['Air Programs']

['Air Emissions']

03/16/2023

...

§1054.201 What are the general requirements for obtaining a certificate of conformity?

Engine manufacturers must certify their engines with respect to the exhaust emission standards in this part. Manufacturers of engines, equipment, or fuel-system components may need to certify their products with respect to evaporative emission standards as described in 40 CFR 1060.1 and 1060.601. The following general requirements apply for obtaining a certificate of conformity:

(a) You must send us a separate application for a certificate of conformity for each engine family. A certificate of conformity is valid starting with the indicated effective date but it is not valid for any production after December 31 of the model year for which it is issued. No certificate will be issued after December 31 of the model year. If you certify with respect to both exhaust and evaporative emissions, you must submit separate applications.

(b) The application must contain all the information required by this part and must not include false or incomplete statements or information (see §1054.255).

(c) We may ask you to include less information than we specify in this subpart as long as you maintain all the information required by §1054.250.

(d) You must use good engineering judgment for all decisions related to your application (see 40 CFR 1068.5).

(e) An authorized representative of your company must approve and sign the application.

(f) See §1054.255 for provisions describing how we will process your application.

(g) We may require you to deliver your test engines to a facility we designate for our testing (see §1054.235(c)).

(h) For engines that become new after being placed into service, such as engines converted to run on a different fuel, we may specify alternate certification provisions consistent with the intent of this part. See §1054.645 and the definition of “new nonroad engine” in §1054.801.

[73 FR 59259, Oct. 8, 2008, as amended at 75 FR 23025, Apr. 30, 2010]

§1054.205 What must I include in my application?

This section specifies the information that must be in your application, unless we ask you to include less information under §1054.201(c). We may require you to provide additional information to evaluate your application. The provisions of this section apply to integrated equipment manufacturers and engine manufacturers selling loose engines. Nonintegrated equipment manufacturers must follow the requirements of 40 CFR part 1060.

(a) Describe the emission family's specifications and other basic parameters of the engine's design and emission controls. List the fuel type on which your engines are designed to operate (for example, all-season gasoline). List each distinguishable engine configuration in the emission family. For each engine configuration in which the maximum modal power of the emission-data engine is at or above 25 kW (or power at or above 15 kW if displacement is above 1000 cc), list the maximum engine power and the range of values for maximum engine power resulting from production tolerances, as described in §1054.140.

(b) Explain how the emission control systems operate. Describe the evaporative emission controls and show how your design will prevent running loss emissions, if applicable. Also describe in detail all system components for controlling exhaust emissions, including all auxiliary emission control devices (AECDs) and all fuel-system components you will install on any production or test engine. Identify the part number of each component you describe. For this paragraph (b), treat as separate AECDs any devices that modulate or activate differently from each other. Include sufficient detail to allow us to evaluate whether the AECDs are consistent with the defeat device prohibition of §1054.115. For example, if your engines will routinely experience in-use operation that differs from the specified duty cycle for certification, describe how the fuel-metering system responds to varying speeds and loads not represented by the duty cycle. If you test an emission-data engine by disabling the governor for full-load operation such that the engine operates at an air-fuel ratio significantly different than under full-load operation with an installed governor, explain why these differences are necessary or appropriate. For conventional carbureted engines without electronic fuel controls, it is sufficient to state that there is no significant difference in air-fuel ratios.

(c) [Reserved]

(d) Describe the engines, equipment, and fuel system components you selected for testing and the reasons for selecting them.

(e) Describe the test equipment and procedures that you used, including any special or alternate test procedures you used. For handheld engines, describe how you selected the value for rated speed.

(f) Describe how you operated the emission-data engine before testing, including the duty cycle and the number of engine operating hours used to stabilize emission levels. Explain why you selected the method of service accumulation. Describe any scheduled maintenance you did.

(g) List the specifications of the test fuel to show that it falls within the required ranges we specify in 40 CFR part 1065.

(h) Identify the emission family's useful life. Describe the basis for selecting useful life values with respect to exhaust emissions (see §1054.107).

(i) Include the maintenance and warranty instructions you will give to the ultimate purchaser of each new engine (see §§1054.120 and 1054.125). Describe your basis for meeting the warranty-assurance provisions in §1054.120(f). Describe your recall repair network if it is different than your warranty repair network. State that you will post a bond as specified in §1054.120(f) and 1054.690 or describe why those requirements do not apply.

