['Air Programs']

['Air Emissions']

03/21/2023

...

§1066.401 Overview.

(a) Use the procedures detailed in this subpart to measure vehicle emissions over a specified drive schedule. Different procedures may apply for criteria pollutants andgreenhouse gas emissions as described in the standard-setting part. This subpart describes how to -

(1) Determine road-load power, test weight, and inertia class.

(2) Prepare the vehicle, equipment, and measurement instruments for an emission test.

(3) Perform pre-test procedures to verify proper operation of certain equipment and analyzers and to prepare them for testing.

(4) Record pre-test data.

(5) Sample emissions.

(6) Record post-test data.

(7) Perform post-test procedures to verify proper operation of certain equipment and analyzers.

(8) Weigh PM samples.

(b) The overall test generally consists of prescribed sequences of fueling, parking, and driving at specified test conditions. An exhaust emission test generally consists of measuring emissions and other parameters while a vehicle follows the drive schedules specified in the standard-setting part. There are two general types of test cycles:

(1) Transient cycles. Transient test cycles are typically specified in the standard-setting part as a second-by-second sequence of vehicle speed commands. Operate a vehicle over a transient cycle such that the speed follows the target values. Proportionally sample emissions and other parameters and calculate emission rates as specified in subpart G of this part to calculate emissions. The standard-setting part may specify three types of transient testing based on the approach to starting the measurement, as follows:

(i) A cold-start transient cycle where you start to measure emissions just before starting an engine that has not been warmed up.

(ii) A hot-start transient cycle where you start to measure emissions just before starting a warmed-up engine.

(iii) A hot-running transient cycle where you start to measure emissions after an engine is started, warmed up, and running.

(2) Cruise cycles. Cruise test cycles are typically specified in the standard-setting part as a discrete operating point that has a single speed command.

(i) Start a cruise cycle as a hot-running test, where you start to measure emissions after the engine is started and warmed up and the vehicle is running at the target test speed.

(ii) Sample emissions and other parameters for the cruise cycle in the same manner as a transient cycle, with the exception that the reference speed value is constant. Record instantaneous and mean speed values over the cycle.

§1066.405 Vehicle preparation, preconditioning, and maintenance.

(a) Prepare the vehicle for testing (including measurement of evaporative and refueling emissions if appropriate), as described in the standard-setting part.

(b) If you inspect a vehicle, keep a record of the inspection and update your application for certification to document any changes that result. You may use any kind of equipment, instrument, or tool that is available at dealerships and other service outlets to identify malfunctioning components or perform maintenance.

(c) You may repair defective parts from a test vehicle if they are unrelated to emission control. You must ask us to approve repairs that might affect the vehicle's emission controls. If we determine that a part failure, system malfunction, or associated repair makes the vehicle's emission controls unrepresentative of production engines, you may not use it as an emission-data vehicle. Also, if the engine installed in the test vehicle has a major mechanical failure that requires you to take the vehicle apart, you may no longer use the vehicle as an emission-data vehicle for exhaust measurements.

[86 FR 34582, Jun. 29, 2021]

§1066.410 Dynamometer test procedure.

(a) Dynamometer testing may consist of multiple drive cycles with both cold-start and hot-start portions, including prescribed soak times before each test interval. The standard-setting part identifies the driving schedules and the associated sample intervals, soak periods, engine startup and shutdown procedures, and operation of accessories, as applicable. Not every test interval includes all these elements.

(b) Place the vehicle onto the dynamometer without starting the engine (for any test cycles) or drive the vehicle onto the dynamometer (for hot-start and hot-running cycles only) and position a fan that directs cooling air to the vehicle during dynamometer operation as described in this paragraph (b). This generally requires squarely positioning the fan in front of the vehicle and directing the airflow to the vehicle's radiator. Use good engineering judgment to design and configure fans to cool the test vehicle in a way that properly simulates in-use operation, consistent with the specifications of §1066.105. Except for the following special cases, use a road-speed modulated fan meeting the requirements of §1066.105(c)(2) that is placed within 90 cm of the front of the vehicle and ensure that the engine compartment cover (i.e., hood) is closed:

(1) For vehicles above 14,000 pounds GVWR, use a fan meeting the requirements of §1066.105(d) that is placed within 90 cm of the front of the vehicle and ensure that the engine compartment cover is closed.

