['Air Programs']

['Air Emissions', 'Air Quality']

01/30/2025

...

Authority: 42 U.S.C. 7401-7671q.

Subpart A - Overview and Applicability

§1060.1 Which products are subject to this part's requirements?

(a) The standards and other requirements in this part 1060 apply to the fuel lines, fuel tanks, couplings and fittings, and fuel caps used or intended to be used in the following categories of new engines and equipment that are fueled with a volatile liquid fuel (such as gasoline, but not including diesel fuel), and to the equipment in which these components are installed, starting with the model years shown in Table 1 to this section:

(1) Compression-ignition engines we regulate under 40 CFR part 1039. This includes stationary compression-ignition engines we regulate under the provisions of 40 CFR part 1039, as indicated under 40 CFR part 60, subpart IIII. See the evaporative emission standards specified in 40 CFR 1048.105. These engines are considered to be Large SI engines for purposes of this part 1060.

(2) Marine compression-ignition engines we regulate under 40 CFR part 1042. See the evaporative emission standards specified in 40 CFR 1045.112. These engines are considered to be Marine SI engines for purposes of this part 1060.

(3) Marine SI engines we regulate under 40 CFR part 1045. See the evaporative emission standards specified in 40 CFR 1045.112.

(4) Large SI engines we regulate under 40 CFR part 1048. This includes stationary spark-ignition engines subject to standards under 40 CFR parts 1048 or 1054 as indicated in 40 CFR part 60, subpart JJJJ. See the evaporative emission standards specified in 40 CFR 1048.105.

(5) Recreational vehicles and engines we regulate under 40 CFR part 1051 (such as snowmobiles and off-highway motorcycles). This includes highway motorcycles subject to standards under 40 CFR part 1051 as indicated in 40 CFR part 86, subpart E since these motorcycles are considered to be recreational vehicles for purposes of this part 1060. See the evaporative emission standards specified in 40 CFR 1051.110.

(6) Small SI engines we regulate under 40 CFR part 1054. See the evaporative emission standards specified for handheld engines in 40 CFR 1054.110 and for nonhandheld engines in 40 CFR 1054.112.

(7) Portable nonroad fuel tanks are considered portable marine fuel tanks for purposes of this part. Portable nonroad fuel tanks and fuel lines associated with such fuel tanks must therefore meet evaporative emission standards specified in 40 CFR 1045.112, whether or not they are used with marine vessels.

(b) The regulations in this part 1060 apply for new replacement components used with any of the engines or equipment specified in paragraph (a) of this section as described in §1060.601.

(c) Fuel caps are subject to evaporative emission standards at the point of installation on a fuel tank. When a fuel cap is certified for use with Marine SI engines or Small SI engines under the optional standards of §1060.103, it becomes subject to all the requirements of this part as if these optional standards were mandatory.

(d) This part does not apply to any diesel-fueled engine or any other engine that does not use a volatile liquid fuel. In addition, this part does not apply to any engines or equipment in the following categories even if they use a volatile liquid fuel:

(1) Light-duty motor vehicles (see 40 CFR part 86).

(2) Heavy-duty motor vehicles and heavy-duty motor vehicle engines (see 40 CFR part 86). This part also does not apply to fuel systems for nonroad engines where such fuel systems are subject to part 86 because they are part of a heavy-duty motor vehicle.

(3) Aircraft engines (see 40 CFR part 87).

(4) Locomotives (see 40 CFR part 1033).

(e) This part 1060 does not apply for fuel lines made wholly of metal.

|

Equipment category or subcategory |

Fuel line permeation | Tank permeation |

Diurnal emissions | Running loss emissions |

|---|---|---|---|---|

| a Implementation is based on the date of manufacture of the equipment. Where we do not identify a specific date, the emission standards start to apply at the beginning of the model year.

b January 1, 2011 for primer bulbs. Standards phase in for under-cowl fuel lines on outboard engines, by length: 30% in 2010, 60% in 2011, 90% in 2012-2014, 100% in 2015. c 2013 for small-volume emission families that do not include cold-weather fuel lines. d 2011 for structurally integrated nylon fuel tanks and 2013 for all small-volume emission families. e Manufacturers may optionally meet diurnal standards as specified in §1060.105(e). | ||||

| Marine SI - portable marine fuel tanks | January 1, 2009 b | January 1, 2011 | January 1, 2010 | Not applicable. |

| Marine SI - personal watercraft | January 1, 2009 | Model year 2011 | Model year 2010 | Not applicable. |

| Marine SI - other vessels with installed fuel tanks | January 1, 2009 b | Model year 2012 | July 31, 2011 | Not applicable. |

| Large SI | Model year 2007 | Not applicable | Model year 2007 (includes tank permeation) | Model year 2007. |

| Recreational vehicles | Model year 2008 | Model year 2008 | Not applicable | Not applicable. |

| Small SI - handheld | Model year 2012 c | Model year 2010 d | Not applicable | Not applicable. |

| Small SI - Class I nonhandheld | January 1, 2009 | Model year 2012 | Not applicable e | Model year 2012. |

| Small SI - Class II nonhandheld | January 1, 2009 | Model year 2011 | Not applicable e | Model year 2011. |

[86 FR 34527, Jun. 29, 2021]

§1060.5 Do the requirements of this part apply to me?

(a) Overall responsibilities. Manufacturers of the engines, equipment, and fuel-system components described in §1060.1 are subject to the standards and other requirements of this part 1060 except as otherwise noted. Multiple manufacturers may be subject to these standards and other requirements. For example, when a Small SI equipment manufacturer buys fuel line manufactured by another person and installs them in its equipment, both the equipment manufacturer and the fuel line manufacturer are subject to the standards and other requirements of this part. The following provisions apply in such cases:

(1) Each person meeting the definition of manufacturer (see §1060.801) for a product that is subject to the standards and other requirements of this part must comply with such requirements. However, if one person complies with a specific requirement for a given product, then all manufacturers are deemed to have complied with that specific requirement. For example, if a Small SI equipment manufacturer uses fuel lines manufactured and certified by another company, the equipment manufacturer is not required to obtain its own certificate with respect to the fuel line emission standards. Such an equipment manufacturer remains subject to the standards and other requirements of this part. However, where a provision in this part requires a specific manufacturer to comply with certain provisions, this paragraph (a) does not change or modify such a requirement. For example, this paragraph (a) does not allow you to rely on another company to certify instead of you if we specifically require you to certify.

(2) The requirements of subparts C and D of this part apply to the manufacturer that obtains the certificate of conformity. Other manufacturers are required to comply with the requirements of subparts C and D of this part only when we send notification. In our notification, we will specify a reasonable period for complying with the requirements identified in the notice. See §1060.601 for the applicability of 40 CFR part 1068 to these other manufacturers.

(3) Certificate holders are responsible for meeting all applicable requirements even if other manufacturers are also subject to those requirements.

(b) Marine SI. Certify vessels, engines, and fuel-system components as follows:

(1) Component manufacturers must certify their fuel lines and fuel tanks intended for installation with Marine SI engines and vessels under this part 1060, except as allowed by §1060.601(f). This includes permeation and diurnal emission standards.

(2) Vessel manufacturers are subject to all the requirements of this part 1060 that apply to Marine SI engines and fuel systems. However, they must certify to the emission standards specified in §§1060.102 through 1060.105 only if one or more of the following conditions apply:

(i) Vessel manufacturers must certify fuel system components they install in their vessels if the components are not certified to meet all applicable evaporative emission standards, including both permeation and diurnal standards. This would include vessel manufacturers that make their own fuel tanks. Vessel manufacturers would need to act as component manufacturers to certify under this part 1060.

(ii) Vessel manufacturers must certify their vessels only if they intend to generate or use evaporative emission credits. Vessel manufacturers would certify under part 40 CFR part 1045 using the emission-credit provisions in subpart H of that part to demonstrate compliance with the emission standard.

(3) Engine manufacturers must meet all the requirements of this part 1060 that apply to vessel manufacturers for all fuel-system components they install on their engines. For example, engine manufacturers that install under-cowl fuel lines and fuel tanks must comply with the requirements specified for vessel manufacturers with respect to those components.

