['Air Programs']

['Air Emissions']

06/26/2024

...

(a) See the standard-setting part for drive schedules. These are defined by a smooth fit of a specified speed vs. time sequence.

(b) The driver must attempt to follow the target schedule as closely as possible, consistent with the specifications in paragraph (b) of this section. Instantaneous speeds must stay within the following tolerances:

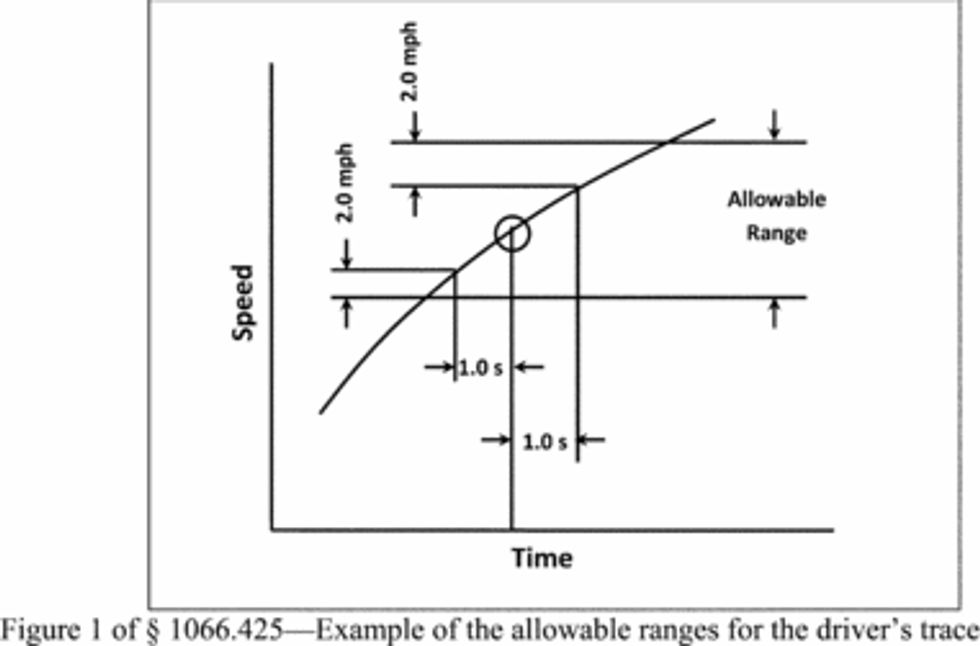

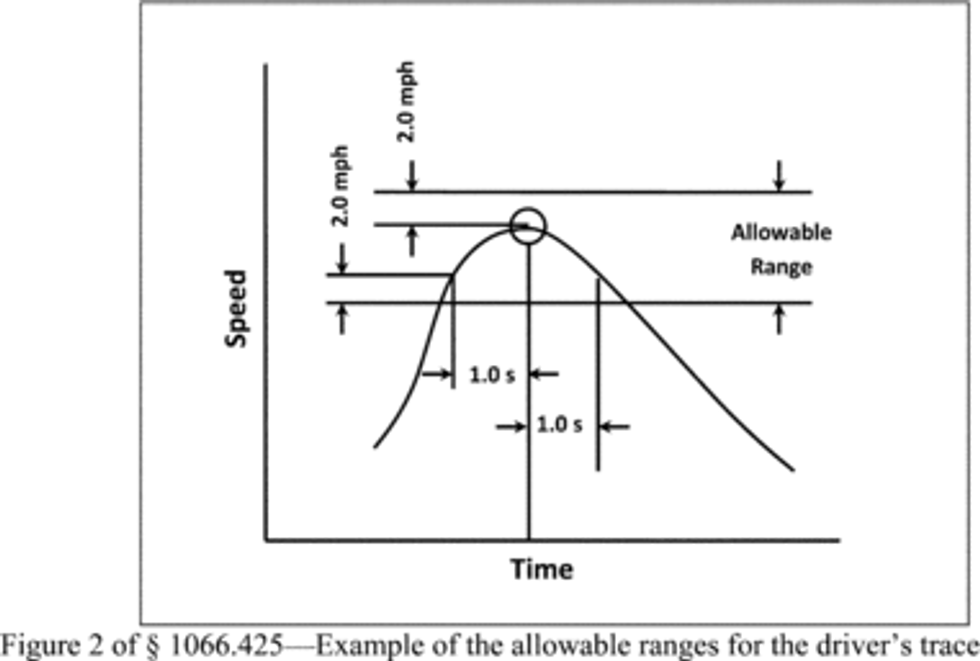

(1) The upper limit is 2.0 mi/hr higher than the highest point on the trace within 1.0 s of the given point in time.

(2) The lower limit is 2.0 mi/hr lower than the lowest point on the trace within 1.0 s of the given time.

(3) The same limits apply for vehicle operation without exhaust measurements, such as vehicle preconditioning and warm-up, except that the upper and lower limits for speed values are ±4.0 mi/hr. In addition, up to three occurrences of speed variations greater than the tolerance are acceptable for vehicle operation in which no exhaust emission standards apply, as long as they occur for less than 15 seconds on any occasion and are clearly documented as to the time and speed at that point of the driving schedule.

(4) Void the test if you do not maintain speed values as specified in this paragraph (b), except as allowed by this paragraph (b)(4). Speed variations (such as may occur during gear changes or braking spikes) may occur as follows, as long as such variations are clearly documented, including the time and speed values and the reason for the deviation:

(i) Speed variations greater than the specified limits are acceptable for up to 2.0 seconds on any occasion.

(ii) For vehicles that are not able to maintain acceleration as specified in §1066.415(e)(5), do not count the insufficient acceleration as being outside the specified limits.

(5) We may approve an alternate test cycle and cycle-validation criteria for vehicles that do not have enough power to follow the specified driving trace. The alternate driving specifications must be based on making best efforts to maintain acceleration and speed to follow the specified test cycle. We must approve these alternate driving specifications before you perform this testing.

