...

(a) New and reconstructed affected sources. For a new or reconstructed affected source, you must meet the requirements of paragraphs (a)(1) through (4) of this section.

(1) All emission capture systems, add-on control devices, and CPMS must be installed and operating no later than the applicable compliance date specified in §63.4483. Except for solvent recovery systems for which you conduct liquid-liquid material balances according to §63.4561(j), you must conduct according to the schedule in paragraphs (a)(1)(i) and (ii) of this section initial and periodic performance tests of each capture system and add-on control device according to the procedures in §§63.4564, 63.4565, and 63.4566 and establish the operating limits required by §63.4492. For a solvent recovery system for which you conduct liquid-liquid material balances according to §63.4561(j), you must initiate the first material balance no later than the applicable compliance date specified in §63.4483.

(i) You must conduct the initial performance test and establish the operating limits required by §63.4492 no later than 180 days after the applicable compliance date specified in §63.4483.

(ii) You must conduct periodic performance tests and establish the operating limits required by §63.4492 within 5 years following the previous performance test. You must conduct the first periodic performance test before July 8, 2023, unless you are already required to complete periodic performance tests as a requirement of renewing your facility's operating permit under 40 CFR part 70 or 40 CFR part 71 and have conducted a performance test on or after July 8, 2018. Thereafter you must conduct a performance test no later than 5 years following the previous performance test. Operating limits must be confirmed or reestablished during each performance test. For any control device for which you are using the catalytic oxidizer control option at §63.4567(b) and following the catalyst maintenance procedures in §63.4567(b)(4), you are not required to conduct periodic control device performance testing as specified by this paragraph. For any control device for which instruments are used to continuously measure organic compound emissions, you are not required to conduct periodic control device performance testing as specified by this paragraph.

(2) You must develop and begin implementing the work practice plan required by §63.4493 no later than the compliance date specified in §63.4483.

(3) You must complete the initial compliance demonstration for the initial compliance period according to the requirements of §63.4561. The initial compliance period begins on the applicable compliance date specified in §63.4483 and ends on the last day of the 12th month following the compliance date. If the compliance date occurs on any day other than the first day of a month, then the initial compliance period extends through the end of that month plus the next 12 months. You must determine the mass of organic HAP emissions and mass of coatings solids used each month and then calculate an organic HAP emission rate at the end of the initial compliance period. The initial compliance demonstration includes the results of emission capture system and add-on control device performance tests conducted according to §§63.4564, 63.4565, and 63.4566; results of liquid-liquid material balances conducted according to §63.4561(j); calculations according to §63.4561 and supporting documentation showing that during the initial compliance period the organic HAP emission rate was equal to or less than the applicable emission limit in §63.4490; the operating limits established during the performance tests and the results of the continuous parameter monitoring required by §63.4568; and documentation of whether you developed and implemented the work practice plan required by §63.4493.

(4) For the initial compliance demonstration, you do not need to comply with the operating limits for the emission capture system and add-on control device required by §63.4492 until after you have completed the initial performance tests specified in paragraph (a)(1) of this section. Instead, you must maintain a log detailing the operation and maintenance of the emission capture system, add-on control device, and continuous parameter monitors during the period between the compliance date and the performance test. You must begin complying with the operating limits established based on the initial performance tests specified in paragraph (a)(1) of this section for your affected source on the date you complete the performance tests. The requirements in this paragraph (a)(4) do not apply to solvent recovery systems for which you conduct liquid-liquid material balances according to the requirements in §63.4561(j).

(b) Existing affected sources. For an existing affected source, you must meet the requirements of paragraphs (b)(1) through (3) of this section.

(1) All emission capture systems, add-on control devices, and CPMS must be installed and operating no later than the applicable compliance date specified in §63.4483. Except for solvent recovery systems for which you conduct liquid-liquid material balances according to §63.4561(j), you must conduct according to the schedule in paragraphs (b)(1)(i) and (ii) of this section initial and periodic performance tests of each capture system and add-on control device according to the procedures in §§63.4564, 63.4565, and 63.4566 and establish the operating limits required by §63.4492. For a solvent recovery system for which you conduct liquid-liquid material balances according to §63.4561(j), you must initiate the first material balance no later than the compliance date specified in §63.4483.

(i) You must conduct the initial performance test and establish the operating limits required by §63.4492 no later than 180 days after the applicable compliance date specified in §63.4483.

(ii) You must conduct periodic performance tests and establish the operating limits required by §63.4492 within 5 years following the previous performance test. You must conduct the first periodic performance test before July 8, 2023, unless you are already required to complete periodic performance tests as a requirement of renewing your facility's operating permit under 40 CFR part 70 or 40 CFR part 71 and have conducted a performance test on or after July 8, 2018. Thereafter you must conduct a performance test no later than 5 years following the previous performance test. Operating limits must be confirmed or reestablished during each performance test. For any control device for which you are using the catalytic oxidizer control option at §63.4567(b) and following the catalyst maintenance procedures in §63.4567(b)(4), you are not required to conduct periodic control device performance testing as specified by this paragraph. For any control device for which instruments are used to continuously measure organic compound emissions, you are not required to conduct periodic control device performance testing as specified by this paragraph.

(2) You must develop and begin implementing the work practice plan required by §63.4493 no later than the compliance date specified in §63.4483.

(3) You must complete the initial compliance demonstration for the initial compliance period according to the requirements of §63.4561. The initial compliance period begins on the applicable compliance date specified in §63.4483 and ends on the last day of the 12th month following the compliance date. If the compliance date occurs on any day other than the first day of a month, then the initial compliance period extends through the end of that month plus the next 12 months. You must determine the mass of organic HAP emissions and mass of coatings solids used each month and then calculate an organic HAP emission rate at the end of the initial compliance period. The initial compliance demonstration includes the results of emission capture system and add-on control device performance tests conducted according to §§63.4564, 63.4565, and 63.4566; results of liquid-liquid material balances conducted according to §63.4561(j); calculations according to §63.4561 and supporting documentation showing that during the initial compliance period the organic HAP emission rate was equal to or less than the applicable emission limit in §63.4490; the operating limits established during the performance tests and the results of the continuous parameter monitoring required by §63.4568; and documentation of whether you developed and implemented the work practice plan required by §63.4493.

(c) You are not required to conduct an initial performance test to determine capture efficiency or destruction efficiency of a capture system or control device if you receive approval to use the results of a performance test that has been previously conducted on that capture system or control device. Any such previous tests must meet the conditions described in paragraphs (c)(1) through (3) of this section. You are still required to conduct a periodic performance test according to the applicable requirements of paragraphs (a)(1)(ii) and (b)(2)(ii) of this section.

(1) The previous test must have been conducted using the methods and conditions specified in this subpart.

(2) Either no process or equipment changes must have been made since the previous test was performed, or the owner or operator must be able to demonstrate that the results of the performance test, with or without adjustments, reliably demonstrate compliance despite process or equipment changes.

(3) Either the required operating parameters were established in the previous test or sufficient data were collected in the previous test to establish the required operating parameters.