(j) Include the emission-related installation instructions you will provide if someone else installs your engines in nonroad equipment (see §1054.130).

(k) Describe your emission control information label (see §1054.135).

(l) Identify the emission standards or FELs for the emission family.

(m) Identify the emission family's deterioration factors and describe how you developed them (see §1054.245). Present any emission test data you used for this.

(n) State that you operated your emission-data engines as described in the application (including the test procedures, test parameters, and test fuels) to show you meet the requirements of this part.

(o) Present emission data to show that you meet exhaust emission standards, as follows:

(1) Present emission data for hydrocarbon (such as THC, THCE, or NMHC, as applicable), NO X, and CO on an emission-data engine to show your engines meet the applicable exhaust emission standards as specified in §1054.101. Show emission figures before and after applying deterioration factors for each engine. Include test data from each applicable duty cycle as specified in §1054.505(b). If we specify more than one grade of any fuel type (for example, low-temperature and all-season gasoline), you need to submit test data only for one grade, unless the regulations of this part specify otherwise for your engine.

(2) Note that §§1054.235 and 1054.245 allow you to submit an application in certain cases without new emission data.

(p) Report test results as follows:

(1) Report all valid test results involving measurement of pollutants for which emission standards apply. Also indicate whether there are test results from invalid tests or from any other tests of the emission-data engine, whether or not they were conducted according to the test procedures of subpart F of this part. We may require you to report these additional test results. We may ask you to send other information to confirm that your tests were valid under the requirements of this part and 40 CFR parts 1060 and 1065.

(2) Report measured CO2, N2O, and CH4 as described in §1054.235. Small-volume engine manufacturers may omit reporting N2O and CH4.

(q) Describe all adjustable operating parameters (see §1054.115(b)), including production tolerances. For any operating parameters that do not qualify as adjustable parameters, include a description supporting your conclusion (see 40 CFR 1068.50(c)). Include the following in your description of each adjustable parameter:

(1) For practically adjustable parameters, include the nominal or recommended setting, the intended practically adjustable range, and the limits or stops used to establish adjustable ranges. State that the limits, stops, or other means of inhibiting adjustment are effective in preventing adjustment of parameters on in-use engines to settings outside your intended practically adjustable ranges and provide information to support this statement.

(2) For programmable operating parameters, state that you have restricted access to electronic controls to prevent parameter adjustments on in-use engines that would allow operation outside the practically adjustable range. Describe how your engines are designed to prevent unauthorized adjustments.

(r) Describe how your nonhandheld engines comply with emission standards at varying atmospheric pressures. Include a description of altitude kits you design to comply with the requirements of §1054.115(c). Identify the part number of each component you describe. Identify the altitude range for which you expect proper engine performance and emission control with and without the altitude kit. State that your engines will comply with applicable emission standards throughout the useful life with the altitude kit installed according to your instructions. Describe any relevant testing, engineering analysis, or other information in sufficient detail to support your statement. In addition, describe your plan for making information and parts available such that you would reasonably expect that altitude kits would be widely used in the high-altitude counties specified in 40 CFR part 1068, Appendix III. For example, engine owners should have ready access to information describing when an altitude kit is needed and how to obtain this service. Similarly, parts and service information should be available to qualified service facilities in addition to authorized service centers if that is needed for owners to have such altitude kits installed locally.

(s) If your engines are subject to handheld emission standards on the basis of meeting weight limitations described in the definition of “handheld” in §1054.801, describe your analysis showing that you meet the applicable weight-related restrictions.

(t) State whether your certification is limited for certain engines. If this is the case, describe how you will prevent use of these engines in applications for which they are not certified. This applies for engines such as the following:

(1) Wintertime engines not certified to the specified HC NOX standard.

(2) Two-stroke snowthrower engines using the provisions of §1054.101(d).

(u) Unconditionally certify that all the engines in the emission family comply with the requirements of this part, other referenced parts of the CFR, and the Clean Air Act.

(v) Provide the following information about your plans for producing and selling engines:

(1) Identify the estimated initial and final dates for producing engines from the engine family for the model year.

(2) Identify the estimated date for initially introducing certified engines into U.S. commerce under this certificate.