(c) Figure 1 and Figure 2 of this section show the range of acceptable speed tolerances for typical points during testing. Figure 1 of this section is typical of portions of the speed curve that are increasing or decreasing throughout the 2-second time interval. Figure 2 of this section is typical of portions of the speed curve that include a maximum or minimum value.

(d) Start testing as follows:

(1) If a vehicle is already running and warmed up, and starting is not part of the test cycle, operate the vehicle as follows:

(i) For transient test cycles, control vehicle speeds to follow a drive schedule consisting of a series of idles, accelerations, cruises, and decelerations.

(ii) For cruise test cycles, control the vehicle operation to match the speed of the first interval of the test cycle. Follow the instructions in the standard-setting part to determine how long to stabilize the vehicle during each interval, how long to sample emissions at each interval, and how to transition between intervals.

(2) If engine starting is part of the test cycle, start recording continuous data, turn on any electronic integrating devices, and start batch sampling before starting the engine. Initiate the driver's trace when the engine starts.

(e) Perform the following at the end of each test interval, except as specified in standard-setting part:

(1) Shut down the vehicle if it is part of the test cycle or if testing is complete.

(2) Continue to operate all sampling and dilution systems to allow the response times to elapse. Then stop all sampling and recording, including background sampling. Finally, stop any integrating devices and indicate the end of the duty cycle in the recorded data.

(f) If testing involves engine shutdown followed by another test interval, start a timer for the vehicle soak when the engine shuts down. Turn off cooling fans, close the engine compartment cover (if applicable), and turn off the CVS or disconnect the exhaust tube from the vehicle's tailpipe(s) unless otherwise instructed in the standard-setting part. If testing is complete, disconnect the laboratory exhaust tubing from the vehicle's tailpipe(s) and drive the vehicle from the dynamometer.

