['Air Programs']

['Hazardous Air Pollutants']

02/25/2022

...

§63.620 Applicability.

(a) Except as provided in paragraphs (c) and (d) of this section, you are subject to the requirements of this subpart if you own or operate a phosphate fertilizer production plant that is a major source as defined in §63.2. You must comply with the emission limitations, work practice standards, and operating parameter requirements specified in this subpart at all times.

(b) The requirements of this subpart apply to emissions of hazardous air pollutants (HAP) emitted from the following affected sources at a phosphate fertilizer production plant:

(1) Each phosphate fertilizer process line (e.g., diammonium and/or monoammonium phosphate process line).

(2) Each granular triple superphosphate process line.

(3) Each granular triple superphosphate storage building.

(4) Evaporative cooling tower.

(c) The requirements of this subpart do not apply to a phosphate fertilizer production plant that is an area source as defined in §63.2.

(d) The provisions of this subpart do not apply to research and development facilities as defined in §63.621.

§63.621 Definitions.

Terms used in this subpart are defined in §63.2 of the Clean Air Act and in this section as follows:

Diammonium and/or monoammonium phosphate process line means any process line manufacturing granular diammonium and/or monoammonium phosphate by reacting ammonia with phosphoric acid that has been derived from or manufactured by reacting phosphate rock and acid. A diammonium and/or monoammonium phosphate process line includes: Reactors, granulators, dryers, coolers, screens, and mills.

Equivalent P 2O5 feed means the quantity of phosphorus, expressed as phosphorus pentoxide (P2O5), fed to the process.

Equivalent P 2O5 stored means the quantity of phosphorus, expressed as phosphorus pentoxide, being cured or stored in the affected facility.

Evaporative cooling tower means an open-water, re-circulating device that uses fans or natural draft to draw or force ambient air through the device to remove heat from process water by direct contact.

Exceedance means a departure from an indicator range established for monitoring under this subpart, consistent with any averaging period specified for averaging the results of the monitoring.

Existing source depends on the date that construction or reconstruction of an affected source commenced. A phosphate fertilizer process line (e.g., diammonium and/or monoammonium phosphate process line), granular triple superphosphate process line, or granular triple superphosphate storage is an existing source if construction or reconstruction of the affected source commenced on or before December 27, 1996.

Fresh granular triple superphosphate means granular triple superphosphate produced within the preceding 72 hours.

Granular triple superphosphate process line means any process line, not including storage buildings, that manufactures granular triple superphosphate by reacting phosphate rock with phosphoric acid. A granular triple superphosphate process line includes: mixers, curing belts (dens), reactors, granulators, dryers, coolers, screens, and mills.

Granular triple superphosphate storage building means any building curing or storing fresh granular triple superphosphate. A granular triple superphosphate storage building includes: storage or curing buildings, conveyors, elevators, screens, and mills.

New source depends on the date that construction or reconstruction of an affected source commences. A phosphate fertilizer process line (e.g., diammonium and/or monoammonium phosphate process line), granular triple superphosphate process line, or granular triple superphosphate storage is a new source if construction or reconstruction of the affected source commenced after December 27, 1996.

Phosphate fertilizer process line means any process line that manufactures a granular phosphate fertilizer by reacting phosphoric acid with ammonia. A phosphate fertilizer process line includes: reactors, granulators, dryers, coolers, screens, and mills.

Phosphate fertilizer production plant means any production plant that manufactures a granular phosphate fertilizer by reacting phosphoric acid with ammonia.

Research and development facility means research or laboratory operations whose primary purpose is to conduct research and development into new processes and products, where the operations are under the close supervision of technically trained personnel, and where the facility is not engaged in the manufacture of products for commercial sale in commerce or other off-site distribution, except in a de minimis manner.

Shutdown commences when feed materials cease to be added to an affected source and ends when the affected source is deactivated, regardless of whether feed material is present in the affected source.

Startup commences when any feed material is first introduced into an affected source and ends when feed material is fully loaded into the affected source.

Total fluorides means elemental fluorine and all fluoride compounds, including the HAP hydrogen fluoride, as measured by reference methods specified in 40 CFR part 60, appendix A, Method 13 A or B, or by equivalent or alternative methods approved by the Administrator pursuant to §63.7(f).

§63.622 Standards and compliance dates.

(a) On and after the dates specified in paragraphs (a)(1) through (3) of this section, for each phosphate fertilizer process line (e.g., diammonium and/or monoammonium phosphate process line), granular triple superphosphate process line, and granular triple superphosphate storage building, you must comply with the emission limits as specified in paragraphs (a)(1) through (3) of this section. If a process line contains more than one emission point, you must sum the emissions from all emission points in a process line to determine compliance with the specified emission limits.

(1) For each existing phosphate fertilizer process line (e.g., diammonium and/or monoammonium phosphate process line), granular triple superphosphate process line, and granular triple superphosphate storage building that commenced construction or reconstruction on or before December 27, 1996, you must comply with the emission limits specified in Table 1 to this subpart beginning on June 10, 2002.

(2) For each new phosphate fertilizer process line (e.g., diammonium and/or monoammonium phosphate process line), granular triple superphosphate process line, and granular triple superphosphate storage building that commences construction or reconstruction after December 27, 1996 and on or before August 19, 2015, you must comply with the emission limits specified in Table 2 to this subpart beginning on June 10, 1999 or at startup, whichever is later.

(3) For each new phosphate fertilizer process line (e.g., diammonium and/or monoammonium phosphate process line), granular triple superphosphate process line, and granular triple superphosphate storage building that commences construction or reconstruction after August 19, 2015, you must comply with the emission limits specified in Table 2 to this subpart immediately upon startup.

(b) Beginning on June 10, 2002, you must not ship fresh granular triple superphosphate from your existing granular triple superphosphate storage building that commenced construction or reconstruction on or before December 27, 1996. Beginning on June 10, 1999 or at startup, whichever is later, you must not ship fresh granular triple superphosphate from your new granular triple superphosphate storage building that commences construction or reconstruction after December 27, 1996.

(c) Beginning on August 19, 2015, you must not introduce into any evaporative cooling tower any liquid effluent from any absorber installed to control emissions from process equipment.

(d) Beginning on August 19, 2015, during periods of startup and shutdown (as defined in §63.621), you must comply with the work practice specified in this paragraph in lieu of the emission limits specified in paragraph (a) of this section. During periods of startup and shutdown, you must operate any control device(s) being used at the affected source, monitor the operating parameters specified in Table 3 of this subpart, and comply with the operating limits specified in Table 4 of this subpart.

§63.624 [Reserved]

§63.625 Operating and monitoring requirements.

(a) For each phosphate fertilizer process line (e.g., diammonium and/or monoammonium phosphate process line), or granular triple superphosphate process line subject to the provisions of this subpart, you must comply with the monitoring requirements specified in paragraphs (a)(1) and (2) of this section.