(3) Include good-faith estimates of U.S.-directed production volumes. Include a justification for the estimated production volumes if they are substantially different than actual production volumes in earlier years for similar models. Also indicate whether you expect the engine family to contain only nonroad engines, only stationary engines, or both.

(w) State that you will post a bond as specified in §1054.690 or describe why those requirements do not apply.

(x) Include the information required by other subparts of this part. For example, include the information required by §1054.725 if you participate in the ABT program and include the information required by §1054.690 if you need to post a bond under that section.

(y) Include other applicable information, such as information specified in this part or 40 CFR part 1068 related to requests for exemptions.

(z) Name an agent for service located in the United States. Service on this agent constitutes service on you or any of your officers or employees for any action by EPA or otherwise by the United States related to the requirements of this part.

(aa) For imported engines or equipment, identify the following:

(1) The port(s) at which you have imported your engines (or equipment containing your engines) over the previous 12 months.

(2) The names and addresses of the agents you have authorized to import your engines or equipment.

(3) The location of a test facility in the United States where you can test your engines if we select them for testing under a selective enforcement audit, as specified in 40 CFR part 1068, subpart E.

[73 FR 59259, Oct. 8, 2008, as amended at 74 FR 56511, Oct. 30, 2009; 75 FR 23025, Apr. 30, 2010; 86 FR 34518, Jun. 29, 2021; 88 FR 4667, Jan. 24, 2023]

§1054.210 May I get preliminary approval before I complete my application?

If you send us information before you finish the application, we will review it and make any appropriate determinations, especially for questions related to emission family definitions, auxiliary emission control devices, deterioration factors, useful life, testing for service accumulation, maintenance, and delegated final assembly. Decisions made under this section are considered to be preliminary approval, subject to final review and approval. We will generally not reverse a decision where we have given you preliminary approval, unless we find new information supporting a different decision. If you request preliminary approval related to the upcoming model year or the model year after that, we will make the appropriate determinations as soon as practicable. We will generally not provide preliminary approval related to a future model year more than two years ahead of time.

§1054.220 How do I amend my maintenance instructions?

You may amend your emission-related maintenance instructions after you submit your application for certification as long as the amended instructions remain consistent with the provisions of §1054.125. You must send the Designated Compliance Officer a written request to amend your application for certification for an engine family if you want to change the emission-related maintenance instructions in a way that could affect emissions. In your request, describe the proposed changes to the maintenance instructions. If operators follow the original maintenance instructions rather than the newly specified maintenance, this does not allow you to disqualify those engines from in-use testing or deny a warranty claim.

(a) If you are decreasing or eliminating any specified maintenance, you may distribute the new maintenance instructions to your customers 30 days after we receive your request, unless we disapprove your request. This would generally include replacing one maintenance step with another. We may approve a shorter time or waive this requirement.

(b) If your requested change would not decrease the specified maintenance, you may distribute the new maintenance instructions anytime after you send your request. For example, this paragraph (b) would cover adding instructions to increase the frequency of filter changes for engines in severe-duty applications.

(c) You need not request approval if you are making only minor corrections (such as correcting typographical mistakes), clarifying your maintenance instructions, or changing instructions for maintenance unrelated to emission control. We may ask you to send us copies of maintenance instructions revised under this paragraph (c).

[73 FR 59259, Oct. 8, 2008, as amended at 75 FR 23025, Apr. 30, 2010; 86 FR 34519, Jun. 29, 2021]

§1054.225 How do I amend my application for certification?

Before we issue you a certificate of conformity, you may amend your application to include new or modified engine or fuel-system configurations, subject to the provisions of this section. After we have issued your certificate of conformity, you may send us an amended application requesting that we include new or modified configurations within the scope of the certificate, subject to the provisions of this section. You must amend your application if any changes occur with respect to any information included in your application.

(a) You must amend your application before you take any of the following actions:

(1) Add an engine or fuel-system configuration to an emission family. In this case, the configuration added must be consistent with other configurations in the emission family with respect to the criteria listed in §1054.230.

(2) Change a configuration already included in an emission family in a way that may affect emissions, or change any of the components you described in your application for certification. This includes production and design changes that may affect emissions any time during the engine's lifetime.

(3) Modify an FEL for an emission family with respect to exhaust emissions as described in paragraph (f) of this section.