(c) Large SI. Certify engines, equipment, and fuel-system components as follows:

(1) Engine manufacturers must certify their engines under 40 CFR part 1048.

(2) Equipment manufacturers and component manufacturers may certify fuel lines and fuel tanks intended for use with Large SI engines under this part 1060.

(d) Recreational vehicles. Certify vehicles, engines and fuel-system components as follows:

(1) Vehicle manufacturers must certify their vehicles under 40 CFR part 1051.

(2) Engine manufacturers must meet all the requirements of 40 CFR part 1051 that apply to vehicle manufacturers for all fuel-system components they install on their engines. For example, engine manufacturers that install fuel-line segments on the engines they ship to vehicle manufacturers must comply with the requirements specified for equipment manufacturers with respect to those components.

(3) Component manufacturers may certify fuel lines and fuel tanks intended for recreational vehicles under this part 1060.

(e) Small SI. Certify engines, equipment, and fuel-system components as follows:

(1) Component manufacturers must certify their fuel lines and fuel tanks intended for Small SI engines and equipment under this part 1060, except as allowed by §1060.601(f).

(2) Equipment manufacturers must certify fuel system components they install in their equipment if the components are not certified to meet applicable evaporative emission standards. Equipment manufacturers would need to act as component manufacturers to certify fuel-system components under this part 1060.

(3) Engine manufacturers must meet all the requirements of this part 1060 that apply to equipment manufacturers for all fuel-system components they install on their engines. Engine manufacturers that produce Small SI engines with complete fuel systems are considered the equipment manufacturers for those engines under this part 1060.

(4) Equipment manufacturers must certify their equipment and are subject to all the requirements of this part 1060; however, this does not apply for equipment using portable nonroad fuel tanks.

(f) Summary of certification responsibilities. Tables 1 through 3 of this section summarize the certification responsibilities for different kinds of manufacturers as described in paragraphs (b) through (e) of this section. The term “No” as used in the tables means that a manufacturer is not required to obtain a certificate of conformity under paragraphs (b) through (e) of this section. In situations where multiple manufacturers are subject to the standards and other requirements of this part, such a manufacturer must nevertheless certify if the manufacturer who is required to certify under paragraphs (b) through (e) of this section fails to obtain a certificate of conformity.

| Equipment type |

Is the engine manufacturer required to certify for evaporative emission standards? a |

Code of Federal Regulations Cite for Certification |

|---|---|---|

| Marine SI | No | |

| Large SI | Yes | 40 CFR part 1048. |

| Recreational vehicles | No | |

| Small SI | No, unless engines are sold with complete fuel systems | 40 CFR part 1060. |

| a Fuel lines and fuel tanks that are attached to or sold with engines must be covered by a certificate of conformity. | ||

| Equipment type | Is the equipment manufacturer required to certify for evaporative emission standards? |

Code of Federal Regulations Cite for Certification |

|---|---|---|

| Marine SI | Yes, but only if vessel manufacturers install uncertified fuel lines or fuel tanks, or they intend to generate or use evaporative emission credits | 40 CFR part 1060. a |

| Large SI | Allowed but not required | 40 CFR part 1060. |

| Recreational vehicles | Yes, even if vehicle manufacturers install certified components | 40 CFR part 1051. |

| Small SI | Yes, unless the equipment uses portable nonroad fuel tanks | 40 CFR part 1060. a |

| a See the exhaust standard-setting part for provisions related to generating or using evaporative emission credits. | ||

| Equipment type | Is the component manufacturer required to certify fuel lines and fuel tanks? |

Code of Federal Regulations Cite for Certification |

|---|---|---|

| Marine SI | Yes, including portable marine fuel tanks and associated fuel lines a | 40 CFR part 1060. |

| Large SI | Allowed but not required | 40 CFR part 1060. |

| Recreational vehicles | Allowed but not required | 40 CFR part 1060. |

| Small SI | Yes a | 40 CFR part 1060. |

| a See §1060.601 for an allowance to make contractual arrangements with engine or equipment manufacturers instead of certifying. | ||

[86 FR 34528, Jun. 29, 2021]

§1060.10 How is this part organized?

This part 1060 is divided into the following subparts:

(a) Subpart A of this part defines the applicability of part 1060 and gives an overview of regulatory requirements.

(b) Subpart B of this part describes the emission standards and other requirements that must be met to certify equipment or components under this part. Note that §1060.110 discusses certain interim requirements and compliance provisions that apply only for a limited time.

(c) Subpart C of this part describes how to apply for a certificate of conformity.

(d) Subpart D of this part describes the requirements related to verifying that products are being produced as described in an approved application for certification.

(e) Subpart E of this part describes the requirements related to verifying that products are meeting the standards in use.

(f) Subpart F of this part describes how to measure evaporative emissions.

(g) Subpart G of this part and 40 CFR part 1068 describe requirements, prohibitions, and other provisions that apply to manufacturers, owners, operators, and all others.

(h) Subpart H of this part describes how to certify your equipment or components for inclusion in an emission averaging program allowed by an exhaust standard-setting part.

(i) Subpart I of this part contains definitions and other reference information.

§1060.15 Do any other CFR parts apply to me?

(a) There is a separate part of the CFR that includes exhaust emission requirements for each particular application, as described in §1060.1(a). We refer to these as the exhaust standard-setting parts. In cases where an exhaust standard-setting part includes evaporative requirements, apply this part 1060 as specified in the exhaust standard-setting part, as follows:

(1) The requirements in the exhaust standard-setting part may differ from the requirements in this part. In cases where it is not possible to comply with both the exhaust standard-setting part and this part, you must comply with the requirements in the exhaust standard-setting part. The exhaust standard-setting part may also allow you to deviate from the procedures of this part for other reasons.

(2) The exhaust standard-setting parts may reference some sections of this part 1060 or may allow or require certification under this part 1060. See the exhaust standard-setting parts to determine what provisions of this part 1060 apply for these equipment types.

(b) The requirements and prohibitions of part 1068 of this chapter apply to everyone, including anyone who manufactures, imports, owns, operates, or services any of the fuel systems subject to this part 1060. Part 1068 of this chapter describes general provisions, including the following areas:

(1) Prohibited acts and penalties for engine manufacturers, equipment manufacturers, and others.

(2) Exclusions and exemptions for certain products.

(3) Importing products.

(4) Defect reporting and recall.

(5) Procedures for hearings.

(c) Other parts of this chapter apply if referenced in this part.

Subpart B - Emission Standards and Related Requirements

§1060.101 What evaporative emission requirements apply under this part?

Products subject to this part must meet emission standards and related requirements as follows:

(a) Section 1060.102 describes permeation emission control requirements for fuel lines.

(b) Section 1060.103 describes permeation emission control requirements for fuel tanks.

(c) Section 1060.104 describes running loss emission control requirements for fuel systems.

(d) Section 1060.105 describes diurnal emission control requirements for fuel tanks.

(e) The following general requirements apply for components and equipment subject to the emission standards in §§1060.102 through 1060.105:

(1) Adjustable parameters. Components or equipment with adjustable parameters must meet all the requirements of this part for any adjustment in the practically adjustable range. See 40 CFR 1068.50.

(2) Prohibited controls. The following controls are prohibited:

(i) For anyone to design, manufacture, or install emission control systems so they cause or contribute to an unreasonable risk to public health, welfare, or safety while operating.

(ii) For anyone to design, manufacture, or install emission control systems with features that disable, deactivate, or bypass the emission controls, either actively or passively. For example, you may not include a manual vent that the operator can open to bypass emission controls. You may ask us to allow such features if needed for safety reasons or if the features are fully functional during emission tests described in subpart F of this part.

(3) Emission credits. Equipment manufacturers are allowed to comply with the emission standards in this part using evaporative emission credits only if the exhaust standard-setting part explicitly allows it for evaporative emissions. See the exhaust standard-setting part and subpart H of this part for information about complying with evaporative emission credits. For equipment manufacturers to generate or use evaporative emission credits, components must be certified to a family emission limit, which serves as the standard for those components.