(2) For FTP, LA-92, US06, or HFET testing of vehicles at or below 14,000 pounds GVWR, you may use a fixed-speed fan as specified in the following table, with the engine compartment cover open:

| Test cycle |

Maximum fan

capacity | Approximate distance from the front of the vehicle |

|---|---|---|

| FTP | Up to 2.50 m 3/s | 0 to 30 cm. |

| US06 | Up to 7.10 m 3/s | 0 to 60 cm. |

| LA-92 | Up to 7.10 m 3/s | 0 to 60 cm. |

| HFET | Up to 2.50 m 3/s | 0 to 30 cm. |

(3) For SC03 and AC17 testing, use a road-speed modulated fan meeting the requirements of §1066.105(c)(5) that is placed within 60 to 90 cm of the front of the vehicle and ensure that the engine compartment cover is closed. Position the discharge nozzle such that its lowest point is not more than 16 cm above the floor of the test cell.

(c) Record the vehicle's speed trace based on the time and speed data from the dynamometer at the recording frequencies given in Table 1 of §1066.125. Record speed to at least the nearest 0.01 mi/hr and time to at least the nearest 0.1 s.

(d) You may perform practice runs for operating the vehicle and the dynamometer controls to meet the driving tolerances specified in §1066.425 or adjust the emission sampling equipment. Verify that the accelerator pedal allows for enough control to closely follow the prescribed driving schedule. We recommend that you verify your ability to meet the minimum dilution factor requirements of §1066.110(b)(2)(iii)(B) during these practice runs.

(e) Inflate tires on drive wheels according to the vehicle manufacturer's specifications. The tire pressure for drive wheels must be the same for dynamometer operation and for dynamometer coastdown procedures used for determining road-load coefficients. Report these measured tire pressure values with the test results.

(f) Tie down or load the test vehicle as needed to provide a normal force at the tire and dynamometer roll interface to prevent wheel slip. For vehicles above 14,000 pounds GVWR, report this measured force with the test results.

(g) Use good engineering judgment when testing vehicles in four-wheel drive or all-wheel drive mode. (For purposes of this paragraph (g), the term four-wheel drive includes other multiple drive-axle configurations.) This may involve testing on a dynamometer with a separate dynamometer roll for each drive axle; or two drive axles may use a single roll, as described in §1066.210(d)(1); or you may deactivate the second set of drive wheels and operate the vehicle on a single roll. For all vehicles at or below 14,000 GVWR, we will test your vehicle using the same dynamometer roll arrangement that you used. We may also test your vehicle using another dynamometer roll arrangement for information-gathering purposes. If we choose to perform additional testing that requires vehicle modifications, we will ask you to configure the vehicle appropriately.

(h) Determine equivalent test weight as follows:

(1) For vehicles at or below 14,000 pounds GVWR, determine ETW as described in §1066.805. Set dynamometer vehicle inertia, I, based on dynamometer type, as follows:

(i) For two-wheel drive dynamometers, set I = ETW.

(ii) For four-wheel drive dynamometers, set I = 0.985 · ETW.

(2) For vehicles above 14,000 pounds GVWR, determine the vehicle's effective mass as described in §1066.310 and use this as the test weight.

(i) Warm up the dynamometer as recommended by the dynamometer manufacturer.

(j) Following the test, determine the actual driving distance by counting the number of dynamometer roll or shaft revolutions, or by integrating speed over the course of testing from a high-resolution encoder system.

[79 FR 23823, Apr. 28, 2014, as amended at 80 FR 9121, Feb. 19, 2015; 81 FR 74202, Oct. 25, 2016]

§1066.415 Vehicle operation.

This section describes how to test a conventionally configured vehicle (vehicles with transmission shifters, foot pedal accelerators, etc). You may ask us to modify these procedures for vehicles that do not have these control features.

(a) Start the vehicle as follows:

(1) At the beginning of the test cycle, start the vehicle according to the procedure described in the owners manual. In the case of HEVs, this would generally involve activating vehicle systems such that the engine will start when the vehicle's control algorithms determine that the engine should provide power instead of or in addition to power from the rechargeable energy storage system (RESS). Unless we specify otherwise, engine starting throughout this part generally refers to this step of activating the system on HEVs, whether or not that causes the engine to start running.

(2) Place the transmission in gear as described by the test cycle in the standard-setting part. During idle operation, apply the brakes if necessary to keep the drive wheels from turning.

