Employees in industry and construction are often asked to perform work in confined spaces. But many confined spaces contain serious hazards that endanger the employees who enter those spaces. For this reason, the Occupational Safety and Health Administration requires employers to implement certain procedures that protect workers from the hazards posed by confined spaces. These include procedures for identifying physical hazards and hazardous atmospheres in confined spaces, for controlling and eliminating these hazards, and for regulating the conditions under which employees may safely enter permit-required confined spaces.

How do regulations differ between general industry and construction?

- There are five key differences between the regulations for confined spaces in construction and the regulations for confined spaces in general industry.

The Occupational Safety and Health Administration (OSHA) regulates confined spaces in two places:

- The standard for general industry, 29 CFR 1910.146, “Permit-required confined spaces,” and Appendices; and

- The standard for construction, 29 CFR 1926.1200–1926.1213 Subpart AA, “Confined Spaces in Construction.”

While these two standards have much in common, there are five key differences between the confined space regulations for construction and those for general industry:

- For construction, employers must follow additional coordination requirements when multiple employers have workers on a site.

- For construction, employers must ensure that a competent person identifies all confined spaces on a worksite and evaluates whether these spaces are permit spaces.

- For general industry, it is the employer who must identify confined spaces in the workplace and determining which are permit spaces

- For construction, employers must provide continuous monitoring for atmospheric hazards whenever possible.

- For general industry, the atmosphere in a permit space must be monitored as often as is needed to know whether entry conditions remain acceptable during entry.

- For construction, employers must provide continuous monitoring for engulfment hazards and an early-warning system that alerts workers to such hazards early enough for them to evacuate safely.

- For general industry, if isolating a permit space is infeasible, then engulfment hazards must be continuously monitored in the areas where entrants are working.

- For construction, when a prohibited condition arises in or near a permit space, the entry permit may be suspended rather than canceled if that condition is temporary and does not reconfigure the space or create new hazards. Reentry is allowed once the acceptable entry conditions specified on the entry permit are re-established in the space.

- For general industry, the entry permit for a permit space must be canceled immediately when a prohibited condition arises in or near that space. Reentry is prohibited until the prohibited condition is corrected, the permit program is revised, and a new entry permit is produced.

To know whether to follow the OSHA standard for construction or the standard for general industry, an employer must evaluate whether the work to be done in a confined space is considered maintenance or construction work.

If the work to be done in the space is maintenance, which includes activities such as keeping equipment or structures in proper condition without significant alteration, then the employer should refer to the standard for general industry, 1910.146.

If the work to be done in a confined space is considered construction work (which means work like alteration, and/or repair, including painting and decorating) then the employer should refer to the standard for construction, 29 CFR 1926.1200–1926.1213 Subpart AA.

An employer whose workers are engaged in both construction and general industry work in confined spaces will meet OSHA requirements if that employer meets the requirements of 29 CFR 1926.1200–1926.1213 Subpart AA.

Key definitions

Acceptable entry conditions: The conditions that must exist in a permit-required confined space, before employees may enter, to ensure that they can safely enter and work in the space.

Attendant: An individual stationed outside one or more permit-required confined spaces who monitors the authorized entrants and who performs all duties assigned to attendants under the employer’s permit space program.

Authorized entrant: An employee who is authorized by the employer to enter a permit-required confined space and who performs all duties assigned to entrants under the employer’s permit space program.

Competent person: An employee capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has the authorization to take prompt corrective measures to eliminate them.

Confined space: A space that:

- Is large enough and so configured that an employee can enter and perform assigned work; and

- Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits); and

- Is not designed for continuous employee occupancy.

Construction work: Work for construction, alteration, and/or repair, including painting and decorating.

Double block and bleed: The closure of a line, duct, or pipe by closing and locking or tagging two in-line valves and by opening and locking or tagging a drain or vent valve in the line between the two closed valves.

Early-warning system: The method used to alert authorized entrants and attendants that an engulfment hazard may be developing. Examples of early-warning systems include but are not limited to: Alarms activated by remote sensors; and lookouts with equipment for immediately communicating with the authorized entrants and attendants.

Emergency: Any occurrence (including any failure of hazard control or monitoring equipment) internal or external to a permit-required confined space that could endanger entrants.

Engulfment: The surrounding of a person by a liquid or flowable solid that can cause death if inhaled or by strangulation, constriction, or crushing.

Entry: The action by which a person passes through an opening into a permit-required confined space. Entry includes all ensuing work activities in the space and begins the moment any part of the entrant’s body breaks the plane of an opening into the space.

Entry permit (Permit): The written or printed document that the employer provides to allow and control entry into a permit space and that contains the information specified in either 29 CFR 1910.146(f) for general industry or 29 CFR 1926.1206 for construction.

Entry supervisor: The person (such as the employer, foreperson, or crew chief) responsible for determining whether acceptable entry conditions are present in a permit space where entry is planned, for authorizing entry, for overseeing entry operations, and for terminating entry.

- NOTE: An entry supervisor may also serve as an attendant or as an authorized entrant if the supervisor is trained and equipped for such roles. Additionally, the duties of entry supervisor may pass from one person to another during an entry operation.

Non-permit confined space: A confined space that neither contains nor could contain atmospheric hazards capable of causing death or serious physical harm.

Permit-required confined space (Permit space): A confined space with one or more of the following characteristics:

- It contains or has a potential to contain a hazardous atmosphere,

- It contains a material that has the potential to engulf an entrant,

- It is configured such that an entrant could be trapped or asphyxiated by converging walls or by a floor that slopes downward and tapers to a smaller cross section; or

- It contains any other recognized serious safety or health hazard.

Permit-required confined space program (Permit space program): The employer’s overall program for regulating employee entry into permit spaces, for controlling the hazards in permit spaces, and for protecting employees from these hazards.

Prohibited condition: Any condition in a permit space that is not allowed by the entry permit during the period when entry is authorized.

Qualified person: An employee who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training, and experience, has successfully demonstrated his ability to solve or resolve problems relating to the subject matter, the work, or the project.

Rescue service: The personnel designated to rescue employees from permit-required confined spaces.

Testing: The process of identifying and evaluating the hazards posed by permit spaces. Testing includes specifying the tests to be performed in the permit space.

- NOTE: Testing lets employers implement adequate control measures for protecting authorized entrants and determine whether acceptable entry conditions are present before and during entry.

What is the host employer/contractor relationship? (Construction)

- A host employer is required to share certain information with a contractor hired to work in a permit space.

- A host employer and contractor should work together to choose the best permit program for their project.

- Regular communication about work performed in permit spaces is essential for employers and contractors.

Host employer responsibilities

The Occupational Safety and Health Administration (OSHA) requires that host employers who hire contractors to work in permit-required confined spaces share specific information and coordinate entry procedures with those contractors (29 CFR 1926.1203(h)). If an outside contractor is hired to perform work in a permit space, it is the host employer’s responsibility to ensure that the contractor uses a written permit space program. The host employer must verify that the contractor’s workers are adequately trained in permit space entry and that they understand the hazards in the host’s facility as it relates to their work.

Host employers must provide contractors with several key pieces of information:

- The number and location of the host employer’s permit spaces,

- The host employer’s permit space program,

- Established precautions and procedures for working in permit spaces, and

- Any likely hazards that the contractor’s workers may encounter in the space.

Once work has begun in the permit space, the host employer should routinely check that the contractor is following the agreed-upon procedures. Once entry has terminated, the host employer must debrief the contractor about the permit program that was followed and about any hazards encountered in the permit space.

Contractor responsibilities

Contractors working in a permit space must ensure that all necessary information regarding the space, its hazards, and its entry procedures are obtained from the host employer. Contractors must also report any hazards encountered during work in a permit space to the host employer.

The host employer and contractor should work together to select the permit program best suited to the specifics of the permit space and the work to be done. Importantly, host employers and contractors are required to coordinate entry operations whenever personnel of both the host employer and contractor will be working in or near a permit space.

Contractor personnel enter permit spaces under many different circumstances. There are circumstances in which a contractor sets up a complete permit space program at the host employer’s workplace, and there are situations in which both contractor and host employer employees work side by side in a permit space.

What is the host employer/contractor relationship? (General industry)

- A host employer is required to share certain information with a contractor hired to work in a permit space.

- A host employer and contractor should work together to choose the best permit program for their project.