(1) Install, calibrate, maintain, and operate a continuous monitoring system (CMS) according to your site-specific monitoring plan specified in §63.628(c). The CMS must have an accuracy of ±5 percent over its operating range and must determine and permanently record the mass flow of phosphorus-bearing material fed to the process.

(2) Maintain a daily record of equivalent P2O5 feed. Calculate the equivalent P2O5 feed by determining the total mass rate in metric ton/hour of phosphorus bearing feed using the procedures specified in §63.626(f)(3).

(b) For each granular triple superphosphate storage building subject to the provisions of this subpart, you must maintain an accurate record of the mass of granular triple superphosphate in storage to permit the determination of the amount of equivalent P2O5 stored.

(c) For each granular triple superphosphate storage building subject to the provisions of this subpart, you must comply with the requirements specified in paragraphs (c)(1) and (2) of this section.

(1) Maintain a daily record of total equivalent P2O5 stored by multiplying the percentage P2O5 content, as determined by §63.626(f)(3)(ii), by the total mass of granular triple superphosphate stored as specified in paragraph (b) of this section.

(2) Develop for approval by the Administrator a site-specific methodology including sufficient recordkeeping for the purposes of demonstrating compliance with §63.622(b).

(d) If you use a control device(s) to comply with the emission limits specified in Table 1 or 2 of this subpart, you must install a continuous parameter monitoring system (CPMS) and comply with the requirements specified in paragraphs (d)(1) through (4) of this section.

(1) You must monitor the operating parameter(s) applicable to the control device that you use as specified in Table 3 to this subpart and establish the applicable limit or range for the operating parameter limit as specified in paragraphs (d)(1)(i) and (ii) of this section, as applicable.

(i) Except as specified in paragraph (d)(1)(ii) of this section, determine the value(s) as the arithmetic average of operating parameter measurements recorded during the three test runs conducted for the most recent performance test.

(ii) If you use an absorber to comply with the emission limits in Table 1 or 2 to this subpart and you monitor pressure drop across the absorber, you must establish allowable ranges using the methodology specified in paragraphs (d)(1)(ii)(A) and (B) of this section.

(A) The allowable range for the daily averages of the pressure drop across an absorber and of the flow rate of the absorber liquid to each absorber in the process absorbing system, or secondary voltage for a wet electrostatic precipitator, is ±20 percent of the baseline average value determined in paragraph (d)(1)(i) of this section. The Administrator retains the right to reduce the ±20 percent adjustment to the baseline average values of operating ranges in those instances where performance test results indicate that a source's level of emissions is near the value of an applicable emissions standard. However, the adjustment must not be reduced to less than ±10 percent under any instance.

(B) As an alternative to paragraph (d)(1)(ii)(A) of this section, you may establish allowable ranges for the daily averages of the pressure drop across an absorber for the purpose of assuring compliance with this subpart using the procedures described in this paragraph. You must establish the allowable ranges based on the baseline average values recorded during previous performance tests or the results of performance tests conducted specifically for the purposes of this paragraph. You must conduct all performance tests using the methods specified in §63.626. You must certify that the control devices and processes have not been modified since the date of the performance test from which you obtained the data used to establish the allowable ranges. When a source using the methodology of this paragraph is retested, you must determine new allowable ranges of baseline average values unless the retest indicates no change in the operating parameters outside the previously established ranges.

(2) You must monitor, record, and demonstrate continuous compliance using the minimum frequencies specified in Table 4 to this subpart.

(3) You must comply with the calibration and quality control requirements that are applicable to the operating parameter(s) you monitor as specified in Table 5 to this subpart.

(4) If you use a fabric filter system to comply with the emission limits specified in Table 1 or 2 to this subpart, the system must meet the requirements for fabric filters specified in paragraph (e) of this section.

(e) Beginning August 19, 2016, if you use a fabric filter system to comply with the emission limits specified in Table 1 or 2 to this subpart, then the fabric filter must be equipped with a bag leak detection system that is installed, calibrated, maintained and continuously operated according to the requirements in paragraphs (e)(1) through (10) of this section.

(1) Install a bag leak detection sensor(s) in a position(s) that will be representative of the relative or absolute particulate matter loadings for each exhaust stack, roof vent, or compartment (e.g., for a positive-pressure fabric filter) of the fabric filter.

(2) Use a bag leak detection system certified by the manufacturer to be capable of detecting particulate matter emissions at concentrations of 1 milligram per actual cubic meter (0.00044 grains per actual cubic feet) or less.

(3) Use a bag leak detection system equipped with a device to continuously record the output signal from the system sensor.

(4) Use a bag leak detection system equipped with a system that will trigger an alarm when an increase in relative particulate material emissions over a preset level is detected. The alarm must be located such that the alert is observed readily by plant operating personnel.

(5) Install a bag leak detection system in each compartment or cell for positive-pressure fabric filter systems that do not duct all compartments or cells to a common stack. Install a bag leak detector downstream of the fabric filter if a negative-pressure or induced-air filter is used. If multiple bag leak detectors are required, the system's instrumentation and alarm may be shared among detectors.

(6) Calibration of the bag leak detection system must, at a minimum, consist of establishing the baseline output level by adjusting the range and the averaging period of the device and establishing the alarm set points and the alarm delay time.

(7) After initial adjustment, you must not adjust the sensitivity or range, averaging period, alarm set points or alarm delay time, except as established in your site-specific monitoring plan required in §63.628(c). In no event may the sensitivity be increased more than 100 percent or decreased by more than 50 percent over a 365-day period unless such adjustment follows a complete inspection of the fabric filter system that demonstrates that the system is in good operating condition.

(8) Operate and maintain each fabric filter and bag leak detection system such that the alarm does not sound more than 5 percent of the operating time during a 6-month period. If the alarm sounds more than 5 percent of the operating time during a 6-month period, it is considered an operating parameter exceedance. Calculate the alarm time (i.e., time that the alarm sounds) as specified in paragraphs (e)(8)(i) through (iii) of this section.

(i) If inspection of the fabric filter demonstrates that corrective action is not required, the alarm duration is not counted in the alarm time calculation.

(ii) If corrective action is required, each alarm time is counted as a minimum of 1 hour.

(iii) If it takes longer than 1 hour to initiate corrective action, each alarm time (i.e., time that the alarm sounds) is counted as the actual amount of time taken by you to initiate corrective action.

(9) If the alarm on a bag leak detection system is triggered, you must initiate procedures within 1 hour of an alarm to identify the cause of the alarm and then initiate corrective action, as specified in §63.628(d)(2), no later than 48 hours after an alarm. Failure to take these actions within the prescribed time periods is considered a violation.

(10) Retain records of any bag leak detection system alarm, including the date, time, duration, and the percent of the total operating time during each 6-month period that the alarm triggers, with a brief explanation of the cause of the alarm, the corrective action taken, and the schedule and duration of the corrective action.

[80 FR 50450, Aug. 19, 2015, as amended at 82 FR 45200, Sept. 28, 2017]

§63.626 Performance tests and compliance provisions.