(b) If the vehicle does not start after your recommended maximum cranking time, wait and restart cranking according to your recommended practice. If you do not recommend such a cranking procedure, stop cranking after 10 seconds, wait for 10 seconds, then start cranking again for up to 10 seconds. You may repeat this for up to three start attempts. If the vehicle does not start after three attempts, you must determine and record the reason for failure to start. Shut off sampling systems and either turn the CVS off or disconnect the laboratory exhaust tubing from the tailpipe during the diagnostic period to prevent flow through the exhaust system. Reschedule the vehicle for testing. This may require performing vehicle preparation and preconditioning if the testing needs to be rerun from a cold start. If failure to start occurs during a hot-start test, you may reschedule the hot-start test without repeating the cold-start test, as long as you bring the vehicle to a hot-start condition before starting the hot-start test.

(c) Repeat the recommended starting procedure if the engine has a false start (i.e., an incomplete start).

(d) Take the following steps if the engine stalls:

(1) If the engine stalls during an idle period, restart the engine immediately and continue the test. If you cannot restart the engine soon enough to allow the vehicle to follow the next acceleration, stop the driving schedule indicator and reactivate it when the vehicle restarts.

(2) Void the test if the vehicle stalls during vehicle operation. If this happens, remove the vehicle from the dynamometer, take corrective action, and reschedule the vehicle for testing. Record the reason for the malfunction (if determined) and any corrective action. See the standard-setting part for instructions about reporting these malfunctions.

(e) Operate vehicles during testing as follows:

(1) Where we do not give specific instructions, operate the vehicle according to the recommendations in the owners manual, unless those recommendations are unrepresentative of what may reasonably be expected for in-use operation.

(2) If vehicles have features that preclude dynamometer testing, you may modify these features as necessary to allow testing, consistent with good engineering judgment, as long as it does not affect your ability to demonstrate that your vehicles comply with the applicable standards in this chapter. Send us written notification describing these changes along with supporting rationale.

(3) Operate vehicles during idle as follows:

(i) For vehicles with automatic transmission, operate at idle with the transmission in “Drive” with the wheels braked, except that you may shift to “Neutral” for the first idle period and for any idle period longer than one minute. If you put the vehicle in “Neutral” during an idle, you must shift the vehicle into “Drive” with the wheels braked at least 5 seconds before the end of the idle period. Note that this does not preclude vehicle designs involving engine shutdown during idle.

(ii) For vehicles with manual transmission, operate at idle with the transmission in gear with the clutch disengaged, except that you may shift to “Neutral” with the clutch engaged for the first idle period and for any idle period longer than one minute. If you put the vehicle in “Neutral” during idle, you must shift to first gear with the clutch disengaged at least 5 seconds before the end of the idle period. Note that this does not preclude vehicle designs involving engine operation with shutdown during idle.

(4) Operate the vehicle with the appropriate accelerator pedal movement necessary to follow the scheduled speeds in the driving schedule. Avoid smoothing speed variations and unnecessary movement of the accelerator pedal.

(5) Operate the vehicle smoothly, following representative shift speeds and procedures. For manual transmissions, the operator shall release the accelerator pedal during each shift and accomplish the shift without delay. If the vehicle cannot accelerate at the specified rate, operate it at maximum available power until the vehicle speed reaches the value prescribed in the driving schedule.

(6) Decelerate as follows:

(i) For vehicles with automatic transmission, use the brakes or accelerator pedal as necessary, without manually changing gears, to maintain the desired speed.

(ii) For vehicles with manual transmission, shift gears in a way that represents reasonable shift patterns for in-use operation, considering vehicle speed, engine speed, and any other relevant variables. Disengage the clutch when the speed drops below 15 mi/hr, when engine roughness is evident, or when good engineering judgment indicates the engine is likely to stall. Manufacturers may recommend shift guidance in the owners manual that differs from the shift schedule used during testing, as long as both shift schedules are described in the application for certification; in this case, we may shift during testing as described in the owners manual.

[79 FR 23823, Apr. 28, 2016, as amended at 81 FR 74202, Oct. 25, 2016; 88 FR 4708, Jan. 24, 2023]

§1066.420 Test preparation.

(a) Follow the procedures for PM sample preconditioning and tare weighing as described in 40 CFR 1065.590 if you need to measure PM emissions.