- Regular communication about work performed in permit spaces is essential for employers and contractors.

Host employer responsibilities

The Occupational Safety and Health Administration (OSHA) requires that host employers who hire contractors to work in permit-required confined spaces share specific information and coordinate entry procedures with those contractors (29 CFR 1910.146(c)(8)). If an outside contractor is hired to perform work in a permit space, it is the host employer’s responsibility to ensure that the contractor uses a written permit space program. The host employer must verify that the contractor’s workers are adequately trained in permit space entry and that they understand the hazards in the host’s facility as it relates to their work.

Host employers must provide contractors with several key pieces of information:

- The number and location of the host employer’s permit spaces,

- The host employer’s permit space program,

- Established precautions and procedures for working in permit spaces, and

- Any likely hazards that the contractor’s workers may encounter in the space.

Once work has begun in the permit space, the host employer should routinely check that the contractor is following the agreed-upon procedures. Once entry has terminated, the host employer must debrief the contractor about the permit program that was followed and about any hazards encountered in the permit space.

Contractor responsibilities

Contractors working in a permit space must ensure that all necessary information regarding the space, its hazards, and its entry procedures are obtained from the host employer. Contractors must also report any hazards encountered during work in a permit space to the host employer.

The host employer and contractor should work together to select the permit program best suited to the specifics of the permit space and the work to be done. Importantly, host employers and contractors are required to coordinate entry operations whenever personnel of both the host employer and contractor will be working in or near a permit space.

Contractor personnel enter permit spaces under many different circumstances. There are circumstances in which a contractor sets up a complete permit space program at the host employer’s workplace, and there are situations in which both contractor and host employer employees work side by side in a permit space.

Where do employers start? (Construction)

- The decisions an employer must make regarding confined spaces in the workplace may be helpfully visualized using the flowchart provided in 29 CFR 1910.146 Appendix A.

Before work begins, an employer must have a competent person identify all confined spaces on the worksite the work area and determine for each space whether it is a permit-required confined space.

If a worksite contains permit spaces, the employer must:

- Alert employees to the locations and dangers of these spaces using warning signs or equally effective means,

- Determine who will be authorized to enter and work in permit spaces, and

- Prevent all unauthorized entry into these spaces.

If a host employer will authorize contractors to enter permit spaces, then the host employer and controlling contractor must share specific information before entry begins.

For construction, employers face additional coordination-related requirements when there are workers directed by multiple employers on a worksite.

If the employer decides that employees :

- Will not be authorized to enter permit spaces, then the employer must implement the measures necessary to prevent all employee entry into permit spaces.

- Will be authorized to enter permit spaces, then that employer must write and implement a comprehensive program for protecting employees from the hazards of permit spaces and regulating employee entry into these spaces. The employer must still prevent all unauthorized entry into the permit space.

- When a permit space is about to be entered :

- If the space meets the conditions for alternate entry procedures, the employer may authorize employees to enter using the alternate entry procedures instead of the procedures laid out in the employer’s permit space program.

- If the space does not meet the conditions for alternate entry procedures, but the employer can verify that the space meets the acceptable entry conditions detailed on the employer’s permit program, then employees may begin entry according to the terms of the permit program.

Where do employers start? (General Industry)

- The decisions an employer must make regarding confined spaces in the workplace may be helpfully visualized using the flowchart provided in 29 CFR 1910.146, Appendix A.

Before work begins, an employer must identify all confined spaces in the workplace and determine for each space whether it is a permit-required confined space.

If a workplace contains permit spaces, the employer must

- Alert employees to the locations and dangers of these spaces using warning signs or equally effective means,

- Determine who will be authorized to enter and work in permit spaces, and

- Prevent all unauthorized entry into these spaces.

If a host employer will authorize contractors to enter permit spaces, then the host employer and controlling contractor must share specific information before entry begins.

If the employer decides that employees:

- Will not be authorized to enter permit spaces, then the employer must implement the measures necessary to prevent all employee entry into permit spaces.

- Will be authorized to enter permit spaces, then that employer must write and implement a comprehensive program for protecting employees from the hazards of permit spaces and regulating employee entry into these spaces. The employer must still prevent all unauthorized entry into the permit space.

When a permit space is about to be entered:

- If the space meets the conditions for alternate entry procedures, the employer may authorize employees to enter using the alternate entry procedures instead of the procedures laid out in the employer’s permit space program.

- If the space does not meet the conditions for alternate entry procedures, but the employer can verify that the space meets the acceptable entry conditions detailed on the employer’s permit program, then employees may begin entry according to the terms of the permit program.

How are worksites evaluated for permit spaces? (Construction)

- Each employer must designate a competent person to identify confined spaces that are permit spaces on a worksite.

- The competent person determines which spaces are permit spaces by evaluating and testing each space for certain hazards.

Before starting work on a worksite, each employer must ensure that a competent person identifies all confined spaces where employees may work and determines for each space whether it is a permit-required confined space (permit space). The competent person must answer the following four questions, testing as necessary, to determine whether a confined space is a permit space. If the answer to one or more of these questions is “yes,” the space is a permit space.

Question 1: Does the space contain or have the potential to contain a hazardous atmosphere?

Most deaths and injuries in confined spaces result from atmospheric hazards, a class of hazard that includes insufficient oxygen and both toxic and flammable chemicals. The competent person must evaluate whether the following hazards are or may be present before workers enter the space, testing for each as necessary:

- Oxygen deficiency (concentration less than 19.5%) or excess (concentration above 23.5%);

- Concentration of any flammable gas, vapor, or mist greater than 10% of its lower explosive limit;

- Airborne combustible dust at a concentration equal to or greater than its lower explosive limit; and

- Atmospheric concentration of any substance that can cause death, incapacitation, injury, acute illness, or impairment of ability to self-rescue.

In evaluating atmospheric hazards, the competent person must consider:

- The hazards present in the space before any workers enter; and

- Whether the work that will be performed can introduce toxic, flammable, or combustible air contaminants or lead to an excess or deficiency of oxygen.

To perform the second part of this evaluation, the competent person must be familiar with the work to be done in the space and the potential for that work to introduce atmospheric hazards. For example, a confined space that is safe when first entered can become deadly if inert gas welding inside the space leads the inert gas to displace oxygen from a worker’s breathing zone.

The competent person must also evaluate chemicals for which no permissible exposure limit (PEL) is set by the Occupational Safety and Health Administration (OSHA). For example, if a product’s label or the product manufacturer’s safety data sheet warns that a product is harmful if inhaled and should not be used without adequate ventilation, the competent person must evaluate whether use of that product in a confined space requires the space to be classified as a permit space.

Question 2: Does the space contain a material with the potential to engulf an entrant?

Engulfment means the surrounding and effective capture of a person by a liquid or finely divided (flowable) solid substance that can cause death if inhaled or cause death by suffocation, strangulation, constriction, or crushing.

The competent person must consider whether any liquid or flowable solid (such as sand) could enter the space. Any pipe or manhole in an operating water or sewer system in which a worker works is a confined space that could potentially engulf an entrant and must be treated as a permit space.

Question 3: Does the space have an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor that slopes downward and tapers to a smaller cross section?

An area of a confined space with a small cross section can develop a hazardous atmosphere if ventilation is inadequate. In addition, a space of this configuration could prevent an injured worker from escaping the space and make rescuing the worker more difficult.

Question 4: Does the space contain any other recognized serious safety or health hazard(s) that would pose an immediate danger to a worker’s life or health or would impair the worker’s ability to escape from the space if injured?

Hazards that the competent person should consider include fire and explosion hazards; the presence of mechanical, electrical, hydraulic, and pneumatic energy; temperature extremes; radiation; noise; corrosive chemicals; and biological hazards (such as venomous animals or insects).

What are the next steps if permit spaces have been identified?

- Employers must inform workers effectively of the location and dangers of any permit space in the workplace and prevent unauthorized entry.

- Employers must either prevent all employee entry to permit spaces or implement a written permit program detailing the terms for authorized entry.

If a workplace contains one or more permit spaces, the employer must inform workers in the vicinity of the location and dangers of each space. This can be done by posting warning signs at each possible point of entry or by other equally effective means.

In addition to posting warning signs, an employer who learns about a permit space must also notify its employees’ authorized representatives and the controlling contractor of the location and danger of the space. The controlling contractor must then notify other employers on the site, whose activities could create a hazard in the permit space, of the presence and location of such spaces and the hazards associated with them before workers enter the space.

