...

(a) Before September 28, 2021, if alternatives to the operational standards, test methods, procedures, compliance measures, monitoring, recordkeeping, or reporting provisions have already been approved under 40 CFR part 60, subpart WWW; subpart XXX; a federal plan; or an EPA-approved and effective state or tribal plan, these alternatives can be used to comply with this subpart, except that all affected sources must comply with the SSM requirements in subpart A of this part as specified in Table 1 of this subpart and all affected sources must submit compliance reports every 6 months as specified in §63.1981(h), including information on all deviations that occurred during the 6-month reporting period. Deviations for continuous emission monitors or numerical continuous parameter monitors must be determined using a 3-hour monitoring block average. Beginning no later than September 28, 2021, the collection and control system design plan may include for approval collection and control systems that include any alternatives to the operational standards, test methods, procedures, compliance measures, monitoring, recordkeeping, or reporting provisions, as provided in §63.1981(d)(2).

(b) If you own or operate a bioreactor that is located at an MSW landfill that is not permanently closed and has a design capacity equal to or greater than 2.5 million Mg and 2.5 million m3, then you must meet the requirements of this subpart, including requirements in paragraphs (b)(1) and (2) of this section.

(1) You must comply with this subpart starting on the date you are required to install the gas collection and control system.

(2) You must extend the collection and control system into each new cell or area of the bioreactor prior to initiating liquids addition in that area.

(c) At all times, beginning no later than September 27, 2021, the owner or operator must operate and maintain any affected source, including associated air pollution control equipment and monitoring equipment, in a manner consistent with safety and good air pollution control practices for minimizing emissions. The general duty to minimize emissions does not require the owner or operator to make any further efforts to reduce emissions if the requirements of this subpart have been achieved. Determination of whether a source is operating in compliance with operation and maintenance requirements will be based on information available to the Administrator which may include, but is not limited to, monitoring results, review of operation and maintenance procedures, review of operation and maintenance records, and inspection of the source.

[85 FR 17261, March 26, 2020]

(a) Operation. Operate the collection and control device in accordance with the provisions of §§63.1958, 63.1960, and 63.1961.

(b) Removal criteria. The collection and control system may be capped, removed, or decommissioned if the following criteria are met:

(1) The landfill is a closed landfill (as defined in §63.1990). A closure report must be submitted to the Administrator as provided in §63.1981(f);

(2) The gas collection and control system has been in operation a minimum of 15 years or the landfill owner or operator demonstrates that the gas collection and control system will be unable to operate for 15 years due to declining gas flow; and

(3) Following the procedures specified in §63.1959(c), the calculated NMOC emission rate at the landfill is less than 50 Mg/yr on three successive test dates. The test dates must be no less than 90 days apart, and no more than 180 days apart.

[85 FR 17261, March 26, 2020]

Each owner or operator of an MSW landfill with a gas collection and control system used to comply with the provisions of §63.1957 must:

(a) Operate the collection system such that gas is collected from each area, cell, or group of cells in the MSW landfill in which solid waste has been in place for:

(1) 5 years or more if active; or

(2) 2 years or more if closed or at final grade;

(b) Operate the collection system with negative pressure at each wellhead except under the following conditions:

(1) A fire or increased well temperature. The owner or operator must record instances when positive pressure occurs in efforts to avoid a fire. These records must be submitted with the semi-annual reports as provided in §63.1981(h);

(2) Use of a geomembrane or synthetic cover. The owner or operator must develop acceptable pressure limits in the design plan;

(3) A decommissioned well. A well may experience a static positive pressure after shut down to accommodate for declining flows. All design changes must be approved by the Administrator as specified in §63.1981(d)(2).

(c) Operate each interior wellhead in the collection system as specified in 40 CFR 60.753(c), until the landfill owner or operator elects to meet the operational standard for temperature in paragraph (c)(1) of this section.

(1) Beginning no later than September 27, 2021, operate each interior wellhead in the collection system with a landfill gas temperature less than 62.8 degrees Celsius (145 degrees Fahrenheit).

(2) The owner or operator may establish a higher operating temperature value at a particular well. A higher operating value demonstration must be submitted to the Administrator for approval and must include supporting data demonstrating that the elevated parameter neither causes fires nor significantly inhibits anaerobic decomposition by killing methanogens. The demonstration must satisfy both criteria in order to be approved (i.e., neither causing fires nor killing methanogens is acceptable).

(d)(1) Operate the collection system so that the methane concentration is less than 500 parts per million (ppm) above background at the surface of the landfill. To determine if this level is exceeded, the owner or operator must conduct surface testing around the perimeter of the collection area and along a pattern that traverses the landfill at no more than 30-meter intervals and where visual observations indicate elevated concentrations of landfill gas, such as distressed vegetation and cracks or seeps in the cover. The owner or operator may establish an alternative traversing pattern that ensures equivalent coverage. A surface monitoring design plan must be developed that includes a topographical map with the monitoring route and the rationale for any site-specific deviations from the 30-meter intervals. Areas with steep slopes or other dangerous areas may be excluded from the surface testing.

(2) Beginning no later than September 27, 2021, the owner or operator must:

(i) Conduct surface testing using an organic vapor analyzer, flame ionization detector, or other portable monitor meeting the specifications provided in §63.1960(d).

(ii) Conduct surface testing at all cover penetrations. Thus, the owner or operator must monitor any cover penetrations that are within an area of the landfill where waste has been placed and a gas collection system is required.

(iii) Determine the latitude and longitude coordinates of each exceedance using an instrument with an accuracy of at least 4 meters. The coordinates must be in decimal degrees with at least five decimal places.

(e) Operate the system as specified in §60.753(e) of this chapter, except:

(1) Beginning no later than September 27, 2021, operate the system in accordance to §63.1955(c) such that all collected gases are vented to a control system designed and operated in compliance with §63.1959(b)(2)(iii). In the event the collection or control system is not operating:

(i) The gas mover system must be shut down and all valves in the collection and control system contributing to venting of the gas to the atmosphere must be closed within 1 hour of the collection or control system not operating; and

(ii) Efforts to repair the collection or control system must be initiated and completed in a manner such that downtime is kept to a minimum, and the collection and control system must be returned to operation.

(2) [Reserved]

(f) Operate the control system at all times when the collected gas is routed to the system.

(g) If monitoring demonstrates that the operational requirements in paragraph (b), (c), or (d) of this section are not met, corrective action must be taken as specified in §63.1960(a)(3) and (5) or (c). If corrective actions are taken as specified in §63.1960, the monitored exceedance is not a deviation of the operational requirements in this section.