(b) Minimize the effect of nonmethane hydrocarbon contamination in the hydrocarbon sampling system for vehicles with compression-ignition engines as follows:

(1) For vehicles at or below 14,000 pounds GVWR, account for contamination using one of the following methods:

(i) Introduce zero and span gas during analyzer calibration using one of the following methods, noting that the hydrocarbon analyzer flow rate and pressure during zero and span calibration (and background bag reading) must be exactly the same as that used during testing to minimize measurement errors:

(A) Close off the hydrocarbon sampling system sample probe and introduce gases downstream of the probe making sure that you do not pressurize the system.

(B) Introduce zero and span gas directly at the hydrocarbon sampling system probe at a flow rate greater than 125% of the hydrocarbon analyzer flow rate allowing some gas to exit probe inlet.

(ii) Perform the contamination verification in paragraph (b)(2) of this section, except use 0.5 μmol/mol in 40 CFR 1065.520(f)(8)(iii).

(2) For vehicles above 14,000 pounds GVWR, verify the amount of nonmethane hydrocarbon contamination as described in 40 CFR 1065.520(f).

(c) Unless the standard-setting part specifies different tolerances, verify at some point before the test that ambient conditions are within the tolerances specified in this paragraph (c). For purposes of this paragraph (c), “before the test” means any time from a point just prior to engine starting (excluding engine restarts) to the point at which emission sampling begins.

(1) Ambient temperature must be (20 to 30)°C. See §1066.425(h) for circumstances under which ambient temperatures must remain within this range during the test.

(2) Dilution air conditions must meet the specifications in §1066.110(b)(2). We recommend verifying dilution air conditions just before starting each test interval.

(d) Control test cell ambient air humidity as follows:

(1) For vehicles at or below 14,000 pounds GVWR, follow the humidity requirements in Table 1 of this section, unless the standard-setting part specifies otherwise. When complying with humidity requirements in Table 1, where no tolerance is specified, use good engineering judgment to maintain the humidity level near the specified value within the limitations of your test facility.

(2) For vehicles above 14,000 pounds GVWR, you may test vehicles at any humidity.

(3) Table 1 follows:

| Test cycle | Humidity requirement (grains H2O per pound dry air) | Tolerance (grains H2O per pound dry air) |

|---|---|---|

| a FTP humidity requirement does not apply for cold (-7°C), intermediate (10°C), and hot (35°C) temperature testing. | ||

| AC17 | 69 | ±5 average, ±10 instantaneous. |

| FTP a and LA-92 | 50 | |

| HFET | 50 | |

| SC03 | 100 | ±5 average. |

| US06 | 50 | |

(e) You may perform a final calibration of proportional-flow control systems, which may include performing practice runs.

(f) You may perform the following procedure to precondition sampling systems:

(1) Operate the vehicle over the test cycle.

(2) Operate any dilution systems at their expected flow rates. Prevent aqueous condensation in the dilution systems as described in 40 CFR 1065.140(c)(6), taking into account allowances given in §1066.110(b)(2)(iv).

(3) Operate any PM sampling systems at their expected flow rates.

(4) Sample PM using any sample media. You may change sample media during preconditioning. You must discard preconditioning samples without weighing them.

(5) You may purge any gaseous sampling systems during preconditioning.

(6) You may conduct calibrations or verifications on any idle equipment or analyzers during preconditioning.

(g) Take the following steps before emission sampling begins:

(1) For batch sampling, connect clean storage media, such as evacuated bags or tare-weighed filters.

(2) Start all measurement instruments according to the instrument manufacturer's instructions and using good engineering judgment.

(3) Start dilution systems, sample pumps, and the data-collection system.

(4) Pre-heat or pre-cool heat exchangers in the sampling system to within their operating temperature tolerances for a test.

(5) Allow heated or cooled components such as sample lines, filters, chillers, and pumps to stabilize at their operating temperatures.

(6) Adjust the sample flow rates to desired levels using bypass flow, if desired.

(7) Zero or re-zero any electronic integrating devices before the start of any test interval.

(8) Select gas analyzer ranges. You may not switch the gain of an analyzer's analog operational amplifier(s) during a test. However, you may switch (automatically or manually) gas analyzer ranges during a test if such switching changes only the range over which the digital resolution of the instrument is applied. For batch analyzers, select ranges before final bag analysis.