(f) This paragraph (f) specifies requirements that apply to equipment manufacturers subject to requirements under this part, whether or not they are subject to and certify to any of the emission standards in §§1060.102 through 1060.105. Equipment manufacturers meeting these requirements will be deemed to be certified as in conformity with the requirements of this paragraph (f) without submitting an application for certification, as follows:

(1) Fuel caps, vents, and carbon canisters. You are responsible for ensuring that proper caps and vents are installed on each new piece of equipment that is subject to emission standards under this part. The following particular requirements apply to equipment that is subject to running loss or diurnal emission standards, including portable marine fuel tanks:

(i) All equipment must have a tethered fuel cap. Fuel caps must also include a visual, audible, or other physical indication that they have been properly sealed.

(ii) You may not add vents unless they are specified in or allowed by the applicable certificates of conformity.

(iii) If the emission controls rely on carbon canisters, they must be installed in a way that prevents exposing the carbon to water or liquid fuel.

(2) Fuel-line fittings. The following requirements apply for fuel-line fittings that will be used with fuel lines that must meet permeation emission standards:

(i) Use good engineering judgment to ensure that all fuel-line fittings will remain securely connected to prevent fuel leakage throughout the useful life of the equipment.

(ii) Fuel lines that are intended to be detachable (such as those for portable marine fuel tanks) must be self-sealing when detached from the fuel tank or engine.

(3) Refueling. For any equipment using fuel tanks that are subject to diurnal or permeation emission standards under this part, you must design and build your equipment such that operators can reasonably be expected to fill the fuel tank without spitback or spillage during the refueling event. The following examples illustrate designs that meet this requirement:

(i) Equipment that is commonly refueled using a portable gasoline container should have a fuel tank inlet that is larger than a typical dispensing spout. The fuel tank inlet should be located so the operator can place the nozzle directly in the fuel tank inlet and see the fuel level in the tank while pouring the fuel from an appropriately sized refueling container (either through the tank wall or the fuel tank inlet). We will deem you to comply with the requirements of this paragraph (f)(3)(i) if you design your equipment to meet applicable industry standards related to fuel tank inlets.

(ii) Marine SI vessels with a filler neck extending to the side of the boat should be designed for automatic fuel shutoff. Alternatively, the filler neck should be designed such that the orientation of the filler neck allows dispensed fuel that collects in the filler neck to flow back into the fuel tank. A filler neck that ends with a horizontal or nearly horizontal segment at the opening where fuel is dispensed would not be an acceptable design.

(g) Components and equipment must meet the standards specified in this part throughout the applicable useful life. Where we do not specify procedures for demonstrating the durability of emission controls, use good engineering judgment to ensure that your products will meet the standards throughout the useful life. The useful life is one of the following values:

(1) The useful life in years specified for the components or equipment in the exhaust standard-setting part.

(2) The useful life in years specified for the engine in the exhaust standard-setting part if the exhaust standards are specified for the engine rather than the equipment and there is no useful life given for components or equipment.

(3) Five years if no useful life is specified in years for the components, equipment, or engines in the exhaust standard-setting part.

[88 FR 4669, Jan. 24, 2023]

§1060.102 What permeation emission control requirements apply for fuel lines?

(a) Nonmetal fuel lines must meet permeation requirements as follows:

(1) Marine SI fuel lines, including fuel lines associated with outboard engines or portable marine fuel tanks, must meet the permeation requirements in this section.

(2) Large SI fuel lines must meet the permeation requirements specified in 40 CFR 1048.105.

(3) Fuel lines for recreational vehicles must meet the permeation requirements specified in 40 CFR 1051.110 or in this section.

(4) Small SI fuel lines must meet the permeation requirements in this section, unless they are installed in equipment certified to meet diurnal emission standards under §1060.105(e).

(b) Different categories of nonroad equipment are subject to different requirements with respect to fuel line permeation. Fuel lines are classified based on measured emissions over the test procedure specified for the class.

(c) The regulations in 40 CFR part 1048 require that fuel lines used with Large SI engines must meet the standards for EPA Low-Emission Fuel Lines. The regulations in 40 CFR part 1054 require that fuel lines used with handheld Small SI engines installed in cold-weather equipment must meet the standards for EPA Cold-Weather Fuel Lines. Unless specified otherwise in this subchapter U, fuel lines used with all other engines and equipment subject to the provisions of this part 1060, including fuel lines associated with outboard engines or portable marine fuel tanks, must meet the standards for EPA Nonroad Fuel Lines.

(d) The following standards apply for each fuel line classification:

(1) EPA Low-Emission Fuel Lines must have permeation emissions at or below 10 g/m 2/day when measured according to the test procedure described in §1060.510. Fuel lines that comply with this emission standard are deemed to comply with all the emission standards specified in this section.

(2) EPA Nonroad Fuel Lines must have permeation emissions at or below 15 g/m 2/day when measured according to the test procedure described in §1060.515.

(3) EPA Cold-Weather Fuel Lines must meet the following permeation emission standards when measured according to the test procedure described in §1060.515:

| Model year |

Standard (g/m 2/day) |

|---|---|

| 2012 | 290 |

| 2013 | 275 |

| 2014 | 260 |

| 2015 | 245 |

| 2016 and later | 225 |

(e) You may certify fuel lines as follow:

(1) You may certify straight-run fuel lines as sections of any length.

(2) You may certify molded fuel lines in any configuration representing your actual production, subject to the provisions for selecting a worst-case configuration in §1060.235(b).

(3) You may certify fuel line assemblies as aggregated systems that include multiple sections of fuel line with connectors and fittings. For example, you may certify fuel lines for portable marine fuel tanks as assemblies of fuel hose, primer bulbs, and self-sealing end connections. The length of such an assembly must not be longer than a typical in-use installation and must always be less than 2.5 meters long. You may also certify primer bulbs separately. The standard applies with respect to the total permeation emissions divided by the wetted internal surface area of the assembly. Where it is not practical to determine the actual internal surface area of the assembly, you may assume that the internal surface area per unit length of the assembly is equal to the ratio of internal surface area per unit length of the hose section of the assembly.

[73 FR 59298, Oct. 8, 2008, as amended at 74 FR 8426, Feb. 24, 2009]

§1060.103 What permeation emission control requirements apply for fuel tanks?

(a) Fuel tanks must meet permeation requirements as follows:

(1) Marine SI fuel tanks, including engine-mounted fuel tanks and portable marine fuel tanks, must meet the permeation requirements in this section.

(2) Large SI fuel tanks must meet diurnal emission standards as specified in §1060.105, which includes measurement of permeation emissions. No separate permeation standard applies.

(3) Fuel tanks for recreational vehicles must meet the permeation requirements specified in 40 CFR 1051.110 or in this section.

(4) Small SI fuel tanks must meet the permeation requirements in this section unless they are installed in equipment certified to meet diurnal emission standards under §1060.105(e).

