['Vehicle Technology', 'Passenger carriers']

['Vehicle Technology', 'School buses', 'Passenger vehicles']

10/08/2024

...

DEPARTMENT OF TRANSPORTATION

National Highway Traffic Safety Administration

49 CFR Part 571

[Docket No. NHTSA-2021-0088]

RIN 2127-AK96

Federal Motor Vehicle Safety Standards; Bus Rollover Structural Integrity

AGENCY: National Highway Traffic Safety Administration (NHTSA), Department of Transportation (DOT).

ACTION: Final rule.

SUMMARY: NHTSA is issuing this final rule to establish Federal Motor Vehicle Safety Standard (FMVSS) No. 227, “Bus rollover structural integrity,” to enhance the rollover structural integrity of over-the-road buses (motorcoaches), and other buses with a gross vehicle weight rating (GVWR) greater than 11,793 kilograms (kg) (26,000 pounds (lb)). This final rule, issued pursuant to the Moving Ahead for Progress in the 21st Century Act (MAP-21), requires the buses to provide a “survival space” in a rollover test to protect occupants from possible collapse of the bus structure around them. In addition, to reduce the likelihood of ejection, this final rule prohibits emergency exits from opening in the rollover test. This final rule ensures that bus roofs and side wall panels will resist deformation and intrusion into the occupant space in rollover crashes, and reduces the risk of emergency exits becoming ejection portals in a crash.

DATES: The effective date of this final rule is: December 30, 2024. Optional early compliance is permitted.

Petitions for reconsideration: Petitions for reconsideration of this final rule must be received not later than February 14, 2022.

ADDRESSES: Petitions for reconsideration of this final rule must refer to the docket number set forth above and be submitted to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue SE, Washington, DC 20590. Note that all petitions received will be posted without change to https://www.regulations.gov , including any personal information provided.

Privacy Act: Please see the Privacy Act heading under Rulemaking Analyses and Notices.

FOR FURTHER INFORMATION CONTACT: For non-legal issues, you may contact James Myers, NHTSA Office of Crashworthiness Standards, telephone 202-493-0031, fax 202-493-2990. For legal issues: Deirdre Fujita, NHTSA Office of Chief Counsel, telephone 202-366-2992, fax 202-366-3820. Address: National Highway Traffic Safety Administration, U.S. Department of Transportation, 1200 New Jersey Avenue SE, West Building, Washington, DC 20590.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Executive Summary

a. Introduction

b. How This Final Rule Differs From the Notice of Proposed Rulemaking

c. NTSB Recommendations

d. Costs and Benefits

e. NHTSA's Determination of MAP-21 Requirements and Considerations

f. Retrofitting

II. Introduction

III. NHTSA's Statutory Authority

a. National Traffic and Motor Vehicle Safety Act (Safety Act)

b. MAP-21 (The Motorcoach Enhanced Safety Act of 2012)

IV. Safety Need (FARS 2004-2018 Data Analysis)

V. Summary of the NPRM

VI. High Level Summary of the Comments

VII. Scope and Purpose of the Rule

VIII. Applicability of the Rule

a. Medium-Size Buses (Buses With a GVWR of 4,536 to 11,793 kg (10,000-26,000 lb))

b. Large Buses

IX. School Bus Derivative Buses

X. Performance Requirements

a. Severity of the Rollover Test

b. Intrusion Into the Survival Space

c. Luggage Racks and Seat Anchorages

d. Emergency Exits

XI. Glazing Issues

a. Side Glazing on the Non-Struck Side of the Bus

b. Type of Glazing

c. Moon Roofs

d. Struck-Side Window Evaluations

XII. Test Procedure Issues

a. Ballasting the Vehicle

b. Vehicle Fluids

c. Additional Tools for Survival Space Evaluation During Testing

XIII. Other Issues

a. ECE R.66 Alternative Compliance Methods

b. Regulatory Alternatives

1. FMVSS No. 216

2. FMVSS No. 220

c. Additional MAP-21 Considerations

XIV. Lead Time

XV. Retrofitting Used Buses

XVI. Overview of Costs and Benefits

XVII. Rulemaking Analyses and Notices

I. Executive Summary

a. Introduction

This final rule substantially improves motorcoach safety. It establishes an FMVSS to improve the resistance of motorcoach roofs and side wall panels to deformation and intrusion into the occupant compartment in rollover crashes, and fulfills a mandate in section 32703(b)(1) of MAP-21. This final rule also accords with section 32703(b)(2) of MAP-21 by requiring emergency exits to remain closed in a rollover to prevent partial and complete ejection of passengers.

This final rule achieves longstanding NHTSA and Departmental goals to enhance motorcoach safety. NHTSA identified four priority areas in which to improve the safety of motorcoaches and other large buses: Requiring passenger seat belts, improved rollover structural integrity, improved emergency evacuation, and fire safety. 1 With this final rule, NHTSA has completed research and rulemaking on the first two priority areas and completed research on the other two.

1 See “NHTSA's Approach to Motorcoach Safety,” Docket No. NHTSA-2007-28793. In NHTSA's plan, “motorcoach” referred to inter-city transport buses. In 2009, DOT also issued a Motorcoach Safety Action Plan that addressed additional factors, such as driver fatigue and operator maintenance schedules. An update to the Departmental plan was issued in December 2012, https://www.fmcsa.dot.gov/sites/fmcsa.dot.gov/files/docs/Motorcoach-Safety-Action-Plan-2012.pdf . This final rule is an action included in the Departmental plan.

Congress also focused on these and other areas in incorporating the Motorcoach Enhanced Safety Act of 2012 into MAP-21 (Pub. L. 112-141). Among other matters, MAP-21 directed NHTSA (as delegated by the Secretary of Transportation) to require seat belts in “motorcoaches,” a term, Congress stated, that has the same meaning given the term “over-the-road bus” in section 3038(a)(3) of the Transportation Equity Act for the 21st Century (49 U.S.C. 5310 note). An over-the-road bus (OTRB) is a bus characterized by an elevated passenger deck located over a baggage compartment. 2 NHTSA has used the term “over-the-road bus” in the FMVSSs issued pursuant to the MAP-21 mandates. For example, NHTSA fulfilled MAP-21's seat belt mandate by amending FMVSS No. 208, “Occupant crash protection,” to require seat belts in each passenger seating position in OTRBs, as well as in other buses that are not OTRBs (non-OTRBs) with a GVWR greater than 11,793 kg (26,000 lb). 3 (For the convenience of the reader, NHTSA uses the term “large buses” in this final rule to refer to OTRBs regardless of GVWR and non-OTRBs with a GVWR greater than 11,793 kg (26,000 lb), with some exceptions.)

2 Under section 32701(6) of the Motorcoach Enhanced Safety Act, “motorcoach” does not include a bus used in public transportation provided by, or on behalf of, a public transportation agency, or a school bus.

3 78 FR 70416, November 25, 2013; denial of petitions for reconsideration, 81 FR 19902, April 6, 2016.

Section 32703(b)(1) of MAP-21 also directed NHTSA to pursue rulemaking for OTRBs to establish improved roof and roof support standards that substantially improve the resistance of bus roofs to deformation and intrusion in rollovers. MAP-21 requires NHTSA to adopt a final rule if NHTSA determines that such standards meet the requirements and considerations in subsections (a) and (b) of section 30111 of the National Traffic and Motor Vehicle Safety Act. 4 As discussed in this final rule, NHTSA has made such a determination regarding an FMVSS for all large buses.

4 MAP-21, section 32703(b) and (b)(1)).

This final rule complements the November 2013 seat belt rule. With all new large buses manufactured since 2016 required to have lap and shoulder seat belts for passengers, increasing numbers of passengers can be belted. This final rule establishing FMVSS No. 227 will ensure that these belted passengers will be significantly protected against unreasonable risk of injury in frontal crashes and significantly protected against the risk of ejection in rollovers. Hand-in-hand with the seat belt rule, this final rule enhances the safety of these belted passengers by providing a “survival space” in a rollover, a space where the belted occupants are protected from intruding structures such as a collapsing roof or a detached luggage rack. The new standard's improvements to the roof and sidewall strength of the buses will also protect unbelted occupants against structural failure of the bus compartment. This final rule improves transportation safety for the most vulnerable in our society since more than half of motorcoach trips are made by children and senior citizens. 5 It furthers transportation equity by providing the same occupant crash protection to these passengers as the protection provided to occupants of other passenger motor vehicles, 6 by reducing deaths and injuries due to the crushing of the roof into the occupant compartment in rollover crashes.

5 “Motorcoach Census 2013, A Study of the Size and Activity of the Motorcoach Industry in the United States and Canada in 2012,” American Bus Association Foundation, February 27, 2014.

6 Passenger vehicles under 4,536 kg (10,000 lb) GVWR are subject to the requirements of FMVSS No. 216, “Roof crush resistance; Applicable unless a vehicle is certified to §216a,” or to FMVSS No. 216a, “Roof crush resistance, Upgraded standard.”