[85 FR 17261, March 26, 2020; 85 FR 64400, Oct. 13, 2020]

(a) Calculate the NMOC emission rate using the procedures specified in §60.754(a) of this chapter, except:

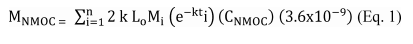

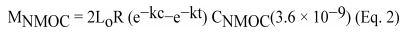

(1) NMOC emission rate. Beginning no later than September 27, 2021 the landfill owner or operator must calculate the NMOC emission rate using either Equation 1 provided in paragraph (a)(1)(i) of this section or Equation 2 provided in paragraph (a)(1)(ii) of this section. Both Equation 1 and Equation 2 may be used if the actual year-to-year solid waste acceptance rate is known, as specified in paragraph (a)(1)(i) of this section, for part of the life of the landfill and the actual year-to-year solid waste acceptance rate is unknown, as specified in paragraph (a)(1)(ii) of this section, for part of the life of the landfill. The values to be used in both Equation 1 and Equation 2 are 0.05 per year for k, 170 cubic meters per megagram (m3/Mg) for LO, and 4,000 parts per million by volume (ppmv) as hexane for the CNMOC. For landfills located in geographical areas with a 30-year annual average precipitation of less than 25 inches, as measured at the nearest representative official meteorologic site, the k value to be used is 0.02 per year.

(i)(A) Equation 1 must be used if the actual year-to-year solid waste acceptance rate is known.

Where:

MNMOC = Total NMOC emission rate from the landfill, Mg/yr.

k = Methane generation rate constant, year−1.

Lo = Methane generation potential, m3/Mg solid waste.

Mi = Mass of solid waste in the ith section, Mg.

ti = Age of the ith section, years.

CNMOC = Concentration of NMOC, ppmv as hexane.

3.6 × 10−9 = Conversion factor.

(B) The mass of nondegradable solid waste may be subtracted from the total mass of solid waste in a particular section of the landfill when calculating the value for Mi if documentation of the nature and amount of such wastes is maintained.

(ii)(A) Equation 2 must be used if the actual year-to-year solid waste acceptance rate is unknown.

Where:

MNMOC = Mass emission rate of NMOC, Mg/yr.

Lo = Methane generation potential, m3/Mg solid waste.

R = Average annual acceptance rate, Mg/yr.

k = Methane generation rate constant, year−1.

t = Age of landfill, years.

CNMOC = Concentration of NMOC, ppmv as hexane.

c = Time since closure, years; for active landfill c=0 and e−kc = 1.

3.6 × 10−9 = Conversion factor.

(B) The mass of nondegradable solid waste may be subtracted from the total mass of solid waste in a particular section of the landfill when calculating the value of R, if documentation of the nature and amount of such wastes is maintained.

(2) Tier 1. The owner or operator must compare the calculated NMOC mass emission rate to the standard of 50 Mg/yr.

(i) If the NMOC emission rate calculated in paragraph (a)(1) of this section is less than 50 Mg/yr, then the landfill owner or operator must submit an NMOC emission rate report according to §63.1981(c) and must recalculate the NMOC mass emission rate annually as required under paragraph (b) of this section.

(ii) If the calculated NMOC emission rate as calculated in paragraph (a)(1) of this section is equal to or greater than 50 Mg/yr, then the landfill owner must either:

(A) Submit a gas collection and control system design plan within 1 year as specified in §63.1981(d) and install and operate a gas collection and control system within 30 months of the first annual report in which the NMOC emission rate equals or exceeds 50 Mg/yr, according to paragraphs (b)(2)(ii) and (iii) of this section;

(B) Determine a site-specific NMOC concentration and recalculate the NMOC emission rate using the Tier 2 procedures provided in paragraph (a)(3) of this section; or

(C) Determine a site-specific methane generation rate constant and recalculate the NMOC emission rate using the Tier 3 procedures provided in paragraph (a)(4) of this section.

(3) Tier 2. The landfill owner or operator must determine the site-specific NMOC concentration using the following sampling procedure. The landfill owner or operator must install at least two sample probes per hectare, evenly distributed over the landfill surface that has retained waste for at least 2 years. If the landfill is larger than 25 hectares in area, only 50 samples are required. The probes should be evenly distributed across the sample area. The sample probes should be located to avoid known areas of nondegradable solid waste. The owner or operator must collect and analyze one sample of landfill gas from each probe to determine the NMOC concentration using EPA Method 25 or 25C of appendix A-7 to part 60. Taking composite samples from different probes into a single cylinder is allowed; however, equal sample volumes must be taken from each probe. For each composite, the sampling rate, collection times, beginning and ending cylinder vacuums, or alternative volume measurements must be recorded to verify that composite volumes are equal. Composite sample volumes should not be less than one liter unless evidence can be provided to substantiate the accuracy of smaller volumes. Terminate compositing before the cylinder approaches ambient pressure where measurement accuracy diminishes. If more than the required number of samples are taken, all samples must be used in the analysis. The landfill owner or operator must divide the NMOC concentration from EPA Method 25 or 25C of appendix A-7 to part 60 by 6 to convert from CNMOC as carbon to CNMOC as hexane. If the landfill has an active or passive gas removal system in place, EPA Method 25 or 25C samples may be collected from these systems instead of surface probes provided the removal system can be shown to provide sampling as representative as the two sampling probe per hectare requirement. For active collection systems, samples may be collected from the common header pipe. The sample location on the common header pipe must be before any gas moving, condensate removal, or treatment system equipment. For active collection systems, a minimum of three samples must be collected from the header pipe.

(i) Within 60 days after the date of completing each performance test (as defined in §63.7 of subpart A), the owner or operator must submit the results according to §63.1981(l)(1).

(ii) The landfill owner or operator must recalculate the NMOC mass emission rate using Equation 1 or Equation 2 provided in paragraph (a)(1)(i) or (ii) of this section and use the average site-specific NMOC concentration from the collected samples instead of the default value provided in paragraph (a)(1) of this section.

(iii) If the resulting NMOC mass emission rate is less than 50 Mg/yr, then the owner or operator must submit a periodic estimate of NMOC emissions in an NMOC emission rate report according to §63.1981(c) and must recalculate the NMOC mass emission rate annually as required under paragraph (b) of this section. The site-specific NMOC concentration must be retested every 5 years using the methods specified in this section.

(iv) If the NMOC mass emission rate as calculated using the Tier 2 site-specific NMOC concentration is equal to or greater than 50 Mg/yr, the landfill owner or operator must either:

(A) Submit a gas collection and control system design plan within 1 year as specified in §63.1981(d) and install and operate a gas collection and control system within 30 months according to paragraphs (b)(2)(ii) and (iii) of this section; or

(B) Determine a site-specific methane generation rate constant and recalculate the NMOC emission rate using the site-specific methane generation rate using the Tier 3 procedures specified in paragraph (a)(4) of this section.