(a) You must conduct an initial performance test to demonstrate compliance with the emission limits specified in Tables 1 and 2 to this subpart, within 180 days of the applicable compliance date specified in §63.622.

(b) After you conduct the initial performance test specified in paragraph (a) of this section, you must conduct a performance test once per calendar year.

(c) For affected sources (as defined in §63.620) that have not operated since the previous annual performance test was conducted and more than 1 year has passed since the previous performance test, you must conduct a performance test no later than 180 days after the re-start of the affected source according to the applicable provisions in §63.7(a)(2).

(d)(1) You must conduct the performance tests specified in this section at representative (normal) conditions for the process. Representative (normal) conditions means those conditions that:

(i) Represent the range of combined process and control measure conditions under which the facility expects to operate (regardless of the frequency of the conditions); and

(ii) Are likely to most challenge the emissions control measures of the facility with regard to meeting the applicable emission standards, but without creating an unsafe condition.

(2) Operations during startup, shutdown, and malfunction do not constitute representative (normal) operating conditions for purposes of conducting a performance test. You must record the process information that is necessary to document the operating conditions during the test and include in such record an explanation to support that such conditions represent representative (normal) conditions. Upon request, you must make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

(e) In conducting all performance tests, you must use as reference methods and procedures the test methods in 40 CFR part 60, appendix A, or other methods and procedures as specified in this section, except as provided in §63.7(f).

(f) For each phosphate fertilizer process line (e.g., diammonium and/or monoammonium phosphate process line), and granular triple superphosphate process line, you must determine compliance with the applicable total fluorides standards specified in Tables 1 and 2 to this subpart as specified in paragraphs (f)(1) through (3) of this section.

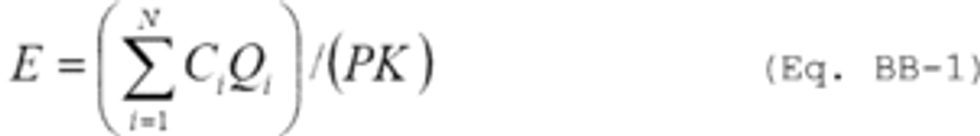

(1) Compute the emission rate (E) of total fluorides for each run using Equation BB-1:

Where:

E = Emission rate of total fluorides, gram/metric ton (pound/ton) of equivalent P2O5 feed.

Ci = Concentration of total fluorides from emission point “i,” milligram/dry standard cubic meter (milligram/dry standard cubic feet).

Qi = Volumetric flow rate of effluent gas from emission point “i,” dry standard cubic meter/hour (dry standard cubic feet/hour).

N = Number of emission points associated with the affected facility.

P = Equivalent P2O5 feed rate, metric ton/hour (ton/hour).

K = Conversion factor, 1000 milligram/gram (453,600 milligram/pound).

(2) You must use Method 13A or 13B (40 CFR part 60, appendix A) to determine the total fluorides concentration (Ci) and the volumetric flow rate (Qi) of the effluent gas at each emission point. The sampling time for each run at each emission point must be at least 60 minutes. The sampling volume for each run at each emission point must be at least 0.85 dscm (30 dscf). If Method 13B is used, the fusion of the filtered material described in Section 7.3.1.2 and the distillation of suitable aliquots of containers 1 and 2, described in section 7.3.3 and 7.3.4 in Method 13 A, may be omitted.

(3) Compute the equivalent P2O5 feed rate (P) using Equation BB-2:

Where:

P = P2O5 feed rate, metric ton/hour (ton/hour).

Mp = Total mass flow rate of phosphorus-bearing feed, metric ton/hour (ton/hour).

Rp = P2O5 content, decimal fraction.

(i) Determine the mass flow rate (Mp) of the phosphorus-bearing feed using the measurement system described in §63.625(a).

(ii) Determine the P2O5 content (Rp) of the feed using, as appropriate, the following methods specified in the Book of Methods Used and Adopted By The Association of Florida Phosphate Chemists (incorporated by reference, see §63.14) where applicable:

(A) Section IX, Methods of Analysis for Phosphate Rock, No. 1 Preparation of Sample.

(B) Section IX, Methods of Analysis for Phosphate Rock, No. 3 Phosphorus-P2O5 or Ca3(PO4)2, Method A - Volumetric Method.

(C) Section IX, Methods of Analysis for Phosphate Rock, No. 3 Phosphorus-P2O5 or Ca3(PO4)2, Method B - Gravimetric Quimociac Method.

(D) Section IX, Methods of Analysis for Phosphate Rock, No. 3 Phosphorus-P2O5 or Ca3(PO4)2, Method C - Spectrophotometric Method.

(E) Section XI, Methods of Analysis for Phosphoric Acid, Superphosphate, Triple superphosphate, and Ammonium Phosphates, No. 3 Total Phosphorus-P2O5, Method A - Volumetric Method.

(F) Section XI, Methods of Analysis for Phosphoric Acid, Superphosphate, Triple Superphosphate, and Ammonium Phosphates, No. 3 Total Phosphorus-P2O5, Method B - Gravimetric Quimociac Method.

(G) Section XI, Methods of Analysis for Phosphoric Acid, Superphosphate, Triple Superphosphate, and Ammonium Phosphates, No. 3 Total Phosphorus-P2O5, Method C - Spectrophotometric Method.

(g) For each granular triple superphosphate storage building, you must determine compliance with the applicable total fluorides standards specified in Tables 1 and 2 to this subpart as specified in paragraphs (g)(1) through (7) of this section.

(1) You must conduct performance tests only when the following quantities of product are being cured or stored in the facility:

(i) Total granular triple superphosphate is at least 10 percent of the building capacity, and

(ii) Fresh granular triple superphosphate is at least six percent of the total amount of granular triple superphosphate, or

(iii) If the provision in paragraph (g)(1)(ii) of this section exceeds production capabilities for fresh granular triple superphosphate, the fresh granular triple superphosphate is equal to at least 5 days maximum production.

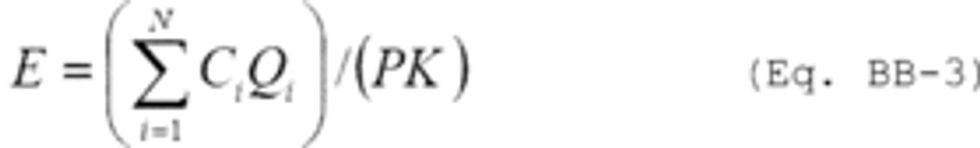

(2) Compute the emission rate (E) of total fluorides for each run using Equation BB-3:

Where:

E = Emission rate of total fluorides, gram/hour/metric ton (pound/hour/ton) of equivalent P2O5 stored.

Ci = Concentration of total fluorides from emission point “i”, milligram/dry standard cubic meter (milligram/dry standard cubic feet).

