['Air Programs']

['Air Emissions']

03/03/2023

...

§1036.101 Overview of exhaust emission standards.

(a) You must show that engines meet the following exhaust emission standards:

(1) Criteria pollutant standards for NO X , HC, PM, and CO apply as described in §1036.104.

(2)Greenhouse gas (GHG) standards for CO 2 , CH 4 , and N 2 O apply as described in §1036.108.

(b) You may optionally demonstrate compliance with the emission standards of this part by testing hybrid engines and hybrid powertrains, rather than testing the engine alone. Except as specified, provisions of this part that reference engines apply equally to hybrid engines and hybrid powertrains.

[88 FR 4487, Jan. 24, 2023]

§1036.104 Criteria pollutant emission standards—NO , HC, PM, and CO.

This section describes the applicable NO X, HC, CO, and PM standards for model years 2027 and later. These standards apply equally for all primary intended service classes unless otherwise noted.

(a) Emission standards. Exhaust emissions may not exceed the standards in this section, as follows:

(1) The following emission standards apply for Light HDE, Medium HDE, and Heavy HDE over the FTP, SET, and LLC duty cycles using the test procedures described in subpart F of this part:

| Duty cycle | NO X mg/hp·hr | HC mg/hp·hr | PM mg/hp·hr | CO g/hp·hr |

|---|---|---|---|---|

| SET and FTP | 35 | 60 | 5 | 6.0 |

| LLC | 50 | 140 | 5 | 6.0 |

(2) The following emission standards apply for Spark-ignition HDE over the FTP and SET duty cycles using the test procedures described in subpart F of this part:

| Duty cycle | NOX mg/hp·hr | HC mg/hp·hr | PM mg/hp·hr | CO g/hp·hr |

|---|---|---|---|---|

| SET | 35 | 60 | 5 | 14.4 |

| FTP | 35 | 60 | 5 | 6.0 |

(3) The following off-cycle emission standards apply for Light HDE, Medium HDE, and Heavy HDE using the procedures specified in §1036.530, as follows:

| Off-cycle Bin | NO X | Temperature adjustment a | HC mg/hp·hr | PM mg/hp·hr | CO g/hp·hr |

|---|---|---|---|---|---|

| Bin 1 | 10.0 g/hr | (25.0? T amb) · 0.25 | |||

| Bin 2 | 58 mg/hp·hr | (25.0? T amb) · 2.2 | 120 | 7.5 | 9 |

| a T amb is the mean ambient temperature over a shift-day, or equivalent. Adjust the off-cycle NO X standard for T amb below 25.0 °C by adding the calculated temperature adjustment to the specified NO X standard. Round the temperature adjustment to the same precision as the NO X standard for the appropriate bin. If you declare a NO X FEL for the engine family, do not apply the FEL scaling calculation from paragraph (c)(3) of this section to the calculated temperature adjustment. | |||||

(b) Clean Idle. You may optionally certify compression-ignition engines to the Clean Idle NO X emission standard using the Clean Idle test specified in §1036.525. The optional Clean Idle NO X emission standard is 30.0 g/h for model years 2024 through 2026, and 10.0 g/hr for model year 2027 and later. The standard applies separately to each mode of the Clean Idle test. If you certify an engine family to the Clean Idle standards, it is subject to all these voluntary standards as if they were mandatory.

(c) Averaging, banking, and trading. You may generate or use emission credits under the averaging, banking, and trading (ABT) program described in subpart H of this part for demonstrating compliance with NO X emission standards in paragraph (a) of this section. You must meet the PM, HC, and CO emission standards in §1036.104(a) without generating or using emission credits.

(1) To generate or use emission credits, you must specify a family emission limit for each engine family. Declare the family emission limit corresponding to full useful life for engine operation over the FTP duty cycle, FEL FTP , expressed to the same number of decimal places as the emission standard. Use FEL FTP to calculate emission credits in subpart H of this part.

(2) The following NO X FEL caps are the maximum value you may specify for FEL FTP :

(i) 65 mg/hp·hr for model years 2027 through 2030.

(ii) 50 mg/hp·hr for model year 2031 and later.

(iii) 70 mg/hp·hr for model year 2031 and later Heavy HDE.

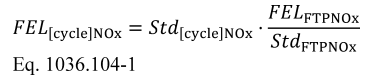

(3) Calculate the NO X family emission limit, FEL [cycle]NO, that applies for each duty-cycle or off-cycle standard using the following equation:

Where:

Std [cycle]NO, = the NO X emission standard that applies for the applicable cycle or for off-cycle testing under paragraph (a) of this section for engines not participating in the ABT program.

FEL FTPNO = the engine family's declared FEL for NO X over the FTP duty cycle from paragraph (c)(1) of this section.

Std FTPNO = the NO X emission standard that applies for the FTP duty cycle under paragraph (a) of this section for engines not participating in the ABT program.

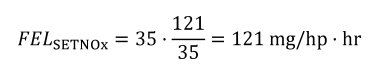

Example for model year 2029 Medium HDE for the SET:

Std SETNO = 35 mg/hp·hr

FEL FTP = 121 mg/hp·hr

Std FTPNO = 35 mg/hp·hr

FEL SETNO = 121 mg/hp·hr

(4) The family emission limits you select under this paragraph (c) serve as the emission standards for compliance testing instead of the standards specified in this section.

(d) Fuel types. The exhaust emission standards in this section apply for engines using the fuel type on which the engines in the engine family are designed to operate. You must meet the numerical emission standards for HC in this section based on the following types of hydrocarbon emissions for engines powered by the following fuels:

(1) Alcohol-fueled engines: NMHCE emissions.

(2) Gaseous-fueled engines: NMNEHC emissions.

(3) Other engines: NMHC emissions.

(e) Useful life. The exhaust emission standards of this section apply for the useful life, expressed in vehicle miles, or hours of engine operation, or years in service, whichever comes first, as follows:

| Primary intended service class | Model year 2026 and earlier | Model year 2027 and later | ||||

|---|---|---|---|---|---|---|

| Miles | Years | Hours | Miles | Years | Hours | |

| Spark-ignition HDE | 110,000 | 10 | 200,000 | 15 | 10,000 | |

| Light HDE | 110,000 | 10 | 270,000 | 15 | 13,000 | |

| Medium HDE | 185,000 | 10 | 350,000 | 12 | 17,000 | |

| Heavy HDE | 435,000 | 10 | 22,000 | 650,000 | 11 | 32,000 |

(f) Applicability for testing. The emission standards in this subpart apply to all testing, including certification, selective enforcement audits, and in-use testing. For selective enforcement audits, we may require you to perform the appropriate duty-cycle testing as specified in §§1036.510, 1036.512, and 1036.514. We may direct you to do additional testing to show that your engines meet the off-cycle standards.

[88 FR 4487, Jan. 24, 2023]

§1036.108 Greenhouse gas emission standards—CO , CH , and N O.

This section contains standards and other regulations applicable to the emission of the air pollutant defined as the aggregate group of six greenhouse gases: carbon dioxide, nitrous oxide, methane, hydrofluorocarbons, perfluorocarbons, and sulfur hexafluoride. This section describes the applicable CO 2, N 2 O, and CH 4 standards for engines.

(a) Emission standards. Emission standards apply for engines and optionally powertrains measured using the test procedures specified in subpart F of this part as follows:

(1) CO 2 emission standards in this paragraph (a)(1) apply based on testing as specified in subpart F of this part. The applicable test cycle for measuring CO 2 emissions differs depending on the engine family's primary intended service class and the extent to which the engines will be (or were designed to be) used in tractors. For Medium HDE and Heavy HDE certified as tractor engines, measure CO 2 emissions using the SET steady-state duty cycle specified in §1036.510. This testing with the SET duty cycle is intended for engines designed to be used primarily in tractors and other line-haul applications. Note that the use of some SET-certified tractor engines in vocational applications does not affect your certification obligation under this paragraph (a)(1); see other provisions of this part and 40 CFR part 1037 for limits on using engines certified to only one cycle. For Medium HDE and Heavy HDE certified as both tractor and vocational engines, measure CO 2 emissions using the SET duty cycle specified in §1036.510 and the FTP transient duty cycle specified in §1036.512. Testing with both SET and FTP duty cycles is intended for engines that are designed for use in both tractor and vocational applications. For all other engines (including Spark-ignition HDE), measure CO 2 emissions using the FTP transient duty cycle specified in §1036.512.

