While OSHA compliance and hazard mitigation are commonplace in the safety industry, “risk” is also important. Understanding risk is critical for safety professionals to manage priorities and communicate with upper management. Simply stated, risk refers to the probability an incident will occur multiplied by the severity that would result from such an incident. By assessing for risk, safety professionals can prioritize which projects to address first, as well as which controls should be utilized. Further, safety professionals can use risk to communicate to upper management the impact of specific issues on the business. Many safety management standards, such as ISO 45001 or ANSI Z10, offer risk matrices or guidance tools to assist in this effort.

Risk assessment and management

While many people use the terms “hazard” and “risk” interchangeably, they are actually quite different. “Hazard” refers to something that can cause harm, like a machine, electricity, or toxic fumes. “Risk” refers to how likely a hazard is to occur and how damaging it will be should it occur. Hazard is generally used within the context of safety/injury, while risk can refer to financial “hazards” (losses), IT networks, and a variety of other topics.

Most safety professionals have at some point handed upper management a list of hazards or “compliance issues” found in an audit. In response, a member of upper management likely asked, “So, what does this mean?” Too often, the safety professional responds by mentioning the possibility of the company being inspected and fined, or listing the regulations being violated. To better communicate with upper management, safety professionals should learn the language of upper management and frame their safety guidance and advice in terms of risk.

Risk rating matrix

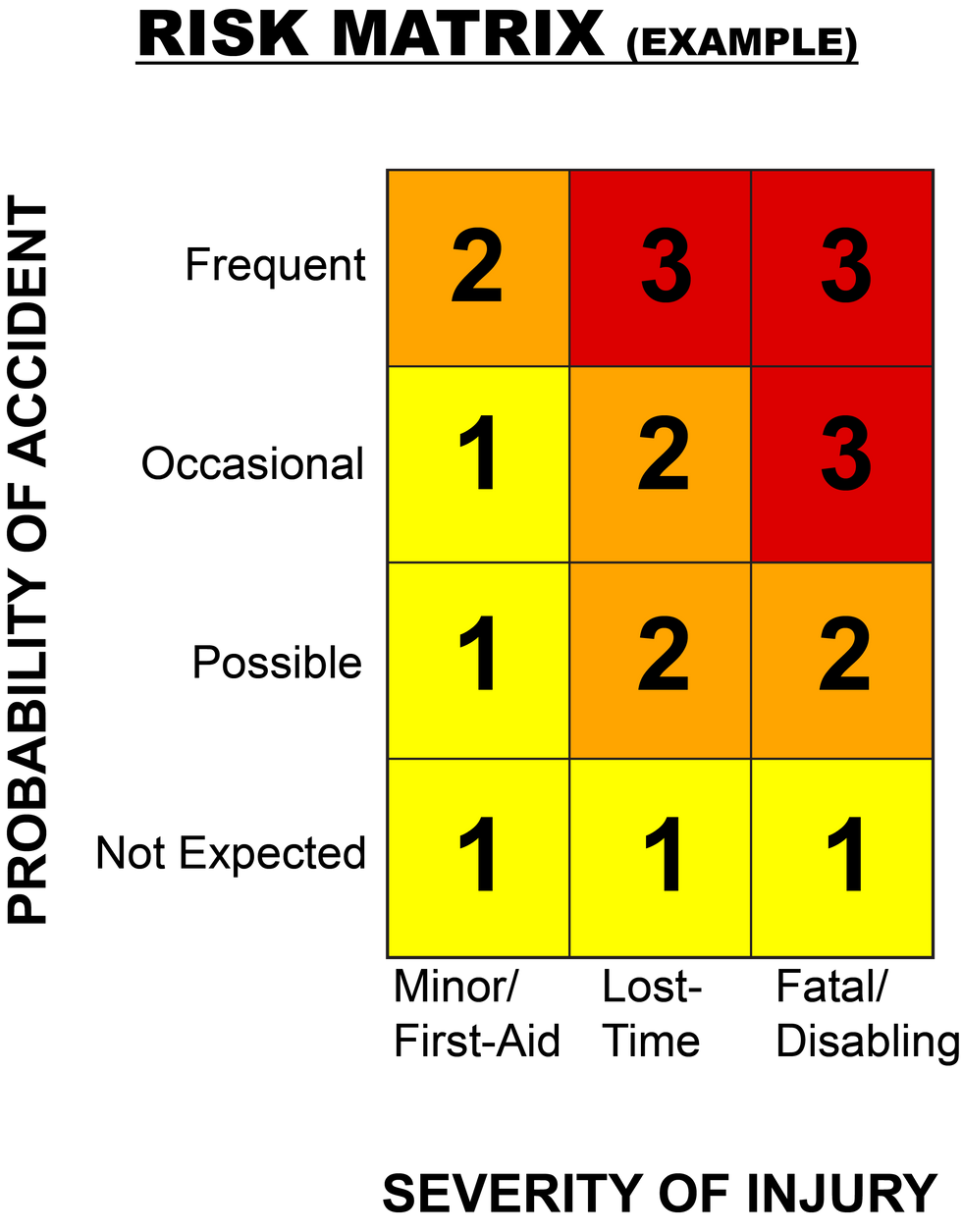

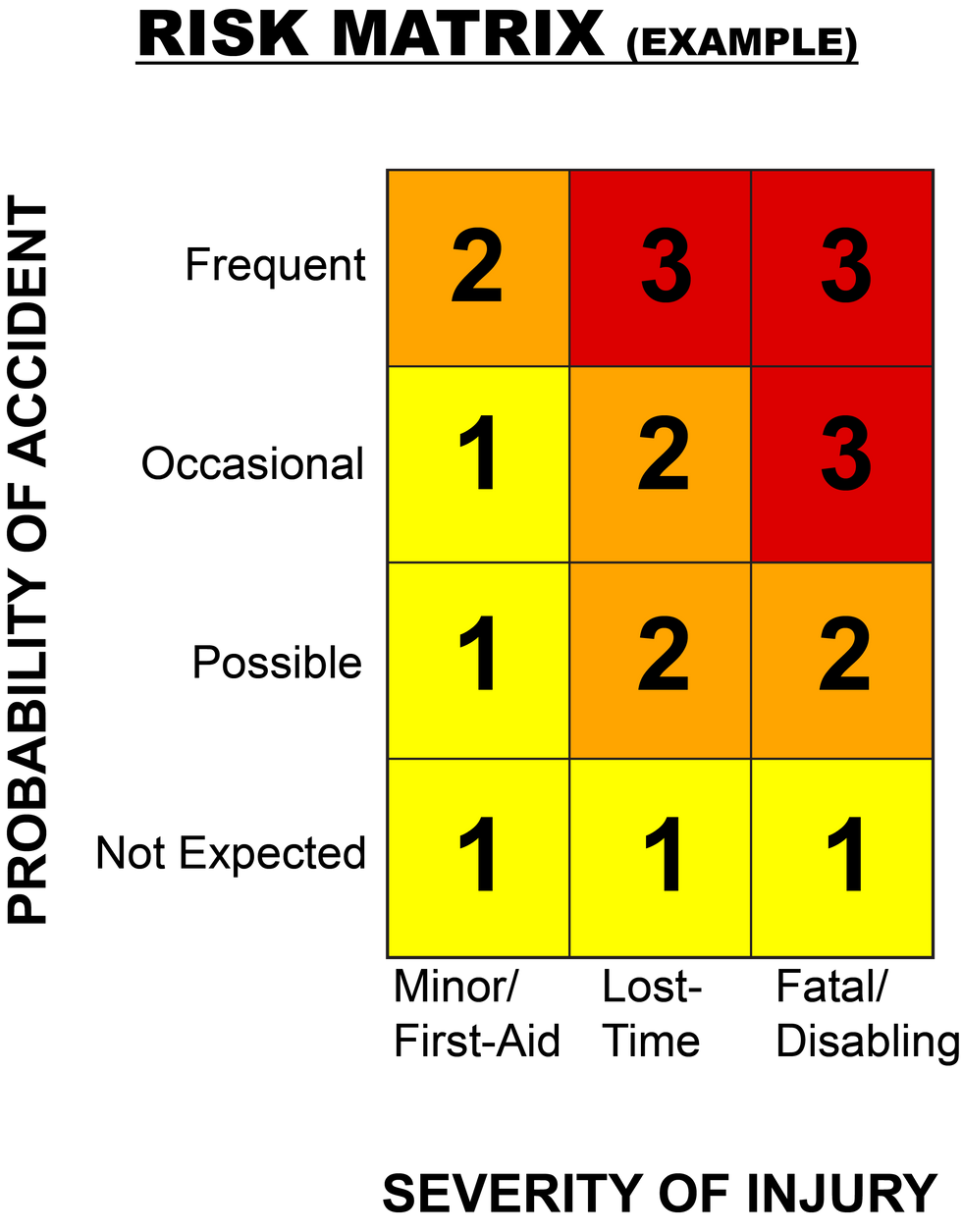

- When assessing risk, employers must take into account the severity of injury or illness that could result from a hazard, as well as the likelihood of such an incident occurring. Hazards with high severity and high probability of occurring are the greatest risk.