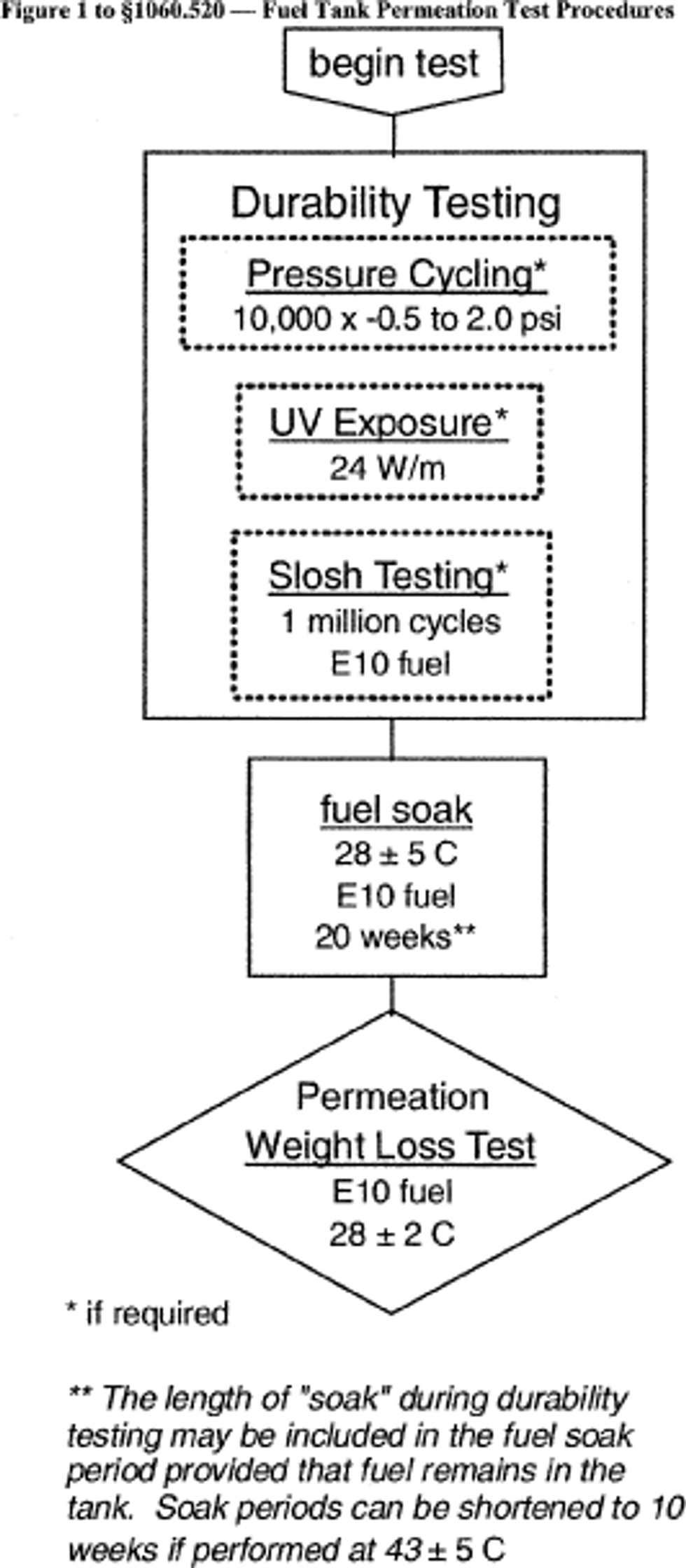

(b) Permeation emissions from fuel tanks may not exceed 1.5 g/m 2/day when measured at a nominal temperature of 28°C with the test procedures for tank permeation in §1060.520. You may also choose to meet a standard of 2.5 g/m 2/day if you perform testing at a nominal temperature of 40°C under §1060.520(d).

(c) The exhaust standard-setting part may allow for certification of fuel tanks to a family emission limit for calculating evaporative emission credits as described in subpart H of this part instead of meeting the emission standards in this section.

(d) For purposes of this part, fuel tanks do not include fuel lines that are subject to §1060.102, petcocks designed for draining fuel, grommets used with fuel lines, or grommets used with other hose or tubing excluded from the definition of “fuel line.” Fuel tanks include other fittings (such as fuel caps, gaskets, and O-rings) that are directly mounted to the fuel tank.

(e) Fuel caps may be certified separately relative to the permeation emission standard in paragraph (b) of this section using the test procedures specified in §1060.521. Fuel caps certified alone do not need to meet the emission standard. Rather, fuel caps would be certified with a Family Emission Limit, which is used for demonstrating that fuel tanks meet the emission standard as described in §1060.520(b)(5). For the purposes of this paragraph (e), gaskets or O-rings that are produced as part of an assembly with the fuel cap are considered part of the fuel cap.

(f) Metal fuel tanks that meet the permeation criteria in §1060.240(d)(2) or use certified nonmetal fuel caps will be deemed to be certified as in conformity with the requirements of this section without submitting an application for certification.

[73 FR 59298, Oct. 8, 2008, as amended at 74 FR 8427, Feb. 24, 2009; 75 FR 23026, Apr. 30, 2010]

§1060.104 What running loss emission control requirements apply?

(a) Engines and equipment must meet running loss requirements as follows:

(1) Marine SI engines and vessels are not subject to running loss emission standards.

(2) Large SI engines and equipment must prevent fuel boiling during operation as specified in 40 CFR 1048.105.

(3) Recreational vehicles are not subject to running loss emission standards.

(4) Nonhandheld Small SI engines and equipment that are not used in wintertime equipment must meet running loss requirements described in this section. Handheld Small SI engines and equipment are not subject to running loss emission standards.

(b) You must demonstrate control of running loss emissions in one of the following ways if your engines or equipment are subject to the requirements of this section:

(1) Route running loss emissions into the engine intake system so fuel vapors vented from the tank during engine operation are combusted in the engine. This may involve routing vapors through a carbon canister. If another company has certified the engine with respect to exhaust emissions, state in your application for certification that you have followed the engine manufacturer's installation instructions.

(2) Use a fuel tank that remains sealed under normal operating conditions. This may involve a bladder or other means to prevent pressurized fuel tanks.

(3) Get an approved executive order or other written approval from the California Air Resources Board showing that your system meets applicable running loss standards in California.

(c) If you are subject to both running loss and diurnal emission standards, use good engineering judgment to ensure that the emission controls are compatible.

[86 FR 34528, Jun. 29, 2021]

§1060.105 What diurnal requirements apply for equipment?

(a) Fuel tanks must meet diurnal emission requirements as follows:

(1) Marine SI fuel tanks, including engine-mounted fuel tanks and portable marine fuel tanks, must meet the requirements related to diurnal emissions specified in this section.

(2) Large SI fuel tanks must meet the requirements related to diurnal emissions specified in 40 CFR 1048.105.

(3) Recreational vehicles are not subject to diurnal emission standards.

(4) Small SI fuel tanks are not subject to diurnal emission standards, except as specified in paragraph (e) of this section.

(b) Diurnal emissions from Marine SI fuel tanks may not exceed 0.40 g/gal/day when measured using the test procedures specified in §1060.525 for general fuel temperatures. An alternative standard of 0.16 g/gal/day applies for fuel tanks installed in nontrailerable boats when measured using the corresponding fuel temperature profile in §1060.525. Portable marine fuel tanks are not subject to the requirements of this paragraph (b), but must instead comply with the requirements of paragraphs (c) and (d) of this section.

(c) Portable marine fuel tanks and associated fuel-system components must meet the following requirements:

(1) They must be self-sealing when detached from the engines. The tanks may not vent to the atmosphere when attached to an engine, except as allowed under paragraph (c)(2) of this section. An integrated or external manually activated device may be included in the fuel tank design to temporarily relieve pressure before refueling or connecting the fuel tank to the engine. However, the default setting for such a vent must be consistent with the requirement in paragraph (c)(2) of this section.

(2) They must remain sealed up to a positive pressure of 24.5 kPa (3.5 psig); however, they may contain air inlets that open when there is a vacuum pressure inside the tank. Such fuel tanks may not contain air outlets that vent to the atmosphere at pressures below 34.5 kPa (5.0 psig).

(d) Detachable fuel lines that are intended for use with portable marine fuel tanks must have connection points that are self-sealing when not attached to the engine or fuel tank.

(e) Manufacturers of nonhandheld Small SI equipment may optionally meet the diurnal emission standards adopted by the California Air Resources Board. To meet the requirement in this paragraph (e), equipment must be certified to the performance standards specified in Title 13 California Code of Regulations (CCR) 2754(a) based on the applicable requirements specified in CP-902 and TP-902, including the requirements related to fuel caps in Title 13 CCR 2756. Equipment certified under this paragraph (e) does not need to use fuel lines or fuel tanks that have been certified separately. Equipment certified under this paragraph (e) are subject to all the referenced requirements in this paragraph (e) as if these specifications were mandatory.

(f) The following general provisions apply for controlling diurnal emissions:

(1) If you are subject to both running loss and diurnal emission standards, use good engineering judgment to ensure that the emission controls are compatible.