Qi = Volumetric flow rate of effluent gas from emission point “i”, dry standard cubic meter/hour (dry standard cubic feet/hour).

N = Number of emission points in the affected facility.

P = Equivalent P2O5 stored, metric tons (tons).

K = Conversion factor, 1000 milligram/gram (453,600 milligram/pound).

(3) You must use Method 13A or 13B (40 CFR part 60, appendix A) to determine the total fluorides concentration (Ci) and the volumetric flow rate (Qi) of the effluent gas at each emission point. The sampling time for each run at each emission point must be at least 60 minutes. The sampling volume for each run at each emission point must be at least 0.85 dscm (30 dscf). If Method 13B is used, the fusion of the filtered material described in Section 7.3.1.2 and the distillation of suitable aliquots of containers 1 and 2, described in section 7.3.3 and 7.3.4 in Method 13A, may be omitted.

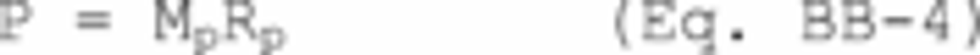

(4) Compute the equivalent P2O5 stored (P) using Equation BB-4:

Where:

P = P2O5 stored (ton).

Mp = Amount of product in storage, metric ton (ton).

Rp = P2O5 content of product in storage, weight fraction.

(5) Determine the amount of product (Mp) in storage using the measurement system described in §63.625(b) and (c).

(6) Determine the P2O5 content (Rp) of the product stored using, as appropriate, the following methods specified in the Book of Methods Used and Adopted By The Association of Florida Phosphate Chemists (incorporated by reference, see §63.14) where applicable:

(i) Section XI, Methods of Analysis For Phosphoric Acid, Superphosphate, Triple superphosphate, and Ammonium Phosphates, No. 3 Total Phosphorus-P2O5, Method A - Volumetric Method.

(ii) Section XI, Methods of Analysis For Phosphoric Acid, Superphosphate, Triple superphosphate, and Ammonium Phosphates, No. 3 Total Phosphorus-P2O5, Method B - Gravimetric Quimociac Method.

(iii) Section XI, Methods of Analysis For Phosphoric Acid, Superphosphate, Triple superphosphate, and Ammonium Phosphates, No. 3 Total Phosphorus-P2O5, Method C - Spectrophotometric Method, or,

(7) Determine the P2O5 content (Rp) of the product stored using, as appropriate, the following methods specified in the Official Methods of Analysis of AOAC International (incorporated by reference, see §63.14) where applicable:

(i) AOAC Official Method 957.02 Phosphorus (Total) In Fertilizers, Preparation of Sample Solution.

(ii) AOAC Official Method 929.01 Sampling of Solid Fertilizers.

(iii) AOAC Official Method 929.02 Preparation of Fertilizer Sample.

(iv) AOAC Official Method 978.01 Phosphorus (Total) in Fertilizers, Automated Method.

(v) AOAC Official Method 969.02 Phosphorus (Total) in Fertilizers, Alkalimetric Quinolinium Molybdophosphate Method.

(vi) AOAC Official Method 962.02 Phosphorus (Total) in Fertilizers, Gravimetric Quinolinium Molybdophosphate Method.

(vii) AOAC Official Method 958.01 Phosphorus (Total) in Fertilizers, Spectrophotometric Molybdovanadophosphate Method.

(h) If you use a CMS, you must conduct a performance evaluation, as specified in §63.8(e), in accordance with your site-specific monitoring plan in §63.628(c). For fabric filters, you must conduct a performance evaluation of the bag leak detection system consistent with the guidance provided in Office Of Air Quality Planning And Standards (OAQPS), Fabric Filter Bag Leak Detection Guidance (incorporated by reference, see §63.14). You must record the sensitivity of the bag leak detection system to detecting changes in particulate matter emissions, range, averaging period, and alarm set points during the performance test.

§63.627 Notification, recordkeeping, and reporting requirements.

(a) You must comply with the notification requirements specified in §63.9. During the most recent performance test, if you demonstrate compliance with the emission limit while operating your control device outside the previously established operating limit, you must establish a new operating limit based on that most recent performance test and notify the Administrator that the operating limit changed based on data collected during the most recent performance test. When a source is retested and the performance test results are submitted to the Administrator pursuant to paragraph (b)(1) of this section, §63.7(g)(1), or §63.10(d)(2), you must indicate whether the operating limit is based on the new performance test or the previously established limit. Upon establishment of a new operating limit, you must thereafter operate under the new operating limit. If the Administrator determines that you did not conduct the compliance test in accordance with the applicable requirements or that the operating limit established during the performance test does not correspond to representative (normal) conditions, you must conduct a new performance test and establish a new operating limit.

(b) You must comply with the reporting and recordkeeping requirements in §63.10 as specified in paragraphs (b)(1) through (5) of this section.

(1) You must comply with the general recordkeeping requirements in §63.10(b)(1); and

(2) As required by §63.10(d), you must report the results of the initial and subsequent performance tests as part of the notification of compliance status required in §63.9(h). You must verify in the performance test reports that the operating limits for each process have not changed or provide documentation of revised operating limits established according to §63.625, as applicable. In the notification of compliance status, you must also:

(i) Certify to the Administrator that you have not shipped fresh granular triple superphosphate from an affected facility.

(ii) Certify to the Administrator annually that you have complied with the evaporative cooling tower requirements specified in §63.622(c).

(iii) Submit analyses and supporting documentation demonstrating conformance with the Office Of Air Quality Planning And Standards (OAQPS), Fabric Filter Bag Leak Detection Guidance (incorporated by reference, see §63.14) and specifications for bag leak detection systems as part of the notification of compliance status report.

(iv) If you elect to demonstrate compliance by following the procedures in §63.625(d)(1)(ii)(B), certify to the Administrator annually that the control devices and processes have not been modified since the date of the performance test from which you obtained the data used to establish the allowable ranges.

(3) As required by §63.10(e)(1), you must submit an excess emissions report for any exceedance of an emission or operating parameter limit if the total duration of the exceedances for the reporting period is 1 percent of the total operating time for the reporting period or greater. The report must contain the information specified in §63.10 and paragraph (b)(4) of this section. When exceedances of an emission limit or operating parameter have not occurred, you must include such information in the report. You must submit the report semiannually and the report must be delivered or postmarked by the 30th day following the end of the calendar half. If exceedances are reported, you must submit the excess emissions report quarterly until a request to reduce reporting frequency is approved as described in §63.10(e)(3).

(4) In the event that an affected unit fails to meet an applicable standard, record and report the following information for each failure:

(i) The date, time and duration of the failure.

(ii) A list of the affected sources or equipment for which a failure occurred.

(iii) An estimate of the volume of each regulated pollutant emitted over any emission limit.

(iv) A description of the method used to estimate the emissions.

(v) A record of actions taken to minimize emissions in accordance with §63.628(b), and any corrective actions taken to return the affected unit to its normal or usual manner of operation.