This final rule applies to all new large buses, with limited exceptions. The standard does not apply to school buses, prison buses, buses with perimeter seating, or to transit buses that are not OTRBs. School buses already meet an FMVSS for roof strength, which is FMVSS No. 220, “School bus rollover protection” (49 CFR 571.220). In response to comments, NHTSA has also decided not to apply the standard to “school bus derivative buses,” which this final rule defines as buses built on a school bus platform. These vehicles may not have school bus lights and stop arms meeting FMVSS No. 108 and No. 131, respectively, or seating systems meeting FMVSS No. 222, “School bus seating and passenger protection,” but the buses have safety systems that are otherwise identical to school buses regarding their emergency exits, rollover protection (FMVSS No. 220), bus body joint strength, and fuel system integrity. The vehicles could be certified as meeting the FMVSSs for “school buses” if they had school bus lights meeting FMVSS No. 108, stop arms meeting FMVSS No. 131, and seating systems meeting FMVSS No. 222. Because school bus derivative buses already meet the roof crush resistance requirements in FMVSS No. 220, it would be redundant to require the buses to meet Standard No. 227 established by this final rule.

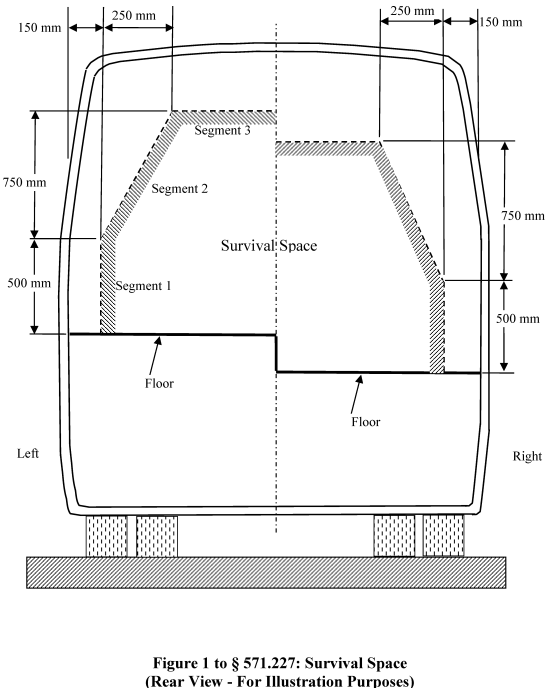

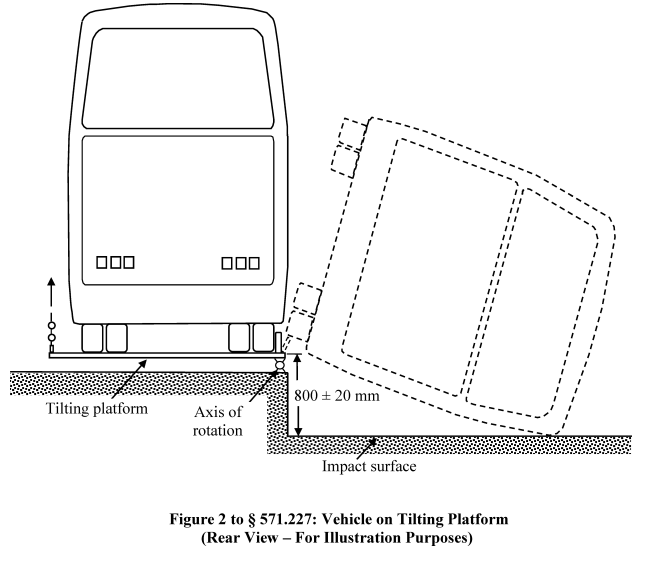

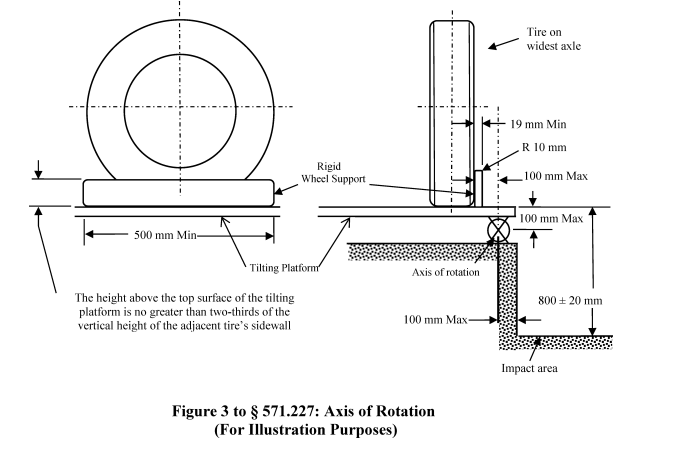

The test for the large buses adopted by this final rule is the complete vehicle rollover test of United Nations Economic Commission for Europe (ECE) Regulation 66, “Uniform Technical Prescriptions Concerning the Approval for Large Passenger Vehicles with Regard to the Strength of their Superstructure,” (ECE R.66). 7 The test simulates a real-world rollover crash of a large bus. The test bus is placed on a tilting platform that is 800 mm (24 inches) above a smooth and level concrete surface. One side of the tilting platform along the length of the bus is raised at a steady rate of not more than 5 degrees/second until the vehicle becomes unstable, rolls off the platform, and impacts the concrete surface below. Some commenters to the August 6, 2014 notice of proposed rulemaking (NPRM) (79 FR 46090) thought that the test was too lenient, but NHTSA believes that those views are mistaken. As explained in this preamble, this test imparts severe crash forces that the buses must resist. FMVSS No. 227 prohibits any intrusion into the “survival space” by any part of the vehicle outside the survival space, except for minute objects weighing less than 15.0 grams, such as pebbles of glazing, or bolts and screws, which do not pose an unreasonable risk to safety for occupants.

7 Dated February 2006, https://live.unece.org/fileadmin/DAM/trans/main/wp29/wp29regs/r066r1e.pdf . ECE R.66 defines “superstructure” as “the load-bearing components of the bodywork as defined by the manufacturer, containing those coherent parts and elements which contribute to the strength and energy absorbing capability of the bodywork, and preserve the residual space in the rollover test.” “Bodywork” means “the complete structure of the vehicle in running order, including all the structural elements which form the passenger compartment, driver's compartment, baggage compartment and spaces for the mechanical units and components.”

The “survival space” requirement ensures at least a minimum level of structural integrity for the buses by prohibiting intrusions into the occupant space that can cause harm. It establishes “improved roof and roof support standards” that substantially improve the resistance of the roof to deformation and intrusion, in accordance with MAP-21. It ensures that buses are constructed so that structures outside of the survival space, such as luggage racks and large pieces of glazing, do not enter the survival space in the rollover.

The requirement that emergency exits remain shut during and after the rollover test reduces the likelihood of emergency exits becoming ejection portals during rollovers, which is a goal consistent with MAP-21. Section 32703(b)(2) of MAP-21 requires NHTSA to consider requiring advanced glazing 8 standards for each motorcoach portal and “other portal improvements to prevent partial and complete ejection of motorcoach passengers, including children.” In NHTSA's motorcoach tests conducted during development of this rulemaking, roof and side emergency exits opened during the rollover event and the panes of advanced glazing popped out of their mounting. The requirement that emergency exits remain closed is a “portal improvement” established pursuant to section 32703(b)(2). Additionally, the requirement that the glazing panels not intrude into the survival space by detaching from the non-struck side of the bus will ensure the glazing panels remain intact in their mounting during bus rollover crashes and not form ejection portals. 9

8 MAP-21 (section 32702(1)) defines “advanced glazing” as “glazing installed in a portal on the side or the roof of a motorcoach that is designed to be highly resistant to partial or complete occupant ejection in all types of motor vehicle crashes.”)

9 On May 6, 2016 (81 FR 27904), NHTSA issued an NPRM proposing to establish FMVSS No. 217a to improve glazing materials used in motorcoaches and other large buses. The NPRM proposed an impactor test of glazing material to simulate the loading from an average size adult male impacting a window on the opposite side of a large bus in a rollover. Countermeasures used to meet the test would likely involve the use of advanced glazing. This final rule adopting FMVSS No. 227 would complement FMVSS No. 217a by improving the securement of the advanced glazing in the buses.

b. How This Final Rule Differs From the Notice of Proposed Rulemaking (NPRM)

The most noteworthy differences between this final rule and the NPRM 10 are highlighted below.

10 NPRM, August 6, 2014 (79 FR 46090).

1. This final rule adopts the NPRM's proposed ECE R.66 full vehicle test to improve the roof and structural integrity of OTRBs (except for a few buses with unique configurations), and non-OTRBs with a GVWR greater than 11,793 kg (26,000 lb)). The agency proposed to exclude non-OTRBs with perimeter seating from the standard. After evaluation of the comments received, this final rule excludes all perimeter seating buses, as there is not a sufficient reason to distinguish between buses just based on the location of a luggage compartment. Further, all prison buses are excluded due to the unique interior configuration of the buses, as are school bus derived buses, as the latter vehicles already meet NHTSA's school bus roof crush resistance standard.

2. This final rule adopts the NPRM's proposed prohibition that no part of the bus that is outside the survival space shall intrude into the survival space, both during movement of the tilting platform or resulting from impact of the bus on the impact surface. However, given the high force applications imparted to the bus structure in the rollover test, this final rule permits debris caused by the impact to fall into the survival space, such as small glazing pebbles or bolts and screws. The objects must not weigh more than 15.0 grams.