(b) To amend your application for certification, send the following relevant information to the Designated Compliance Officer.

(1) Describe in detail the addition or change in the model or configuration you intend to make.

(2) Include engineering evaluations or data showing that the amended emission family complies with all applicable requirements in this part. You may do this by showing that the original emission-data engine or emission-data equipment is still appropriate for showing that the amended family complies with all applicable requirements in this part.

(3) If the original emission-data engine for the engine family is not appropriate to show compliance for the new or modified engine configuration, include new test data showing that the new or modified engine configuration meets the requirements of this part.

(4) Include any other information needed to make your application correct and complete.

(c) We may ask for more test data or engineering evaluations. You must give us these within 30 days after we request them.

(d) For emission families already covered by a certificate of conformity, we will determine whether the existing certificate of conformity covers your new or modified configuration. You may ask for a hearing if we deny your request (see §1054.820).

(e) For emission families already covered by a certificate of conformity, you may start producing the new or modified configuration anytime after you send us your amended application and before we make a decision under paragraph (d) of this section. However, if we determine that the affected configurations do not meet applicable requirements, we will notify you to cease production of the configurations and may require you to recall the engine or equipment at no expense to the owner. Choosing to produce engines under this paragraph (e) is deemed to be consent to recall all engines or equipment that we determine do not meet applicable emission standards or other requirements and to remedy the nonconformity at no expense to the owner. If you do not provide information required under paragraph (c) of this section within 30 days after we request it, you must stop producing the new or modified engine or equipment.

(f) You may ask us to approve a change to your FEL with respect to exhaust emissions in certain cases after the start of production. The changed FEL may not apply to engines you have already introduced into U.S. commerce, except as described in this paragraph (f). If we approve a changed FEL after the start of production, you must identify the month and year for applying the new FEL. You may ask us to approve a change to your FEL in the following cases:

(1) You may ask to raise your FEL for your emission family at any time. In your request, you must show that you will still be able to meet the emission standards as specified in subparts B and H of this part. If you amend your application by submitting new test data to include a newly added or modified engine, as described in paragraph (b)(3) of this section, use the appropriate FELs with corresponding production volumes to calculate emission credits for the model year, as described in subpart H of this part. In all other circumstances, you must use the higher FEL for the entire family to calculate emission credits under subpart H of this part.

(2) You may ask to lower the FEL for your emission family only if you have test data from production engines showing that emissions are below the proposed lower FEL. The lower FEL does not apply to engines you produce before the new FEL starts to apply, as specified in this paragraph (f). Use the appropriate FELs with corresponding production volumes to calculate emission credits for the model year, as described in subpart H of this part.

(g) You may produce engines as described in your amended application for certification and consider those engines to be in a certified configuration if we approve a new or modified engine configuration during the model year under paragraph (d) of this section. Similarly, you may modify in-use engines as described in your amended application for certification and consider those engines to be in a certified configuration if we approve a new or modified engine configuration at any time under paragraph (d) of this section. Modifying a new or in-use engine to be in a certified configuration does not violate the tampering prohibition of 40 CFR 1068.101(b)(1), as long as this does not involve changing to a certified configuration with a higher family emission limit.

[86 FR 34519, Jun. 29, 2021]

§1054.230 How do I select emission families?

(a) For purposes of certification, divide your product line into families of engines that are expected to have similar emission characteristics throughout their useful life as described in this section. Your emission family is limited to a single model year. For evaporative emissions, group engines into emission families as described in 40 CFR 1060.230.

(b) Group engines into the same emission family for exhaust emissions if they are the same in all the following aspects:

(1) The combustion cycle and fuel. See paragraph (g) of this section for special provisions that apply for dual-fuel engines.

(2) The cooling system (liquid-cooled vs. air-cooled).

(3) Valve configuration (for example, side-valve vs. overhead valve).

(4) Method of air aspiration (for example, turbocharged vs. naturally aspirated).

(5) The number, location, volume, and composition of catalytic converters.

(6) The number and arrangement of cylinders (such as in-line or vee configuration) and approximate total displacement.

(7) Engine class, as defined in §1054.801.

(8) Method of control for engine operation, other than governing. For example, multi-cylinder engines with port fuel injection may not be grouped into an emission family with engines that have a single throttle-body injector or carburetor.

