['Air Programs']

['Hazardous Air Pollutants']

02/27/2022

...

§63.560 Applicability and designation of affected source.

(a) Maximum achievable control technology (MACT) standards. (1) The provisions of this subpart pertaining to the MACT standards in §63.562(b) and (d) of this subpart are applicable to existing and new sources with emissions of 10 or 25 tons, as that term is defined in §63.561, except as specified in paragraph (d) of this section, and are applicable to new sources with emissions less than 10 and 25 tons, as that term is defined in §63.561, except as specified in paragraph (d) of this section.

(2) Existing sources with emissions less than 10 and 25 tons are not subject to the emissions standards in §63.562(b) and (d).

(3) The recordkeeping requirements of §63.567(j)(4) and the emission estimation requirements of §63.565(l) apply to existing sources with emissions less than 10 and 25 tons.

(4) Existing sources with emissions less than 10 and 25 tons must meet the submerged fill standards of 46 CFR 153.282.

(b) Reasonably available control technology (RACT) standards. (1) The provisions of this subpart pertaining to RACT standards in §63.562(c) and (d) of this subpart are applicable to sources with throughput of 10 M barrels or 200 M barrels, as that term is defined in §63.561, except as specified in paragraph (d) of this section.

(2) Sources with throughput less than 10 M barrels and 200 M barrels, as that term is defined in §63.561, are not subject to the emissions standards in §63.562(c) and (d).

(c) General Provisions applicability. Owners or operators of affected sources, as that term is defined in §63.561, of this subpart must comply with the requirements of subpart A of this part in accordance with the provisions for applicability of subpart A to this subpart in Table 1 of this section.

(d) Exemptions from MACT and RACT standards. (1) This subpart does not apply to emissions resulting from marine tank vessel loading operations, as that term is defined in §63.561, of commodities with vapor pressures less than 10.3 kilopascals (kPa) (1.5 pounds per square inch, absolute) (psia) at standard conditions, 20°C and 760 millimeters Hg (mm Hg).

(2) The provisions of this subpart pertaining to the MACT standards in §63.562(b)(2), (3) and (4) and to the RACT standards in §63.562(c)(3) and (4) do not apply to marine tank vessel loading operations where emissions are reduced by using a vapor balancing system, as that term is defined in §63.561. The provisions pertaining to the vapor collection system, ship-to-shore compatibility, and vapor tightness of marine tank vessels in §63.562(b)(1) and (c)(2) do apply.

(3) The provisions of this subpart pertaining to the MACT standards in §63.562(b)(2), (3), and (4) do not apply to marine tank vessel loading operations that are contiguous with refinery operations at sources subject to and complying with subpart CC of this part, National Emissions Standards for Organic Hazardous Air Pollutants from Petroleum Refineries, except to the extent that any such provisions of this subpart are made applicable by subpart CC of this part.

(4) The provisions of this subpart pertaining to the MACT standards in §63.562(b) and (d) do not apply to benzene emissions from marine tank vessel loading operations that are subject to and complying with 40 CFR part 61, subpart BB, National Emissions Standards for Benzene Emissions from Benzene Transfer Operations, except that benzene emissions or other HAP emissions (i.e., nonbenzene HAP emissions) from marine tank vessel loading operations that are not subject to subpart BB are subject to the provisions of this subpart.

(5) The provisions of this subpart pertaining to the MACT standards in §63.562(b) and (d) do not apply to marine tank vessel loading operations at loading berths that only transfer liquids containing organic HAP as impurities, as that term is defined in §63.561.

(6) The provisions of this subpart do not apply to marine tank vessel loading operations at existing offshore loading terminals, as that term is defined in §63.561, however existing offshore loading terminals must meet the submerged fill standards of 46 CFR 153.282.

(7) The provisions of this subpart do not apply to ballasting operations, as that term is defined in §63.561.

(e) Compliance dates - (1) MACT standards compliance dates, except the Valdez Marine Terminal (VMT) source. (i) A new or existing source with emissions of 10 or 25 tons, except the VMT source, and a new source with emissions less than 10 and 25 tons, except the VMT source, that has an initial startup date on or before September 20, 1999 shall comply with the provisions of this subpart pertaining to the MACT standards in §63.562(b) no later than 4 years after the effective date.

(ii) A new source with emissions of 10 or 25 tons, except the VMT source, and a new source with emissions less than 10 and 25 tons, except the VMT source, that has an initial startup date after September 20, 1999 shall comply with provisions of this subpart pertaining to the MACT standards in §63.562(b) immediately upon startup.