3. This final rule does not adopt the NPRM's proposal that each anchorage of an interior overhead luggage rack or other compartment must not completely separate from its mounting structure during movement of the tilting platform or resulting from impact of the bus on the impact surface. This final rule also does not adopt the NPRM's proposal that seat anchorages must not become dislodged during the test. Under the NPRM, those proposed prohibitions would have applied even if the luggage rack does not enter the survival space, or the seat anchorages dislodged within the survival space. NHTSA has decided that the primary purpose of this rulemaking is to establish a roof strength and crush resistance standard that improves the resistance of roofs to deformation and intrusion, i.e., by providing a survival space to occupants in rollovers. The purpose is achieved by prohibiting any structure, such as overhead luggage racks, from intruding into the survival space. By prohibiting overhead luggage racks from impeding into the survival space in the rollover, overhead luggage racks will have to be better anchored to the bus wall than they had in the past so that they do not detach and intrude into the survival space in the test. Thus, the proposed luggage rack provision is not needed to ensure that a survival space is provided since luggage racks are prohibited from intruding on the survival space. Similarly, the proposed seat anchorage provision is not necessary to achieve a survival space for occupants.

4. This final rule does not adopt the proposed provision that each side window glazing opposite the impacted side of the vehicle must remain attached to its mounting structure so as not to allow the passage of a 102 mm (5-inch) diameter sphere. The sphere test was proposed to ensure that, after the rollover test, the glazing remain firmly attached to its mounting. Because the primary purpose of this rulemaking is to provide a necessary survival space to occupants in rollovers, the purpose is achieved by prohibiting panes of glazing from falling into the survival space. The proposed requirement that the glazing not form openings is not germane to the survival space specification and unnecessarily complicates this rulemaking.

These changes and others are discussed in this preamble.

c. NTSB Recommendations

This final rule accords with the following National Transportation Safety Board (NTSB) recommendations that NTSB issued to NHTSA to improve motorcoach safety.

In an NTSB Highway Special Investigation Report (1999), Bus Crashworthiness Issues, 11 NTSB cited an October 1971 rollover of a 1970 Motor Coach Industries (MCI) bus as justification for the following recommendations:

11 National Transportation Safety Board. 1999, Bus Crashworthiness Issues . Highway Special Investigation Report NTSB/SIR-99/04. Washington, DC.

“H-99-50 (MW): In 2 years, issue performance standards for motorcoach roof strength that provide maximum survival space for all seating positions and that take into account current typical motorcoach window dimensions.”

“H-99-51: Once performance standards have been developed for motorcoach roof strength, require newly manufactured motorcoaches to meet those standards.”

In November 2009, after investigating an August 2008 Sherman, Texas bus crash, 12 the NTSB issued two safety recommendations. In this rollover crash, the failure of the overhead luggage rack on the vehicle impeded passenger egress and rescue efforts. Thus, NTSB stated that the Sherman accident and NHTSA's motorcoach testing indicate that the lack of standards for overhead luggage racks on motorcoaches leaves passengers at risk of serious injury from interaction with overhead luggage racks in a crash and made the following recommendations:

12 NTSB/HAR-09/02 PB2009-916202; Motorcoach Run-Off-the-Bridge and Rollover Sherman, Texas August 8, 2008; October 2009; https://www.ntsb.gov/investigations/AccidentReports/Reports/HAR0902.pdf , last accessed 09/08/2021.

“H-09-23: Develop performance standards for newly manufactured motorcoaches to require that overhead luggage racks remain anchored during an accident sequence.”

“H-09-24: Develop performance standards for newly manufactured motorcoaches that prevent head and neck injuries from overhead luggage racks.”

This final rule is consistent with the above NTSB recommendations. NHTSA is issuing performance standards for motorcoach roof strength that provide a survival space for all seating positions and is requiring new motorcoaches to meet those requirements. The standard established by this final rule requires that overhead luggage racks remain anchored during a rollover such that they do not enter the requisite survival space and injure passengers in the survival space.

d. Costs and Benefits

NHTSA has examined the benefits and costs of this final rule to ensure that the agency adopts only those amendments that contribute to improved safety and that are consistent with the directives of MAP-21 and the principles for regulatory decision-making set forth in Executive Order 12866, Regulatory Planning and Review . Over the 15-year period between 2004 and 2018, on average 22 fatalities occurred annually to occupants of these buses. Though a relatively small percentage of overall traffic fatalities, data show that rollover crashes are particularly deadly for large buses. Among the 122 fatal crashes, 56 were rollover crashes resulting in 189 fatalities. This final rule enhances passenger protection in rollover crashes in a reasonable and achievable way. As discussed in the next section, NHTSA adopts this final rule because a rollover structural integrity standard meets the requirements and considerations in subsections (a) and (b) of section 30111 of the Safety Act. This rule provides safety to passengers in a reasonable, objective, and cost-effective manner while harmonizing the standard internationally.

NHTSA has determined this rulemaking to be cost beneficial. 13

13 NHTSA has developed a Final Regulatory Evaluation (FRE) that discusses issues relating to the potential costs, benefits and other impacts of this regulatory action. The FRE is available in the docket for this final rule and may be obtained by downloading it or by contacting Docket Management at the address or telephone number provided at the beginning of this document.

The agency estimates the annual cost of this final rule to be between $4.81 million and $11.84 million (see Table 1 below). The countermeasures may include stronger roof structure, support pillars, side walls, shock resistant latches for emergency exits, and improved window mounting, resulting in material costs for each bus covered under this final rule ranging from $325 to $591. We estimate the total weight increase will range from 181 to 356 kilograms (kg) (399 to 784 pounds (lb)) for each of these buses and cost an additional $1,862 to $4,790 in fuel per vehicle over the lifetime of the vehicle.

We estimated the benefits of this rule taking into account the benefits attributable to the agency's final rules on seat belts and electronic stability control (ESC), as those rules also applied to this universe of vehicles. We estimate that requiring the subject buses to meet the rollover structural integrity performance criteria will save approximately 2-3 lives annually. In addition, we expect that the rule will reduce the number of seriously injured occupants by 4 annually. Thus, we estimate that approximately 3.12 equivalent lives are saved annually if 15 percent of occupants use seat belts, and approximately 2.45 equivalent lives are saved annually (undiscounted) if 90 percent of occupants use seat belts (see Table 2 below).

The cost per equivalent life saved is estimated to be $2.48 million to $4.99 million when belt use is estimated to be 15 percent, and $3.17 million to $6.38 million when belt use is estimated to be 90 percent (see Table 3 below). The net cost/benefit impact ranges from a net benefit of $13.09 million to $23.31 million if seat belt usage is 15 percent. If the seat belt usage rate is 90 percent, the estimated net cost/benefit impact ranges from a net benefit of $8.25 million to a net benefit of $16.97 million (see Table 4 below). While the cost and benefits of this rule will vary depending on the material/fuel costs per vehicle and on the belt use rate, per all available information this final rule will be cost beneficial.

| Potential Costs: | |

| Material Costs per Vehicle | $325 to $591. |

| Material Costs, Total New Fleet | $0.71 million to $1.30 million. |

| Fuel Costs per Vehicle @ 3% | $2,441 to $4,790. |

| Fuel Costs per Vehicle @ 7% | $1,862 to $3,654. |

| Fuel Costs, Total New Fleet | $4.10 million to $10.54 million. |

| Total Annual Cost | $4.81 million to $11.84 million. |

| 15 percent belt usage | 3.12 |

| 90 percent belt usage | 2.45 |

| 15 percent belt usage | 2.48-4.99 |

| 90 percent belt usage | 3.17-6.38 |

| 15% belt usage: | |||

| 3% Discount Rate | 6.08-11.84 | 29.40 | 17.56-23.31 |

| 7% Discount Rate | 4.81-9.34 | 22.43 | 13.09-17.61 |

| 90% belt usage: | |||

| 3% Discount Rate | 6.08-11.84 | 23.05 | 11.21-16.97 |

| 7% Discount Rate | 4.81-9.34 | 17.59 | 8.25-12.78 |

e. NHTSA's Determination of MAP-21 Requirements and Considerations

Section 32703(b) and (b)(1) of MAP-21 direct NHTSA: (a) To establish improved roof and roof support standards for motorcoaches that substantially improve the resistance of motorcoach roofs to deformation and intrusion to prevent serious occupant injury in rollover crashes involving motorcoaches; if (b) NHTSA determines that such standards meet the requirements and considerations set forth in subsections (a) and (b) of section 30111 of the Safety Act. In addition, section 32703(b)(2) directs NHTSA to consider portal improvements to prevent partial and complete ejection of motorcoach passengers, including children, if such standards meet the requirements and considerations set forth in subsections (a) and (b) of section 30111 of the Safety Act.

NHTSA has determined that the standard issued by this final rule meets the requirements and considerations of section 30111(a) and (b) of the Safety Act.

Section 30111(a)

The provision at 49 U.S.C. 30111(a) of the Safety Act authorizes the Secretary (NHTSA, by delegation) to prescribe Federal motor vehicle safety standards that are practicable, meet the need for motor vehicle safety, and are stated in objective terms. “Motor vehicle safety” is defined in the Safety Act as “the performance of a motor vehicle or motor vehicle equipment in a way that protects the public against unreasonable risk of accidents occurring because of the design, construction, or performance of a motor vehicle, and against unreasonable risk of death or injury in an accident, and includes nonoperational safety of a motor vehicle.” 14

14 49 U.S.C. 30102(a)(8).