(9) The numerical level of the applicable emission standards. For example, an emission family may not include engines certified to different family emission limits, though you may change family emission limits without recertifying as specified in §1054.225.

(10) Useful life.

(c) You may subdivide a group that is identical under paragraph (b) of this section into different emission families if you show the expected emission characteristics are different during the useful life.

(d) You may group engines that are not identical with respect to the things listed in paragraph (b) of this section into the same emission family, as follows:

(1) In unusual circumstances, you may group such engines into the same emission family if you show that their emission characteristics during the useful life will be similar.

(2) If you are a small-volume engine manufacturer, you may group any nonhandheld engines with the same useful life that are subject to the same emission standards into a single emission family.

(3) The provisions of this paragraph (d) do not exempt any engines from meeting all the applicable standards and requirements in subpart B of this part.

(e) Select test engines from the emission family as described in 40 CFR 1065.401.

(f) You may combine engines from different classes into a single emission family under paragraph (d)(1) of this section if you certify the emission family to the more stringent set of standards from the two classes in that model year.

(g) You may certify dual-fuel or flexible-fuel engines in a single engine family. You may include dedicated-fuel versions of this same engine model in the same engine family, as long as they are identical to the engine configuration with respect to that fuel type for the dual-fuel or flexible-fuel version of the engine. For example, if you produce an engine that can alternately run on gasoline and natural gas, you can include the gasoline-only and natural gas-only versions of the engine in the same engine family as the dual-fuel engine if engine operation on each fuel type is identical with or without installation of components for operating on the other fuel.

[73 FR 59259, Oct. 8, 2008, as amended at 75 FR 23025, Apr. 30, 2010; 88 FR 4667, Jan. 24, 2023; 88 FR 4667, Jan. 24, 2023]

§1054.235 What testing requirements apply for certification?

This section describes the exhaust emission testing you must perform to show compliance with the emission standards in §§1054.103 and 1054.105. See §§1054.240 and 1054.245 and 40 CFR part 1065, subpart E, regarding service accumulation before emission testing.

(a) Select an emission-data engine from each engine family for testing as described in 40 CFR 1065.401. Select a configuration and set adjustable parameters in a way that is most likely to exceed the HC NOX standard in subpart B of this part, using good engineering judgment. Configurations must be tested as they will be produced, including installed governors, if applicable.

(b) Test your emission-data engines using the procedures and equipment specified in subpart F of this part. In the case of dual-fuel engines, measure emissions when operating with each type of fuel for which you intend to certify the engine. In the case of flexible-fuel engines, measure emissions when operating with the fuel mixture that is most likely to cause the engine to exceed the applicable HC NOX emission standard, though you may ask us to instead perform tests with both fuels separately if you can show that intermediate mixtures are not likely to occur in use.

(c) We may perform confirmatory testing by measuring emissions from any of your emission-data engines or other engines from the emission family, as follows:

(1) We may decide to do the testing at your plant or any other facility. If we do this, you must deliver the engine to a test facility we designate. The engine you provide must include appropriate manifolds, aftertreatment devices, electronic control units, and other emission-related components not normally attached directly to the engine block. If we do the testing at your plant, you must schedule it as soon as possible and make available the instruments, personnel, and equipment we need.

(2) If we measure emissions on one of your engines, the results of that testing become the official emission results for the engine.

(3) We may set the adjustable parameters of your engine to any point within the physically adjustable ranges (see §1054.115(b)).

(4) Before we test one of your engines, we may calibrate it within normal production tolerances for anything we do not consider an adjustable parameter. For example, we may calibrate it within normal production tolerances for a parameter that is subject to production variability because it is adjustable during production, but is not considered an adjustable parameter (as defined in §1054.801) because it is permanently sealed.

(d) You may ask to use carryover emission data from a previous model year instead of doing new tests, but only if all the following are true:

(1) The emission family from the previous model year differs from the current emission family only with respect to model year, items identified in §1054.225(a), or other characteristics unrelated to emissions. We may waive this paragraph (d)(1) for differences we determine not to be relevant.

(2) The emission-data engine from the previous model year remains the appropriate emission-data engine under paragraph (b) of this section.

(3) The data show that the emission-data engine would meet all the requirements of this part that apply to the emission family covered by the application for certification.