The employer in a workplace where there are permit spaces must either:

- Develop and implement a written permit space program that details the location and danger of permit spaces in the workplace, or

- Prevent employees from entering permit spaces.

In addition to posting the warnings above, an employer who will not authorize employees to enter permit spaces must take steps to prevent any employees from entering those spaces. An employer might accomplish this by providing effective training on and enforcing a work rule against entry.

How are workplaces evaluated for permit spaces? (General Industry)

- Each employer is required to identify the confined spaces in a workplace that are permit spaces.

- An employer must determine which spaces are permit spaces by evaluating and testing each space for certain hazards.

Each employer is required to identify all confined spaces present in a workplace and evaluate each to determine whether it is a permit-required confined space (a “permit space”). The employer must answer the following four questions to determine whether a confined space is a permit space. If the answer to one or more of the questions is “yes,” the space is a permit space.

Question 1: Does the space contain or have the potential to contain a hazardous atmosphere?

Most deaths and injuries in confined spaces result from atmospheric hazards, a class of hazard that includes insufficient oxygen and both toxic and flammable chemicals. The employer must evaluate whether the following hazards are or may be present before workers enter the space, testing for each as necessary:

- Oxygen deficiency (concentration less than 19.5%) or excess (concentration above 23.5%);

- Concentration of any flammable gas, vapor, or mist greater than 10% of its lower explosive limit;

- Airborne combustible dust at a concentration equal to or greater than its lower explosive limit; and

- Atmospheric concentration of any substance that can cause death, incapacitation, injury, acute illness, or impairment of ability to self-rescue.

In evaluating atmospheric hazards, the employer must consider:

- The hazards present in the space before any workers enter; and

- Whether the work that will be performed can introduce toxic, flammable, or combustible air contaminants or lead to an excess or deficiency of oxygen.

To perform the second part of this evaluation, the employer must be familiar with the work to be done in the space and the potential for that work to introduce atmospheric hazards. For example, a confined space that is safe when first entered can become deadly if inert gas welding inside the space leads the inert gas to displace oxygen from a worker’s breathing zone.

The employer must also evaluate chemicals for which no permissible exposure limit (PEL) is set by the Occupational Safety and Health Administration (OSHA). For example, if a product’s label or the product manufacturer’s safety data sheet warns that a product is harmful if inhaled and should not be used without adequate ventilation, the employer must evaluate whether use of that product in a confined space requires the space to be classified as a permit space.

Question 2: Does the space contain a material with the potential to engulf an entrant?

Engulfment means the surrounding and effective capture of a person by a liquid or finely divided (flowable) solid substance that can cause death if inhaled or cause death by suffocation, strangulation, constriction, or crushing.

The employer must consider whether any liquid or flowable solid (such as sand) could enter the space. Any pipe or manhole in an operating water or sewer system in which a worker works is a confined space that could potentially engulf an entrant and must be treated as a permit space.

Question 3: Does the space have an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor that slopes downward and tapers to a smaller cross section?

An area of a confined space with a small cross section can develop a hazardous atmosphere if ventilation is inadequate. In addition, a space of this configuration could prevent an injured worker from escaping the space and make rescuing the worker more difficult.

Question 4: Does the space contain any other recognized serious safety or health hazard(s) that would pose an immediate danger to a worker’s life or health or would impair the worker’s ability to escape from the space if injured?

Hazards that the employer should consider include fire and explosion hazards; the presence of mechanical, electrical, hydraulic, and pneumatic energy; temperature extremes; radiation; noise; corrosive chemicals; and biological hazards (such as venomous animals or insects).

What are the next steps if permit spaces have been identified?

- Employers must inform workers effectively of the location and dangers of any permit space in the workplace and prevent unauthorized entry.

- Employers must either prevent all employee entry to permit spaces or implement a written permit program detailing the terms for authorized entry.

If a workplace contains one or more permit spaces, the employer must inform workers in the vicinity of the location and dangers of each space. This can be done by posting warning signs at each possible point of entry or by other equally effective means.

In addition to posting warning signs, an employer who learns about a permit space must also notify its employees’ authorized representatives and the controlling contractor of the location and danger of the space. The controlling contractor must then notify other employers on the site, whose activities could create a hazard in the permit space, of the presence and location of such spaces and the hazards associated with them before workers enter the space.

The employer in a workplace where there are permit spaces must either:

- Develop and implement a written permit space program that details the location and danger of permit spaces in the workplace, or

- Prevent employees from entering permit spaces.

In addition to posting the warnings above, an employer who will not authorize employees to enter permit spaces must take steps to prevent any employees from entering those spaces. An employer might accomplish this by providing effective training on and enforcing a work rule against entry.

What elements are required for a permit space program? (Construction)

- Any employer whose employees enter permit spaces must develop a permit space program that details the terms of entry.

- An effective permit program lays out the procedures necessary to protect employees from permit space hazards, including testing and monitoring.

Each employer who will direct employees to enter permit spaces must develop a written permit space program that establishes procedures for safe entry, including procedures for testing and monitoring for hazardous conditions. Entry into the permit space will only be permitted under the terms of this program. That employer must prevent unauthorized persons from entering the permit space and remove any unauthorized persons who do so.

Under the program, the employer must provide specified equipment to employees involved in confined space entry; have an attendant stationed outside permit spaces during entry; establish procedures to summon rescuers and prevent unauthorized personnel from attempting rescue; and develop a system for preparing, issuing, using, and canceling entry permits.

A permit space program must:

- Implement measures to prevent unauthorized entry;

- Identify and evaluate permit space hazards before allowing employee entry;

- Arrange for the atmospheric conditions in the permit space to be tested before entry operations and for the space to be monitored during entry;

- Provide an early-warning system that continuously monitors for non-isolated engulfment hazards. The system must alert authorized entrants and attendants in sufficient time for the authorized entrants to safely exit the space;

- Continuously monitor atmospheric hazards unless the employer can demonstrate that the equipment for continuously monitoring a hazard is not commercially available or that periodic monitoring is of sufficient frequency to ensure that the atmospheric hazard is being controlled at safe levels. If continuous monitoring is not used, periodic monitoring is required with sufficient frequency to ensure that acceptable entry conditions are being maintained during the course of entry operations;

- Require appropriate testing for the following atmospheric hazards in this sequence: oxygen, combustible gases or vapors, and toxic gases or vapors;

- Establish the means and procedures necessary to eliminate or control hazards for safe permit space entry operations;

- Identify employee job duties;

- Provide and maintain personal protective equipment and other equipment necessary for safe entry at no cost to the employee, and require employees to use this equipment properly;

- Ensure that at least one attendant is stationed outside the permit space during entry operations;

- Implement the procedures that any attendant who is required to monitor multiple spaces will follow during an emergency in one or more of those spaces;

- Coordinate entry operations with the controlling contractor when employees of more than one employer are working in the permit space; and

- Establish procedures for summoning rescue and emergency services and preventing unauthorized personnel from attempting rescue.

Review the permit space program at least annually.

The permit space program must also establish a system for preparing, using, suspending, and canceling entry permits, which are written or printed documents that allow and control entry into permit spaces.

What are the elements of the permitting process? (Construction)

- Part of an employer’s permit space program is a system for preparing, issuing, using, suspending, and canceling entry permits.

Before employees begin work in a permit space, the employer must develop a permit system that details procedures for preparing, issuing, using, suspending, and canceling entry permits. (29 CFR 1926.1205(a)–(f))

Written entry permits must be prepared and signed by a designated, trained entry supervisor. It is the responsibility of the entry supervisor to authorize entry into a permit space, to order corrective measures when necessary, and to cancel an entry permit when work in the space is completed.

Permits must be available to all permit space entrants at the time of entry and should extend only for the duration of the task. Canceled permits must be retained for one year for use in a review of the confined space program.

An entry permit documents the essential elements of an entry and must include:

- Identification of the space,

- Purpose of the entry,

- Date and duration of the permit,

- Names of authorized entrants,

- Names of attendants and the entry supervisor,

- List of hazards in the space,

- List of measures to isolate the space and eliminate or control the hazards,

- Acceptable entry conditions,

- Results of tests initialed by the person(s) performing the tests,

- Rescue and emergency services available and how to summon them,

- Communication procedures for attendants and entrants,

- Equipment used for the entry (respirators, communication, alarms, etc.),

- Any other necessary information, and

- Additional permits (such as for hot work, including riveting, welding, etc.).

