Use protective systems

- OSHA mandates that all excavations that come with the risk of cave-ins be protected by a system such as sloping or benching, or the use of shielding.

- Tables and charts approved by a registered professional engineer can facilitate the process of designing an excavation.

When done safely, trenching operations can reduce worker exposure to cave-ins, falling loads, hazardous atmospheres, and hazards from mobile equipment.

One of the most important ways to ensure workers in excavations are safe is to use protective systems, which are designed to protect workers by preventing trench walls from collapsing.

Prevent cave-ins

The Occupational Safety and Health Administration (OSHA) requires that all excavations in which employees could potentially be exposed to cave-ins be protected by one of the following methods:

- Sloping or benching the sides of the excavation, or

- Supporting the sides of the excavation by placing a shield between the side of the excavation and the work area.

Choose appropriate protective system design

Designing a protective system can be complex because many factors must be considered: soil classification, depth of cut, water content of soil, changes due to weather and climate, or other operations in the vicinity. An employer is free to choose the most practical design approach for any particular circumstance. Once an approach is selected, however, the system must meet the required performance criteria.

The OSHA standard describes methods and approaches for designing protective systems such as the following:

- Sloping/Benching

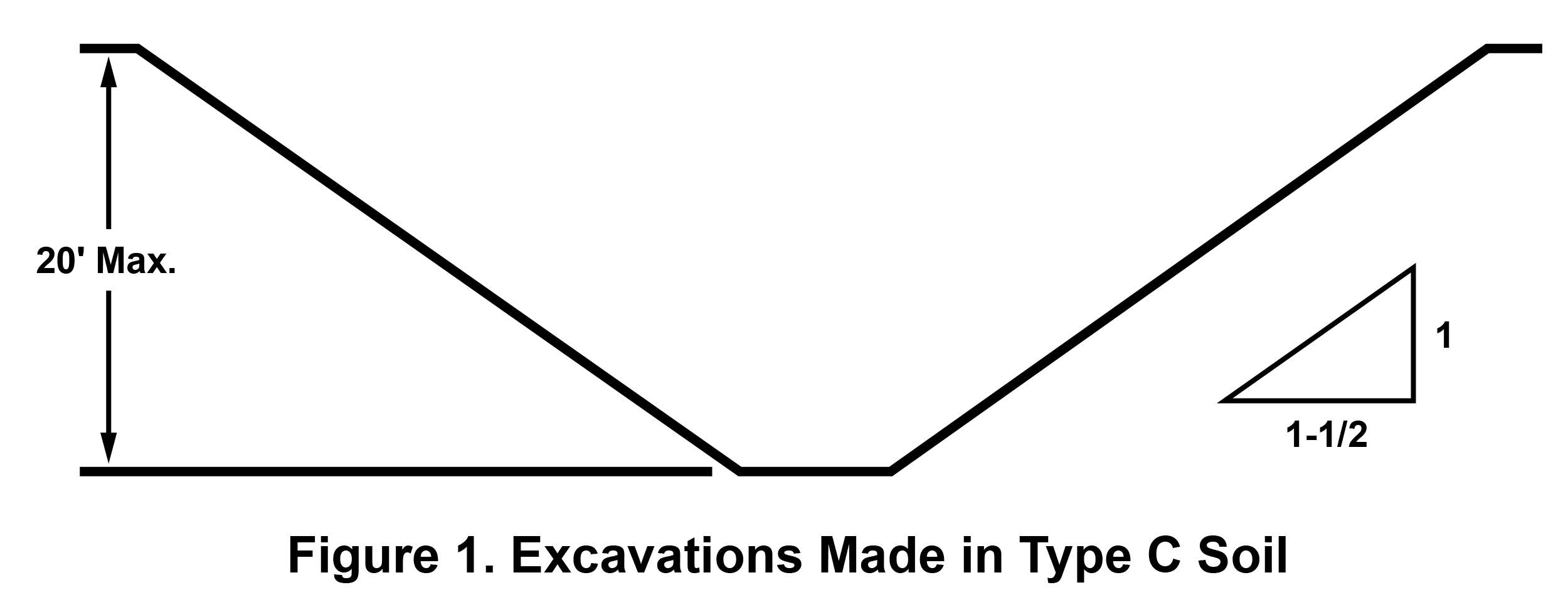

Sloping consists of forming sides of an excavation that are inclined away from the excavation. Slope the sides to an angle not steeper than 1½ to 1; for example, for every foot of depth, the trench must be excavated back 1½ feet. All simple slope excavations 20 feet or less deep should have a maximum allowable slope of 1½ to 1. These slopes must be excavated to form configurations similar to those for Type C soil, as described in Appendix B of the standard. A slope of this gradation or less is safe for any type of soil.