(4) Tier 3. The site-specific methane generation rate constant must be determined using the procedures provided in EPA Method 2E of appendix A-1 to part 60 of this chapter. The landfill owner or operator must estimate the NMOC mass emission rate using Equation 1 or Equation 2 in paragraph (a)(1)(i) or (ii) of this section and using a site-specific methane generation rate constant, and the site-specific NMOC concentration as determined in paragraph (a)(3) of this section instead of the default values provided in paragraph (a)(1) of this section. The landfill owner or operator must compare the resulting NMOC mass emission rate to the standard of 50 Mg/yr.

(i) If the NMOC mass emission rate as calculated using the Tier 2 site-specific NMOC concentration and Tier 3 site-specific methane generation rate is equal to or greater than 50 Mg/yr, the owner or operator must:

(A) Submit a gas collection and control system design plan within 1 year as specified in §63.1981(d) and install and operate a gas collection and control system within 30 months of the first annual report in which the NMOC emission rate equals or exceeds 50 Mg/yr, according to paragraphs (b)(2)(ii) and (iii) of this section.

(B) [Reserved]

(ii) If the NMOC mass emission rate is less than 50 Mg/yr, then the owner or operator must recalculate the NMOC mass emission rate annually using Equation 1 or Equation 2 in paragraph (a)(1) of this section and using the site-specific Tier 2 NMOC concentration and Tier 3 methane generation rate constant and submit a periodic NMOC emission rate report as provided in §63.1981(c). The calculation of the methane generation rate constant is performed only once, and the value obtained from this test must be used in all subsequent annual NMOC emission rate calculations.

(5) Other methods. The owner or operator may use other methods to determine the NMOC concentration or a site-specific methane generation rate constant as an alternative to the methods required in paragraphs (a)(3) and (4) of this section if the method has been approved by the Administrator.

(b) Each owner or operator of an affected source having a design capacity equal to or greater than 2.5 million Mg and 2.5 million m3 must either comply with paragraph (b)(2) of this section or calculate an NMOC emission rate for the landfill using the procedures specified in paragraph (a) of this section. The NMOC emission rate must be recalculated annually, except as provided in §63.1981(c)(1)(ii)(A).

(1) If the calculated NMOC emission rate is less than 50 Mg/yr, the owner or operator must:

(i) Submit an annual NMOC emission rate emission report to the Administrator, except as provided for in §63.1981(c)(1)(ii); and

(ii) Recalculate the NMOC emission rate annually using the procedures specified in paragraph (a)(1) of this section until such time as the calculated NMOC emission rate is equal to or greater than 50 Mg/yr, or the landfill is closed.

(A) If the calculated NMOC emission rate, upon initial calculation or annual recalculation required in paragraph (b) of this section, is equal to or greater than 50 Mg/yr, the owner or operator must either: comply with paragraph (b)(2) of this section or calculate NMOC emissions using the next higher tier in paragraph (a) of this section.

(B) If the landfill is permanently closed, a closure report must be submitted to the Administrator as provided for in §63.1981(f).

(2) If the calculated NMOC emission rate is equal to or greater than 50 Mg/yr using Tier 1, 2, or 3 procedures, the owner or operator must either:

(i) Submit a collection and control system design plan prepared by a professional engineer to the Administrator within 1 year as specified in §63.1981(d) or calculate NMOC emissions using the next higher tier in paragraph (a) of this section. The collection and control system must meet the requirements in paragraphs (b)(2)(ii) and (iii) of this section.

(ii) Collection system. Install and start up a collection and control system that captures the gas generated within the landfill as required by paragraphs (b)(2)(ii)(B) or (C) and (b)(2)(iii) of this section within 30 months after:

(A) The first annual report in which the NMOC emission rate equals or exceeds 50 Mg/yr, unless Tier 2 or Tier 3 sampling demonstrates that the NMOC emission rate is less than 50 Mg.

(B) An active collection system must:

(1) Be designed to handle the maximum expected gas flow rate from the entire area of the landfill that warrants control over the intended use period of the gas control system equipment;

(2) Collect gas from each area, cell, or group of cells in the landfill in which the initial solid waste has been placed for a period of 5 years or more if active; or 2 years or more if closed or at final grade;

(3) Collect gas at a sufficient extraction rate; and

(4) Be designed to minimize off-site migration of subsurface gas.

(C) A passive collection system must:

(1) Comply with the provisions specified in paragraphs (b)(2)(ii)(B)(1), (2), and (3) of this section; and

(2) Be installed with liners on the bottom and all sides in all areas in which gas is to be collected. The liners must be installed as required under §258.40 of this chapter.

(iii) Control system. Route all the collected gas to a control system that complies with the requirements in either paragraph (b)(2)(iii)(A), (B), or (C) of this section.

(A) A non-enclosed flare designed and operated in accordance with the parameters established in §63.11(b) except as noted in paragraph (e) of this section; or

(B) A control system designed and operated to reduce NMOC by 98 weight-percent, or, when an enclosed combustion device is used for control, to either reduce NMOC by 98 weight-percent or reduce the outlet NMOC concentration to less than 20 ppmv, dry basis as hexane at 3-percent oxygen. The reduction efficiency or ppmv must be established by an initial performance test to be completed no later than 180 days after the initial startup of the approved control system using the test methods specified in paragraph (e) of this section. The performance test is not required for boilers and process heaters with design heat input capacities equal to or greater than 44 megawatts that burn landfill gas for compliance with this subpart.

(1) If a boiler or process heater is used as the control device, the landfill gas stream must be introduced into the flame zone.

(2) The control device must be operated within the parameter ranges established during the initial or most recent performance test. The operating parameters to be monitored are specified in §§63.1961(b) through (e);

(C) A treatment system that processes the collected gas for subsequent sale or beneficial use such as fuel for combustion, production of vehicle fuel, production of high-British thermal unit (Btu) gas for pipeline injection, or use as a raw material in a chemical manufacturing process. Venting of treated landfill gas to the ambient air is not allowed. If the treated landfill gas cannot be routed for subsequent sale or beneficial use, then the treated landfill gas must be controlled according to either paragraph (b)(2)(iii)(A) or (B) of this section.

(D) All emissions from any atmospheric vent from the gas treatment system are subject to the requirements of paragraph (b)(2)(iii)(A) or (B) of this section. For purposes of this subpart, atmospheric vents located on the condensate storage tank are not part of the treatment system and are exempt from the requirements of paragraph (b)(2)(iii)(A) or (B) of this section.