If a condition that is not allowed under the entry permit arises in or near the permit space and that condition is temporary in nature and does not change the configuration of the space or create any new hazards within it, then suspend or cancel the entry permit and fully reassess the space before allowing reentry.

What elements are required for a permit space program? (General Industry)

- Any employer whose employees enter permit spaces must develop a permit space program that details the terms of entry.

- An effective permit program lays out the procedures necessary to protect employees from permit space hazards, including testing and monitoring.

Each employer who will direct employees to enter permit spaces must develop a written permit space program that establishes procedures for safe entry, including procedures for testing and monitoring for hazardous conditions. Entry into the permit space will only be permitted under the terms of this program. That employer must prevent unauthorized persons from entering the permit space and remove any unauthorized persons who do so.

Under the program, the employer must provide specified equipment to employees involved in confined space entry; have an attendant stationed outside permit spaces during entry; establish procedures to summon rescuers and prevent unauthorized personnel from attempting rescue; and develop a system for preparing, issuing, using, and canceling entry permits.

A permit space program must:

- Implement measures to prevent unauthorized entry;

- Identify and evaluate permit space hazards before allowing employee entry;

- Arrange for the atmospheric conditions in the permit space to be tested before entry operations and for the space to be monitored during entry;

- Require appropriate testing for the following atmospheric hazards in this sequence: oxygen, combustible gases or vapors, and toxic gases or vapors;

- Establish the means and procedures necessary to eliminate or control hazards for safe permit space entry operations;

- Identify employee job duties;

- Provide and maintain personal protective equipment and other equipment necessary for safe entry at no cost to the employee, and require employees to use this equipment properly;

- Ensure that at least one attendant is stationed outside the permit space during entry operations;

- Implement the procedures that any attendant who is required to monitor multiple spaces will follow during an emergency in one or more of those spaces;

- Coordinate entry operations with the controlling contractor when employees of more than one employer are working in the permit space; and

- Establish procedures for summoning rescue and emergency services and preventing unauthorized personnel from attempting rescue.

In addition, procedures need to be in place for coordinated entry when employees of more than one employer are involved. The permit space program must be reviewed at least annually.

The permit space program must also establish a system for preparing, using, suspending, and canceling entry permits, which are written or printed documents that allow and control entry into permit spaces.

What are the elements of a permit system? (General Industry)

- Part of an employer’s permit space program is a system for preparing, issuing, using, and canceling entry permits.

Before employees begin work in a permit space, the employer must develop a permit system that details procedures for preparing, issuing, using, and canceling entry permits.

Written entry permits must be prepared and signed by a designated, trained entry supervisor. It is the responsibility of the entry supervisor to authorize entry into a permit space, to order corrective measures when necessary, and to cancel an entry permit when work in the space is completed.

Permits must be available to all permit space entrants at the time of entry and should extend only for the duration of the task. Canceled permits must be retained for one year for use in a review of the confined space program.

An entry permit documents the essential elements of an entry and must include:

- Identification of the space;

- Purpose of the entry;

- Date and duration of the permit;

- Names of authorized entrants;

- Names of attendants and the entry supervisor;

- List of hazards in the space;

- List of measures to isolate the space and eliminate or control the hazards;

- Acceptable entry conditions;

- Results of tests initialed by the person(s) performing the tests;

- Rescue and emergency services available and how to summon them;

- Communication procedures for attendants and entrants;

- Equipment used for the entry (respirators, communication, alarms, etc.);

- Any other necessary information; and

- Additional permits (such as for hot work, including riveting, welding, etc.).

What are the duties of attendants, entrants, and entry supervisors? (Construction)

- The three roles involved in entry to permit spaces are authorized attendant, authorized entrant, and entry supervisor.

- All employees authorized to enter permit spaces are assigned specific duties and must receive appropriate training.

All employees who work in permit spaces must be trained to understand the hazards of confined spaces and obtain the skills necessary to safely perform their assigned duties. Training must be done:

- Before an employee is first assigned duties,

- Before there is a change in assigned duties,

- Whenever a change in operations presents a new hazard, and

- Whenever an employee deviates from entry procedures or demonstrates inadequate knowledge.

The employer must certify that the training has been completed. Required training documentation includes each employee’s name, the signatures or initials of the trainers, and the dates of training.

Attendant duties

- An attendant’s primary duty is to monitor and protect the entrants.

- The authorized attendant of a permit space must understand what hazards the space poses and what to do if they arise.

Authorized attendants of permit-required confined spaces are required to know enough about each space to perform their duties successfully. These duties include:

- Knowing the hazards that may be faced during entry and the mode, signs, symptoms, and consequences of exposure to these hazards;

- Maintaining an accurate count of entrants and ensuring that they are accurately identified;

- Remaining outside the space during entry operations until relieved by another attendant;

- NOTE: If the entry program allows it, attendants may enter a permit space to attempt a rescue if they have been trained and equipped for rescue operations and if they have been relieved by another attendant.

- Communicating with entrants to monitor their status and to alert them to evacuate the space if necessary;

- Monitoring activities inside and outside the space to determine whether entrants may safely remain there;

- Ordering entrants to evacuate the space immediately under any of the following conditions:

- The attendant detects a prohibited condition,

- The attendant notices the behavioral effects of hazard exposure in an entrant,

- The attendant detects a situation outside the space that could endanger the entrants, or

- The attendant cannot effectively and safely perform all the required duties.

- Summoning rescue and other emergency services as soon as it is determined that entrants may need assistance escaping;

- Warning unauthorized personnel to stay away from the permit space, or telling them to exit the permit space if they have already entered it;

- Alerting entrants and the entry supervisor if unauthorized persons enter the space;

- Performing non-entry rescues, if specified by the employer’s rescue procedure; and

- Performing no duties that might interfere with the attendant’s primary duty to monitor and protect entrants.

Authorized entrant duties

- An authorized entrant to a permit space must know the possible hazards and communicate with the attendant effectively.

Authorized entrants to a permit-required confined space are required to know enough about the space and their tasks inside the space to perform their duties successfully. These duties include:

- Knowing the hazards that may be faced during entry and knowing the mode, signs, symptoms, and consequences of exposure to these hazards;

- Using equipment properly;

- Communicating with the permit space attendant;

- Alerting the attendant whenever:

- The entrant recognizes any warning sign or symptom of exposure to a hazard, or

- The entrant detects a prohibited condition; and

- Exiting from the permit space as quickly as possible whenever:

- The attendant or entry supervisor gives an order to evacuate,

- The entrant recognizes any warning sign or symptom of exposure to a hazard

- The entrant detects a prohibited condition, or

- An evacuation alarm is activated.

Entry supervisor duties (Construction)

- The entry supervisor of a permit space is responsible for the successful implementation of the entry permit.

- The duties of an entry supervisor include verifying that required tests have been conducted.

Supervisors of entry to permit-required confined spaces are required to know enough about each space to perform their duties successfully. Entry supervisors for permit spaces where construction work occurs must also meet the characteristics of a “qualified person” as defined in 29 CFR 1926.1202. Supervisor duties include:

- Knowing the hazards that may be faced during entry and knowing the mode, signs, symptoms, and consequences of exposure to these hazards;

- Verifying that all tests specified by the entry permit have been conducted and that all procedures and equipment are in place before endorsing the permit and allowing entry to begin;

- Terminating the entry and canceling the entry permit when work in the space has been completed or when a prohibited condition arises;

- Suspending rather than canceling the entry permit when conditions specified in 1926.1205(e)(2) apply;

- Verifying that rescue services are available and that the means to summon them are operable; and

- Removing unauthorized individuals who enter or who attempt to enter the permit space during entry operations.

Supervisors must also determine that the acceptable conditions specified in the permit are still present whenever shifts and entry supervisors change.

What atmospheric hazards can exist in confined spaces?

- Knowing the proper methods for testing and eliminating hazards is essential for keeping workers safe in confined spaces.

- Physical hazards are dangerous, but atmospheric hazards in confined spaces are even more deadly.

The greatest danger to entrants in confined spaces comes from the many and often invisible hazards associated with permit space environments. To properly identify the hazards in confined spaces, each space must be surveyed and tested for hazards individually. By assessing each specific space as well as the work to be performed there, the appropriate measures can be taken to avoid tragic incidents.

