...

(a) Each owner or operator subject to the provisions of this subpart shall comply with the test methods and procedures requirements provided in this section.

(b) Monitoring, as required under this subpart, shall comply with the following requirements:

(1) Monitoring shall comply with Method 21 of 40 CFR part 60, appendix A.

(2)(i) Except as provided for in paragraph (b)(2)(ii) of this section, the detection instrument shall meet the performance criteria of Method 21 of 40 CFR part 60, appendix A, except the instrument response factor criteria in Section 3.1.2(a) of Method 21 shall be for the average composition of the process fluid not each individual VOC in the stream. For process streams that contain nitrogen, water, air, or other inerts which are not organic HAP's or VOC's, the average stream response factor may be calculated on an inert-free basis. The response factor may be determined at any concentration for which monitoring for leaks will be conducted.

(ii) If no instrument is available at the plant site that will meet the performance criteria specified in paragraph (b)(2)(i) of this section, the instrument readings may be adjusted by multiplying by the average response factor of the process fluid, calculated on an inert-free basis as described in paragraph (b)(2)(i) of this section.

(3) The instrument shall be calibrated before use on each day of its use by the procedures specified in Method 21 of 40 CFR part 60, appendix A.

(4) Calibration gases shall be:

(i) Zero air (less than 10 parts per million of hydrocarbon in air); and

(ii) Mixtures of methane in air at the concentrations specified in paragraphs (b)(4)(ii)(A) through (b)(4)(ii)(C) of this section. A calibration gas other than methane in air may be used if the instrument does not respond to methane or if the instrument does not meet the performance criteria specified in paragraph (b)(2)(i) of this section. In such cases, the calibration gas may be a mixture of one or more of the compounds to be measured in air.

(A) For Phase I, a mixture of methane or other compounds, as applicable, in air at a concentration of approximately, but less than, 10,000 parts per million.

(B) For Phase II, a mixture of methane or other compounds, as applicable, and air at a concentration of approximately, but less than, 10,000 parts per million for agitators, 5,000 parts per million for pumps, and 500 parts per million for all other equipment, except as provided in paragraph (b)(4)(iii) of this section.

(C) For Phase III, a mixture of methane or other compounds, as applicable, and air at a concentration of approximately, but less than, 10,000 parts per million methane for agitators; 2,000 parts per million for pumps in food/medical service; 5,000 parts per million for pumps in polymerizing monomer service; 1,000 parts per million for all other pumps; and 500 parts per million for all other equipment, except as provided in paragraph (b)(4)(iii) of this section.

(iii) The instrument may be calibrated at a higher methane concentration than the concentration specified for that piece of equipment. The concentration of the calibration gas may exceed the concentration specified as a leak by no more than 2,000 parts per million. If the monitoring instrument's design allows for multiple calibration scales, then the lower scale shall be calibrated with a calibration gas that is no higher than 2,000 parts per million above the concentration specified as a leak and the highest scale shall be calibrated with a calibration gas that is approximately equal to 10,000 parts per million. If only one scale on an instrument will be used during monitoring, the owner or operator need not calibrate the scales that will not be used during that day's monitoring.

(5) Monitoring shall be performed when the equipment is in organic HAP service, in use with an acceptable surrogate volatile organic compound which is not an organic HAP, or is in use with any other detectable gas or vapor.

(6) Monitoring data that do not meet the criteria specified in paragraphs (b)(1) through (b)(5) of this section may be used to qualify for less frequent monitoring under the provisions in §63.168(d)(2) and (d)(3) or §63.174(b)(3)(ii) or (b)(3)(iii) of this subpart provided the data meet the conditions specified in paragraphs (b)(6)(i) and (b)(6)(ii) of this section.

(i) The data were obtained before April 22, 1994.

(ii) The departures from the criteria specified in paragraphs (b)(1) through (b)(5) of this section or from the specified monitoring frequency of §63.168(c) are minor and do not significantly affect the quality of the data. Examples of minor departures are monitoring at a slightly different frequency (such as every six weeks instead of monthly or quarterly), following the performance criteria of section 3.1.2(a) of Method 21 of appendix A of 40 CFR part 60 instead of paragraph (b)(2) of this section, or monitoring at a different leak definition if the data would indicate the presence or absence of a leak at the concentration specified in this subpart. Failure to use a calibrated instrument is not considered a minor departure.

(c) When equipment is monitored for compliance as required in §§63.164(i), 63.165(a) or (e)(1), and 63.172(f) or when equipment subject to a leak definition of 500 ppm is monitored for leaks as required by this subpart, the owner or operator may elect to adjust or not to adjust the instrument readings for background. If an owner or operator elects to not adjust instrument readings for background, the owner or operator shall monitor the equipment according to the procedures specified in paragraphs (b)(1) through (4) of this section. In such case, all instrument readings shall be compared directly to the applicable leak definition to determine whether there is a leak. If an owner or operator elects to adjust instrument readings for background, the owner or operator shall monitor the equipment according to the procedures specified in paragraphs (c)(1) through (c)(4) of this section.

(1) The requirements of paragraphs (b) (1) through (4) of this section shall apply.

(2) The background level shall be determined, using the same procedures that will be used to determine whether the equipment is leaking.

(3) The instrument probe shall be traversed around all potential leak interfaces as close to the interface as possible as described in Method 21 of 40 CFR part 60, appendix A.