(2) You may not use diurnal emission controls that increase the occurrence of fuel spitback or spillage during in-use refueling. Also, if you use a carbon canister, you must incorporate design features that prevent liquid gasoline from reaching the canister during refueling or as a result of fuel sloshing or fuel expansion.

(3) You must meet the following provisions from ABYC H-25, July 2010 (incorporated by reference in §1060.810) with respect to portable marine fuel tanks:

(i) Provide information related to the pressure relief method (25.8.2.1 and 25.8.2.1.1).

(ii) Perform system testing (25.10 through 25.10.5).

[73 FR 59298, Oct. 8, 2008, as amended at 74 FR 8427, Feb. 24, 2009; 75 FR 56482, Sept. 16, 2010; 86 FR 34528, Jun. 29, 2021]

§1060.120 What emission-related warranty requirements apply?

(a) General requirements. The certifying manufacturer must warrant to the ultimate purchaser and each subsequent purchaser that the new nonroad equipment, including its evaporative emission control system, meets two conditions:

(1) It is designed, built, and equipped so it conforms at the time of sale to the ultimate purchaser with the requirements of this part.

(2) It is free from defects in materials and workmanship that may keep it from meeting these requirements.

(b) Warranty period. Your emission-related warranty must be valid for at least two years from the date the equipment is sold to the ultimate purchaser.

(c) Components covered. The emission-related warranty covers all components whose failure would increase the evaporative emissions, including those listed in 40 CFR part 1068, appendix I, and those from any other system you develop to control emissions. Your emission-related warranty does not need to cover components whose failure would not increase evaporative emissions.

(d) Relationships between manufacturers. (1) The emission-related warranty required for equipment manufacturers that certify equipment must cover all specified components even if another company produces the component.

(2) Where an equipment manufacturer fulfills a warranty obligation for a given component, the component manufacturer is deemed to have also met that obligation.

[86 FR 34528, Jun. 29, 2021]

§1060.125 What maintenance instructions must I give to buyers?

Give ultimate purchasers written instructions for properly maintaining and using the emission control system. You may not specify any maintenance more frequently than once per year. For example, if you produce cold-weather equipment that requires replacement of fuel cap gaskets or O-rings, provide clear instructions to the ultimate purchaser, including the required replacement interval.

§1060.130 What installation instructions must I give to equipment manufacturers?

(a) If you sell a certified fuel-system component for someone else to install in equipment, give the installer instructions for installing it consistent with the requirements of this part.

(b) Make sure the instructions have the following information:

(1) Include the heading: “Emission-related installation instructions”.

(2) State: “Failing to follow these instructions when installing [IDENTIFY COMPONENT(S)] in a piece of nonroad equipment violates federal law (40 CFR 1068.105(b)), subject to fines or other penalties as described in the Clean Air Act.”

(3) Describe how your certification is limited for any type of application. For example:

(i) For fuel tanks sold without fuel caps, you must specify the requirements for the fuel cap, such as the allowable materials, thread pattern, how it must seal, etc. You must also include instructions to tether the fuel cap as described in §1060.101(f)(1) if you do not sell your fuel tanks with tethered fuel caps. The following instructions apply for specifying a certain level of emission control for fuel caps that will be installed on your fuel tanks:

(A) If your testing involves a default emission value for fuel cap permeation as specified in §1060.520(b)(5)(ii)(C), specify in your installation instructions that installed fuel caps must either be certified with a Family Emission Limit at or below 30 g/m2/day, or have gaskets made of certain materials meeting the definition of “low-permeability material” in §1060.801.

(B) If you certify your fuel tanks based on a fuel cap certified with a Family Emission Limit above 30 g/m2/day, specify in your installation instructions that installed fuel caps must either be certified with a Family Emission Limit at or below the level you used for certifying your fuel tanks, or have gaskets made of certain materials meeting the definition of “low-permeability material” in §1060.801.

(ii) If your fuel lines do not meet permeation standards specified in §1060.102 for EPA Low-Emission Fuel Lines, tell equipment manufacturers not to install the fuel lines with Large SI engines that operate on gasoline or another volatile liquid fuel.

(4) Describe instructions for installing components so they will operate according to design specifications in your application for certification. Specify sufficient detail to ensure that the equipment will meet the applicable standards when your component is installed.

(5) If you certify a component with a family emission limit above the emission standard, be sure to indicate that the equipment manufacturer must have a source of credits to offset the higher emissions. Also indicate the applications for which the regulations allow for compliance using evaporative emission credits.

(6) Instruct the equipment manufacturers that they must comply with the requirements of §1060.202.

(c) You do not need installation instructions for components you install in your own equipment.

(d) Provide instructions in writing or in an equivalent format. For example, you may post instructions on a publicly available Web site for downloading or printing, provided you keep a copy of these instructions in your records. If you do not provide the instructions in writing, explain in your application for certification how you will ensure that each installer is informed of the installation requirements.

[86 FR 34528, Jun. 29, 2021]

§1060.135 How must I label and identify the engines and equipment I produce?

The labeling requirements of this section apply for all equipment manufacturers that are required to certify their equipment or use certified fuel-system components. Note that engine manufacturers are also considered equipment manufacturers if they install a complete fuel system on an engine. See §1060.137 for the labeling requirements that apply separately for fuel lines, fuel tanks, and other fuel-system components.

(a) At the time of manufacture, you must affix a permanent and legible label identifying each engine or piece of equipment. The label must be—

(1) Attached in one piece so it is not removable without being destroyed or defaced.

(2) Secured to a part of the engine or equipment needed for normal operation and not normally requiring replacement.

(3) Durable and readable for the equipment's entire life.

(4) Written in English.

(5) Readily visible in the final installation. It may be under a hinged door or other readily opened cover. It may not be hidden by any cover attached with screws or any similar designs. Labels on marine vessels (except personal watercraft) must be visible from the helm.

(b) If you hold a certificate under this part for your engine or equipment, the engine or equipment label specified in paragraph (a) of this section must—

(1) Include the heading “EMISSION CONTROL INFORMATION”.

(2) Include your corporate name and trademark. You may identify another company and use its trademark instead of yours if you comply with the branding provisions of 40 CFR 1068.45.

(3) State the date of manufacture [MONTH and YEAR] of the equipment; however, you may omit this from the label if you stamp, engrave, or otherwise permanently identify it elsewhere on the equipment, in which case you must also describe in your application for certification where you will identify the date on the equipment.

(4) State: “THIS [equipment, vehicle, boat, etc.] MEETS U.S. EPA EVAP STANDARDS.”

(5) Identify the certified fuel-system components installed on the equipment as described in this paragraph (b)(5). Establish a component code for each certified fuel-system component, including those certified by other companies. You may use part numbers, certification numbers, or any other unique code that you or the certifying component manufacturer establish. This identifying information must correspond to printing or other labeling on each certified fuel-system component, whether you or the component manufacturer certifies the individual component. You may identify multiple part numbers if your equipment design might include an option to use more than one component design (such as from multiple component manufacturers). Use one of the following methods to include information on the label that identifies certified fuel-system components:

(i) Use the component codes to identify each certified fuel-system component on the label specified in this paragraph (b).

(ii) Identify the emission family on the label using EPA's standardized designation or an abbreviated equipment code that you establish in your application for certification. Equipment manufacturers that also certify their engines with respect to exhaust emissions may use the same emission family name for both exhaust and evaporative emissions. If you use the provisions of this paragraph (b)(5)(ii), you must identify all the certified fuel-system components and the associated component codes in your application for certification. In this case the label specified in this paragraph (b) may omit the information related to specific fuel-system components.

(c) If you produce equipment without certifying with respect to evaporative emissions, the equipment label specified in paragraph (a) of this section must —

(1) State: “MEETS U.S. EPA EVAP STANDARDS USING CERTIFIED COMPONENTS.”

(2) Include your corporate name.

(d) You may add information to the emission control information label as follows:

(1) You may identify other emission standards that the engine meets or does not meet (such as California standards). You may include this information by adding it to the statement we specify or by including a separate statement.

(2) You may add other information to ensure that the engine will be properly maintained and used.

(3) You may add appropriate features to prevent counterfeit labels. For example, you may include the engine's unique identification number on the label.

