['Air Programs']

['Mobile Emission Sources', 'Air Emissions']

12/22/2025

...

§86.101 General applicability.

(a) General provisions. This subpart describes test procedures for measuring exhaust, evaporative, and refueling emissions from motor vehicles subject to emission standards under subpart S of this part. This generally includes light-duty vehicles, light-duty trucks, and complete heavy-duty vehicles at or below 14,000 pounds GVWR. The following provisions apply for all testing under this subpart:

(1) Provisions of this subpart apply to tests performed by both the Administrator and manufacturers.

(2) References in this subpart to engine families and emission control systems apply to durability groups and test groups as applicable.

(3) Except as noted, heavy-duty vehicles are subject to all the same provisions of this subpart that apply to light-duty trucks.

(4) The procedures in this subpart apply for testing vehicles powered by any fuel, except as specified in subpart S of this part.

(5) For exhaust emission testing, measure emissions for all pollutants with an applicable emission standard.

(6) All emission control systems designed for production vehicles must be functioning during testing. Maintenance to correct component malfunction or failure must be authorized in accordance with §86.1834.

(7) The test sequence for the Federal Test Procedure (FTP) includes steps to precondition vehicles for evaporative emission measurements; these steps are required for exhaust testing whether or not testing includes evaporative emission measurements.

(8) Evaporative emission measurement procedures of this subpart include specifications for testing methanol-fueled vehicles. For vehicles fueled with other oxygenated fuels, use good engineering judgment to apply these procedures. For example, if you are testing an ethanol-fueled vehicle, perform diagnostics in your evaporative emission enclosure with ethanol and propane.

(9) For exhaust emission testing with ethanol-gasoline blends that have less than 25% ethanol by volume, if you use NMHC-to-NMOG conversion factors instead of measuring oxygenates as described in 40 CFR 1066.635, the testing specifications and diagnostic requirements in this part 86 that are specific to ethanol-gasoline blends do not apply.

(b) Migration to 40 CFR parts 1065 and 1066. This subpart transitions to rely on the test procedure specifications in 40 CFR parts 1065 and 1066 as follows:

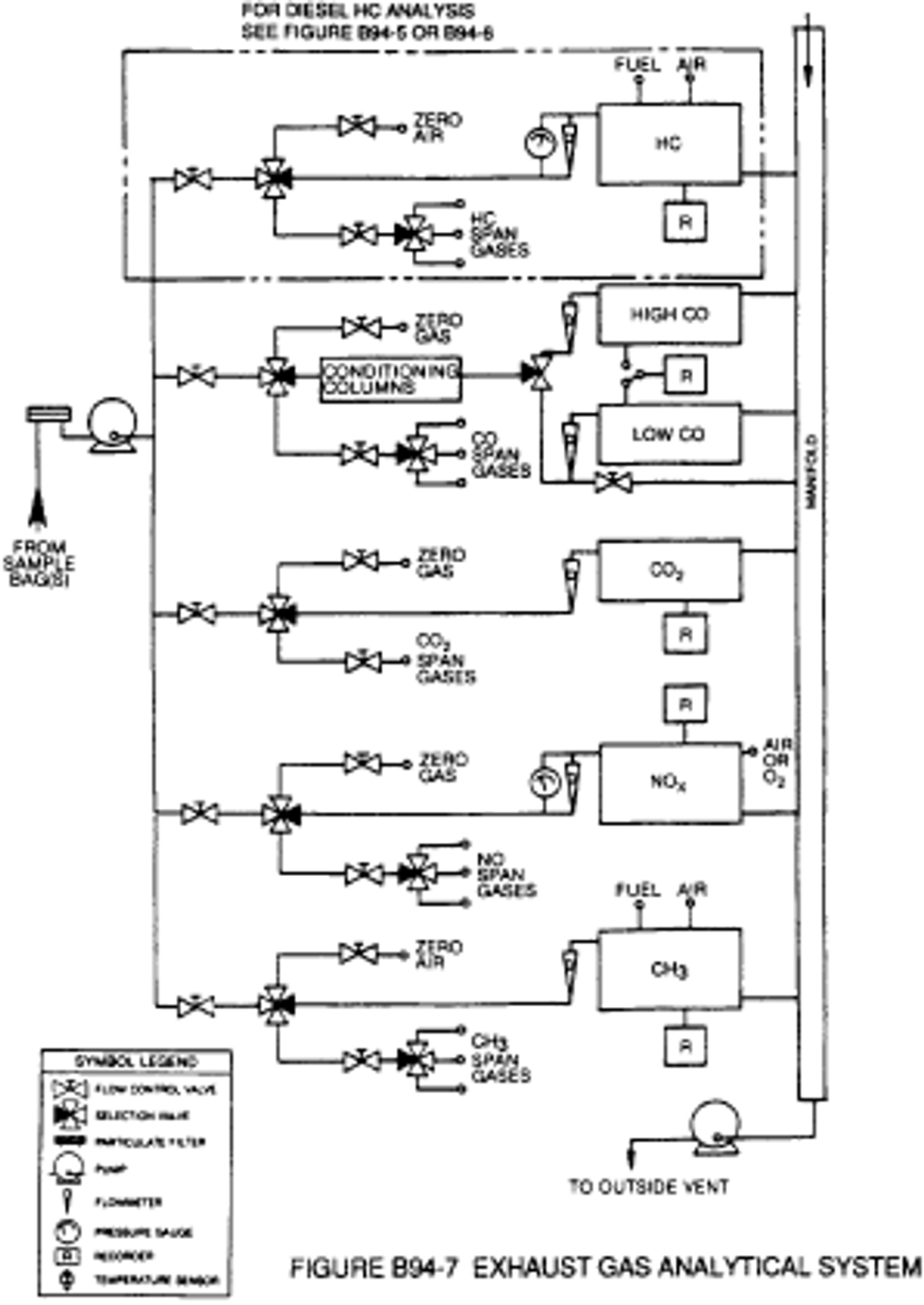

(1) Through model year 2021, manufacturers may use the test procedures specified in paragraph (c) or (d) of this section or, using good engineering judgement, elements of both. For any EPA testing before model year 2022, EPA will use the manufacturer's selected procedures for applying acceptable speed-tolerance criteria (either §86.115-78 or 40 CFR 1066.425(c)). For any other parameters, EPA may conduct testing using either of the specified procedures. As allowed under this part, manufacturers may use carryover data from previous model years to demonstrate compliance with emission standards, without regard to the provisions of this section.

(2) Manufacturers must use the following procedures before model year 2022:

(i) For vehicles certified to any of the Tier 3 emission standards specified in subpart S of this part, determine overall driver accuracy based on drive-cycle metrics as described in 40 CFR 1066.425(j).

(ii) Equipment specifications and measurement procedures that are specific to PM emissions from 40 CFR part 1066 apply for any vehicles certified to the Tier 3 PM emission standards specified in subpart S of this part.

(iii) Use 40 CFR 1066.635 to determine NMOG for any vehicles certified to the Tier 3 NMOG + NOX emission standards in subpart S of this part.

(3) For model years 2022 and later, manufacturers must use the test procedures specified in paragraph (d) of this section. Manufacturers may continue to use data based on the test procedures specified in paragraph (c) of this section for an engine family in 2022 and later model years, as long as the engine family is eligible for certification with carryover emission data.

(c) Interim procedures. Test vehicles as described in this subpart for the appropriate model year, through model year 2021, as follows:

(1) Sections 86.106 through 86.115 set forth general testing specifications and equipment requirements. Sections 86.116 through 86.126 discuss calibration methods and frequency. Sections 86.127 through 86.145_82 describe procedures for measuring exhaust and evaporative emissions. Sections 86.146 through 86.157 lay out refueling test procedures. Sections 86.158 through 86.166 cover procedures related to the Supplemental Federal Test Procedure and testing related to air conditioning systems. The test procedure for measuring fuel system leaks is described in 40 CFR 1066.985.

(2) Alternate equipment, procedures, and calculation methods may be used if shown to yield equivalent or superior results, and if approved in advance by the Administrator.

(d) Long-term procedures. Test vehicles as described in 40 CFR parts 1065 and 1066. The following requirements from this subpart also apply:

(1) Use fuel for testing and service accumulation as specified in §86.113.

(2) Perform evaporative emission tests as follows:

(i) Use evaporative testing equipment meeting the specifications in §86.107. This equipment must meet calibration requirements as specified in §86.117.

(ii) Generate fuel test temperature profiles as described in §86.129-94(d).

(iii) Follow the general provisions and driving schedules described in 40 CFR part 1066, subpart I. Evaporative testing consists of vehicle preconditioning as described in §86.132, diurnal measurement as described in §86.133, running loss testing as described in §86.134, and hot soak testing as described in §86.138.

(iv) Calculate emission results as described in §86.143.

(3) Keep records as described in §86.142

(4) Perform refueling emission tests, calculate emission results, and keep associated records as described in §86.146 through 86.157.

[79 FR 23691, Apr. 28, 2014, as amended at 80 FR 9102, Feb. 19, 2015]

§86.102 Definitions.

The definitions in §86.1803 apply to this subpart.

[79 FR 23692, Apr. 28, 2014]

§86.103 Abbreviations.

The abbreviations in subpart A apply to this subpart.

[45 FR 14508, Mar. 5, 1980]

§86.104 Section numbering; construction.

(a) The model year of initial applicability is indicated by the section number. The two digits following the hyphen designate the first model year for which a section is effective. A section remains effective until superseded.

Example.

Section 86.111-78 applies to the 1978 and subsequent model years until superseded. If a §86.111-81 is promulgated it would take effect beginning with the 1981 model year; §86.111-78 would apply to model years 1978 through 1980.

(b) A section reference without a model year suffix refers to the section applicable for the appropriate model year.

(c) Unless indicated otherwise, all provisions in this subpart apply to petroleum-fueled, natural gas-fueled, liquefied petroleum gas-fueled and methanol-fueled vehicles.

[42 FR 32954, June 28, 1977. Redesignated at 45 FR 14508, Mar. 5, 1980, as amended at 54 FR 14499, Apr. 11, 1989; 59 FR 48504, Sept. 21, 1994]

§86.105 Introduction; structure of subpart.

(a) This subpart describes the equipment required and the procedures to follow in order to perform gaseous exhaust, particulate, and evaporative emission tests on light-duty vehicles and light-duty trucks. Subpart A of this part sets forth testing requirements and test intervals necessary to comply with EPA certification procedures. Not all emission measurement techniques described in this subpart will be necessary for all vehicles. Subpart A of this part defines the conditions under which vehicles may be exempted from measuring methane and/or waived from measuring particulate matter.

(b) Three topics are addressed in this subpart. Sections 86.106 through 86.115 set forth specifications and equipment requirements; §§86.116 through 86.126 discuss calibration methods and frequency; test procedures and data requirements are listed in §§86.127 through 86.157.

[56 FR 25760, June 5, 1991, as amended at 59 FR 16295, Apr. 6, 1994; 59 FR 48504, Sept. 21, 1994]

§86.106-96 Equipment required; overview.

(a) This subpart contains procedures for exhaust emission tests on petroleum-fueled, natural gas-fueled, liquefied petroleum gas-fueled, and methanol-fueled light-duty vehicles and light-duty trucks, and for evaporative emission tests on gasoline-fueled, natural gas-fueled, liquefied petroleum gas-fueled, and methanol-fueled light-duty vehicles and light-duty trucks. Certain items of equipment are not necessary for a particular test, e.g., evaporative enclosure when testing petroleum-fueled diesel vehicles. Alternate equipment, procedures, and calculation methods may be used if shown to yield equivalent or superior results, and if approved in advance by the Administrator. Equipment required and specifications are as follows:

(1) Evaporative emission tests, gasoline-fueled vehicles. The evaporative emission test is closely related to and connected with the exhaust emission test. All vehicles tested for evaporative emissions must undergo testing according to the test sequences described in §86.130-96; however, the Administrator may omit measurement of exhaust emissions to test for evaporative emissions. The Administrator may truncate a test after any valid emission measurement without affecting the validity of the test. Further, unless the evaporative emission test is waived by the Administrator under §86.090-26 or §86.1810, as applicable, all vehicles must undergo both tests. (Petroleum-fueled diesel vehicles are excluded from the evaporative emission standard.) Section 86.107 specifies the necessary equipment.

(2) Exhaust emission tests. All vehicles subject to this subpart are subject to testing for both gaseous and particulate exhaust emissions using the CVS concept (see §86.109), except where exemptions or waivers are expressly provided in subpart A of this part. Vehicles subject to the “Tier 0” (i.e., phase-out) standards described under subpart A of this part are exempted from testing for methane emissions. Otto-cycle vehicles subject to the “Tier 0” standards are waived from testing for particulates. For vehicles waived from the requirement for measuring particulate emissions, use of a dilution tunnel is not required (see §86.109). The CVS must be connected to the dilution tunnel if particulate emission sampling is required (see §86.110). Petroleum- and methanol-fueled diesel-cycle vehicle testing requires that a PDP-CVS or CFV-CVS with heat exchanger be used. (This equipment may be used with methanol-fueled Otto-cycle vehicles; however, particulates need not be measured for vehicles that are waived from the requirement). All vehicles equipped with evaporative canisters are preconditioned by loading the canisters with hydrocarbon vapors. Petroleum-fueled diesel vehicles are excluded from this requirement.

(3) Fuel, analytical gas, and driving schedule specifications. Fuel specifications for exhaust and evaporative emission testing and for mileage accumulation for petroleum-fueled and methanol-fueled vehicles are specified in §86.113. Analytical gases are specified in §86.114. The Urban Dynamometer Driving Schedule (UDDS), US06, and SC03 driving schedules, for use in exhaust emission tests, and the New York City Cycle (NYCC), for use with the UDDS in running loss tests, are specified in §§86.115, 86.130, 86.159, 86.160, and appendix I to this part.