NHTSA has determined that the standard issued by this final rule meets the requirements and considerations of section 30111(a) of the Safety Act. The standard is practicable, since it is based on the 2006 ECE R. 66 complete vehicle rollover test. New buses sold in Europe and other countries have been designed to meet the ECE R.66 rollover test requirements for over a decade. Further, NHTSA has conducted the vehicle rollover test of ECE R.66 in developing the NPRM. The three bus rollover tests the agency conducted using the ECE R.66 complete vehicle rollover test procedure showed that the test is feasible and practical for evaluating how well a bus structure maintains occupant survival space in a rollover. The standard is also cost beneficial, and thus is economically practicable.

Standard No. 227 meets the need for safety. Two of the real-world rollover crashes examined for this rule involved buses that had complete roof separation during the rollovers. 15 Almost all the passengers in those two crashes were ejected due to the loss of the bus roofs. This standard will increase the likelihood that bus structures maintain their roof structure and provide a residual survival space for the vehicle occupants. Studies of bus structures before and after implementation of ECE R.66 have concluded those requirements are effective in protecting bus occupants in rollover crashes. 16 A bus design in use prior to ECE R.66 experienced complete structural collapse of the roof in a rollover crash with one and a half full 360 degree rolls down a 6-meter embankment. That bus model redesigned to meet ECE R.66 requirements was able to maintain adequate survival space in a rollover crash with two and a quarter full 360 degree rolls down a 9-10 meter embankment. 17

15 These rollover crashes occurred in Turrell, Arkansas in 2004 and Mexican Hat, Utah in 2008.

16 Matolcsy, M. (2007), “The Severity of Bus Rollover Accidents,” Enhanced Safety of Vehicles (ESV) Paper 07-152, 20th ESV Conference, Lyon, France. Available at: https://www-esv.nhtsa.dot.gov/Proceedings/20/07-0152-O.pdf , last accessed April 26, 2021.

17 Matolcsy, M. (2006), “Rollover accident with ejection of occupants.” Informal working document of GRSG, No. GRSG-91-7. GRSG, 91st session, Geneva, October 2006.

This final rule meets the need for safety on many fronts. NHTSA's Motorcoach Safety Action Plan targeted safety improvements for buses to reduce the incidence of fatalities and serious injuries caused by bus rollover accidents. The seat belt requirements in FMVSS No. 208 18 for large buses provided a means for belted bus occupants to remain within the survival space in a crash. Buses designed to FMVSS No. 227 will provide a survival space for bus occupants. Anti-ejection requirements adopted for bus window portals 19 will reduce the incidence of partial ejection of belted occupants as well as reduce the occurrence of partial or full ejection of unbelted occupants. Further, NHTSA has proposed to establish an FMVSS to require advanced glazing that is highly resistant to occupant ejection for each motorcoach portal, pursuant to section 32703(b)(2) of MAP-21. 20 This final rule adopting FMVSS No. 227 would complement FMVSS No. 217a by improving the securement of the advanced glazing in the buses.

18 78 FR 70416, November 25, 2013.

19 81 FR 27904, May 6, 2016.

20 May 6, 2016 (81 FR 27904), supra.

The available information shows this final rule is cost beneficial. NHTSA estimates that requiring the subject buses to meet the performance criteria in this final rule will save approximately 2-3 lives and prevent 4 serious injuries annually. NHTSA estimates the net benefits range from $8.3 million to $23.3 million.

Standard No. 227 is stated in objective terms. The residual survival space is well defined, based upon a specified boundary at each transverse cross-section of the vehicle, with the cross-sections bounded by specified forwardmost and rearmost vehicle landmarks. Potential intrusion into the residual survival space may be objectively measured using standard test measurement methodologies-such as templates representing the outline of the residual survival space and high-speed video. The FMVSS No. 227 test procedure matches the full vehicle test procedure of ECE R.66. Studies have shown the ECE R.66 full vehicle rollover test to be a relatively severe loading condition replicating real-world bus rollover crashes. 21

21 Matolcsy, M. (2007), “The Severity of Bus Rollover Accidents,” Enhanced Safety of Vehicles (ESV) Paper 07-152, 20th ESV Conference, Lyon, France. Available at: https://www-esv.nhtsa.dot.gov/Proceedings/20/07-0152-O.pdf , last accessed April, 26 2021.

Section 30111(b)

The provision at 49 U.S.C. 30111(b) specifies that, when prescribing such standards, the Secretary must consider all relevant, available motor vehicle safety information, consult with the states as appropriate, consider whether a standard is reasonable, practicable, and appropriate for the types of motor vehicles or motor vehicle equipment for which it is prescribed, and consider the extent to which the standard will carry out the statutory purpose of section 30101 of the Act. Section 30101 states that the purpose of the statute is to reduce traffic accidents and deaths and injuries resulting from traffic accidents, and that it is therefore necessary to prescribe FMVSS, and to carry out needed safety research and development.

NHTSA has issued this final rule in accordance with section 30111(b). As discussed throughout this document, the agency concludes, after comprehensive reviews of relevant available safety information that includes over 15 years of crash data and development of a NHTSA plan for motorcoach safety, 22 that adopting FMVSS No. 227 meets the requirements and considerations of the Safety Act. NHTSA has provided the public with opportunities to review and provide input on the agency's safety plan and comment on adoption of this structural integrity final rule when it was in proposed form. This final rule accords with National Transportation Safety Board Recommendations H-99-50, H-99-51, H-09-23, and H-09-24, and NHTSA expects wide public support overall for this final rule. NHTSA has determined that FMVSS No. 227 is reasonable and appropriate for the vehicles to which the standard applies for improving bus occupant protection in rollover crashes and that establishing FMVSS No. 227 meets the purpose and policy of the Safety Act.

22 NHTSA's Approach to Motorcoach Safety (2007), (Docket No. NHTSA-2007-28793-001), supra.

f. Retrofitting

NHTSA has decided not to require existing large buses to meet the requirements adopted today for new buses. None of the commenters supported a retrofitting requirement. Based on its tests of older buses, the agency believes that many existing buses may need major structural changes to the vehicle's sidewall and roof structure to meet the requirements adopted in this document. Such structural changes are likely to be cost-prohibitive, making retrofitting impracticable.

II. Introduction

Over the 15-year period between 2004 and 2018, data from NHTSA's Fatality Analysis Reporting System (FARS) indicate there were 122 fatal crashes involving large buses. These crashes resulted in 326 occupant fatalities (274 passenger and 52 driver fatalities). During this period, on average 22 fatalities occurred annually to occupants of these buses.

Data indicate that rollover crashes are a particular safety problem for these buses. Among the 122 fatal crashes, 56 were rollover crashes resulting in 189 fatalities. While fatal rollover crashes constitute about 43 percent of all fatal crashes involving these bus types, they represent about 58 percent of all the occupant fatalities. Further, 56 percent of the rollover crash fatalities were attributable to occupant ejections (106 ejection fatalities out of the total of 189 fatalities in bus rollover crashes).

Congress was especially concerned about motorcoach rollover crashes in passing provisions of MAP-21 relevant to this final rule. MAP-21 requires DOT to “establish improved roof and roof support standards for motorcoaches that substantially improve the resistance of motorcoach roofs to deformation and intrusion to prevent serious occupant injury in rollover crashes involving motorcoaches” if such standards meet the requirements and considerations set forth in subsections (a) and (b) of section 30111 of title 49, United States Code. 23 Under MAP-21, “motorcoach” means an OTRB, but does not include a bus used in public transportation provided by, or on behalf of, a public transportation agency, or a school bus. MAP-21 24 also directs DOT to consider “portal improvements to prevent partial and complete ejection of motorcoach passengers, including children.”

23 MAP-21, section 32703(b)-(b)(1).

24 Id., section 32703(b)(2).

In accordance with MAP-21 and the Safety Act, we have issued this rollover-specific rule to apply to buses associated with an unreasonable risk of fatal rollover involvement. Thus, this final rule applies to OTRBs, and to all non-OTRBs with a GVWR greater than 11,793 kg (26,000 lb) (large buses), with some exceptions. The final rule excludes school buses, prison buses, non-OTRB transit buses, and buses with perimeter seating. 25 We have applied this rule to meet the requirements and considerations of MAP-21 and the Safety Act.

25 Under the standard, a bus with perimeter seating is a bus with 7 or fewer designated seating positions rearward of the driver's seating position that are forward-facing or can convert to forward-facing without the use of tools.

NHTSA is enhancing the safety of large buses in rollovers both by providing a survival space in the occupant compartment, and by reducing the likelihood of emergency exits opening during bus rollovers and becoming ejection portals. NHTSA achieved an important first step enhancing the safety of the buses in rollovers by the November 25, 2013 final rule that requires lap/shoulder belts for all passengers in large capacity buses. 26 This final rule builds on the rollover protection provided by seat belts by ensuring the buses provide a protective survival space for belted and unbelted retained occupants in rollovers. The 2013 seat belt rule significantly increased the ability of occupants of large buses to be retained in the bus structure in rollover crashes. This final rule provides the retained occupants a survival space in the bus structure, and strengthens the bus structure and emergency exit portals to protect unbelted occupants as well.