The risk/hazard rating of a job or task usually considers two factors:

- Severity — the seriousness of the injury or illness (e.g., first-aid, minor, lost-time, permanent disability, fatality) that could result from an incident.

- Probability — the likelihood that an incident will occur (e.g., frequently, occasionally, unlikely).

A job or task with a high probability and high severity has the highest risk; when there is low probability and low severity, that is the lowest risk. However, there are numerous combinations of severity/probability in between.

Many companies utilize a risk matrix or table that assigns numeric measures to risk based on probability and severity; the ratings are used to prioritize safety efforts. A sample risk matrix is provided below.

The risk matrix should be tailored to suit each organization’s risk tolerance and should take into account the specific operations, hazards, and available controls.

Priority legend

3 Highest priority — stop task until hazards are controlled

2 Hazards must be controlled as soon as possible

1 Risks are acceptable — no further controls required

Using the language of risk

- Safety professionals should learn to communicate safety needs in the workplace in terms of risk management to help business owners and executives understand the full impact of not managing hazards properly.

Imagine a safety professional asking upper management for a $500,000 investment to keep from getting a $7,000 fine from the Occupational Safety and Health Administration (OSHA). The request is unlikely to be approved. Stating the request in terms of risk management, however, would involve explaining an analysis and prioritizing of risk, along with the financial implications.

Risk is a common language between business owners and executives who manage risk every day. Putting hazards into the language of risk helps executives see the need for managing the identified safety risks or hazards.

Financial implications include suffering operational delays, which directly impacts the number of products a company might produce, for example, and could result in direct consequences.

Unfortunately, many safety professionals haven’t had formal training in risk management, so learning the concepts may take some time. However, it doesn’t have to be daunting, and tools are available to help.

Risk management industry standard

- The AASP Risk Management technical report offers expert guidance and tools to help safety professionals understand, assess, and manage risk in the workplace.

A technical report published by the American Society of Safety Professionals (ASSP) provides safety professionals with techniques and implementation strategies to combat risk and better protect workers. ASSP TR-31010-2020 Risk Management – Techniques for Safety Practitioners is designed to assist safety practitioners and company decision-makers in understanding, assessing, and managing risk so organizations can achieve their business objectives.

The technical report provides expert guidance on the selection, modification, combination, and application of 50 risk management techniques to help improve the way risk and uncertainty are managed. It includes basic techniques for industry newcomers and complex methods for seasoned safety professionals. The safety resource explains the fundamentals of risk assessment and risk treatment and covers prevention-through-design practices that are applicable throughout the life cycle of a system. Safety professionals can apply the techniques to a range of occupational settings, situations, and operational stages of a business.

Analysis tools

Examples of some of the 50 tools covered by the ASSP Technical Report include:

- ALARP – Getting to a risk level that is “as low as reasonably practicable” by classifying risks into specific categories.

- Risk Hierarchy – A comprehensive portfolio of risks organized by type.

- Causal Mapping – Identifies causality by mapping interactions between risks.

- Ishikawa (Fishbone) Analysis/Cause and Effect Analysis – A team-based approach using a pictorial display to help consider all possible scenarios and causes of a specific effect.

- Business Impact Analysis – A method to evaluate effects of incidents on critical business operations.

The Technical Report contains a table that provides information on the complexity of each of the 50 tools, along with guidance on how each may or may not apply to different situations a safety professional might encounter. For example, ALARP is a medium complexity tool strongly applicable to determining risk context, as well as for risk evaluation. However, it is not very applicable to risk analysis. On the other hand, Risk Hierarchy is low complexity and strongly applicable to communicating risk, but not as applicable to analysis.

Safety professionals don’t have to learn all 50 tools at once. To start out, the professional should choose about five tools for communicating with the next level manager. As safety professionals make progress and get invited to decision-makers’ meetings, they go back to the Technical Report and learn more. Then, next time, they’re part of the solution. Eventually, as safety professionals get into upper-level safety and start communicating with the CEO, there are tools in the report to help, focusing on enterprise-wide risk management.

Safety management industry standards

- There are two major industry standards to help guide employers in implementing a safety plan for the workplace: ISO 45001 and ANSI Z10.

- In certain industries, suppliers or potential contracts may require companies to implement one standard over the other.

Two major voluntary industry standards can help employers design and implement a safety and health management system:

- ISO 45001 — Occupational health and safety management systems – Requirements with guidance for use

- ANSI/ASSP Z10 — Occupational Health and Safety Management Systems

ISO 45001

The International Organization for Standardization (ISO) 45001 Occupational health and safety management systems — Requirements with guidance for use is a standard for the implementation and maintenance of occupational safety and health management systems. The standard guides companies in taking a systematic and proactive approach to worker safety, giving safety an equal “seat at the table” alongside other management systems such as environmental, quality, IT and data security, and product safety, all of which have had international standards for a while.

Like other management systems standards, ISO 45001 reduces risk and increases performance. In the case of ISO 45001, the risk is to worker safety and health. The standard provides a framework to systematically improve safety and business processes at the same time. It requires using concepts and techniques such as the hierarchy of controls, risk assessment, and root-cause analysis, along with significant input and participation from workers. While these techniques help reduce injuries and illnesses, they also improve business performance.

The indirect benefits of obtaining certification include recognition for achieving an international benchmark, lowering costs, reducing turnover and lost time, and reducing equipment and process downtime. The standard has other benefits as well. Investors will likely feel more confident in an ISO 45001-certified company because the company has shown it is actually identifying and managing the risks.

To achieve the maximum benefits and to claim official certification, a company must go through a third-party audit and approval process from an accredited registrar. Completing full certification is certainly no easy task. If a company already has an ISO management system in place, however, the transition will be less complicated.

For companies that want to implement a management system but are not interested in certification, the ISO 45001 standard can be used as a best-practice guidance. A company can purchase the standard and self-implement to whatever degree is appropriate, understanding that internal impacts (such as fewer injuries and better performance) may be seen, but external benefits (such as recognition) will not be gained without certification.

ANSI Z10

The American National Standards Institute (ANSI) Z10 Occupational Health and Safety Management Systems standard was originally released in 2005. Like most other ANSI standards, ANSI Z10 is “self-certifying” in that there is not necessarily a requirement for a third-party auditor to conduct a conformance assessment. A company can purchase the standard and implement it with no assistance from a third party.

The ANSI standard follows the same general principles as the Occupational Safety and Health Administration (OSHA)’s Recommended Practices, but provides much more guidance and many tools, covering such topics as management leadership, employee involvement, hazard identification/prevention/control, training, and evaluation. It contains tools such as job hazard analysis guidance and risk matrices.

Deciding on a standard

In choosing a standard, a company should consider what the organization hopes to accomplish and also what the stakeholders or customers are asking for. Some companies may choose to achieve certification to ISO 45001, but implement additional elements from ANSI Z10.

In certain industries, suppliers or potential contracts may ask for one standard over the other. Employers should talk with some organizations that have used these systems to find out pros and cons of each.

Hazard identification and assessment

- To properly assess the risks posed by hazards, employers first need to identify all potential hazards.

- Employers should include assessments of emergency and non-routine situations that may arise.

“Risk” is the product of hazard and exposure. Thus, risk can be reduced by controlling or eliminating the hazard or by reducing workers’ exposure to hazards. An assessment of risk helps employers understand hazards in the context of their own workplaces and prioritize hazards for permanent control.