(b) [Reserved]

[58 FR 16026, Mar. 24, 1993, as amended at 59 FR 48504, Sept. 21, 1994; 60 FR 43888, Aug. 23, 1995; 64 FR 23921, May 4, 1999; 79 FR 23692, Apr. 28, 2014]

§86.107-96 Sampling and analytical systems; evaporative emissions.

(a) Testing enclosures - (1) Diurnal emission test. The enclosure shall be readily sealable, rectangular in shape, with space for personnel access to all sides of the vehicle. When sealed, the enclosure shall be gas tight in accordance with §86.117-96. Interior surfaces must be impermeable and nonreactive to hydrocarbons (and to methanol, if the enclosure is used for methanol-fueled vehicles). The temperature conditioning system shall be capable of controlling the internal enclosure air temperature to follow the prescribed temperature versus time cycle as specified in §86.133-96 and appendix II of this part, within an instantaneous tolerance of ±3.0°F of the nominal temperature versus time profile throughout the test, and an average tolerance of 2.0°F over the duration of the test (where the average is calculated using the absolute value of each measured deviation). The control system shall be tuned to provide a smooth temperature pattern that has a minimum of overshoot, hunting, and instability about the desired long-term ambient temperature profile. Interior surface temperatures shall not be less than 40°F at any time during the diurnal emission test. To accommodate the volume changes due to enclosure temperature changes, either a variable-volume or fixed-volume enclosure may be used for diurnal emission testing:

(i) Variable-volume enclosure. The variable-volume enclosure expands and contracts in response to the temperature change of the air mass in the enclosure. Two potential means of accommodating the internal volume changes are movable panel(s), or a bellows design, in which impermeable bag(s) inside the enclosure expand and contract in response to internal pressure changes by exchanging air from outside the enclosure. Any design for volume accommodation must maintain the integrity of the enclosure as specified in §86.117-96 over the specified temperature range. Any method of volume accommodation shall limit the differential between the enclosure internal pressure and the barometric pressure to a maximum value of ±2.0 inches of water. The enclosure shall be capable of latching to a fixed volume. A variable-volume enclosure must be capable of accommodating a ±7 percent change from its “nominal volume” (see §86.117-96(b)), accounting for temperature and barometric pressure variation during testing.

(ii) Fixed-volume enclosure. The fixed-volume enclosure shall be constructed with rigid panels that maintain a fixed enclosure volume, and meet the following requirements.

(A) The enclosure shall be equipped with a mechanism to maintain a fixed internal air volume. This may be accomplished either by withdrawing air at a constant rate and providing makeup air as needed, or by reversing the flow of air into and out of the enclosure in response to rising or falling temperatures. If inlet air is added continuously throughout the test, it should be filtered with activated carbon to provide a relatively low and constant hydrocarbon level. Any method of volume accommodation shall maintain the differential between the enclosure internal pressure and the barometric pressure to a maximum value of ±2.0 inches of water.

(B) The equipment shall be capable of measuring the mass of hydrocarbon and methanol (if the enclosure is used for methanol-fueled vehicles) in the inlet and outlet flow streams with a resolution of 0.01 gram per hour. A bag sampling system may be used to collect a proportional sample of the air withdrawn from and admitted to the enclosure. Alternatively, the inlet and outlet flow streams may be continuously analyzed using an on-line FID analyzer and integrated with the flow measurements to provide a continuous record of the mass hydrocarbon and methanol removal.

(2) Running loss test. The enclosure shall be readily sealable, rectangular in shape, with space for personnel access to all sides of the vehicle. When sealed, the enclosure shall be gas tight in accordance with §86.117-96. The enclosure may be equipped with a personnel door, provided that the enclosure can still meet the requirements of §86.117-96 with the door installed. Interior surfaces must be impermeable and nonreactive to hydrocarbons and to methanol (if the enclosure is used for methanol-fueled vehicles). Interior surface temperatures shall not be less than 40°F. If a running loss enclosure meets all the requirements of paragraph (a)(1) of this section, it may be used as a diurnal evaporative emission enclosure. The enclosure must contain a dynamometer that meets the requirements of §86.108. Provisions shall be made to remove exhaust gases from the enclosure. During the running loss test, ambient temperatures must be maintained at 95±5°F (95±2°F on average). An air or oxygen cylinder with an attached self-contained breathing apparatus may be provided for the vehicle operator. The air required for vehicle operation shall be provided by one of the following methods:

(i) The running loss enclosure may be equipped to supply air to the vehicle, at a temperature of 95±5°F, from sources outside of the running loss enclosure directly into the operating engine's air intake system. Supplemental air requirements (e.g., for an air pump) shall be supplied by drawing air from the engine intake source.

(ii) If it is shown to yield equivalent or superior results, the running loss enclosure may be designed with an air makeup system that brings outside air into the enclosure to accommodate the aspiration needs of the engine and any auxiliary devices. The makeup air shall be monitored to establish the background hydrocarbon levels (or hydrocarbon and methanol, levels, if applicable) of the makeup air. A filter may be used to provide dry air with a stable concentration of background hydrocarbon. The makeup-air vent shall be readily sealable for calibration of the enclosure and other purposes. For calculation of running loss emissions, it may be assumed that the hydrocarbon and methanol concentration in the air consumed by the vehicle is the same as that of the rest of the air in the enclosure.

(3) Hot soak test. The hot soak test may be conducted by holding the vehicle in an enclosure that meets the requirements for either diurnal emission or running loss tests. The enclosure shall be configured to provide an internal enclosure ambient temperature of 95±10°F for the first 5 minutes, and 95±5°F (95±2°F on average) for the remainder of the hot soak test.

(i) If the hot soak test is conducted in the same enclosure as the immediately preceding running loss test, interior surface temperatures shall not be below 70°F for the last 55 minutes of the hot soak test.

(ii) If the hot soak test is not conducted in the same enclosure as the immediately preceding running loss test, interior surface temperatures shall not be below 70°F for the duration of the hot soak test.

(b) Evaporative emission hydrocarbon and methanol analyzers. (1) For gasoline fueled, natural gas-fueled, liquefied petroleum gas-fueled and methanol-fueled vehicles a hydrocarbon analyzer utilizing the hydrogen flame ionization principle (FID) shall be used to monitor the atmosphere within the enclosure (a heated FID (HFID)(235°±15°F (113±8°C)) is recommended for methanol-fueled vehicles). For natural gas-fueled vehicles, the FID may be calibrated using methane, or if calibrated using propane the FID response to methane shall be determined and applied to the FID hydrocarbon reading. Provided evaporative emission results are not effected, a probe may be used to detect or verify hydrocarbon sources during a running loss test. Instrument bypass flow may be returned to the enclosure. The FID shall have a response time to 90 percent of final reading of less than 1.5 seconds.

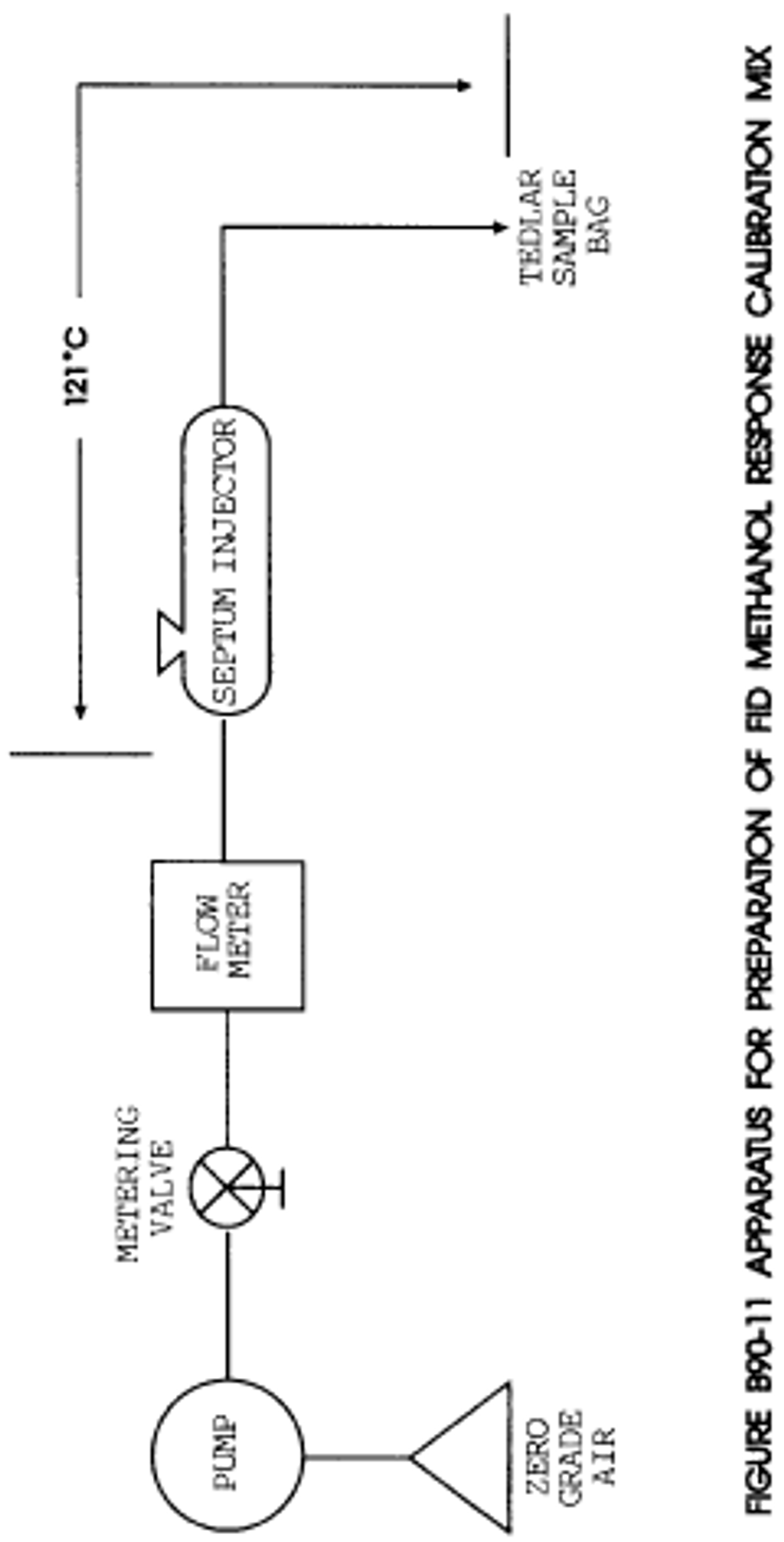

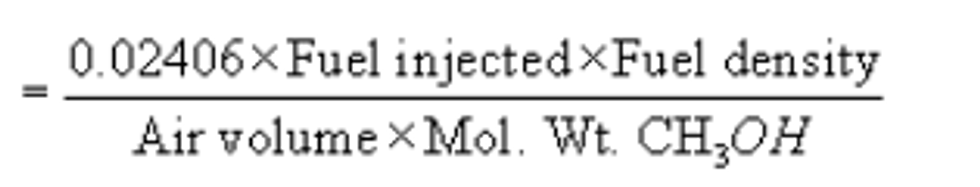

(2) For methanol-fueled vehicles, a methanol sampling and analyzing system is required in addition to the FID analyzer. The methanol sampling equipment shall consist of impingers for collecting the methanol sample and appropriate equipment for drawing the sample through the impingers. The analytical equipment shall consist of a gas chromatograph equipped with a flame ionization detector.

(3) The methanol sampling system shall be designed such that, if a test vehicle emitted the maximum allowable level of methanol (based on all applicable standards) during any phase of the test, the measured concentration in the primary impinger would exceed either 25 mg/l or a concentration equal to 25 times the limit of detection for the GC analyzer, and such that the primary impinger collects at least 90 percent of the analyte in the samples. The remaining analyte shall be collected by the secondary impinger. This requirement does not apply to dilution air samples, since they do not require secondary impingers, or to samples in which the concentrations approach the limit of detection. The provisions of this paragraph apply to the design of sampling systems, not to individual tests.

(c) Evaporative emission hydrocarbon and methanol data recording system. (1) The electrical output of the FID used for measuring hydrocarbons (or hydrocarbons plus methanol, as appropriate) shall be recorded at least at the initiation and termination of each running loss and hot soak test, and at least at the initiation and termination of the enclosure sampling period(s) for the diurnal emission test, as described in §86.133. The recording may be taken by means of a strip chart potentiometric recorder, by use of an on-line computer system or other suitable means. In any case, the recording system must have operational characteristics (signal-to-noise ratio, speed of response, etc.) equivalent to or better than those of the signal source being recorded, and must provide a permanent record of results. The record shall show a positive indication of the initiation and completion of each hot soak, running loss, or diurnal emission test (including initiation and completion of sampling period(s)), along with the time elapsed during each soak.

(2) For the methanol sample, permanent records shall be made of the following: the volumes of deionized water introduced into each impinger, the rate and time of sample collection, the volumes of each sample introduced into the gas chromatograph, the flow rate of carrier gas through the column, the column temperature, and the chromatogram of the analyzed sample.

(d) Fuel temperature control system. Fuel temperatures of the test vehicle shall be controlled, as specified in §86.134(g)(1)(xv), with the following combination of fans. The control system shall be tuned and operated to provide a smooth and continuous fuel temperature profile that is representative of the on-road temperature profile. The running loss test configuration should be designed to avoid heating or cooling the fuel tank's vapor space in a way that would cause vapor temperature behavior to be unrepresentative of the vehicle's on-road profile.

(1) A vehicle cooling fan shall discharge air to the front of the vehicle. The fan shall be a road-speed modulated fan that is controlled to a discharge velocity that follows the dynamometer roll speed, at least up to speeds of 30 mph, throughout the driving cycle. If a warning light or gauge indicates that the vehicle's engine coolant has overheated, subsequent test runs on the vehicle must include a vehicle cooling fan that follows the dynamometer roll speed at all speeds throughout the test cycle. The fan may direct airflow to both the vehicle radiator air inlet(s) and the vehicle underbody.

