['Air Programs']

['Air Quality']

05/08/2024

...

This section applies to the performance testing of control devices used to demonstrate compliance with the emissions standards for your centrifugal compressor affected facility or storage vessel affected facility. You must demonstrate that a control device achieves the performance requirements of §60.5412a(a)(1) or (2) or (d)(1) or (2) using the performance test methods and procedures specified in this section. For condensers and carbon adsorbers, you may use a design analysis as specified in paragraph (c) of this section in lieu of complying with paragraph (b) of this section. In addition, this section contains the requirements for enclosed combustion control device performance tests conducted by the manufacturer applicable to storage vessel and centrifugal compressor affected facilities.

(a) Performance test exemptions. You are exempt from the requirements to conduct performance tests and design analyses if you use any of the control devices described in paragraphs (a)(1) through (7) of this section.

(1) A flare that is designed and operated in accordance with §60.18(b). You must conduct the compliance determination using Method 22 of appendix A-7 of this part to determine visible emissions.

(2) A boiler or process heater with a design heat input capacity of 44 megawatts or greater.

(3) A boiler or process heater into which the vent stream is introduced with the primary fuel or is used as the primary fuel.

(4) A boiler or process heater burning hazardous waste for which you have been issued a final permit under 40 CFR part 270 and comply with the requirements of 40 CFR part 266, subpart H; you have certified compliance with the interim status requirements of 40 CFR part 266, subpart H; you have submitted a Notification of Compliance under 40 CFR 63.1207(j) and comply with the requirements of 40 CFR part 63, subpart EEE; or you comply with 40 CFR part 63, subpart EEE and will submit a Notification of Compliance under 40 CFR 63.1207(j) by the date specified in §60.5420(b)(9) for submitting the initial performance test report.

(5) A hazardous waste incinerator for which you have submitted a Notification of Compliance under 40 CFR 63.1207(j), or for which you will submit a Notification of Compliance under 40 CFR 63.1207(j) by the date specified in §60.5420a(b)(9) for submitting the initial performance test report, and you comply with the requirements of 40 CFR part 63, subpart EEE.

(6) A performance test is waived in accordance with §60.8(b).

(7) A control device whose model can be demonstrated to meet the performance requirements of §60.5412a(a)(1) or (d)(1) through a performance test conducted by the manufacturer, as specified in paragraph (d) of this section.

(b) Test methods and procedures. You must use the test methods and procedures specified in paragraphs (b)(1) through (5) of this section, as applicable, for each performance test conducted to demonstrate that a control device meets the requirements of §60.5412a(a)(1) or (2) or (d)(1) or (2). You must conduct the initial and periodic performance tests according to the schedule specified in paragraph (b)(5) of this section. Each performance test must consist of a minimum of 3 test runs. Each run must be at least 1 hour long.

(1) You must use Method 1 or 1A of appendix A-1 of this part, as appropriate, to select the sampling sites specified in paragraphs (b)(1)(i) and (ii) of this section. Any references to particulate mentioned in Methods 1 and 1A do not apply to this section.

(i) Sampling sites must be located at the inlet of the first control device and at the outlet of the final control device to determine compliance with a control device percent reduction requirement.

(ii) The sampling site must be located at the outlet of the combustion device to determine compliance with a TOC exhaust gas concentration limit.

(2) You must determine the gas volumetric flowrate using Method 2, 2A, 2C, or 2D of appendix A-2 of this part, as appropriate.

(3) To determine compliance with the control device percent reduction performance requirement in §60.5412a(a)(1)(i), (a)(2) or (d)(1)(iv)(A), you must use Method 25A of appendix A-7 of this part. You must use Method 4 of appendix A-3 of this part to convert the Method 25A results to a dry basis. You must use the procedures in paragraphs (b)(3)(i) through (iii) of this section to calculate percent reduction efficiency.

(i) You must compute the mass rate of TOC using the following equations:

Ei = K2CiMpQi

Eo = K2CoMpQo

Where:

Ei, Eo = Mass rate of TOC at the inlet and outlet of the control device, respectively, dry basis, kilograms per hour.

K2 = Constant, 2.494 × 10−6 (parts per million) (gram-mole per standard cubic meter) (kilogram/gram) (minute/hour), where standard temperature (gram-mole per standard cubic meter) is 20°Celsius.

Ci, Co = Concentration of TOC, as propane, of the gas stream as measured by Method 25A at the inlet and outlet of the control device, respectively, dry basis, parts per million by volume.