26 NHTSA estimates that seat belts are 77 percent effective in preventing fatalities in rollover crashes.

III. NHTSA's Statutory Authority

NHTSA is issuing this final rule pursuant to and in accordance with its authority under the National Traffic and Motor Vehicle Safety Act and the relevant provisions of MAP-21.

a. National Traffic and Motor Vehicle Safety Act (Safety Act)

Under 49 United States Code (U.S.C.) Chapter 301, Motor Vehicle Safety (49 U.S.C. 30101 et seq. ), the Secretary of Transportation is responsible for prescribing motor vehicle safety standards that are practicable, meet the need for motor vehicle safety, and are stated in objective terms (section 30111(a)). “Motor vehicle safety” is defined in the Safety Act (section 30102(a)(8)) as “the performance of a motor vehicle or motor vehicle equipment in a way that protects the public against unreasonable risk of accidents occurring because of the design, construction, or performance of a motor vehicle, and against unreasonable risk of death or injury in an accident, and includes nonoperational safety of a motor vehicle.” “Motor vehicle safety standard” means a minimum standard for motor vehicle or motor vehicle equipment performance (section 30102(a)(9)). When prescribing such standards, the Secretary must consider all relevant available motor vehicle safety information (section 30111(b)(1)). The Secretary must also consider whether a proposed standard is reasonable, practicable, and appropriate for the particular type of motor vehicle or motor vehicle equipment for which it is prescribed (section 30111(b)(3)) and the extent to which the standard will further the statutory purpose of reducing traffic accidents and associated deaths and injuries (section 30111(b)(4)). The responsibility for promulgation of FMVSSs is delegated to NHTSA (49 CFR 1.95).

b. MAP-21 (Incorporating the Motorcoach Enhanced Safety Act of 2012)

NHTSA is issuing this final rule in accordance with MAP-21, which incorporates the “Motorcoach Enhanced Safety Act of 2012” into Subtitle G. 27 Section 32703(b) of MAP-21 requires the Secretary (NHTSA by delegation) to prescribe regulations that would address certain aspects of motorcoach crash performance within two years if the agency determines that the standards would meet the requirements and considerations of section 30111(a) and (b) of the National Traffic and Motor Vehicle Safety Act. 28

27 Moving Ahead for Progress in the 21st Century Act, Public Law 112-141 (Jul. 6, 2012).

28 Id. at section 32703(b).

There are two subsections of section 32703(b) that are particularly relevant to this final rule. Subsection (b)(1) specifies that the Secretary is to establish improved roof and roof support standards that “substantially improve the resistance of motorcoach roofs to deformation and intrusion to prevent serious occupant injury in rollover crashes involving motorcoaches.” Subsection (b)(2) directs the Secretary to “consider advanced glazing standards for each motorcoach portal and [to] consider other portal improvements to prevent partial and complete ejection of motorcoach passengers, including children.” 29

29 While this final rule is mainly aimed at addressing the rollover structural integrity of specific large bus types, the reduced deformation of the bus structure would ensure that any advanced glazing installed on portals would be retained on their mounting and reduce the risk of occupant ejection in rollover crashes. Further, the requirement that emergency exits should not open during the rollover test would also ensure that the exits do not become ejection portals. Thus, both subsection (b)(1) and subsection (b)(2) are relevant to this rule.

MAP-21 contains other provisions pertaining to this rulemaking. Section 32702 states that “motorcoach” has the meaning given to the term “over-the-road bus” in section 3038(a)(3) of the Transportation Equity Act for the 21st Century (TEA-21). 30 Section 3038(a)(3) of TEA-21 (see 49 U.S.C. 5310 note) defines “over-the-road bus” as “a bus characterized by an elevated passenger deck located over a baggage compartment.” However, section 32702 of MAP-21 excludes transit buses and school buses from the “motorcoach” definition. 31

30 Moving Ahead for Progress in the 21st Century Act, Public Law 112-141, section 32702(6).

31 Id. at section 32702(6)(A)-(B).

MAP-21 further directs the Secretary to apply any regulation prescribed in accordance with section 32703(b) to all motorcoaches manufactured more than 3 years after the date on which the regulation is published. 32 In addition, the Secretary may assess the feasibility, benefits, and costs of applying any requirement established under section 32703(b)(2) to “motorcoaches manufactured before the date on which the requirement applies to new motorcoaches” (retrofit). 33 Finally, MAP-21 also authorizes the Secretary to combine the required rulemaking actions as the Secretary deems appropriate. 34

32 Id. at section 32703(e)(1).

33 Id. at section 32703(e)(2). “Retrofit Assessment for Existing Motorcoaches.”

34 Id. at section 32706.

IV. Safety Need (FARS 2004-2018 Data Analysis)

This rulemaking is conducted pursuant to the requirements of the Safety Act and MAP-21. It investigates whether there are unreasonable safety risks associated with rollover crashes in OTRB transportation, and if there are such risks, whether those safety risks can be reasonably reduced by having at least minimum levels of performance specified for rollover structural integrity and portal improvements.

This rulemaking improves occupant safety in large bus rollover crashes. While developing the November 25, 2013 seat belt final rule, NHTSA found that most fatalities in OTRB crashes are attributable to rollovers. Because more than half of the rollover fatalities are attributable to ejections, NHTSA issued a seat belt requirement to mitigate those ejections.

Enhancing the structural integrity of the interior of these buses works together with the seat belt rule. More occupants will be able to be retained in the bus compartment because of the belts, so it makes sense to require a survival space that protects these restrained occupants in a rollover. Moreover, regardless of whether occupants are belted, data 35 show that the risk of serious injuries and fatalities can be reduced by improving the vehicle structure to protect occupants against collapsing roofs and bus components falling or intruding into the survival space. Additionally, emergency exits should remain closed in a crash, as an open exit forms a portal through which occupants could be completely or partially ejected. This final rule adopts requirements to meet these objectives. 36

35 Maétolcsy, M (2012), “Passenger's Ejection in Bus Rollover Accident,” FISITA 2012 World Automotive Congress, paper F2012 F02-005. Available at https://unece.org/DAM/trans/doc/2012/wp29grsg/GRSG-103-02e.pdf . Last accessed May 03, 2021.

36 This final rule does not address the issue of glazing breaking in a rollover crash that would result in openings through which occupants could be completely or partially ejected even if emergency exits remain closed. This matter is addressed in the 2016 NPRM for advanced glazing (81 FR 27904), supra .

Updated Data Analysis (FARS Data 2004-2018)

After the August 6, 2014 NPRM, NHTSA re-analyzed FARS data files for the years 2004 to 2018 to assess the impacts of this rulemaking. 37 The bus body types coded in FARS are “school bus,” “transit bus,” “cross country/intercity bus” to represent OTRBs (motorcoaches), “other bus” to represent other types of buses, and “unknown bus” to represent buses that could not be categorized into the other four bus body type categories. Since 2011, a new bus body type, “van-based buses” was included. We also examined the FARS body type “Large Van” for van-based bus crashes for the years 2004-2018 where the vehicle was used to transport people. The buses can also be categorized by their GVWR: GVWR less than or equal to 10,000 lb, GVWR greater than 10,000 lb and less than or equal to 26,000 lb, and GVWR greater than 26,000 lb. The manner in which a bus was used is coded in FARS as “school bus,” “intercity bus,” “transit/city bus,” “shuttle bus,” and “modified for personal/private use.”

37 Later in this preamble we discuss our analysis of updated data regarding buses with a GVWR of 10,000-26,000 lb.

To assess the benefits and costs of this rule, the agency selected buses of body type “over-the-road bus (OTRB)” regardless of GVWR 38 and “other bus,” “unknown bus” and “van-based bus” body types with a GVWR greater than 26,000 lb, regardless of the manner in which they were used. 39 NHTSA also included fatal crashes of large vans with a GVWR greater than 26,000 lb used for transporting people (used as intercity bus, charter/tour bus, commuter bus, and shuttle bus) and found none for the 15-year period from 2004 to 2018.

38 All OTRBs (cross country/intercity buses) are covered under MAP-21.

39 Crashes and fatalities of unknown GVWR buses were proportionally distributed amongst the known values.

For the 15-year period from 2004 to 2018, there were a total of 326 bus occupant fatalities in the bus types covered by of FMVSS No. 227 (see Table 5). Among these fatalities, 230 were occupants of OTRBs with a GVWR greater than 26,000 lb, 15 were occupants of OTRBs with GVWR <26,000 lb, and 81 were occupants in buses coded as “other bus,” “unknown bus,” and “van-based bus” with a GVWR greater than 26,000 lb. In this 15-year period, fatalities among occupants of OTRBs account for 75 percent of the 326 fatalities.

| Year | OTRB GVWR <26,000 lb | OTRB GVWR >26,000 lb | Other bus GVWR >26,000 lb | Unknown bus GVWR >26,000 lb | Van-based GVWR >26,000 lb | Total |

|---|---|---|---|---|---|---|

| 2004 | 0 | 23 | 4 | 0 | 27 | |

| 2005 | 0 | 10 | 3 | 4 | 17 | |

| 2006 | 0 | 8 | 2 | 3 | 13 | |

| 2007 | 1 | 18 | 8 | 0 | 27 | |

| 2008 | 0 | 38 | 2 | 0 | 40 | |

| 2009 | 0 | 9 | 1 | 0 | 10 | |

| 2010 | 0 | 11 | 1 | 0 | 12 | |

| 2011 | 0 | 30 | 0 | 0 | 30 | |

| 2012 | 2 | 12 | 1 | 0 | 1 | 16 |

| 2013 | 9 | 8 | 3 | 1 | 0 | 21 |

| 2014 | 1 | 18 | 5 | 1 | 0 | 25 |

| 2015 | 0 | 12 | 3 | 6 | 0 | 21 |

| 2016 | 1 | 8 | 26 | 0 | 0 | 35 |

| 2017 | 1 | 5 | 1 | 0 | 0 | 7 |

| 2018 | 0 | 13 | 5 | 0 | 0 | 18 |

| Total | 15 | 230 | 65 | 15 | 1 | 326 |

The bus occupant fatalities were further classified by the type of crash (rollover, front, side, rear). FARS also coded fatal bus events “other” that could not be classified into one of the four crash types. The bus occupant fatalities in these “other” bus crash types were further analyzed and found to result from occupants jumping or falling off the bus, bus fire, explosion inside the bus, heavy object falling on an occupant, and fatal injuries to an occupant that are not crash related. Because these fatalities were not crash related, we did not include them in the count of bus crash fatalities.