(2) An additional fan may be used to discharge airflow from the front of the vehicle directly to the vehicle underbody to control fuel temperatures. Such a fan shall provide a total discharge airflow not to exceed 8,000 cfm.

(3) Additional fans may be used to route heating or cooling air directly at the bottom of the vehicle's fuel tank. The air supplied to the tank shall be between 85° and 160°F, with a total discharge airflow not to exceed 4,000 cfm. For exceptional circumstances, manufacturers may direct up to 6,000 cfm at the bottom of the fuel tank with the advance approval of the Administrator.

(4) Direct fuel heating may be needed for canister preconditioning, as specified in §86.132(j)(2), Also, under exceptional circumstances in which airflow alone is insufficient to control fuel temperatures during the running loss test, direct fuel tank heating may be used (see §86.134-96(g)(1)(v)). The heating system must not cause hot spots on the tank wetted surface that could cause local overheating of the fuel. Heat must not be applied directly to the tank's vapor space, nor to the liquid-vapor interface.

(e) [Reserved]

(f) Pressure recording system. A strip chart potentiometric recorder, an on-line computer system, or other suitable means, shall be used to record the enclosure gage pressure for any testing in an enclosure, as well as the vehicle's fuel tank pressure during the running loss test and the outdoor driving procedure specified in §86.129-94(d). Fuel tank pressure measurement and recording equipment are optional during the running loss test. The recording system shall record each pressure at least once every minute. The recording system shall be capable of resolving time to ±15 s and capable of resolving pressure to ±0.1 inches of water. The pressure recording system (recorder and sensor) shall have an accuracy of ±1.0 inch of water. The recorder (data processor) shall have a time accuracy of ±15 s and a precision of ±15 s. The pressure transducer shall be installed to measure the pressure in the vapor space of the fuel tank.

(g) Purge blower. One or more portable or fixed blowers shall be used to purge the enclosure. The blowers shall have sufficient flow capacity to reduce the enclosure hydrocarbon and/or methanol concentration from the test level to the ambient level between tests. Actual flow capacity will depend upon the time available between tests.

(h) Mixing blower. Blowers or fans shall be used to mix the enclosure contents during evaporative emission testing. The inlets and outlets of the air circulation blower(s) shall be configured to provide a well dispersed air circulation pattern that produces effective internal mixing and avoids significant temperature or hydrocarbon stratification. Maintenance of uniform concentrations throughout the enclosure is important to the accuracy of testing.

(1) Diurnal emission test. Blowers or fans shall have a capacity of 0.8±0.2 cfm per cubic foot of the nominal enclosure volume for mixing in the enclosure. Additional fans may be used to maintain a minimum wind speed of 5 mph (8 km/h) under the fuel tank of the test vehicle.

(2) Running loss test. Blowers or fans shall have a total capacity of at least 1.0 cfm per cubic foot of the nominal enclosure volume.

(3) Hot soak test. Blowers or fans must have a capacity of 0.8±0.2 cfm per cubic foot of the nominal enclosure volume. Circulated air shall not be aimed directly at the vehicle.

(i) Point-source running loss measurement facility. Some system requirements pertain specifically to running loss testing by the point-source method, in which emissions from potential sources are collected and routed to a sampling system. Emissions are sampled with the same equipment and techniques as for exhaust emission measurement. The test environment must contain a dynamometer that meets the requirements of §86.108. During the running loss test, ambient temperatures must be maintained at 95±5°F (95±2°F on average). An air or oxygen cylinder with an attached self-contained breathing apparatus may be provided for the vehicle operator.

(1) The running loss vapor vent collection system shall be configured to collect all running loss emissions from each of the discrete point sources that function as vehicle fuel system vapor vents, and transport the collected vapor emissions to a CFV- or PDP-based dilution and measurement system. The collection system shall consist of a collector at each vehicle vapor vent, lengths of heated sample line connecting each collector to the inlet of the heated sample pump, and lengths of heated sample line connecting the outlet of the heated sample pump to the inlet of the running loss fuel vapor sampling system. Up to 3 feet of unheated line connecting each of the vapor collectors to the heated sample lines shall be allowed. Each heated sample pump and its associated sample lines shall be maintained at a temperature between 175°F and 200°F to prevent condensation of fuel vapor in the sample lines. The heated sample pump(s) and its associated flow controls shall be configured and operated to draw a flow of ambient air into each collector at a flow rate of at least 0.67 cfm. The flow controls on each heated sampling system shall include an indicating flow meter that provides an alarm output to the data recording system if the flow rate drops below 0.67 cfm by more than 5 percent. The collector inlet for each discrete vapor vent shall be placed in proximity to the vent as necessary to capture any fuel vapor emissions without significantly affecting flow or pressure of the normal action of the vent. The collector inlets shall be designed to interface with the configuration and orientation of each specific vapor vent. For vapor vents that terminate in a tube or hose barb, a short length of tubing of an inside diameter larger throughout its length than the inside diameter of the vent outlet may be used to extend the vent into the mouth of the collector. For those vapor vent designs that are not compatible with such collector configurations, the vehicle manufacturer shall supply a collector that is configured to interface with the vapor vent design and that terminates in a fitting that is capable of capturing all vapor emitted from the vent. The Administrator may test for running losses by the point-source method without heating sample lines or pumps.

(2) The running loss fuel vapor sampling system shall be a CFV- or PDP-based dilution and measurement system that further dilutes the running loss fuel vapors collected by the vapor vent collection system(s) with ambient air, collects continuously proportional samples of the diluted running loss vapors and dilution air in sample bags, and measures the total dilute flow through the sampling system over each test interval. In practice, the system shall be configured and operated in a manner that is directly analogous to an exhaust emissions constant volume sampling system, except that the input flow to the system is the flow from the running loss vapor vent collection system(s) instead of vehicle exhaust flow. The system shall be configured and operated to meet the following requirements:

(i) The running loss fuel vapor sampling system shall be designed to measure the true mass of fuel vapor emissions collected by the running loss vapor vent collection system from the specified fuel vapor vents. The total volume of the mixture of running loss emissions and dilution air shall be measured and a continuously proportioned sample of volume shall be collected for analysis. Mass emissions shall be determined from the sample concentration and total flow over the test period.

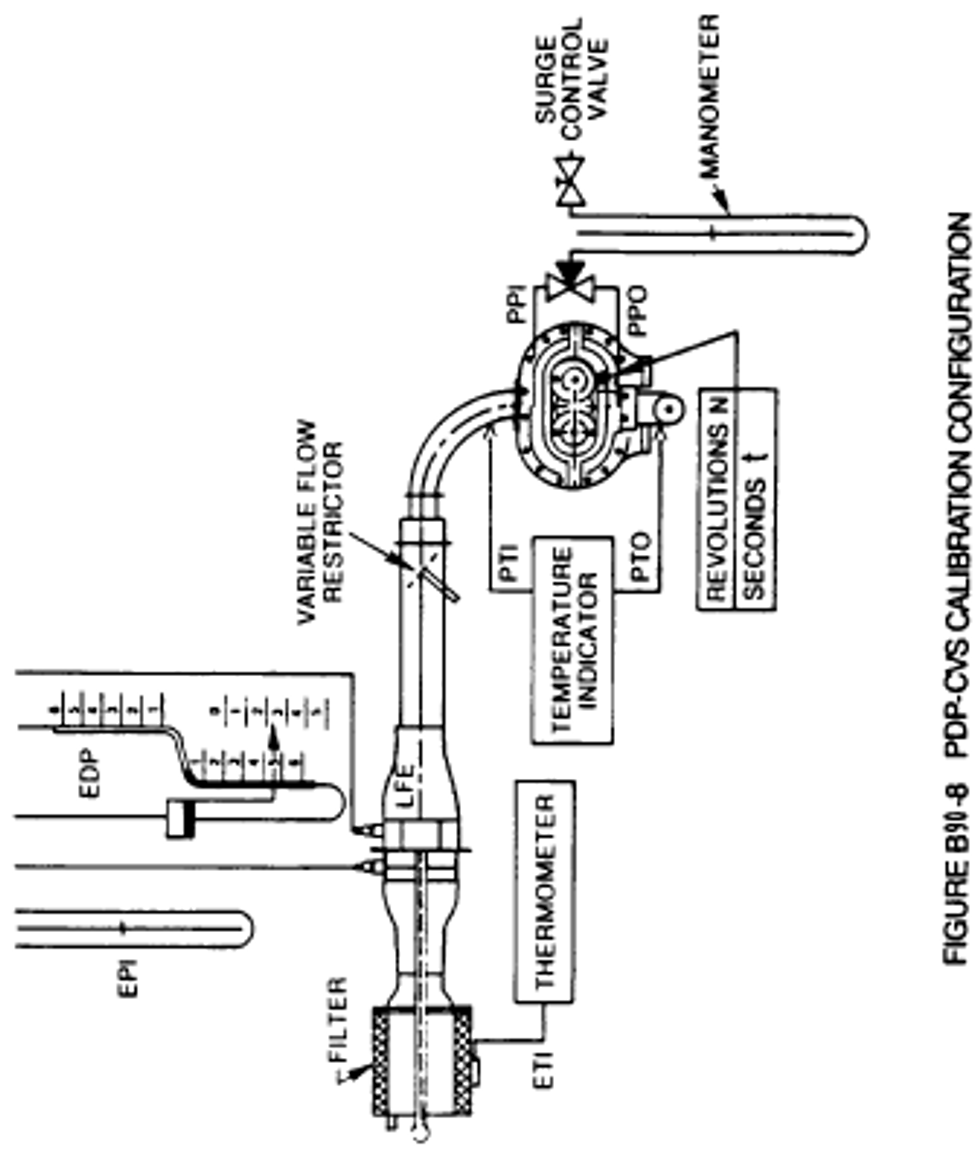

(ii) The PDP-CVS shall consist of a dilution air filter and mixing assembly, heat exchanger, positive-displacement pump, sampling system, and associated valves, pressure and temperature sensors. The PDP-CVS shall conform to the following requirements:

(A) The gas mixture temperature, measured at a point immediately ahead of the positive-displacement pump, shall be within ±10°F of the designed operating temperature at the start of the test. The gas mixture temperature variation from its value at the start of the test shall be limited to ±10°F during the entire test. The temperature measuring system shall have an accuracy and precision of ±2°F.

(B) The pressure gauges shall have an accuracy and precision of ±1.6 inches of water (±0.4 kPa).

(C) The flow capacity of the CVS shall not exceed 350 cfm.

(D) Sample collection bags for dilution air and running loss fuel vapor samples shall be sufficient size so as not to impede sample flow.

(iii) The CFV sample system shall consist of a dilution air filter and mixing assembly, a sampling venturi, a critical flow venturi, a sampling system and assorted valves, and pressure and temperature sensors. The CFV sample system shall conform to the following requirements:

(A) The temperature measuring system shall have an accuracy and precision of ±2°F and a response time of 0.100 seconds of 62.5 percent of a temperature change (as measured in hot silicone oil).

(B) The pressure measuring system shall have an accuracy and precision of ±1.6 inches of water (0.4 kPa).

(C) The flow capacity of the CVS shall not exceed 350 cfm.

(D) Sample collection bags for dilution air and running loss fuel vapor samples shall be of sufficient size so as not to impede sample flow.

(3) An on-line computer system or strip-chart recorder shall be used to record the following additional parameters during the running loss test sequence:

(i) CFV (if used) inlet temperature and pressure.

(ii) PDP (if used) inlet temperature, pressure, and differential pressure.

[58 FR 16027, Mar. 24, 1993, as amended at 59 FR 48505, Sept. 21, 1994; 60 FR 34335, June 30, 1995; 60 FR 43888, Aug. 23, 1995; 79 FR 23692, Apr. 28, 2014]

§86.107-98 Sampling and analytical system.

Section 86.107-98 includes text that specifies requirements that differ from §86.107-96. Where a paragraph in §86.107-96 is identical and applicable to §86.107-98, this may be indicated by specifying the corresponding paragraph and the statement “[Reserved]. For guidance see §86.107-96.” Where a corresponding paragraph of §86.107-96 is not applicable, this is indicated by the statement “[Reserved].”

(a)(1)-(a)(3) [Reserved]. For guidance see §86.107-96.

(a)(4) Refueling emissions test. The requirements detailed in §86.107-90 (a)(1) shall apply. Alternatively, an enclosure meeting the specifications detailed in §86.107-96 (a)(1), (2), or (3) may be used if approved in advance by the Administrator. In addition, the enclosure shall have one or more access ports leading to flexible, automatic sealing boots, in the wall(s) of the enclosure. The function of the access port(s) and boots shall be to allow fueling of the test vehicle from a fuel nozzle and hose located outside of the enclosure, with only the spout of the nozzle passing through the automatic sealing opening of the boot during fueling. There shall be no loss in the gas tightness of the enclosure at the opening of the boot either when the nozzle is inserted or when the nozzle is not inserted.

(b)-(d) [Reserved]. For guidance see §86.107-96.