(e) Anyone subject to the labeling requirements in this part 1060 may ask us to approve modified labeling requirements if it is necessary or appropriate. We will approve the request if the alternate label is consistent with the requirements of this part.

[73 FR 59298, Oct. 8, 2008, as amended at 75 FR 23026, Apr. 30, 2010; 86 FR 34529, Jun. 29, 2021]

§1060.137 How must I label and identify the fuel-system components I produce?

The requirements of this section apply for manufacturers of fuel-system components subject to emission standards under this part 1060. However, these requirements do not apply if you produce fuel-system components that will be covered by a certificate of conformity from another company under §1060.601(f). These requirements also do not apply for components you certify if you also certify the equipment in which the component is installed and meet the labeling requirements in §1060.135.

(a) Label the components identified in this paragraph (a), unless the components are too small to be properly labeled. Unless we approve otherwise, we consider parts large enough to be properly labeled if they have space for 12 characters in six-point font (approximately 2 mm × 12 mm). For these small parts, you may omit the label as long as you identify those part numbers in your maintenance and installation instructions.

(1) All fuel tanks, except for metal fuel tanks that are deemed certified under §1060.103(f).

(2) Fuel lines. This includes primer bulbs unless they are excluded from the definition of “fuel line” under the standard-setting part. Label primer bulbs separately.

(3) Carbon canisters.

(4) Fuel caps, as described in this paragraph (a)(4). Fuel caps must be labeled if they are separately certified under §1060.103. If the equipment has a diurnal control system that requires the fuel tank to hold pressure, identify the part number on the fuel cap.

(5) Replaceable pressure-relief assemblies. This does not apply if the component is integral to the fuel tank or fuel cap.

(6) Other components we determine to be critical to the proper functioning of evaporative emission controls.

(b) Label your certified fuel-system components at the time of manufacture. The label must be —

(1) Attached so it is not removable without being destroyed or defaced. This may involve printing directly on the product. For molded products, you may use the mold to apply the label.

(2) Durable and readable for the equipment's entire life.

(3) Written in English.

(c) Except as specified in paragraph (d) of this section, you must create the label specified in paragraph (b) of this section as follows:

(1) Include your corporate name. You may identify another company instead of yours if you comply with the provisions of 40 CFR 1068.45.

(2) Include EPA's standardized designation for the emission family.

(3) State: “EPA COMPLIANT”.

(4) Fuel tank labels must identify the FEL, if applicable.

(5) Fuel line labels must identify the applicable permeation level. This may involve any of the following approaches:

(i) Identify the applicable numerical emission standard (such as 15 g/m 2/day).

(ii) Identify the applicable emission standards using EPA classifications (such as EPA Nonroad Fuel Lines).

(iii) Identify the applicable industry standard specification (such as SAE J30 R12).

(6) Fuel line labels must be continuous, with no more than 12 inches before repeating. We will consider labels to be continuous if the space between repeating segments is no longer than that of the repeated information. You may add a continuous stripe or other pattern to help identify the particular type or grade of your products.

(d) You may create an abbreviated label for your components. Such a label may rely on codes to identify the component. The code must at a minimum identify the certification status, your corporate name, and the emission family. For example, XYZ Manufacturing may label its fuel lines as “EPA-XYZ-A15” to designate that their “A15” family was certified to meet EPA's 15 g/m 2/day standard. If you do this, you must describe the abbreviated label in your application for certification and identify all the associated information specified in paragraph (c) of this section.

(e) You may ask us to approve modified labeling requirements in this section as described in §1060.135(e).

[73 FR 59298, Oct. 8, 2008, as amended at 75 FR 23026, Apr. 30, 2010; 86 FR 34529, Jun. 29, 2021]

Subpart C - Certifying Emission Families

§1060.201 What are the general requirements for obtaining a certificate of conformity?

Manufacturers of engines, equipment, or fuel-system components may need to certify their products with respect to evaporative emission standards as described in §§1060.1 and 1060.601. See §1060.202 for requirements related to certifying with respect to the requirements specified in §1060.101(f). The following general requirements apply for obtaining a certificate of conformity:

(a) You must send us a separate application for a certificate of conformity for each emission family. A certificate of conformity for equipment is valid starting with the indicated effective date but it is not valid for any production after December 31 of the model year for which it is issued. No certificate will be issued after December 31 of the model year. A certificate of conformity for a component is valid starting with the indicated effective date but it is not valid for any production after the end of the production period for which it is issued.

(b) The application must contain all the information required by this part and must not include false or incomplete statements or information (see §1060.255).

(c) We may ask you to include less information than we specify in this subpart as long as you maintain all the information required by §1060.250. For example, equipment manufacturers might use only components that are certified by other companies to meet applicable emission standards, in which case we would not require submission of emission data already submitted by the component manufacturer.

(d) You must use good engineering judgment for all decisions related to your application (see 40 CFR 1068.5).

(e) An authorized representative of your company must approve and sign the application.

(f) See §1060.255 for provisions describing how we will process your application.

(g) We may specify streamlined procedures for small-volume equipment manufacturers.

§1060.202 What are the certification requirements related to the general standards in § 1060.101?

Equipment manufacturers must ensure that their equipment is certified with respect to the general standards specified in §1060.101(f) as follows:

(a) If §1060.5 requires you to certify your equipment to any of the emission standards specified in §§1060.102 through 1060.105, describe in your application for certification how you will meet the general standards specified in §1060.101(f).

(b) If §1060.5 does not require you to certify your equipment to any of the emission standards specified in §§1060.102 through 1060.105, your equipment is deemed to be certified with respect to the general standards specified in §1060.101(f) if you design and produce your equipment to meet those standards.

(1) You must keep records as described in §1060.210. The other provisions of this part for certificate holders apply only as specified in §1060.5.

(2) Your equipment is deemed to be certified only to the extent that it meets the general standards in §1060.101(f). Thus, it is a violation of 40 CFR 1068.101(a)(1) to introduce into U.S. commerce such equipment that does not meet applicable requirements under §1060.101(f).

(c) Instead of relying on paragraph (b) of this section, you may submit an application for certification and obtain a certificate from us. The provisions of this part apply in the same manner for certificates issued under this paragraph (c) as for any other certificate issued under this part.

§1060.205 What must I include in my application?

This section specifies the information that must be in your application, unless we ask you to include less information under §1060.201(c). We may require you to provide additional information to evaluate your application.

(a) Describe the emission family's specifications and other basic parameters of the emission controls. Describe how you meet the running loss emission control requirements in §1060.104, if applicable. Describe how you meet any applicable equipment-based requirements of §1060.101(e) and (f). State whether you are requesting certification for gasoline or some other fuel type. List each distinguishable configuration in the emission family. For equipment that relies on one or more certified components, identify the EPA-issued emission family name for all the certified components.

(b) Describe the products you selected for testing and the reasons for selecting them.

(c) Describe the test equipment and procedures that you used, including any special or alternate test procedures you used (see §1060.501).

(d) List the specifications of the test fuel to show that it falls within the required ranges specified in subpart F of this part.

(e) State the equipment applications to which your certification is limited. For example, if your fuel system meets the emission requirements of this part applicable only to handheld Small SI equipment, state that the requested certificate would apply only for handheld Small SI equipment.

(f) Identify the emission family's useful life.

(g) Include the maintenance instructions you will give to the ultimate purchaser of each new nonroad engine (see §1060.125).

(h) Include the emission-related installation instructions you will provide if someone else will install your component in a piece of nonroad equipment (see §1060.130).

(i) Describe your emission control information label (see §§1060.135 and 1060.137).

(j) Identify the emission standards or FELs to which you are certifying the emission family.

(k) Present emission data to show your products meet the applicable emission standards. Note that §§1060.235 and 1060.240 allow you to submit an application in certain cases without new emission data.

(l) State that your product was tested as described in the application (including the test procedures, test parameters, and test fuels) to show you meet the requirements of this part. If you did not do the testing, identify the source of the data.