In the 15-year period from 2004 to 2018, there were 122 fatal bus crashes of bus types covered by FMVSS No. 227, among which 71 involved OTRBs with a GVWR greater than 26,000 lb (Table 6). Among the 122 crashes, 56 were rollover events, 59 were frontal crashes, 7 were side crashes, and 0 were rear crashes.

| Bus body type and GVWR | Rollover | Frontal | Side | Rear | Total |

|---|---|---|---|---|---|

| OTRB (GVWR ≤26,000 lb) | 7 | 2 | 0 | 0 | 9 |

| OTRB (GVWR >26,000 lb) | 35 | 33 | 3 | 0 | 71 |

| Other (GVWR >26,000 lb) | 11 | 18 | 3 | 0 | 32 |

| Unknown (GVWR >26,000 lb) | 3 | 5 | 1 | 0 | 9 |

| Van-based (GVWR >26,000 lb) | 0 | 1 | 0 | 0 | 1 |

| Total | 56 | 59 | 7 | 0 | 122 |

The 122 fatal bus crashes (involving bus types covered under FMVSS No. 227) resulted in 326 bus occupant fatalities (52 drivers and 274 passengers), as shown in Table 7. Among these fatalities, 189 persons (11 drivers, 178 passengers) died in 56 rollover crashes. In contrast, 116 persons (40 drivers, 76 passengers) died in 59 frontal crashes. Bus rollover crashes accounted for 58 percent of the total bus occupant fatalities and 65 percent of the passenger fatalities.

These data show the devastating nature of bus rollover events, where a significant number of fatal or serious injuries can occur in a single bus rollover event. Among the 189 fatalities in bus rollover events, 149 fatalities (79 percent) were in OTRBs with a GVWR greater than 26,000 lb.

| Bus body type and GVWR | Rollover | Front | Side | Rear | All types | Total Driv ± Pass | |||||

| Driv | Pass | Driv | Pass | Driv | Pass | Driv | Pass | Driv | Pass | ||

| OTRB (GVWR ≤26,000 lb) | 2 | 11 | 1 | 1 | 0 | 0 | 0 | 0 | 3 | 12 | 15 |

| OTRB (GVWR >26,000 lb) | 7 | 142 | 25 | 46 | 1 | 9 | 0 | 0 | 33 | 197 | 230 |

| Other (GVWR >26,000 lb) | 1 | 23 | 12 | 23 | 0 | 6 | 0 | 0 | 13 | 52 | 65 |

| Unknown (GVWR >26,000 lb) | 1 | 2 | 2 | 5 | 0 | 5 | 0 | 0 | 3 | 12 | 15 |

| Van-based (GVWR >26,000 lb) | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| Total | 11 | 178 | 40 | 76 | 1 | 20 | 0 | 0 | 52 | 274 | 326 |

NHTSA also examined bus rollover events by the ejection status of occupants, among bus types covered by FMVSS No. 227 (see Table 8). Among the 178 passenger fatalities in bus rollover events, 98 were to occupants ejected or partially ejected from the bus.

| Bus body type and GVWR | Driver | Passenger | ||

| Not ejected | Ejected | Not ejected | Ejected | |

| OTRB (GVWR ≤26,000 lb) | 0 | 2 | 4 | 7 |

| OTRB (GVWR >26,000 lb) | 3 | 4 | 60 | 82 |

| Other bus (GVWR >26,000 lb) | 0 | 1 | 16 | 7 |

| Unknown bus (GVWR >26,000 lb) | 0 | 1 | 0 | 2 |

| Van-based bus (GVWR >26,000 lb) | 0 | 0 | 0 | 0 |

| Total | 3 | 8 | 80 | 98 |

These data show that while transportation by OTRBs (and other similar large buses) is an overall safe form of transportation, given the high occupancy of these vehicles, a significant number of fatal or serious injuries can occur in a single crash. This is especially true in bus rollover crashes that result in occupant ejections.

V. Summary of the NPRM

The NPRM underlying this final rule published August 6, 2014 (79 FR 46090). The agency proposed adoption of a new FMVSS No. 227 to set performance requirements that large buses must meet when tested using the full vehicle ECE R.66 test.

In support of the NPRM, the agency researched two existing roof crush/rollover standards: FMVSS No. 220, “School bus rollover protection,” and ECE R.66, “Uniform Technical Prescriptions Concerning the Approval of Large Passenger Vehicles with Regard to the Strength of their Superstructure.” 40 The agency purchased three different bus models for this test program. Two older models were selected because they were representative of the range of roof characteristics (such as design, material, pillars, shape, etc.) of large bus roofs in the U.S. fleet. The vehicles selected were two 12.2 meters (m) (40 feet) long model year (MY) 1992 MCI model MC-12, and two 12.2 m (40 feet) long MY 1991 Prevost model (Prevost) LeMirage buses. The agency also procured a MY 2000 MCI bus, Model 102-EL3, that was 13.7 m (45 foot) in length. All five of the buses purchased were tested to requirements in either FMVSS No. 220 or ECE R.66. A summary of the testing program can be found in the NPRM, supra , in section IV.b (79 FR 46100-46102). 41

40 ECE R.66 defines “superstructure” as “the load-bearing components of the bodywork as defined by the manufacturer, containing those coherent parts and elements which contribute to the strength and energy absorbing capability of the bodywork, and preserve the residual space in the rollover test.” “Bodywork” means “the complete structure of the vehicle in running order, including all the structural elements which form the passenger compartment, driver's compartment, baggage compartment and spaces for the mechanical units and components.” (Footnote added.)

41 For further information on the four older buses tested, a detailed discussion of the tests and results are available in the docket entry NHTSA-2007-28793-0019. For further information on the newer vehicle tested, see the test report, “ECE Regulation 66 Based Research Test of Motorcoach Roof Strength, 2000 MCI 102-EL3 Series Motorcoach, NHTSA No.: MY0800,” October 1, 2009, Report No.: ECE 66-MGA-2009-001, which can be found on NHTSA's website. https://www-nrd.nhtsa.dot.gov/database/aspx/searchmedia2.aspx?database=v_=6797&mediatype=r&r_tstno=6797 , Report 8. Step-by-step instructions on accessing the research report can be found in a memorandum in Docket No. NHTSA-2007-28793-0025.

Applicability

NHTSA proposed FMVSS No. 227 to apply to: (a) All new OTRBs, regardless of GVWR; and (b) all new buses other than OTRBs with a GVWR greater than 11,793 kg (26,000 lb), including prison buses and double-decker buses. 42 NHTSA focused on improving the rollover protection of buses with a GVWR greater than 26,000 lb because these were high-occupancy vehicles with an exceptionally high involvement in fatal rollovers. The agency also focused on the buses to which the agency's November 25, 2013 final rule on passenger seat belts applied.

42 Excepted from the NPRM were all school buses, and non-OTRB transit buses and non-OTRBs with perimeter seating.

Performance Requirements

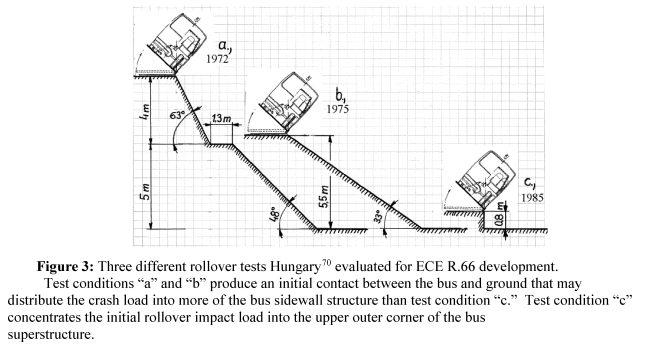

The NPRM proposed performance requirements that the buses must meet when subjected to a dynamic rollover test. The proposed test procedure replicated a rollover crash in a controlled manner. In the proposed test, the bus is placed on a tilting platform that is 800 mm (31.50 inches) above a smooth and level concrete surface. One side of the tilting platform along the length of the vehicle is raised at a steady rate of not more than 5 degrees/second until the vehicle becomes unstable, rolls off the platform, and impacts the concrete surface below with its roof leading edge. The rollover structural integrity test is illustrated below in Figure 1.