[73 FR 59259, Oct. 8, 2008, as amended at 74 FR 56511, Oct. 30, 2009; 86 FR 34519, Jun. 29, 2021]

§1054.240 How do I demonstrate that my emission family complies with exhaust emission standards?

(a) For purposes of certification, your emission family is considered in compliance with the emission standards in §1054.101(a) if all emission-data engines representing that family have test results showing official emission results and deteriorated emission levels at or below these standards. This paragraph (a) also applies for all test points for emission-data engines within the family used to establish deterioration factors. Note that your FELs are considered to be the applicable emission standards with which you must comply if you participate in the ABT program in subpart H of this part.

(b) Your engine family is deemed not to comply if any emission-data engine representing that family has test results showing an official emission result or a deteriorated emission level for any pollutant that is above an applicable emission standard in subpart B of this part. This paragraph (b) also applies for all test points for emission-data engines within the family used to establish deterioration factors.

(c) Determine a deterioration factor to compare emission levels from the emission-data engine with the applicable emission standards in subpart B of this part. Section 1054.245 specifies how to test engines to develop deterioration factors that represent the expected deterioration in emissions over your engines' full useful life. Calculate a multiplicative deterioration factor as described in §1054.245(b). If the deterioration factor is less than one, use one. Specify the deterioration factor to one more significant figure than the emission standard. In the case of dual-fuel and flexible-fuel engines, apply deterioration factors separately for each fuel type. You may use assigned deterioration factors that we establish for up to 10,000 nonhandheld engines from small-volume emission families in each model year, except that small-volume engine manufacturers may use assigned deterioration factors for any or all of their engine families.

(d) Determine the official emission result for each pollutant to at least one more decimal place than the applicable standard in subpart B of this part. Apply the deterioration factor to the official emission result, as described in §1054.245(b), then round the adjusted figure to the same number of decimal places as the emission standard. Compare the rounded emission levels to the emission standard for each emission-data engine. In the case of HC NOX standards, add the official emission results and apply the deterioration factor to the sum of the pollutants before rounding. However, if your deterioration factors are based on emission measurements that do not cover the engine's full useful life, apply deterioration factors to each pollutant and then add the results before rounding.

(e) The provisions of this paragraph (e) apply only for engine families with a useful life at or below 300 hours. To apply the deterioration factor to engines other than the original emission-data engine, they must be operated for the same number of hours before starting emission measurements that you used for the original emission-data engine, within one hour. For example, if the original emission-data engine operated for 8 hours before the low-hour emission test, operate the other test engines for 7 to 9 hours before starting emission measurements.

[86 FR 34520, Jun. 29, 2021]

§1054.245 How do I determine deterioration factors from exhaust durability testing?

This section describes how to determine deterioration factors, either with pre-existing test data or with new emission measurements.

(a) You may ask us to approve deterioration factors for an emission family based on emission measurements from similar engines if you have already given us these data for certifying other engines in the same or earlier model years. Use good engineering judgment to decide whether the two engines are similar. We will approve your request if you show us that the emission measurements from other engines reasonably represent in-use deterioration for the engine family for which you have not yet determined deterioration factors.

(b) If you are unable to determine deterioration factors for an emission family under paragraph (a) of this section, select engines, subsystems, or components for testing. Determine deterioration factors based on service accumulation and related testing. Include consideration of wear and other causes of deterioration expected under typical consumer use. Determine deterioration factors as follows:

(1) Measure emissions from the emission-data engine at a low-hour test point, at the midpoint of the useful life, and at the end of the useful life, except as specifically allowed by this paragraph (b). You may test at additional evenly spaced intermediate points. Collect emission data using measurements to at least one more decimal place than the emission standard in subpart B of this part.

(2) Operate the engine over a duty cycle that is representative of in-use operation for a period at least as long as the useful life (in hours). You may operate the engine continuously. You may also use an engine installed in nonroad equipment to accumulate service hours instead of running the engine only in the laboratory.

(3)In the case of dual-fuel or flexible-fuel engines, you may accumulate service hours on a single emission-data engine using the type or mixture of fuel expected to have the highest combustion and exhaust temperatures; you may ask us to approve a different fuel mixture for flexible-fuel engines if you demonstrate that a different criterion is more appropriate. For dual-fuel engines, you must measure emissions on each fuel type at each test point, either with separate engines dedicated to a given fuel, or with different configurations of a single engine.

