, CdArun, from the yaw angle of each run, ψrun, to ±4.5° to represent a wind-averaged drag area value, CdAwa by applying Eq. 1037.305-1 as follows:

(5) Perform additional coastdown measurements until you reach a pass or fail decision under this paragraph (a). The minimum number of runs to pass is 24. The minimum number of runs to fail is 100.

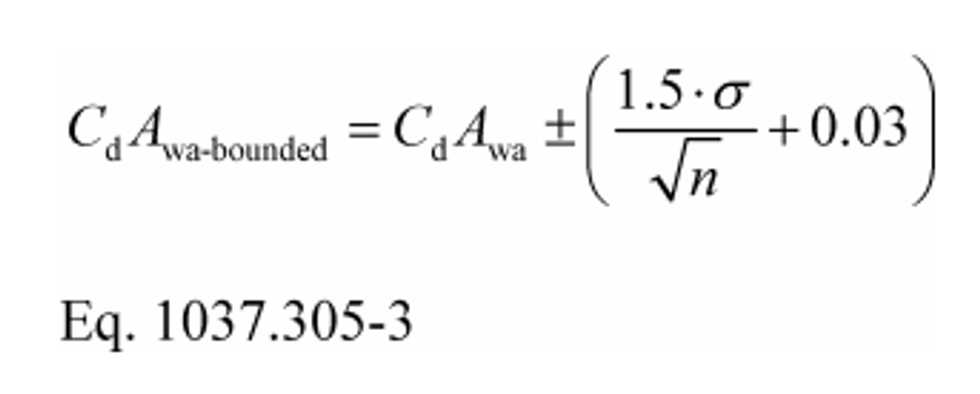

(6) Calculate statistical values to characterize cumulative test results at least once per day based on an equal number of coastdown runs in each direction. Determine the wind-averaged drag area value for the test CdAwa by averaging all CdAwa-run values for all days of testing. Determine the upper and lower bounds of the drag area value, CdAwa-bounded, expressed to two decimal places, using a confidence interval as follows:

Where:

CdAwa-bounded = the upper bound, CdAwa-upper, and lower bound, CdAwa-lower, of the drag area value, where CdAwa-upper is the larger number.

CdAwa = the average of all CdAwa-run values.

σ = the standard deviation of all CdAwa-run values (see 40 CFR 1065.602(c)).

n = the total number of coastdown runs.

(7) Determine compliance based on the values of CdAwa-upper and CdAwa-lower relative to the adjusted bin boundary. For purposes of this section, the upper limit of a bin is expressed as the specified value plus 0.05 to account for rounding. For example, for a bin including values of 5.5-5.9 m2, being above the upper limit means exceeding 5.95 m2. The vehicle passes or fails relative to the adjusted bin boundary based on one of the following criteria:

(i) The vehicle passes if CdAwa-upper is less than or equal to the upper limit of the bin to which you certified the vehicle.

(ii) The vehicle fails if CdAwa-lower is greater than the upper limit of the bin to which you certified the vehicle.

(iii) The vehicle passes if you perform 100 coastdown runs and CdAwa-upper is greater than and CdAwa-lower is lower than the upper limit of the bin to which you certified the vehicle.

(iv) The vehicle fails if you choose to stop testing before reaching a final determination under this paragraph (a)(7).

(v) You may continue testing beyond the stopping point specified in this paragraph (a)(7). We may consider the additional data in making pass/fail determinations.

[86 FR 34463, Jun. 29, 2021]

§1037.315 Audit procedures related to powertrain testing.

(a) For vehicles certified based on powertrain testing as specified in 40 CFR 1036.545, we may apply the selective enforcement audit requirements to the powertrain. If engine manufacturers perform the powertrain testing and include those results in their certification under 40 CFR part 1036, they are responsible for selective enforcement audits related to those results. Otherwise, the certificate holder for the vehicle is responsible for the selective enforcement audit.

(b) The following provisions apply for a selective enforcement audit with respect to powertrain testing:

(1) A selective enforcement audit for powertrains would generally consist of performing a test with the complete powertrain (engine and transmission together). We may alternatively allow you to test the engine on a dynamometer with no installed transmission as described in §1037.551.

(2) Recreate a set of test results for each of three separate powertrains. Generate GEM results for each of the configurations that are defined as the centers of each group of four points that define a boundary of cycle work and average powertrain speed divided by average vehicle speed, for each of the three selected powertrains. See 40 CFR 1036.301(b)(2) for an example on how these points are defined. Each unique map for a given configuration with a particular powertrain constitutes a separate test for purposes of evaluating whether the vehicle family meets the pass-fail criteria under 40 CFR 1068.420. The test result for a single test run in the audit is considered passing if it is at or below the value selected as an input for GEM. Perform testing with the same GEM configurations for additional powertrains as needed to reach a pass-fail decision under 40 CFR 1068.240.