(5) You must submit a summary report containing the information specified in §63.10(e)(3)(vi). You must submit the summary report semiannually and the report must be delivered or postmarked by the 30th day following the end of the calendar half.

(c) Your records must be in a form suitable and readily available for expeditious review. You must keep each record for 5 years following the date of each recorded action. You must keep each record on site, or accessible from a central location by computer or other means that instantly provide access at the site, for at least 2 years after the date of each recorded action. You may keep the records off site for the remaining 3 years.

(d) In computing averages to determine compliance with this subpart, you must exclude the monitoring data specified in paragraphs (d)(1) through (3) of this section.

(1) Periods of non-operation of the process unit;

(2) Periods of no flow to a control device; and

(3) Any monitoring data recorded during continuous parameter monitoring system (CPMS) breakdowns, out-of-control periods, repairs, maintenance periods, instrument adjustments or checks to maintain precision and accuracy, calibration checks, and zero (low-level), mid-level (if applicable), and high-level adjustments.

(e) Within 60 days after the date of completing each performance test (as defined in §63.2) required by this subpart, you must submit the results of the performance tests, including any associated fuel analyses, following the procedure specified in either paragraph (e)(1) or (2) of this section.

(1) For data collected using test methods supported by the EPA's Electronic Reporting Tool (ERT) as listed on the EPA's ERT Web site (http://www.epa.gov/ttn/chief/ert/index.html), you must submit the results of the performance test to the EPA via the Compliance and Emissions Data Reporting Interface (CEDRI). CEDRI can be accessed through the EPA's Central Data Exchange (CDX) (http://cdx.epa.gov/epa_home.asp). Performance test data must be submitted in a file format generated through the use of the EPA's ERT. Alternatively, you may submit performance test data in an electronic file format consistent with the extensible markup language (XML) schema listed on the EPA's ERT Web site once the XML schema is available. If you claim that some of the performance test information being submitted is confidential business information (CBI), you must submit a complete file generated through the use of the EPA's ERT or an alternate electronic file consistent with the XML schema listed on the EPA's ERT Web site, including information claimed to be CBI, on a compact disc, flash drive, or other commonly used electronic storage media to the EPA. The electronic media must be clearly marked as CBI and mailed to U.S. EPA/OAPQS/CORE CBI Office, Attention: Group Leader, Measurement Policy Group, MD C404-02, 4930 Old Page Rd., Durham, NC 27703. The same ERT or alternate file with the CBI omitted must be submitted to the EPA via the EPA's CDX as described earlier in this paragraph.

(2) For data collected using test methods that are not supported by the EPA's ERT as listed on the EPA's ERT Web site, you must submit the results of the performance test to the Administrator at the appropriate address listed in §63.13.

§63.628 General requirements and applicability of general provisions of this part.

(a) You must comply with the general provisions in subpart A of this part as specified in appendix A to this subpart.

(b) At all times, you must operate and maintain any affected source, including associated air pollution control equipment and monitoring equipment, in a manner consistent with safety and good air pollution control practices for minimizing emissions. The general duty to minimize emissions does not require you to make any further efforts to reduce emissions if levels required by this standard have been achieved. Determination by the Administrator of whether a source is operating in compliance with operation and maintenance requirements will be based on information available to the Administrator that may include, but is not limited to, monitoring results, review of operation and maintenance procedures, review of operation and maintenance records, and inspection of the source.

(c) For each CMS used to demonstrate compliance with any applicable emission limit, you must develop, and submit to the Administrator for approval upon request, a site-specific monitoring plan according to the requirements specified in paragraphs (c)(1) through (3) of this section. You must submit the site-specific monitoring plan, if requested by the Administrator, at least 60 days before the initial performance evaluation of the CMS. The requirements of this paragraph also apply if a petition is made to the Administrator for alternative monitoring parameters under §63.8(f).

(1) You must include the information specified in paragraphs (c)(1)(i) through (vi) of this section in the site-specific monitoring plan.

(i) Location of the CMS sampling probe or other interface. You must include a justification demonstrating that the sampling probe or other interface is at a measurement location relative to each affected process unit such that the measurement is representative of control of the exhaust emissions (e.g., on or downstream of the last control device).

(ii) Performance and equipment specifications for the sample interface, the pollutant concentration or parametric signal analyzer, and the data collection and reduction systems.

(iii) Performance evaluation procedures and acceptance criteria (e.g., calibrations).

(iv) Ongoing operation and maintenance procedures in accordance with the general requirements of §63.8(c)(1)(ii), (c)(3), (c)(4)(ii), and Table 4 to this subpart.

(v) Ongoing data quality assurance procedures in accordance with the general requirements of §63.8(d)(1) and (2) and Table 5 to this subpart.

(vi) Ongoing recordkeeping and reporting procedures in accordance with the general requirements of §63.10(c), (e)(1), (e)(2)(i).

(2) You must include a schedule for conducting initial and subsequent performance evaluations in the site-specific monitoring plan.

(3) You must keep the site-specific monitoring plan on site for the life of the affected source or until the affected source is no longer subject to the provisions of this part, to be made available for inspection, upon request, by the Administrator. If you revise the site-specific monitoring plan, you must keep previous (i.e., superseded) versions of the plan on site to be made available for inspection, upon request, by the Administrator, for a period of 5 years after each revision to the plan. You must include the program of corrective action required under §63.8(d)(2) in the plan.

(d) For each bag leak detection system installed to comply with the requirements specified in §63.625(e), you must include the information specified in paragraphs (d)(1) and (2) of this section in the site-specific monitoring plan specified in paragraph (c) of this section.

(1) Performance evaluation procedures and acceptance criteria (e.g., calibrations), including how the alarm set-point will be established.

(2) A corrective action plan describing corrective actions to be taken and the timing of those actions when the bag leak detection alarm sounds. Corrective actions may include, but are not limited to, the actions specified in paragraphs (d)(2)(i) through (vi) of this section.

(i) Inspecting the fabric filter for air leaks, torn or broken bags or filter media, or any other conditions that may cause an increase in regulated material emissions.

(ii) Sealing off defective bags or filter media.

(iii) Replacing defective bags or filter media or otherwise repairing the control device.

(iv) Sealing off a defective fabric filter compartment.

(v) Cleaning the bag leak detection system probe or otherwise repairing the bag leak detection system.

(vi) Shutting down the process controlled by the fabric filter.

(e) If you use blower design capacity to determine the gas flow rate through the absorber for use in the liquid-to-gas ratio as specified in Table 3 to this subpart, then you must include in the site-specific monitoring plan specified in paragraph (c) of this section calculations showing how you determined the maximum possible gas flow rate through the absorber based on the blower's specifications (including any adjustments you made for pressure drop).