(4) You may perform maintenance on emission-data engines as described in §1054.125 and 40 CFR part 1065, subpart E. If you change one or more spark plugs on an emission-data engine as allowed under §1054.125, you must measure emissions before and after this maintenance. If you clean or change an air filter on an emission-data engine as allowed under §1054.125, you must measure emissions before and after every second time you perform this maintenance. Use the average values from these two measurements to calculate deterioration factors. The emission-data engine must meet applicable emission standards before and after maintenance to be considered in compliance, as described in §1054.240(a) and (b).

(5) Calculate your deterioration factor using a linear least-squares fit of your test data but treat the low-hour test point as occurring at hour zero. Your deterioration factor is the ratio of the calculated emission level at the point representing the full useful life to the calculated emission level at zero hours, expressed to one more significant figure than the emission standard in subpart B of this part.

(6) If you test more than one engine to establish deterioration factors, average the deterioration factors from all the engines before rounding.

(7) If your durability engine fails between 80 percent and 100 percent of useful life, you may use the last emission measurement as the test point representing the full useful life, provided it occurred after at least 80 percent of the useful life.

(8) If your useful life is 1,000 hours or longer, and your durability engine fails between 50 percent and 100 percent of useful life, you may extrapolate your emission results to determine the emission level representing the full useful life, provided emissions were measured at least once after 50 percent of the useful life.

(9) Use good engineering judgment for all aspects of the effort to establish deterioration factors under this paragraph (b).

(10) You may use other testing methods to determine deterioration factors, consistent with good engineering judgment, as long as we approve those methods in advance.

(c) If you qualify for using assigned deterioration factors under §1054.240, determine the deterioration factors as follows:

(1) For two-stroke engines without aftertreatment, use a deterioration factor of 1.1 for HC, NOX, and CO. For four-stroke engines without aftertreatment, use deterioration factors of 1.4 for HC, 1.0 for NOX, and 1.1 for CO for Class 2 engines, and use 1.5 for HC and NOX, and 1.1 for CO for all other engines.

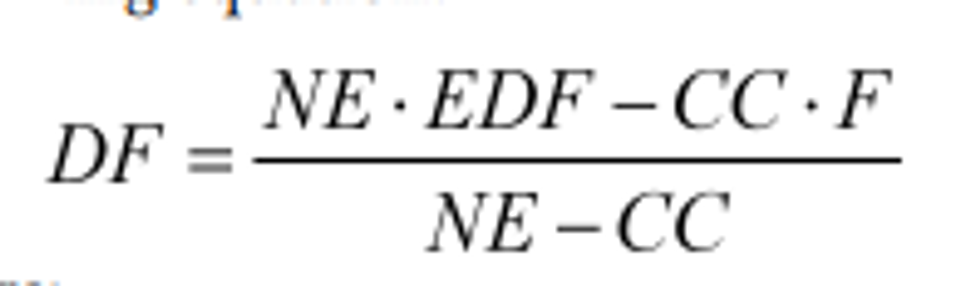

(2) For Class 2 engines with aftertreatment, use a deterioration factor of 1.0 for NOX. For all other cases involving engines with aftertreatment, calculate separate deterioration factors for HC, NOX, and CO using the following equation:

Where:

NE = engine-out emission levels (pre-catalyst) from the low-hour test result for a given pollutant, in g/kW-hr.

EDF = the deterioration factor specified in paragraph (c)(1) of this section for the type of engine for a given pollutant.

CC = the catalyst conversion from the low-hour test, in g/kW-hr. This is the difference between the official emission result and NE.

F = 1.0 for NOX and 0.8 for HC and CO.

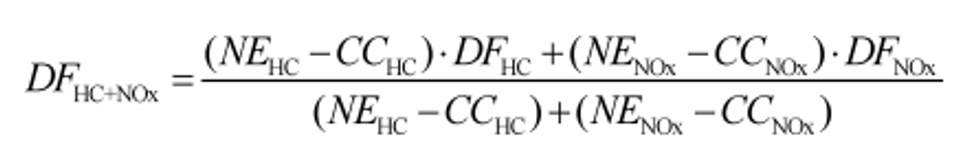

(3) Combine separate deterioration factors for HC and NOX from paragraph (c)(2) of this section into a combined deterioration factor for HC NOX using the following equation:

(d) Include the following information in your application for certification:

(1) If you determine your deterioration factors based on test data from a different emission family, explain why this is appropriate and include all the emission measurements on which you base the deterioration factor.