(e) Temperature recording system - (1) For all emission testing. A strip chart potentiometric recorder, an on-line computer system, or other suitable means shall be used to record enclosure ambient temperature during all evaporative emission test segments, as well as vehicle fuel tank temperature during the running loss test. The recording system shall record each temperature at least once every minute. The recording system shall be capable of resolving time to ±15 s and capable of resolving temperature to ±0.75°F (±0.42°C). The temperature recording system (recorder and sensor) shall have an accuracy of ±3°F (±1.7°C). The recorder (data processor) shall have a time accuracy of ±15 s and a precision of ±15 s. Enclosures shall be equipped with two ambient temperature sensors, connected to provide one average output, located 3 feet above the floor at the approximate mid-length of each side wall of the enclosure and within 3 to 12 inches of each side wall. For diurnal emission testing, an additional temperature sensor shall be located underneath the vehicle to provide a temperature measurement representative of the temperature of the air under the fuel tank. For running loss testing, an ambient temperature sensor shall be located at the inlet to the fan that provides engine cooling. Manufacturers shall arrange that vehicles furnished for testing at federal certification facilities be equipped with temperature sensors for measurement of fuel tank temperature. Vehicles shall be equipped with 2 temperature sensors installed to provide an average liquid fuel temperature. The temperature sensors shall be placed to measure the temperature at the mid-volume of the liquid fuel at a fill level of 40 percent of nominal tank capacity. An additional temperature sensor may be placed to measure vapor temperatures approximately at the mid-volume of the vapor space, though measurement of vapor temperatures is optional during the running loss test. In-tank temperature sensors are not required for the supplemental two-diurnal test sequence specified in §86.130-96 or for the refueling test specified in §86.151-98.

(2) Refueling emission testing only. In addition to the enclosure ambient temperature recording system described in paragraph (e)(1) of this section, strip chart recorder(s) or automatic data processor shall be used to record vehicle soak area ambient temperature and dispensed fuel temperature at the nozzle during the test. The temperature recorder(s) or data processor shall record each temperature at least once every 20 seconds (the soak area ambient temperature recorder may be a continuous recording system). The recording system shall be capable of resolving time to ±15s and be capable of resolving temperature to ±0.75°F (0.42°C).

(f)-(h)(3) [Reserved]. For guidance see §86.107-96.

(h)(4) Refueling emission test. Blowers or fans must have a capacity of 0.8±0.2 cfm per cubic foot of the nominal enclosure volume. Circulated air shall not be aimed directly at the vehicle.

(5) Spilled fuel mixing blower; refueling emission test. An explosion-proof blower of 100-200 ft 3/min (2.8-5.7 m 3/min) capacity is required to enhance mixing of vapors from spilled fuel through the enclosure atmosphere during tests. The discharge from this blower shall be directed toward the region of the enclosure floor where fuel spillage during fueling may occur.

(i) [Reserved]. For guidance see §86.107-96.

(j) Refueling equipment. The refueling equipment shall consist of a fuel delivery system with temperature control equipment, fuel flow safety switch, dispensing pump, hose, nozzle and a meter to measure the dispensed fuel volume. The dispensing nozzle shall be a commercial model, not equipped with vapor recovery hardware. A fuel recirculation system may be utilized to avoid trapping of unheated fuel in the hose. The fuel delivery system must be capable of delivering fuel at 67±1.5°F (19.4±0.8°C) and a constant flow rate between 4.2 and 9.8 gal/min (15.9 and 37.1 liter/min) with a tolerance of ±0.3 gal/min (±1.1 liter/min) during the refueling emissions measurement phase of the test. The accuracy of the meter for measuring the dispensed fuel volume shall be ±2 percent at the test flow rate.

[59 FR 16295, Apr. 6, 1994, as amended at 60 FR 43890, Aug. 23, 1995]

§86.108-00 Dynamometer.

(a) The dynamometer shall simulate the road load force and inertia specified for the vehicle being tested, and shall determine the distance traveled during each phase of the test procedure.

(b) Two types of dynamometer roll configurations are currently approved by the Administrator:

(1) A small twin-roll dynamometer that has a nominal roll diameter of 8.65 inches and a nominal roll spacing of 17 inches; and

(2)(i) An electric dynamometer that has a single roll with a nominal diameter of 48 inches (1.20 to 1.25 meters).

(ii)(A) The dynamometer must be capable of dynamically controlling inertia load during the US06 test cycle as a function of a vehicle throttle position signal if a manufacturer desires using the following test option. Any time the duration of throttle operation greater than or equal to 85% of wide open throttle (WOT) is greater than or equal to eight seconds, the test inertia load may be adjusted during any of five EPA specified accelerationevents by an amount of load that will eliminate additional throttle operation greater than or equal to 85% of WOT.

(B)(1) The specific US06 schedule accelerations time periods where inertia load adjustments may be applied are:

(i) 49 through 69 seconds;

(ii) 83 through 97 seconds;

(iii) 135 through 165 seconds;

(iv) 315 through 335 seconds; and

(v) 568 through 583 seconds.

(2) During these five time intervals when inertia load adjustment is occurring, inertia load adjustment is discontinued when throttle operation is less than 85% of WOT or at the end of the specified time interval.

(C) Each type of generic application for implementing this concept must receive the Administrator's approval before a manufacturer may use these inertia adjustments for official US06 schedule certification tests.

(c) Other dynamometer configurations may be used for testing if it can be demonstrated that the simulated road load power and inertia are equivalent, and if approved in advance by the Administrator.

(d) An electric dynamometer meeting the requirements of paragraph (b)(2) of this section, or a dynamometer approved as equivalent under paragraph (c) of this section, must be used for all types of emission testing in the following situations.

(1)(i) Gasoline vehicles which are part of an engine family which is designated to meet the phase-in of SFTP compliance required under the implementation schedule of table A00-1 of §86.000-08, or table A00-3, or table A00-5 of §86.000-09.

(ii) Diesel LDVs and LDT1s which are part of an engine family which is designated to meet the phase-in of SFTP compliance required under the implementation schedule of table A00-1 of §86.000-08, or table A00-3, or table A00-5 of §86.000-09.

(2) Starting with the 2002 model year, any light-duty vehicle or light light-duty truck which uses any regulated fuel.

(3) Starting with the 2004 model year, any heavy light-duty truck which uses any regulated fuel.

[61 FR 54890, Oct. 22, 1996]

§86.109-94 Exhaust gas sampling system; Otto-cycle vehicles not requiring particulate emission measurements.

(a)(1) General. The exhaust gas sampling system described in this paragraph is designed to measure the true mass of gaseous emissions in the exhaust of either Otto-cycle light-duty vehicles or light-duty trucks which are waived from requirements for the measurement of particulate emissions. In the CVS concept of measuring mass emissions, two conditions must be satisfied: the total volume of the mixture of exhaust and dilution air must be measured, and a continuously proportioned volume of sample must be collected for analysis. Mass emissions are determined from the sample concentration and total flow over the test period.

(2) Vehicle tailpipe to CVS Duct. For methanol-fueled vehicles, cooling of the exhaust gases in the duct connecting the vehicle tailpipe to the CVS shall be minimized. This may be accomplished by:

(i) Using a duct of unrestricted length maintained at a temperature above the maximum dew point of the exhaust, but below 250°F (121°C); heating and possibly cooling capabilities are required; or

(ii) Using a short duct (up to 12 feet long) constructed of smooth wall pipe with a minimum of flexible sections, maintained at a temperature above the maximum dew point of the exhaust, but below 250°F (121°C), prior to the test and during the 10 minute hot soak segment and uninsulated during the test (insulation may remain in place and/or heating may occur during testing provided maximum temperature is not exceeded); or

(iii) Using smooth wall duct less than five feet long with no required heating. A maximum of two short flexible connectors are allowed under this option; or

(iv) Omitting the duct and performing the exhaust gas dilution function at the vehicle tailpipe exit.

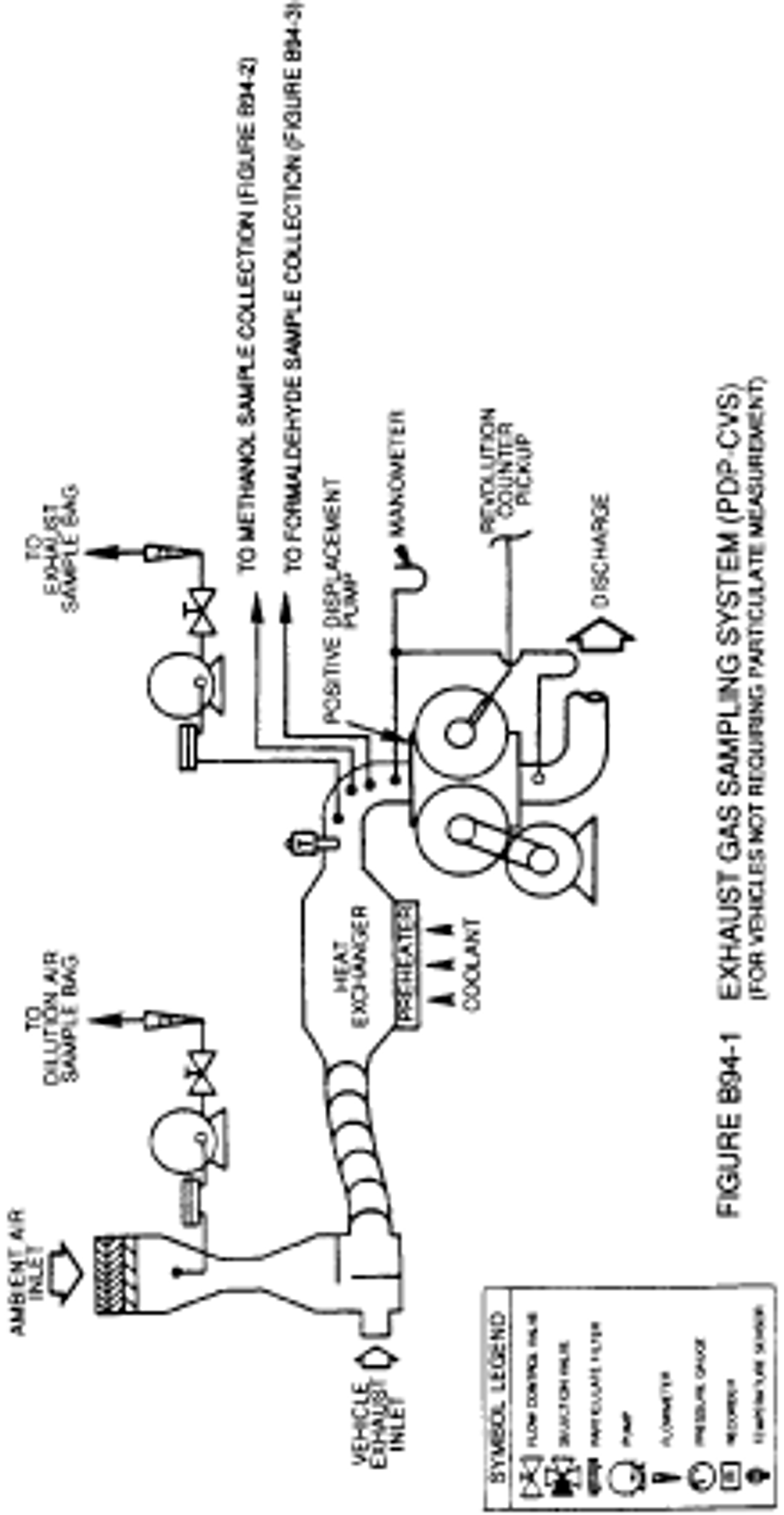

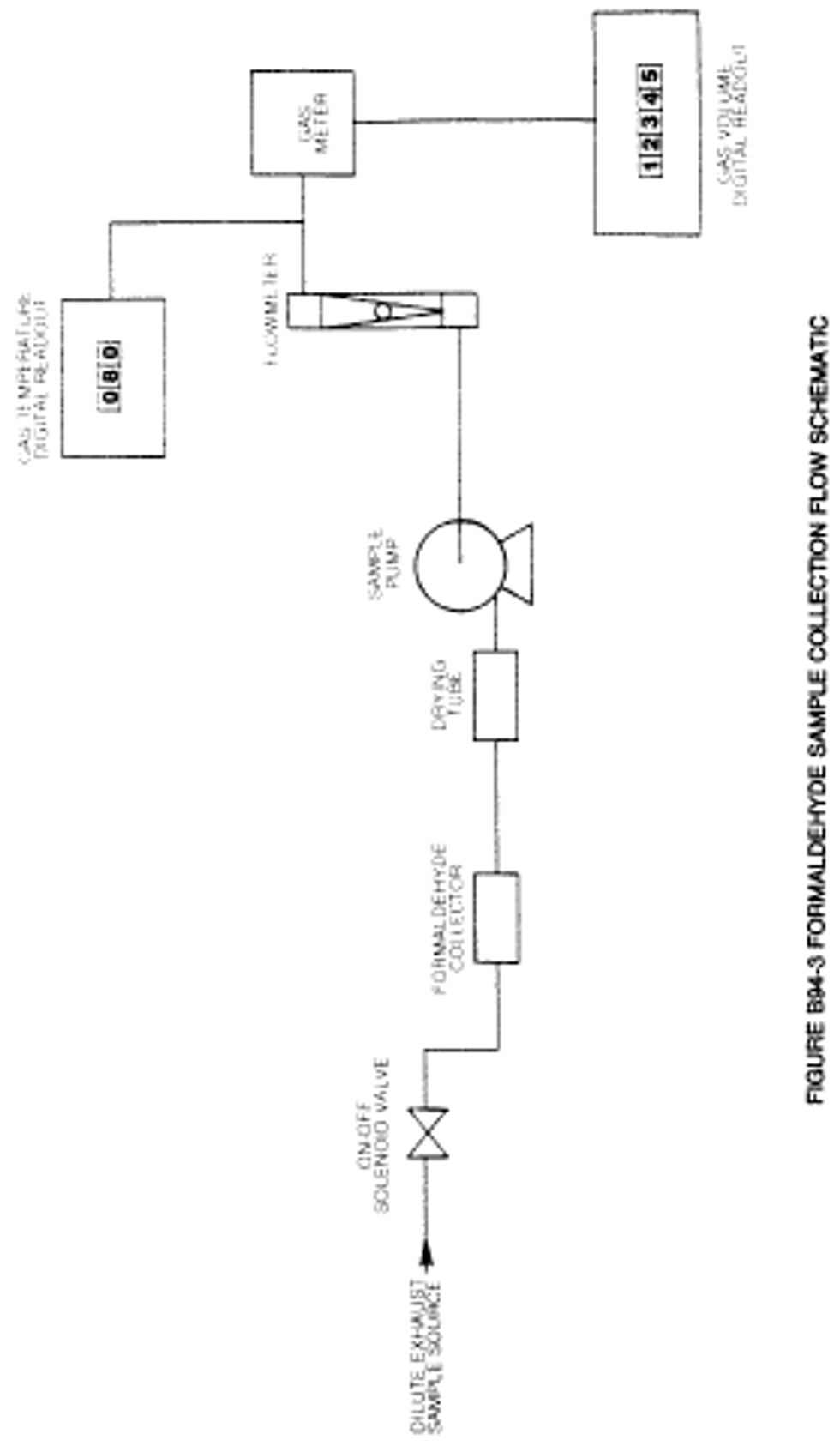

(3) Positive displacement pump. The Positive Displacement Pump-Constant Volume Sampler (PDP-CVS), Figure B94-1 satisfies the first condition by metering at a constant temperature and pressure through the pump. The total volume is measured by counting the revolutions made by the calibrated positive displacement pump. The proportional samples for the bag sample, and for methanol-fueled vehicles, the methanol sample (Figure B94-2) and the formaldehyde sample (Figure B94-3), are achieved by sampling at a constant flow rate. For methanol-fueled vehicles, the sample lines for the methanol and formaldehyde samples are heated to prevent condensation. The temperature of the sample lines shall be more than 5°F (3°C) above the maximum dew point of the sample, but below 250°F (121°C). (Note: For 1990 through 1994 model year methanol-fueled vehicles, methanol and formaldehyde sampling may be omitted provided the bag sample (hydrocarbons and methanol) is analyzed using a HFID calibrated with methanol.)