(f) If you use a regression model to determine the gas flow rate through the absorber for use in the liquid-to-gas ratio as specified in Table 3 to this subpart, then you must include in the site-specific monitoring plan specified in paragraph (c) of this section the calculations that were used to develop the regression model, including the calculations you use to convert amperage of the blower to brake horsepower. You must describe any constants included in the equations (e.g., efficiency, power factor), and describe how these constants were determined. If you want to change a constant in your calculation, then you must conduct a regression model verification to confirm the new value of the constant. In addition, the site-specific monitoring plan must be updated annually to reflect the data used in the annual regression model verification that is described in Table 3 to this subpart.

[80 FR 50450, Aug. 19, 2015, as amended at 82 FR 45200, Sept. 28, 2017]

§63.629 Miscellaneous requirements.

The Administrator retains the authority to approve site-specific test plans for uncontrolled granular triple superphosphate storage buildings developed pursuant to §63.7(c)(2)(i).

§63.630 [Reserved]

§63.631 Exemption from new source performance standards.

Any affected source subject to the provisions of this subpart is exempted from any otherwise applicable new source performance standard contained in 40 CFR part 60, subpart V, subpart W, or subpart X. To be exempt, a source must have a current operating permit pursuant to title V of the Clean Air Act and the source must be in compliance with all requirements of this subpart. For each affected source, this exemption is upon the date that you demonstrate to the Administrator that the requirements of §§63.625 and 63.626 have been met.

§63.632 Implementation and enforcement.

(a) This subpart is implemented and enforced by the U.S. EPA, or a delegated authority such as the applicable state, local, or Tribal agency. If the U.S. EPA Administrator has delegated authority to a state, local, or Tribal agency, then that agency, in addition to the U.S. EPA, has the authority to implement and enforce this subpart. Contact the applicable U.S. EPA Regional Office to find out if implementation and enforcement of this subpart is delegated to a state, local, or Tribal agency.

(b) The authorities specified in paragraphs (b)(1) through (5) of this section are retained by the Administrator of U.S. EPA and cannot be delegated to State, local, or Tribal agencies.

(1) Approval of alternatives to the requirements in §§63.620, 63.622, 63.625, 63.629, and 63.631.

(2) Approval of requests under §§63.7(e)(2)(ii) and 63.7 (f) for alternative requirements or major changes to the test methods specified in this subpart, as defined in §63.90.

(3) Approval of requests under §63.8(f) for alternative requirements or major changes to the monitoring requirements specified in this subpart, as defined in §63.90.

(4) Waiver or approval of requests under §63.10(f) for alternative requirements or major changes to the recordkeeping and reporting requirements specified in this subpart, as defined in §63.90.

(5) Approval of an alternative to any electronic reporting to the EPA required by this subpart.

Table 1 to Subpart BB of Part 63 - Existing Source Emission Limits a b

| For the following existing sources . . . | You must meet the emission limits for the specified pollutant . . . |

|---|---|

| Total fluorides | |

| a The existing source compliance date is June 10, 2002. b During periods of startup and shutdown, for emission limits stated in terms of pounds of pollutant per ton of feed, you are subject to the work practice standards specified in §63.622(d). | |

| Phosphate Fertilizer Process Line (e.g., Diammonium and/or Monoammonium Phosphate Process Line) | 0.060 lb/ton of equivalent P2O5 feed. |

| Granular Triple Superphosphate Process Line | 0.150 lb/ton of equivalent P2O5 feed. |

| GTSP storage building | 5.0 × 10?4 lb/hr/ton of equivalent P2O5 stored. |

Table 2 to Subpart BB of Part 63 - New Source Emission Limits a b

| For the following new sources . . . | You must meet the emission limits for the specified pollutant . . . |

|---|---|

| Total fluorides | |

| a The new source compliance dates are based on date of construction or reconstruction as specified in §63.622(a). b During periods of startup and shutdown, for emission limits stated in terms of pounds of pollutant per ton of feed, you are subject to the work practice standards specified in §63.622(d). | |

| Phosphate Fertilizer Process Line (e.g., Diammonium and/or Monoammonium Phosphate Process Line) | 0.0580 lb/ton of equivalent P2O5 feed. |

| Granular Triple Superphosphate Process Line | 0.1230 lb/ton of equivalent P2O5 feed. |

| GTSP storage building | 5.0 × 10?4 lb/hr/ton of equivalent P2O5 stored. |

Table 3 to Subpart BB of Part 63 - Monitoring Equipment Operating Parameters

| You must . . . | If . . . | And you must monitor . . . a | And . . . a |

|---|---|---|---|

| a To monitor an operating parameter that is not specified in this table (including process-specific techniques not specified in this table to determine gas flow rate through an absorber), you must request, on a site-specific basis, an alternative monitoring method under the provisions of §63.8(f). b For new sources that commence construction or reconstruction after August 19, 2015, the compliance date is immediately upon startup. For existing sources, and new sources that commence construction or reconstruction after December 27, 1996, and on or before August 19, 2015, if your absorber is designed and operated with pressure drops of 5 inches of water column or less, then the compliance date is August 19, 2018. In the interim, for existing sources, and new sources that commence construction or reconstruction after December 27, 1996, and on or before August 19, 2015, with an absorber designed and operated with pressure drops of 5 inches of water column or less, you must comply with one of the following: (i) The monitoring requirements in this Table 3 for absorbers designed and operated with pressure drops of 5 inches of water column or less; (ii) the applicable monitoring provisions included in a permit issued under 40 CFR part 70 to assure compliance with subpart BB; (iii) the applicable monitoring provisions of an Alternative Monitoring Plan approved pursuant to §63.8(f); or (iv) install CPMS for pressure at the gas stream inlet and outlet of the absorber, and monitor pressure drop through the absorber. c If you select this option, then you must comply with §63.628(e). The option to use blower design capacity is intended to establish the maximum possible gas flow through the absorber; and is available regardless of the location of the blower (influent or effluent), as long as the gas flow rate through the absorber can be established. Establish the minimum liquid-to-gas ratio operating limit by dividing the minimum liquid flow rate to the absorber (determined during a performance test) by the maximum possible gas flow rate through the absorber (determined using blower design capacity). d If you select this option, then you must comply with §63.628(f). The regression model must be developed using direct measurements of gas flow rate, and design fan curves that correlate gas flow rate to static pressure (i.e., fan suction pressure) and brake horsepower of the blower. You must conduct an annual regression model verification using direct measurements of gas flow rate to ensure the correlation remains accurate. Direct measurements of gas flow rate used to develop or verify regression models may be collected during, or separately from, the annual performance testing that is required in §63.626(b). | |||

| Absorbers (Wet Scrubbers) | |||

| Install a continuous parameter monitoring system (CPMS) for liquid flow at the inlet of the absorber. | Your absorber is designed and operated with pressure drops of 5 inches of water column or more; and you choose to monitor only the influent liquid flow, rather than the liquid-to-gas ratio | Influent liquid flow. | |

| Install CPMS for liquid and gas flow at the inlet of the absorber b | Your absorber is designed and operated with pressure drops of 5 inches of water column or less; or Your absorber is designed and operated with pressure drops of 5 inches of water column or more, and you choose to monitor the liquid-to-gas ratio, rather than only the influent liquid flow, and you want the ability to lower liquid flow with changes in gas flow | Liquid-to-gas ratio as determined by dividing the influent liquid flow rate by the gas flow rate through the absorber. The units of measure must be consistent with those used to calculate this ratio during the performance test | You must determine the gas flow rate through the absorber by: Measuring the gas flow rate at the absorber inlet or outlet; Using the blower design capacity, with appropriate adjustments for pressure drop; c or Using a regression model. d |

| Install CPMS for pressure at the gas stream inlet and outlet of the absorber | Your absorber is designed and operated with pressure drops of 5 inches of water column or more | Pressure drop through the absorber | You may measure the pressure of the inlet gas using amperage on the blower if a correlation between pressure and amperage is established. |