(g) Take the following steps after emission sampling is complete:

(1) For any proportional batch sample, such as a bag sample or PM sample, verify that proportional sampling was maintained according to 40 CFR 1065.545. Void any samples that did not maintain proportional sampling according to those specifications.

(2) Place any used PM samples into covered or sealed containers and return them to the PM-stabilization environment. Follow the PM sample post-conditioning and total weighing procedures in 40 CFR 1065.595.

(3) As soon as practical after the interval or test cycle is complete, or optionally during the soak period if practical, perform the following:

(i) Begin drift check for all continuous gas analyzers as described in paragraph (g)(5) of this section and zero and span all batch gas analyzers as soon as practical before any batch sample analysis. You may perform this batch analyzer zero and span before the end of the test interval.

(ii) Analyze any conventional gaseous batch samples (HC, CH4, CO, NOX, and CO2) no later than 30 minutes after a test interval is complete, or during the soak period if practical. Analyze background samples no later than 60 minutes after the test interval is complete.

(iii) Analyze nonconventional gaseous batch samples (including background), such as NMHCE, N2O, or NMOG sampling with ethanol, as soon as practicable using good engineering judgment.

(4) If an analyzer operated above 100% of its range at any time during the test, perform the following steps:

(i) For batch sampling, re-analyze the sample using the lowest analyzer range that results in a maximum instrument response below 100%. Report the result from the lowest range from which the analyzer operates below 100% of its range.

(ii) For continuous sampling, repeat the entire test using the next higher analyzer range. If the analyzer again operates above 100% of its range, repeat the test using the next higher range. Continue to repeat the test until the analyzer consistently operates at less than 100% of its range. Keep records of any tests where the analyzer exceeds its range. We may consider these results to determine that the test vehicle exceeded an emission standard, consistent with good engineering judgment.

(5) After quantifying exhaust gases, verify drift as follows:

(i) For batch and continuous gas analyzers, record the mean analyzer value after stabilizing a zero gas to the analyzer. Stabilization may include time to purge the analyzer of any sample gas, plus any additional time to account for analyzer response.

(ii) Record the mean analyzer value after stabilizing the span gas to the analyzer. Stabilization may include time to purge the analyzer of any sample gas, plus any additional time to account for analyzer response.

(iii) Use these data to verify that analyzer drift does not exceed 2.0% of the analyzer full scale.

(h) Measure and record ambient pressure. Measure and record ambient temperature continuously to verify that it remains within the temperature range specified in §1066.420(c)(1) throughout the test. Also measure humidity if required, such as for correcting NOX emissions, or meeting the requirements of §1066.420(d).

(i) [Reserved]

(j) For vehicles at or below 14,000 pounds GVWR, determine overall driver accuracy as follows:

(1) Compare the following drive-cycle metrics, based on measured vehicle speeds, to a reference value based on the target cycle that would have been generated by driving exactly to the target trace as described in SAE J2951 (incorporated by reference, see §1066.1010):

(i) Determine the Energy Economy Rating as described in Section 5.4 of SAE J2951.

(ii) Determine the Absolute Speed Change Rating as described in Section 5.5 of SAE J2951.

(iii) Determine the Inertia Work Rating as described in Section 5.6 of SAE J2951.

(iv) Determine the phase-weighted composite Energy Based Drive Metrics for the criteria specified in this paragraph (j)(1) as described in Section 5.7 of SAE J2951.

(2) The standard-setting part may require you to give us 10 Hz data to characterize both target and actual values for cycle energy. Calculate target values based on the vehicles speeds from the specified test cycle.

[79 FR 23823, Apr. 28, 2016, as amended at 81 FR 74203, Oct. 25, 2016; 89 FR 28212, Apr. 18, 2024]

READ MORESHOW LESS

['Air Programs']

['Air Emissions']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.