One of the root causes of workplace injuries, illnesses, and incidents is the failure to identify or recognize hazards that are present, or that could have been anticipated. A critical element of any effective safety and health program is a proactive, ongoing process to identify and assess such hazards.

To identify and assess hazards, employers and workers should:

- Collect and review information about the hazards present or likely to be present in the workplace.

- Conduct initial and periodic workplace inspections of the workplace to identify new or recurring hazards.

- Investigate injuries, illnesses, incidents, and close calls/near misses to determine the underlying hazards, their causes, and safety and health program shortcomings.

- Group similar incidents and identify trends in injuries, illnesses, and hazards reported.

- Consider hazards associated with emergency or non-routine situations.

- Determine the severity and likelihood of incidents that could result for each hazard identified, and use this information to prioritize corrective actions.

Some hazards, such as housekeeping and tripping hazards, can and should be fixed as they are found. Fixing hazards on the spot emphasizes the importance of safety and health and takes advantage of a safety leadership opportunity.

Emergency and non-routine situations

Emergencies present hazards that need to be recognized and understood. Non-routine or infrequent tasks, including maintenance and startup/shutdown activities, also present potential hazards. Develop plans and procedures for responding appropriately and safely to hazards associated with foreseeable emergency scenarios and non-routine situations.

Identify foreseeable emergency scenarios and non-routine tasks, taking into account the types of material and equipment in use and the location within the facility. Scenarios such as the following may be foreseeable:

- Fires and explosions;

- Chemical releases;

- Hazardous material spills;

- Startups after planned or unplanned equipment shutdowns;

- Non-routine tasks, such as infrequently performed maintenance activities;

- Structural collapse;

- Disease outbreaks;

- Weather emergencies and natural disasters;

- Medical emergencies; and

- Workplace violence.

Gathering information and performing inspections

- Employers may already have internal and external data available to help with identifying hazards, including equipment operating manuals, Safety Data Sheets, inspection reports, records of previous illness/injury, and more.

- Employers must arrange for regular safety inspections, as well as inspections whenever working conditions (work processes, equipment, etc.) change. A follow-up plan is needed to ensure any safety issues found are corrected.

Information on hazards may already be available to employers and workers, from both internal and external sources.

Employers should collect, organize, and review information with workers to determine what types of hazards may be present and to which workers may be exposed or potentially exposed. Information available may include:

- Equipment and machinery operating manuals.

- Safety Data Sheets (SDS) provided by chemical manufacturers.

- Self-inspection reports and inspection reports from insurance carriers, government agencies, and consultants.

- Records of previous injuries and illnesses, such as Occupational Safety and Health Administration (OSHA) 300 and 301 logs and reports of incident investigations.

- Workers’ compensation records and reports.

- Patterns of frequently-occurring injuries and illnesses.

- Exposure monitoring results, industrial hygiene assessments, and medical records (appropriately redacted to ensure patient/worker privacy).

- Existing safety and health programs (lockout/tagout, confined spaces, process safety management, personal protective equipment, etc.).

- Input from workers, including surveys or minutes from safety and health committee meetings.

- Results of job hazard analyses, also known as job safety analyses.

Information about hazards may also be available from outside sources such as:

- Occupational Safety and Health Administration (OSHA), National Institute for Occupational Safety and Health (NIOSH), and Centers for Disease Control and Prevention (CDC) websites, publications, and alerts.

- Trade associations.

- Labor unions, state and local occupational safety and health committees/coalitions (“COSH groups”), and worker advocacy groups.

- Safety and health consultants.

Inspecting the workplace for safety hazards

Hazards can be introduced over time as workstations and processes change, equipment or tools become worn, maintenance is neglected, or housekeeping practices decline. Setting aside time to regularly inspect the workplace for hazards can help identify shortcomings so that they can be addressed before an incident occurs. Employers should:

- Conduct regular inspections of all operations, equipment, work areas and facilities. Have workers participate on the inspection team and talk to them about hazards that they see or report.

- Document inspections to later verify that hazardous conditions are corrected. Take photos or video of problem areas to facilitate later discussion and brainstorming about how to control them, and for use as learning aids.

- Include all areas and activities in these inspections, such as storage and warehousing, facility and equipment maintenance, purchasing and office functions, and the activities of on-site contractors, subcontractors, and temporary employees.

- Regularly inspect both plant vehicles (e.g., forklifts, powered industrial trucks) and transportation vehicles (e.g., cars, trucks).

- Use checklists that highlight things to look for. Typical hazards fall into several major categories, such as those listed below, although each workplace will have its own list:

- General housekeeping;

- Slip, trip, and fall hazards;

- Electrical hazards;

- Equipment operation;

- Equipment maintenance;

- Fire protection;

- Work organization and process flow (including staffing and scheduling);

- Work practices;

- Workplace violence;

- Ergonomic problems; and

- Lack of emergency procedures.

Employers should also plan to do safety inspections before changing operations, workstations, or workflow; making major organizational changes; or introducing new equipment, materials, or processes, seeking the input of workers and evaluating the planned changes for potential hazards and related risks.

Many hazards can be identified using common knowledge and available tools. For example, workers can easily identify or remove hazards such as broken stair rails or frayed electrical cords. Workers can be a very useful internal resource, especially if they are trained in how to identify and assess risks.

Identifying health hazards

- Health hazards that may be identified might be chemical, physical, biological, or ergonomic.

- In some cases, identifying such hazards may require specialized knowledge; small businesses can often obtain this help for free through OSHA’s On-Site Consultation Program.

Identifying health hazards is typically more complex than identifying physical safety hazards. For example, gases and vapors may be invisible, often have no odor, and may not have an immediately noticeable harmful health effect.

Health hazards include chemical hazards (solvents, adhesives, paints, toxic dusts, etc.); physical hazards (noise, radiation, heat, etc.); biological hazards (infectious diseases); and ergonomic risk factors (heavy lifting, repetitive motions, vibration).

Reviewing workers’ medical records (appropriately redacted to ensure patient/worker privacy) can be useful in identifying health hazards associated with workplace exposures. Employers should:

- Identify chemical hazards — Review Safety Data Sheets (SDSs) and product labels to identify chemicals in the workplace that have low exposure limits, are highly volatile, or are used in large quantities or in unventilated spaces. Identify activities that may result in skin exposure to chemicals.

- Identify physical hazards — Identify any exposures to excessive noise (areas where workers must raise their voices to be heard by others), elevated heat (indoor and outdoor), or sources of radiation (radioactive materials, X-rays, or radiofrequency radiation).

- Identify biological hazards — Determine whether workers may be exposed to sources of infectious diseases, molds, toxic or poisonous plants, or animal materials (fur or scat) capable of causing allergic reactions or occupational asthma.

- Identify ergonomic risk factors — Examine work activities that require heavy lifting, work above shoulder height, repetitive motions, or tasks with significant vibration.

- Conduct quantitative exposure assessments — When possible, using air sampling or direct reading instruments.

- Review medical records — To identify cases of musculoskeletal injuries, skin irritation or dermatitis, hearing loss, or lung disease that may be related to workplace exposures.

Identifying and assessing health hazards may require specialized knowledge. Small businesses can obtain free and confidential occupational safety and health advice services, including help identifying and assessing workplace hazards, through the Occupational Safety and Health Administration (OSHA)’s On-Site Consultation Program.

Conducting incident investigations

- Thoroughly investigating all safety incidents helps an employer to identify where hazards exist in their workplaces.

- Effective incident investigations will not stop when a single cause of an incident is found, but should continue until the root cause — the “why” — is identified.

Workplace incidents — including injuries, illnesses, close calls/near misses, and reports of other concerns — provide a clear indication of where hazards exist. Thoroughly investigating incidents and reports will help identify hazards that are likely to cause future harm. The purpose of an investigation must always be to identify the root causes (and there is often more than one) of the incident or concern, in order to prevent future occurrences. Employers should:

- Develop a clear plan and procedure for conducting incident investigations, so that an investigation can begin immediately when an incident occurs. The plan should cover items such as:

- Who will be involved;

- Lines of communication;

- Materials, equipment, and supplies needed; and

- Reporting forms and templates.

- Train investigative teams on incident investigation techniques, emphasizing objectivity and open-mindedness throughout the investigation process.

- Conduct investigations with a trained team that includes representatives of both management and workers.

- Investigate close calls/near misses.