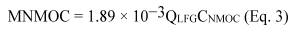

(c) After the installation and startup of a collection and control system in compliance with this subpart, the owner or operator must calculate the NMOC emission rate for purposes of determining when the system can be capped, removed, or decommissioned as provided in §63.1957(b)(3) using Equation 3:

Where:

MNMOC = Mass emission rate of NMOC, Mg/yr.

QLFG = Flow rate of landfill gas, m3 per minute.

CNMOC = Average NMOC concentration, ppmv as hexane.

1.89 × 10−3 = Conversion factor.

(1) The flow rate of landfill gas, QLFG, must be determined by measuring the total landfill gas flow rate at the common header pipe that leads to the control system using a gas flow measuring device calibrated according to the provisions of section 10 of EPA Method 2E of appendix A-1 of part 60.

(2) The average NMOC concentration, CNMOC, must be determined by collecting and analyzing landfill gas sampled from the common header pipe before the gas moving or condensate removal equipment using the procedures in EPA Method 25 or 25C of appendix A-7 to part 60 of this chapter. The sample location on the common header pipe must be before any condensate removal or other gas refining units. The landfill owner or operator must divide the NMOC concentration from EPA Method 25 or 25C of appendix A-7 to part 60 by 6 to convert from CNMOC as carbon to CNMOC as hexane.

(3) The owner or operator may use another method to determine landfill gas flow rate and NMOC concentration if the method has been approved by the Administrator.

(i) Within 60 days after the date of completing each performance test (as defined in §63.7), the owner or operator must submit the results of the performance test, including any associated fuel analyses, according to §63.1981(l)(1).

(ii) [Reserved]

(d) For the performance test required in §63.1959(b)(2)(iii)(B), EPA Method 25 or 25C (EPA Method 25C of appendix A-7 to part 60 of this chapter may be used at the inlet only) of appendix A of this part must be used to determine compliance with the 98 weight-percent efficiency or the 20- ppmv outlet concentration level, unless another method to demonstrate compliance has been approved by the Administrator as provided by §63.1981(d)(2). EPA Method 3, 3A, or 3C of appendix A-7 to part 60 must be used to determine oxygen for correcting the NMOC concentration as hexane to 3 percent. In cases where the outlet concentration is less than 50 ppm NMOC as carbon (8 ppm NMOC as hexane), EPA Method 25A should be used in place of EPA Method 25. EPA Method 18 may be used in conjunction with EPA Method 25A on a limited basis (compound specific, e.g., methane) or EPA Method 3C may be used to determine methane. The methane as carbon should be subtracted from the EPA Method 25A total hydrocarbon value as carbon to give NMOC concentration as carbon. The landowner or operator must divide the NMOC concentration as carbon by 6 to convert from the CNMOC as carbon to CNMOC as hexane. Equation 4 must be used to calculate efficiency:

Where:

NMOCin = Mass of NMOC entering control device.

NMOCout = Mass of NMOC exiting control device.

(e) For the performance test required in §63.1959(b)(2)(iii)(A), the net heating value of the combusted landfill gas as determined in §63.11(b)(6)(ii) is calculated from the concentration of methane in the landfill gas as measured by EPA Method 3C of appendix A to part 60 of this chapter. A minimum of three 30-minute EPA Method 3C samples are determined. The measurement of other organic components, hydrogen, and carbon monoxide is not applicable. EPA Method 3C may be used to determine the landfill gas molecular weight for calculating the flare gas exit velocity under §63.11(b)(7) of subpart A.

(1) Within 60 days after the date of completing each performance test (as defined in §63.7), the owner or operator must submit the results of the performance tests, including any associated fuel analyses, required by §63.1959(c) or (e) according to §63.1981(l)(1).

(2) [Reserved]

(f) The performance tests required in §§63.1959(b)(2)(iii)(A) and (B), must be conducted under such conditions as the Administrator specifies to the owner or operator based on representative performance of the affected source for the period being tested. Representative conditions exclude periods of startup and shutdown unless specified by the Administrator. The owner or operator may not conduct performance tests during periods of malfunction. The owner or operator must record the process information that is necessary to document operating conditions during the test and include in such record an explanation to support that such conditions represent normal operation. Upon request, the owner or operator shall make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

[85 FR 17261, March 26, 2020; 85 FR 64400, Oct. 13, 2020]

(a) Except as provided in §63.1981(d)(2), the specified methods in paragraphs (a)(1) through (5) of this section must be used to determine whether the gas collection system is in compliance with §63.1959(b)(2)(ii).

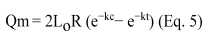

(1) For the purposes of calculating the maximum expected gas generation flow rate from the landfill to determine compliance with §63.1959(b)(2)(ii)(C)(1), either Equation 5 or Equation 6 must be used. The owner or operator may use another method to determine the maximum gas generation flow rate, if the method has been approved by the Administrator. The methane generation rate constant (k) and methane generation potential (Lo) kinetic factors should be those published in the most recent Compilation of Air Pollutant Emission Factors (AP-42) or other site-specific values demonstrated to be appropriate and approved by the Administrator. If k has been determined as specified in §63.1959(a)(4), the value of k determined from the test must be used. A value of no more than 15 years must be used for the intended use period of the gas mover equipment. The active life of the landfill is the age of the landfill plus the estimated number of years until closure.

(i) For sites with unknown year-to-year solid waste acceptance rate:

Where:

Qm = Maximum expected gas generation flow rate, m3/yr.

Lo = Methane generation potential, m3/Mg solid waste.

R = Average annual acceptance rate, Mg/yr.

k = Methane generation rate constant, year−1.

t = Age of the landfill at equipment installation plus the time the owner or operator intends to use the gas mover equipment or active life of the landfill, whichever is less. If the equipment is installed after closure, t is the age of the landfill at installation, years.

c = Time since closure, years (for an active landfill c = 0 and e−kc = 1).

2 = Constant.

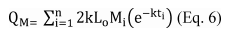

(ii) For sites with known year-to-year solid waste acceptance rate:

Where:

Qm = Maximum expected gas generation flow rate, m3/yr.

k = Methane generation rate constant, year−1.

Lo = Methane generation potential, m3/Mg solid waste.

Mi = Mass of solid waste in the ith section, Mg.

ti = Age of the ith section, years.

(iii) If a collection and control system has been installed, actual flow data may be used to project the maximum expected gas generation flow rate instead of, or in conjunction with, Equation 5 or Equation 6 in paragraphs (a)(1)(i) and (ii) of this section. If the landfill is still accepting waste, the actual measured flow data will not equal the maximum expected gas generation rate, so calculations using Equation 5 or Equation 6 in paragraph (a)(1)(i) or (ii) of this section or other methods must be used to predict the maximum expected gas generation rate over the intended period of use of the gas control system equipment.