(iii) A source with emissions less than 10 and 25 tons that increases its emissions subsequent to September 20, 1999 such that it becomes a source with emissions of 10 or 25 tons shall comply with the provisions of this subpart pertaining to the MACT standards in §63.562(b) within 3 years following the exceedance of the threshold level.

(iv) Existing sources with emissions less than 10 and 25 tons, and existing offshore loading terminals, shall comply with the submerged fill requirements in paragraph (a)(4) and (d)(6) of this section by April 23, 2012.

(2) RACT standards compliance dates, except the VMT source. (i) A source with throughput of 10 M barrels or 200 M barrels, except the VMT source, with an initial startup date on or before September 21, 1998 shall comply with §63.562(c)(1) no later than 2 years after the effective date.

(ii) A source with throughput of 10 M barrels or 200 M barrels, except the VMT source, with an initial startup date on or before September 21, 1998 shall comply with the provisions of this subpart pertaining to the RACT standards in §63.562(c) other than §63.562(c)(1), no later than 3 years after the effective date.

(iii) A source with throughput of 10 M barrels or 200 M barrels, except the VMT source, with an initial startup date after September 21, 1998 shall comply with the provisions of this subpart pertaining to the RACT standards in §63.562(c) immediately upon startup.

(iv) A source with throughput less than 10 M barrels and 200 M barrels that increases its throughput subsequent to September 21, 1998 such that it becomes a source with throughput of 10 M barrels or 200 M barrels shall comply with the provisions of this subpart pertaining to the RACT standards in §63.562(c) within 3 years following the exceedance of the threshold levels.

(v) A source with throughput of 10 M barrels or 200 M barrels may apply for approval from the Administrator for an extension of the compliance date of up to 1 year if it can demonstrate that the additional time is necessary for installation of the control device.

(3) MACT and RACT compliance dates for the VMT source. The VMT source, as that term is defined in §63.561, shall comply with the provisions of this subpart pertaining to the MACT and RACT standards in §63.562(d) no later than 30 months after the effective date.

| Reference | Applies to affected sources in subpart Y | Comment |

|---|---|---|

| 63.1(a)(1) | Yes | Additional terms are defined in §63.561; when overlap between subparts A and Y occurs, subpart Y takes precedence. |

| 63.1(a)(2) | Yes | |

| 63.1(a)(3) | Yes | |

| 63.1(a)(4) | Yes | Subpart Y clarifies the applicability of each paragraph in subpart A to sources subject to subpart Y in this table. |

| .63.1(a)(5) | No | Reserved. |

| 63.1(a)(6) | Yes | |

| 63.1(a)(7) | Yes | |

| 63.1(a)(8) | Yes | |

| 63.1(a)(9) | No | Reserved. |

| 63.1(a)(10) | Yes | |

| 63.1(a)(11) | Yes | §63.567(a) also allows report submissions via facsimile and on electronic media. |

| 63.1(a)(12) | Yes | |

| 63.1(a)(13) | Yes | |

| 63.1(a)(14) | Yes | |

| 63.1(b)(1) | Yes | |

| 63.1(b)(2) | Yes | |

| 63.1(b)(3) | No | §63.560 specifies applicability. |

| 63.1(c)(1) | Yes | Subpart Y clarifies the applicability of each paragraph in subpart A to sources subject to subpart Y in this table. |

| 63.1(c)(2) | Yes | Subpart Y is not applicable to area sources. |

| 63.1(c)(3) | No | Reserved. |

| 63.1(c)(4) | Yes | |

| 63.1(c)(5) | No | §63.560 specifies applicability. |

| 63.1(c)(6) | Yes | |

| 63.1(d) | No | Reserved. |

| 63.1(e) | Yes | |

| 63.2 | Yes | Additional terms are defined in §63.561; when overlap between subparts A and Y occurs, subpart Y takes precedence. |

| 63.3 | Yes | Other units used in subpart Y are defined in the text of subpart Y. |