[85 FR 41153, July 8, 2020]

(a) You may use the emission rate with add-on controls option for any coating operation, for any group of coating operations in the affected source, or for all of the coating operations in the affected source. You may include both controlled and uncontrolled coating operations in a group for which you use this option. You must use either the compliant material option or the emission rate without add-on controls option for any coating operation in the affected source for which you do not use the emission rate with add-on controls option. To demonstrate initial compliance, the coating operation(s) for which you use the emission rate with add-on controls option must meet the applicable emission limitations in §§63.4490, 63.4492, and 63.4493. You must conduct a separate initial compliance demonstration for each general use, TPO, automotive lamp, and assembled on-road vehicle coating operation, unless you are demonstrating compliance with a predominant activity or facility-specific emission limit as provided in §63.4490(c). If you are demonstrating compliance with a predominant activity or facility-specific emission limit as provided in §63.4490(c), you must demonstrate that all coating operations included in the predominant activity determination or calculation of the facility-specific emission limit comply with that limit. You must meet all the requirements of this section. When calculating the organic HAP emission rate according to this section, do not include any coatings, thinners and/or other additives, or cleaning materials used on coating operations for which you use the compliant material option or the emission rate without add-on controls option. You do not need to redetermine the mass of organic HAP in coatings, thinners and/or other additives, or cleaning materials that have been reclaimed onsite (or reclaimed off-site if you have documentation showing that you received back the exact same materials that were sent off-site) and reused in the coatings operation(s) for which you use the emission rate with add-on controls option. If you use coatings, thinners and/or other additives, or cleaning materials that have been reclaimed on-site, the amount of each used in a month may be reduced by the amount of each that is reclaimed. That is, the amount used may be calculated as the amount consumed to account for materials that are reclaimed.

(b) Compliance with operating limits. Except as provided in §63.4560(a)(4), and except for solvent recovery systems for which you conduct liquid-liquid material balances according to the requirements of paragraph (j) of this section, you must establish and demonstrate continuous compliance during the initial compliance period with the operating limits required by §63.4492, using the procedures specified in §§63.4567 and 63.4568.

(c) Compliance with work practice requirements. You must develop, implement, and document your implementation of the work practice plan required by §63.4493 during the initial compliance period, as specified in §63.4530.

(d) Compliance with emission limits. You must follow the procedures in paragraphs (e) through (n) of this section to demonstrate compliance with the applicable emission limit in §63.4490 for each affected source in each subcategory.

(e) Determine the mass fraction of organic HAP, density, volume used, and mass fraction of coating solids. Follow the procedures specified in §63.4551(a) through (d) to determine the mass fraction of organic HAP, density, and volume of each coating, thinner and/or other additive, and cleaning material used during each month; and the mass fraction of coating solids for each coating used during each month.

(f) Calculate the total mass of organic HAP emissions before add-on controls. Using Equation 1 of §63.4551, calculate the total mass of organic HAP emissions before add-on controls from all coatings, thinners and/or other additives, and cleaning materials used during each month in the coating operation or group of coating operations for which you use the emission rate with add-on controls option.

(g) Calculate the organic HAP emission reduction for each controlled coating operation. Determine the mass of organic HAP emissions reduced for each controlled coating operation during each month. The emission reduction determination quantifies the total organic HAP emissions that pass through the emission capture system and are destroyed or removed by the add-on control device. Use the procedures in paragraph (h) of this section to calculate the mass of organic HAP emission reduction for each controlled coating operation using an emission capture system and add-on control device other than a solvent recovery system for which you conduct liquid-liquid material balances. For each controlled coating operation using a solvent recovery system for which you conduct a liquid-liquid material balance, use the procedures in paragraph (j) of this section to calculate the organic HAP emission reduction.

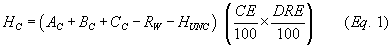

(h) Calculate the organic HAP emission reduction for each controlled coating operation not using liquid-liquid material balance. Use Equation 1 of this section to calculate the organic HAP emission reduction for each controlled coating operation using an emission capture system and add-on control device other than a solvent recovery system for which you conduct liquid-liquid material balances. The calculation applies the emission capture system efficiency and add-on control device efficiency to the mass of organic HAP contained in the coatings, thinners and/or other additives, and cleaning materials that are used in the coating operation served by the emission capture system and add-on control device during each month. You must assume zero efficiency for the emission capture system and add-on control device for any period of time a deviation specified in §63.4563(c) or (d) occurs in the controlled coating operation, including a deviation during a period of startup, shutdown, or malfunction, unless you have other data indicating the actual efficiency of the emission capture system and add-on control device and the use of these data is approved by the Administrator. Equation 1 of this section treats the materials used during such a deviation as if they were used on an uncontrolled coating operation for the time period of the deviation.

Where:

HC = Mass of organic HAP emission reduction for the controlled coating operation during the month, kg.

AC = Total mass of organic HAP in the coatings used in the controlled coating operation during the month, kg, as calculated in Equation 1A of this section.

BC = Total mass of organic HAP in the thinners and/or other additives used in the controlled coating operation during the month, kg, as calculated in Equation 1B of this section.

CC = Total mass of organic HAP in the cleaning materials used in the controlled coating operation during the month, kg, as calculated in Equation 1C of this section.

Rw = Total mass of organic HAP in waste materials sent or designated for shipment to a hazardous waste TSDF for treatment or disposal during the compliance period, kg, determined according to §63.4951(e)(4). (You may assign a value of zero to Rw if you do not wish to use this allowance.)

HUNC = Total mass of organic HAP in the coatings, thinners and/or other additives, and cleaning materials used during all deviations specified in §63.4563(c) and (d) that occurred during the month in the controlled coating operation, kg, as calculated in Equation 1D of this section.

CE = Capture efficiency of the emission capture system vented to the add-on control device, percent. Use the test methods and procedures specified in §§63.4564 and 63.4565 to measure and record capture efficiency.

DRE = Organic HAP destruction or removal efficiency of the add-on control device, percent. Use the test methods and procedures in §§63.4564 and 63.4566 to measure and record the organic HAP destruction or removal efficiency.

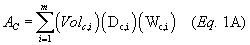

(1) Calculate the mass of organic HAP in the coatings used in the controlled coating operation, kg (lb), using Equation 1A of this section:

Where:

AC = Total mass of organic HAP in the coatings used in the controlled coating operation during the month, kg.

Volc,i = Total volume of coating, i, used during the month, liters.

Dc,i = Density of coating, i, kg per liter.

Wc,i = Mass fraction of organic HAP in coating, i, kg per kg. For reactive adhesives as defined in §63.4581, use the mass fraction of organic HAP that is emitted as determined using the method in appendix A to this subpart.

m = Number of different coatings used.

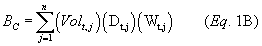

(2) Calculate the mass of organic HAP in the thinners and/or other additives used in the controlled coating operation, kg (lb), using Equation 1B of this section:

Where:

BC = Total mass of organic HAP in the thinners and/or other additives used in the controlled coating operation during the month, kg.

Volt,j = Total volume of thinner and/or other additive, j, used during the month, liters.

Dt,j = Density of thinner and/or other additive, j, kg per liter.

Wt,j = Mass fraction of organic HAP in thinner and/or other additive, j, kg per kg. For reactive adhesives as defined in §63.4581, use the mass fraction of organic HAP that is emitted as determined using the method in appendix A to this subpart.

n = Number of different thinners and/or other additives used.

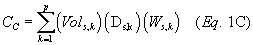

(3) Calculate the mass of organic HAP in the cleaning materials used in the controlled coating operation during the month, kg (lb), using Equation 1C of this section:

Where:

CC = Total mass of organic HAP in the cleaning materials used in the controlled coating operation during the month, kg.