The hazards of confined spaces are generally categorized into atmospheric hazards and physical hazards. The hazards in these categories pose distinct risks and require taking several distinct precautions.

Atmospheric hazards are usually the most lethal hazards because many dangerous atmospheres cannot be detected by the senses. The atmosphere in a confined space may also be extremely hazardous because of the lack of natural air movement. This characteristic of confined spaces can result in:

- Oxygen-deficient atmospheres,

- Oxygen displacement,

- Flammable/combustible atmospheres, and

- Toxic atmospheres.

Oxygen-deficient atmospheres

- Oxygen concentrations below 19.5 percent pose serious dangers to workers in confined spaces.

Normal air has an oxygen content of 20.8 percent. An atmosphere is considered oxygen-deficient when the available oxygen content is less than 19.5 percent. No atmosphere with less than 19.5 percent oxygen should be entered without an approved self-contained breathing apparatus (SCBA).

When the oxygen level in a space drops below 17 percent, an entrant may experience rapid breathing and an accelerated heartbeat. As the oxygen content decreases further, additional physical effects arise, including poor muscle coordination, rapid fatigue, intermittent respiration, nausea, and an inability to perform tasks. At concentrations less than 6 percent, entrants rapidly lose consciousness and death occurs within minutes.

Oxygen deficiency occurs from chemical or biological reactions that displace or consume oxygen from the atmosphere in a space. Drivers of oxygen displacement and consumption include:

- The combustion of flammable substances, such as in welding, cutting, or brazing; and

- Bacterial action, such as in fermentation.

Oxygen deficiency due to bacterial action can occur in excavations and manholes located near garbage dumps, landfills, and swampy areas. Slow chemical reactions, such as in the formation of rust on the surfaces of metal tanks, vats, and ship holds, will also consume oxygen in the atmosphere of a confined space.

Oxygen displacement

- Normally harmless gases can be deadly if they displace necessary oxygen from confined spaces.

A simple asphyxiating atmosphere contains one or more inert gases that are not directly harmful to the body. In sufficiently large quantities, however, an inert gas will displace oxygen and result in an atmosphere that fails to support normal breathing. If 100 percent nitrogen — a non-toxic, colorless, and odorless gas — were to displace the oxygen in a poorly ventilated confined space, workers in that space would suffer immediate collapse and death. Carbon dioxide, argon, and helium are further examples of simple asphyxiants that have claimed workers’ lives in confined spaces.

Flammable/Combustible atmospheres

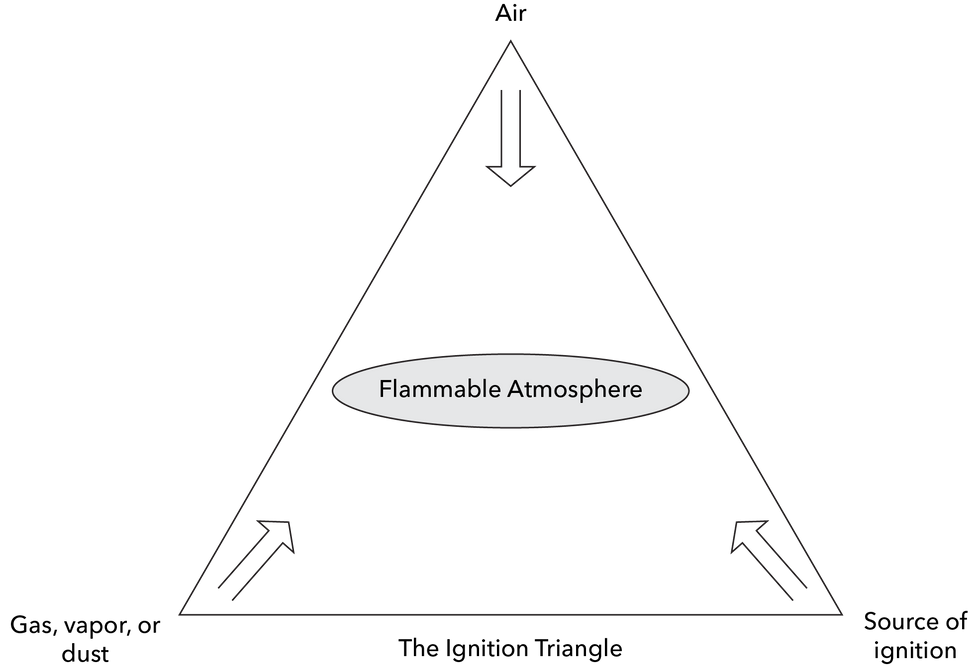

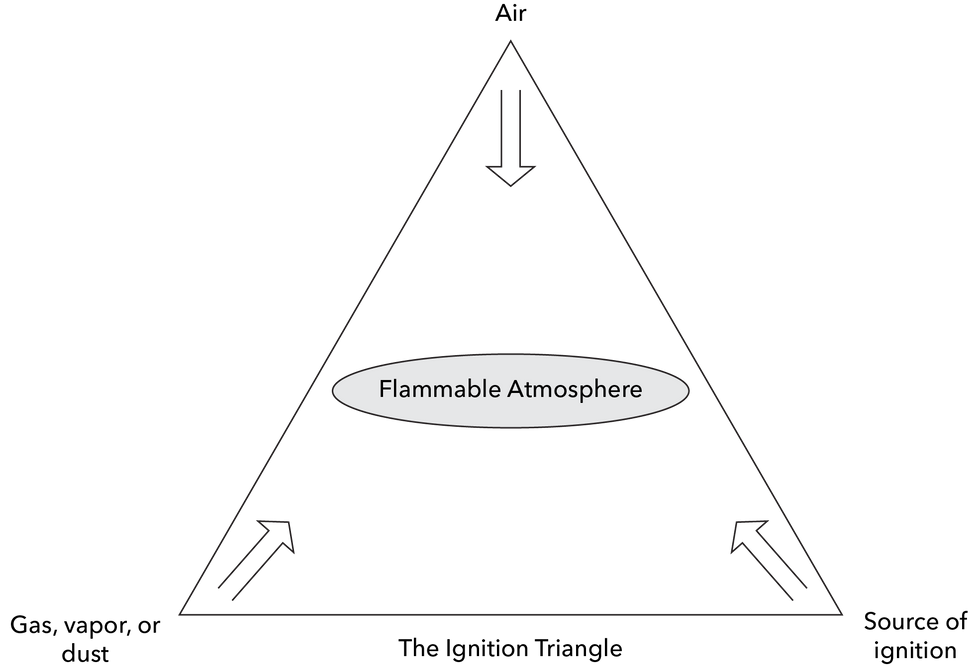

- Fuel, oxygen, and a source of ignition are the three key elements of a flammable atmosphere.

- If the percentage of a flammable gas in the air of a space is within the gas’s flammable range, then that space has a flammable atmosphere.

A flammable atmosphere generally results from vaporized flammable liquids, the by-products of chemical reactions, enriched oxygen atmospheres, or high concentrations of combustible dusts. For combustion to occur, three elements — fuel, oxygen, and a source of ignition — must be present in the atmosphere. In the right amounts, these ingredients produce an unrestricted chemical reaction that in turn produces a fire. If an element is lacking or present in the wrong amount, combustion will not occur.

- Fuel is any a flammable gas, vapor, or dust.

- Oxygen is required to support combustion.

- A source of ignition, such as heat, sparks, pressure, shock, or impact, is required to trigger combustion.

A mixture of fuel and oxygen will lead to combustion only when the fuel’s concentration in the air is within that fuel’s flammable range, which varies across different gases and vapors. The flammable range of a gas or vapor is measured in terms of two percentages, the lower flammability limit (LFL) and the upper flammability limit (UFL). Different fuels have different limits, but concentrations below 10 percent of a gas or vapor’s LFL are generally considered safe.

Example: The flammable range for methane is between 5 percent and 15 percent in air. Concentrations below 5 percent methane are below the flammable range and are too “lean” to support combustion; concentrations above 15 percent are too “rich” to support combustion. Importantly, if a confined space contains 30 percent methane and forced ventilation is introduced to the space, the influx of new air can dilute the methane concentration and lower its percentage into the flammable range.

An oxygen-enriched atmosphere (above 23.5 percent) will cause flammable materials, such as clothing and hair, to burn violently when ignited. For this reason, pure oxygen should never be used to ventilate a confined space; it is always better to ventilate with normal air.