[89 FR 29778, Apr. 22, 2024]

§1037.320 Audit procedures for axles and transmissions.

Selective enforcement audit provisions apply for axles and transmissions relative to the efficiency demonstrations of §§1037.560 and 1037.565 as specified in this section. The following provisions apply instead of 40 CFR 1068.415 through 1068.445 for the selective enforcement audit.

(a) A selective enforcement audit for axles or transmissions would consist of performing measurements with a production axle or transmission to determine mean power loss values as declared for GEM simulations, and running GEM over one or more applicable duty cycles based on those measured values. The axle or transmission is considered passing for a given configuration if the new modeled emission result for every applicable duty cycle is at or below the modeled emission result corresponding to the declared GEM inputs.

(b) Run GEM with the define vehicles to determine whether the transmission or axle family passes the audit.

(1) For transmission audits, run GEM for each applicable vehicle configuration and GEM regulatory subcategory identified in 40 CFR 1036.540 and for each vehicle class as defined in §1037.140(g) using the applicable default engine map in appendix C of 40 CFR part 1036, the cycle-average fuel map in Table 1 of this section, the torque curve in Table 2 of this section for both the engine full-load torque curve and parent engine full-load torque curve, the motoring torque curve in Table 3 of this section, the idle fuel map in Table 4 of this section. For transmission testing, use the test transmission's gear ratios in place of the gear ratios defined in 40 CFR 1036.540. Table 1 through Table 4 follow:

| Light HDV and medium HDV—spark-ignition | Light HDV and medium HDV—compression-ignition | Heavy HDV | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine cycle work (kW·hr) | N/V (r/min) | Fuel mass (g) | Idle speed (r/min) | Idle torque (N·m) | Engine cycle work (kW·hr) | N/V (r/min) | Fuel mass (g) | Idle speed (r/min) | Idle torque (N·m) | Engine cycle work (kW·hr) | N/V (r/min) | Fuel mass (g) | Idle speed (r/min) | Idle torque (N·m) |

| 3.5404 | 2.8739 | 1109.31 | 600.5 | 37.997 | 3.3057 | 2.3317 | 919.01 | 750.3 | 36.347 | 11.4255 | 2.3972 | 2579.58 | 600.7 | 89.658 |

| 3.6574 | 3.0198 | 1153.35 | 600.4 | 37.951 | 3.3822 | 2.5075 | 982.53 | 750.2 | 36.461 | 11.6112 | 2.2432 | 2591.08 | 601.2 | 90.428 |

| 3.8119 | 3.0370 | 1188.66 | 600.2 | 37.956 | 3.4917 | 2.5320 | 998.64 | 750.2 | 36.608 | 12.5052 | 2.1620 | 2763.28 | 602.4 | 92.014 |

| 4.0121 | 3.1983 | 1250.76 | 600.1 | 38.153 | 3.6087 | 2.6181 | 1036.34 | 750.2 | 36.734 | 17.7747 | 2.5195 | 3835.77 | 602.2 | 91.780 |

| 5.5567 | 3.1325 | 1585.32 | 604.6 | 56.535 | 5.2397 | 2.5050 | 1354.33 | 753.0 | 51.992 | 18.4901 | 2.4155 | 3994.29 | 603.5 | 93.724 |

| 5.6814 | 3.2956 | 1639.08 | 604.0 | 56.549 | 5.3153 | 2.7289 | 1417.20 | 751.9 | 51.488 | 20.1904 | 2.3800 | 4374.06 | 605.1 | 96.340 |

| 5.8720 | 3.3255 | 1686.14 | 602.5 | 56.234 | 5.4112 | 2.6689 | 1416.75 | 751.3 | 51.280 | |||||

| 6.1774 | 3.4848 | 1773.39 | 601.7 | 56.038 | 5.5590 | 2.7231 | 1450.67 | 751.0 | 51.254 | |||||

| Light HDV and medium HDV—spark-ignition | Light HDV and medium HDV—compression-ignition | Heavy HDV | |||

|---|---|---|---|---|---|

| Engine speed (r/min) | Engine torque (N·m) | Engine speed (r/min) | Engine torque (N·m) | Engine speed (r/min) | Engine torque (N·m) |