(9) Zero and span all continuous gas analyzers using gases that meet the specifications of 40 CFR 1065.750. For FID analyzers, you may account for the carbon number of your span gas either during the calibration process or when calculating your final emission value. For example, if you use a C3H8 span gas of concentration 200 ppm (µmol/mol), you may span the FID to respond with a value of 600 ppm (µmol/mol) of carbon or 200 ppm of propane. However, if your FID response is equivalent to propane, include a factor of three to make the final calculated hydrocarbon mass consistent with a molar mass of 13.875389. When utilizing an NMC-FID, span the FID analyzer consistent with the determination of their respective response factors, RF, and penetration fractions, PF, according to 40 CFR 1065.365.

(10) We recommend that you verify gas analyzer responses after zeroing and spanning by sampling a calibration gas that has a concentration near one-half of the span gas concentration. Based on the results, use good engineering judgment to decide whether or not to re-zero, re-span, or re-calibrate a gas analyzer before starting a test.

(11) If you correct for dilution air background concentrations of associated engine exhaust constituents, start sampling and recording background concentrations at the same time you start sampling exhaust gases.

(12) Turn on cooling fans immediately before starting the test.

(h) Proceed with the test sequence described in §1066.425.

[79 FR 23823, Apr. 28, 2014, as amended at 80 FR 9121, Feb. 19, 2015; 86 FR 34582, Jun. 29, 2021; 88 FR 4708, Jan. 24, 2023]

§1066.425 Performing emission tests.

(a) See the standard-setting part for drive schedules. These are defined by a smooth fit of a specified speed vs. time sequence.