BILLING CODE 4910-59-P

BILLING CODE 4910-59-C

NHTSA proposed that the agency could position the bus such that either side (right or left) of the vehicle may be tested for compliance, at the agency's option. The NPRM proposed that a mass of up to 68 kg (150 lb) (ballast) be secured in each designated seating position (DSP) equipped with a seat belt.

The main proposed performance requirements were as follows:

(1) Intrusion into the survival space by any part of the vehicle outside the survival space would be prohibited;

(2) Each anchorage of all seats and interior overhead luggage racks and compartments would be prohibited from completely separating from its mounting structure during movement of the tilting platform or from impact of the bus on the impact surface; 43

43 One reason for the proposal for overhead luggage racks was to further enhance structural integrity. NHTSA thought that, to meet the luggage rack retention requirement, a bus would have to limit its deformation and “racking” in the test. “Racking” means the tilting of the sides of the bus relative to the bus floor. The retention requirement would have applied to luggage racks regardless of their position relative to the survival space. If the rack separated from its mounting it would be a failure, even if the overhead luggage rack did not enter the survival space.

(3) Emergency exits would be required to remain shut during the test, and, after the test, be operable in the manner required under FMVSS No. 217, “Bus emergency exits and window retention and release”; and,

(4) Each side window glazing on the non-impacted side and roof of the vehicle would be required to remain attached to its mounting such that there is no opening that allows the passage of a 102 mm (4 inch) diameter sphere when a force of no more than 22 Newtons (N) is applied to the sphere at any vector in a direction from the interior to the exterior of the vehicle.

The proposed requirements described in paragraphs (2), (3) and (4) are beyond those specified in ECE R.66. The ECE regulation mainly assesses the strength of the “superstructure” 44 in preventing intrusion into the survival space (ECE R.66 uses the term “residual space” rather than survival space). The regulation specifies that the superstructure of the vehicle shall have sufficient strength such that no part of the vehicle that is outside the residual space at the start of the test ( e.g. , pillars, luggage racks) shall intrude into the residual space during the test.

44 ECE R.66 Revision 1 defines “superstructure” as “the load-bearing components of the bodywork as defined by the manufacturer, containing those coherent parts and elements which contribute to the strength and energy absorbing capability of the bodywork, and preserve the residual space in the rollover test.”

VI. High Level Summary of the Comments

NHTSA received 19 comments on the NPRM from commenters that included large bus manufacturers producing large buses domestically and abroad (Van Hool, TEMSA, Prevost, MCI, Daimler EvoBus, Daimler Trucks/Thomas Built Buses, IC Bus), small (final-stage) manufacturers (Hemphill Brothers (Hemphill), NiteTrain Coach (NiteTrain)), a bus industry group (American Bus Association (ABA)), a glazing industry group (Enhanced Protective Glass Automotive Association (EPGAA)), motorcoach operators (Greyhound, Hemphill, NiteTrain 45 ), the National Transportation Safety Board (NTSB), a research laboratory (Florida A&M University's and Florida State University's Crashworthiness and Impact Analysis Laboratory (CIAL)), a consumer advocacy group (Advocates for Highway Safety (Advocates)), a group of families of passengers involved in six bus crashes, and two private citizens.

45 Both Hemphill and NiteTrain describe themselves not only as manufacturers of “entertainer buses” but also providers of motorcoach transportation services to the entertainment industry, operating the vehicles under contractual arrangements. Hemphill states that the majority of the contractual arrangements for operating the motorcoaches exceed 30 days, with many contracts covering periods of more than one year. Both Hemphill and NiteTrain describe “entertainer buses” as customized vehicles that include kitchens, bathrooms, bedrooms and lounging areas. Passengers are members of entertainment groups, including the lead artists, band members, road managers, stage hands and others, traveling on the road to different performance venues.

There was almost unanimous support for an FMVSS on large bus structural integrity, but differing views on what that standard should require. European bus manufacturers Van Hool and TEMSA opposed the proposed requirements and test procedures that differed from ECE R.66, believing that the ECE R.66 test was appropriate for assessing the strength of the bus superstructure and that subsystems such as seats, overhead racks, emergency exits, and glazing should not be assessed under the proposed standard. ABA concurred with this view. Daimler Trucks/Thomas Built Buses and IC Bus generally supported the intent and requirements of the NPRM but supported incorporating the test procedure of FMVSS No. 220, “School bus rollover protection” (49 CFR 571.220), rather than the test of ECE R.66, for school bus derived buses.

Hemphill and NiteTrain expressed concern about the test burdens on small manufacturers and suggested, as did ABA and Prevost, excluding entertainer buses from the standard. MCI and Van Hool suggested excluding prison transport buses and double-decker buses, respectively.

Consumers and consumer groups believed the proposal was not stringent enough or sufficiently representative of a high speed motorcoach rollover crash involving a bus sliding down an embankment. There were concerns expressed about the sphere test not representing the force imposed by an unbelted passenger thrown against the bus window. EPGAA believed that the proposed requirements should have accounted more for the potential use of advanced glazing as an ejection-mitigation countermeasure.

NTSB and CIAL believed the proposed standard should apply to all non-OTRBs with a GVWR greater than 4,536 kg (10,000 lb), rather than just to non-OTRBs with a GVWR greater than 11,793 kg (26,000 lb). NTSB also suggested the proposed performance requirements should apply to “moon roofs” and to side emergency doors.

No commenter supported a retrofit requirement.

VII. Scope and Purpose of the Rule

NHTSA proposed in the NPRM that the scope of FMVSS No. 227 would be to establish performance requirements for bus rollover structural integrity, and that the purpose of the standard would be to reduce death and injuries resulting from the structural collapse of the bus body structure, the unintended opening of emergency exits, and the detachment of window glazing, seats, and overhead luggage racks.

Van Hool, TEMSA, and the ABA opposed the scope of the proposed requirements and test procedures. The commenters believed that the ECE R.66 test was appropriate for assessing the strength of the bus “superstructure” but that subsystems such as seats, overhead racks, emergency exits, and glazing should not be assessed under FMVSS No. 227. Those commenters, and Prevost, believed that the ECE R.66 rollover test is only designed for, and is capable only of, providing an evaluation of the bus superstructure strength.

ECE R.66 defines “superstructure” as “the load-bearing components of the bodywork as defined by the manufacturer, containing those coherent parts and elements which contribute to the strength and energy absorbing capability of the bodywork, and preserve the residual space in the rollover test.” ECE R.66 requires that the superstructure of the bus must have sufficient strength to ensure that, during and after the rollover test, no part of the vehicle that is outside the survival space at the start of the test intrudes into the survival space during the test.

Agency Response

This final rule adopts the NPRM's proposed prohibition that no part of the bus that is outside the survival space shall intrude into the survival space, both during movement of the tilting platform or resulting from impact of the bus on the impact surface. 46 However, after consideration of the comments, NHTSA has decided not to adopt the NPRM's proposal that each anchorage of an interior overhead luggage rack or other compartment must not completely separate from its mounting structure during movement of the tilting platform or resulting from impact of the bus on the impact surface or that seat anchorages not become dislodged during the test.

46 In response to comments, however, the final rule permits detritus and other debris caused by the impact to fall into the survival space, such as small glazing pebbles or bolts and screws. The objects must not weigh more than 15.0 grams. This issue is discussed in detail below.

Under the NPRM, those proposed prohibitions would have applied even if the luggage rack does not enter the survival space, or the seat anchorages dislodge within the survival space. NHTSA has decided that the primary purpose of this rulemaking is to establish a roof strength and crush resistance standard that improves the resistance of the bus superstructure to deformation and intrusion, i.e. , by providing a survival space to occupants in rollovers. The purpose is achieved by prohibiting any structure, such as overhead luggage racks, from intruding into the survival space. By prohibiting overhead luggage racks from impeding into the survival space in the rollover, overhead luggage racks will have to be better anchored to the bus wall than they had been in the past, so that they do not detach and intrude into the survival space in the test. Thus, the proposed luggage rack provision is not needed to provide a survival space, since luggage racks are prohibited from intruding into the survival space. By being securely anchored so that they do not fall into the survival space, luggage racks will be less likely to impede egress in an emergency, or fall and cause head and neck injuries to occupants.

NHTSA has decided against adopting the NPRM's proposal that seat anchorages must not become dislodged during the test. The agency believes the seat anchorage provision is not necessary to achieve a survival space for occupants. NHTSA proposed the requirement for the retention of seat anchorages because of the agency's test of the MY 1991 Prevost LeMirage bus. 47 In the test, anchorages of a seat with a restrained mid-size adult male dummy completely separated from its bus attachment location, allowing the seat to fall across the bus with the restrained dummy attached to the seat. NHTSA believed at the NPRM stage that the failure of the seat anchorages during the rollover test presented a significant safety risk to restrained occupants in bus rollover events and reduced the effectiveness of seat belts.