(i) The Phase 1 CO 2 standard is 627 g/hp·hr for all spark-ignition engines for model years 2016 through 2020. This standard continues to apply in later model years for all spark-ignition engines that are not Heavy HDE.

(ii) The following Phase 1 CO 2 standards apply for compression-ignition engines (in g/hp·hr):

| Model years | Light HDE | Medium HDE—vocational | Heavy HDE—vocational | Medium HDE—tractor | Heavy HDE—tractor |

|---|---|---|---|---|---|

| 2014-2016 | 600 | 600 | 567 | 502 | 475 |

| 2017-2020 | 576 | 576 | 555 | 487 | 460 |

(iii) The following Phase 2 CO 2 standards apply for compression-ignition engines and all Heavy HDE (in g/hp·hr):

| Model years | Light HDE | Medium HDE—vocational | Heavy HDE—vocational | Medium HDE—tractor | Heavy HDE—tractor |

|---|---|---|---|---|---|

| 2021-2023 | 563 | 545 | 513 | 473 | 447 |

| 2024-2026 | 555 | 538 | 506 | 461 | 436 |

| 2027 and later | 552 | 535 | 503 | 457 | 432 |

(iv) You may certify spark-ignition engines to the compression-ignition standards for the appropriate model year under this paragraph (a). If you do this, those engines are treated as compression-ignition engines for all the provisions of this part.

(2) The CH 4 emission standard is 0.10 g/hp·hr when measured over the applicable FTP transient duty cycle specified in §1036.512. This standard begins in model year 2014 for compression-ignition engines and in model year 2016 for spark-ignition engines. Note that this standard applies for all fuel types just like the other standards of this section.

(3) The N 2 O emission standard is 0.10 g/hp·hr when measured over the applicable FTP transient duty cycle specified in §1036.512. This standard begins in model year 2014 for compression-ignition engines and in model year 2016 for spark-ignition engines.

(b) Family Certification Levels. You must specify a CO 2 Family Certification Level (FCL) for each engine family expressed to the same number of decimal places as the emission standard. The FCL may not be less than the certified emission level for the engine family. The CO 2 family emission limit (FEL) for the engine family is equal to the FCL multiplied by 1.03.

(c) Averaging, banking, and trading. You may generate or use emission credits under the averaging, banking, and trading (ABT) program described in subpart H of this part for demonstrating compliance with CO 2 emission standards. Credits (positive and negative) are calculated from the difference between the FCL and the applicable emission standard. As described in §1036.705, you may use CO 2 credits to certify your engine families to FELs for N 2 O and/or CH 4, instead of the N 2 O/CH 4 standards of this section that otherwise apply. Except as specified in §§1036.150 and 1036.705, you may not generate or use credits for N 2 O or CH 4 emissions.

(d) Useful life. The exhaust emission standards of this section apply for the useful life, expressed as vehicle miles, or hours of engine operation, or years in service, whichever comes first, as follows:

| Primary intended service class | Miles | Years |

|---|---|---|

| Spark-ignition HDE a | 150,000 | 15 |

| Light HDE a | 150,000 | 15 |

| Medium HDE | 185,000 | 10 |

| Heavy HDE b | 435,000 | 10 |

| a Useful life for Spark-ignition HDE and Light HDE before model year 2021 is 110,000 miles or 10 years, whichever occurs first. | ||

| b Useful life for Heavy HDE is also expressed as 22,000 operating hours. For an individual engine, the useful life is no shorter than 10 years or 100,000 miles, whichever occurs first, regardless of operating hours. | ||

(e) Applicability for testing. The emission standards in this subpart apply as specified in this paragraph (e) to all duty-cycle testing (according to the applicable test cycles) of testable configurations, including certification, selective enforcement audits, and in-use testing. The CO 2 FCLs serve as the CO 2 emission standards for the engine family with respect to certification and confirmatory testing instead of the standards specified in paragraph (a)(1) of this section. The FELs serve as the emission standards for the engine family with respect to all other duty-cycle testing. See §§1036.235 and 1036.241 to determine which engine configurations within the engine family are subject to testing. Note that engine fuel maps and powertrain test results also serve as standards as described in §§1036.535, 1036.540, and 1036.630 and 40 CFR 1037.550.

[88 FR 4487, Jan. 24, 2023]

§1036.110 Diagnostic controls.

Onboard diagnostic (OBD) systems must generally detect malfunctions in the emission control system, store trouble codes corresponding to detected malfunctions, and alert operators appropriately. Starting in model year 2027, new engines must have OBD systems as described in this section. You may optionally comply with any or all of the requirements of this section instead of 40 CFR 86.010-18 in earlier model years.

(a) Chassis-based OBD requirements apply instead of the requirements of this section for certain engines as follows:

(1) Heavy-duty engines intended to be installed in heavy duty vehicles at or below 14,000 pounds GVWR must meet the requirements in 40 CFR 86.1806. Note that 40 CFR 86.1806 allows for using later versions of specified OBD requirements from the California Air Resources Board, which includes meeting the 2019 heavy-duty OBD requirements adopted for California and updated emission thresholds as described in this section.

(2) Heavy-duty spark-ignition engines intended to be installed in heavy-duty vehicles above 14,000 pounds GVWR may meet the requirements in 40 CFR 86.1806 if the same engines are also installed in vehicles certified under 40 CFR part 86, subpart S, where both sets of vehicles share similar emission controls.

(b) Engines must comply with the 2019 heavy-duty OBD requirements adopted for California as described in this paragraph (b). California's 2019 heavy-duty OBD requirements are part of 13 CCR 1968.2, 1968.5, 1971.1, and 1971.5 (incorporated by reference in §1036.810). We may approve your request to certify an OBD system meeting alternative specifications if you submit information as needed to demonstrate that it meets the intent of this section. For example, we may approve your request for a system that meets a later version of California's OBD requirements if you demonstrate that it meets the intent of this section; the demonstration must include identification of any approved deficiencies and your plans to resolve such deficiencies. To demonstrate that your engine meets the intent of this section, the OBD system meeting alternative specifications must address all the provisions described in this paragraph (b) and in paragraph (c) of this section. The following clarifications and exceptions apply for engines certified under this part:

(1) We may approve a small manufacturer's request to delay complying with the requirements of this section for up to three model years if that manufacturer has not certified those engines or other comparable engines in California for those model years.

(2) For engines not certified in California, references to vehicles meeting certain California Air Resources Board emission standards are understood to refer to the corresponding EPA emission standards for a given family, where applicable. Use good engineering judgment to correlate the specified standards with the EPA standards that apply under this part. You must describe in your application for certification how you will perform testing to demonstrate compliance with OBD requirements to represent all your engine families over five or fewer model years.

(3) Engines must comply with OBD requirements throughout the useful life as specified in §1036.104(e).

(4) The purpose and applicability statements in 13 CCR 1971.1(a) and (b) do not apply.

(5) Emission thresholds apply as follows:

(i) Spark-ignition engines are subject to a NO X threshold of 0.35 g/hp·hr for catalyst monitoring and 0.30 g/hp·hr in all other cases. Spark-ignition engines are subject to a PM threshold of 0.015 g/hp·hr. Thresholds apply for operation on the FTP and SET duty cycles.

(ii) Compression-ignition engines are subject to a NO X threshold of 0.40 g/hp·hr and a PM threshold of 0.03 g/hp·hr for operation on the FTP and SET duty cycles.

(iii) All engines are subject to HC and CO thresholds as specified in 13 CCR 1968.2 and 1971.1, except that the “applicable standards” for determining these thresholds are 0.14 g/hp·hr for HC, 14.4 g/hp·hr for CO from spark-ignition engines, and 15.5 g/hp·hr for CO from compression-ignition engines.

(iv) Compression-ignition engines may be exempt from certain monitoring in 13 CCR 1968.2 and 1971.1 based on specified test-out criteria. To calculate these test-out criteria, the “applicable standards” are 0.20 g/hp·hr for NO X, 0.14 g/hp·hr for HC, 0.01 g/hp·hr for PM, 14.4 g/hp·hr for CO from spark-ignition engines, and 15.5 g/hp·hr for CO from compression-ignition engines.