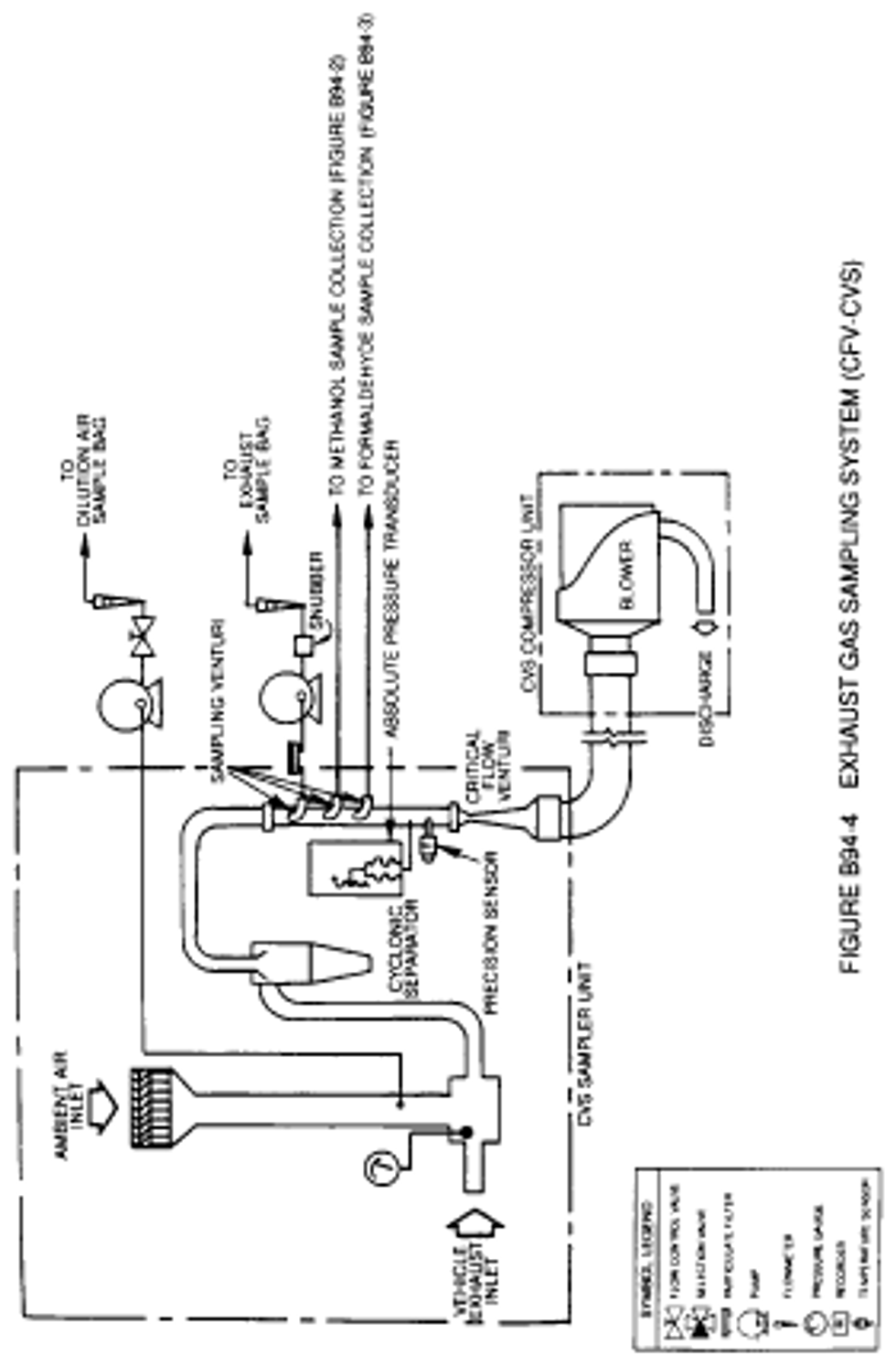

(4) Critical flow venturi. The operation of the Critical Flow Venturi-Constant Volume Sampler (CFV-CVS) sample system, Figure B94-4, is based upon the principles of fluid dynamics associated with critical flow. Proportional sampling throughout temperature excursions is maintained by use of small CFVs in the sample lines (for methanol-fueled vehicles, one line supplies sample for the bag sample, another line supplies sample for the methanol sample, and a third line supplies sample for the formaldehyde sample.) The methanol and formaldehyde sample lines are heated to prevent condensation. The temperature of the sample lines shall be more than 5°F (3°C) above the maximum dew point of the sample, but below 250°F (121°C). Care should be taken to ensure that the CFVs of the sample probes are not heated since heating of the CFVs would cause loss of proportionality. The variable mixture flow rate is maintained at sonic velocity, is inversely proportional to the square root of the gas temperature, and is computed continuously. Since the pressure and temperature are the same at all venturi inlets, the sample volume is proportional to the total volume. (Note: For 1990 through 1994 model year methanol-fueled vehicles, methanol and formaldehyde sampling may be omitted provided the bag sample (hydrocarbons and methanol) is analyzed using a HFID calibrated with methanol.)

(5) Electronic flow control. The Critical Flow Venturi-Electronic Flow Control-Constant Volume Sampler (CFV-EFC-CVS) system is identical to the CFV-CVS system described in paragraphs (a)(4) and (c) of this section, except that it maintains proportional sampling for methanol and formaldehyde by measuring the CVS flow rate, and electronically controlling sample flow rates. For methanol-fueled vehicles, the samples lines for the methanol and formaldehyde samples are heated to prevent condensation. The temperature of the sample lines shall be more than 5°F (3°C) above the maximum dew point of the sample, but below 250°F (121°C).

(6) Other systems. Other sampling systems may be used if shown to yield equivalent or superior results, and if approved in advance by the Administrator.

(b) Component description, PDP-CVS. The PDP-CVS, Figure B94-1, consists of a dilution air filter and mixing assembly, heat exchanger, positive displacement pump, sampling systems (see Figure B94-2 for methanol sampling system and Figure B94-3 for formaldehyde sampling system) sampling lines which are heated to a temperature that is more than 5°F (3°C) above the maximum dew point of the sample, but below 250°F (121°C) in the case of the methanol-fueled vehicles (heating of the sample lines may be omitted, provided the methanol and formaldehyde sample collection systems are close coupled to the probes thereby preventing loss of sample due to cooling and resulting condensation in the sample lines), and associated valves, pressure and temperature sensors. The PDP-CVS shall conform to the following requirements:

(1) Static pressure variations at the tailpipe(s) of the vehicle shall remain within ±5 inches of water (1.2 kPa) of the static pressure variations measured during a dynamometer driving cycle with no connection to the tailpipe(s). (Sampling systems capable of maintaining the static pressure to within ±1 inch of water (0.25 kPa) will be used by the Administrator if a written request substantiates the need for this closer tolerance.)

(2) The gas mixture temperature, measured at a point immediately ahead of the positive displacement pump, shall be within ±10°F (±5.6°C) of the designed operating temperature at the start of the test. The gas mixture temperature variation from its value at the start of the test shall be limited to ±10°F (±5.6°C) during the entire test. The temperature measuring system shall have an accuracy and precision of ±2°F (1.1°C).

(3) The pressure gauges shall have an accuracy and precision of ±1.6 inches of water (0.4 kPa).

(4) The flow capacity of the CVS shall be large enough to completely eliminate water condensation in the dilution and sampling systems. (300 to 350 cfm (0.142 to 0.165 m 3/s) is sufficient for most petroleum-fueled vehicles. Higher flow rates are required for methanol-fueled vehicles and may be required for natural gas-fueled and liquefied petroleum gas-fueled vehicles. Procedures for determining CVS flow rates are detailed in “Calculation of Emissions and Fuel Economy When Using Alternative Fuels,” EPA 460/3-83-009.) (Copies may be obtained from U.S. Department of Commerce, NTIS, Springfield, Virginia 22161; order #PB84104702.) Dehumidifying the dilution air before entering the CVS is allowed. Hearing the dilution air is also allowed, provided:

(i) The air (or air plus exhaust gas) temperature does not exceed 250°F.

(ii) Calculation of the CVS flow rate necessary to prevent water condensation is based on the lowest temperature encountered in the CVS prior to sampling. (It is recommended that the CVS system be insulated when heated dilution air is used.)

(iii) The dilution ratio is sufficiently high to prevent condensation in bag samples as they cool to room temperature.

(5) Sample collection bags for dilution air and exhaust samples shall be of sufficient size so as not to impede sample flow. A single dilution air sample, covering the total test period, may be collected for the determination of methanol and formaldehyde background (methanol-fueled vehicles).

(6) The methanol sample collection system and the formaldehyde sample collection system shall each be of sufficient capacity so as to collect samples of adequate size for analysis without significant impact on the volume of dilute exhaust passing through the PDP. The systems shall also comply with the following requirements that apply to the design of the systems, not to individual tests.

(i) The methanol system shall be designed such that, if a test vehicle emitted the maximum allowable level of methanol (based on all applicable standards) during the first phase of the test, the measured concentration in the primary impinger would exceed either 25 mg/l or a concentration equal to 25 times the limit of detection for the GC analyzer. Sampling systems for all phases shall be identical.

(ii) The formaldehyde system shall be designed such that, if a test vehicle emitted formaldehyde at a rate equal to twenty percent of the maximum allowable level of NMHCE (i.e., 0.05 g/mi for a 0.25 g/mi NMHCE standard), or the maximum formaldehyde level allowed by a specific formaldehyde standard, whichever is less, during the first phase of the test, the concentration of formaldehyde in the DNPH solution of the primary impinger, or solution resulting from the extraction of the DNPH cartridge, shall exceed either 2.5 mg/l or a concentration equal to 25 times the limit of detection for the HPLC analyzer. Sampling systems for all phases shall be identical.

(iii) The methanol and formaldehyde impinger systems shall be designed such that the primary impinger collects at least 90 percent of the analyte in the samples. The remaining analyte shall be collected by the secondary impinger. This requirement does not apply to dilution air samples, since they do not require secondary impingers, or to samples in which the concentrations approach the limit of detection.

(c) Component description, CFV-CVS. The CFV-CVS sample system, Figure B94-4, consists of a dilution air filter and mixing assembly, a cyclone particulate separator, unheated sampling venturies for the bag samples, and for the methanol and formaldehyde samples from methanol-fueled vehicles, samples lines heated to a temperature that is more than 5°F (3°C) above the maximum dew point of the sample, but below 250°F (121°C) for the methanol and formaldehyde samples from methanol fueled vehicles (heating of the sample lines may be omitted provided, the methanol and formaldehyde sample collection systems are close coupled to the probes thereby preventing loss of sample due to cooling and resulting condensation in the sample lines), a critical flow venturi, and assorted valves, and pressure and temperature sensors. The CFV sample system shall conform to the following requirements:

(1) Static pressure variations at the tailpipe(s) of the vehicle shall remain within ±5 inches of water (1.2 kPa) of the static pressure variations measured during a dynamometer driving cycle with no connection to the tailpipe(s). (Sampling systems capable of maintaining the static pressure to within ±1 inch of water (0.25 kPa) will be used by the Administrator if a written request substantiates the need for this closer tolerance.)

(2) The temperature measuring system shall have an accuracy and precision of ±2°F (1.1°C) and a response time of 0.100 seconds to 62.5 percent of a temperature change (as measured in hot silicone oil).

(3) The pressure measuring system shall have an accuracy and precision of ±1.6 inches of water (0.4 kPa).

(4) The flow capacity of the CVS shall be large enough to completely eliminate water condensation in the dilution and sampling systems. (300 to 350 cfm (0.142 to 0.165 m 3/s) is sufficient for most petroleum-fueled vehicles. Higher flow rates are required for methanol-fueled vehicles and may be required for natural gas-fueled and liquefied petroleum gas-fueled vehicles. Procedures for determining CVS flow rates are detailed in “Calculation of Emissions and Fuel Economy When Using Alternative Fuels,” EPA 460/3-83-009.) Dehumidifying the dilution air before entering the CVS is allowed. Heating the dilution air is also allowed, provided:

(i) The air (or air plus exhaust gas) temperature does not exceed 250°F (121°C).