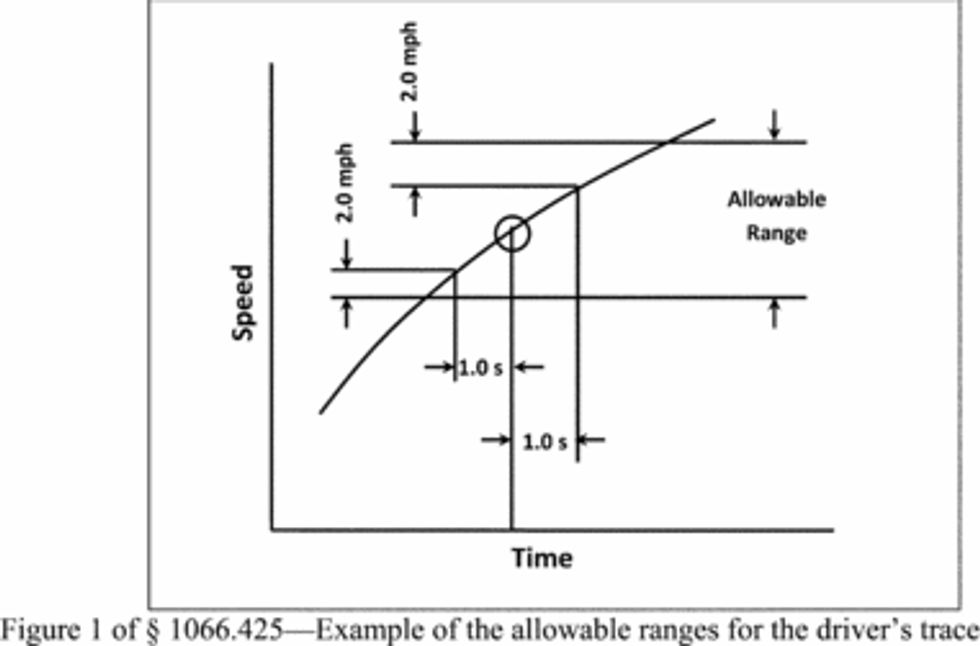

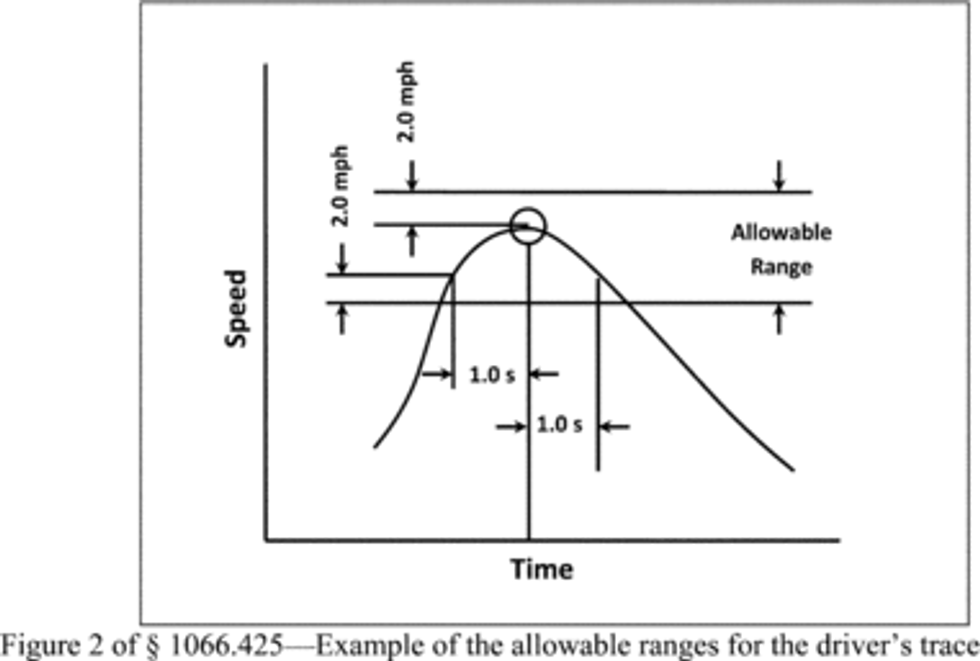

(b) The driver must attempt to follow the target schedule as closely as possible, consistent with the specifications in paragraph (b) of this section. Instantaneous speeds must stay within the following tolerances:

(1) The upper limit is 2.0 mi/hr higher than the highest point on the trace within 1.0 s of the given point in time.

(2) The lower limit is 2.0 mi/hr lower than the lowest point on the trace within 1.0 s of the given time.

(3) The same limits apply for vehicle operation without exhaust measurements, such as vehicle preconditioning and warm-up, except that the upper and lower limits for speed values are ±4.0 mi/hr. In addition, up to three occurrences of speed variations greater than the tolerance are acceptable for vehicle operation in which no exhaust emission standards apply, as long as they occur for less than 15 seconds on any occasion and are clearly documented as to the time and speed at that point of the driving schedule.

(4) Void the test if you do not maintain speed values as specified in this paragraph (b), except as allowed by this paragraph (b)(4). Speed variations (such as may occur during gear changes or braking spikes) may occur as follows, as long as such variations are clearly documented, including the time and speed values and the reason for the deviation:

(i) Speed variations greater than the specified limits are acceptable for up to 2.0 seconds on any occasion.

(ii) For vehicles that are not able to maintain acceleration as specified in §1066.415(e)(5), do not count the insufficient acceleration as being outside the specified limits.

(5) We may approve an alternate test cycle and cycle-validation criteria for vehicles that do not have enough power to follow the specified driving trace. The alternate driving specifications must be based on making best efforts to maintain acceleration and speed to follow the specified test cycle. We must approve these alternate driving specifications before you perform this testing.

(c) Figure 1 and Figure 2 of this section show the range of acceptable speed tolerances for typical points during testing. Figure 1 of this section is typical of portions of the speed curve that are increasing or decreasing throughout the 2-second time interval. Figure 2 of this section is typical of portions of the speed curve that include a maximum or minimum value.

(d) Start testing as follows:

(1) If a vehicle is already running and warmed up, and starting is not part of the test cycle, operate the vehicle as follows:

(i) For transient test cycles, control vehicle speeds to follow a drive schedule consisting of a series of idles, accelerations, cruises, and decelerations.

(ii) For cruise test cycles, control the vehicle operation to match the speed of the first interval of the test cycle. Follow the instructions in the standard-setting part to determine how long to stabilize the vehicle during each interval, how long to sample emissions at each interval, and how to transition between intervals.

(2) If engine starting is part of the test cycle, start recording continuous data, turn on any electronic integrating devices, and start batch sampling before starting the engine. Initiate the driver's trace when the engine starts.

(e) Perform the following at the end of each test interval, except as specified in standard-setting part:

(1) Shut down the vehicle if it is part of the test cycle or if testing is complete.