| 63.4(a)(1) | Yes | |

| 63.4(a)(2) | Yes | |

| 63.4(a)(3) | Yes | |

| 63.4(a)(4) | No | Reserved. |

| 63.4(a)(5) | Yes | |

| 63.4(b) | Yes | |

| 63.4(c) | Yes | |

| 63.5(a) | Yes | |

| 63.5(b)(1)(i) | Yes | |

| 63.5(b)(1)(ii) | No | |

| 63.5(b)(2) | No | Reserved. |

| 63.5(b)(3) | Yes | |

| 63.5(b)(4)-(5) | No | |

| 63.5(b)(6) | Yes | |

| 63.5(c) | No | Reserved. |

| 63.5(d)(1)(i) | No | See §63.566(b)(2). |

| 63.5(d)(1)(ii)(A)(H) | Yes | |

| 63.5(d)(1)(ii)(I) | No | Reserved. |

| 63.5(d)(1)(ii)(J) | Yes | |

| 63.5(d)(1)(iii) | Yes | |

| 63.5(d)(2)-(4) | Yes | |

| 63.5(e) | Yes | |

| 63.5(f)(1)(i) and (ii) | Yes | |

| 63.5(f)(1)(iii) and (iv) | No | |

| 63.5(f)(2) | No | See §63.566(c). |

| 63.6(a)(1) | Yes | |

| 63.6(a)(2) | No | §63.560 specifies applicability. |

| 63.6(b)(1)-(5) | No | §63.560(e) specifies compliance dates for sources. |

| 63.6(b)(6) | No | Reserved. |

| 63.6(b)(7) | No | §63.560(e) specifies compliance dates for sources. |

| 63.6(c)(1) | No | §63.560(e) specifies compliance dates for sources. |

| 63.6(c)(2) | No | |

| 63.6(c)(3)-(4) | No | Reserved. |

| 63.6(c)(5) | No | §63.560(e) specifies compliance dates for sources. |

| 63.6(d) | No | Reserved. |

| 63.6(e) | No | See §63.562(e). |

| 63.6(f)(1) | No. | |

| 63.6(f)(2)(i) | Yes | |

| 63.6(f)(2)(ii) | No | |

| 63.6(f)(2)(iii) | Yes | |

| 63.6(f)(2)(iv) | Yes | |

| 63.6(f)(2)(v) | No | See §63.562(e)(1). |

| 63.6(f)(3) | Yes | |

| 63.6(g) | Yes | |

| 63.6(h) | No | No opacity monitoring is required under subpart Y. |

| 63.6(i)(1)-(3) | Yes | |

| 63.6(i)(4)(i)(A) | No | |

| 63.6(i)(4)(i)(B) | Yes | |

| 63.6(i)(4)(ii) | No | |

| 63.6(i)(5)-(12) | Yes | |

| 63.6(i)(13) | No | |

| 63.6(i)(14) | Yes | |

| 63.6(i)(15) | No | Reserved. |

| 63.6(i)(16) | Yes | |

| 63.6(j) | Yes | |

| 63.7(a)(1) | Yes | |

| 63.7(a)(2)(i)-(iv) | No | See §63.563(b)(1). |

| 63.7(a)(2)(v) | Yes | |

| 63.7(a)(2)(vi) | No | |

| 63.7(a)(2)(vii)-(viii) | No | Reserved. |

| 63.7(a)(2)(ix) | No | |

| 63.7(a)(3) | Yes | |

| 63.7(b) | Yes | |

| 63.7(c)(1)-(2) | Yes | The site-specific test plan must be submitted only if requested by the Administrator. |

| 63.7(c)(3)(i)-(ii)(A) | Yes | |

| 63.7(c)(3)(ii)(B) | No | See §63.565(m)(2). |

| 63.7(c)(3)(iii) | Yes | |

| 63.7(c)(4) | Yes | |

| 63.7(d) | Yes | |

| 63.7(e)(1) | No | See 63.563(b)(1). Any cross reference to 63.7(e)(1) in any other general provision incorporated by reference shall be treated as a cross-reference to 63.563(b)(1). |

| 63.7(e)(2)-(4) | Yes. | |

| 63.7(f) | Yes | |

| 63.7(g)(1) | Yes | |

| 63.7(g)(2) | No | Reserved. |

| 63.7(g)(3) | Yes | |

| 63.7(h) | Yes | |

| 63.8(a)(1)-(2) | Yes | |

| 63.8(a)(3) | No | Reserved. |

| 63.8(a)(4) | Yes | |

| 63.8(b)(1) | Yes | |

| 63.8(b)(2) | No | |

| 63.8(b)(3) | Yes | |

| 63.8(c)(1) | No. | |

| 63.8(c)(2) | Yes | |

| 63.8(c)(3) | Yes | |

| 63.8(c)(4) | No | See §63.564(a)(3). |

| 63.8(c)(5) | No | |

| 63.8(c)(6) | Yes | See also performance specifications for continuous monitoring systems §63.564(a)(4). |