- Identify and analyze root causes to address underlying program shortcomings that allowed the incidents to happen.

- Communicate the results of the investigation to managers, supervisors, and workers to prevent recurrence.

Effective incident investigations do not stop at identifying a single factor that triggered an incident. They ask the questions “Why?” and “What led to the failure?” For example, if a piece of equipment fails, a good investigation asks: “Why did it fail?” “Was it maintained properly?” “Was it beyond its service life?” and “How could this failure have been prevented?” Similarly, a good incident investigation does not stop when it concludes that a worker made an error. It asks such questions as: “Was the worker provided with appropriate tools and time to do the work?” “Was the worker adequately trained?” and “Was the worker properly supervised?”

Identifying Physical Hazards

What are physical hazards?

Physical hazards abound in the workplace. The mere fact that a company exists makes it prone to physical hazards — even the benign office has tripping and falling hazards. In an industrial setting, the huge variety of machines, processes, and equipment create a challenging set of hazards that a safety professional must deal with.

Processes that use large quantities of chemicals present a unique set of challenges. The physical properties of certain chemicals, such as flammable and combustible liquids, compressed gases, solvents, and explosives make them highly dangerous.

You may not think much about falls, but trips and falls often result in injury and lost time. Falls can even be fatal. In the workplace, there are many situations that contribute to falls:

- Floors with water, grease, or cracks

- Trash or stock piled in pedestrian walkways

- Ladders in need of repair

- Stairs with loose rails or step treads

Maintaining equipment in peak condition, practicing good housekeeping techniques, and providing signs to warn of physical hazards goes a long way to improve overall safe working conditions. Part of the safety professional’s job is to assess the workplace for physical hazards and see that they are corrected or controlled. There are many OSHA standards that have specific requirements for ensuring that physical hazards in the workplace are eliminated. In this section, you will find action steps, training action plans, tips, and checklists on a variety of topics related to controlling physical hazards.

Combustible dust

Combustible dusts are fine particles that present an explosion hazard when suspended in air in certain conditions. A dust explosion can be catastrophic and cause employee deaths, injuries, and destruction of entire buildings. In many combustible dust accidents, employers and employees were unaware that a hazard even existed. It is important that employers determine if their operations have this hazard, and if so, that they take action now to prevent tragic consequences.

A wide range of industries possess combustible dust hazards and a wide variety of materials cause combustible dust incidents. (Combustible dusts can be intentionally manufactured powders, such as corn starch or aluminum powder coatings, or may be generated by handling and processing solid combustible materials such as wood and plastic pellets. For example, polishing, grinding, transporting, and shaping many of these materials can produce very small particles.)

Action steps

The following are general action steps that should be taken to identify and control dust hazards. For detailed guidance specific to your operations, consult with a qualified professional, as well as industry standards, as applicable (for example, those published by the National Fire Protection Association).

- Assess your facility for processes that generate dust. Have dusts analyzed for combustibility hazards. (There are several factors that determine how explosive a dust can be, as well as some key measurements for determining dust explosibility. These include particle size, moisture content, ambient humidity, oxygen available for combustion, the shape of the dust particle, and the concentration of dust in the air, i.e., minimum explosive concentration or MEC.)

- Understand the five elements needed for a combustible dust explosion: Combustible dust (fuel); ignition source (heat); oxygen in air (oxidizer); dispersion of dust particles in sufficient quantity and concentration; and confinement of the dust cloud.

- Understand that there can be a primary explosion or event that shakes loose hidden dust (for example, from piping or rafters) which can cause a devastating secondary explosion.

- Ensure operations have proper engineering design and controls and inspect/maintain those controls. Seek outside assistance/expertise as needed to ensure proper dust control procedures/methods are in place.

- Develop an ignition control program, limiting and controlling potential ignition sources in dust accumulation areas.

- Train employees on the explosion hazards of combustible dusts.

- Implement a housekeeping program with regular cleaning frequencies for floors and horizontal surfaces, such as ducts, pipes, hoods, ledges, and beams, to minimize dust accumulations within operating areas of the facility. (Even seemingly small amounts of accumulated dust can cause catastrophic damage. The CSB estimated, for example, that the explosion that devastated a pharmaceutical plant in 2003 and killed six employees was caused by dust accumulations mainly under 0.25 inches deep. The CSB study references National Fire Protection Administration (NFPA) warnings that a catastrophic explosion can occur from as little as 1/32 of an inch of accumulated dust — around the thickness of a dime — covering just 5 percent of a room’s surface.)

- Ensure working surfaces are designed in a manner to minimize dust accumulation and facilitate cleaning.

- Ensure electrical equipment and electrically-powered cleaning devices such as vacuum cleaners are approved for the hazard classification for Class II locations.

- Select and use industrial trucks that are approved for the combustible dust locations.

- Prohibit the use of cleaning methods that can disperse combustible dust into the air (i.e., compressed air and dry sweeping).

- Ensure the ready availability of SDSs for the chemicals which could become combustible dust under normal operations. Note: The Chemical Safety Board has found that many SDSs do not provide sufficient data on combustible dust hazards. However, OSHA revised the HazCom rule in 2012. In the revised rule, combustible dust hazards must be addressed on labels and SDSs. Label elements are provided for combustible dust in the final HCS and include the signal word “warning” and the hazard statement “May form combustible dust concentrations in the air.”

- Implement an emergency action plan and maintain exit routes properly.

For chemicals in a solid form that do not present a combustible dust hazard, but may form combustible dusts while being processed in normal downstream uses, OSHA allows the chemical manufacturer some flexibility in labeling requirements. The manufacturer or importer may transmit the label to the customer at the time of the initial shipment, but the label does not need to be included with subsequent shipments unless it changes. This provides the needed information to the downstream users on the potential hazards in the workplace, while acknowledging that the solid metal or other materials do not present the same hazards that are produced when these materials are processed under normal conditions of use.

Training action plan

Workers are the first line of defense in preventing and mitigating fires and explosions. If the people closest to the source of the hazard are trained to recognize and prevent hazards associated with combustible dust in the plant, they can be instrumental in recognizing unsafe conditions, taking preventative action, and/or alerting management. While OSHA standards require training for certain employees, all employees should be trained in safe work practices applicable to their job tasks, as well as on the overall plant programs for dust control and ignition source control. They should be trained before they start work, periodically to refresh their knowledge, when reassigned, and when hazards or processes change.

- Define combustible dusts.

Combustible dusts are fine particles,

fibers, chips, chunks, or flakes

that could be an explosion hazard

when they’re suspended in air

under certain conditions.

Many products can be fuel for a

dust explosion when they’re used in powdered form. Here are some

examples:

- Flour, sugar, powdered milk, or other food-related products;

- Wood;

- Paper;

- Textiles;

- Charcoal and other carbon-rich materials;

- Sulfur and other chemicals;

- Aluminum, zinc, and other metals; and

- Epoxy resin and other plastics.

- Introduce the hazards.

A dust explosion can cause deaths

and serious injuries. An explosion

can destroy an entire building. In

many combustible dust incidents,

employers and employees didn’t

know that a hazard even existed.

Here’s an example of what happens

during a combustible dust explosion.

- In February 1999, a deadly fire and explosion occurred in a foundry in Massachusetts. An investigation found that a fire started in a molding machine and then spread to ventilation ducts. The small initial explosion in the ductwork disturbed resin dust that had settled on the outside of the ducts, creating a dust cloud. This dust provided fuel for a secondary explosion that was powerful enough to lift the roof and cause walls to collapse.

- Identify the types of industries that may be at risk. Combustible dust explosion hazards can exist in a variety of industries, including: agriculture, chemicals, food, grain, fertilizer, tobacco, plastics, wood, paper, tire and rubber, furniture, textiles, pesticides, pharmaceuticals, coal, metal processing, recycling operations, and others.

- Explain how dust explosions can happen. The familiar fire triangle is made up of: oxygen, an ignition source (heat), and fuel. All three conditions must be present for a fire to start. Because oxygen is normally always present in the air, fires are usually prevented by keeping the fuel separate from the ignition source. In addition to the fire triangle elements, the “dust explosion pentagon” adds two more conditions: dust particles and the confinement of the dust cloud. Similar to the fire triangle, if one part of the pentagon is missing, a combustible dust explosion can’t occur. If a dust cloud is ignited in an enclosed area such as a room, vessel, ductwork, or process equipment, it burns very fast and may explode. Even if the initial explosion is small, it could shake up accumulated dust in the area to form another dust cloud. Often these secondary explosions are far more destructive.