(2) For the purposes of determining sufficient density of gas collectors for compliance with §63.1959(b)(2)(ii)(B)(2), the owner or operator must design a system of vertical wells, horizontal collectors, or other collection devices, satisfactory to the Administrator, capable of controlling and extracting gas from all portions of the landfill sufficient to meet all operational and performance standards.

(3) For the purpose of demonstrating whether the gas collection system flow rate is sufficient to determine compliance with §63.1959(b)(2)(ii)(B)(3), the owner or operator must measure gauge pressure in the gas collection header applied to each individual well monthly. Any attempted corrective measure must not cause exceedances of other operational or performance standards. An alternative timeline for correcting the exceedance may be submitted to the Administrator for approval. If a positive pressure exists, follow the procedures as specified in §60.755(a)(3), except:

(i) Beginning no later than September 27, 2021, if a positive pressure exists, action must be initiated to correct the exceedance within 5 days, except for the three conditions allowed under §63.1958(b).

(A) If negative pressure cannot be achieved without excess air infiltration within 15 days of the first measurement of positive pressure, the owner or operator must conduct a root cause analysis and correct the exceedance as soon as practicable, but no later than 60 days after positive pressure was first measured. The owner or operator must keep records according to §63.1983(e)(3).

(B) If corrective actions cannot be fully implemented within 60 days following the positive pressure measurement for which the root cause analysis was required, the owner or operator must also conduct a corrective action analysis and develop an implementation schedule to complete the corrective action(s) as soon as practicable, but no more than 120 days following the positive pressure measurement. The owner or operator must submit the items listed in §63.1981(h)(7) as part of the next semi-annual report. The owner or operator must keep records according to §63.1983(e)(4).

(C) If corrective action is expected to take longer than 120 days to complete after the initial exceedance, the owner or operator must submit the root cause analysis, corrective action analysis, and corresponding implementation timeline to the Administrator, according to §63.1981(j). The owner or operator must keep records according to §63.1983(e)(5).

(ii) [Reserved]

(4) Where an owner or operator subject to the provisions of this subpart seeks to demonstrate compliance with the temperature and nitrogen or oxygen operational standards in introductory paragraph §63.1958(c), for the purpose of identifying whether excess air infiltration into the landfill is occurring, the owner or operator must follow the procedures as specified in §60.755(a)(5) of this chapter, except:

(i) Once an owner or operator subject to the provisions of this subpart seeks to demonstrate compliance with the operational standard for temperature in §63.1958(c)(1), the owner or operator must monitor each well monthly for temperature for the purpose of identifying whether excess air infiltration exists. If a well exceeds the operating parameter for temperature as provided in §63.1958(c)(1), action must be initiated to correct the exceedance within 5 days. Any attempted corrective measure must not cause exceedances of other operational or performance standards.

(A) If a landfill gas temperature less than or equal to 62.8 degrees Celsius (145 degrees Fahrenheit) cannot be achieved within 15 days of the first measurement of landfill gas temperature greater than 62.8 degrees Celsius (145 degrees Fahrenheit), the owner or operator must conduct a root cause analysis and correct the exceedance as soon as practicable, but no later than 60 days after a landfill gas temperature greater than 62.8 degrees Celsius (145 degrees Fahrenheit) was first measured. The owner or operator must keep records according to §63.1983(e)(3).

(B) If corrective actions cannot be fully implemented within 60 days following the temperature measurement for which the root cause analysis was required, the owner or operator must also conduct a corrective action analysis and develop an implementation schedule to complete the corrective action(s) as soon as practicable, but no more than 120 days following the measurement of landfill gas temperature greater than 62.8 degrees Celsius (145 degrees Fahrenheit). The owner or operator must submit the items listed in §63.1981(h)(7) as part of the next semi-annual report. The owner or operator must keep records according to §63.1983(e)(4).

(C) If corrective action is expected to take longer than 120 days to complete after the initial exceedance, the owner or operator must submit the root cause analysis, corrective action analysis, and corresponding implementation timeline to the Administrator, according to §63.1981(h)(7) and (j). The owner or operator must keep records according to §63.1983(e)(5).

(D) If a landfill gas temperature measured at either the wellhead or at any point in the well is greater than or equal to 76.7 degrees Celsius (170 degrees Fahrenheit) and the carbon monoxide concentration measured, according to the procedures in §63.1961(a)(5)(vi) is greater than or equal to 1,000 ppmv the corrective action(s) for the wellhead temperature standard (62.8 degrees Celsius or 145 degrees Fahrenheit) must be completed within 15 days.

(5) An owner or operator seeking to demonstrate compliance with §63.1959(b)(2)(ii)(B)(4) through the use of a collection system not conforming to the specifications provided in §63.1962 must provide information satisfactory to the Administrator as specified in §63.1981(d)(3) demonstrating that off-site migration is being controlled.

(b) For purposes of compliance with §63.1958(a), each owner or operator of a controlled landfill must place each well or design component as specified in the approved design plan as provided in §63.1981(d). Each well must be installed no later than 60 days after the date on which the initial solid waste has been in place for a period of:

(1) 5 years or more if active; or

(2) 2 years or more if closed or at final grade.

(c) The following procedures must be used for compliance with the surface methane operational standard as provided in §63.1958(d).

(1) After installation and startup of the gas collection system, the owner or operator must monitor surface concentrations of methane along the entire perimeter of the collection area and along a pattern that traverses the landfill at 30 meter intervals (or a site-specific established spacing) for each collection area on a quarterly basis using an organic vapor analyzer, flame ionization detector, or other portable monitor meeting the specifications provided in paragraph (d) of this section.

(2) The background concentration must be determined by moving the probe inlet upwind and downwind outside the boundary of the landfill at a distance of at least 30 meters from the perimeter wells.

(3) Surface emission monitoring must be performed in accordance with section 8.3.1 of EPA Method 21 of appendix A-7 of part 60 of this chapter, except that the probe inlet must be placed within 5 to 10 centimeters of the ground. Monitoring must be performed during typical meteorological conditions.

(4) Any reading of 500 ppm or more above background at any location must be recorded as a monitored exceedance and the actions specified in paragraphs (c)(4)(i) through (v) of this section must be taken. As long as the specified actions are taken, the exceedance is not a violation of the operational requirements of §63.1958(d).

(i) The location of each monitored exceedance must be marked and the location and concentration recorded. Beginning no later than September 27, 2021, the location must be recorded using an instrument with an accuracy of at least 4 meters. The coordinates must be in decimal degrees with at least five decimal places.