(4) The arithmetic difference between the maximum concentration indicated by the instrument and the background level is compared with 500 parts per million for determining compliance.

(d)(1) Each piece of equipment within a process unit that can reasonably be expected to contain equipment in organic HAP service is presumed to be in organic HAP service unless an owner or operator demonstrates that the piece of equipment is not in organic HAP service. For a piece of equipment to be considered not in organic HAP service, it must be determined that the percent organic HAP content can be reasonably expected not to exceed 5 percent by weight on an annual average basis. For purposes of determining the percent organic HAP content of the process fluid that is contained in or contacts equipment, Method 18 of 40 CFR part 60, appendix A shall be used. ASTM D6420-18 (incorporated by reference, see §63.14) may also be used in lieu of Method 18, if the target compounds are all known and are all listed in Section 1.1 of ASTM D6420-18 as measurable; ASTM D6420-18 must not be used for methane and ethane; and ASTM D6420-18 may not be used as a total VOC method.

(2)(i) An owner or operator may use good engineering judgment rather than the procedures in paragraph (d)(1) of this section to determine that the percent organic HAP content does not exceed 5 percent by weight. When an owner or operator and the Administrator do not agree on whether a piece of equipment is not in organic HAP service, however, the procedures in paragraph (d)(1) of this section shall be used to resolve the disagreement.

(ii) Conversely, the owner or operator may determine that the organic HAP content of the process fluid does not exceed 5 percent by weight by, for example, accounting for 98 percent of the content and showing that organic HAP is less than 3 percent.

(3) If an owner or operator determines that a piece of equipment is in organic HAP service, the determination can be revised after following the procedures in paragraph (d)(1) of this section, or by documenting that a change in the process or raw materials no longer causes the equipment to be in organic HAP service.

(4) Samples used in determining the percent organic HAP content shall be representative of the process fluid that is contained in or contacts the equipment.

(e) When a flare is used to comply with §63.172(d), the owner or operator shall comply with paragraphs (e)(1) through (3) of this section, except as specified in paragraph (a) of §63.108. The owner or operator is not required to conduct a performance test to determine percent emission reduction or outlet organic HAP or TOC concentration.

(1) Conduct a visible emission test using the techniques specified in §63.11(b)(4).

(2) Determine the net heating value of the gas being combusted using the techniques specified in §63.11(b)(6).

(3) Determine the exit velocity using the techniques specified in either §63.11(b)(7)(i) (and §63.11(b)(7)(iii), where applicable) or §63.11(b)(8), as appropriate.

(f) The following procedures shall be used to pressure test batch product-process equipment for pressure or vacuum loss to demonstrate compliance with the requirements of §63.178(b)(3)(i) of this subpart.

(1) The batch product-process equipment train shall be pressurized with a gas to a pressure less than the set pressure of any safety relief devices or valves or to a pressure slightly above the operating pressure of the equipment, or alternatively, the equipment shall be placed under a vacuum.

(2) Once the test pressure is obtained, the gas source or vacuum source shall be shut off.

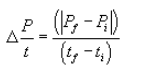

(3) The test shall continue for not less than 15 minutes unless it can be determined in a shorter period of time that the allowable rate of pressure drop or of pressure rise was exceeded. The pressure in the batch product-process equipment shall be measured after the gas or vacuum source is shut off and at the end of the test period. The rate of change in pressure in the batch product-process equipment shall be calculated using the following equation:

where:

Δ P/t = Change in pressure, psig/hr.

Pf = Final pressure, psig.

Pi = Initial pressure, psig.

tf−ti = Elapsed time, hours.

(4) The pressure shall be measured using a pressure measurement device (gauge, manometer, or equivalent) which has a precision of ±2.5 millimeter mercury in the range of test pressure and is capable of measuring pressures up to the relief set pressure of the pressure relief device. If such a pressure measurement device is not reasonably available, the owner or operator shall use a pressure measurement device with a precision of at least + 10 percent of the test pressure of the equipment and shall extend the duration of the test for the time necessary to detect a pressure loss or rise that equals a rate of one psig per hour.

(5) An alternative procedure may be used for leak testing the equipment if the owner or operator demonstrates the alternative procedure is capable of detecting a pressure loss or rise.

(g) The following procedures shall be used to pressure-test batch product-process equipment using a liquid to demonstrate compliance with the requirements of §63.178(b)(3)(ii) of this subpart.

(1) The batch product-process equipment train, or section of the train, shall be filled with the test liquid (e.g., water, alcohol) until normal operating pressure is obtained. Once the equipment is filled, the liquid source shall be shut off.

(2) The test shall be conducted for a period of at least 60 minutes, unless it can be determined in a shorter period of time that the test is a failure.

(3) Each seal in the equipment being tested shall be inspected for indications of liquid dripping or other indications of fluid loss. If there are any indications of liquids dripping or of fluid loss, a leak is detected.

(4) An alternative procedure may be used for leak testing the equipment, if the owner or operator demonstrates the alternative procedure is capable of detecting losses of fluid.

[59 FR 19568, Apr. 22, 1994, as amended at 59 FR 48177, Sept. 20, 1994; 61 FR 31440, June 20, 1996; 62 FR 2792, Jan. 17, 1997; 66 FR 6936, Jan. 22, 2001; 89 FR 43067, May 16, 2024]