- Outline how to look for combustible

dust hazards.

To identify the factors that could

contribute to an explosion, employers

should evaluate the hazards of

all: materials, operations, spaces (including hidden ones),

and potential ignition sources. Some likely areas where dust can

build up include:

- Parts of the building’s structure,

- Conduit and pipe racks,

- Electrical cable trays,

- Floors,

- Areas above suspended ceilings, and

- On and around equipment (including leaks around dust collectors and ductwork).

- Discuss what can be done to

control dust build-up.

If the dust isn’t building up, it lowers the risk of a dust explosion. There

are many ways to keep dust under

control. Some of these methods are

to:

- Conduct regularly scheduled inspections,

- Clean up dust on a regular basis,

- Use proper dust collection systems and filters,

- Keep dust from escaping from equipment or ventilation systems,

- Use surfaces that are easy to clean,

- Provide easy access to inspect and clean hidden areas where dust might build up,

- Use cleaning methods that don’t stir up dust clouds, and

- Use vacuum cleaners approved for dust collection.

- Describe methods to prevent

dust from igniting.

Keeping ignition sources under

control is an important part of any

fire safety program. Some actions

employers can take include the following:

- Use proper wiring methods;

- Make sure electrically powered equipment (including forklifts) is approved for the location;

- Control static electricity (bond equipment to ground);

- Keep smoking areas, open flames, sparks, and heated surfaces separate from dusts;

- Follow a hot work permit program; and

- Follow a preventive maintenance program.

- Discuss some methods to minimize

injuries and damage from

a combustible dust explosion.

Some of the steps employers can

take to minimize injuries and damage

from a combustible dust explosion

could include:

- Developing an emergency action plan,

- Maintaining emergency exit routes,

- Setting up operations in areas where the hazards are away from workers and equipment,

- Setting up isolation barriers around hazardous operations,

- Making sure dust handling equipment has pressure relief venting that’s directed away from workers and equipment, and

- Installing specialized spark detection and fire suppression systems in dust handling equipment.

Tips

The amount of dust accumulation necessary to cause an explosive concentration can vary greatly. This is because there are so many variables — the particle size of the dust, the method of dispersion, ventilation system modes, air currents, physical barriers, and the volume of the area in which the dust cloud exists or may exist. As a result, simple rules of thumb regarding accumulation (such as writing in the dust or visibility in a dust cloud) can be subjective and misleading. The hazard analysis should be tailored to the specific circumstances in each facility and the full range of variables affecting the hazard.

Many locations need to be considered in an assessment. One obvious place for a dust explosion to initiate is where dust is concentrated. In equipment such as dust collectors, a combustible mixture could be present whenever the equipment is operating.

Other locations to consider are those where dust can settle, both in occupied areas and in hidden concealed spaces. A thorough analysis will consider all possible scenarios in which dust can be disbursed, both in the normal process and potential failure modes.The facility analysis must identify areas requiring special electrical equipment classification due to the presence (or potential presence) of combustible dust. Various OSHA standards as well as industry (e.g., NFPA) can be consulted.

Checklist

Follow these checklists to prevent combustible dust hazards.

Hazard assessment

- Are there processes that accumulate dust? If so, have the dusts been analyzed for combustibility?

- Are periodic assessments conducted to determine dust explosion possibilities?

- Are employees and supervisors involved in identifying dust explosion hazards, for example through job hazard analyses?

- Is particular attention given during the hazard assessment to dust collection systems and areas not in plain view?

Prevention

- Have proper engineering design and controls been implemented for operations involving combustible dust; for example, dust control in process equipment and fugitive dust control; grounding and bonding; and separator devices?

- Is a comprehensive housekeeping program implemented?

- Are potential ignition sources limited and controlled in dust accumulation areas?

- Is it prohibited to use compressed air and similar cleaning methods that could disperse combustible dusts into the air?

- Are electrical services appropriate for Class II location? Consult applicable codes, for example the National Electrical Code.

- Are industry standards, such as NFPA 654, followed as applicable?

- Is a preventive maintenance program in place to minimize release of fugitive dust?

Note: Minor, but steady leaks, can cause large amounts of dust to accumulate.

Training

- Have employees received training on the hazards of dust?

- Have employees received training on specific characteristics of the dust that they work with?

- Have employees been trained to recognize potential ignition sources?

- Do employees know which processes/locations accumulate dust (for example, cable trays, pipe racks, floors, above ceilings, and structural members)?

- Are employees instructed to report plant fires and near misses?

Confined spaces

Employees in industry and construction are often asked to perform work in confined spaces, but many confined spaces contain serious hazards that endanger the employees who enter those spaces. For this reason, the Occupational Safety and Health Administration requires employers to implement certain procedures that protect workers from the hazards posed by confined spaces. These include procedures for identifying physical hazards and hazardous atmospheres in confined spaces, controlling and eliminating these hazards, and more.

Action steps

- Evaluate the workplace to determine if any spaces are permit-required confined spaces.

- Inform exposed employees, by posting danger signs or by any other equally effective means, of the existence and location of and the danger posed by the permit spaces.

- Decide whether employees will enter spaces. (If employees will not enter spaces, take appropriate, effective prevention measures.)

- Implement a written permit space program.

- Evaluate hazards of permit spaces.

- Provide employees with the opportunity to observe any monitoring or testing of permit spaces.

- Develop and implement the means, procedures, and practices necessary for safe permit space entry operations.

- Establish a permit system.

- Provide training.

- Perform entry according to OSHA requirements.

- Verify that conditions in the permit space are acceptable for entry throughout the duration of an authorized entry.

- Provide appropriate equipment (PPE, rescue equipment, testing, monitoring, ventilation, lighting, etc.)

- Provide at least one attendant outside the permit space into which entry is authorized for the duration of entry operations.

- Develop and implement rescue procedures.

- If contractors are involved in the confined space entry, follow pertinent OSHA requirements.

Training action plans

Training must be such that all employees whose work is regulated by OSHA’s confined spaces standard acquire the understanding, knowledge, and skills necessary for the safe performance of the duties assigned.

Training must be provided to each affected employee:

- Before the employee is first assigned duties relative to the confined space.

- Before there is a change in assigned duties.

- Whenever there is a change in permit space operations that presents a hazard about which an employee has not previously been trained.

- Whenever you have reason to believe either that there are deviations from the permit space entry procedures or that there are inadequacies in the employee’s knowledge or use of these procedures.

The training must establish employee proficiency in the duties required by the confined spaces standard and must introduce new or revised procedures, as necessary, for compliance.

Training should be specific to the employee’s function relative to the confined space. For instance, if the employee is an authorized entrant, then training should focus specifically on tasks and hazards he may face in this role.

In general, training should cover:

- Equipment to be used,

- Communicating with others involved in the work,

- Hazard awareness and recognition,

- Specific roles and duties,

- Monitoring,

- Medical and first aid, and

- Rescue.

Any work that involves contractors also requires special training and communication, both from the host to the contractor and from the contractor to the host.

Documentation

The employer must certify that required training has been accomplished. The certification must contain:

- Each employee’s name,

- The signatures or initials of the trainers, and

- The dates of training.

Tips

- A permit-required confined space is a confined space that has one or more of the following characteristics:

- Contains or has the potential to contain a hazardous atmosphere;

- Contains a material that has the potential for engulfing an entrant;

- Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor which slopes downward and tapers to a smaller cross section; or

- Contains any other recognized serious safety or health hazard.

- When workers enter a permit space, at least one person must remain outside to monitor, summon help, or provide assistance.

- An attendant may attend to more than one permit space provided he/she can perform all required duties without compromising the safety of any entrant in all spaces being monitored (there is no proximity requirement).

- An employee can be both an entry supervisor and entrant as long as the employee has had the appropriate training and the duties of one activity do not conflict with the duties of the other.

- The entrants need to wear chest or full body harnesses with retrieval lines to make non-entry rescue attempts easier.

- The attendant needs to communicate with the entrants to monitor their conditions. If a situation arises that requires emergency rescue, the attendant should summon the rescue service and stay outside of the permit space entrance.