Mp = Molecular weight of propane, 44.1 gram/gram-mole.

Qi, Qo = Flowrate of gas stream at the inlet and outlet of the control device, respectively, dry standard cubic meter per minute.

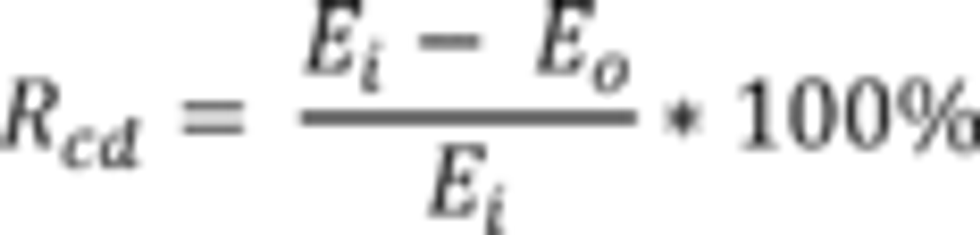

(ii) You must calculate the percent reduction in TOC as follows:

Where:

Rcd = Control efficiency of control device, percent.

Ei, = Mass rate of TOC at the inlet to the control device as calculated under paragraph (b)(3)(i) of this section, kilograms per hour.

Eo = Mass rate of TOC at the outlet of the control device, as calculated under paragraph (b)(3)(i) of this section, kilograms per hour.

(iii) If the vent stream entering a boiler or process heater with a design capacity less than 44 megawatts is introduced with the combustion air or as a secondary fuel, you must determine the weight-percent reduction of total TOC across the device by comparing the TOC in all combusted vent streams and primary and secondary fuels with the TOC exiting the device, respectively.

(4) You must use Method 25A of appendix A–7 to this part to measure TOC, as propane, to determine compliance with the TOC exhaust gas concentration limit specified in §60.5412a(a)(1)(ii) or (d)(1)(iv)(B). If you are determining compliance with the TOC exhaust gas concentration limit specified in §60.5412a(d)(1)(iv)(B), you may also use Method 18 of appendix A–6 to this part to measure methane and ethane, and you may subtract the measured concentration of methane and ethane from the Method 25A measurement to demonstrate compliance with the concentration limit. You must determine the concentration in parts per million by volume on a wet basis and correct it to 3 percent oxygen, using the procedures in paragraphs (b)(4)(i) through (iii) of this section.

(i) If you use Method 18 to determine methane and ethane, you must take either an integrated sample or a minimum of four grab samples per hour. If grab sampling is used, then the samples must be taken at approximately equal intervals in time, such as 15-minute intervals during the run. You must determine the average methane and ethane concentration per run. The samples must be taken during the same time as the Method 25A sample.

(ii) If you are determining compliance with the TOC exhaust gas concentration limit specified in §60.5412a(d)(1)(iv)(B), you may subtract the concentration of methane and ethane from the Method 25A TOC, as propane, concentration for each run.

(iii) You must correct the TOC concentration (minus methane and ethane, if applicable) to 3 percent oxygen as specified in paragraphs (b)(4)(iii)(A) and (B) of this section.

(A) You must use the emission rate correction factor for excess air, integrated sampling and analysis procedures of Method 3A or 3B of appendix A-2 of this part, ASTM D6522-00 (Reapproved 2005), or ANSI/ASME PTC 19.10-1981, Part 10 (manual portion only) (incorporated by reference as specified in §60.17) to determine the oxygen concentration. The samples must be taken during the same time that the samples are taken for determining TOC concentration.

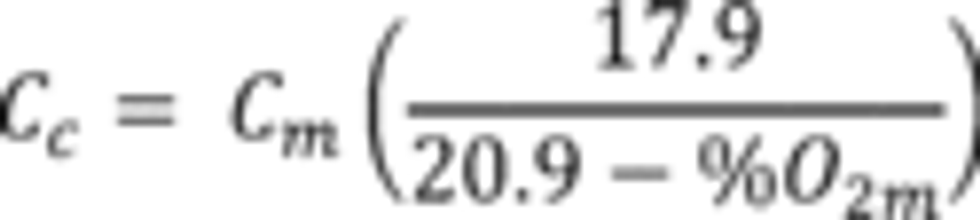

(B) You must correct the TOC concentration for percent oxygen as follows:

Where:

Cc = TOC concentration, as propane, corrected to 3 percent oxygen, parts per million by volume on a wet basis.

Cm = TOC concentration, as propane, (minus methane and ethane, if applicable), parts per million by volume on a wet basis.