(ii) Calculation of the CVS flow rate necessary to prevent water condensation is based on the lowest temperature encountered in the CVS prior to sampling. (It is recommended that the CVS system be insulated when heated dilution air is used.)

(iii) The dilution ratio is sufficiently high to prevent condensation in bag samples as they cool to room temperature.

(5) Sample collection bags for dilution air and exhaust samples shall be of sufficient size so as not to impede sample flow. A single dilution air sample, covering the total test period, may be collected for the determination of methanol and formaldehyde background (methanol-fueled vehicles).

(6) The methanol sample collection system and the formaldehyde sample collection system shall each be of sufficient capacity so as to collect samples of adequate size for analysis without significant impact on the volume of dilute exhaust passing through the CVS. The systems shall also comply with the following requirements that apply to the design of the systems, not to individual tests.

(i) The methanol system shall be designed such that, if a test vehicle emitted the maximum allowable level of methanol (based on all applicable standards) during the first phase of the test, the measured concentration in the primary impinger would exceed either 25 mg/l or a concentration equal to 25 times the limit of detection for the GC analyzer. Sampling systems for all phases shall be identical.

(ii) The formaldehyde system shall be designed such that, if a test vehicle emitted formaldehyde at a rate equal to twenty percent of the maximum allowable level of NMHCE (i.e., 0.05 g/mi for a 0.25 g/mi NMHCE standard), or the maximum formaldehyde level allowed by a specific formaldehyde standard, whichever is less, during the first phase of the test, the concentration of formaldehyde in the DNPH solution of the primary impinger, or solution resulting from the extraction of the DNPH cartridge, shall exceed either 2.5 mg/l or a concentration equal to 25 times the limit of detection for the HPLC analyzer. Sampling systems for all phases shall be identical.

(iii) The methanol and formaldehyde systems shall be designed such that the primary impinger collects at least 90 percent of the analyte in the samples. The remaining analyte shall be collected by the secondary impinger. This requirement does not apply to dilution air samples, since they do not require secondary impingers, or to samples in which the concentrations approach the limit of detection.

(d) Component description, CFV-EFC-CVS. The CVS sample system is identical to the system described in paragraph (c) of this section, plus includes a means of electronically measuring the CVS flow rate, and electronic mass flow controllers for the methanol and formaldehyde sample lines. The EFC sample system shall conform to all of the requirements listed in paragraph (c), except that the methanol and formaldehyde samples must both be drawn from a static probe. It also must comply with the following additional requirements:

(1) The ratio of the CVS mass flow rate to the sample mass flow rate shall not deviate from the design ratio by more than ±5 percent. (The volumetric sample flow rate shall be varied inversely with the square root of the bulk stream temperature.)

(2) Flow meters to totalize sample volumes for methanol and/or formaldehyde samples shall meet the accuracy specifications of §86.120. Total sample volumes may be obtained from the flow controllers, provided that the controllers meet the accuracy specifications of §86.120.

[56 FR 25760, June 5, 1991, as amended at 59 FR 48505, Sept. 21, 1994; 60 FR 34336, June 30, 1995]

§86.110-94 Exhaust gas sampling system; diesel-cycle vehicles, and Otto-cycle vehicles requiring particulate emissions measurements.

Section 86.110-94 includes text that specifies requirements that differ from §86.110-90. Where a paragraph in §86.110-90 is identical and applicable to §86.110-94, this may be indicated by specifying the corresponding paragraph and the statement “[Reserved]. For guidance see §86.110-90.” Where a corresponding paragraph of §86.110-90 is not applicable, this is indicated by the statement “[Reserved].”

(a) General. The exhaust gas sampling system described in this paragraph is designed to measure the true mass of both gaseous and particulate emissions in the exhaust of either diesel-cycle or Otto-cycle light-duty vehicles and light-duty trucks. This system utilizes the CVS concept (described in §86.109) of measuring mass emissions. The mass of gaseous emissions is determined from the sample concentration and total flow over the test period. The mass of particulate emissions is determined from a proportional mass sample collected on a filter and from the total flow over the test period. General requirements are as follows:

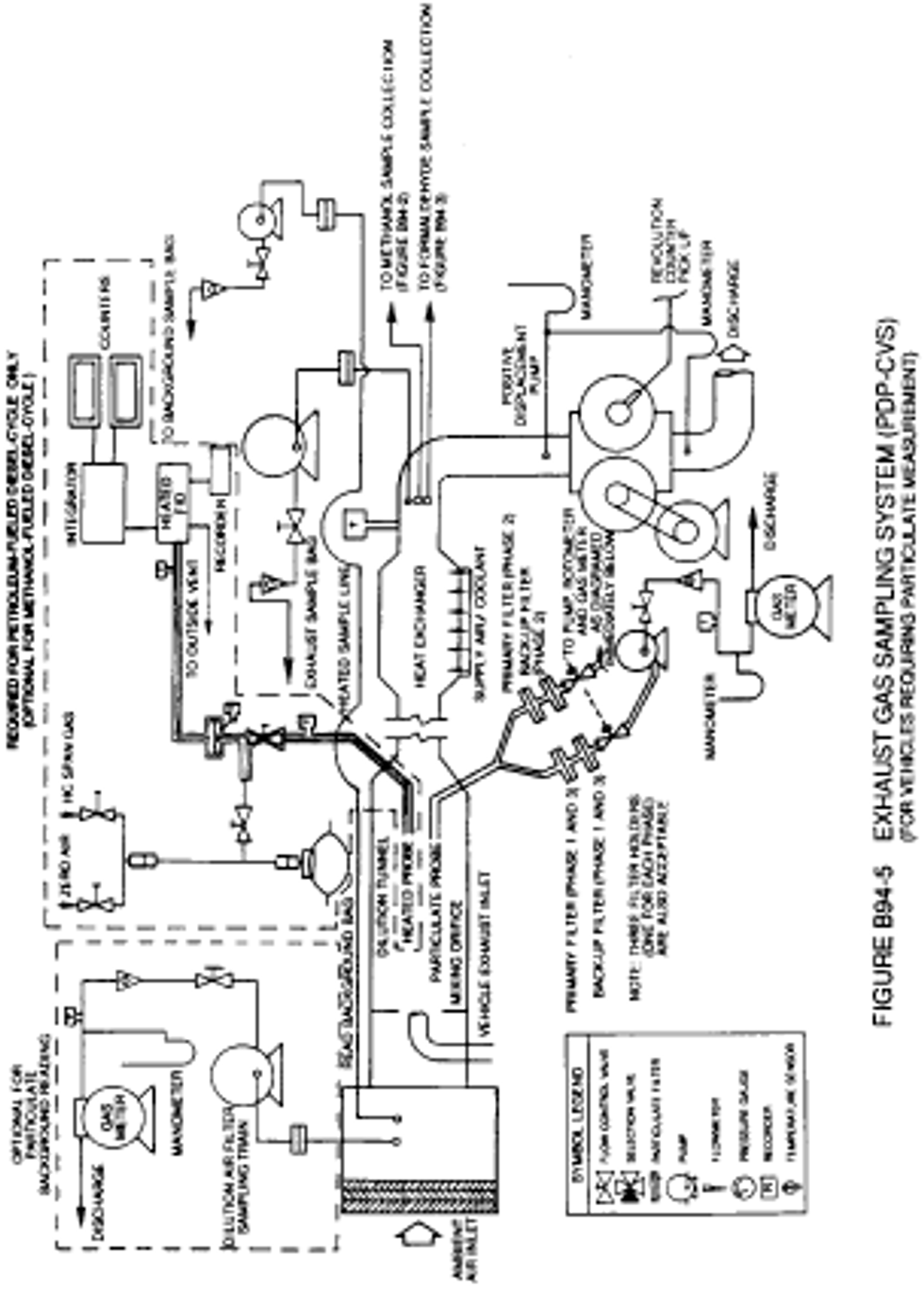

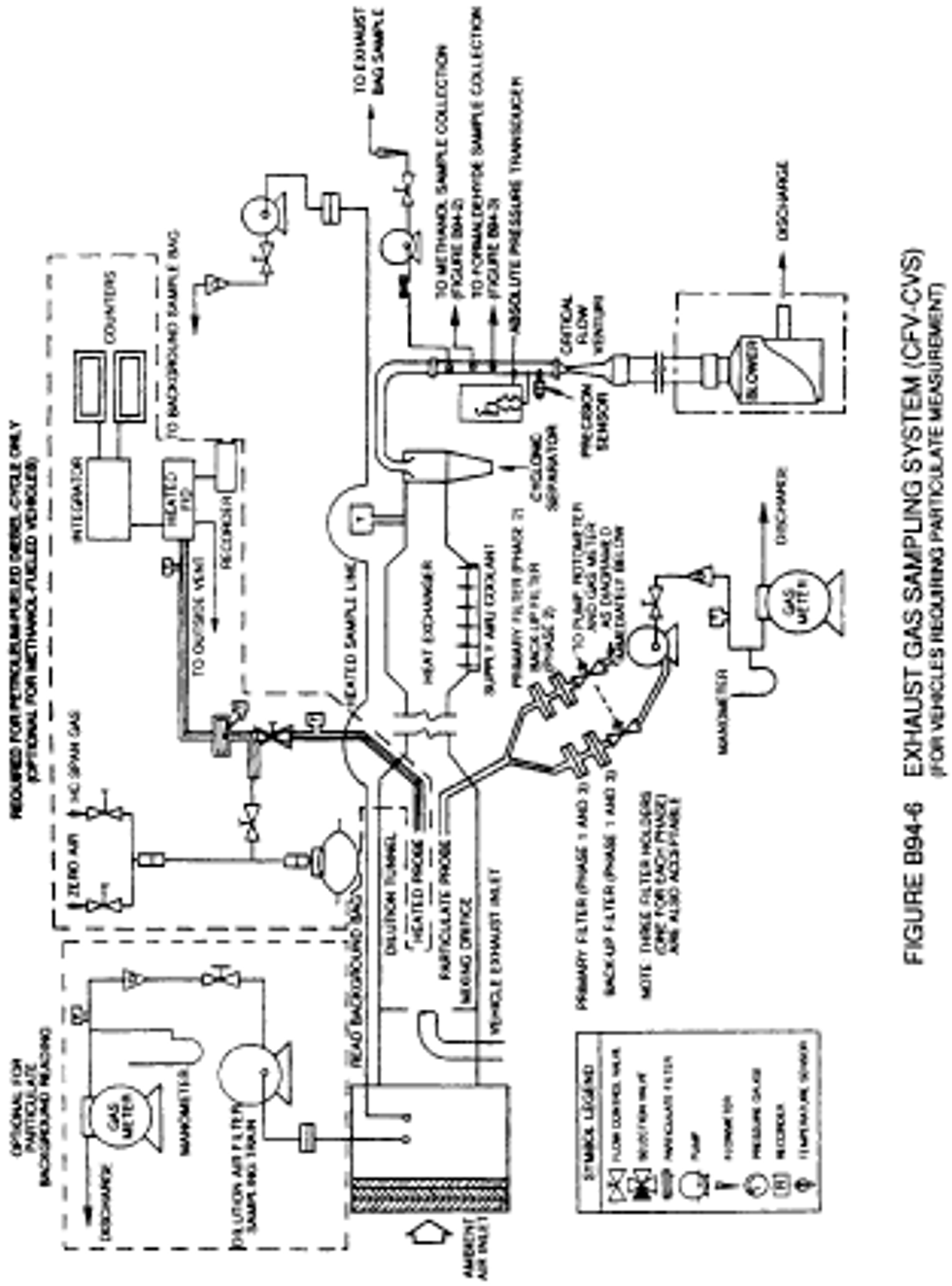

(1) This sampling system requires the use of a PDP-CVS, CFV-CVS (or a CFV-EFC-CVS), sample system with heat exchanger connected to a dilution tunnel. The heat exchanger is not required for the CFV-CVS or EFC-CFV-CVS if electronic flow controllers are used to maintain proportionality for the particulate sample. Figure B94-5 is a schematic drawing of the PDP system. Figure B94-6 is a schematic drawing of the CFV-CVS system. (Methanol-fueled Otto-cycle vehicles may be tested using this test equipment, without measuring particulate emissions.)

(2) Bag, continuous HFID (required for petroleum-fueled diesel-cycle and optional for methanol-fueled, natural gas-fueled and liquefied petroleum gas-fueled diesel-cycle vehicles), and particulate sampling capabilities as shown in Figure B94-5 (or Figure B94-6) are required to provide both gaseous and particulate emissions sampling capabilities from a single system.

(3) Petroleum-fueled diesel-cycle vehicles require a heated flame ionization detector (HFID) (375°±20°F (191°±11°C)) sample for total hydrocarbon (THC) analysis. The HFID sample must be taken directly from the diluted exhaust stream through a heated probe in the dilution tunnel.

(4) Methanol-fueled vehicles require the use of a heated flame ionization detector (HFID) (235°±15°F (113°±8°C)) for hydrocarbon analysis. With an HFID, the hydrocarbon analysis can be made on the bag sample and the methanol and formaldehyde analyses are performed on the samples collected for these purposes (Figures B94-2 and B94-3).

Note:

For 1990 through 1994 model year methanol-fueled vehicles, methanol and formaldehyde sampling may be omitted provided the bag sample is analyzed using a HFID calibrated with methanol.

(5) For methanol-fueled vehicles, the vehicle tailpipe-to-dilution tunnel connection shall be made by:

(i) A tailpipe to dilution tunnel duct of unrestricted length maintained at a temperature above the dew point of the mixture, but below 250°F (121°C) through heating and cooling as required; or

(ii) Using a short duct (up to 12 feet long) constructed of smooth wall pipe with a minimum of flexible sections maintained at a temperature above the dew point of the mixture, but below 250°F (121°C) prior to the test and during breaks in testing (insulation may remain in place and or heating may occur during the testing provided the maximum temperature is not exceeded); or

(iii) Using smooth wall duct less than five feet long with no required heating. A maximum of two short flexible connectors are allowed under this option; or

(iv) By omitting the duct and performing the exhaust gas dilution function at the vehicle tailpipe exit.