- An attendant can be a trained member of the rescue service, but cannot enter the permit space until the rest of the team has arrived to start proper rescue procedures.

Checklist

View these confined space checklists to ensure safety and compliance at your facility.

Monitoring

- When working in permit-required confined spaces, are environmental monitoring tests taken?

- Are authorized entrants or their representatives provided an opportunity to observe any monitoring or testing of permit spaces?

- Are permit spaces tested to determine if acceptable entry conditions exist prior to entry?

- Are permit spaces tested or monitored as necessary to determine if acceptable entry conditions are being maintained during the course of entry operations?

Equipment

- Is necessary personal protective equipment available?

- Is rescue and emergency services equipment available?

- Is communications equipment provided to allow the attendant to communicate with authorized entrants as necessary to monitor entrant status and to alert entrants of the need to evacuate the permit space?

General

- Are those having active roles in entry operations appropriately designated (for example, authorized entrants, attendants, entry supervisors, and persons who test or monitor the atmosphere in a confined space)?

- Is at least one attendant stationed outside the confined space for the duration of the entry operation?

- Are appropriate rescue personnel available?

- Are permit spaces flushed, ventilated, purged, and rendered inert to eliminate or control atmospheric hazards prior to entry?

Emergency action plans

This regulation applies to all companies that fall under a particular OSHA standard that requires an emergency action plan. However, it is wise for all employers to have action plans for any emergency that may be reasonably expected to occur in the workplace. Where required by OSHA, employers must develop a plan (called an emergency action plan or EAP) for emergency situations so that there is a literal “plan of action” for employees to take in the event of fires, toxic chemical releases, hurricanes, tornadoes, blizzards, floods, and other similar catastrophic events.

Action steps

Include the following minimum requirements in the EAP to ensure that it covers those designated actions employers and employees must take to ensure employee safety from fire and other emergencies.

- Establish emergency escape procedures and emergency escape route assignments.

- Develop procedures to be followed by employees who remain to operate critical plant operations before they evacuate.

- Establish procedures to account for all employees after emergency evacuation has been completed.

- Assign rescue and medical duties for those employees who are to perform them.

- List the preferred means of reporting fires and other emergencies.

- Develop a list of employee names or regular job titles of persons or departments who can be contacted for further information or explanation of duties under the plan.

- Establish an employee alarm system. If the employee alarm system is used for alerting fire brigade members, or for other purposes, use a distinctive signal for each purpose.

- List the types of evacuation to be used in emergency circumstances.

- Designate and train a sufficient number of employees to assist in the safe and orderly emergency evacuation of employees before implementing the EAP.

- Review the EAP with each covered employee upon initial assignment, when the employee’s responsibility or designated actions under the plan change, and when the plan changes.

Training action plan

You should develop an emergency action team prior to implementing the EAP. Begin by designating and training a sufficient number of employees to assist in the safe and orderly emergency evacuation of their coworkers.

- List the names or job titles of persons who can be contacted for more information on the plan. Trainees should understand:

- The employee alarm system,

- How to report fires and other emergencies, and

- Which personnel are designated to perform rescue and medical duties and their individual responsibilities.

- Explain how all employees will be accounted for after the emergency evacuation has been completed. Make sure employees understand:

- Critical plant operations and who is designated to remain behind to operate it/shut it down before they evacuate, and

- Emergency escape procedures and emergency escape routes.

Tips

A map of the facility showing specific areas, exit routes, exit doors, and head count locations is a useful training tool and should also be posted around the company.

If a fire occurs, safe and orderly evacuation is necessary. Your company should have an established evacuation plan, with procedures and exits indicated. Find out what it is and where you are expected to go during a fire or fire drill. A head count location should be established so that once everyone is evacuated, you meet at a designated spot to account for each employee.

Other than fires, severe weather emergencies are the most common emergency situations that occur. Severe weather emergencies include hurricanes, tornadoes, excessive heat, heavy snow, and extreme cold weather conditions.

If a bomb threat is made at your facility, always take the threat seriously. Immediately notify a supervisor or the safety manager of the threat and evacuate the premises (do not search for a bomb unless instructed by police to look for foreign or suspicious objects).

Checklist

Follow these checklists to ensure you and your employees are prepared for any potential emergencies.

Emergency action plan

- Is there an emergency action plan (EAP) in place detailing procedures employees should follow in an emergency?

- Does the EAP include procedures for all anticipated emergency situations (i.e., fire, tornado, bomb threat, or explosion)?

- Does the EAP include escape procedures and routes?

- Does the EAP contain procedures for those remaining in the facility to perform critical operations?

- Do you have headcount procedures (location or methods for accounting for employees)?

- If your company is located in a high-rise building, does your emergency program include appropriate escape information?

- Do you have an employee assistance program or some other means to provide counseling to employees should a disaster occur?

Disaster recovery

- Have you established a work location that could be used should your facility be unavailable due to disaster or emergency?

- Does the temporary work location have all necessary equipment so critical business functions can be carried out?

- Have necessary safety measures been taken to ensure that the temporary location is safe and will have necessary protective equipment?

Rescue workers

- Is air monitoring conducted to make sure rescue area is safe?

- Are rescue workers protected against hazards that may be encountered (i.e., asbestos, silica)?

- Are rescue workers provided proper protective equipment for the hazards they face?

Alarms and warnings

- Does the employee alarm system provide warning for necessary emergency action as called for in the emergency action plan?

- Is the employee alarm capable of being perceived above ambient noise or light levels by all employees in the affected portions of the workplace?

- Is the employee alarm distinctive and recognizable as a signal to evacuate the work area or take necessary actions?

- Have all employees been informed of the preferred means of reporting emergencies, such as manual pull box alarms, public address systems, radio or telephones?

- Are emergency telephone numbers posted near telephones, or employee notice boards, and other conspicuous locations?

- Have procedures been established for sounding emergency alarms in the workplace?

Fire alarm systems

- If you have a non-supervised fire alarm system, is it tested bimonthly?

- If you have a supervised employee alarm system (that is, does the alarm have a device that indicates system malfunction), is it tested yearly?

Entrances and exits

If you are a general industry employer, the Subpart E Exit routes regulations apply to your company. Your facility must provide a safe means of exiting from buildings or structures for the purpose of general egress, or for the purpose of exiting in the case of fire or other emergencies. In addition, you must also provide a clear and unobstructed path to the entrance of your facility.

Action steps

- Make sure exit routes are permanent.

- Separate exits using fire resistant materials.

- Limit openings into an exit.

- Ensure the number of exit routes is adequate.

- Ensure there are at least two exit routes.

- Provide adequate exit discharge.

- Make sure exit doors are unlocked.

- Use side-hinged exit doors.

- Ensure the capacity of exit routes is adequate.

- Provide exit routes that meet minimum height and width requirements.

- Keep exit routes free of explosive or highly flammable furnishings or other decorations.

- Maintain exit routes free and unobstructed.

- Ensure lighting and marking is adequate and appropriate.

- Maintain exit routes during construction, repairs, or alterations.

- Ensure that the alarm system is operable.

Training action plan

You must designate and train employees to assist in a safe and orderly evacuation of other employees.

You must also review the emergency action plan with each employee covered by the plan. This review should be conducted:

- When the plan is developed or the employee is assigned initially to a job,

- When the employee’s responsibilities under the plan change, and

- When the plan is changed.

Tips

- The line-of-sight to an exit sign must be clearly visible at all times.

- Maintain exit routes during construction, repairs, or alterations.

- Ceilings of exit routes must be at least 7 feet, 6 inches high.

- Exit access must be at least 28 inches wide at all points.

Checklist

Review these checklists to ensure exit routes at your facility meet compliance.

Exit design

- Are exit routes made of approved components and permanently attached to the building?

- Are exit routes designed and maintained to provide adequate headroom?

- Are exit doors designed so that no device or alarm failure will impede or prevent emergency use of exits?

Capacity of means of egress

- Are width and capacity of exit routes in compliance with OSHA standards?

- Is the capacity of the exit route sufficient for the occupant load?

- Where more than one way of exit access leads to an exit, does each have a width adequate for the number of persons it must accommodate?

Arrangement of exits

- Have you assured that no furnishings, decorations, or other objects are placed as to obstruct exits or exit visibility?

- Are exits adequately lighted so an employee with normal vision can see along the exit route?

Access to exits

- Are exit doors unlocked?