| 600 | 433 | 750 | 470 | 600 | 1200 |

| 700 | 436 | 907 | 579 | 750 | 1320 |

| 800 | 445 | 1055 | 721 | 850 | 1490 |

| 900 | 473 | 1208 | 850 | 950 | 1700 |

| 1000 | 492 | 1358 | 876 | 1050 | 1950 |

| 1100 | 515 | 1507 | 866 | 1100 | 2090 |

| 1200 | 526 | 1660 | 870 | 1200 | 2100 |

| 1300 | 541 | 1809 | 868 | 1250 | 2100 |

| 1400 | 542 | 1954 | 869 | 1300 | 2093 |

| 1500 | 542 | 2105 | 878 | 1400 | 2092 |

| 1600 | 542 | 2258 | 850 | 1500 | 2085 |

| 1700 | 547 | 2405 | 800 | 1520 | 2075 |

| 1800 | 550 | 2556 | 734 | 1600 | 2010 |

| 1900 | 551 | 2600 | 0 | 1700 | 1910 |

| 2000 | 554 | 1800 | 1801 | ||

| 2100 | 553 | 1900 | 1640 | ||

| 2200 | 558 | 2000 | 1350 | ||

| 2300 | 558 | 2100 | 910 | ||

| 2400 | 566 | 2250 | 0 | ||

| 2500 | 571 | ||||

| 2600 | 572 | ||||

| 2700 | 581 | ||||

| 2800 | 586 | ||||

| 2900 | 587 | ||||

| 3000 | 590 | ||||

| 3100 | 591 | ||||

| 3200 | 589 | ||||

| 3300 | 585 | ||||

| 3400 | 584 | ||||

| 3500 | 582 | ||||

| 3600 | 573 | ||||

| 3700 | 562 | ||||

| 3800 | 555 | ||||

| 3900 | 544 | ||||

| 4000 | 534 | ||||

| 4100 | 517 | ||||

| 4200 | 473 | ||||

| 4291 | 442 | ||||

| 4500 | 150 | ||||

| Light HDV and medium HDV—spark-ignition | Light HDV and medium HDV—compression-ignition | Heavy HDV | |||

|---|---|---|---|---|---|

| Engine speed (r/min) | Engine torque (N·m) | Engine speed (r/min) | Engine torque (N·m) | Engine speed (r/min) | Engine torque (N·m) |

| 700 | −41 | 750 | −129 | 600 | −98 |

| 800 | −42 | 907 | −129 | 750 | −121 |

| 900 | −43 | 1055 | −130 | 850 | −138 |

| 1000 | −45 | 1208 | −132 | 950 | −155 |

| 1100 | −48 | 1358 | −135 | 1050 | −174 |

| 1200 | −49 | 1507 | −138 | 1100 | −184 |

| 1300 | −50 | 1660 | −143 | 1200 | −204 |

| 1411 | −51 | 1809 | −148 | 1250 | −214 |

| 1511 | −52 | 1954 | −155 | 1300 | −225 |

| 1611 | −53 | 2105 | −162 | 1400 | −247 |

| 1711 | −56 | 2258 | −170 | 1500 | −270 |

| 1811 | −56 | 2405 | −179 | 1520 | −275 |

| 1911 | −57 | 2556 | −189 | 1600 | −294 |

| 2011 | −57 | 1700 | −319 | ||

| 2111 | −58 | 1800 | −345 | ||

| 2211 | −60 | 1900 | −372 | ||

| 2311 | −65 | 2000 | −400 | ||

| 2411 | −81 | 2100 | −429 | ||

| 2511 | −85 | ||||

| 2611 | −87 | ||||

| 2711 | −88 | ||||

| 2811 | −89 | ||||

| 2911 | −91 | ||||

| 3011 | −91 | ||||

| 3111 | −96 | ||||

| 3211 | −96 | ||||

| 3311 | −97 | ||||

| 3411 | −98 | ||||

| 3511 | −99 | ||||

| 3611 | −104 | ||||

| 3711 | −105 | ||||

| 3811 | −108 | ||||

| 3911 | −108 | ||||

| 4011 | −111 | ||||

| 4111 | −111 | ||||

| 4211 | −115 | ||||

| 4291 | −112 | ||||

| Light HDV and medium HDV— spark-ignition | Light HDV and medium HDV— compression-ignition | Heavy HDV | ||||||

|---|---|---|---|---|---|---|---|---|

| Engine speed (r/min) | Engine torque (N·m) | Fuel mass rate (g/s) | Engine speed (r/min) | Engine torque (N·m) | Fuel mass rate (g/s) | Engine speed (r/min) | Engine torque (N·m) | Fuel mass rate (g/s) |