%O2m = Concentration of oxygen, percent by volume as measured, wet.

(5) You must conduct performance tests according to the schedule specified in paragraphs (b)(5)(i) and (ii) of this section.

(i) You must conduct an initial performance test within 180 days after initial startup for your affected facility. You must submit the performance test results as required in §60.5420a(b)(9).

(ii) You must conduct periodic performance tests for all control devices required to conduct initial performance tests except as specified in paragraphs (b)(5)(ii)(A) and (B) of this section. You must conduct the first periodic performance test no later than 60 months after the initial performance test required in paragraph (b)(5)(i) of this section. You must conduct subsequent periodic performance tests at intervals no longer than 60 months following the previous periodic performance test or whenever you desire to establish a new operating limit. You must submit the periodic performance test results as specified in §60.5420a(b)(9).

(A) A control device whose model is tested under, and meets the criteria of paragraph (d) of this section. For centrifugal compressor affected facilities, if you do not continuously monitor the gas flow rate in accordance with §60.5417a(d)(1)(viii), then you must comply with the periodic performance testing requirements of paragraph (b)(5)(ii).

(B) A combustion control device tested under paragraph (b) of this section that meets the outlet TOC performance level specified in §60.5412a(a)(1)(ii) or (d)(1)(iv)(B) and that establishes a correlation between firebox or combustion chamber temperature and the TOC performance level. For centrifugal compressor affected facilities, you must establish a limit on temperature in accordance with §60.5417a(f) and continuously monitor the temperature as required by §60.5417a(d).

(c) Control device design analysis to meet the requirements of §60.5412a(a)(2) or (d)(2). (1) For a condenser, the design analysis must include an analysis of the vent stream composition, constituent concentrations, flowrate, relative humidity and temperature and must establish the design outlet organic compound concentration level, design average temperature of the condenser exhaust vent stream and the design average temperatures of the coolant fluid at the condenser inlet and outlet.

(2) For a regenerable carbon adsorption system, the design analysis shall include the vent stream composition, constituent concentrations, flowrate, relative humidity and temperature and shall establish the design exhaust vent stream organic compound concentration level, adsorption cycle time, number and capacity of carbon beds, type and working capacity of activated carbon used for the carbon beds, design total regeneration stream flow over the period of each complete carbon bed regeneration cycle, design carbon bed temperature after regeneration, design carbon bed regeneration time and design service life of the carbon.

(3) For a nonregenerable carbon adsorption system, such as a carbon canister, the design analysis shall include the vent stream composition, constituent concentrations, flowrate, relative humidity and temperature and shall establish the design exhaust vent stream organic compound concentration level, capacity of the carbon bed, type and working capacity of activated carbon used for the carbon bed and design carbon replacement interval based on the total carbon working capacity of the control device and source operating schedule. In addition, these systems shall incorporate dual carbon canisters in case of emission breakthrough occurring in one canister.

(4) If you and the Administrator do not agree on a demonstration of control device performance using a design analysis, then you must perform a performance test in accordance with the requirements of paragraph (b) of this section to resolve the disagreement. The Administrator may choose to have an authorized representative observe the performance test.

(d)Performance testing for combustion control devices - manufacturers' performance test. (1) This paragraph (d) applies to the performance testing of a combustion control device conducted by the device manufacturer. The manufacturer must demonstrate that a specific model of control device achieves the performance requirements in paragraph (d)(11) of this section by conducting a performance test as specified in paragraphs (d)(2) through (10) of this section. You must submit a test report for each combustion control device in accordance with the requirements in paragraph (d)(12) of this section.

(2) Performance testing must consist of three 1-hour (or longer) test runs for each of the four firing rate settings specified in paragraphs (d)(2)(i) through (iv) of this section, making a total of 12 test runs per test. Propene (propylene) gas must be used for the testing fuel. All fuel analyses must be performed by an independent third-party laboratory (not affiliated with the control device manufacturer or fuel supplier).

(i) 90-100 percent of maximum design rate (fixed rate).

(ii) 70-100-70 percent (ramp up, ramp down). Begin the test at 70 percent of the maximum design rate. During the first 5 minutes, incrementally ramp the firing rate to 100 percent of the maximum design rate. Hold at 100 percent for 5 minutes. In the 10-15 minute time range, incrementally ramp back down to 70 percent of the maximum design rate. Repeat three more times for a total of 60 minutes of sampling.