- Are exits readily accessible at all times?

- Are doors, from a room to an exit or to a way of exit access, of the side-hinged, swinging type?

- Is access to an exit NOT through a bathroom, or other room subject to locking (except where the exit is required to serve only the room subject to locking)?

- Are ways of exit access and the doors to exits to which they lead clearly recognizable as such?

- Is exit access arranged so that it will not be necessary to travel toward any area of high hazard occupancy in order to reach the nearest exit?

- Is exit access travel effectively shielded from high hazard locations by suitable partitions or other physical barriers?

- Is the minimum width of any way of exit access at least 28 inches?

Arrangement of exits

- Are exits marked by a readily visible sign?

- Is access to exits marked by readily visible signs if it is not immediately visible?

- Is any door, passage, or stairway that could be mistaken for an exit or a way of exit access, identified by a sign reading “Not an Exit” or similar designation, or identified by a sign indicating its actual character?

Protective enclosure of exits

- When an exit is protected by separation from other parts of the building, does the separating construction meet OSHA requirements (i.e., 1-hour fire resistance rating when the exit connects three stories or less)?

Fire protection

OSHA has many requirements concerning fire protection in the workplace. These requirements are found in Subpart L and in some other specific standards. Among the items addressed by OSHA standards is fire brigades, all portable and fixed fire suppression equipment, fire detection systems, and fire or employee alarm systems.

Action steps

- Provide approved and appropriate portable fire extinguishers.

- Mount, locate, and identify portable fire extinguishers so that they are readily accessible to employees without subjecting the employees to possible injury.

- Maintain fire extinguishers in a fully charged and operable condition.

- Inspect, maintain, and test fire extinguishers.

- Provide necessary training to employees who are expected to use portable fire extinguishers.

- Ensure that hose and standpipe systems meet OSHA requirements.

- Ensure all automatic sprinkler systems meet OSHA requirements.

- Maintain any fixed extinguishing systems per OSHA requirements.

- Follow OSHA requirements for any fire brigade you choose to form.

- Ensure fire detection systems are maintained properly.

- Provide an employee alarm system that gives warning for necessary emergency action as called for in the emergency action plan, or for reaction time for safe escape of employees from the workplace or the immediate work area, or both.

Training action plan

The level and type of training needed for fire protection depends on the level and type of fire protection your facility has in place. For instance, if you have a fire brigade, extensive training must be provided to fire brigade members, per 1910.156.

Similarly, if you provide portable fire extinguishers for employee use, such employees must be trained. This training must familiarize employees with the general principles of fire extinguisher use and the hazards involved with incipient stage fire fighting. Training must be provided upon initial employment and at least annually thereafter.

You must also provide training to any employees who have been designated to use fire fighting equipment as part of an emergency action plan. Training must be provided upon initial employment and at least annually thereafter.

You should also train all employees on the actions they need to take relative to your emergency alarm system. They should be familiar with the distinct sounds of the system and what each sound means.

Tips

- Fire extinguishers have to be kept in their designated locations at all times when not being used.

- When extinguishers are removed for maintenance or testing, they must be replaced by an operable unit.

Checklists

Review these checklists to ensure fire safety at your facility.

Fire extinguishers

- Are portable fire extinguishers provided, mounted, located, and identified so that they are readily accessible to employees?

- Are only approved portable fire extinguishers used?

- Are portable fire extinguishers maintained, fully charged, operating properly, and kept in designated places?

- Are portable fire extinguishers provided for employee use and selected and distributed based on the classes of anticipated fires and on the size and degree of hazard that would affect their use?

- Are travel distances to extinguishers appropriate?

- Are all portable fire extinguishers in the workplace inspected, maintained, and tested?

- Is hydrostatic testing performed by trained persons with suitable testing equipment and facilities?

- Are portable extinguishers hydrostatically tested at the intervals listed in Table L-1 of 1910.157?

- Has an educational program been provided to familiarize employees with the general principles of fire extinguisher use and the hazards involved with incipient stage fire fighting?

- Have employees been trained (who have been designated to use fire fighting equipment) in the use of the equipment?

Fire alarm

- Have you established an employee alarm system that complies with 1910.165?

- If the employee alarm system is used for alerting fire brigade members, or for other purposes, is a distinctive signal used for each purpose?

- Are all employee alarm systems in proper working condition, except when undergoing repairs or maintenance?

Fire detection systems

- Are all devices approved for use?

- Are fire detection systems and components returned to normal operating condition as soon as possible after each use or test?

Fire brigades

- If you choose to form a fire brigade, are the requirements of 1910.156 met?

Sprinkler systems

- Are automatic sprinkler system water control valves, air and water pressure checked weekly/periodically as required?

- Are fire control sprinkler heads kept clean?

- Are sprinkler heads protected by metal guards when exposed to physical damage?

- Is proper clearance maintained below sprinkler heads?

Flammable liquids

OSHA’s Flammable Liquids regulation, 1910.106, applies to all persons who handle, use, store, or transport flammable liquids. A flammable liquid means any liquid having a flashpoint at or below 199.4°F (within that definition, there are four categories of flammable liquids).

Action steps

- Ensure flammable liquids are stored and handled properly.

- Familiarize yourself with the different categories of flammable liquids (this will determine storage and usage requirements).

- Ensure containers meet the design requirements in 1910.106.

- Provide adequate drainage, dikes, and walls for tanks.

- Take precautions to prevent ignition by eliminating or controlling sources of ignition.

- Ensure the design (including selection of materials) fabrication, assembly, test, and inspection of piping systems containing flammable liquids is suitable for the expected working pressures and structural stresses.

- Provide suitable emergency and fire protection.

- Ensure adequate ventilation.

- Install electrical wiring properly.

- Follow proper procedures for dispensing liquids.

Training action plan

Any employee involved in storage, transfer, use, or disposal of flammable liquids needs to be trained to handle them safely and to follow your company’s established procedure.

Generally, training content should cover:

- Categories of flammable liquids,

- Handling procedures,

- Storage procedures, and

- Spill cleanup.

In addition, if your company receives, stores, or handles flammable liquids in storage tanks in areas that have the potential to flood, you need to have employees trained on emergency response procedures.

A hands-on approach is appropriate in this part of the training session. In fact, you may want to demonstrate how to do specific procedures related to flammables at your facility. Then allow each employee to try the procedure, so they can perform them correctly and so they will remember them better.

Tips

- When transferring flammable liquids, always bond and ground the containers.

- If purchasing plastic containers of five gallons or less for use with flammable liquids, purchase those with a built-in metal grounding strip.

Checklist

Review these checklists to ensure flammable liquid safety at your facility.

Containers

- Are all connections on drums and piping, vapor and liquid tight?

- Are all flammable liquids kept in closed containers when not in use (e.g., parts cleaning tanks, pans, etc.)?

- Are approved containers and portable tanks used for the storage and handling of flammable liquids?

- Are bulk drums of flammable liquids grounded and bonded to containers during dispensing?

- Are flammable liquids, such as gasoline, kept in an approved safety can?

- Are portable storage tanks equipped with emergency venting that will relieve excessive internal pressure caused by fire exposure?

- Are safety cans used for dispensing flammable liquids at a point of use?

- Are storage cabinets used to hold flammable liquids, labeled “Flammable — Keep Fire Away”?

- Are storage tanks adequately vented to prevent the development of excessive vacuum or pressure as a result of filling, emptying, or atmosphere temperature changes?

Handling

- Are all containers over 30 gallons in inside storage rooms stacked individually?

- Are firm separators placed between containers of combustibles or flammables, when stacked one upon another, to assure their support and stability?

Storage

- Are “No Smoking” rules enforced in areas involving storage and use of hazardous materials?

- Are all solvent wastes, and flammable liquids kept in fire-resistant, covered containers until they are removed from the worksite?

- Are all spills of flammable liquids cleaned up promptly?

- Is proper storage of flammable materials practiced to minimize the risk of fire including spontaneous combustion?

- Is there one clear aisle at least 3 feet wide?

Ladders

OSHA’s ladder regulations, at 1910.23, apply to any general industry workplace that uses ladders to perform duties (other than construction work) at high elevations.

Action steps

- Use ladders that are designed and approved for the intended purpose.

- Ensure ladders meet OSHA specifications.

- Follow all ladder safety requirements.