(ii) Cover maintenance or adjustments to the vacuum of the adjacent wells to increase the gas collection in the vicinity of each exceedance must be made and the location must be re-monitored within 10 days of detecting the exceedance.

(iii) If the re-monitoring of the location shows a second exceedance, additional corrective action must be taken and the location must be monitored again within 10 days of the second exceedance. If the re-monitoring shows a third exceedance for the same location, the action specified in paragraph (c)(4)(v) of this section must be taken, and no further monitoring of that location is required until the action specified in paragraph (c)(4)(v) of this section has been taken.

(iv) Any location that initially showed an exceedance but has a methane concentration less than 500 ppm methane above background at the 10-day re-monitoring specified in paragraph (c)(4)(ii) or (iii) of this section must be re-monitored 1 month from the initial exceedance. If the 1-month re-monitoring shows a concentration less than 500 ppm above background, no further monitoring of that location is required until the next quarterly monitoring period. If the 1-month re-monitoring shows an exceedance, the actions specified in paragraph (c)(4)(iii) or (v) of this section must be taken.

(v) For any location where monitored methane concentration equals or exceeds 500 ppm above background three times within a quarterly period, a new well or other collection device must be installed within 120 days of the initial exceedance. An alternative remedy to the exceedance, such as upgrading the blower, header pipes or control device, and a corresponding timeline for installation may be submitted to the Administrator for approval.

(5) The owner or operator must implement a program to monitor for cover integrity and implement cover repairs as necessary on a monthly basis.

(d) Each owner or operator seeking to comply with the provisions in paragraph (c) of this section must comply with the following instrumentation specifications and procedures for surface emission monitoring devices:

(1) The portable analyzer must meet the instrument specifications provided in section 6 of EPA Method 21 of appendix A of part 60 of this chapter, except that “methane” replaces all references to “VOC”.

(2) The calibration gas must be methane, diluted to a nominal concentration of 500 ppm in air.

(3) To meet the performance evaluation requirements in section 8.1 of EPA Method 21 of appendix A of part 60 of this chapter, the instrument evaluation procedures of section 8.1 of EPA Method 21 of appendix A of part 60 must be used.

(4) The calibration procedures provided in sections 8 and 10 of EPA Method 21 of appendix A of part 60 of this chapter must be followed immediately before commencing a surface monitoring survey.

(e)(1) Where an owner or operator subject to the provisions of this subpart seeks to demonstrate compliance with the operational standards in introductory paragraph §63.1958(e), the provisions of this subpart apply at all times, except during periods of SSM, provided that the duration of SSM does not exceed 5 days for collection systems and does not exceed 1 hour for treatment or control devices. You must comply with the provisions in Table 1 to subpart AAAA that apply before September 28, 2021.

(2) Once an owner or operator subject to the provisions of this subpart seeks to demonstrate compliance with the operational standard in §63.1958(e)(1), the provisions of this subpart apply at all times, including periods of SSM. During periods of SSM, you must comply with the work practice requirement specified in §63.1958(e) in lieu of the compliance provisions in §63.1960.

[85 FR 17261, March 26, 2020; 85 FR 64400, Oct. 13, 2020; 87 FR 8203, Feb. 14, 2022]

Except as provided in §63.1981(d)(2):

(a) Each owner or operator seeking to comply with §63.1959(b)(2)(ii)(B) for an active gas collection system must install a sampling port and a thermometer, other temperature measuring device, or an access port for temperature measurements at each wellhead and:

(1) Measure the gauge pressure in the gas collection header on a monthly basis as provided in §63.1960(a)(3); and

(2) Monitor nitrogen or oxygen concentration in the landfill gas on a monthly basis as follows:

(i) The nitrogen level must be determined using EPA Method 3C of appendix A-2 to part 60 of this chapter, unless an alternative test method is established as allowed by §63.1981(d)(2).

(ii) Unless an alternative test method is established as allowed by §63.1981(d)(2), the oxygen level must be determined by an oxygen meter using EPA Method 3A or 3C of appendix A-2 to part 60 of this chapter or ASTM D6522-11 (incorporated by reference, see §63.14). Determine the oxygen level by an oxygen meter using EPA Method 3A or 3C of appendix A-2 to part 60 or ASTM D6522-11 (if sample location is prior to combustion) except that:

(A) The span must be set between 10- and 12-percent oxygen;

(B) A data recorder is not required;

(C) Only two calibration gases are required, a zero and span;

(D) A calibration error check is not required; and

(E) The allowable sample bias, zero drift, and calibration drift are ±10 percent.

(iii) A portable gas composition analyzer may be used to monitor the oxygen levels provided:

(A) The analyzer is calibrated; and

(B) The analyzer meets all quality assurance and quality control requirements for EPA Method 3A of appendix A-2 to part 60 of this chapter or ASTM D6522-11 (incorporated by reference, see §63.14).

(3) Where an owner or operator subject to the provisions of this subpart seeks to demonstrate compliance with the temperature and nitrogen or oxygen operational standards in introductory paragraph §63.1958(c), the owner or operator must follow the procedures as specified in §60.756(a)(2) and (3) of this chapter. Monitor temperature of the landfill gas on a monthly basis as provided in §63.1960(a)(4). The temperature measuring device must be calibrated annually using the procedure in Section 10.3 of EPA Method 2 of appendix A-1 to part 60 of this chapter.

(4) Where an owner or operator subject to the provisions of this subpart seeks to demonstrate compliance with the operational standard for temperature in §63.1958(c)(1), monitor temperature of the landfill gas on a monthly basis as provided in §63.1960(a)(4). The temperature measuring device must be calibrated annually using the procedure in Section 10.3 of EPA Method 2 of appendix A-1 to part 60 of this chapter. Keep records specified in §63.1983(e).

(5) Where an owner or operator subject to the provisions of this subpart seeks to demonstrate compliance with the operational standard for temperature in §63.1958(c)(1) unless a higher operating temperature value has been approved by the Administrator under this subpart or under 40 CFR part 60, subpart WWW; 40 CFR part 60, subpart XXX; or a federal plan or EPA-approved and effective state plan or tribal plan that implements either 40 CFR part 60, subpart Cc or 40 CFR part 60, subpart Cf, you must initiate enhanced monitoring at each well with a measurement of landfill gas temperature greater than 62.8 degrees Celsius (145 degrees Fahrenheit) as follows:

(i) Visual observations for subsurface oxidation events (smoke, smoldering ash, damage to well) within the radius of influence of the well.

(ii) Monitor oxygen concentration as provided in paragraph (a)(2) of this section;

(iii) Monitor temperature of the landfill gas at the wellhead as provided in paragraph (a)(4) of this section.

(iv) Monitor temperature of the landfill gas every 10 vertical feet of the well as provided in paragraph (a)(6) of this section.