| 63.8(c)(7)(i)(A)-(B) | Yes | See also §63.564(a)(5). |

| 63.8(c)(7)(i)(C) | No | |

| 63.8(c)(7)(ii) | Yes | |

| 63.8(c)(8) | No | See §63.564(a)(5). |

| 63.8(d) | No | See §63.562(e)(2)(iv). |

| 63.8(e)(1)-(4) | Yes | |

| 63.8(e)(5)(i) | Yes | |

| 63.8(e)(5)(ii) | No | |

| 63.8(f)(1) | Yes | |

| 63.8(f)(2)(i)-(vii) | Yes | |

| 63.8(f)(2)(viii) | No | |

| 63.8(f)(2)(ix) | Yes | |

| 63.8(f)(3)-(6) | Yes | |

| 63.8(g) | Yes | |

| 63.9(a)(1) | Yes | |

| 63.9(a)(2) | Yes | |

| 63.9(a)(3) | Yes | |

| 63.9(a)(4) | Yes | |

| 63.9(b)(1)(i) | Yes | |

| 63.9(b)(1)(ii) | No | See §63.567(b)(1) |

| 63.9(b)(1)(iii) | Yes | |

| 63.9(b)(2) | No | See §63.567(b)(2). |

| 63.9(b)(3) | No | See §63.567(b)(3). |

| 63.9(b)(4) | No | See §63.567(b)(4). |

| 63.9(b)(5) | No | See §63.567(b)(4). |

| 63.9(c) | No | See §63.567(c). |

| 63.9(d) | No | |

| 63.9(e) | Yes | |

| 63.9(f) | No | |

| 63.9(g)(1) | Yes | |

| 63.9(g)(2) | No | |

| 63.9(g)(3) | Yes | |

| 63.9(h)(1)-(3) | Yes | |

| 63.9(h)(4) | No | Reserved. |

| 63.9(h)(5)-(6) | Yes | |

| 63.9(i) | Yes | |

| 63.9(j) | Yes | |

| 63.9(k) | Yes | Only as specified in §63.9(j). |

| 63.10(a) | Yes | |

| 63.10(b)(1) | Yes | |

| 63.10(b)(2)(i)-(ii) | No | See 63.567(m). |

| 63.10(b)(2)(iii) | Yes. | |

| 63.10(b)(2)(iv) | No | |

| 63.10(b)(2)(v) | No | |

| 63.10(b)(2)(vi)-(xiv) | Yes | |

| 63.10(b)(3) | No | See §63.567(j)(4). |

| 63.10(c)(1) | Yes | |

| 63.10(c)(2)-(4) | No | Reserved. |

| 63.10(c)(5) | Yes | |

| 63.10(c)(6) | No | See §63.564(a)(5). |

| 63.10(c)(7) | No | |

| 63.10(c)(8) | Yes | |

| 63.10(c)(9) | No | Reserved. |

| 63.10(c)(10)-(11) | No | See 63.567(m) for reporting malfunctions. Any cross-reference to 63.10(c)(10) or 63.10(c)(11) in any other general provision incorporated by reference shall be treated as a cross-reference to 63.567(m). |

| 63.10(c)(12)-(13) | Yes. | |

| 63.10(c)(14) | No | See §63.562(d)(2)(iv). |

| 63.10(c)(15) | No | |

| 63.10(d)(1)-(2) | Yes | |

| 63.10(d)(3) | No | See §63.567(d). |

| 63.10(d)(4) | Yes | |

| 63.10(d)(5) | No | |

| 63.(10)(e)(1) | Yes | |

| 63.10(e)(2)(i) | Yes | |

| 63.10(e)(2)(ii) | No | |

| 63.10(e)(3)(i)-(v) | No | See §63.567(e) |

| 63.10(e)(3)(vi). | Yes | |

| 63.10(e)(3)(vii)-(viii) | No | See §63.567(e) |

| 63.10(e)(4) | No | |

| 63.10(f) | Yes | |

| 63.11 | Yes | |

| 63.12-63.15 | Yes |

[60 FR 48399, Sept. 19, 1995, as amended at 76 FR 22595, Apr. 21, 2011; 80 FR 75237, Dec. 1, 2015; 85 FR 73892, Nov. 19, 2020]

§63.561 Definitions.