(m) Report all valid test results. Also indicate whether there are test results from invalid tests or from any other tests of the emission-data unit, whether or not they were conducted according to the test procedures of subpart F of this part. We may require you to report these additional test results. We may ask you to send other information to confirm that your tests were valid under the requirements of this part.

(n) Unconditionally certify that all the products in the emission family comply with the requirements of this part, other referenced parts of the CFR, and the Clean Air Act.

(o) Include good-faith estimates of U.S.-directed production volumes. Include a justification for the estimated production volumes if they are substantially different than actual production volumes in earlier years for similar models.

(p) Include other applicable information, such as information required by other subparts of this part.

(q) Name an agent for service located in the United States. Service on this agent constitutes service on you or any of your officers or employees for any action by EPA or otherwise by the United States related to the requirements of this part.

[86 FR 34529, Jun. 29, 2021]

§1060.210 What records should equipment manufacturers keep if they do not apply for certification?

If you are an equipment manufacturer that does not need to obtain a certificate of conformity for your equipment as described in §1060.5, you must keep the records specified in this section to document compliance with applicable requirements. We may review these records at any time. If we ask, you must send us these records within 30 days. You must keep these records for eight years from the end of the model year.

(a) Identify your equipment models and the annual U.S.-directed production volumes for each model.

(b) Identify the emission family names of the certificates that will cover your equipment, the part numbers of those certified components, and the names of the companies that hold the certificates. You must be able to identify this information for each piece of equipment you produce.

(c) Describe how you comply with any emission-related installation instructions, labeling requirements, and the general standards in §1060.101(e) and (f).

§1060.225 How do I amend my application for certification?

Before we issue a certificate of conformity, you may amend your application to include new or modified configurations, subject to the provisions of this section. After we have issued your certificate of conformity, you may send us an amended application requesting that we include new or modified configurations within the scope of the certificate, subject to the provisions of this section. You must amend your application if any changes occur with respect to any information included in your application.

(a) You must amend your application before you take any of the following actions:

(1) Add a configuration to an emission family. In this case, the configuration added must be consistent with other configurations in the emission family with respect to the criteria listed in §1060.230.

(2) Change a configuration already included in an emission family in a way that may affect emissions, or change any of the components you described in your application for certification. This includes production and design changes that may affect emissions any time during the equipment's lifetime.

(3) Modify an FEL for an emission family as described in paragraph (f) of this section. Note however that component manufacturers may not modify an FEL for their products unless they submit a separate application for a new emission family.

(b) To amend your application for certification, send the following relevant information to the Designated Compliance Officer.

(1) Describe in detail the addition or change in the configuration you intend to make.

(2) Include engineering evaluations or data showing that the amended emission family complies with all applicable requirements in this part. You may do this by showing that the original emission data are still appropriate for showing that the amended family complies with all applicable requirements in this part.

(3) If the original emission data for the emission family are not appropriate to show compliance for the new or modified configuration, include new test data showing that the new or modified configuration meets the requirements of this part.

(4) Include any other information needed to make your application correct and complete.

(c) We may ask for more test data or engineering evaluations. Within 30 days after we make our request, you must provide the information or describe your plan for providing it in a timely manner.

(d) For emission families already covered by a certificate of conformity, we will determine whether the existing certificate of conformity covers your new or modified configuration. You may ask for a hearing if we deny your request (see §1060.820).

(e) For emission families already covered by a certificate of conformity, you may start producing the new or modified configuration anytime after you send us your amended application and before we make a decision under paragraph (d) of this section. However, if we determine that the affected configurations do not meet applicable requirements, we will notify you to cease production of the configurations and may require you to recall the equipment at no expense to the owner. Choosing to produce equipment under this paragraph (e) is deemed to be consent to recall all equipment that we determine do not meet applicable emission standards or other requirements and to remedy the nonconformity at no expense to the owner. If you do not provide information we request under paragraph (c) of this section within 30 days after we request it, you must stop producing the new or modified equipment.

(f) If you hold a certificate of conformity for equipment and you have certified the fuel tank that you install in the equipment, you may ask us to approve a change to your FEL after the start of production. The changed FEL may not apply to equipment you have already introduced into U.S. commerce, except as described in this paragraph (f). If we approve a changed FEL after the start of production, you must identify the date or serial number for applying the new FEL. If you identify this by month and year, we will consider that a lowered FEL applies on the last day of the month and a raised FEL applies on the first day of the month. You may ask us to approve a change to your FEL in the following cases:

(1) You may ask to raise your FEL for your emission family at any time. In your request, you must show that you will still be able to meet the emission standards as specified in the exhaust standard-setting part. If you amend your application by submitting new test data to include a newly added or modified fuel tank configuration, as described in paragraph (b)(3) of this section, use the appropriate FELs with corresponding production volumes to calculate your production-weighted average FEL for the model year. In all other circumstances, you must use the higher FEL for the entire family to calculate your production-weighted average FEL under subpart H of this part.

(2) You may ask to lower the FEL for your emission family only if you have test data from production units showing that emissions are below the proposed lower FEL. The lower FEL applies only for units you produce after we approve the new FEL. Use the appropriate FELs with corresponding production volumes to calculate your production-weighted average FEL for the model year.

(g) You may produce equipment or components as described in your amended application for certification and consider those equipment or components to be in a certified configuration if we approve a new or modified configuration during the model year or production period under paragraph (d) of this section. Similarly, you may modify in-use products as described in your amended application for certification and consider those products to be in a certified configuration if we approve a new or modified configuration at any time under paragraph (d) of this section. Modifying a new or in-use product to be in a certified configuration does not violate the tampering prohibition of 40 CFR 1068.101(b)(1), as long as this does not involve changing to a certified configuration with a higher family emission limit.

(h) Component manufacturers may not change an emission family's FEL under any circumstances. Changing the FEL would require submission of a new application for certification.

[86 FR 34529, Jun. 29, 2021]

§1060.230 How do I select emission families?

(a) For purposes of certification, divide your product line into families of equipment (or components) that are expected to have similar emission characteristics throughout their useful life.

(b) Group fuel lines into the same emission family if they are the same in all the following aspects:

(1) Type of material including barrier layer.

(2) Production method.

(3) Types of connectors and fittings (material, approximate wall thickness, etc.) for fuel line assemblies certified together.

(c) Group fuel tanks (or fuel systems including fuel tanks) into the same emission family if they are the same in all the following aspects:

(1) Type of material, including any pigments, plasticizers, UV inhibitors, or other additives that are expected to affect control of emissions.

(2) Production method.

(3) Relevant characteristics of fuel cap design for fuel systems subject to diurnal emission requirements.

(4) Gasket material.

(5) Emission control strategy.

(6) Family emission limit, if applicable.

(d) Group other fuel-system components and equipment into the same emission family if they are the same in all the following aspects:

(1) Emission control strategy and design.

(2) Type of material (such as type of charcoal used in a carbon canister). This paragraph (d)(2) does not apply for materials that are unrelated to emission control performance.

(3) The fuel systems meet the running loss emission standard based on the same type of compliance demonstration specified in §1060.104(b), if applicable.

(e) You may subdivide a group of equipment or components that are identical under paragraphs (b) through (d) of this section into different emission families if you show the expected emission characteristics are different during the useful life.

(f) In unusual circumstances, you may group equipment or components that are not identical with respect to the things listed in paragraph (b) through (d) of this section into the same emission family if you show that their emission characteristics during the useful life will be similar. The provisions of this paragraph (f) do not exempt any engines or equipment from meeting all the applicable standards and requirements in subpart B of this part.

(g) Emission families may include components used in multiple equipment categories. Such families are covered by a single certificate. For example, a single emission family may contain fuel tanks used in both Small SI equipment and Marine SI vessels.

[86 FR 34529, Jun. 29, 2021]

§1060.235 What testing requirements apply for certification?

This section describes the emission testing you must perform to show compliance with the emission standards in subpart B of this part.

(a) Test your products using the procedures and equipment specified in subpart F of this part.