Toxic atmospheres

- Many commonplace operations in industry produce toxic gases that are serious hazards to workers in confined spaces.

- It is important to know which products can produce toxic gases when stored in or used in a confined space.

Most substances like liquids, vapors, gases, mists, and dusts should be considered hazardous in a confined space. In addition, toxic gases may be present due to the:

- Products stored in the space can give off toxic gases. Many products are manufactured through processes involving toxic gases. If stored in a confined space over time, such products can release toxic gases that are then absorbed by the walls and fixtures of the space. In this way, any biological or chemical processes that occur in products stored in confined spaces can give off toxic gases that become a longstanding part of the atmosphere in that space.

- For example, hydrogen chloride and vinyl chloride monomer, which are both gases at room temperature, are used in the production of polyvinyl chloride (PVC). The gases can be absorbed into the walls and give off toxic gases when removed; or when cleaning out the residue of a stored product, toxic gases can be given off.

- Work performed in the space can give off toxic gases. Operations performed in confined spaces sometimes cause the release of toxic gases. Welding, cutting, and brazing work can release nitrogen, ozone, and carbon monoxide. Painting, scraping, sanding, degreasing can also release toxic gases depending on the substances involved:

- Many cleaning solvents commonly used in industry produce highly toxic vapors that pose serious hazards to entrants in confined spaces. The use of acidic cleaning agents on surfaces in confined spaces, for instance, can produce toxic gases when the acids used for cleaning react with certain substances.

- When hydrochloric acid is used to remove accumulations of iron sulfide in storage tanks and oil wells, hydrochloric acid and iron sulfide react to produce hydrogen sulfide, an extremely toxic gas. Hydrogen sulfide is heavier than air and will settle at the bottom of confined spaces; if a worker in such a space is exposed to it, the gas can cause olfactory paralysis, cognitive impairment, respiratory failure, unconsciousness, and ultimately death.

- Other chlorinated and fluorinated hydrocarbon solvents are toxic to the heart and may lead to sudden death in confined spaces.

- Additionally, methylene chloride can be toxic in confined spaces both because of its solvent properties and because it is metabolized in the body to carbon monoxide.

- Work near the space can give off toxic gases that settle in the space. Toxic byproducts of work performed near a confined space can travel into and accumulate in that space. Because gases that are heavier than the surrounding air will settle at the bottom of a site, workers in a confined space, such as a maintenance pit, below where a heavy toxic gas is produced are especially vulnerable to that hazard.

- Toxic gases that are difficult to detect, such as phosgene and carbon monoxide, are particularly dangerous in confined spaces. Carbon monoxide, hydrogen cyanide, hydrogen sulfide, arsine, chlorine, oxides of nitrogen, and ammonia are all toxic gases that are hard to detect and have caused the death of workers in confined spaces.

NIOSH classification scheme

- Confined spaces are classified by the most dangerous atmospheric hazard they contain.

- This classification is useful for identifying the precautions necessary for a given confined space.

The National Institute for Occupational Safety and Health (NIOSH) has developed a classification scheme for atmospheric hazards in confined spaces. This scheme is based on the oxygen content of the air, the flammable characteristics of gases and vapors, and the concentration of toxic substances that may be present in a space.

A confined space is listed in Class A, B, or C based on the most hazardous atmospheric condition present in the space. This classification provides a useful framework for recommending appropriate work practices and rescue procedures.

Characteristics| Class A | Class B | Class C |

|---|

| Immediately dangerous to life | Dangerous, but not immediately life threatening | Potential hazard |

Oxygen| Class A | Class B | Class C |

|---|

| 16% or less* (122 mm Hg) or greater than 25% (190 mm Hg) | 16.1% to 19.4%* (122-147 mm Hg), or 21.5% to 25% (163-190 mm Hg) | 19.5%-21.4%* (148-163 mm Hg) |

Flammability characteristics| Class A | Class B | Class C |

|---|

| 20% or greater of lower flammable limit (LFL) | 10-19% LFL | 10% LFL or less |

* Based upon a total atmospheric pressure of 760mm Hg (at sea level)

What physical hazards can exist in confined spaces?

- Knowing the physical hazards posed by confined spaces is crucial for protecting the employees who work in those spaces.

- Workers in confined spaces are often vulnerable to hazards that originate outside of the space

In addition to atmospheric hazards, a confined space must also be assessed for physical hazards. These hazards include:

- Engulfment

- Flow path

- Bridging

- Hazardous energy releases

- External hazards

| - Surfaces

- Equipment

- Temperatures

- Noise

- Biological hazards

|

Engulfment

Engulfment in loose materials is one of the leading causes of death from physical hazards in confined spaces. Engulfment and suffocation are hazards associated with storage bins, silos, and hoppers where grain, sand, gravel, or other loose material are stored, handled, or transferred. These kinds of material behave unpredictably and can cause entrapment or burial in a matter of seconds.

Flow path

In some cases, material being drawn from the bottom of storage bins can cause the surface to act like quicksand. When a storage bin is emptied from the bottom, the flow of material forms a funnel-shaped path over the outlet. The rate of material flow increases toward the center of the funnel. During a typical unloading operation, the flow rate can become so great that once a worker is drawn into the flow path, escape is virtually impossible.

Bridging

A condition known as “bridging” can create additional hazardous situations. Bridging occurs when grain or other loose material clings to the sides of a container or vessel that is being emptied from below, allowing a hollow space to be created. The bridge of material over the space is unstable and may collapse without warning, entrapping unaware workers standing below or on top of the bridge.

Bridging can occur in storage bins, silos, and hoppers that contain ground grains, soybean meal and other meals, or other loose materials such as cement, limestone, coal, and sawdust. The diameter of the storage vessel and the moisture content of the stored materials are factors that contribute to bridging.

Hazardous energy releases

The nature of confined space work may make it difficult to separate the worker from hazardous forms of energy such as powered machinery, electrical energy, and hydraulic or pneumatic lines. Activation of electrical or mechanical equipment can cause injury to workers in a confined space. It is essential to de-energize and lock out all electrical circuits and physically disconnect mechanical equipment prior to any work in confined spaces.

The release of material through lines that are integral to the confined space pose a life-threatening hazard. All lines should be physically disconnected, blanked off, or isolated by a double block and bleed system.

External hazards

Falling objects can pose a hazard in confined spaces, particularly in spaces that have topside openings for entry through which tools and other objects could fall and strike a worker. Traffic hazards from forklifts, street traffic, and even inattentive pedestrians can pose a danger to entrants. Operational processes near the space may also create hazards or release toxic substances that migrate into the space.

Surfaces

Interior surfaces that are uneven, wet, or slick can cause falls in confined spaces. In addition, wet surfaces can provide a grounding path and increase the hazard of electrocution in areas where electrical equipment, circuits, and tools are used. Workers in some confined spaces need to be aware that objects may fall on them from surfaces above, particularly in spaces with topside openings and where tasks are being done overhead.

Equipment

Grinding equipment, agitators, steam or steam fittings, mulching equipment, drive shafts, gears, and other moving parts pose a danger if they are not locked or blocked out prior to entry.

Temperatures

Extremely hot or cold temperatures can make work inside a confined space hazardous. Heat stress increases fatigue and decreases the ability to concentrate. In cold environments, jobs requiring manual dexterity are more difficult. Entrants working in spaces with great temperature variances should wear appropriate protective clothing. If a confined space has been steam-cleaned, it should be allowed to cool thoroughly before any entry is made.

Noise

Noise within a confined space may be amplified because of the design and acoustic properties of the space. Excessive noise is not only harmful to a worker’s hearing but can also obstruct communication, such as causing a warning to go unheard. This is especially true when workers wear hearing protection, which makes others’ voices even harder to make out above the noise.

Biological hazards

Biological hazards such as molds, mildews, and spores frequently found in dark, damp spaces can irritate the respiratory system. Bacteria and viruses in sewage treatment expose the entrant to a variety of illnesses. In addition, rodents, snakes, spiders, insects, and the feces of birds and other animals can present serious health hazards.

Many entrants overlook the risks posed by dust in confined spaces. In addition to reducing visibility and making surfaces slippery, dust in a confined space threatens entrants with respiratory hazards and can even cause combustion or an explosion.