(6) The provisions related to verification of in-use compliance in 13 CCR 1971.1(l) do not apply. The provisions related to manufacturer self-testing in 13 CCR 1971.5(c) also do not apply.

(7) The deficiency provisions described in paragraph (d) of this section apply instead of 13 CCR 1971.1(k).

(8) Include the additional data-stream signals in 13 CCR 1971.1(h)(4.2.3)(E), (F), and (G) as freeze-frame conditions as required in 13 CCR 1971.1(h)(4.3).

(9) Design compression-ignition engines to make the following additional data-stream signals available on demand with a generic scan tool according to 13 CCR 1971.1(h)(4.2), if the engine is so equipped:

(i) Engine and vehicle parameters. Status of parking brake, neutral switch, brake switch, and clutch switch, wastegate control solenoid output, wastegate position (commanded and actual), speed and output shaft torque consistent with §1036.115(d).

(ii) Diesel oxidation catalyst parameters. Include inlet and outlet pressure and temperature for the diesel oxidation catalyst.

(iii) Particulate filter parameters. Include filter soot load and ash load for all installed particulate filters.

(iv) EGR parameters. Include differential pressure for exhaust gas recirculation.

(v) SCR parameters. Include DEF quality-related signals, DEF coolant control valve position (commanded and actual), DEF tank temperature, DEF system pressure, DEF pump commanded percentage, DEF doser control status, DEF line heater control outputs, aftertreatment dosing quantity commanded and actual.

(vi) Derating parameters. Include any additional parameters used to apply inducements under §1036.111 or any other SCR-related or DPF-related engine derates under §1036.125.

(10) Design spark-ignition engines to make the following additional parameters available for reading with a generic scan tool, if applicable:

(i) Air-fuel enrichment parameters. Percent of time in enrichment, both for each trip (key-on to key-off) and as a cumulative lifetime value. Track values separately for enrichment based on throttle, engine protection, and catalyst protection. Include all time after engine warm-up when the engine is not operating at the air-fuel ratio designed for peak three-way catalyst efficiency. Peak efficiency typically involves closed-loop feedback control.

(ii) [Reserved]

(11) If you have an approved Executive order from the California Air Resources Board for a given engine family, we may rely on that Executive order to evaluate whether you meet federal OBD requirements for that same engine family or an equivalent engine family. Engine families are equivalent if they are identical in all aspects material to emission characteristics; for example, we would consider different inducement strategies and different warranties not to be material to emission characteristics relevant to these OBD testing requirements. EPA would count two equivalent engine families as one for the purposes of determining OBD demonstration testing requirements. Send us the following information:

(i) You must submit additional information as needed to demonstrate that you meet the requirements of this section that are not covered by the California Executive order.

(ii) Send us results from any testing you performed for certifying engine families (including equivalent engine families) with the California Air Resources Board, including the results of any testing performed under 13 CCR 1971.1(l) for verification of in-use compliance and 13 CCR 1971.5(c) for manufacturer self-testing within the deadlines set out in 13 CCR 1971.1.

(iii) We may require that you send us additional information if we need it to evaluate whether you meet the requirements of this paragraph (b)(11). This may involve sending us copies of documents you send to the California Air Resources Board.

(12) You may ask us to approve conditions for which the diagnostic system may disregard trouble codes, as described in 13 CCR 1971.1(g)(5.3)-(5.6).

(13) References to the California ARB Executive Officer are deemed to be the EPA Administrator.

(c) Design the diagnostic system to display the following information in the cab:

(1) For inducements specified in §1036.111 and any other AECD that derates engine output related to SCR or DPF systems, indicate the fault code for the detected problem, a description of the fault code, and the current speed restriction. For inducement faults under §1036.111, identify whether the fault condition is for DEF quantity, DEF quality, or tampering; for other faults, identify whether the fault condition is related to SCR or DPF systems. If there are additional derate stages, also indicate the next speed restriction and the time remaining until starting the next restriction. If the derate involves something other than restricting vehicle speed, such as a torque derate, adjust the information to correctly identify any current and pending restrictions.

(2) Identify on demand the total number of diesel particulate filter regenerationevents that have taken place since installing the current particulate filter.

(3) Identify on demand the historical and current rate of DEF consumption, such as gallons of DEF consumed per mile or gallons of DEF consumed per gallon of diesel fuel consumed. Design the system to allow the operator to reset the current rate of DEF consumption.

(d) You may ask us to accept as compliant an engine that does not fully meet specific requirements under this section. The following provisions apply regarding OBD system deficiencies:

(1) We will not approve a deficiency for gasoline-fueled or diesel-fueled engines if it involves the complete lack of a major diagnostic monitor, such as monitors related to exhaust aftertreatment devices, oxygen sensors, air-fuel ratio sensors, NO X sensors, engine misfire, evaporative leaks, and diesel EGR (if applicable). We may approve such deficiencies for engines using other fuels if you demonstrate that the alternative fuel causes these monitors to be unreliable.

(2) We will approve a deficiency only if you show us that full compliance is infeasible or unreasonable considering any relevant factors, such as the technical feasibility of a given monitor, or the lead time and production cycles of vehicle designs and programmed computing upgrades.

(3) Our approval for a given deficiency applies only for a single model year, though you may continue to ask us to extend a deficiency approval in renewable one-year increments. We may approve an extension if you demonstrate an acceptable level of progress toward compliance and you show that the necessary hardware or software modifications would pose an unreasonable burden. We will approve a deficiency for more than three years only if you further demonstrate that you need the additional lead time to make substantial changes to engine hardware.

(4) We will not approve deficiencies retroactively.

[88 FR 4487, Jan. 24, 2023]

§1036.111 Inducements related to SCR.

Engines using SCR to control emissions depend on a constant supply of diesel exhaust fluid (DEF). This section describes how manufacturers must design their engines to derate power output to induce operators to take appropriate actions to ensure the SCR system is working properly. The requirements of this section apply equally for engines installed in heavy-duty vehicles at or below 14,000 lbs GVWR. The requirements of this section apply starting in model year 2027, though you may comply with the requirements of this section in earlier model years.

(a) General provisions. The following terms and general provisions apply under this section:

(1) As described in §1036.110, this section relies on terms and requirements specified for OBD systems by California ARB in 13 CCR 1968.2 and 1971.1 (incorporated by reference in §1036.810).

(2) The provisions of this section apply differently based on an individual vehicle's speed history. A vehicle's speed category is based on the OBD system's recorded value for average speed for the preceding 30 hours of non-idle engine operation. The vehicle speed category applies at the point that the engine first detects a fault condition identified under paragraph (b) of this section and continues to apply until the fault condition is fully resolved as specified in paragraph (e) of this section. Non-idle engine operation includes all operating conditions except those that qualify as idle based on OBD system controls as specified in 13 CCR 1971.1(h)(5.4.10). Apply speed derates based on the following categories:

| Vehicle category | Average speed (mi/hr) |

|---|---|

| Low-speed | speed <15. |

| Medium-speed | 15 ?speed <25. |

| High-speed | speed ?25. |

(3) Where engines derate power output as specified in this section, the derate must decrease vehicle speed by 1 mi/hr for every five minutes of engine operation until reaching the specified derate speed. This requirement applies at the onset of an inducement, at any transition to a different step of inducement, and for any derate that recurs under paragraph (e)(3) of this section.

(b) Fault conditions. Create derate strategies that monitor for and trigger an inducement based on the following conditions:

(1) DEF supply falling to a level corresponding to three hours of engine operation, based on available information on DEF consumption rates.

(2) DEF quality failing to meet your concentration specifications.

(3) Any signal indicating that a catalyst is missing.

(4) Open circuit faults related to the following: DEF tank level sensor, DEF pump, DEF quality sensor, SCR wiring harness, NO X sensors, DEF dosing valve, DEF tank heater, DEF tank temperature sensor, and aftertreatment control module.

(c) [Reserved]

(d) Derate schedule. Engines must follow the derate schedule described in this paragraph (d) if the engine detects a fault condition identified in paragraph (b) of this section. The derate takes the form of a maximum drive speed for the vehicle. This maximum drive speed decreases over time based on hours of non-idle engine operation without regard to engine starting.