(iii) 30-70-30 percent (ramp up, ramp down). Begin the test at 30 percent of the maximum design rate. During the first 5 minutes, incrementally ramp the firing rate to 70 percent of the maximum design rate. Hold at 70 percent for 5 minutes. In the 10-15 minute time range, incrementally ramp back down to 30 percent of the maximum design rate. Repeat three more times for a total of 60 minutes of sampling.

(iv) 0-30-0 percent (ramp up, ramp down). Begin the test at the minimum firing rate. During the first 5 minutes, incrementally ramp the firing rate to 30 percent of the maximum design rate. Hold at 30 percent for 5 minutes. In the 10-15 minute time range, incrementally ramp back down to the minimum firing rate. Repeat three more times for a total of 60 minutes of sampling.

(3) All models employing multiple enclosures must be tested simultaneously and with all burners operational. Results must be reported for each enclosure individually and for the average of the emissions from all interconnected combustion enclosures/chambers. Control device operating data must be collected continuously throughout the performance test using an electronic Data Acquisition System. A graphic presentation or strip chart of the control device operating data and emissions test data must be included in the test report in accordance with paragraph (d)(12) of this section. Inlet fuel meter data may be manually recorded provided that all inlet fuel data readings are included in the final report.

(4) Inlet testing must be conducted as specified in paragraphs (d)(4)(i) and (ii) of this section.

(i) The inlet gas flow metering system must be located in accordance with Method 2A of appendix A-1 of this part (or other approved procedure) to measure inlet gas flow rate at the control device inlet location. You must position the fitting for filling fuel sample containers a minimum of eight pipe diameters upstream of any inlet gas flow monitoring meter.

(ii) Inlet flow rate must be determined using Method 2A of appendix A-1 of this part. Record the start and stop reading for each 60-minute THC test. Record the gas pressure and temperature at 5-minute intervals throughout each 60-minute test.

(5) Inlet gas sampling must be conducted as specified in paragraphs (d)(5)(i) and (ii) of this section.

(i) At the inlet gas sampling location, securely connect a fused silica-coated stainless steel evacuated canister fitted with a flow controller sufficient to fill the canister over a 3-hour period. Filling must be conducted as specified in paragraphs (d)(5)(i)(A) through (C) of this section.

(A) Open the canister sampling valve at the beginning of each test run, and close the canister at the end of each test run.

(B) Fill one canister across the three test runs such that one composite fuel sample exists for each test condition.

(C) Label the canisters individually and record sample information on a chain of custody form.

(ii) Analyze each inlet gas sample using the methods in paragraphs (d)(5)(ii)(A) through (C) of this section. You must include the results in the test report required by paragraph (d)(12) of this section.

(A) Hydrocarbon compounds containing between one and five atoms of carbon plus benzene using ASTM D1945-03 (incorporated by reference as specified in §60.17).

(B) Hydrogen (H2), carbon monoxide (CO), carbon dioxide (CO2), nitrogen (N2), oxygen (O2) using ASTM D1945-03 (incorporated by reference as specified in §60.17).

(C) Higher heating value using ASTM D3588-98 or ASTM D4891-89 (incorporated by reference as specified in §60.17).

(6) Outlet testing must be conducted in accordance with the criteria in paragraphs (d)(6)(i) through (v) of this section.

(i) Sample and flow rate must be measured in accordance with paragraphs (d)(6)(i)(A) and (B) of this section.

(A) The outlet sampling location must be a minimum of four equivalent stack diameters downstream from the highest peak flame or any other flow disturbance, and a minimum of one equivalent stack diameter upstream of the exit or any other flow disturbance. A minimum of two sample ports must be used.

(B) Flow rate must be measured using Method 1 of appendix A-1 of this part for determining flow measurement traverse point location, and Method 2 of appendix A-1 of this part for measuring duct velocity. If low flow conditions are encountered (i.e., velocity pressure differentials less than 0.05 inches of water) during the performance test, a more sensitive manometer must be used to obtain an accurate flow profile.

(ii) Molecular weight and excess air must be determined as specified in paragraph (d)(7) of this section.

(iii) Carbon monoxide must be determined as specified in paragraph (d)(8) of this section.

(iv) THC must be determined as specified in paragraph (d)(9) of this section.

(v) Visible emissions must be determined as specified in paragraph (d)(10) of this section.

(7) Molecular weight and excess air determination must be performed as specified in paragraphs (d)(7)(i) through (iii) of this section.