(b) Select an emission-data unit from each emission family for testing. If you are certifying with a family emission limit, you must test at least three emission-data units. In general, you must test a preproduction product that will represent actual production. However, for fuel tank permeation, you may test a tank with standardized geometry provided that it is made of the same material(s) and appropriate wall thickness. In general, the test procedures specify that components or systems be tested rather than complete equipment. For example, to certify your family of Small SI equipment, you would need to test a sample of fuel line for permeation emissions and a fuel tank for permeation emissions. Note that paragraph (e) of this section and §1060.240 allow you in certain circumstances to certify without testing an emission-data unit from the emission family. Select test components that are most likely to exceed (or have emissions nearer to) the applicable emission standards as follows:

(1) For fuel tanks, consider the following factors associated with higher emission levels:

(i) Smallest average wall thickness (or barrier thickness, as appropriate).

(ii) Greatest extent of pinch welds for tanks using barrier technologies.

(iii) Greatest relative area of gasket material, especially if gaskets are made of high-permeation materials.

(2) For fuel lines, consider the following factors associated with higher emission levels:

(i) Smallest average wall thickness (or barrier thickness, as appropriate).

(ii) Smallest inner diameter.

(c) You may not do maintenance on emission-data units.

(d) We may perform confirmatory testing by measuring emissions from any of your products from the emission family, as follows:

(1) You must supply your products to us if we choose to perform confirmatory testing. We may require you to deliver your test articles to a facility we designate for our testing.

(2) If we measure emissions on one of your products, the results of that testing become the official emission results for the emission family. Unless we later invalidate these data, we may decide not to consider your data in determining if your emission family meets applicable requirements in this part.

(e) You may ask to use carryover emission data from a previous production period instead of doing new tests, but only if all the following are true:

(1) The emission family from the previous production period differs from the current emission family only with respect to production period, items identified in §1060.225(a), or other characteristics unrelated to emissions. We may waive the criterion in this paragraph (e)(1) for differences we determine not to be relevant.

(2) The emission-data unit from the previous production period remains the appropriate emission-data unit under paragraph (b) of this section. For example, you may not carryover emission data for your family of nylon fuel tanks if you have added a thinner-walled fuel tank than was tested previously.

(3) The data show that the emission-data unit would meet all the requirements that apply to the emission family covered by the application for certification.

(f) We may require you to test another unit of the same or different configuration in addition to the unit(s) tested under paragraph (b) of this section.

(g) If you use an alternate test procedure under §1060.505, and later testing shows that such testing does not produce results that are equivalent to the procedures specified in this part, we may reject data you generated using the alternate procedure.

[86 FR 34529, Jun. 29, 2021]

§1060.240 How do I demonstrate that my emission family complies with evaporative emission standards?

(a) For purposes of certification, your emission family is considered in compliance with an evaporative emission standard in subpart B of this part if you do either of the following:

(1) You have test results showing a certified emission level from the fuel tank or fuel line (as applicable) in the family are at or below the applicable standard.

(2) You comply with design specifications as specified in paragraphs (d) through (f) of this section.

(b) Your emission family is deemed not to comply if any fuel tank or fuel line representing that family has an official emission result above the standard.

(c) Round each official emission result to the same number of decimal places as the emission standard.

(d) You may demonstrate for certification that your emission family complies with the fuel tank permeation standards specified in §1060.103 with any of the following control technologies:

(1) A coextruded high-density polyethylene fuel tank with a continuous ethylene vinyl alcohol barrier layer (with not more than 40 molar percent ethylene) making up at least 2 percent of the fuel tank's overall wall thickness with any of the following gasket and fuel-cap characteristics:

(i) No nonmetal gaskets or fuel caps.

(ii) All nonmetal gaskets and fuel caps made from low-permeability materials.

(iii) Nonmetal gaskets and fuel caps that are not made from low-permeability materials up to the following limits:

(A) Gaskets with a total exposed surface area less than 0.25 percent of the total inside surface area of the fuel tank. For example, a fuel tank with an inside surface area of 0.40 square meters may use high-permeation gasket material representing a surface area of up to 1,000 mm 2 (0.25% × 1/100 × 0.40 m 2 × 1,000,000 mm 2/m 2). Determine surface area based on the amount of material exposed to liquid fuel.

(B) Fuel caps directly mounted to the fuel tank with the surface area of the fuel cap less than 3.0 percent of the total inside surface area of the fuel tank. Use the smallest inside cross-sectional area of the opening on which the cap is mounted as the fuel cap's surface area.

(2) A metal fuel tank with the gasket and fuel-cap characteristics meeting the specifications in paragraphs (d)(1)(i) through (iii) of this section.

(e) You may demonstrate for certification that your emission family complies with the diurnal emission standards specified in §1060.105 with any of the following control technologies:

(1) A Marine SI fuel tank sealed up to a positive pressure of 7.0 kPa (1.0 psig); however, the fuel tank may contain air inlets that open when there is a vacuum pressure inside the tank.

(2) A Marine SI fuel tank equipped with a passively purged carbon canister that meets the requirements of this paragraph (e)(2). The carbon must adsorb no more than 0.5 grams of water per gram of carbon at 90% relative humidity and a temperature of 25±5°C. The carbon granules must have a minimum mean diameter of 3.1 mm based on the procedures in ASTM D2862 (incorporated by reference in §1060.810). The carbon must also pass a dust attrition test based on ASTM D3802 (incorporated by reference in §1060.810), except that hardness is defined as the ratio of mean particle diameter before and after the test and the procedure must involve twenty 1/2-inch steel balls and ten 3/4-inch steel balls. Use good engineering judgment in the structural design of the carbon canister. The canister must have a volume compensator or some other device to prevent the carbon pellets from moving within the canister as a result of vibration or changing temperature. The canister must have a minimum working capacity as follows:

(i) You may use the measurement procedures specified by the California Air Resources Board in Attachment 1 to TP-902 to show that canister working capacity is least 3.6 grams of vapor storage capacity per gallon of nominal fuel tank capacity (or 1.4 grams of vapor storage capacity per gallon of nominal fuel tank capacity for fuel tanks used in nontrailerable boats).

(ii) You may produce canisters with a minimum carbon volume of 0.040 liters per gallon of nominal fuel tank capacity (or 0.016 liters per gallon for fuel tanks used in nontrailerable boats). The carbon canister must have a minimum effective length-to-diameter ratio of 3.5 and the vapor flow must be directed with the intent of using the whole carbon bed. The carbon must have a minimum carbon working capacity of 90 grams per liter.

(f) We may establish additional design certification options where we find that new test data demonstrate that the use of a different technology design will ensure compliance with the applicable emission standards.

(g) You may not establish a family emission limit below the emission standard for components certified based on design specifications under this section even if actual emission rates are much lower.

[86 FR 34530, Jun. 29, 2021]

§1060.250 What records must I keep?

(a) Organize and maintain the following records:

(1) A copy of all applications and any summary information you send us.

(2) Any of the information we specify in §1060.205 that you were not required to include in your application.

(3) A detailed history of each emission-data unit. For each emission data unit, include all of the following:

(i) The emission-data unit's construction, including its origin and buildup, steps you took to ensure that it represents production equipment, any components you built specially for it, and all the components you include in your application for certification.

(ii) All your emission tests (valid and invalid), including the date and purpose of each test and documentation of test parameters described in subpart F of this part.

(iii) All tests to diagnose emission control performance, giving the date and time of each and the reasons for the test.

(iv) Any other significantevents.

(4) Annual production figures for each emission family divided by assembly plant.

(5) Keep a list of equipment identification numbers for all the equipment you produce under each certificate of conformity.

(b) Keep required data from emission tests and all other information specified in this section for eight years after we issue your certificate. If you use the same emission data or other information for a later model year, the eight-year period restarts with each year that you continue to rely on the information.

(c) Store these records in any format and on any media as long as you can promptly send us organized, written records in English if we ask for them. You must keep these records readily available. We may review them at any time.

[86 FR 34530, Jun. 29, 2021]

§1060.255 What decisions may EPA make regarding my certificate of conformity?

(a) If we determine an application is complete and shows that the emission family meets all the requirements of this part and the Clean Air Act, we will issue a certificate of conformity for the emission family for that production period. We may make the approval subject to additional conditions.