(1) Apply speed-limiting derates according to the following schedule:

| High-speed vehicles | Low-speed vehicles | Low-speed vehicles | |||

|---|---|---|---|---|---|

| Hours of non-idle engine operation | Maximum speed (mi/hr) | Hours of non-idle engine operation | Maximum speed (mi/hr) | Hours of non-idle engine operation | Maximum speed (mi/hr) |

| 0 | 65 | 0 | 55 | 0 | 45 |

| 6 | 60 | 6 | 50 | 5 | 40 |

| 12 | 55 | 12 | 45 | 10 | 35 |

| 20 | 50 | 45 | 40 | 30 | 25 |

| 86 | 45 | 70 | 35 | ||

| 119 | 40 | 90 | 25 | ||

| 144 | 35 | ||||

| 164 | 25 | ||||

| a Hours start counting when the engine detects a fault condition specified in paragraph (b) of this section. For DEF supply, you may program the engine to reset the timer to three hours when the engine detects an empty DEF tank. | |||||

(2) You may design and produce engines that will be installed in motorcoaches with an alternative derate schedule that starts with a 65 mi/hr derate when a fault condition is first detected, steps down to 50 mi/hr after 80 hours, and concludes with a final derate speed of 25 mi/hr after 180 hours of non-idle operation.

(e) Deactivating derates. Program the engine to deactivate derates as follows:

(1) Evaluate whether the detected fault condition continues to apply. Deactivate derates if the engine confirms that the detected fault condition is resolved.

(2) Allow a generic scan tool to deactivate inducement-related fault codes while the vehicle is not in motion.

(3) Treat any detected fault condition that recurs within 40 hours of engine operation as the same detected fault condition, which would restart the derate at the same point in the derate schedule that the system last deactivated the derate.

[88 FR 4487, Jan. 24, 2023]

§1036.115 Other requirements.

Engines that are required to meet the emission standards of this part must meet the following requirements, except as noted elsewhere in this part:

(a) Crankcase emissions. Engines may not discharge crankcase emissions into the ambient atmosphere throughout the useful life, other than those that are routed to the exhaust upstream of exhaust aftertreatment during all operation, except as follow:

(1) Engines equipped with turbochargers, pumps, blowers, or superchargers for air induction may discharge crankcase emissions to the ambient atmosphere if the emissions are added to the exhaust emissions (either physically or mathematically) during all emission testing.

(2) If you take advantage of this exception, you must manufacture the engines so that all crankcase emissions can be routed into the applicable sampling systems specified in 40 CFR part 1065. You must also account for deterioration in crankcase emissions when determining exhaust deterioration factors as described in §1036.240(c)(5).

(b) Fuel mapping. You must perform fuel mapping for your engine as described in §1036.505(b).

(c) Evaporative and refueling emissions. You must design and produce your engines to comply with evaporative and refueling emission standards as follows:

(1) For complete heavy-duty vehicles you produce, you must certify the vehicles to emission standards as specified in 40 CFR 1037.103.

(2) For incomplete heavy-duty vehicles, and for engines used in vehicles you do not produce, you do not need to certify your engines to evaporative and refueling emission standards or otherwise meet those standards. However, vehicle manufacturers certifying their vehicles with your engines may depend on you to produce your engines according to their specifications. Also, your engines must meet applicable exhaust emission standards in the installed configuration.

(d) Torque broadcasting. Electronically controlled engines must broadcast their speed and output shaft torque (in newton-meters). Engines may alternatively broadcast a surrogate value for determining torque. Engines must broadcast engine parameters such that they can be read with a remote device or broadcast them directly to their controller area networks.

(e) EPA access to broadcast information. If we request it, you must provide us any hardware, tools, and information we would need to readily read, interpret, and record all information broadcast by an engine's on-board computers and electronic control modules. If you broadcast a surrogate parameter for torque values, you must provide us what we need to convert these into torque units. We will not ask for hardware or tools if they are readily available commercially.

(f) Adjustable parameters. Engines that have adjustable parameters must meet all the requirements of this part for any adjustment in the practically adjustable range.

(1) We may require that you set adjustable parameters to any specification within the practically adjustable range during any testing, including certification testing, selective enforcement auditing, or in-use testing.

(2) General provisions apply for adjustable parameters as specified in 40 CFR 1068.50.

(3) DEF supply and DEF quality are adjustable parameters. The physically adjustable range includes any amount of DEF for which the engine's diagnostic system does not trigger inducement provisions under §1036.111.

(g) Prohibited controls. (1) General provisions. You may not design your engines with emission control devices, systems, or elements of design that cause or contribute to an unreasonable risk to public health, welfare, or safety while operating. For example, this would apply if the engine emits a noxious or toxic substance it would otherwise not emit that contributes to such an unreasonable risk.

(2) Vanadium sublimation in SCR catalysts. For engines equipped with vanadium-based SCR catalysts, you must design the engine and its emission controls to prevent vanadium sublimation and protect the catalyst from high temperatures. We will evaluate your engine design based on the following information that you must include in your application for certification:

(i) Identify the threshold temperature for vanadium sublimation for your specified SCR catalyst formulation as described in 40 CFR 1065.1113 through 1065.1121.

(ii) Describe how you designed your engine to prevent catalyst inlet temperatures from exceeding the temperature you identify in paragraph (g)(2)(i) of this section, including consideration of engine wear through the useful life. Also describe your design for catalyst protection in case catalyst temperatures exceed the specified temperature. In your description, include how you considered elevated catalyst temperature resulting from sustained high-load engine operation, catalyst exotherms, particulate filter regeneration, and component failure resulting in unburned fuel in the exhaust stream.

(h) Defeat devices. You may not equip your engines with a defeat device. A defeat device is an auxiliary emission control device (AECD) that reduces the effectiveness of emission controls under conditions that may reasonably be expected in normal operation and use. However, an AECD is not a defeat device if you identify it in your application for certification and any of the following is true:

(1) The conditions of concern were substantially included in the applicable procedure for duty-cycle testing as described in subpart F of this part.

(2) You show your design is necessary to prevent engine (or vehicle) damage or accidents. Preventing engine damage includes preventing damage to aftertreatment or other emission-related components.

(3) The reduced effectiveness applies only to starting the engine.

(4) The AECD applies only for engines that will be installed in emergency vehicles, and the need is justified in terms of preventing the engine from losing speed, torque, or power due abnormal conditions of the emission control system, or in terms of preventing such abnormal conditions from occurring, during operation related to emergency response. Examples of such abnormal conditions may include excessive exhaust backpressure from an overloaded particulate trap, and running out of diesel exhaust fluid for engines that rely on urea-based selective catalytic reduction.

(i) DEF tanks. Diesel exhaust fluid tanks must be sized to require refilling no more frequently than the vehicle operator will need to refill the fuel tank, even for worst-case assumptions related to fuel efficiency and refueling volumes.

(j) Special provisions for spark-ignition engines. The following provisions apply for spark-ignition engines that control air-fuel ratios at or near stoichiometry starting with model year 2027:

(1) Catalyst bed temperature during extended idle may not fall below 350 °C, or a lower temperature that we approve. Describe how you designed your engine to meet this requirement in your application for certification. You may ask us to approve alternative strategies to prevent emissions from increasing during idle.

(2) In addition to the information requirements of §1036.205(b), describe why you rely on any AECDs instead of other engine designs for thermal protection of catalyst or other emission-related components. Also describe the accuracy of any modeled or measured temperatures used to activate the AECD. We may ask you to submit a second-by-second comparison of any modeled and measured component temperatures as part of your application for certification.

[88 FR 4487, Jan. 24, 2023]

§1036.120 Emission-related warranty requirements.

(a) General requirements. You must warrant to the ultimate purchaser and each subsequent purchaser that the new engine, including all parts of its emission control system, meets two conditions:

(1) It is designed, built, and equipped so it conforms at the time of sale to the ultimate purchaser with the requirements of this part.

(2) It is free from defects in materials and workmanship that may keep it from meeting these requirements.