[80 FR 50450, Aug. 19, 2015, as amended at 82 FR 45200, Sept. 28, 2017]

Table 4 to Subpart BB of Part 63 - Operating Parameters, Operating Limits and Data Monitoring, Recordkeeping and Compliance Frequencies

| For the operating parameter applicable to you, as specified in Table 3 . . . | You must establish the following operating limit during your performance test . . . | And you must monitor, record, and demonstrate continuous compliance using these minimum frequencies . . . | ||

|---|---|---|---|---|

| Data measurement | Data recording | Data averaging period for compliance | ||

| Absorbers (Wet Scrubbers) | ||||

| Influent liquid flow | Minimum inlet liquid flow | Continuous | Every 15 minutes | Daily. |

| Influent liquid flow rate and gas stream flow rate | Minimum influent liquid-to-gas ratio a | Continuous | Every 15 minutes | Daily. |

| For the operating parameter applicable to you, as specified in Table 3 | You must establish the following operating limit | And you must monitor, record, and demonstrate continuous compliance using these minimum frequencies . . . | ||

| Data measurement | Data recording | Data averaging period for compliance. | ||

| Pressure drop | Pressure drop range | Continuous | Every 15 minutes | Daily. |

| Sorbent Injection | ||||

| Sorbent injection rate | Minimum injection rate | Continuous | Every 15 minutes | Daily. |

| Sorbent injection carrier gas flow rate | Minimum carrier gas flow rate | Continuous | Every 15 minutes | Daily. |

| Fabric Filters | ||||

| Alarm time | Maximum alarm time is not established on a site-specific basis but is specified in §63.605(f)(9) | Continuous | Each date and time of alarm start and stop | Maximum alarm time specified in §63.605(f)(9). |

| Wet Electrostatic Precipitator | ||||

| Secondary voltage | Secondary voltage range | Continuous | Every 15 minutes | Daily. |

[82 FR 45201, Sept. 28, 2017]

Table 5 to Subpart BB of Part 63 - Calibration and Quality Control Requirements for Continuous Parameter Monitoring Systems (CPMS)

| If you monitor this parameter . . . | Your accuracy requirements are . . . | And your calibration requirements are . . . |

|---|---|---|

| Flow Rate | ±5 percent over the normal range of flow measured or 1.9 liters per minute (0.5 gallons per minute), whichever is greater, for liquid flow rate. ±5 percent over the normal range of flow measured or 28 liters per minute (10 cubic feet per minute), whichever is greater, for gas flow rate. ±5 percent over the normal range measured for mass flow rate. | Performance evaluation annually and following any period of more than 24 hours throughout which the flow rate exceeded the maximum rated flow rate of the sensor, or the data recorder was off scale. Checks of all mechanical connections for leakage monthly. Visual inspections and checks of CPMS operation every 3 months, unless the CPMS has a redundant flow sensor. Selection of a representative measurement location where swirling flow or abnormal velocity distributions due to upstream and downstream disturbances at the point of measurement are minimized. |

| Pressure | ±5 percent over the normal range measured or 0.12 kilopascals (0.5 inches of water column), whichever is greater. | Checks for obstructions (e.g., pressure tap pluggage) at least once each process operating day. Performance evaluation annually and following any period of more than 24 hours throughout which the pressure exceeded the maximum rated pressure of the sensor, or the data recorder was off scale. Checks of all mechanical connections for leakage monthly. Visual inspection of all components for integrity, oxidation and galvanic corrosion every 3 months, unless the CPMS has a redundant pressure sensor. Selection of a representative measurement location that minimizes or eliminates pulsating pressure, vibration, and internal and external corrosion. |

Appendix A to Subpart BB of Part 63 - Applicability of General Provisions (40 CFR Part 63, Subpart A) to Subpart BB

| 40 CFR citation | Requirement | Applies to subpart BB | Comment |

|---|---|---|---|

| §63.1(a)(1) through (4) | General Applicability | Yes | None. |

| §63.1(a)(5) | No | [Reserved]. | |

| §63.1(a)(6) | Contact information | Yes | None. |

| §63.1(a)(7) through (9) | No | [Reserved]. | |

| §63.1(a)(10) through (12) | Time periods | Yes | None. |

| §63.1(b) | Initial Applicability Determination | Yes | None. |

| §63.1(c)(1) | Applicability After Standard Established | Yes | None. |

| §63.1(c)(2) | Permits | Yes | Some plants may be area sources. |

| §63.1(c)(3) through (4) | No | [Reserved]. | |

| §63.1(c)(5) | Area to Major source change | Yes | None. |

| §63.1(c)(6) | Yes | None. | |

| §63.1(d) | No | [Reserved]. | |

| §63.1(e) | Applicability of Permit Program | Yes | None. |

| §63.2 | Definitions | Yes | Additional definitions in §63.621. |

| §63.3 | Units and Abbreviations | Yes | None. |

| §63.4(a)(1) and (2) | Prohibited Activities | Yes | None. |

| §63.4(a)(3) through (5) | No | [Reserved]. | |

| §63.4(b) and (c) | Circumvention/Fragmentation | Yes | None. |

| §63.5(a) | Construction/Reconstruction Applicability | Yes | None. |

| §63.5(b)(1) | Existing, New, Reconstructed Sources Requirements | Yes | None. |

| §63.5(b)(2) | No | [Reserved]. | |

| §63.5(b)(3), (4), and (6) | Construction/Reconstruction approval and notification | Yes | None. |

| §63.5(b)(5) | No | [Reserved]. | |

| §63.5(c) | No | [Reserved]. | |

| §63.5(d) | Application for Approval of Construction/Reconstruction | Yes | None. |

| §63.5(e) | Approval of Construction/Reconstruction | Yes | None. |

| §63.5(f) | Approval of Construction/Reconstruction Based on State Review | Yes | None. |

| §63.6(a) | Compliance with Standards and Maintenance Applicability | Yes | None. |

| §63.6(b)(1) through (5) | New and Reconstructed Sources Dates | Yes | See also §63.622. |