(2) If you do testing to determine deterioration factors, describe the form and extent of service accumulation, including the method you use to accumulate hours.

(3) If you calculate deterioration factors under paragraph (c) of this section, identify the parameters and variables you used for the calculation.

[86 FR 34520, Jun. 29, 2021]

§1054.250 What records must I keep and what reports must I send to EPA?

(a) Send the Designated Compliance Officer information related to your U.S.-directed production volumes as described in §1054.345. In addition, within 45 days after the end of the model year, you must send us a report describing information about engines you produced during the model year as follows:

(1) State the total production volume for each engine family that is not subject to reporting under §1054.345.

(2) State the total production volume for any engine family for which you produce engines after completing the reports required in §1054.345.

(3) [Reserved]

(4) For production volumes you report under this paragraph (a), identify whether or not the figures include California sales. Include a separate count of production volumes for California sales if those figures are available.

(b) Organize and maintain the following records:

(1) A copy of all applications and any summary information you send us.

(2) Any of the information we specify in §1054.205 that you were not required to include in your application.

(3) A detailed history of all emission-data engines. For each engine, describe all of the following:

(i) The emission-data engine's construction, including its origin and buildup, steps you took to ensure that it represents production engines, any components you built specially for it, and all the components you include in your application for certification.

(ii) How you accumulated engine operating hours (service accumulation), including the dates and the number of hours accumulated.

(iii) All maintenance, including modifications, parts changes, and other service, and the dates and reasons for the maintenance.

(iv) All your emission tests (valid and invalid), including the date and purpose of each test and documentation of test parameters as specified in part 40 CFR part 1065.

(v) All tests to diagnose engine or emission control performance, giving the date and time of each and the reasons for the test.

(vi) Any other significantevents.

(4) Production figures for each emission family divided by assembly plant.

(5) Keep a list of engine identification numbers for all the engines you produce under each certificate of conformity.

(c) Keep required data from emission tests and all other information specified in this section for eight years after we issue your certificate. If you use the same emission data or other information for a later model year, the eight-year period restarts with each year that you continue to rely on the information.

(d) Store these records in any format and on any media as long as you can promptly send us organized, written records in English if we ask for them. You must keep these records readily available. We may review them at any time.

[86 FR 34521, Jun. 29, 2021]

§1054.255 What decisions may EPA make regarding a certificate of conformity?

(a) If we determine an application is complete and shows that the emission family meets all the requirements of this part and the Clean Air Act, we will issue a certificate of conformity for the emission family for that model year. We may make the approval subject to additional conditions.

(b) We may deny an application for certification if we determine that an emission family fails to comply with emission standards or other requirements of this part or the Clean Air Act. We will base our decision on all available information. If we deny an application, we will explain why in writing.

(c) In addition, we may deny your application or suspend or revoke a certificate of conformity if you do any of the following:

(1) Refuse to comply with any testing, reporting, or bonding requirements in this part.

(2) Submit false or incomplete information. This includes doing anything after submitting an application that causes submitted information to be false or incomplete.

(3) Cause any test data to become inaccurate.

(4) Deny us from completing authorized activities (see 40 CFR 1068.20). This includes a failure to provide reasonable assistance.

(5) Produce engines or equipment for importation into the United States at a location where local law prohibits us from carrying out authorized activities.

(6) Fail to supply requested information or amend an application to include all engines or equipment being produced.

(7) Take any action that otherwise circumvents the intent of the Clean Air Act or this part.

(d) We may void a certificate of conformity if you fail to keep records, send reports, or give us information as required under this part or the Clean Air Act. Note that these are also violations of 40 CFR 1068.101(a)(2).

(e) We may void a certificate of conformity if we find that you intentionally submitted false or incomplete information. This includes doing anything after submitting your application that causes the submitted information to be false or incomplete.

(f) If we deny an application or suspend, revoke, or void a certificate of conformity, you may ask for a hearing (see §1054.820).

[86 FR 34521, Jun. 29, 2021]

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.