(b) Warranty period. Your emission-related warranty must be valid for at least as long as the minimum warranty periods listed in this paragraph (b) in vehicle miles, or hours of engine operation, or years in service, whichever comes first. You may offer an emission-related warranty more generous than we require. The emission-related warranty for the engine may not be shorter than any published warranty you offer without charge for the engine. Similarly, the emission-related warranty for any component may not be shorter than any published warranty you offer without charge for that component. If an extended warranty requires owners to pay for a portion of repairs, those terms apply in the same manner to the emission-related warranty. The warranty period begins when the vehicle is placed into service. The following minimum warranty periods apply:

| Primary intended service class | Model year 2026 and earlier | Model year 2027 and later | ||||

| Mileage | Years | Hours | Mileage | Years | Hours | |

| Spark-Ignition HDE | 50,000 | 5 | 160,000 | 10 | 8,000 | |

| Light HDE | 50,000 | 5 | 210,000 | 10 | 10,000 | |

| Medium HDE | 100,000 | 5 | 280,000 | 10 | 14,000 | |

| Heavy HDE | 100,000 | 5 | 450,000 | 10 | 22,000 | |

(c) Components covered. The emission-related warranty covers all components listed in 40 CFR part 1068, appendix A, and components from any other system you develop to control emissions. The emission-related warranty covers any components, regardless of the company that produced them, that are the original components or the same design as components from the certified configuration.

(d) Limited applicability. You may deny warranty claims under this section if the operator caused the problem through improper maintenance or use, subject to the provisions in §1036.125 and 40 CFR 1068.115.

(e) Owners manual. Describe in the owners manual the emission-related warranty provisions from this section that apply to the engine.

[88 FR 4487, Jan. 24, 2023]

§1036.125 Maintenance instructions and allowable maintenance.

Maintenance includes any inspection, adjustment, cleaning, repair, or replacement of components and is classified as either emission-related or not emission-related and each of these can be classified as either scheduled or unscheduled. Further, some emission-related maintenance is also classified as critical emission-related maintenance. Give the ultimate purchaser of each new engine written instructions for maintaining and using the engine. As described in paragraph (h) of this section, these instructions must identify how owners properly maintain and use engines to clarify responsibilities for regulatory requirements such as emission-related warranty and defect reporting.

(a) Critical emission-related maintenance. Critical emission-related maintenance includes any adjustment, cleaning, repair, or replacement of components listed in paragraph (a)(2) of this section. Critical emission-related maintenance may also include other maintenance that you determine is critical, including maintenance on other emission-related components as described in 40 CFR part 1068, appendix A, if we approve it in advance. You may perform scheduled critical emission-related maintenance during service accumulation on your emission-data engines at the intervals you specify.

(1) Maintenance demonstration. You must demonstrate that the maintenance is reasonably likely to be done at your recommended intervals on in-use engines. We will accept DEF replenishment as reasonably likely to occur if your engine meets the specifications in §1036.111. We will accept other scheduled maintenance as reasonably likely to occur if you satisfy any of the following conditions:

(i) You present data showing that, if a lack of maintenance increases emissions, it also unacceptably degrades the engine's performance.

(ii) You design and produce your engines with a system we approve that displays a visible signal to alert drivers that maintenance is due, either as a result of component failure or the appropriate degree of engine or vehicle operation. The signal must clearly display “maintenance needed”, “check engine”, or a similar message that we approve. The signal must be continuous while the engine is operating and not be easily eliminated without performing the specified maintenance. Your maintenance instructions must specify resetting the signal after completing the specified maintenance. We must approve the method for resetting the signal. You may not design the system to be less effective at the end of the useful life. If others install your engine in their vehicle, you may rely on installation instructions to ensure proper mounting and operation of the display. Disabling or improperly resetting the system for displaying these maintenance-related signals without performing the indicated maintenance violates the tampering prohibition in 42 U.S.C. 7522(a)(3).

(iii) You present survey data showing that at least 80 percent of engines in the field get the maintenance you specify at the recommended intervals.

(iv) You provide the maintenance free of charge and clearly say so in your maintenance instructions.

(v) You otherwise show us that the maintenance is reasonably likely to be done at the recommended intervals.

(2) Minimum scheduled maintenance intervals. You may not schedule critical emission-related maintenance more frequently than the minimum intervals specified or allowed in this paragraph (a), except as specified in paragraph (g) of this section. The minimum intervals specified for each component applies to actuators, sensors, tubing, valves, and wiring associated with that component, except as specified.

| Components | Spark-ignition HDE | Light HDE | Medium HDE | Heavy HDE |

|---|---|---|---|---|

| Spark plugs | 25,000 (750) | |||

| DEF filters | 100,000 (3,000) | 100,000 (3,000) | 100,000 (3,000) | |

| Crankcase ventilation valves and filters | 60,000 (1,800) | 60,000 (1,800) | 60,000 (1,800) | 60,000 (1,800) |

| Ignition wires and coils | 50,000 (1,500) | |||

| Oxygen sensors | 80,000 (2,400) | |||

| Air injection system components | 110,000 (3,300) | |||

| Sensors, actuators, and related control modules that are not integrated into other systems | 100,000 (3,000) | 100,000 (3,000) | 150,000 (4,500) | 150,000 (4,500) |

| Particulate filtration systems (other than filter substrates) | 100,000 (3,000) | 100,000 3,000) | 250,000 7,500) | 250,000 (7,500) |

| Catalyst systems (other than catalyst substrates), fuel injectors, electronic control modules, hybrid system components, turbochargers, and EGR system components (including filters and coolers) .. | 110,000 (3,300) | 110,000 (3,300) | 185,000 5,550) | 435,000 (13,050) |

| Catalyst substrates and particulate filter substrates | 200,000 (10,000) | 270,000 (13,000) | 350,000 (17,000) | 650,000 (32,000) |

| Component | Accumulated miles (hours) for components | |||

| Spark-ignition HDE | Light HDE | Medium HDE | Heavy HDE | |

| Spark plugs | 25,000 (750) | |||

| EGR-related filters and coolers, fuel injectors, and crankcase ventilation valves and filters | 50,000 (1,500) | 50,000 (1,500) | 50,000 (1,500) | 50,000 (1,500) |

| DEF filters | 50,000 (1,500) | 50,000 (1,500) | 50,000 (1,500) | |

| Ignition wires and coils | 50,000 (1,500) | |||

| Oxygen sensors | 80,000 (2,400) | |||

| Air injection system components | 100,000 (3,000) | |||

| Catalyst system components, EGR system components (other than filters or coolers), particulate filtration system components, and turbochargers | 100,000 (3,000) | 100,000 (3,000) | 100,000 (3,000), then 50,000 (4,500) | 100,000 (3,000), then 150,000 (4,500) |

(3) New technology. You may ask us to approve scheduled critical emission-related maintenance of components not identified in paragraph (a)(2) of this section that is a direct result of the implementation of new technology not used in model year 2020 or earlier engines, subject to the following provisions:

(i) Your request must include your recommended maintenance interval, including data to support the need for the maintenance, and a demonstration that the maintenance is likely to occur at the recommended interval using one of the conditions specified in paragraph (a)(1) of this section.

(ii) For any such new technology, we will publish a Federal Register notice based on information you submit and any other available information to announce that we have established new allowable minimum maintenance intervals. Any manufacturer objecting to our decision may ask for a hearing (see §1036.820).

(4) System components. The following provisions clarify which components are included in certain systems:

(i) Catalyst system refers to the aftertreatment assembly used for gaseous emission control and generally includes catalyst substrates, substrate housings, exhaust gas temperature sensors, gas concentration sensors, and related control modules. SCR-based catalyst systems also include DEF level sensors, DEF quality sensors, and DEF temperature sensors.

(ii) Particulate filtration system refers to the aftertreatment assembly used for exhaust PM filtration and generally includes filter substrates, substrate housings, pressure sensors, pressure lines and tubes, exhaust gas temperature sensors, fuel injectors for active regeneration, and related control modules.

(b) Recommended additional maintenance. You may recommend any amount of critical emission-related maintenance that is additional to what we approve in paragraph (a) of this section, as long as you state clearly that the recommended additional maintenance steps are not necessary to keep the emission-related warranty valid. If operators do the maintenance specified in paragraph (a) of this section, but not the recommended additional maintenance, this does not allow you to disqualify those engines from in-use testing or deny a warranty claim. Do not take these maintenance steps during service accumulation on your emission-data engines.