| 600 | 0 | 0.4010 | 750 | 0 | 0.2595 | 600 | 0 | 0.3501 |

| 700 | 0 | 0.4725 | 850 | 0 | 0.2626 | 700 | 0 | 0.4745 |

| 600 | 100 | 0.6637 | 750 | 100 | 0.6931 | 600 | 100 | 0.6547 |

| 700 | 100 | 0.7524 | 850 | 100 | 0.7306 | 700 | 100 | 0.8304 |

(2) Follow the procedure in paragraph (b)(1) of this section for axle audits, but cover the range of tire sizes by using good engineering judgment to select three representative tire sizes for each axle ratio for each vehicle configuration instead of using the tire size determined in 40 CFR 1036.540.

(3) The GEM “Default FEL CO 2 Emissions” result for each vehicle configuration counts as a separate test for determining whether the family passes the audit. For vocational vehicles, use the GEM “Default FEL CO 2 Emissions” result for the Regional subcategory.

(c) If the initial axle or transmission passes, the family passes and no further testing is required. If the initial axle or transmission does not pass, select two additional production axles or transmissions, as applicable, to perform additional tests. Note that these could be different axle and transmission configurations within the family. These become official test results for the family. Use good engineering judgment to use the results of these tests to update the declared maps for the axle or transmission family. For example, if you fail the audit test for any of the axles or transmissions tested, the audit result becomes the declared map. This may also require revising any analytically derived maps.

| Light HDV | Medium HDV | Heavy HDV | Light HDV and medium HDV spark-ignition | ||||

| Engine speed (r/min) | Engine torque (N·m) | Engine speed (r/min) | Engine torque (N·m) | Engine speed (r/min) | Engine torque (N·m) | Engine speed (r/min) | Engine torque (N·m) |

| 750 | 470 | 600 | 850 | 600 | 1200 | 600 | 433 |

| 907 | 579 | 750 | 890 | 750 | 1320 | 700 | 436 |

| 1055 | 721 | 850 | 1000 | 850 | 1490 | 800 | 445 |

| 1208 | 850 | 950 | 1200 | 950 | 1700 | 900 | 473 |

| 1358 | 876 | 1050 | 1440 | 1050 | 1950 | 1000 | 492 |

| 1507 | 866 | 1100 | 1520 | 1100 | 2090 | 1100 | 515 |

| 1660 | 870 | 1150 | 1570 | 1200 | 2100 | 1200 | 526 |

| 1809 | 868 | 1250 | 1590 | 1250 | 2100 | 1300 | 541 |

| 1954 | 869 | 1300 | 1590 | 1300 | 2093 | 1400 | 542 |

| 2105 | 878 | 1450 | 1590 | 1400 | 2092 | 1500 | 542 |

| 2258 | 850 | 1500 | 1590 | 1500 | 2085 | 1600 | 542 |

| 2405 | 800 | 1600 | 1540 | 1520 | 2075 | 1700 | 547 |

| 2556 | 734 | 1700 | 1470 | 1600 | 2010 | 1800 | 550 |

| 2600 | 0 | 1800 | 1385 | 1700 | 1910 | 1900 | 551 |

| 1900 | 1300 | 1800 | 1801 | 2000 | 554 | ||

| 2000 | 1220 | 1900 | 1640 | 2100 | 553 | ||

| 2100 | 1040 | 2000 | 1350 | 2200 | 558 | ||

| 2250 | 590 | 2100 | 910 | 2300 | 558 | ||

| 2400 | 0 | 2250 | 0 | 2400 | 566 | ||

| 2500 | 571 | ||||||

| 2600 | 572 | ||||||

| 2700 | 581 | ||||||

| 2800 | 586 | ||||||

| 2900 | 587 | ||||||

| 3000 | 590 | ||||||

| 3100 | 591 | ||||||

| 3200 | 589 | ||||||

| 3300 | 585 | ||||||

| 3400 | 584 | ||||||

| 3500 | 582 | ||||||

| 3600 | 573 | ||||||

| 3700 | 562 | ||||||

| 3800 | 555 | ||||||

| 3900 | 544 | ||||||

| 4000 | 534 | ||||||

| 4100 | 517 | ||||||

| 4200 | 473 | ||||||

| 4291 | 442 | ||||||

| 4500 | 150 | ||||||

[86 FR 34464, Jun. 29, 2021; 88 FR 4639, Jan. 24, 2023]

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.