(i) An integrated bag sample must be collected during the moisture test required by Method 4 of appendix A-3 of this part following the procedure specified in (d)(7)(i)(A) and (B) of this section. Analyze the bag sample using a gas chromatograph-thermal conductivity detector (GC-TCD) analysis meeting the criteria in paragraphs (d)(7)(i)(C) and (D) of this section.

(A) Collect the integrated sample throughout the entire test, and collect representative volumes from each traverse location.

(B) Purge the sampling line with stack gas before opening the valve and beginning to fill the bag. Clearly label each bag and record sample information on a chain of custody form.

(C) The bag contents must be vigorously mixed prior to the gas chromatograph analysis.

(D) The GC-TCD calibration procedure in Method 3C of appendix A-2 of this part must be modified by using EPA Alt-045 as follows: For the initial calibration, triplicate injections of any single concentration must agree within 5 percent of their mean to be valid. The calibration response factor for a single concentration re-check must be within 10 percent of the original calibration response factor for that concentration. If this criterion is not met, repeat the initial calibration using at least three concentration levels.

(ii) Calculate and report the molecular weight of oxygen, carbon dioxide, methane and nitrogen in the integrated bag sample and include in the test report specified in paragraph (d)(12) of this section. Moisture must be determined using Method 4 of appendix A-3 of this part. Traverse both ports with the sampling train required by Method 4 of appendix A-3 of this part during each test run. Ambient air must not be introduced into the integrated bag sample required by Method 3C of appendix A-2 of this part during the port change.

(iii) Excess air must be determined using resultant data from the EPA Method 3C tests and EPA Method 3B of appendix A-2 of this part, equation 3B-1, or ANSI/ASME PTC 19.10-1981, Part 10 (manual portion only) (incorporated by reference as specified in §60.17).

(8) Carbon monoxide must be determined using Method 10 of appendix A-4 of this part. Run the test simultaneously with Method 25A of appendix A-7 of this part using the same sampling points. An instrument range of 0-10 parts per million by volume-dry (ppmvd) is recommended.

(9) Total hydrocarbon determination must be performed as specified by in paragraphs (d)(9)(i) through (vii) of this section.

(i) Conduct THC sampling using Method 25A of appendix A-7 of this part, except that the option for locating the probe in the center 10 percent of the stack is not allowed. The THC probe must be traversed to 16.7 percent, 50 percent, and 83.3 percent of the stack diameter during each test run.

(ii) A valid test must consist of three Method 25A tests, each no less than 60 minutes in duration.

(iii) A 0-10 parts per million by volume-wet (ppmvw) (as propane) measurement range is preferred; as an alternative a 0-30 ppmvw (as propane) measurement range may be used.

(iv) Calibration gases must be propane in air and be certified through EPA Protocol 1 - “EPA Traceability Protocol for Assay and Certification of Gaseous Calibration Standards,” (incorporated by reference as specified in §60.17).

(v) THC measurements must be reported in terms of ppmvw as propane.

(vi) THC results must be corrected to 3 percent CO2, as measured by Method 3C of appendix A-2 of this part. You must use the following equation for this diluent concentration correction:

Where:

Cmeas = The measured concentration of the pollutant.

CO2meas = The measured concentration of the CO2 diluent.

3 = The corrected reference concentration of CO2 diluent.

Ccorr = The corrected concentration of the pollutant.

(vii) Subtraction of methane or ethane from the THC data is not allowed in determining results.

(10) Visible emissions must be determined using Method 22 of appendix A-7 of this part. The test must be performed continuously during each test run. A digital color photograph of the exhaust point, taken from the position of the observer and annotated with date and time, must be taken once per test run and the 12 photos included in the test report specified in paragraph (d)(12) of this section.

(11) Performance test criteria. (i) The control device model tested must meet the criteria in paragraphs (d)(11)(i)(A) through (D) of this section. These criteria must be reported in the test report required by paragraph (d)(12) of this section.

(A) Results from Method 22 of appendix A-7 of this part determined under paragraph (d)(10) of this section with no indication of visible emissions.

(B) Average results from Method 25A of appendix A-7 of this part determined under paragraph (d)(9) of this section equal to or less than 10.0 ppmvw THC as propane corrected to 3.0 percent CO2.

(C) Average CO emissions determined under paragraph (d)(8) of this section equal to or less than 10 parts ppmvd, corrected to 3.0 percent CO2.

(D) Excess air determined under paragraph (d)(7) of this section equal to or greater than 150 percent.