Vols,k = Total volume of cleaning material, k, used during the month, liters.

Ds,k = Density of cleaning material, k, kg per liter.

Ws,k = Mass fraction of organic HAP in cleaning material, k, kg per kg.

p = Number of different cleaning materials used.

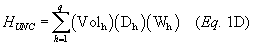

(4) Calculate the mass of organic HAP in the coatings, thinners and/or other additives, and cleaning materials used in the controlled coating operation during deviations specified in §63.4563(c) and (d), using Equation 1D of this section:

Where:

HUNC = Total mass of organic HAP in the coatings, thinners and/or other additives, and cleaning materials used during all deviations specified in §63.4563(c) and (d) that occurred during the month in the controlled coating operation, kg.

Volh = Total volume of coating, thinner and/or other additive, or cleaning material, h, used in the controlled coating operation during deviations, liters.

Dh = Density of coating, thinner and/or other additives, or cleaning material, h, kg per liter.

Wh = Mass fraction of organic HAP in coating, thinner and/or other additives, or cleaning material, h, kg organic HAP per kg coating. For reactive adhesives as defined in §63.4581, use the mass fraction of organic HAP that is emitted as determined using the method in appendix A to this subpart.

q = Number of different coatings, thinners and/or other additives, and cleaning materials used.

(i) [Reserved]

(j) Calculate the organic HAP emission reduction for each controlled coating operation using liquid-liquid material balances. For each controlled coating operation using a solvent recovery system for which you conduct liquid-liquid material balances, calculate the organic HAP emission reduction by applying the volatile organic matter collection and recovery efficiency to the mass of organic HAP contained in the coatings, thinners and/or other additives, and cleaning materials that are used in the coating operation controlled by the solvent recovery system during each month. Perform a liquid-liquid material balance for each month as specified in paragraphs (j)(1) through (6) of this section. Calculate the mass of organic HAP emission reduction by the solvent recovery system as specified in paragraph (j)(7) of this section.

(1) For each solvent recovery system, install, calibrate, maintain, and operate according to the manufacturer's specifications, a device that indicates the cumulative amount of volatile organic matter recovered by the solvent recovery system each month. The device must be initially certified by the manufacturer to be accurate to within ±2.0 percent of the mass of volatile organic matter recovered.

(2) For each solvent recovery system, determine the mass of volatile organic matter recovered for the month, based on measurement with the device required in paragraph (j)(1) of this section.

(3) Determine the mass fraction of volatile organic matter for each coating, thinner and/or other additive, and cleaning material used in the coating operation controlled by the solvent recovery system during the month, kg volatile organic matter per kg coating. You may determine the volatile organic matter mass fraction using EPA Method 24 of 40 CFR part 60, appendix A-7, ASTM D2369-10 (Reapproved 2015)e (incorporated by reference, see§63.14), or an EPA approved alternative method. Alternatively, you may determine the volatile organic matter mass fraction using information provided by the manufacturer or supplier of the coating. In the event of any inconsistency between information provided by the manufacturer or supplier and the results of EPA Method 24 of 40 CFR part 60, appendix A-7, ASTM D2369-10 (Reapproved 2015)e, or an approved alternative method, the test method results will take precedence unless, after consultation you demonstrate to the satisfaction of the enforcement agency that the formulation data are correct.

(4) Determine the density of each coating, thinner and/or other additive, and cleaning material used in the coating operation controlled by the solvent recovery system during the month, kg per liter, according to §63.4551(c).

(5) Measure the volume of each coating, thinner and/or other additive, and cleaning material used in the coating operation controlled by the solvent recovery system during the month, liters.

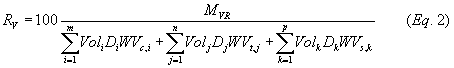

(6) Each month, calculate the solvent recovery system's volatile organic matter collection and recovery efficiency, using Equation 2 of this section:

Where:

RV = Volatile organic matter collection and recovery efficiency of the solvent recovery system during the month, percent.

MVR = Mass of volatile organic matter recovered by the solvent recovery system during the month, kg.

Voli = Volume of coating, i, used in the coating operation controlled by the solvent recovery system during the month, liters.

Di = Density of coating, i, kg per liter.

WVc,i = Mass fraction of volatile organic matter for coating, i, kg volatile organic matter per kg coating. For reactive adhesives as defined in §63.4581, use the mass fraction of organic HAP that is emitted as determined using the method in appendix A to this subpart.

Volj = Volume of thinner and/or other additive, j, used in the coating operation controlled by the solvent recovery system during the month, liters.

Dj = Density of thinner and/or other additive, j, kg per liter.

WVt,j = Mass fraction of volatile organic matter for thinner and/or other additive, j, kg volatile organic matter per kg thinner and/or other additive. For reactive adhesives as defined in §63.4581, use the mass fraction of organic HAP that is emitted as determined using the method in appendix A to this subpart.

Volk = Volume of cleaning material, k, used in the coating operation controlled by the solvent recovery system during the month, liters.

Dk = Density of cleaning material, k, kg per liter.

WVs,k = Mass fraction of volatile organic matter for cleaning material, k, kg volatile organic matter per kg cleaning material.

m = Number of different coatings used in the coating operation controlled by the solvent recovery system during the month.

n = Number of different thinners and/or other additives used in the coating operation controlled by the solvent recovery system during the month.

p = Number of different cleaning materials used in the coating operation controlled by the solvent recovery system during the month.

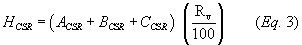

(7) Calculate the mass of organic HAP emission reduction for the coating operation controlled by the solvent recovery system during the month, using Equation 3 of this section and according to paragraphs (j)(7)(i) through (iii) of this section:

Where:

HCSR = Mass of organic HAP emission reduction for the coating operation controlled by the solvent recovery system using a liquid-liquid material balance during the month, kg.

ACSR = Total mass of organic HAP in the coatings used in the coating operation controlled by the solvent recovery system, kg, calculated using Equation 3A of this section.

BCSR = Total mass of organic HAP in the thinners and/or other additives used in the coating operation controlled by the solvent recovery system, kg, calculated using Equation 3B of this section.

CCSR = Total mass of organic HAP in the cleaning materials used in the coating operation controlled by the solvent recovery system, kg, calculated using Equation 3C of this section.

RV = Volatile organic matter collection and recovery efficiency of the solvent recovery system, percent, from Equation 2 of this section.

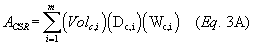

(i) Calculate the mass of organic HAP in the coatings used in the coating operation controlled by the solvent recovery system, kg, using Equation 3A of this section.

Where:

ACSR = Total mass of organic HAP in the coatings used in the coating operation controlled by the solvent recovery system during the month, kg.

Volc,i = Total volume of coating, i, used during the month in the coating operation controlled by the solvent recovery system, liters.

Dc,i = Density of coating, i, kg per liter.

Wc,i = Mass fraction of organic HAP in coating, i, kg organic HAP per kg coating. For reactive adhesives as defined in §63.4581, use the mass fraction of organic HAP that is emitted as determined using the method in appendix A to this subpart.

m = Number of different coatings used.

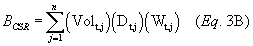

(ii) Calculate the mass of organic HAP in the thinners and/or other additives used in the coating operation controlled by the solvent recovery system, kg, using Equation 3B of this section:

Where:

BCSR = Total mass of organic HAP in the thinners and/or other additives used in the coating operation controlled by the solvent recovery system during the month, kg.