Benching is similar to sloping but involves further excavating the sides of an excavation to form one or a series of horizontal levels or steps. - Shielding/Trench box

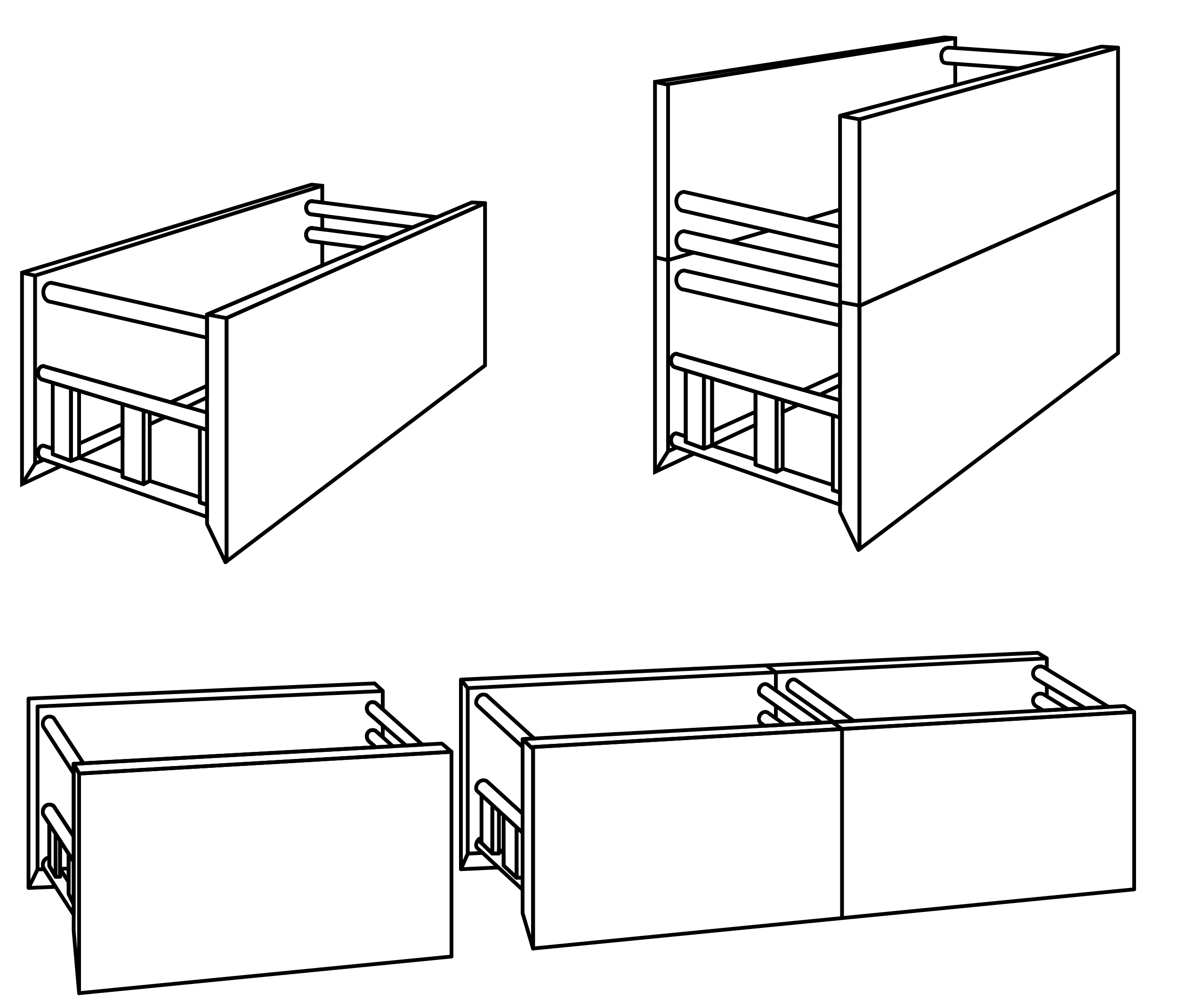

Shielding can be permanent or portable, and it is also known as a trench box or trench shield. Shoring supports the sides of the trench and is often a metal hydraulic, mechanical, or timber shoring system.

Use a trench box or shield designed or approved by a registered professional engineer or based on tabulated data prepared or approved by a registered professional engineer. Timber, aluminum, or other suitable materials may also be used. OSHA standards permit the use of a trench shield (also known as a welder’s hut) if it provides at least the same level of protection as the appropriate shoring system.

Employers can choose the most practical method for the particular circumstance, but that system must meet the required performance criteria. The standard does not require a protective system when an excavation is made entirely in stable rock or is less than five feet deep, if a competent person has examined the ground and found no indication of a potential cave-in.

- Tabulated data

Use tabulated data such as tables and charts approved by a registered professional engineer to design the excavation. These data must be in writing and must include enough explanatory information, including criteria for making a selection and limits on use of the data, for the user to make a selection.

At least one copy of the data, including the identity of the registered professional engineer who approved it, must be kept at the worksite during construction of the protective system. After the system is completed, the data may be stored away from the jobsite, but a copy must be provided upon request to the Assistant Secretary of Labor for OSHA.