(c) Special maintenance. You may specify more frequent maintenance to address problems related to special situations, such as atypical engine operation. For example, you may specify more frequent maintenance if operators fuel the engine with an alternative fuel such as biodiesel. You must clearly state that this special maintenance is associated with the special situation you are addressing. We may disapprove your maintenance instructions if we determine that you have specified special maintenance steps to address engine operation that is not atypical, or that the maintenance is unlikely to occur in use. If we determine that certain maintenance items do not qualify as special maintenance under this paragraph (c), you may identify them as recommended additional maintenance under paragraph (b) of this section.

(d) Noncritical emission-related maintenance. You may specify any amount of emission-related inspection or other maintenance that is not approved critical emission-related maintenance under paragraph (a) of this section, subject to the provisions of this paragraph (d). Noncritical emission-related maintenance generally includes maintenance on the components we specify in 40 CFR part 1068, appendix A, that is not covered in paragraph (a) of this section. You must state in the owners manual that these steps are not necessary to keep the emission-related warranty valid. If operators fail to do this maintenance, this does not allow you to disqualify those engines from in-use testing or deny a warranty claim. Do not take these inspection or other maintenance steps during service accumulation on your emission-data engines.

(e) Maintenance that is not emission-related. You may schedule any amount of maintenance unrelated to emission controls that is needed for proper functioning of the engine. This might include adding engine oil; changing air, fuel, or oil filters; servicing engine-cooling systems; adjusting idle speed, governor, engine bolt torque, valve lash, injector lash, timing, or tension of air pump drive belts; and lubricating the heat control valve in the exhaust manifold. For maintenance that is not emission-related, you may perform the maintenance during service accumulation on your emission-data engines at the least frequent intervals that you recommend to the ultimate purchaser (but not the intervals recommended for special situations).

(f) [Reserved]

(g) Payment for scheduled maintenance. Owners are responsible for properly maintaining their engines, which generally includes paying for scheduled maintenance. However, you may commit to paying for scheduled maintenance as described in paragraph (a)(1)(iv) of this section to demonstrate that the maintenance will occur. You may also schedule maintenance not otherwise allowed by paragraph (a)(2) of this section if you pay for it. You must pay for scheduled maintenance on any component during the useful life if it meets all the following conditions:

(1) Each affected component was not in general use on similar engines before 1980.

(2) The primary function of each affected component is to reduce emissions.

(3) The cost of the maintenance is more than 2 percent of the price of the engine.

(4) Failure to perform the maintenance would not cause clear problems that would significantly degrade the engine's performance.

(h) Owners manual. Include the following maintenance-related information in the owners manual, consistent with the requirements of this section:

(1) Clearly describe the scheduled maintenance steps, consistent with the provisions of this section, using nontechnical language as much as possible. Include a list of components for which you will cover scheduled replacement costs.

(2) Identify all maintenance you consider necessary for the engine to be considered properly maintained for purposes of making valid warranty claims. Describe what documentation you consider appropriate for making these demonstrations. Note that you may identify failure to repair critical emission-related components as improper maintenance if the repairs are related to an observed defect. Your maintenance instructions under this section may not require components or service identified by brand, trade, or corporate name. Also, do not directly or indirectly require that the engine be serviced by your franchised dealers or any other service establishments with which you have a commercial relationship. However, you may disregard these limitations on your maintenance requirements if you do one of the following things:

(i) Provide a component or service without charge under the purchase agreement.

(ii) Get us to waive this prohibition in the public's interest by convincing us the engine will work properly only with the identified component or service.

(3) Describe how the owner can access the OBD system to troubleshoot problems and find emission-related diagnostic information and codes stored in onboard monitoring systems as described in §1036.110(b) and §1036.110(c). These instructions must at a minimum include identification of the OBD communication protocol used, location and type of OBD connector, brief description of what OBD is (including type of information stored, what a MIL is, and explanation that some MILs may self-extinguish), and a note that generic scan tools can provide engine maintenance information.

(4) Describe the elements of the emission control system and provide an overview of how they function.

(5) Include one or more diagrams of the engine and its emission-related components with the following information:

(i) The flow path for intake air and exhaust gas.

(ii) The flow path of evaporative and refueling emissions for spark-ignition engines, and DEF for compression-ignition engines, as applicable.

(iii) The flow path of engine coolant if it is part of the emission control system described in the application for certification.

(iv) The identity, location, and arrangement of relevant sensors, DEF heater and other DEF delivery components, and other critical emission-related components. Terminology to identify components must be consistent with codes you use for the OBD system.

(6) Include one or more exploded-view drawings that allow the owner to identify the following components: EGR valve, EGR actuator, EGR cooler, all emission sensors (such as NO X sensors and soot sensors), temperature and pressure sensors (such as sensors related to EGR, DPF, DOC, and SCR and DEF), quality sensors, DPF filter, DOC, SCR catalyst, fuel (DPF-related) and DEF dosing units and components (e.g., pumps, metering units, filters, nozzles, valves, injectors), aftertreatment-related control modules, any other DEF delivery-related components (such as delivery lines and freeze-protection components), and separately replaceable aftertreatment-related wiring harnesses. Terminology to identify components must be consistent with codes you use for the OBD system. Include part numbers for sensors and filters related to SCR and DPF systems for the current model year or any earlier model year.

(7) Include the following statement: “Technical service bulletins, emission-related recalls, and other information for your engine may be available at www.nhtsa.gov/recalls.”

(8) Include a troubleshooting guide to address the following warning signals related to SCR inducement:

(i) The inducement derate schedule (including indication that inducements will begin prior to the DEF tank being completely empty).

(ii) The meaning of any trouble lights that indicate specific problems (e.g., DEF level).

(iii) A description of the three types of SCR-related derates (DEF quality, DEF quality and tampering) and that further information on the inducement cause (e.g., trouble codes) is available using the OBD system.

(9) Describe how to access OBD fault codes related to DPF-related derates.

(10) Identify a website for the service information required in 40 CFR 86.010-38(j).

[88 FR 4487, Jan. 24, 2023]

§1036.130 Installation instructions for vehicle manufacturers.

(a) If you sell an engine for someone else to install in a vehicle, give the engine installer instructions for installing it consistent with the requirements of this part. Include all information necessary to ensure that an engine will be installed in its certified configuration.

(b) Make sure these instructions have the following information:

(1) Include the heading: “Emission-related installation instructions”.

(2) State: “Failing to follow these instructions when installing a certified engine in a heavy-duty motor vehicle violates federal law, subject to fines or other penalties as described in the Clean Air Act.”

(3) Provide all instructions needed to properly install the exhaust system and any other components. Include any appropriate instructions for configuring the exhaust system in the vehicle to allow for collecting emission samples for in-use testing where that is practical.

(4) Describe any necessary steps for installing any diagnostic system required under §1036.110.

(5) Describe how your certification is limited for any type of application. For example, if you certify Heavy HDE to the CO 2standards using only transient FTP testing, you must make clear that the engine may not be installed in tractors.

(6) Describe any other instructions to make sure the installed engine will operate according to design specifications in your application for certification. This may include, for example, instructions for installing aftertreatment devices when installing the engines.

(7) Give the following instructions if you do not ship diesel exhaust fluid tanks with your engines:

(i) Specify that vehicle manufacturers must install diesel exhaust fluid tanks meeting the specifications of §1036.115(i).

(ii) Describe how vehicle manufacturers must install diesel exhaust fluid tanks with sensors as needed to meet the requirements of §§1036.110 and 1036.111.

(8) State: “If you install the engine in a way that makes the engine's emission control information label hard to read during normal engine maintenance, you must place a duplicate label on the vehicle, as described in 40 CFR 1068.105.”

(9) Describe how vehicle manufacturers need to apply stickers to qualifying vehicles as described in §1036.136 if you certify engines to the Clean Idle NO X standard of §1036.104(b).

(c) Give the vehicle manufacturer fuel map results as described in §1036.505(b).

(d) You do not need installation instructions for engines that you install in your own vehicles.

(e) Provide instructions in writing or in an equivalent format. For example, you may post instructions on a publicly available website for downloading or printing. If you do not provide the instructions in writing, explain in your application for certification how you will ensure that each installer is informed of the installation requirements.

[88 FR 4487, Jan. 24, 2023]

§1036.135 Labeling.

(a) Assign each engine a unique identification number and permanently affix, engrave, or stamp it on the engine in a legible way.

(b) At the time of manufacture, affix a permanent and legible label identifying each engine. The label must meet the requirements of 40 CFR 1068.45.