Volt,j = Total volume of thinner and/or other additive, j, used during the month in the coating operation controlled by the solvent recovery system, liters.

Dt,j = Density of thinner and/or other additive, j, kg per liter.

Wt,j = Mass fraction of organic HAP in thinner and/or other additive, j, kg organic HAP per kg thinner and/or other additive. For reactive adhesives as defined in §63.4581, use the mass fraction of organic HAP that is emitted as determined using the method in appendix A to this subpart.

n = Number of different thinners and/or other additives used.

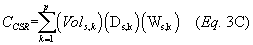

(iii) Calculate the mass of organic HAP in the cleaning materials used in the coating operation controlled by the solvent recovery system during the month, kg, using Equation 3C of this section:

Where:

CCSR = Total mass of organic HAP in the cleaning materials used in the coating operation controlled by the solvent recovery system during the month, kg.

Vols,k = Total volume of cleaning material, k, used during the month in the coating operation controlled by the solvent recovery system, liters.

Ds,k = Density of cleaning material, k, kg per liter.

Ws,k = Mass fraction of organic HAP in cleaning material, k, kg organic HAP per kg cleaning material.

p = Number of different cleaning materials used.

(k) Calculate the total mass of coating solids used. Determine the total mass of coating solids used, kg, which is the combined mass of coating solids for all the coatings used during each month in the coating operation or group of coating operations for which you use the emission rate with add-on controls option, using Equation 2 of §63.4551.

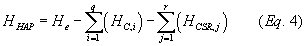

(l) Calculate the mass of organic HAP emissions for each month. Determine the mass of organic HAP emissions, kg, during each month, using Equation 4 of this section:

Where:

HHAP = Total mass of organic HAP emissions for the month, kg.

He = Total mass of organic HAP emissions before add-on controls from all the coatings, thinners and/or other additives, and cleaning materials used during the month, kg, determined according to paragraph (f) of this section.

HC,i = Total mass of organic HAP emission reduction for controlled coating operation, i, not using a liquid-liquid material balance, during the month, kg, from Equation 1 of this section.

HCSR,j = Total mass of organic HAP emission reduction for coating operation, j, controlled by a solvent recovery system using a liquid-liquid material balance, during the month, kg, from Equation 3 of this section.

q = Number of controlled coating operations not controlled by a solvent recovery system using a liquid-liquid material balance.

r = Number of coating operations controlled by a solvent recovery system using a liquid-liquid material balance.

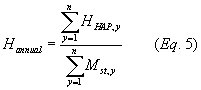

(m) Calculate the organic HAP emission rate for the compliance period. Determine the organic HAP emission rate for the compliance period, kg (lb) of organic HAP emitted per kg (lb) coating solids used, using Equation 5 of this section:

Where:

Hannual = Organic HAP emission rate for the compliance period, kg organic HAP emitted per kg coating solids used.

HHAP,y = Organic HAP emissions for month, y, kg, determined according to Equation 4 of this section.

Mst,y = Total mass of coating solids used during month, y, kg, from Equation 2 of §63.4551.

y = Identifier for months.

n = Number of full or partial months in the compliance period (for the initial compliance period, n equals 12 if the compliance date falls on the first day of a month; otherwise n equals 13; for all following compliance periods, n equals 12).

(n) Compliance demonstration. The organic HAP emission rate for the initial compliance period, calculated using Equation 5 of this section, must be less than or equal to the applicable emission limit for each subcategory in §63.4490 or the predominant activity or facility-specific emission limit allowed in §63.4490(c). You must keep all records as required by §§63.4530 and 63.4531. As part of the notification of compliance status required by §63.4510, you must identify the coating operation(s) for which you used the emission rate with add-on controls option and submit a statement that the coating operation(s) was (were) in compliance with the emission limitations during the initial compliance period because the organic HAP emission rate was less than or equal to the applicable emission limit in §63.4490, and for control devices other than solvent recovery system using a liquid-liquid material balance, you achieved the operating limits required by §63.4492 and the work practice standards required by §63.4493.

[85 FR 41154, July 8, 2020]

(a) To demonstrate continuous compliance with the applicable emission limit in §63.4490, the organic HAP emission rate for each compliance period, determined according to the procedures in §63.4561, must be equal to or less than the applicable emission limit in §63.4490. A compliance period consists of 12 months. Each month after the end of the initial compliance period described in §63.4560 is the end of a compliance period consisting of that month and the preceding 11 months. You must perform the calculations in §63.4561 on a monthly basis using data from the previous 12 months of operation. If you are complying with a facility-specific emission limit under §63.4490(c), you must also perform the calculation using Equation 1 in §63.4490(c)(2) on a monthly basis using the data from the previous 12 months of operation.

(b) If the organic HAP emission rate for any 12-month compliance period exceeded the applicable emission limit in §63.4490, this is a deviation from the emission limitation for that compliance period that must be reported as specified in §§63.4510(c)(6) and 63.4520(a)(7).

(c) You must demonstrate continuous compliance with each operating limit required by §63.4492 that applies to you, as specified in Table 1 to this subpart, when the coating line is in operation.

(1) If an operating parameter is out of the allowed range specified in Table 1 to this subpart, this is a deviation from the operating limit that must be reported as specified in §§63.4510(c)(6) and 63.4520(a)(7).

(2) If an operating parameter deviates from the operating limit specified in Table 1 to this subpart, then you must assume that the emission capture system and add-on control device were achieving zero efficiency during the time period of the deviation, unless you have other data indicating the actual efficiency of the emission capture system and add-on control device and the use of these data is approved by the Administrator.

(d) You must meet the requirements for bypass lines in §63.4568(b) for controlled coating operations for which you do not conduct liquid-liquid material balances. If any bypass line is opened and emissions are diverted to the atmosphere when the coating operation is running, this is a deviation that must be reported as specified in §§63.4510(c)(6) and 63.4520(a)(7). For the purposes of completing the compliance calculations specified in §§63.4561(h), you must treat the materials used during a deviation on a controlled coating operation as if they were used on an uncontrolled coating operation for the time period of the deviation as indicated in Equation 1 of §63.4561.

(e) You must demonstrate continuous compliance with the work practice standards in §63.4493. If you did not develop a work practice plan, or you did not implement the plan, or you did not keep the records required by §63.4530(i)(8), this is a deviation from the work practice standards that must be reported as specified in §§63.4510(c)(6) and 63.4520(a)(7).

(f) As part of each semiannual compliance report required in §63.4520, you must identify the coating operation(s) for which you used the emission rate with add-on controls option. If there were no deviations from the emission limits in §63.4490, the operating limits in §63.4492, and the work practice standards in §63.4493, submit a statement that you were in compliance with the emission limitations during the reporting period because the organic HAP emission rate for each compliance period was less than or equal to the applicable emission limit in §63.4490, and you achieved the operating limits required by §63.4492 and the work practice standards required by §63.4493 during each compliance period.

(g) On and after January 5, 2021, deviations that occur due to malfunction of the emission capture system, add-on control device, or coating operation that may affect emission capture or control device efficiency are required to operate in accordance with §63.4500(b). The Administrator will determine whether the deviations are violations according to the provisions in §63.4500(b).