(ii) The manufacturer must determine a maximum inlet gas flow rate which must not be exceeded for each control device model to achieve the criteria in paragraph (d)(11)(iii) of this section. The maximum inlet gas flow rate must be included in the test report required by paragraph (d)(12) of this section.

(iii) A manufacturer must demonstrate a destruction efficiency of at least 95 percent for THC, as propane. A control device model that demonstrates a destruction efficiency of 95 percent for THC, as propane, will meet the control requirement for 95 percent destruction of VOC and methane (if applicable) required under this subpart.

(12) The owner or operator of a combustion control device model tested under this paragraph (d)(12) must submit the information listed in paragraphs (d)(12)(i) through (vi) of this section for each test run in the test report required by this section in accordance with §60.5420a(b)(10). Owners or operators who claim that any of the performance test information being submitted is confidential business information (CBI) must submit a complete file including information claimed to be CBI, on a compact disc, flash drive, or other commonly used electronic storage media to the EPA. The electronic media must be clearly marked as CBI and mailed to Attn: CBI Document Control Officer; Office of Air Quality Planning and Standards (OAQPS), Room 521; 109 T.W. Alexander Drive; Research Triangle Park, NC 27711. The same file with the CBI omitted must be submitted to Oil_and_Gas_PT@EPA.GOV.

(i) A full schematic of the control device and dimensions of the device components.

(ii) The maximum net heating value of the device.

(iii) The test fuel gas flow range (in both mass and volume). Include the maximum allowable inlet gas flow rate.

(iv) The air/stream injection/assist ranges, if used.

(v) The test conditions listed in paragraphs (d)(12)(v)(A) through (O) of this section, as applicable for the tested model.

(A) Fuel gas delivery pressure and temperature.

(B) Fuel gas moisture range.

(C) Purge gas usage range.

(D) Condensate (liquid fuel) separation range.

(E) Combustion zone temperature range. This is required for all devices that measure this parameter.

(F) Excess air range.

(G) Flame arrestor(s).

(H) Burner manifold.

(I) Pilot flame indicator.

(J) Pilot flame design fuel and calculated or measured fuel usage.

(K) Tip velocity range.

(L) Momentum flux ratio.

(M) Exit temperature range.

(N) Exit flow rate.

(O) Wind velocity and direction.

(vi) The test report must include all calibration quality assurance/quality control data, calibration gas values, gas cylinder certification, strip charts, or other graphic presentations of the data annotated with test times and calibration values.

(e) Continuous compliance for combustion control devices tested by the manufacturer in accordance with paragraph (d) of this section. This paragraph (e) applies to the demonstration of compliance for a combustion control device tested under the provisions in paragraph (d) of this section. Owners or operators must demonstrate that a control device achieves the performance criteria in paragraph (d)(11) of this section by installing a device tested under paragraph (d) of this section, complying with the criteria specified in paragraphs (e)(1) through (8) of this section, maintaining the records specified in §60.5420a(c)(2) or (c)(5)(vi) and submitting the report specified in §60.5420a(b)(10).

(1) The inlet gas flow rate must be equal to or less than the maximum specified by the manufacturer.

(2) A pilot flame must be present at all times of operation.

(3) Devices must be operated with no visible emissions, except for periods not to exceed a total of 1 minute during any 15-minute period. A visible emissions test conducted according to section 11 of EPA Method 22 of appendix A-7 of this part must be performed at least once every calendar month, separated by at least 15 days between each test. The observation period shall be 15 minutes.

(4) Devices failing the visible emissions test must follow manufacturer's repair instructions, if available, or best combustion engineering practice as outlined in the unit inspection and maintenance plan, to return the unit to compliant operation. All repairs and maintenance activities for each unit must be recorded in a maintenance and repair log and must be available for inspection.

(5) Following return to operation from maintenance or repair activity, each device must pass a visual observation according to EPA Method 22 of appendix A-7 of this part as described in paragraph (e)(3) of this section.

(6) If the owner or operator operates a combustion control device model tested under this section, an electronic copy of the performance test results required by this section shall be submitted via email to Oil_and_Gas_PT@EPA.GOV unless the test results for that model of combustion control device are posted at the following Web site: epa.gov/airquality/oilandgas/.

(7) Ensure that each enclosed combustion control device is maintained in a leak free condition.

(8) Operate each control device following the manufacturer's written operating instructions, procedures and maintenance schedule to ensure good air pollution control practices for minimizing emissions.

[85 FR 57071, Sep. 14, 2020; 85 FR 57447, Sep. 15, 2020; 89 FR 17033, March 8, 2024]

['Air Programs']

['Air Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.