(c) The label must—

(1) Include the heading “EMISSION CONTROL INFORMATION”.

(2) Include your full corporate name and trademark. You may identify another company and use its trademark instead of yours if you comply with the branding provisions of 40 CFR 1068.45.

(3) Include EPA's standardized designation for the engine family.

(4) Identify the primary intended service class.

(5) State the engine's displacement (in liters); however, you may omit this from the label if all the engines in the engine family have the same per-cylinder displacement and total displacement.

(6) State the date of manufacture [DAY (optional), MONTH, and YEAR]; however, you may omit this from the label if you stamp, engrave, or otherwise permanently identify it elsewhere on the engine, in which case you must also describe in your application for certification where you will identify the date on the engine.

(7) State the NO X FEL to which the engines are certified if applicable. Identify the Clean Idle standard if you certify the engine to the NO X standard of §1036.104(b).

(8) State: “THIS ENGINE COMPLIES WITH U.S. EPA REGULATIONS FOR [MODEL YEAR] HEAVY-DUTY HIGHWAY ENGINES.”

(9) Identify any limitations on your certification. For example, if you certify Heavy HDE to the CO 2 standards using only steady-state testing, include the statement “TRACTORS ONLY”. Similarly, for engines with one or more approved AECDs for emergency vehicle applications under §1036.115(h)(4), the statement: “THIS ENGINE IS FOR INSTALLATION IN EMERGENCY VEHICLES ONLY”.

(d) You may add information to the emission control information label as follows:

(1) You may identify other emission standards that the engine meets or does not meet. You may add the information about the other emission standards to the statement we specify, or you may include it in a separate statement.

(2) You may add other information to ensure that the engine will be properly maintained and used.

(3) You may add appropriate features to prevent counterfeit labels. For example, you may include the engine's unique identification number on the label.

(e) You may ask us to approve modified labeling requirements in this part if you show that it is necessary or appropriate. We will approve your request if your alternate label is consistent with the requirements of this part. We may also specify modified labeling requirements to be consistent with the intent of 40 CFR part 1037.

(f) If you obscure the engine label while installing the engine in the vehicle such that the label cannot be read during normal maintenance, you must place a duplicate label on the vehicle. If others install your engine in their vehicles in a way that obscures the engine label, we require them to add a duplicate label on the vehicle (see 40 CFR 1068.105); in that case, give them the number of duplicate labels they request and keep the following records for at least five years:

(1) Written documentation of the request from the vehicle manufacturer.

(2) The number of duplicate labels you send for each engine family and the date you sent them.

[88 FR 4487, Jan. 24, 2023]

§1036.136 Clean Idle sticker.

(a) Design and produce stickers showing that your engines meet the federal Clean Idle standard if you certify engines to the Clean Idle NO X standard of §1036.104(b). The sticker must—

(1) Meet the requirements of 40 CFR 1068.45 for permanent labels. The preferred location for sticker placement is on the driver's side of the hood.

(2) Include one or both of your corporate name and trademark.

(3) Identify that the engine is qualified to meet the federal Clean Idle NO X standard.

(4) Include a serial number or other method to confirm that stickers have been properly applied to vehicles.

(b) The following provisions apply for placing Clean Idle stickers on vehicles with installed engines that have been certified to the NO X standard of §1036.104(b):

(1) If you install engines in vehicles you produce, you must apply a sticker to each vehicle certified to the Clean Idle standard.

(2) If you ship engines for others to install in vehicles, include in your purchasing documentation the manufacturer's request for a specific number of labels corresponding to the number of engines ordered. Supply the vehicle manufacturer with exactly one sticker for each shipped engine certified to the Clean Idle standard. Prepare your emission-related installation instructions to ensure that vehicle manufacturers meet all application requirements. Keep the following records for at least five years:

(i) Written documentation of the vehicle manufacturer's request for stickers.

(ii) Tracking information for stickers you send and the date you sent them.

(c) The provisions in 40 CFR 1068.101 apply for the Clean Idle sticker in the same way that those provisions apply for emission control information labels.

[88 FR 4487, Jan. 24, 2023]

§1036.140 Primary intended service class and engine cycle.

You must identify a single primary intended service class for each engine family that best describes vehicles for which you design and market the engine, as follows:

(a) Divide compression-ignition engines into primary intended service classes based on the following engine and vehicle characteristics:

(1) Light HDE includes engines that are not designed for rebuild and do not have cylinder liners. Vehicle body types in this group might include any heavy-duty vehicle built from a light-duty truck chassis, van trucks, multi-stop vans, and some straight trucks with a single rear axle. Typical applications would include personal transportation, light-load commercial delivery, passenger service, agriculture, and construction. The GVWR of these vehicles is normally at or below 19,500 pounds.

(2) Medium HDE includes engines that may be designed for rebuild and may have cylinder liners. Vehicle body types in this group would typically include school buses, straight trucks with single rear axles, city tractors, and a variety of special purpose vehicles such as small dump trucks, and refuse trucks. Typical applications would include commercial short haul and intra-city delivery and pickup. Engines in this group are normally used in vehicles whose GVWR ranges from 19,501 to 33,000 pounds.

(3) Heavy HDE includes engines that are designed for multiple rebuilds and have cylinder liners. Vehicles in this group are normally tractors, trucks, straight trucks with dual rear axles, and buses used in inter-city, long-haul applications. These vehicles normally exceed 33,000 pounds GVWR.

(b) Divide spark-ignition engines into primary intended service classes as follows:

(1) Spark-ignition engines that are best characterized by paragraph (a)(1) or (2) of this section are in a separate Spark-ignition HDE primary intended service class.

(2) Spark-ignition engines that are best characterized by paragraph (a)(3) of this section are included in the Heavy HDE primary intended service class along with compression-ignition engines. Gasoline-fueled engines are presumed not to be characterized by paragraph (a)(3) of this section; for example, vehicle manufacturers may install some number of gasoline-fueled engines in Class 8 trucks without causing the engine manufacturer to consider those to be Heavy HDE.

(c) References to “spark-ignition standards” in this part relate only to the spark-ignition engines identified in paragraph (b)(1) of this section. References to “compression-ignition standards” in this part relate to compression-ignition engines, to spark-ignition engines optionally certified to standards that apply to compression-ignition engines, and to all engines identified under paragraph (b)(2) of this section as Heavy HDE.

[88 FR 4487, Jan. 24, 2023]

§1036.150 Interim provisions.

The provisions in this section apply instead of other provisions in this part. This section describes when these interim provisions expire, if applicable.

(a) Transitional ABT credits for NO emissions. You may generate NO X credits from model year 2026 and earlier engines and use those as transitional credits for model year 2027 and later engines using any of the following methods:

(1) Discounted credits. Generate discounted credits by certifying any model year 2022 through 2026 engine family to meet all the requirements that apply under 40 CFR part 86, subpart A. Calculate discounted credits for certifying engines in model years 2027 through 2029 as described in §1036.705 relative to a NO X emission standard of 200 mg/hp·hr and multiply the result by 0.6. You may not use discounted credits for certifying model year 2030 and later engines.

(2) Partial credits. Generate partial credits by certifying any model year 2024 through 2026 compression-ignition engine family as described in this paragraph (a)(2). You may not use partial credits for certifying model year 2033 and later engines. Certify engines for partial credits to meet all the requirements that apply under 40 CFR part 86, subpart A, with the following adjustments:

(i) Calculate credits as described in §1036.705 relative to a NO X emission standard of 200 mg/hp·hr using the appropriate useful life mileage from 40 CFR 86.004-2. Your declared NO X family emission limit applies for the FTP and SET duty cycles.

(ii) Engines must meet a NO X standard when tested over the Low Load Cycle as described in §1036.514. Engines must also meet an off-cycle NO X standard as specified in §1036.104(a)(3). Calculate the NO X family emission limits for the Low Load Cycle and for off-cycle testing as described in §1036.104(c)(3) with Std FTPNOx set to 35 mg/hp·hr and Std [cycle]NOx set to the values specified in §1036.104(a)(2) or (3), respectively. No standard applies for HC, PM, and CO emissions for the Low Load Cycle or for off-cycle testing, but you must record measured values for those pollutants and include those measured values where you report NO X emission results.