(i) [Reserved]

(j) You must maintain records as specified in §§63.4530 and 63.4531.

[69 FR 20990, Apr. 19, 2004, as amended at 71 FR 20465, Apr. 20, 2006; 85 FR 41154, July 8, 2020]

(a) Before January 5, 2021, you must conduct each performance test required by §63.4560 according to the requirements in §63.7(e)(1) and under the conditions in this section, unless you obtain a waiver of the performance test according to the provisions in §63.7(h). On and after January 5, 2021, you must conduct each performance test required by §63.4560 according to the requirements in this section unless you obtain a waiver of the performance test according to the provisions in §63.7(h).

(1) Representative coating operation operating conditions. You must conduct the performance test under representative operating conditions for the coating operation. Operations during periods of startup, shutdown, or nonoperation do not constitute representative conditions for purposes of conducting a performance test. The owner or operator may not conduct performance tests during periods of malfunction. You must record the process information that is necessary to document operating conditions during the test and explain why the conditions represent normal operation. Upon request, you must make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

(2) Representative emission capture system and add-on control device operating conditions. You must conduct the performance test when the emission capture system and add-on control device are operating at a representative flow rate, and the add-on control device is operating at a representative inlet concentration. You must record information that is necessary to document emission capture system and add-on control device operating conditions during the test and explain why the conditions represent normal operation.

(b) You must conduct each performance test of an emission capture system according to the requirements in §63.4565. You must conduct each performance test of an add-on control device according to the requirements in §63.4566.

[85 FR 41155, July 8, 2020]

You must use the procedures and test methods in this section to determine capture efficiency as part of each performance test required by §63.4560.

(a) Assuming 100 percent capture efficiency. You may assume the capture system efficiency is 100 percent if both of the conditions in paragraphs (a)(1) and (2) of this section are met:

(1) The capture system meets the criteria in Method 204 of appendix M to 40 CFR part 51 for a PTE and directs all the exhaust gases from the enclosure to an add-on control device.

(2) All coatings, thinners and/or other additives, and cleaning materials used in the coating operation are applied within the capture system; coating solvent flash-off, curing, and drying occurs within the capture system; and the removal or evaporation of cleaning materials from the surfaces they are applied to occurs within the capture system. For example, this criterion is not met if parts enter the open shop environment when being moved between a spray booth and a curing oven.

(b) Measuring capture efficiency. If the capture system does not meet both of the criteria in paragraphs (a)(1) and (2) of this section, then you must use one of the three protocols described in paragraphs (c), (d), and (e) of this section to measure capture efficiency. The capture efficiency measurements use TVH capture efficiency as a surrogate for organic HAP capture efficiency. For the protocols in paragraphs (c) and (d) of this section, the capture efficiency measurement must consist of three test runs. Each test run must be at least 3 hours duration or the length of a production run, whichever is longer, up to 8 hours. For the purposes of this test, a production run means the time required for a single part to go from the beginning to the end of the production, which includes surface preparation activities and drying and curing time.

(c) Liquid-to-uncaptured-gas protocol using a temporary total enclosure or building enclosure. The liquid-to-uncaptured-gas protocol compares the mass of liquid TVH in materials used in the coating operation to the mass of TVH emissions not captured by the emission capture system. Use a temporary total enclosure or a building enclosure and the procedures in paragraphs (c)(1) through (6) of this section to measure emission capture system efficiency using the liquid-to-uncaptured-gas protocol.

(1) Either use a building enclosure or construct an enclosure around the coating operation where coatings, thinners and/or other additives, and cleaning materials are applied, and all areas where emissions from these applied coatings and materials subsequently occur, such as flash-off, curing, and drying areas. The areas of the coating operation where capture devices collect emissions for routing to an add-on control device, such as the entrance and exit areas of an oven or spray booth, must also be inside the enclosure. The enclosure must meet the applicable definition of a temporary total enclosure or building enclosure in Method 204 of appendix M to 40 CFR part 51.

(2) Use Method 204A or 204F of appendix M to 40 CFR part 51 to determine the mass fraction of TVH liquid input from each coating, thinner and/or other additive, and cleaning material used in the coating operation during each capture efficiency test run. To make the determination, substitute TVH for each occurrence of the term volatile organic compounds (VOC) in the methods.

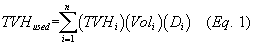

(3) Use Equation 1 of this section to calculate the total mass of TVH liquid input from all the coatings, thinners and/or other additives, and cleaning materials used in the coating operation during each capture efficiency test run:

Where:

TVHused = Mass of liquid TVH in materials used in the coating operation during the capture efficiency test run, kg.

TVHi = Mass fraction of TVH in coating, thinner and/or other additive, or cleaning material, i, that is used in the coating operation during the capture efficiency test run, kg TVH per kg material.

Voli = Total volume of coating, thinner and/or other additive, or cleaning material, i, used in the coating operation during the capture efficiency test run, liters.

Di = Density of coating, thinner and/or other additive, or cleaning material, i, kg material per liter material.

n = Number of different coatings, thinners and/or other additives, and cleaning materials used in the coating operation during the capture efficiency test run.

(4) Use Method 204D or 204E of appendix M to 40 CFR part 51 to measure the total mass, kg, of TVH emissions that are not captured by the emission capture system. They are measured as they exit the temporary total enclosure or building enclosure during each capture efficiency test run. To make the measurement, substitute TVH for each occurrence of the term VOC in the methods.

(i) Use Method 204D of appendix M to 40 CFR part 51 if the enclosure is a temporary total enclosure.

(ii) Use Method 204E of appendix M to 40 CFR 51 if the enclosure is a building enclosure. During the capture efficiency measurement, all organic compound emitting operations inside the building enclosure, other than the coating operation for which capture efficiency is being determined, must be shut down, but all fans and blowers must be operating normally.

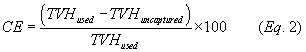

(5) For each capture efficiency test run, determine the percent capture efficiency of the emission capture system using Equation 2 of this section:

Where:

CE = Capture efficiency of the emission capture system vented to the add-on control device, percent.

TVHused = Total mass of TVH liquid input used in the coating operation during the capture efficiency test run, kg.

TVHuncaptured = Total mass of TVH that is not captured by the emission capture system and that exits from the temporary total enclosure or building enclosure during the capture efficiency test run, kg.

(6) Determine the capture efficiency of the emission capture system as the average of the capture efficiencies measured in the three test runs.

(d) Gas-to-gas protocol using a temporary total enclosure or a building enclosure. The gas-to-gas protocol compares the mass of TVH emissions captured by the emission capture system to the mass of TVH emissions not captured. Use a temporary total enclosure or a building enclosure and the procedures in paragraphs (d)(1) through (5) of this section to measure emission capture system efficiency using the gas-to-gas protocol.

(1) Either use a building enclosure or construct an enclosure around the coating operation where coatings, thinners and/or other additives, and cleaning materials are applied, and all areas where emissions from these applied coatings and materials subsequently occur, such as flash-off, curing, and drying areas. The areas of the coating operation where capture devices collect emissions generated by the coating operation for routing to an add-on control device, such as the entrance and exit areas of an oven or a spray booth, must also be inside the enclosure. The enclosure must meet the applicable definition of a temporary total enclosure or building enclosure in Method 204 of appendix M to 40 CFR part 51.