(2) Continue to operate all sampling and dilution systems to allow the response times to elapse. Then stop all sampling and recording, including background sampling. Finally, stop any integrating devices and indicate the end of the duty cycle in the recorded data.

(f) If testing involves engine shutdown followed by another test interval, start a timer for the vehicle soak when the engine shuts down. Turn off cooling fans, close the engine compartment cover (if applicable), and turn off the CVS or disconnect the exhaust tube from the vehicle's tailpipe(s) unless otherwise instructed in the standard-setting part. If testing is complete, disconnect the laboratory exhaust tubing from the vehicle's tailpipe(s) and drive the vehicle from the dynamometer.

(g) Take the following steps after emission sampling is complete:

(1) For any proportional batch sample, such as a bag sample or PM sample, verify that proportional sampling was maintained according to 40 CFR 1065.545. Void any samples that did not maintain proportional sampling according to those specifications.

(2) Place any used PM samples into covered or sealed containers and return them to the PM-stabilization environment. Follow the PM sample post-conditioning and total weighing procedures in 40 CFR 1065.595.

(3) As soon as practical after the interval or test cycle is complete, or optionally during the soak period if practical, perform the following:

(i) Begin drift check for all continuous gas analyzers as described in paragraph (g)(5) of this section and zero and span all batch gas analyzers as soon as practical before any batch sample analysis. You may perform this batch analyzer zero and span before the end of the test interval.

(ii) Analyze any conventional gaseous batch samples (HC, CH4, CO, NOX, and CO2) no later than 30 minutes after a test interval is complete, or during the soak period if practical. Analyze background samples no later than 60 minutes after the test interval is complete.

(iii) Analyze nonconventional gaseous batch samples (including background), such as NMHCE, N2O, or NMOG sampling with ethanol, as soon as practicable using good engineering judgment.

(4) If an analyzer operated above 100% of its range at any time during the test, perform the following steps:

(i) For batch sampling, re-analyze the sample using the lowest analyzer range that results in a maximum instrument response below 100%. Report the result from the lowest range from which the analyzer operates below 100% of its range.

(ii) For continuous sampling, repeat the entire test using the next higher analyzer range. If the analyzer again operates above 100% of its range, repeat the test using the next higher range. Continue to repeat the test until the analyzer consistently operates at less than 100% of its range. Keep records of any tests where the analyzer exceeds its range. We may consider these results to determine that the test vehicle exceeded an emission standard, consistent with good engineering judgment.

(5) After quantifying exhaust gases, verify drift as follows:

(i) For batch and continuous gas analyzers, record the mean analyzer value after stabilizing a zero gas to the analyzer. Stabilization may include time to purge the analyzer of any sample gas, plus any additional time to account for analyzer response.

(ii) Record the mean analyzer value after stabilizing the span gas to the analyzer. Stabilization may include time to purge the analyzer of any sample gas, plus any additional time to account for analyzer response.

(iii) Use these data to verify that analyzer drift does not exceed 2.0% of the analyzer full scale.

(h) Measure and record ambient pressure. Measure and record ambient temperature continuously to verify that it remains within the temperature range specified in §1066.420(c)(1) throughout the test. Also measure humidity if required, such as for correcting NOX emissions, or meeting the requirements of §1066.420(d).

(i) [Reserved]

(j) For vehicles at or below 14,000 pounds GVWR, determine overall driver accuracy as follows:

(1) Compare the following drive-cycle metrics, based on measured vehicle speeds, to a reference value based on the target cycle that would have been generated by driving exactly to the target trace as described in SAE J2951 (incorporated by reference, see §1066.1010):

(i) Determine the Energy Economy Rating as described in Section 5.4 of SAE J2951.

(ii) Determine the Absolute Speed Change Rating as described in Section 5.5 of SAE J2951.

(iii) Determine the Inertia Work Rating as described in Section 5.6 of SAE J2951.

(iv) Determine the phase-weighted composite Energy Based Drive Metrics for the criteria specified in this paragraph (j)(1) as described in Section 5.7 of SAE J2951.

(2) The standard-setting part may require you to give us 10 Hz data to characterize both target and actual values for cycle energy. Calculate target values based on the vehicles speeds from the specified test cycle.

[79 FR 23823, Apr. 28, 2016, as amended at 81 FR 74203, Oct. 25, 2016; 89 FR 28212, Apr. 18, 2024]

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.