(v) Monitor the methane concentration with a methane meter using EPA Method 3C of appendix A-6 to part 60, EPA Method 18 of appendix A-6 to part 60 of this chapter, or a portable gas composition analyzer to monitor the methane levels provided that the analyzer is calibrated and the analyzer meets all quality assurance and quality control requirements for EPA Method 3C or EPA Method 18.

(vi) Monitor and determine carbon monoxide concentrations, as follows:

(A) Collect the sample from the wellhead sampling port in a passivated canister or multi-layer foil gas sampling bag (such as the Cali-5-Bond Bag) and analyze that sample using EPA Method 10 of appendix A-4 to part 60 of this chapter, or an equivalent method with a detection limit of at least 100 ppmv of carbon monoxide in high concentrations of methane; or

(B) Collect and analyze the sample from the wellhead using EPA Method 10 of appendix A-4 to part 60 to measure carbon monoxide concentrations.

(C) When sampling directly from the wellhead, you must sample for 5 minutes plus twice the response time of the analyzer. These values must be recorded. The five 1-minute averages are then averaged to give you the carbon monoxide reading at the wellhead.

(D) When collecting samples in a passivated canister or multi-layer foil sampling bag, you must sample for the period of time needed to assure that enough sample is collected to provide five (5) consecutive, 1-minute samples during the analysis of the canister or bag contents, but no less than 5 minutes plus twice the response time of the analyzer. The five (5) consecutive, 1-minute averages are then averaged together to give you a carbon monoxide value from the wellhead.

(vii) The enhanced monitoring described in this paragraph (a)(5) must begin 7 calendar days after the first measurement of landfill gas temperature greater than 62.8 degrees Celsius (145 degrees Fahrenheit); and

(viii) The enhanced monitoring in this paragraph (a)(5) must be conducted on a weekly basis. If four consecutive weekly carbon monoxide readings are under 100 ppmv, then enhanced monitoring may be decreased to monthly. However, if carbon monoxide readings exceed 100 ppmv again, the landfill must return to weekly monitoring.

(ix) The enhanced monitoring in this paragraph (a)(5) can be stopped once a higher operating value is approved, at which time the monitoring provisions issued with the higher operating value should be followed, or once the measurement of landfill gas temperature at the wellhead is less than or equal to 62.8 degrees Celsius (145 degrees Fahrenheit).

(6) For each wellhead with a measurement of landfill gas temperature greater than or equal to 73.9 degrees Celsius (165 degrees Fahrenheit), annually monitor temperature of the landfill gas every 10 vertical feet of the well. This temperature can be monitored either with a removable thermometer, or using temporary or permanent thermocouples installed in the well.

(b) Each owner or operator seeking to comply with §63.1959(b)(2)(iii) using an enclosed combustor must calibrate, maintain, and operate according to the manufacturer's specifications, the following equipment:

(1) A temperature monitoring device equipped with a continuous recorder and having a minimum accuracy of ±1 percent of the temperature being measured expressed in degrees Celsius or ±0.5 degrees Celsius, whichever is greater. A temperature monitoring device is not required for boilers or process heaters with design heat input capacity equal to or greater than 44 megawatts.

(2) A device that records flow to the control device and bypass of the control device (if applicable). The owner or operator must:

(i) Install, calibrate, and maintain a gas flow rate measuring device that must record the flow to the control device at least every 15 minutes; and

(ii) Secure the bypass line valve in the closed position with a car-seal or a lock-and-key type configuration. A visual inspection of the seal or closure mechanism must be performed at least once every month to ensure that the valve is maintained in the closed position and that the gas flow is not diverted through the bypass line.

(c) Each owner or operator seeking to comply with §63.1959(b)(2)(iii) using a non-enclosed flare must install, calibrate, maintain, and operate according to the manufacturer's specifications the following equipment:

(1) A heat sensing device, such as an ultraviolet beam sensor or thermocouple, at the pilot light or the flame itself to indicate the continuous presence of a flame; and

(2) A device that records flow to the flare and bypass of the flare (if applicable). The owner or operator must:

(i) Install, calibrate, and maintain a gas flow rate measuring device that records the flow to the control device at least every 15 minutes; and

(ii) Secure the bypass line valve in the closed position with a car-seal or a lock-and-key type configuration. A visual inspection of the seal or closure mechanism must be performed at least once every month to ensure that the valve is maintained in the closed position and that the gas flow is not diverted through the bypass line.

(d) Each owner or operator seeking to demonstrate compliance with §63.1959(b)(2)(iii) using a device other than a non-enclosed flare or an enclosed combustor or a treatment system must provide information satisfactory to the Administrator as provided in §63.1981(d)(2) describing the operation of the control device, the operating parameters that would indicate proper performance, and appropriate monitoring procedures. The Administrator must review the information and either approve it, or request that additional information be submitted. The Administrator may specify additional appropriate monitoring procedures.

(e) Each owner or operator seeking to install a collection system that does not meet the specifications in §63.1962 or seeking to monitor alternative parameters to those required by §§63.1958 through 63.1961 must provide information satisfactory to the Administrator as provided in §63.1981(d)(2) and (3) describing the design and operation of the collection system, the operating parameters that would indicate proper performance, and appropriate monitoring procedures. The Administrator may specify additional appropriate monitoring procedures.

(f) Each owner or operator seeking to demonstrate compliance with the 500-ppm surface methane operational standard in §63.1958(d) must monitor surface concentrations of methane according to the procedures in §63.1960(c) and the instrument specifications in §63.1960(d). If you are complying with the 500-ppm surface methane operational standard in §63.1958(d)(2), for location, you must determine the latitude and longitude coordinates of each exceedance using an instrument with an accuracy of at least 4 meters and the coordinates must be in decimal degrees with at least five decimal places. In the semi-annual report in §63.1981(h), you must report the location of each exceedance of the 500-ppm methane concentration as provided in §63.1958(d) and the concentration recorded at each location for which an exceedance was recorded in the previous month. Any closed landfill that has no monitored exceedances of the operational standard in three consecutive quarterly monitoring periods may skip to annual monitoring. Any methane reading of 500 ppm or more above background detected during the annual monitoring returns the frequency for that landfill to quarterly monitoring.

(g) Each owner or operator seeking to demonstrate compliance with §63.1959(b)(2)(iii)(C) using a landfill gas treatment system must calibrate, maintain, and operate according to the manufacturer's specifications a device that records flow to the treatment system and bypass of the treatment system (if applicable). Beginning no later than September 27, 2021, each owner or operator must maintain and operate all monitoring systems associated with the treatment system in accordance with the site-specific treatment system monitoring plan required in §63.1983(b)(5)(ii). The owner or operator must:

(1) Install, calibrate, and maintain a gas flow rate measuring device that records the flow to the treatment system at least every 15 minutes; and

(2) Secure the bypass line valve in the closed position with a car-seal or a lock-and-key type configuration. A visual inspection of the seal or closure mechanism must be performed at least once every month to ensure that the valve is maintained in the closed position and that the gas flow is not diverted through the bypass line.