- Train employees in safe ladder use.

- Maintain ladders in a safe condition.

- Inspect ladders as needed.

- Remove defective ladders from service.

Training action plan

Training content for ladders and stairways depends on the types of equipment and structures your facility has and what work will be performed. In general, workers need to be trained as follows:

Ladders

Content should include:

- Inspecting the ladder,

- Setting up the ladder,

- Safe ladder use,

- Ascending and descending the ladder,

- Maintaining three points of contact,

- Recognizing hazards,

- Carrying tools and equipment, and

- Using the right ladder for the job.

Tips

- Workers on ladders generally do not require fall protection.

- Be careful that painting ladders or applying stickers does not hide damage.

- Make sure the ladder is the best tool for the job.

- Ensure workers understand associated hazards (e.g., electrical, wind) that they may have to consider with selecting and/or using a ladder.

Checklist

Review these checklists to ensure ladder safety at your facility.

Design and construction

- If wood, is the portable ladder not coated with any material that may obscure structural defects?

- If metal, is the portable ladder made of corrosion-resistant material or protected against corrosion?

- If metal, are the rungs and steps of the portable ladder corrugated, knurled, dimpled, coated with skid-resistant material, or otherwise treated to minimize slipping?

- Are the rungs, steps, and cleats of the portable ladder spaced at least 10 inches and not more than 14 inches apart?

- Do the rungs, steps, and cleats of the portable ladder have a minimum clear width of 11.5 inches?

Stepladders

- Is the stepladder equipped with a metal spreader or locking device that securely holds the front and back sections in an open position while the ladder is in use?

Stepstools

- Are the steps on the stepstool spaced at least 8 inches and not more than 12 inches apart?

- Does the stepstool have a minimum clear width of 10.5 inches?

Inspection and maintenance

- Are portable ladders inspected regularly, and as necessary, to ensure they are in safe condition?

- Are deficiencies corrected or repaired before an employee uses the portable ladder again?

- If a portable ladder correction or repair cannot be made immediately, are employees prevented from using the portable ladder until repaired?

- If a portable ladder repair involves structural integrity, does a qualified person perform or supervise the correction or repair?

Training

- Is each employee who uses a portable ladder trained on how to properly use the ladder?

- Is each employee who uses a portable ladder trained to recognize the fall hazards in the work area?

- Is training conducted by a qualified person?

Note: Qualified, under this OSHA requirement, describes a person who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training, and experience has successfully demonstrated the ability to solve or resolve problems relating to the subject matter, the work, or the project. - Is information and training provided in a manner that each employee understands?

- Is retraining provided when deficiencies in performance or knowledge are noted, or there are changes in the workplace or equipment?

Personal protective equipment

OSHA’s Subpart I regulations apply to all persons involved in hazardous processes; environmental, chemical, radiological hazards; or mechanical irritants that are capable of causing injury or impairment of any body part through absorption, inhalation, or physical contact. The categories of personal protective equipment (PPE) include: eye and face equipment, head protection, hand protection, foot protection, fall protection, and respiratory protection (information about respiratory protection is provided in a separate topic area under Respiratory Protection, 1910.134).

Action steps

- Assess the workplace to determine what hazards are present that require PPE.

- Document and certify the PPE assessment.

- Provide appropriate and approved PPE based on the workplace hazards.

- Instruct employees in proper PPE usage.

- Ensure employees wear proper PPE.

- Establish inspection and maintenance procedures for PPE.

Training action plan

OSHA requires that you provide training to each employee who is required to use PPE. Each such employee shall be trained to know at least the following:

- When PPE is necessary.

- What PPE is necessary.

- How to properly don, doff, adjust, and wear PPE.

- The limitations of the PPE.

- The proper care, maintenance, useful life, and disposal of the PPE.

Each affected employee must also demonstrate an understanding of the training and the ability to use PPE properly, before being allowed to perform work requiring the use of PPE.

When you have reason to believe that any affected employee who has already been trained does not have the understanding and skill required, you must retrain each such employee. Circumstances where retraining is required include, but are not limited to, situations where:

- Changes in the workplace render previous training obsolete.

- Changes in the types of PPE to be used render previous training obsolete.

- Inadequacies in an employee’s knowledge or use of assigned PPE indicate that the employee has not retained the requisite understanding or skill.

Tips

- Make sure that protective eyewear does not affect the fit of respirators.

- Make sure that protective eyewear does not disturb the proper positioning of corrective lenses so as to inhibit or limit the employee’s vision.

- Ensure employees disinfect shared protective eyewear after each use.

- Always replace a hard hat if it sustains an impact, even if damage is not noticeable.

- Don’t let workers wear hard hats backward unless the hat has been tested and approved for such use.

Checklist

Review these checklists to ensure proper PPE usage at your facility.

General

- Are all employees required to use PPE as needed?

- Is PPE functional and in good repair?

- Is protective clothing and equipment provided and used when cleaning up spilled toxic or otherwise hazardous materials or liquids?

- Is PPE provided and are all employees required to use PPE as needed to protect against injury?

- Does PPE have ANSI or ASTM specifications marked on it?

Training

- Has each individual who is required to use PPE been provided with training?

- Have the trained individuals demonstrated an understanding of the training and the ability to use PPE properly before being allowed to perform work requiring the use of PPE?

- Are individuals retrained when there is reason to believe that they do not have the understanding or skill to use PPE properly?

Recordkeeping

- Have you documented that a hazard assessment has been done, when, and by whom?

- Have you documented that PPE training has been done, who has received it, and when?

Head, foot, and hand protection

- Are protective helmets used wherever there is the possible danger of head injury from impact, or from falling or flying objects, or from electrical shock and burns?

- Is protective footwear used wherever there is the danger of foot injuries due to falling or rolling objects, or objects piercing the sole, and where feet are exposed to electrical hazards?

- Are appropriate protective gloves used wherever there is the danger to hands of exposure to hazards such as those from skin absorption of harmful substances, severe cuts or lacerations, severe abrasions, punctures, chemical burns, thermal burns, and harmful temperature extremes?

Eye and face protection

- Are individuals issued and required to wear appropriate eye protective devices while participating or observing activities which present a potential eye safety hazard?

Personal fall protection

- Have all impacted individuals been trained to use personal fall protection equipment?

- Is the equipment inspected daily before use?

- Does fall protection meet the design requirements in 1910.140?

- Are ropes, belts, lanyards, lifelines, and harnesses used for personal fall protection compatible with connectors used?

Posting requirements

- Are all areas and equipment requiring the use of PPE devices posted with a sign indicating this requirement?

Process safety management

OSHA’s 1910.119 regulation applies to those companies that deal with any of more than 130 specific toxic and reactive chemicals in listed quantities (See 1910.119 Appendix A); it also includes any Category 1 flammable gas (as defined in 1910.1200(c)) or a flammable liquid with a flashpoint below 100°F (37.8°C) on site in one location, in a quantity of 10,000 pounds (4535.9 kg) or more (with a few exceptions, as outlined in 1910.119(a)(1)(ii)(A) and (B)).

Action steps

- Ensure employee participation in the process safety management program.

- Conduct adequate hazard analyses.Implement safety operating procedures.

- Conduct process safety training.

- Ensure process safety for contractors.

- Conduct pre-startup safety reviews.

- Ensure integrity of process equipment.

- Ensure management of change process and procedures are adequate.

- Investigate incidents per OSHA requirements.

- Ensure emergency planning and response efforts are adequate.

- Establish a process safety compliance audit process.

Training action plan

You must train each employee involved in operating a process and each employee before being involved in operating a newly assigned process. Training must include:

- An overview of the process and the operating procedures.

- Specific safety and health hazards.

- Emergency operations including shutdown.

- Safe work practices applicable to the employee’s job tasks.

Also, you must provide refresher training at least every three years, and more often if necessary, to each employee involved in operating a process to assure that the employee understands and adheres to the current operating procedures of the process. You, in consultation with the employees involved in operating the process, must determine the appropriate frequency of refresher training.

Documentation

You must prepare a record that contains the identity of the employee, the date of training, and the means used to verify that the employee understood the training.

Tips

- OSHA’s Process Safety Management (PSM) standard requires that mechanical integrity inspections have to be documented (including the name of the person performing the inspection or test) and list the information to be recorded.

- The PSM standard states that the employer must establish and implement written procedures.