(6) For natural gas-fueled and liquefied petroleum gas-fueled diesel vehicles either a heated flame ionization detector (HFID) [375°±20°F (191°±11°C)] or a non-heated flame ionization detector may be used for hydrocarbon analysis.

(7) Since various configurations can produce equivalent results, exact conformance with these drawings is not required. Additional components such as instruments, valves, solenoids, pumps, and switches may be used to provide additional information and coordinate the functions of the component systems.

(8) Other sampling systems may be used if shown to yield equivalent or superior results and if approved in advance by the Administrator.

(b) Component description - petroleum-fueled, natural gas-fueled and liquefied petroleum gas-fueled vehicles. The components necessary for petroleum-fueled, natural gas-fueled and liquefied petroleum gas-fueled vehicle exhaust sampling shall meet the following requirements:

(1) The PDP-CVS, Figure B94-5, shall contain a proportional particulate sampling system, and shall conform to all of the requirements listed for the exhaust gas PDP-CVS (§86.109(b)), with one exception: a flow rate of sufficient volume is required to maintain the diluted exhaust stream, from which the particulate sample flow is taken, at a temperature of 125°F (52°C) or less.

(2) The CFV sample system, Figure B94-6, shall contain a proportional particulate sampling system, and shall conform to all of the requirements listed for the exhaust gas CFV sample system (§86.109(c)), except for the following:

(i) A flow rate of sufficient volume is required to maintain the diluted exhaust stream, from which the particulate sample flow is taken, at a temperature of 125°F (52°C) or less.

(ii) If a constant volume particulate sample is collected, a heat exchanger is required.

(iii) If a heat exchanger is used, the gas mixture temperature, measured at a point immediately ahead of the critical flow venturi, shall be within ±20°F (11°C) of the designed operating temperature at the start of the test. The gas mixture temperature variation from its value at the start of the test shall be limited to ±20°F (11°C) during the entire test. The temperature measuring system shall have an accuracy and precision of ±2°F (1.1°C).

(iv) The cyclonic separator is optional.

(3) For gasoline-fueled, natural gas-fueled and liquefied petroleum gas-fueled Otto-cycle and petroleum-fueled, natural gas- fueled and liquefied petroleum gas-fueled diesel-cycle vehicles, the transfer of heat from the vehicle exhaust gas shall be minimized between the point where it leaves the vehicle tailpipe(s) and the point where it enters the dilution tunnel airstream. To accomplish this, a short length (not more than 12 feet (365 cm) if uninsulated, or not more than 20 feet (610 cm) if insulated) of smooth stainless steel tubing from the tailpipe to the dilution tunnel is required. This tubing shall have a maximum inside diameter of 4.0 inches (10.2 cm). Short sections of flexible tubing at connection points are allowed.

(4) The vehicle exhaust shall be directed downstream at the point where it is introduced into the dilution tunnel.

(5) The dilution air shall be between 68°F (20°C) and 86°F (30°C) during the test.

(6) The dilution tunnel shall be:

(i) Sized to permit development of turbulent flow (Reynolds No. >>4000) and complete mixing of the exhaust and dilution air between the mixing orifice and each of the two sample probes (i.e., the particulate probe and the heated THC sample probe). It is recommended that uniform mixing be demonstrated by the user.

(ii) At least 8.0 inches (20.3 cm) in diameter.

(iii) Constructed of electrically conductive material which does not react with the exhaust components.

(iv) Grounded.

(7) The temperature of the diluted exhaust stream inside of the dilution tunnel shall be sufficient to prevent water condensation. However, the sample zone dilute exhaust temperature shall not exceed 125°F (52°C) at any time during the test.

(8) The particulate sample probe shall be:

(i) Installed facing upstream at a point where the dilution air and exhaust are well mixed (i.e., near the tunnel centerline, approximately 10 tunnel diameters downstream from the point where the exhaust enters the dilution tunnel).

(ii) Sufficiently distant (radially) from the THC probe (when the THC probe is required) so as to be free from the influence of any wakes or eddies produced by the THC probe.

(iii) 0.5 inch (1.27 cm) minimum inside diameter.

(iv) The distance from the sampling tip to the filter holder shall be at least 5 probe diameters (for filters located inside of the tunnel), but not more than 40.0 inches (102 cm) for filters located outside of the dilution tunnel.

(v) Free from sharp bends.

(vi) Configured so that a clean particulate filter (including back-up filter) can be selected simultaneously with the selection of an empty gaseous emissions bag.

(9) The flow rate through the particulate probe shall be maintained to a constant value within ±5 percent of the set flow rate.

(10) The particulate sample pump shall be located sufficiently distant from the dilution tunnel so that the inlet gas temperature is maintained at a constant temperature (±5.0°F (2.8°C)).

(11) The gas meters or flow instrumentation shall be located sufficiently distant from the tunnel so that the inlet gas temperature remains constant (±5.0°F (2.8°C)).

(12) The THC probe (when the THC probe is required) shall be:

(i) Installed facing upstream at a point where the dilution air and exhaust are well mixed (i.e., approximately 10 tunnel diameters downstream from the point where the exhaust enters the dilution tunnel).

(ii) Sufficiently distant (radially) from the particulate probe so as to be free from the influence of any wakes or eddies produced by the particulate probe.

(iii) Heated and insulated over the entire length to maintain a 375°±20°F (191°±11°C) wall temperature.

(iv) 0.19 in. (0.48 cm) minimum inside diameter.

(13) It is intended that the THC probe be free from cold spots (i.e., free from spots where the probe wall temperature is less than 355°F). This will be determined by a temperature sensor located on a section of the probe wall outside of the dilution tunnel. The temperature sensor shall be insulated from any heating elements on the probe. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(14) The dilute exhaust gas flowing in the THC sample system shall be:

(i) At 375°F±10°F (191°C±6°C) immediately before the heated filter. This will be determined by a temperature sensor located immediately upstream of the filter. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(ii) At 375°F±10°F (191°C ±6°C) immediately before the HFID. This will be determined by a temperature sensor located at the exit of the heated sample line. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(15) It is intended that the dilute exhaust gas flowing in the THC sample system be between 365°F and 385°F (185°C and 197°C).

(c) Component description - methanol-fueled vehicles. The components necessary for methanol-fueled vehicle exhaust sampling shall meet the following requirements:

(1) The PDP-CVS, Figure B94-5, shall contain a proportional particulate sampling system, and shall conform to all of the requirements listed for the exhaust gas PDP-CVS (§86.109), with one exception: a flow rate of sufficient volume is required to maintain the diluted exhaust stream, from which the particulate sample flow is taken, at a temperature of 125°F (52°C) or less.

(2) The CFV-CVS sample system, Figure B94-6, shall contain a proportional particulate sampling system, and shall conform to all of the requirements listed for the exhaust gas CFV sample system (§86.109), except for the following:

(i) A flow rate of sufficient volume is required to maintain the diluted exhaust stream, from which the particulate sample flow is taken, at a temperature of 125°F (52°C) or less.

(ii) If a constant volume particulate sample is collected, a heat exchanger is required.

(iii) If a heat exchanger is used, the gas mixture temperature, measured at a point immediately ahead of the critical flow venturi, shall be within ±20°F (11°C) of the designed operating temperature at the start of the test. The gas mixture temperature variation from its value at the start of the test shall be limited to ±20°F (11°C) during the entire test. The temperature measuring system shall have an accuracy and precision of ±2°F (1.1°C).

(iv) The cyclonic separator is optional.

(3) The EFC-CFV-CVS sample system shall conform to all of the requirements listed for the exhaust gas EFC sample system (§86.109) with three exceptions:

(i) A flow rate of sufficient volume is required to maintain the diluted exhaust stream, from which the particulate sample flow is taken, at a temperature of 125°F (52°C) or less.

(ii) A proportional particulate sample shall be collected using an electronic flow controller that meets the performance criteria listed in §86.109 for methanol and formaldehyde EFC systems.

(iii) The cyclonic separator is optional.

(4) Losses of methanol due to condensation of water in the duct connecting the vehicle tail pipe to the dilution tunnel must be eliminated. This may be accomplished by:

(i) The use of a duct of unrestricted length maintained at a temperature above the maximum dew point of the exhaust, but below 250°F (121°C), through heating and cooling as required; or

(ii) The use of a short duct (up to 12 feet long) constructed of smooth wall pipe with a minimum of flexible sections maintained at a temperature above the maximum dew point of the exhaust, but below 250°F (121°C), prior to the test and during breaks in testing (insulation may remain in place and/or heating may occur during testing provided maximum temperature is not exceeded); or

(iii) Using smooth wall duct less than five feet long with no required heating. A maximum of two short flexible connectors are allowed under this option; or

(iv) Omitting the duct and performing the exhaust gas dilution function at the vehicle tailpipe exit.

(5) The vehicle exhaust shall be directed downstream at the point where it is introduced into the dilution tunnel.

(6) The dilution air shall be between 68°F (20°C) and 86°F (30°C) during the test (unless the requirements of §86.109-94(b)(4) are also met).

(7) The dilution tunnel shall be:

(i) Sized to permit development of turbulent flow (Reynold's No. >>4000) and complete mixing of the exhaust and dilution air between the mixing orifice and the particulate sample probe. It is recommended that uniform mixing be demonstrated by the user.

(ii) At least 8.0 inches (20.3 cm) in diameter.

(iii) Constructed of electrically conductive material which does not react with the exhaust components.

(iv) Grounded.

(8) The temperature of the diluted exhaust stream inside of the dilution tunnel shall be sufficient to prevent water condensation. However, the sample zone dilute exhaust temperature shall not exceed 125°F (52°C) at any time during the test.

(9) The particulate sample probe shall be:

(i) Installed facing upstream at a point where the dilution air and exhaust are well mixed (i.e., near the tunnel centerline, approximately 10 tunnel diameters downstream from the point where the exhaust enters the dilution tunnel).

(ii) Sufficiently distant (radially) from the THC probe so as to be free from the influence of any wakes or eddies produced by the THC probe.

(iii) 0.5 inch (1.27 cm) minimum inside diameter.

(iv) The distance from the sampling tip to the filter holder shall be at least five probe diameters (for filters located inside the tunnel), but not more than 40.0 inches (102 cm) for filters located outside of the dilution tunnel.

(v) Free from sharp bends.

(vi) Configured so that a clean particulate filter (including back up filter) can be selected simultaneously with the selection of an empty gaseous emissions bag.

(10) The flow rate through the particulate probe shall be maintained to a constant value within ±5 percent of the set flow rate.

(11) The particulate sample pump shall be located sufficiently distant from the dilution tunnel so that the inlet gas temperature is maintained at a constant temperature (±5.0°F (2.8°C)).

(12) The gas meters or flow instrumentation shall be located sufficiently distant from the tunnel so that the inlet gas temperature remains constant (±5.0°F (2.8°C)).

(13) The hydrocarbon probe shall be:

(i) Installed facing upstream at a point where the dilution air and exhaust are well mixed (i.e., approximately ten tunnel diameters downstream from the point where the exhaust enters the dilution tunnel).

(ii) Sufficiently distant (radially) from the particulate probe so as to be free from the influence of any wakes of eddies produced by the particulate probe.

(iii) Heated and insulated over the entire length to maintain a wall temperature more than 5°F (3°C) above the maximum dew point of the sample, but below 250°F (121°C).

(iv) 0.19 in. (0.48 cm) minimum inside diameter.

(14) It is intended that the THC probe be free from cold spots (i.e., free from cold spots where the probe wall temperature is less than 5°F (3°C) above the maximum dew point of the sample.) This will be determined by a temperature sensor located on a section of the probe wall outside of the dilution tunnel. The temperature sensor shall be insulated from any heating elements on the probe. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(15) The dilute exhaust gas flowing in the hydrocarbon sample system shall be:

(i) At 235°F ±15°F (113°C ±8°C) immediately before the heated filter. This will be determined by a temperature sensor located immediately upstream of the filter. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(ii) At 235° ±15°F (113°C ±8°C) immediately before the HFID. This will be determined by a temperature sensor located at the exit of the heated sample line. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(16) It is intended that the dilute exhaust gas flowing in the hydrocarbon sample system between 220°F and 250°F (105°C and 121°C).

(17) For methanol-fueled vehicles, bag sampling procedures for the measurement of hydrocarbons as described in §86.109 may be employed.

(d) Filters, particulate sampling. Use fluorocarbon-coated glass fiber filters or fluorocarbon-based (membrane) filters to collect particulate matter, as follows:

(1) Use primary and back-up test filters as follows for particulate measurements:

(i) During each phase of the UDDS, sample dilute exhaust simultaneously with paired primary and back-up test filters.

(ii) Position the back-up filter holder 3 to 4 inches downstream of the primary filter holder.

(iii) Determine the net weight of particulate material collected on each primary test filter and each back-up test filter using the procedure described in §86.139.