47 A summary of the test may be found in the NPRM, supra , in section IV.b 79 FR 46100-46102.

However, after considering the comments and other information, NHTSA concludes a specific requirement in FMVSS No. 227 for seat anchorages to remain completely attached is unnecessary for several reasons. First, the seat anchorages in the MY 1991 Prevost LeMirage separated from the bus because the seat was bolted to unreinforced sheet metal of the bus sidewall. In NHTSA's test of the newer MY 2000 MCI bus Model 102-EL3, none of the seats anchorages failed—despite the fact that certain seats were ballasted with either a 150 lb anthropomorphic ballast or with 150 lb steel weights. That is, the seats remained attached even while tested under highly demanding conditions, with the ballasts attached to the seats. This test of the MY 2000 MCI bus demonstrates that bus seat anchorage designs have improved since the MY 1991 and 1992 buses NHTSA tested in its test program.

Second, it is likely the connectivity strength of seat anchorage designs have improved even more since the design of the MY 2000 bus because of the agency's 2013 final rule requiring lap/shoulder belts on all large buses. The final rule requires the lap/shoulder belts to be integral to the bus seats, and that the belt anchorage, together with the seat anchorage to the bus, meet the rigorous strength requirements of FMVSS No. 210, “Seat belt assembly anchorages” (49 CFR 571.210). FMVSS No. 210 requires seat anchorages, attachment hardware, and attachment bolts to withstand loads of 13,345 N (3,000 lb) applied simultaneously to the lap belt portion and the shoulder belt portion of the Type 2 restraint system. The seat anchorages of new large buses meeting FMVSS No. 210 will be reinforced over and beyond the design of a MY 2000 bus, which reduces the risk even further that the seats will detach from the bus structure in a rollover as had been observed in the tests of the MY 1991 and 1992 buses. Thus, adding a specific requirement in FMVSS No. 227 for the seat anchorages to remain completely attached duplicates the seat anchorage retention requirements of FMVSS No. 210.

The agency's bus rollover tests found that glazing panels vacated their window mountings during the rollover. In adopting the proposal that items outside of the survival space must not enter the survival space, this final rule prohibits large panes of glazing falling into the survival space from the non-struck side of the bus and injuring occupants. Strengthening the structure of the bus and glazing mountings to resist the rollover crash forces that act to pop out window glazing is an important “portal improvement” to prevent partial and complete ejection of motorcoach passengers,” as directed by MAP-21 section 32703(b)(2). Further, strengthening the frames is critical to rollover safety if the subject buses employ advanced glazing that mitigate the risk of occupant ejection in rollovers. NHTSA research into advanced glazing as a means of mitigating occupant ejection 48 revealed the need for significant improvement in the structural integrity of motorcoaches before the benefits of advanced glazing materials could be achieved. FMVSS No. 227's survival space requirement will help prevent glazing from popping out or otherwise detaching from its window mount and will help ensure the safety countermeasures are retained in the window frames in a crash.

48 Martec Limited, “Motorcoach Glazing Retention Test Development For Occupant Impact During a Rollover,” August 2006; Docket No. NHTSA-2002-11876-0015. Among other things, this research found that advanced glazing, such as laminate glazing, could pop out of its mounting due to torsional deformation of the structure around the window.

This final rule adopts the requirement for emergency exits to remain closed. This requirement is beyond ECE R.66 but is needed to address concerns relevant to the U.S. NHTSA's bus rollover tests found that emergency exit windows and roof hatches opened during the rollover. NHTSA considers open emergency exits potential safety hazards, as open emergency exits create unsafe ejection portals during a rollover crash. Approximately two-thirds of the fatalities in bus rollover crashes in this country involve occupants ejected from the bus. Reducing the likelihood of ejections through these portals by upgrading latches and hinges will reduce the fatality risk in rollovers and conform to the mandate of MAP-21 section 32703(b)(2).

ABA states that NHTSA placed too much emphasis on preventing unbelted passenger ejection rather than on ensuring the integrity of the body structure. It also states that the FMVSS No. 227 requirements that are not in ECE R.66 replicate the benefits already achieved through the bus seat belt rule.

NHTSA does not agree that FMVSS No. 227 overemphasizes unbelted passengers. Passengers using seat belts, and those that do not, will benefit from the standard by being protected from collapsing bus structures or contact with loose heavy objects. The requirements of FMVSS No. 227 supplement, and do not replicate, the agency's final rule on passenger seat belts. With belted passengers more likely to be retained in the bus interior because of the belts, FMVSS No. 227 improves the protective attributes of the occupant compartment in which they are retained. FMVSS No. 227 will benefit unbelted occupants by helping retain glazing in window frames and providing at least a minimum level of protection against dangerous structural collapse into the occupant compartment. The requirement that emergency exits remain closed during the rollover test increases the likelihood that emergency exits do not become ejection portals during rollover crashes, including crashes involving more than a quarter turn. These requirements will benefit belted and unbelted occupants, as keeping side window exits closed protects against partial ejection of belted occupants and partial and complete ejections of unbelted occupants, including children.

VIII. Applicability of the Rule

NHTSA proposed to apply FMVSS No. 227 to high-occupancy vehicles with an unreasonably high involvement in fatal rollovers, and on which Congress focused in MAP-21. 49 NHTSA proposed to apply FMVSS No. 227 to buses to which the agency's November 25, 2013 final rule on passenger seat belts applied. 50 NHTSA's view in the NPRM was that FMVSS No. 227 should apply to those buses with seat belts, so that a survival space could be provided to the belted occupants. 51

49 MAP-21 Subtitle G, the “Motorcoach Enhanced Safety Act of 2012,” defined “motorcoach” as having the meaning given the term “over-the-road bus” in section 3038(a)(3) of TEA-21 (49 U.S.C. 5310 note) but did not include a transit bus or a school bus. Under MAP-21, an over-the-road bus is a bus characterized by an elevated passenger deck located over a baggage compartment.

50 NHTSA's seat belt rule applied to all new over-the-road buses regardless of GVWR, including transit buses, prison buses, and perimeter-seating buses). The rule also applied to non-OTRBs that have a GVWR greater than 11,793 kg (26,000 lb), except for non-OTRB transit buses, prison buses, and perimeter-seating buses. The seat belt rule did not apply to school buses.

51 The proposed rollover structural integrity requirements applied to all new over-the-road buses regardless of GVWR (except for school buses). The rule also applied to all new non-OTRBs with a GVWR greater than 11,793 kg (26,000 lb), except for school buses, transit buses, and perimeter-seating buses.

The agency received a number of comments relating to the proposed applicability of FMVSS No. 227. Two commenters requested us to include medium-size buses (buses with a GVWR between 4,536-11,793 kg (10,000-26,000 lb), two suggested excluding entertainer buses, one suggested excluding prison transport buses and another suggested excluding double-decker buses.

a. Medium-Size Buses (Buses With a GVWR of 4,536 to 11,793 kg (10,000-26,000 lb))

In the NPRM, NHTSA proposed not applying FMVSS No. 227 to medium-size buses. NHTSA based the decision on an analysis of crash data for medium-size buses. The agency examined 2000-2009 FARS data showing 42 occupant fatalities in buses with a GVWR between 4,536-11,793 kg (10,000-26,000 lb), of which 24 fatalities were a result of 13 rollover crashes. Over the ten-year period between 2000-2009, medium-size buses were associated with an average of 1.3 rollover crashes per year and 2.4 fatalities per year. In contrast, there was an average of 3.2 rollover crashes annually among large buses (OTRBs and non-OTRBs with a GVWR greater than 11,793 kg (26,000 lb)). These large bus rollover crashes resulted in an average of 11.4 fatalities per year. Among all fatalities occurring in rollover crashes in buses coded in FARS as “cross-country,” “other,” and “unknown” with a GVWR greater than 4,536 kg (10,000 lb), 83 percent were in buses with a GVWR greater than 11,793 kg (26,000 lb).

Two commenters (NTSB, CIAL) disagreed with the agency and commented that NHTSA should include medium-sized buses in the applicability of FMVSS No. 227. 52

52 While CIAL focused on paratransit medium-size buses, it requests applying FMVSS No. 227 to all medium-size buses. Further, as its comment does show that paratransit buses have a different safety concern compared other medium-size buses, we are responding to the comment about the whole weight class rather than specifically regarding paratransit buses only.

NTSB Comment

NTSB commented that medium-size buses are often used in a similar fashion as motorcoaches with GVWRs over 11,793 kg (26,000 lb). It disagreed with the data analysis in the NPRM showing that medium-size buses do not have the same crash involvement as OTRBs and non-OTRBs with a GVWR over 11,793 kg (26,000 lb). NTSB stated that FARS has coding issues that may result in undercounting fatalities for the medium-size bus type. It references several crashes that it believes were not counted in the FARS database and suggest that the University of Michigan's Buses Involved in Fatal Accidents (BIFA) database has a more accurate classification of crashes.

Agency Response

NTSB correctly pointed out that we had not included the data that NTSB discussed in its comment. We have updated our FARS data analysis on medium-size buses to include these data. Even with the adjustment, however, our analyses find that medium-size buses do not pose a sufficient safety need to warrant application of FMVSS No. 227 to the buses.

After NTSB commented, NHTSA carefully reexamined and updated FARS data to determine whether the agency under-counted the medium-size bus fatalities. We specifically used FARS data from 2004 to 2018 to ascertain the fatalities attributable to medium-size buses.

FARS has five relevant categories for medium-size buses that are non-OTRBs: “other bus,” “unknown bus,” “van-based bus,” “school bus,” and “transit bus.” Due to the intended scope of this rulemaking, NHTSA focused on only the first three categories.