(2) Use Method 204B or 204C of appendix M to 40 CFR part 51 to measure the total mass, kg, of TVH emissions captured by the emission capture system during each capture efficiency test run as measured at the inlet to the add-on control device. To make the measurement, substitute TVH for each occurrence of the term VOC in the methods.

(i) The sampling points for the Method 204B or 204C measurement must be upstream from the add-on control device and must represent total emissions routed from the capture system and entering the add-on control device.

(ii) If multiple emission streams from the capture system enter the add-on control device without a single common duct, then the emissions entering the add-on control device must be simultaneously measured in each duct and the total emissions entering the add-on control device must be determined.

(3) Use Method 204D or 204E of appendix M to 40 CFR part 51 to measure the total mass, kg, of TVH emissions that are not captured by the emission capture system; they are measured as they exit the temporary total enclosure or building enclosure during each capture efficiency test run. To make the measurement, substitute TVH for each occurrence of the term VOC in the methods.

(i) Use Method 204D of appendix M to 40 CFR part 51 if the enclosure is a temporary total enclosure.

(ii) Use Method 204E of appendix M to 40 CFR part 51 if the enclosure is a building enclosure. During the capture efficiency measurement, all organic compound emitting operations inside the building enclosure, other than the coating operation for which capture efficiency is being determined, must be shut down, but all fans and blowers must be operating normally.

(4) For each capture efficiency test run, determine the percent capture efficiency of the emission capture system using Equation 3 of this section:

Where:

CE = Capture efficiency of the emission capture system vented to the add-on control device, percent.

TVHcaptured = Total mass of TVH captured by the emission capture system as measured at the inlet to the add-on control device during the emission capture efficiency test run, kg.

TVHuncaptured = Total mass of TVH that is not captured by the emission capture system and that exits from the temporary total enclosure or building enclosure during the capture efficiency test run, kg.

(5) Determine the capture efficiency of the emission capture system as the average of the capture efficiencies measured in the three test runs.

(e) Alternative capture efficiency protocol. As an alternative to the procedures specified in paragraphs (c) and (d) of this section and subject to the approval of the Administrator, you may determine capture efficiency using any other capture efficiency protocol and test methods that satisfy the criteria of either the DQO or LCL approach as described in appendix A to subpart KK of this part.

[85 FR 41155, July 8, 2020]

You must use the procedures and test methods in this section to determine the add-on control device emission destruction or removal efficiency as part of the performance test required by §63.4560. For each performance test, you must conduct three test runs as specified in §63.7(e)(3) and each test run must last at least 1 hour.

(a) For all types of add-on control devices, use the test methods specified in paragraphs (a)(1) through (5) of this section.

(1) Use EPA Method 1 or 1A of appendix A-1 to 40 CFR part 60, as appropriate, to select sampling sites and velocity traverse points.

(2) Use EPA Method 2, 2A, 2C, 2D, or 2F of appendix A-1 to 40 CFR part 60, or 2G of appendix A-2 to 40 CFR part 60, as appropriate, to measure gas volumetric flow rate.

(3) Use EPA Method 3, 3A, or 3B of appendix A-2 to 40 CFR part 60, as appropriate, for gas analysis to determine dry molecular weight.

(4) Use EPA Method 4 of appendix A-3 to 40 CFR part 60, to determine stack gas moisture.

(5) Methods for determining gas volumetric flow rate, dry molecular weight, and stack gas moisture must be performed, as applicable, during each test run.

(b) Measure total gaseous organic mass emissions as carbon at the inlet and outlet of the add-on control device simultaneously, using either EPA Method 25 or 25A of appendix A-7 to 40 CFR part 60.

(1) Use EPA Method 25 of appendix A-7 if the add-on control device is an oxidizer and you expect the total gaseous organic concentration as carbon to be more than 50 parts per million (ppm) at the control device outlet.

(2) Use EPA Method 25A of appendix A-7 if the add-on control device is an oxidizer and you expect the total gaseous organic concentration as carbon to be 50 ppm or less at the control device outlet.

(3) Use EPA Method 25A of appendix A-7 if the add-on control device is not an oxidizer.

(4) You may use EPA Method 18 in appendix A-6 of part 60 to subtract methane emissions from measured total gaseous organic mass emissions as carbon.

(c) If two or more add-on control devices are used for the same emission stream, then you must measure emissions at the outlet to the atmosphere of each device. For example, if one add-on control device is a concentrator with an outlet to the atmosphere for the high-volume dilute stream that has been treated by the concentrator, and a second add-on control device is an oxidizer with an outlet to the atmosphere for the low-volume concentrated stream that is treated with the oxidizer, you must measure emissions at the outlet of the oxidizer and the high volume dilute stream outlet of the concentrator.

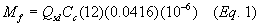

(d) For each test run, determine the total gaseous organic emissions mass flow rates for the inlet and the outlet of the add-on control device, using Equation 1 of this section. If there is more than one inlet or outlet to the add-on control device, you must calculate the total gaseous organic mass flow rate using Equation 1 of this section for each inlet and each outlet and then total all of the inlet emissions and total all of the outlet emissions:

Where:

Mf = Total gaseous organic emissions mass flow rate, kg/per hour (h).

Cc = Concentration of organic compounds as carbon in the vent gas, as determined by Method 25 or Method 25A, parts per million by volume (ppmv), dry basis.

Qsd = Volumetric flow rate of gases entering or exiting the add-on control device, as determined by Method 2, 2A, 2C, 2D, 2F, or 2G, dry standard cubic meters/hour (dscm/h).

0.0416 = Conversion factor for molar volume, kg-moles per cubic meter (mol/m 3) (@ 293 Kelvin (K) and 760 millimeters of mercury (mmHg)).

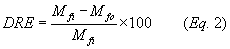

(e) For each test run, determine the add-on control device organic emissions destruction or removal efficiency, using Equation 2 of this section:

Where:

DRE = Organic emissions destruction or removal efficiency of the add-on control device, percent.

Mfi = Total gaseous organic emissions mass flow rate at the inlet(s) to the add-on control device, using Equation 1 of this section, kg/h.

Mfo = Total gaseous organic emissions mass flow rate at the outlet(s) of the add-on control device, using Equation 1 of this section, kg/h.

(f) Determine the emission destruction or removal efficiency of the add-on control device as the average of the efficiencies determined in the three test runs and calculated in Equation 2 of this section.

[85 FR 41155, July 8, 2020]

During performance tests required by §63.4560 and described in §§63.4564, 63.4565, and 63.4566, you must establish the operating limits required by §63.4492 according to this section, unless you have received approval for alternative monitoring and operating limits under §63.8(f) as specified in §63.4492.

(a) Thermal oxidizers. If your add-on control device is a thermal oxidizer, establish the operating limits according to paragraphs (a)(1) and (2) of this section.

(1) During performance tests, you must monitor and record the combustion temperature at least once every 15 minutes during each of the three test runs. You must monitor the temperature in the firebox of the thermal oxidizer or immediately downstream of the firebox before any substantial heat exchange occurs.

(2) For each performance test, use the data collected during the performance test to calculate and record the average combustion temperature maintained during the performance test. This average combustion temperature is the minimum operating limit for your thermal oxidizer.

(b) Catalytic oxidizers. If your add-on control device is a catalytic oxidizer, establish the operating limits according to either paragraphs (b)(1) and (2) or paragraphs (b)(3) and (4) of this section.