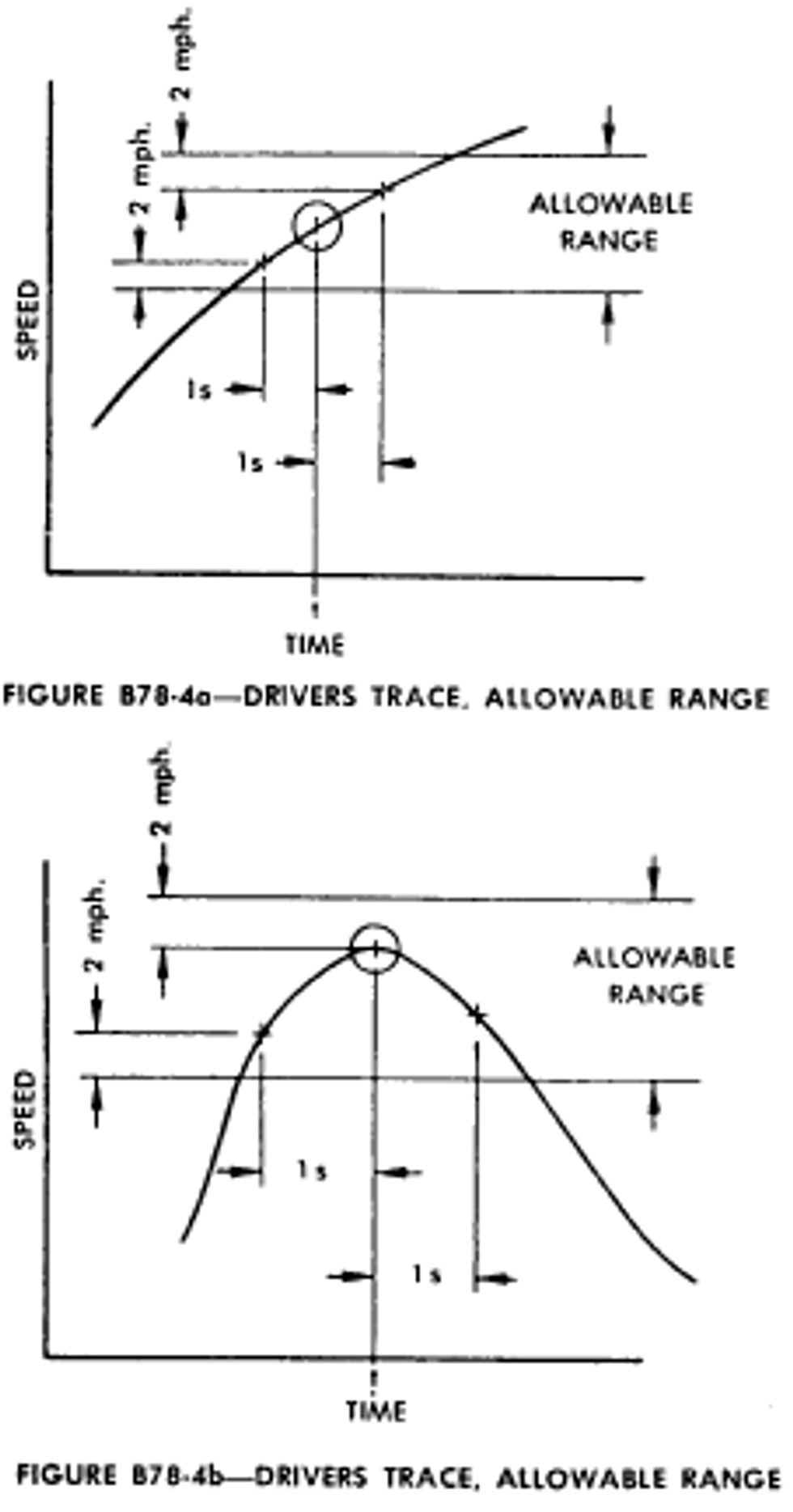

(iv) Determine a ratio of net weights using the following formula:

(v) If the ratio is greater than 0.95, base the particulate emission calculations on the net weight of the primary filter only.

(vi) If the ratio is less than 0.95, base the particulate emission calculations on the combined net weights of the back-up test filter and the primary test filter.

(2) The particulate filter must have a 47 mm diameter (37 mm stain area).

[56 FR 25767, June 5, 1991, as amended at 59 FR 48505, Sept. 21, 1994; 60 FR 34342, June 30, 1995; 79 FR 23692, Apr. 28, 2014]

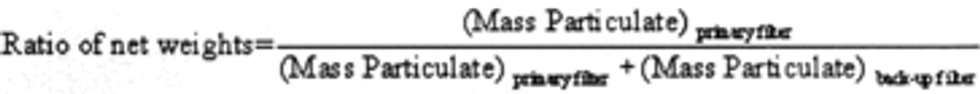

§86.111-94 Exhaust gas analytical system.

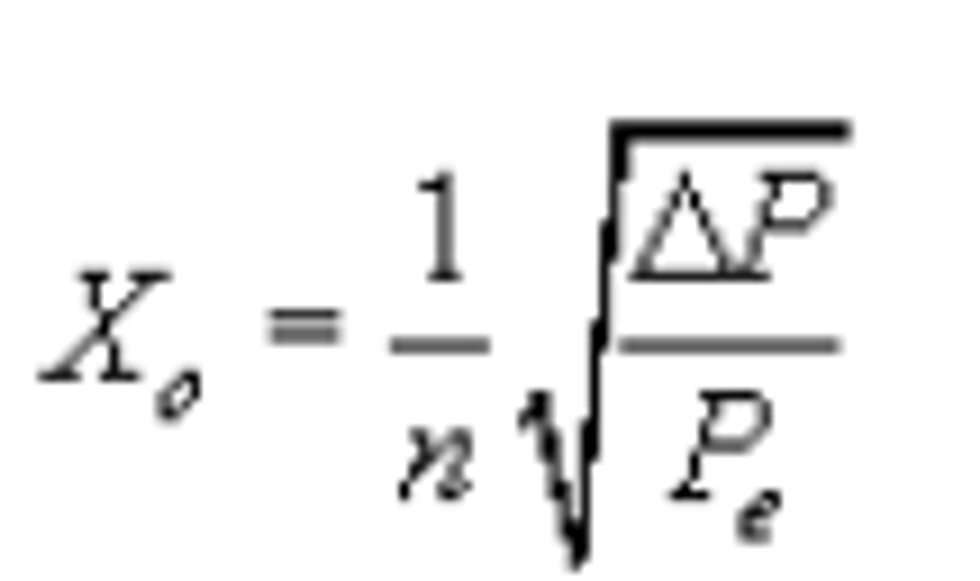

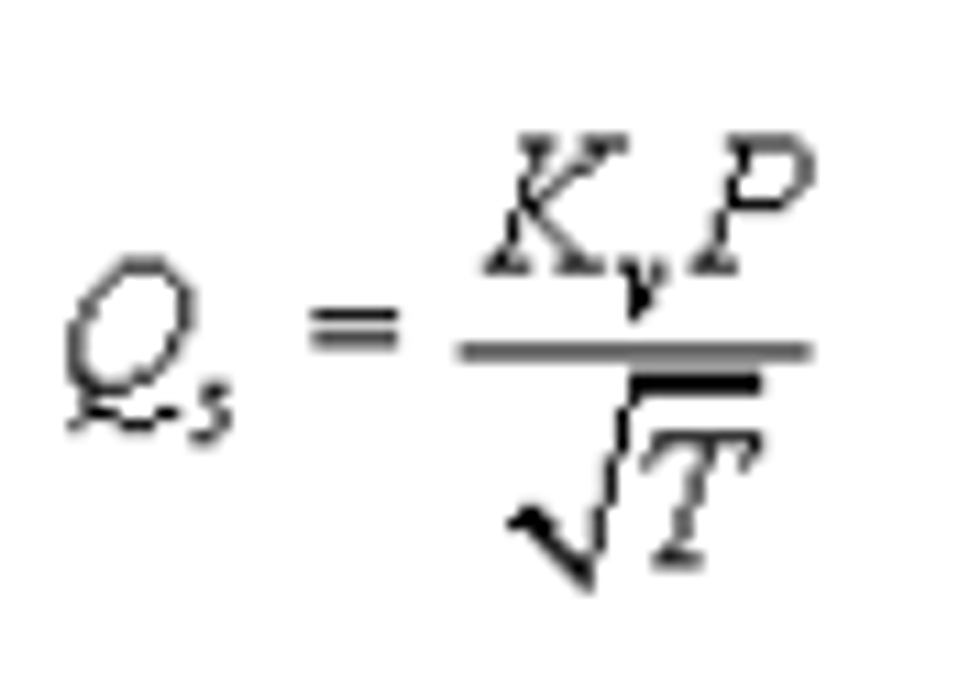

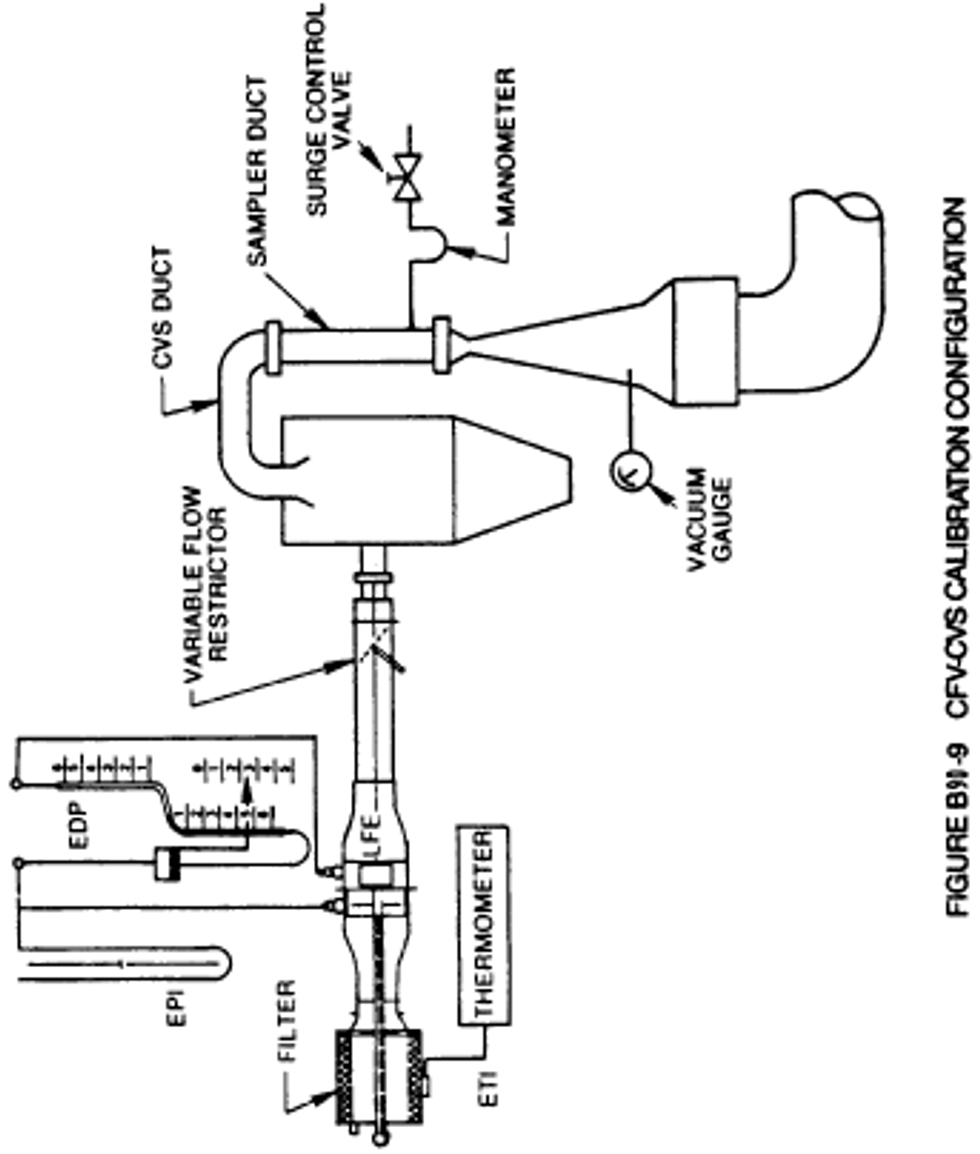

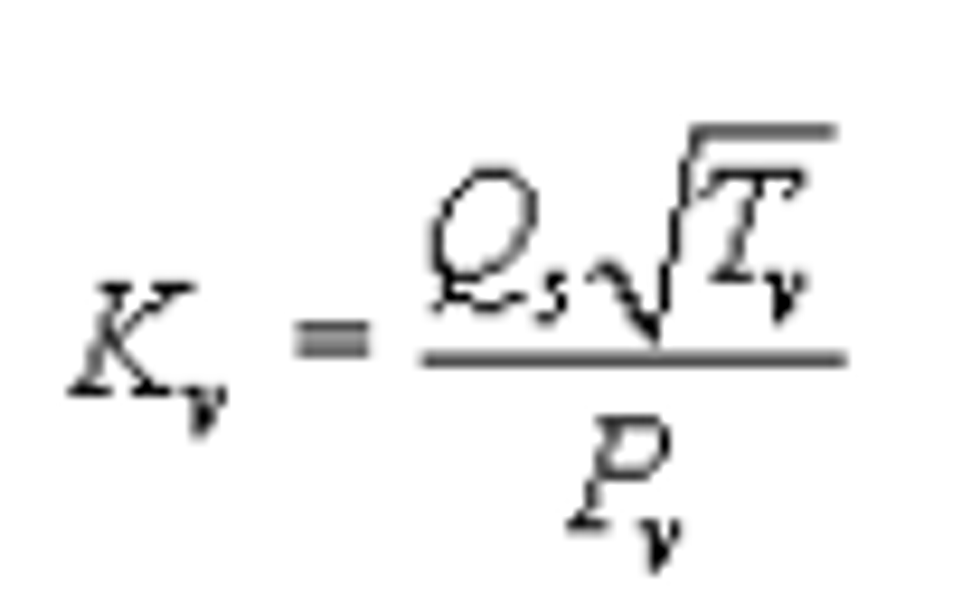

Section 86.111-94 includes text that specifies requirements that differ from §86.111-90. Where a paragraph in §86.111-90 is identical and applicable to §86.111-94, this may be indicated by specifying the corresponding paragraph and the statement “[Reserved]. For guidance see §86.111-90.” Where a corresponding paragraph of §86.111-90 is not applicable, this is indicated by the statement “[Reserved].”