| §63.6(b)(6) | No | [Reserved]. | |

| §63.6(b)(7) | Area to major source change | Yes | None. |

| §63.6(c)(1) and (2) | Existing Sources Dates | Yes | §63.622 specifies dates. |

| §63.6(c)(3) and (4) | No | [Reserved]. | |

| §63.6(c)(5) | Area to major source change | Yes | None. |

| §63.6(d) | No | [Reserved]. | |

| §63.6(e)(1)(i) and (ii) | Operation & Maintenance Requirements | No | See §63.628(b) for general duty requirement. |

| §63.6(e)(iii) | Yes | None. | |

| §63.6(e)(2) | No | [Reserved]. | |

| §63.6(e)(3) | Startup, Shutdown, and Malfunction Plan | No | None. |

| §63.6(f) | Compliance with Emission Standards | No | See general duty at §63.628(b). |

| §63.6(g) | Alternative Standard | Yes | None. |

| §63.6(h) | Compliance with Opacity/VE Standards | No | Subpart BB does not include VE/opacity standards. |

| §63.6(i)(1) through (14) | Extension of Compliance | Yes | None. |

| §63.6(i)(15) | No | [Reserved]. | |

| §63.6(i)(16) | Yes | None. | |

| §63.6(j) | Exemption from Compliance | Yes | None. |

| §63.7(a) | Performance Test Requirements Applicability | Yes | None. |

| §63.7(b) | Notification | Yes | None. |

| §63.7(c) | Quality Assurance/Test Plan | Yes | None. |

| §63.7(d) | Testing Facilities | Yes | None. |

| §63.7(e)(1) | Conduct of Tests; startup, shutdown and malfunction provisions | No | §63.626 specifies additional requirements. |

| §63.7(e)(2) through (4) | Conduct of Tests | Yes | §63.626 specifies additional requirements. |

| §63.7(f) | Alternative Test Method | Yes | None. |

| §63.7(g) | Data Analysis | Yes | None. |

| §63.7(h) | Waiver of Tests | Yes | None. |

| §63.8(a) | Monitoring Requirements Applicability | Yes | None. |

| §63.8(b) | Conduct of Monitoring | Yes | None. |

| §63.8(c)(1)(i) | General duty to minimize emissions and CMS operation | No | See §63.628(b) for general duty requirement. |

| §63.8(c)(1)(ii) | Yes | None. | |

| §63.8(c)(1)(iii) | Requirement to develop SSM Plan for CMS | No | None. |

| §63.8(c)(2) through (4) | CMS Operation/Maintenance | Yes | None. |

| §63.8(c)(5) | COMS Operation | No | Subpart BB does not require COMS. |

| §63.8(c)(6) through (8) | CMS requirements | Yes | None. |

| §63.8(d)(1) and (2) | Quality Control | Yes | None. |

| §63.8(d)(3) | Written procedure for CMS | No | See §63.628 for requirement. |

| §63.8(e) | CMS Performance Evaluation | Yes | None. |

| §63.8(f)(1) through (5) | Alternative Monitoring Method | Yes | None. |

| §63.8(f)(6) | Alternative to RATA Test | No | Subpart BB does not require CEMS. |

| §63.8(g)(1) | Data Reduction | Yes | None. |

| §63.8(g)(2) | No | Subpart BB does not require COMS or CEMS. | |

| §63.8(g)(3) through (5) | Yes | None. | |

| §63.9(a) | Notification Requirements Applicability | Yes | None. |

| §63.9(b) | Initial Notifications | Yes | None. |

| §63.9(c) | Request for Compliance Extension | Yes | None. |

| §63.9(d) | New Source Notification for Special Compliance Requirements | Yes | None. |

| §63.9(e) | Notification of Performance Test | Yes | None. |

| §63.9(f) | Notification of VE/Opacity Test | No | Subpart BB does not include VE/opacity standards. |

| §63.9(g) | Additional CMS Notifications | Yes | None. |

| §63.9(h)(1) through (3) | Notification of Compliance Status | Yes | None. |

| §63.9(h)(4) | No | [Reserved]. | |

| §63.9(h)(5) and (6) | Yes | None. | |

| §63.9(i) | Adjustment of Deadlines | Yes | None. |

| §63.9(j) | Change in Previous Information | Yes | None. |

| §63.9(k) | Yes | Only as specified in §63.9(j). | |

| §63.10(a) | Recordkeeping/Reporting-Applicability | Yes | None. |

| §63.10(b)(1) | General Recordkeeping Requirements | Yes | None. |

| §63.10(b)(2)(i) | Startup or shutdown duration | No | None. |

| §63.10(b)(2)(ii) | Malfunction | No | See §63.627 for recordkeeping and reporting requirement. |

| §63.10(b)(2)(iii) | Maintenance records | Yes | None. |

| §63.10(b)(2)(iv) and (v) | Startup, shutdown, malfunction actions | No | None. |

| §63.10(b)(2)(vi) through (xiv) | General Recordkeeping Requirements | Yes | None. |

| §63.10(b)(3) | General Recordkeeping Requirements | Yes | None. |

| §63.10(c)(1) | Additional CMS Recordkeeping | Yes | None. |

| §63.10(c)(2) through (4) | No | [Reserved]. | |

| §63.10(c)(5) | Yes | None. | |

| §63.10(c)(6) | Yes | None. | |

| §63.10(c)(7) and (8) | Yes | None. | |

| §63.10(c)(9) | No | [Reserved]. | |

| §63.10(c)(10) through (13) | Yes | None. | |

| §63.10(c)(14) | Yes | None. | |

| §63.10(c)(15) | Startup Shutdown Malfunction Plan Provisions | No | None. |

| §63.10(d)(1) | General Reporting Requirements | Yes | None. |

| §63.10(d)(2) | Performance Test Results | Yes | None. |

| §63.10(d)(3) | Opacity or VE Observations | No | Subpart BB does not include VE/opacity standards. |

| §63.10(d)(4) | Progress Reports | Yes | None. |

| §63.10(d)(5) | Startup, Shutdown, and Malfunction Reports | No | See §63.627 for reporting of excess emissions. |

| §63.10(e)(1) and (2) | Additional CMS Reports | Yes | None. |

| §63.10(e)(3) | Excess Emissions/CMS Performance Reports | Yes | None. |

| §63.10(e)(4) | COMS Data Reports | No | Subpart BB does not require COMS. |

| §63.10(f) | Recordkeeping/Reporting Waiver | Yes | None. |

| §63.11 | Control Device and Work Practice Requirements | Yes | None. |

| §63.12 | State Authority and Delegations | Yes | None. |

| §63.13 | Addresses | Yes | None. |

| §63.14 | Incorporation by Reference | Yes | None. |

| §63.15 | Information Availability/Confidentiality | Yes | None. |

| §63.16 | Performance Track Provisions | No | Terminated. |

[85 FR 73892, Nov. 19, 2020]

Source: 80 FR 50450, Aug. 19, 2015, unless otherwise noted.

['Air Programs']

['Hazardous Air Pollutants']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.