(iii) For engines selected for in-use testing, we may specify that you perform testing as described in 40 CFR part 86, subpart T, or as described in subpart E of this part.

(iv) Add the statement “Partial credit” to the emission control information label.

(3) Full credits. Generate full credits by certifying any model year 2024 through 2026 engine family to meet all the requirements that apply under this part. Calculate credits as described in §1036.705 relative to a NO X emission standard of 200 mg/hp·hr. You may not use full credits for certifying model year 2033 and later engines.

(4) 2026 service class pull-ahead credits. Generate credits from diesel-fueled engines under this paragraph (a)(4) by certifying all your model year 2026 diesel-fueled Heavy HDE to meet all the requirements that apply under this part, with a NO X family emission limit for FTP testing at or below 50 mg/hp·hr. Calculate credits as described in §1036.705 relative to a NO X emission standard of 200 mg/hp·hr. You may use credits generated under this paragraph (a)(4) through model year 2034, but not for later model years. Credits generated by Heavy HDE may be used for certifying Medium HDE after applying a 10 percent discount (multiply credits by 0.9). Engine families using credits generated under this paragraph (a)(4) are subject to a NO X FEL cap of 50 mg/hp·hr for FTP testing.

(b) Model year 2014 N O standards. In model year 2014 and earlier, manufacturers may show compliance with the N 2 O standards using an engineering analysis. This allowance also applies for later families certified using carryover CO 2 data from model 2014 consistent with §1036.235(d).

(c) Engine cycle classification. Through model year 2020, engines meeting the definition of spark-ignition, but regulated as compression-ignition engines under §1036.140, must be certified to the requirements applicable to compression-ignition engines under this part. Such engines are deemed to be compression-ignition engines for purposes of this part. Similarly, through model year 2020, engines meeting the definition of compression-ignition, but regulated as Otto-cycle under 40 CFR part 86 must be certified to the requirements applicable to spark-ignition engines under this part. Such engines are deemed to be spark-ignition engines for purposes of this part. See §1036.140 for provisions that apply for model year 2021 and later.

(d) Small manufacturers. The greenhouse gas standards of this part apply on a delayed schedule for manufacturers meeting the small business criteria specified in 13 CFR 121.201. Apply the small business criteria for NAICS code 336310 for engine manufacturers with respect to gasoline-fueled engines and 333618 for engine manufacturers with respect to other engines; the employee limits apply to the total number employees together for affiliated companies. Qualifying small manufacturers are not subject to the greenhouse gas emission standards in §1036.108 for engines with a date of manufacture on or after November 14, 2011 but before January 1, 2022. In addition, qualifying small manufacturers producing engines that run on any fuel other than gasoline, E85, or diesel fuel may delay complying with every later greenhouse gas standard under this part by one model year. Small manufacturers may certify their engines and generate emission credits under this part before standards start to apply, but only if they certify their entire U.S.-directed production volume within that averaging set for that model year. Note that engines not yet subject to standards must nevertheless supply fuel maps to vehicle manufacturers as described in paragraph (n) of this section. Note also that engines produced by small manufacturers are subject to criteria pollutant standards.

(e) Alternate phase-in standards for greenhouse gas emissions. Where a manufacturer certifies all of its model year 2013 compression-ignition engines within a given primary intended service class to the applicable alternate standards of this paragraph (e), its compression-ignition engines within that primary intended service class are subject to the standards of this paragraph (e) for model years 2013 through 2016. This means that once a manufacturer chooses to certify a primary intended service class to the standards of this paragraph (e), it is not allowed to opt out of these standards.

| Vehicle type | Model years | Light HDE | Medium HDE | Heavy HDE |

|---|---|---|---|---|

| Tractors | 2013-2015 2016 and later a | NA NA | 512 g/hp·hr 487 g/hp·hr | 485 g/hp·hr. 460 g/hp·hr. |

| Vocational | 2013-2015 2016 through 2020 a | 618 g/hp·hr 576 g/hp·hr | 618 g/hp·hr 576 g/hp·hr | 577 g/hp·hr. 555 g/hp·hr. |

| a Note: these alternate standards for 2016 and later are the same as the otherwise applicable standards for 2017 through 2020. | ||||

(f) [Reserved]

(g) Default deterioration factors for greenhouse gas standards. You may use default deterioration factors (DFs) without performing your own durability emission tests or engineering analysis as follows:

(1) You may use a default additive DF of 0.0 g/hp·hr for CO 2 emissions from engines that do not use advanced or off-cycle technologies. If we determine it to be consistent with good engineering judgment, we may allow you to use a default additive DF of 0.0 g/hp·hr for CO 2 emissions from your engines with advanced or off-cycle technologies.

(2) You may use a default additive DF of 0.010 g/hp·hr for N 2 O emissions from any engine through model year 2021, and 0.020 g/hp·hr for later model years.

(3) You may use a default additive DF of 0.020 g/hp·hr for CH 4 emissions from any engine.

(h) Advanced-technology credits. If you generate CO 2 credits from model year 2020 and earlier engines certified for advanced technology, you may multiply these credits by 1.5.

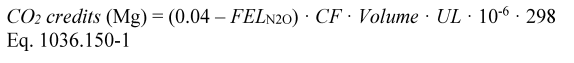

(i) CO credits for low N O emissions . If you certify your model year 2014, 2015, or 2016 engines to an N 2 O FEL less than 0.04 g/hp·hr (provided you measure N 2 O emissions from your emission-data engines), you may generate additional CO 2 credits under this paragraph (i). Calculate the additional CO 2 credits from the following equation instead of the equation in §1036.705:

(j) Alternate standards under 40 CFR part 86. This paragraph (j) describes alternate emission standards for loose engines certified under 40 CFR 86.1819-14(k)(8). The standards of §1036.108 do not apply for these engines. The standards in this paragraph (j) apply for emissions measured with the engine installed in a complete vehicle consistent with the provisions of 40 CFR 86.1819-14(k)(8)(vi). The only requirements of this part that apply to these engines are those in this paragraph (j), §§1036.115 through 1036.135, 1036.535, and 1036.540.

(k) Limited production volume allowance under ABT. You may produce a limited number of Heavy HDE that continue to meet the standards that applied under 40 CFR 86.007-11 in model years 2027 through 2029. The maximum number of engines you may produce under this limited production allowance is 5 percent of the annual average of your actual U.S.-directed production volume of Heavy HDE in model years 2023-2025. Engine certification under this paragraph (k) is subject to the following conditions and requirements:

(1) Engines must meet all the standards and other requirements that apply under 40 CFR part 86 for model year 2026. Engine must be certified in separate engine families that qualify for carryover certification as described in §1036.235(d).

(2) The NO X FEL must be at or below 200 mg/hp·hr. Calculate negative credits as described in §1036.705 by comparing the NO X FEL to the FTP emission standard specified in §1036.104(a)(1), with a value for useful life of 650,000 miles. Meet the credit reporting and recordkeeping requirements in §§1036.730 and 1036.735.

(3) Label the engine as described in 40 CFR 86.095-35, but include the following alternate compliance statement: “THIS ENGINE CONFORMS TO U.S. EPA REGULATIONS FOR MODEL YEAR 2026 ENGINES UNDER 40 CFR 1036.150(k).”

(l) Credit adjustment for spark-ignition engines and light heavy-duty compression-ignition engines. For greenhouse gas emission credits generated from model year 2020 and earlier spark-ignition and light heavy-duty engines, multiply any banked CO 2 credits that you carry forward to demonstrate compliance with model year 2021 and later standards by 1.36.

(m) Infrequent regeneration. For model year 2020 and earlier, you may invalidate any test interval with respect to CO 2 measurements if an infrequent regeneration event occurs during the test interval. Note that §1036.580 specifies how to apply infrequent regeneration adjustment factors for later model years.

(n) Supplying fuel maps. Engine manufacturers not yet subject to standards under §1036.108 in model year 2021 must supply vehicle manufacturers with fuel maps (or powertrain test results) as described in §1036.130 for those engines.

(o) Engines used in glider vehicles. For purposes of recertifying a used engine for installation in a glider vehicle, we may allow you to include in an existing certified engine family those engines you modify (or otherwise demonstrate) to be identical to engines already covered by the certificate. We would base such an approval on our review of any appropriate documentation. These engines must have emission control information labels that accurately describe their status.