(1) During performance tests, you must monitor and record the temperature just before the catalyst bed and the temperature difference across the catalyst bed at least once every 15 minutes during each of the three test runs.

(2) For each performance test, use the data collected during the performance test to calculate and record the average temperature just before the catalyst bed and the average temperature difference across the catalyst bed maintained during the performance test. These are the minimum operating limits for your catalytic oxidizer.

(3) You must monitor the temperature at the inlet to the catalyst bed and implement a site-specific inspection and maintenance plan for your catalytic oxidizer as specified in paragraph (b)(4) of this section. During performance tests, you must monitor and record the temperature just before the catalyst bed at least once every 15 minutes during each of the three test runs. For each performance test, use the data collected during the performance test to calculate and record the average temperature just before the catalyst bed during the performance test. This is the minimum operating limit for your catalytic oxidizer.

(4) You must develop and implement an inspection and maintenance plan for your catalytic oxidizer(s) for which you elect to monitor according to paragraph (b)(3) of this section. The plan must address, at a minimum, the elements specified in paragraphs (b)(4)(i) through (iii) of this section.

(i) Annual sampling and analysis of the catalyst activity (i.e., conversion efficiency) following the manufacturer's or catalyst supplier's recommended procedures. If problems are found during the catalyst activity test, you must replace the catalyst bed or take other corrective action consistent with the manufacturer's recommendations.

(ii) Monthly external inspection of the catalytic oxidizer system, including the burner assembly and fuel supply lines for problems and, as necessary, adjust the equipment to assure proper air-to-fuel mixtures.

(iii) Annual internal inspection of the catalyst bed to check for channeling, abrasion, and settling. If problems are found during the annual internal inspection of the catalyst, you must replace the catalyst bed or take other corrective action consistent with the manufacturer's recommendations. If the catalyst bed is replaced and is not of like or better kind and quality as the old catalyst then you must conduct a new performance test to determine destruction efficiency according to §63.4566. If a catalyst bed is replaced and the replacement catalyst is of like or better kind and quality as the old catalyst, then a new performance test to determine destruction efficiency is not required and you may continue to use the previously established operating limits for that catalytic oxidizer.

(c) Regenerative carbon adsorbers. If your add-on control device is a regenerative carbon adsorber, establish the operating limits according to paragraphs (c)(1) and (2) of this section.

(1) During performance tests, you must monitor and record the total regeneration desorbing gas (e.g., steam or nitrogen) mass flow for each regeneration cycle, and the carbon bed temperature after each carbon bed regeneration and cooling cycle for the regeneration cycle either immediately preceding or immediately following the performance test.

(2) The operating limits for your regenerative carbon adsorber are the minimum total desorbing gas mass flow recorded during the regeneration cycle and the maximum carbon bed temperature recorded after the cooling cycle.

(d) Condensers. If your add-on control device is a condenser, establish the operating limits according to paragraphs (d)(1) and (2) of this section.

(1) During performance tests, you must monitor and record the condenser outlet (product side) gas temperature at least once every 15 minutes during each of the three test runs of the performance test.

(2) For each performance test, use the data collected during the performance test to calculate and record the average condenser outlet (product side) gas temperature maintained during the performance test. This average condenser outlet gas temperature is the maximum operating limit for your condenser.

(e) Concentrators. If your add-on control device includes a concentrator, you must establish operating limits for the concentrator according to paragraphs (e)(1) through (4) of this section.

(1) During performance tests, you must monitor and record the desorption concentrate stream gas temperature at least once every 15 minutes during each of the three runs of the performance test.

(2) For each performance test, use the data collected during the performance test to calculate and record the average temperature. This is the minimum operating limit for the desorption concentrate gas stream temperature.

(3) During each performance test, you must monitor and record the pressure drop of the dilute stream across the concentrator at least once every 15 minutes during each of the three runs of the performance test.

(4) For each performance test, use the data collected during the performance test to calculate and record the average pressure drop. This is the minimum operating limit for the dilute stream across the concentrator.

(f) Emission capture systems. For each capture device that is not part of a PTE that meets the criteria of §63.4565(a), establish an operating limit for either the gas volumetric flow rate or duct static pressure, as specified in paragraphs (f)(1) and (2) of this section. The operating limit for a PTE is specified in Table 1 to this subpart.

(1) During the capture efficiency determination required by §63.4560 and described in §§63.4564 and 63.4565, you must monitor and record either the gas volumetric flow rate or the duct static pressure for each separate capture device in your emission capture system at least once every 15 minutes during each of the three test runs at a point in the duct between the capture device and the add-on control device inlet.

(2) Calculate and record the average gas volumetric flow rate or duct static pressure for the three test runs for each capture device. This average gas volumetric flow rate or duct static pressure is the minimum operating limit for that specific capture device.

[85 FR 41155, July 8, 2020]

(a) General. You must install, operate, and maintain each CPMS specified in paragraphs (c), (e), (f), and (g) of this section according to paragraphs (a)(1) through (6) of this section. You must install, operate, and maintain each CPMS specified in paragraphs (b) and (d) of this section according to paragraphs (a)(3) through (5) of this section.

(1) The CPMS must complete a minimum of one cycle of operation for each successive 15-minute period. You must have a minimum of four equally spaced successive cycles of CPMS operation in 1 hour.

(2) You must determine the average of all recorded readings for each successive 3-hour period of the emission capture system and add-on control device operation.

(3) You must record the results of each inspection, calibration, and validation check of the CPMS.

(4) Before January 5, 2021, you must maintain the CPMS at all times and have available necessary parts for routine repairs of the monitoring equipment. On and after January 5, 2021, you must maintain the CPMS at all times in accordance with §63.4500(b) and keep necessary parts readily available for routine repairs of the monitoring equipment.

(5) Before January 5, 2021, you must operate the CPMS and collect emission capture system and add-on control device parameter data at all times that a controlled coating operation is operating, except during monitoring malfunctions, associated repairs, and required quality assurance or control activities (including, if applicable, calibration checks and required zero and span adjustments). On and after January 5, 2021, you must operate the CPMS and collect emission capture system and add-on control device parameter data at all times in accordance with §63.4500(b).

(6) You must not use emission capture system or add-on control device parameter data recorded during monitoring malfunctions, associated repairs, out-of-control periods, or required quality assurance or control activities when calculating data averages. You must use all the data collected during all other periods in calculating the data averages for determining compliance with the emission capture system and add-on control device operating limits.

(7) A monitoring malfunction is any sudden, infrequent, not reasonably preventable failure of the CPMS to provide valid data. Monitoring failures that are caused in part by poor maintenance or careless operation are not malfunctions. Before January 5, 2021, any period for which the monitoring system is out-of-control and data are not available for required calculations is a deviation from the monitoring requirements. On and after January 5, 2021, except for periods of required quality assurance or control activities, any period for which the CPMS fails to operate and record data continuously as required by paragraph (a)(5) of this section, or generates data that cannot be included in calculating averages as specified in (a)(6) of this section constitutes a deviation from the monitoring requirements.

(b) Capture system bypass line. You must meet the requirements of paragraphs (b)(1) and (2) of this section for each emission capture system that contains bypass lines that could divert emissions away from the add-on control device to the atmosphere.

(1) You must monitor or secure the valve or closure mechanism controlling the bypass line in a nondiverting position in such a way that the valve or closure mechanism cannot be opened without creating a record that the valve was opened. The method used to monitor or secure the valve or closure mechanism must meet one of the requirements specified in paragraphs (b)(1)(i) through (v) of this section.