Other conditions, such as inadequate lighting and the presence of radioactive matter within the space, must also be evaluated before entry.

How should the air in confined spaces be tested? (Construction)

- Testing the air in confined spaces can reveal hazardous gases that cannot be detected with the senses alone.

- Clearing out a hazardous atmosphere always requires proper testing.

It is important to understand that some gases and vapors are heavier than air and will settle to the bottom of a confined space. Gases and vapors that are lighter than air, on the other hand, will rise to the top of a confined space. Therefore, all areas of a confined space — top, middle, and bottom — must be tested with properly calibrated instruments to determine which gases are present.

If testing reveals oxygen deficiency or the presence of toxic gases or vapors, then the space should be ventilated, and the air should be tested again before entry. Allow sufficient time for diffusion during the ventilation/purging process. If ventilation is not possible and entry is necessary, such as for an emergency rescue, then workers must wear appropriate respiratory protection.

CAUTION: It is never enough to rely on the five senses to decide whether the air in a confined space is safe. Many toxic gases and vapors cannot be seen or smelled, and there is no sense for determining oxygen levels.

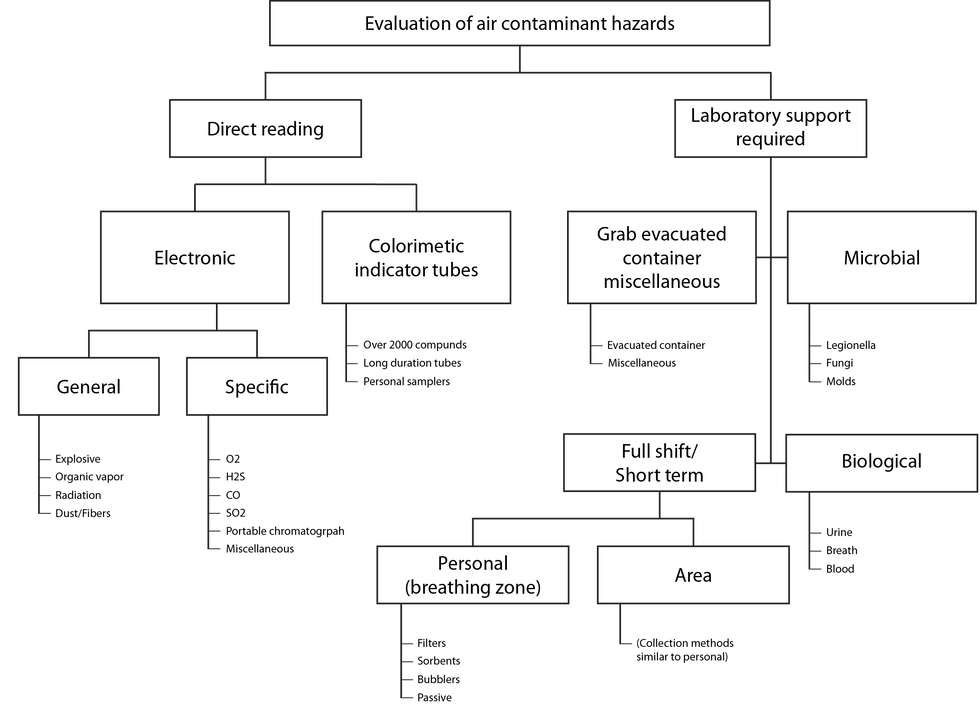

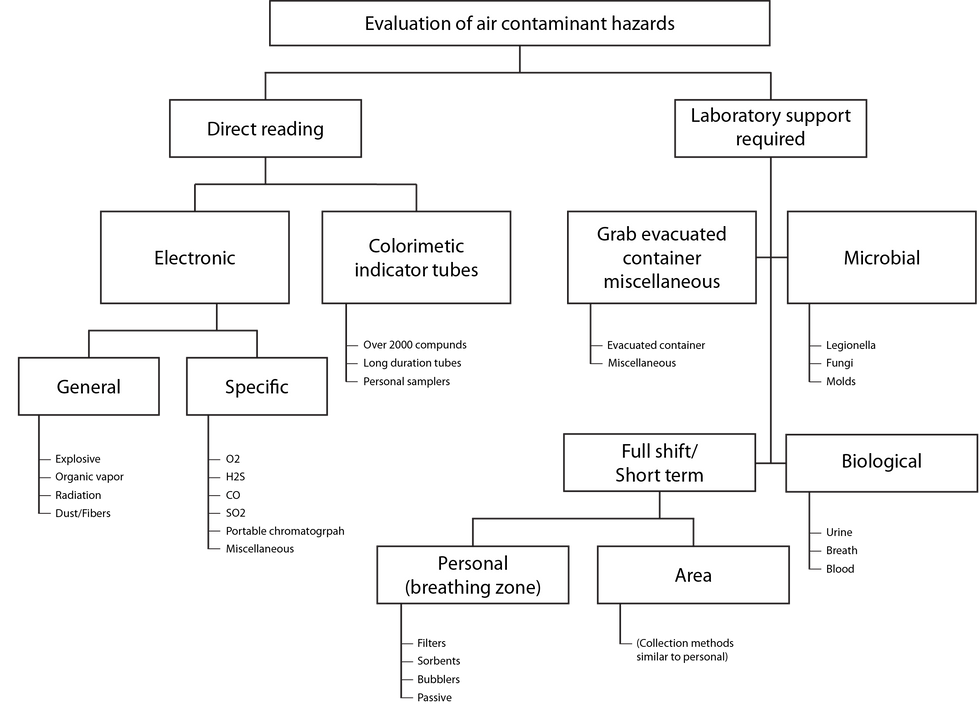

Atmospheric testing procedures

- Proper atmospheric testing requires a proper understanding of how to use and read different test instruments.

Atmospheric testing is required to evaluate the hazards of the permit space and to verify that acceptable entry conditions exist. The person performing the testing must know how to operate and read the test instrument. A monitoring device should be calibrated before every use or as required by the manufacturer to ensure that the device provides accurate measurements.

For construction operations, the atmosphere within the space must be continuously monitored unless the entry employer can demonstrate that equipment for continuous monitoring is not commercially available or periodic monitoring is sufficient. If continuous monitoring is used, the employer must ensure that the monitoring equipment has an alarm that will notify all entrants if a specified atmospheric threshold is achieved, or that an employee will check the monitor with sufficient frequency to ensure that entrants have adequate time to escape. If continuous monitoring is not used, periodic monitoring is required. All monitoring must ensure that the continuous forced air ventilation is preventing the accumulation of a hazardous atmosphere.

Air samples should be drawn through a weep hole or other small entry port leading into the space. When combustible or flammable gases could be present, a non-sparking probe should be used. If possible, the entry portal to the confined space should not be opened until this step has been completed. Sudden changes in atmospheric composition within the space could cause violent reactions or dilute the contaminants, giving a false low initial gas concentration.

Enough time must always be allowed for the instruments to respond to full scale. As many space conditions as possible should be assessed from outside the space; if entry is necessary for some part of the assessment, respiratory protective equipment may be needed for entrants’ safety. All entrants must be permitted to observe the testing and review the results before they enter the space.

Safety depends on taking at least three sets of readings:

- Readings before ventilation,

- Readings after ventilation, and

- The entrant’s reading during the initial entry survey.

Testing sequence

- Atmospheric testing must always be performed in a specific sequence.

- Always measure for at least the minimum duration specified by the manufacturer of the measuring instrument.

- Air in spaces with stratified atmospheres must be tested in a specific way.

Additional or continuous monitoring of the atmospheric conditions in a confined space is sometimes necessary. Because of the way test instruments operate, atmospheric monitoring must always be performed in a specific sequence.

- Oxygen — Oxygen tests must always be taken first because most combustible gas meters are oxygen-dependent. While too little oxygen in a space can cause a low combustible gas reading, too much oxygen can cause a combustible gas meter to explode if gases and vapors are present in ignitable quantities. Oxygen concentrations are generally measured over a range of 0 to 25 percent oxygen in air, with readings displayed on either an electronic readout or an analog meter. Oxygen indicators are calibrated with uncontaminated fresh air containing a minimum of 20.8 percent oxygen. With some models, an alarm is activated when oxygen levels drop below 19.5 percent or rise above 23.5 percent.

- Flammable and combustible gases — Flammable and combustible gases are measured next because the risk posed by fire or explosion is more immediate and life-threatening than the risk posed by exposure to toxic gases and vapors.