(h) The monitoring requirements of paragraphs (a), (b), (c), (d), and (g) of this section apply at all times the affected source is operating, except for periods of monitoring system malfunctions, repairs associated with monitoring system malfunctions, and required monitoring system quality assurance or quality control activities. A monitoring system malfunction is any sudden, infrequent, not reasonably preventable failure of the monitoring system to provide valid data. Monitoring system failures that are caused in part by poor maintenance or careless operation are not malfunctions. You are required to complete monitoring system repairs in response to monitoring system malfunctions and to return the monitoring system to operation as expeditiously as practicable. Where an owner or operator subject to the provisions of this subpart seeks to demonstrate compliance with the temperature and nitrogen or oxygen operational standards in introductory paragraph §63.1958(c)(1), (d)(2), and (e)(1), the standards apply at all times.

[85 FR 17261, March 26, 2020; 85 FR 64401, Oct. 13, 2020; 87 FR 8203, Feb. 14, 2022]

(a) Each owner or operator seeking to comply with §63.1959(b)(2)(i) must site active collection wells, horizontal collectors, surface collectors, or other extraction devices at a sufficient density throughout all gas producing areas using the following procedures unless alternative procedures have been approved by the Administrator as provided in §63.1981(d)(2) and (3):

(1) The collection devices within the interior must be certified to achieve comprehensive control of surface gas emissions by a professional engineer. The following issues must be addressed in the design: Depths of refuse, refuse gas generation rates and flow characteristics, cover properties, gas system expandability, leachate and condensate management, accessibility, compatibility with filling operations, integration with closure end use, air intrusion control, corrosion resistance, fill settlement, resistance to the refuse decomposition heat, and ability to isolate individual components or sections for repair or troubleshooting without shutting down entire collection system.

(2) The sufficient density of gas collection devices determined in paragraph (a)(1) of this section must address landfill gas migration issues and augmentation of the collection system through the use of active or passive systems at the landfill perimeter or exterior.

(3) The placement of gas collection devices determined in paragraph (a)(1) of this section must control all gas producing areas, except as provided by paragraphs (a)(3)(i) and (ii) of this section.

(i) Any segregated area of asbestos or nondegradable material may be excluded from collection if documented as provided under §63.1983(d). The documentation must provide the nature, date of deposition, location and amount of asbestos or nondegradable material deposited in the area and must be provided to the Administrator upon request.

(ii) Any nonproductive area of the landfill may be excluded from control, provided that the total of all excluded areas can be shown to contribute less than 1 percent of the total amount of NMOC emissions from the landfill. The amount, location, and age of the material must be documented and provided to the Administrator upon request. A separate NMOC emissions estimate must be made for each section proposed for exclusion, and the sum of all such sections must be compared to the NMOC emissions estimate for the entire landfill.

(A) The NMOC emissions from each section proposed for exclusion must be computed using Equation 7:

Where:

Qi = NMOC emission rate from the ith section, Mg/yr.

k = Methane generation rate constant, year −1.

Lo = Methane generation potential, m3/Mg solid waste.

Mi = Mass of the degradable solid waste in the ith section, Mg.

ti = Age of the solid waste in the ith section, years.

CNMOC = Concentration of NMOC, ppmv.

3.6 × 10−9 = Conversion factor.

(B) If the owner/operator is proposing to exclude, or cease gas collection and control from, nonproductive physically separated (e.g., separately lined) closed areas that already have gas collection systems, NMOC emissions from each physically separated closed area must be computed using either Equation 3 in §63.1959(c) or Equation 7 in paragraph (a)(3)(ii)(A) of this section.

(iii) The values for k and CNMOC determined in field testing must be used if field testing has been performed in determining the NMOC emission rate or the radii of influence (the distance from the well center to a point in the landfill where the pressure gradient applied by the blower or compressor approaches zero). If field testing has not been performed, the default values for k, Lo and CNMOC provided in §63.1959(a)(1), or the alternative values from §63.1959(a)(5) must be used. The mass of nondegradable solid waste contained within the given section may be subtracted from the total mass of the section when estimating emissions provided the nature, location, age, and amount of the nondegradable material is documented as provided in paragraph (a)(3)(i) of this section.

(b) Each owner or operator seeking to comply with §63.1959(b)(2)(ii) must construct the gas collection devices using the following equipment or procedures:

(1) The landfill gas extraction components must be constructed of polyvinyl chloride (PVC), high density polyethylene (HDPE) pipe, fiberglass, stainless steel, or other nonporous corrosion resistant material of suitable dimensions to: Convey projected amounts of gases; withstand installation, static, and settlement forces; and withstand planned overburden or traffic loads. The collection system must extend as necessary to comply with emission and migration standards. Collection devices such as wells and horizontal collectors must be perforated to allow gas entry without head loss sufficient to impair performance across the intended extent of control. Perforations must be situated with regard to the need to prevent excessive air infiltration.

(2) Vertical wells must be placed so as not to endanger underlying liners and must address the occurrence of water within the landfill. Holes and trenches constructed for piped wells and horizontal collectors must be of sufficient cross-section so as to allow for their proper construction and completion including, for example, centering of pipes and placement of gravel backfill. Collection devices must be designed so as not to allow indirect short circuiting of air into the cover or refuse into the collection system or gas into the air. Any gravel used around pipe perforations should be of a dimension so as not to penetrate or block perforations.

(3) Collection devices may be connected to the collection header pipes below or above the landfill surface. The connector assembly must include a positive closing throttle valve, any necessary seals and couplings, access couplings and at least one sampling port. The collection devices must be constructed of PVC, HDPE, fiberglass, stainless steel, or other nonporous material of suitable thickness.

(c) Each owner or operator seeking to comply with §63.1959(b)(2)(iii) must convey the landfill gas to a control system in compliance with §63.1959(b)(2)(iii) through the collection header pipe(s). The gas mover equipment must be sized to handle the maximum gas generation flow rate expected over the intended use period of the gas moving equipment using the following procedures:

(1) For existing collection systems, the flow data must be used to project the maximum flow rate. If no flow data exists, the procedures in paragraph (c)(2) of this section must be used.

(2) For new collection systems, the maximum flow rate must be in accordance with §63.1960(a)(1).

[85 FR 17261, March 26, 2020]