(i) Flow control position indicator. Install, calibrate, maintain, and operate according to the manufacturer's specifications a flow control position indicator that takes a reading at least once every 15 minutes and provides a record indicating whether the emissions are directed to the add-on control device or diverted from the add-on control device. The time of occurrence and flow control position must be recorded, as well as every time the flow direction is changed. The flow control position indicator must be installed at the entrance to any bypass line that could divert the emissions away from the add-on control device to the atmosphere.

(ii) Car-seal or lock-and-key valve closures. Secure any bypass line valve in the closed position with a car-seal or a lock-and-key type configuration. You must visually inspect the seal or closure mechanism at least once every month to ensure that the valve is maintained in the closed position, and the emissions are not diverted away from the add-on control device to the atmosphere.

(iii) Valve closure monitoring. Ensure that any bypass line valve is in the closed (nondiverting) position through monitoring of valve position at least once every 15 minutes. You must inspect the monitoring system at least once every month to verify that the monitor will indicate valve position.

(iv) Automatic shutdown system. Use an automatic shutdown system in which the coating operation is stopped when flow is diverted by the bypass line away from the add-on control device to the atmosphere when the coating operation is running. You must inspect the automatic shutdown system at least once every month to verify that it will detect diversions of flow and shut down the coating operation.

(v) Flow direction indicator. Install, calibrate, maintain, and operate according to the manufacturer's specifications a flow direction indicator that takes a reading at least once every 15 minutes and provides a record indicating whether the emissions are directed to the add-on control device or diverted from the add-on control device. Each time the flow direction changes, the next reading of the time of occurrence and flow direction must be recorded. The flow direction indicator must be installed in each bypass line or air makeup supply line that could divert the emissions away from the add-on control device to the atmosphere.

(2) If any bypass line is opened, you must include a description of why the bypass line was opened and the length of time it remained open in the semiannual compliance reports required in §63.4520.

(c) Thermal oxidizers and catalytic oxidizers. If you are using a thermal oxidizer or catalytic oxidizer as an add-on control device (including those used with concentrators or with carbon adsorbers to treat desorbed concentrate streams), you must comply with the requirements in paragraphs (c)(1) through (3) of this section:

(1) For a thermal oxidizer, install a gas temperature monitor in the firebox of the thermal oxidizer or in the duct immediately downstream of the firebox before any substantial heat exchange occurs.

(2) For a catalytic oxidizer, install gas temperature monitors upstream and/or downstream of the catalyst bed as required in §63.3967(b).

(3) For all thermal oxidizers and catalytic oxidizers, you must meet the requirements in paragraphs (a) and (c)(3)(i) through (v) of this section for each gas temperature monitoring device. For the purposes of this paragraph (c)(3), a thermocouple is part of the temperature sensor.

(i) Locate the temperature sensor in a position that provides a representative temperature.

(ii) Use a temperature sensor with a measurement sensitivity of 5 degrees Fahrenheit or 1.0 percent of the temperature value, whichever is larger.

(iii) Before using the sensor for the first time or when relocating or replacing the sensor, perform a validation check by comparing the sensor output to a calibrated temperature measurement device or by comparing the sensor output to a simulated temperature.

(iv) Conduct an accuracy audit every quarter and after every deviation. Accuracy audit methods include comparisons of sensor output to redundant temperature sensors, to calibrated temperature measurement devices, or to temperature simulation devices.

(v) Conduct a visual inspection of each sensor every quarter if redundant temperature sensors are not used.

(d) Regenerative carbon adsorbers. If you are using a regenerative carbon adsorber as an add-on control device, you must monitor the total regeneration desorbing gas (e.g., steam or nitrogen) mass flow for each regeneration cycle, the carbon bed temperature after each regeneration and cooling cycle, and comply with paragraphs (a)(3) through (5) and (d)(1) through (3) of this section.

(1) The regeneration desorbing gas mass flow monitor must be an integrating device having a measurement sensitivity of plus or minus 10 percent capable of recording the total regeneration desorbing gas mass flow for each regeneration cycle.

(2) The carbon bed temperature monitor must be capable of recording the temperature within 15 minutes of completing any carbon bed cooling cycle.

(3) For all regenerative carbon adsorbers, you must meet the requirements in paragraphs (c)(3)(i) through (v) of this section for each temperature monitoring device.

(e) Condensers. If you are using a condenser, you must monitor the condenser outlet (product side) gas temperature and comply with paragraphs (a) and (e)(1) and (2) of this section.

(1) The temperature monitor must provide a gas temperature record at least once every 15 minutes.

(2) For all condensers, you must meet the requirements in paragraphs (c)(3)(i) through (v) of this section for each temperature monitoring device.

(f) Concentrators. If you are using a concentrator, such as a zeolite wheel or rotary carbon bed concentrator, you must comply with the requirements in paragraphs (f)(1) and (2) of this section.

(1) You must install a temperature monitor in the desorption gas stream. The temperature monitor must meet the requirements in paragraphs (a) and (c)(3) of this section.

(2) You must install a device to monitor pressure drop across the zeolite wheel or rotary carbon bed. The pressure monitoring device must meet the requirements in paragraphs (a) and (g)(2) of this section.

(g) Emission capture systems. The capture system monitoring system must comply with the applicable requirements in paragraphs (g)(1) and (2) of this section.

(1) For each flow measurement device, you must meet the requirements in paragraphs (a) and (g)(1)(i) through (vii) of this section.

(i) Locate a flow sensor in a position that provides a representative flow measurement in the duct from each capture device in the emission capture system to the add-on control device.

(ii) Use a flow sensor with an accuracy of at least 10 percent of the flow.

(iii) Perform an initial sensor calibration in accordance with the manufacturer's requirements.

(iv) Perform a validation check before initial use or upon relocation or replacement of a sensor. Validation checks include comparison of sensor values with electronic signal simulations or via relative accuracy testing.

(v) Conduct an accuracy audit every quarter and after every deviation. Accuracy audit methods include comparisons of sensor values with electronic signal simulations or via relative accuracy testing.

(vi) Perform leak checks monthly.

(vii) Perform visual inspections of the sensor system quarterly if there is no redundant sensor.

(2) For each pressure drop measurement device, you must comply with the requirements in paragraphs (a) and (g)(2)(i) through (vii) of this section.

(i) Locate the pressure sensor(s) in or as close to a position that provides a representative measurement of the pressure drop across each opening you are monitoring.

(ii) Use a pressure sensor with an accuracy of at least 0.5 inches of water column or 5 percent of the measured value, whichever is larger.

(iii) Perform an initial calibration of the sensor according to the manufacturer's requirements.

(iv) Conduct a validation check before initial operation or upon relocation or replacement of a sensor. Validation checks include comparison of sensor values to calibrated pressure measurement devices or to pressure simulation using calibrated pressure sources.

(v) Conduct accuracy audits every quarter and after every deviation. Accuracy audits include comparison of sensor values to calibrated pressure measurement devices or to pressure simulation using calibrated pressure sources.

(vi) Perform monthly leak checks on pressure connections. A pressure of at least 1.0 inches of water column to the connection must yield a stable sensor result for at least 15 seconds.

(vii) Perform a visual inspection of the sensor at least monthly if there is no redundant sensor.

[85 FR 41156, July 8, 2020]