- Toxic gases and vapors — Toxic gases and vapors, which are often found in confined spaces, are measured last. A toxic sensor requires that the specific toxic substance be identified in advance of the testing. Each substance has a specific level to ensure entrant safety and the sensors are specific to these levels. Substance-specific detectors should be used whenever the actual contaminants have been identified.

The time spent measuring the values of each atmospheric substance should be at least as great as the minimum response time that the manufacturer specifies for the test instrument.

CAUTION: When monitoring for entries involving a descent into atmospheres that may be stratified, the space should be tested at approximately four feet (1.22 meters) in the direction of travel and to each side. If a sampling probe is used, the entrant’s rate of progress should be slowed to accommodate the sampling speed and detector response.

Evaluation and verification

- The evaluation of data collected on hazards in a permit space should inform the entry procedure developed for that space.

- Permit spaces should be tested for the residue of hazardous contaminants.

The results of the atmospheric testing will have a direct impact on the selection of protective equipment required to work in the confined space. These results may also dictate how long workers will be permitted to be exposed to the environment in that space, or whether entry will be allowed at all. The entry procedure for the permit space should be developed and implemented based on the evaluation and interpretation of the data collected on all serious hazards that could be present in the space.

The atmosphere of a permit space that may contain atmospheric hazards should be tested for the residue of all identified contaminants using permit-specified equipment. This will determine if residual concentrations at the time of testing and entry are within the range of acceptable entry conditions. Results of testing (i.e., actual concentration) should be recorded on the confined space permit in the area provided adjacent to the acceptable entry condition.

How should the air in confined spaces be tested? (General Industry)

- Testing the air in confined spaces can reveal hazardous gases that cannot be detected with the senses alone.

- Clearing out a hazardous atmosphere always requires proper testing.

It is important to understand that some gases and vapors are heavier than air and will settle to the bottom of a confined space. Gases and vapors that are lighter than air, on the other hand, will rise to the top of a confined space. Therefore, all areas of a confined space — top, middle, and bottom — must be tested with properly calibrated instruments to determine which gases are present.

If testing reveals oxygen deficiency or the presence of toxic gases or vapors, then the space should be ventilated and the air should be tested again before entry. Allow sufficient time for diffusion during the ventilation/purging process. If ventilation is not possible and entry is necessary, such as for an emergency rescue, then workers must wear appropriate respiratory protection.

CAUTION: It is never enough to rely on the five senses to decide whether the air in a confined space is safe. Many toxic gases and vapors cannot be seen or smelled, and there is no sense for determining oxygen levels.

Atmospheric testing procedures

- Proper atmospheric testing requires a proper understanding of how to use and read different test instruments.

Atmospheric testing is required to evaluate the hazards of the permit space and to verify that acceptable entry conditions exist. The person performing the testing must know how to operate and read the test instrument. A monitoring device should be calibrated before every use or as required by the manufacturer to ensure that the device provides accurate measurements.

Air samples should be drawn through a weep hole or other small entry port leading into the space. When combustible or flammable gases could be present, a non-sparking probe should be used. If possible, the entry portal to the confined space should not be opened until this step has been completed. Sudden changes in atmospheric composition within the space could cause violent reactions or dilute the contaminants, giving a false low initial gas concentration.

Enough time must always be allowed for the instruments to respond to full scale. As many space conditions as possible should be assessed from outside the space; if entry is necessary for some part of the assessment, respiratory protective equipment may be needed for entrants’ safety. All entrants must be permitted to observe the testing and review the results before they enter the space.

Safety depends on taking at least three sets of readings:

- Readings before ventilation,

- Readings after ventilation, and

- The entrant’s reading during the initial entry survey.

Testing sequence

- Atmospheric testing must always be performed in a specific sequence.

- Always measure for at least the minimum duration specified by the manufacturer of the measuring instrument.

- Air in spaces with stratified atmospheres must be tested in a specific way.

Additional or continuous monitoring of the atmospheric conditions in a confined space is sometimes necessary. Because of the way test instruments operate, atmospheric monitoring must always be performed in a specific sequence.

- Oxygen — Oxygen tests must always be taken first because most combustible gas meters are oxygen-dependent. While too little oxygen in a space can cause a low combustible gas reading, too much oxygen can cause a combustible gas meter to explode if gases and vapors are present in ignitable quantities. Oxygen concentrations are generally measured over a range of 0 to 25 percent oxygen in air, with readings displayed on either an electronic readout or an analog meter. Oxygen indicators are calibrated with uncontaminated fresh air containing a minimum of 20.8 percent oxygen. With some models, an alarm is activated when oxygen levels drop below 19.5 percent or rise above 23.5 percent.

- Flammable and combustible gases — Flammable and combustible gases are measured next because the risk posed by fire or explosion is more immediate and life-threatening than the risk posed by exposure to toxic gases and vapors.

- Toxic gases and vapors — Toxic gases and vapors, which are commonly found in confined spaces, are measured last. A toxic sensor requires that the specific toxic substance be identified in advance of the testing. Each substance has a specific level to ensure entrant safety and the sensors are specific to these levels. Substance-specific detectors should be used whenever the actual contaminants have been identified.

The time spent measuring the values of each atmospheric substance should be at least as great as the minimum response time that the manufacturer specifies for the test instrument.

CAUTION: When monitoring for entries involving a descent into atmospheres that may be stratified, the space should be tested at approximately four feet (1.22 meters) in the direction of travel and to each side. If a sampling probe is used, the entrant’s rate of progress should be slowed to accommodate the sampling speed and detector response.

Evaluation and verification

- The evaluation of data collected on hazards in a permit space should inform the entry procedure developed for that space.

- Permit spaces should be tested for the residue of hazardous contaminants.

The results of the atmospheric testing will have a direct impact on the selection of protective equipment required to work in the confined space. These results may also dictate how long workers will be permitted to be exposed to the environment in that space, or whether entry will be allowed all. The entry procedure for the permit space should be developed and implemented based on the evaluation and interpretation of the data collected on all serious hazards that could be present in the space.

The atmosphere of a permit space that may contain atmospheric hazards should be tested for the residue of all identified contaminants using permit-specified equipment. This will determine if residual concentrations at the time of testing and entry are within the range of acceptable entry conditions. Results of testing (i.e., actual concentration) should be recorded on the confined space permit in the area provided adjacent to the acceptable entry condition.

How else can employers protect employees? (Construction)

- Worker safety depends on outfitting confined spaces with proper ventilation and equipping workers with proper respiratory protection.

There are many ways to protect employees working in a confined space. Inerting, purging, ventilation, isolation, and the use of respiratory protection are all important tools for guarding against hazards. In addition, effective communication is also key in protecting workers.

Inerting and purging

- There are two ways to displace existing old air from a space before beginning ventilation.

Introducing a non-reactive gas is called inerting. Displacing an existing atmosphere with a non-reactive gas, such as nitrogen, results in an atmosphere that is noncombustible. The hazards of fire, explosion, and chemical reaction are often best addressed by inerting. But while this procedure does remove an existing hazard, inerting introduces a new atmospheric hazard by creating a lack of oxygen in the space. Any personnel entering a space where inerting has just occurred must wear some form of air-supplied respiratory equipment.

Purging is the process of initially clearing a confined space of atmospheric contaminants before beginning ventilation. The purpose of purging is to exchange the air in a confined space completely prior to entry. Normally a purge is considered complete when atmospheric tests indicate the air is of suitable quality to sustain the life of entrants.

Ventilation

- Ventilation moves fresh air through a confined space to maintain safe oxygen levels and expel harmful gases.

- Choosing the right ventilation depends on several factors.

Ventilation is the process of continuously moving fresh, uncontaminated air through a confined space to offset a hazardous atmosphere. Ventilation dilutes and displaces air contaminants, assures that an adequate supply of oxygen is maintained during entry, and exhausts contaminants formed by processes such as welding, oxy-fuel gas cutting, and abrasive blasting. Ventilation ensures that oxygen levels remain within the required range of 19.5 to 23.5 percent.

Ventilation by a blower or fan may be necessary to remove harmful gases and vapors from a confined space. There are several ventilating methods and equipment options to choose from, depending on the size of openings to the confined space, the gases to be exhausted, and the source of makeup air.

Ventilation equipment should be selected based on the following considerations:

- Physical structure of the space,