As used in this subpart, all terms not defined herein shall have the meaning given them in the Clean Air Act or in subpart A of this part.

Affected source means a source with emissions of 10 or 25 tons, a new source with emissions less than 10 and 25 tons, a new major source offshore loading terminal, a source with throughput of 10 M barrels or 200 M barrels, or the VMT source, that is subject to the emissions standards in §63.562.

Affirmative defense means, in the context of an enforcement proceeding, a response or a defense put forward by a defendant, regarding which the defendant has the burden of proof, and the merits of which are independently and objectively evaluated in a judicial or administrative proceeding.

Air pollution control device or control device means a combustion device or vapor recovery device.

Ballasting operations means the introduction of ballast water into a cargo tank of a tankship or oceangoing barge.

Baseline operating parameter means a minimum or maximum value of a process parameter, established for a control device during a performance test where the control device is meeting the required emissions reduction or established as the manufacturer recommended operating parameter, that, if achieved by itself or in combination with one or more other operating parameters, determines if a control device is operating properly.

Boiler means a device that combusts any fuel and produces steam or heats water or any other heat transfer medium. This term includes any duct burner that combusts fuel and is part of a combined cycle system.

Car-seal means a seal that is placed on a device used to change the position of a valve (e.g., from open to closed) in such a way that the position of the valve cannot be changed without breaking the seal.

Combustion device means all equipment, including, but not limited to, thermal incinerators, catalytic incinerators, flares, boilers, and process heaters used for combustion or destruction of organic vapors.

Commenced means, with respect to construction of an air pollution control device, that an owner or operator has undertaken a continuous program of construction or that an owner or operator has entered into a contractual obligation to undertake and complete, within a reasonable time, a continuous program of construction.

Commodity means a distinct product that a source loads onto marine tank vessels.

Continuous means, with respect to monitoring, reading and recording (either in hard copy or computer readable form) of data values measured at least once every 15 minutes.

Crude oil means a naturally occurring mixture consisting predominantly of hydrocarbons and/or sulfur, nitrogen, and oxygen derivatives of hydrocarbons that is removed from the earth in a liquid state or is capable of being so removed.

Exceedance or Variance means, with respect to parametric monitoring, the operating parameter of the air pollution control device that is monitored as an indication of proper operation of the control device is outside the acceptable range or limits for the baseline parameter given in §63.563(b)(4) through (9).

Excess emissions means, with respect to emissions monitoring, the concentration of the outlet stream of the air pollution control device is outside the acceptable range or limits for the baseline concentration given in §63.563(b)(4) through (9).

Flow indicator means a device that indicates whether gas flow is present in a line or vent system.

Gasoline means any petroleum distillate or petroleum distillate/alcohol blend having a Reid vapor pressure of 27.6 kPa (4.0 psia) or greater, that is used as a fuel for internal combustion engines.

Impurity means HAP substances that are present in a commodity or that are produced in a process coincidentally with the primary product or commodity and that are 0.5 percent total HAP by weight or less. An impurity does not serve a useful purpose in the production or use of the primary product or commodity and is not isolated.

Leak means a reading of 10,000 parts per million volume (ppmv) or greater as methane that is determined using the test methods in Method 21, appendix A of part 60 of this chapter.

Lightering or Lightering operation means the offshore transfer of a bulk liquid cargo from one marine tank vessel to another vessel.

Loading berth means the loading arms, pumps, meters, shutoff valves, relief valves, and other piping and valves necessary to fill marine tank vessels. The loading berth includes those items necessary for an offshore loading terminal.

Loading cycle means the time period from the beginning of filling a single marine tank vessel until commodity flow to the marine tank vessel ceases.

Maintenance allowance means a period of time that an affected source is allowed to perform maintenance on the loading berth without controlling emissions from marine tank vessel loading operations.

Marine tank vessel loading operation means any operation under which a commodity is bulk loaded onto a marine tank vessel from a terminal, which may include the loading of multiple marine tank vessels during one loading operation. Marine tank vessel loading operations do not include refueling of marine tank vessels.

Marine vessel or Marine tank vessel means any tank ship or tank barge that transports liquid product such as gasoline or crude oil in bulk.

Nonvapor-tight means any marine tank vessel that does not pass the required vapor-tightness test.

Offshore loading terminal means a location that has at least one loading berth that is 0.81 km (0.5 miles) or more from the shore that is used for mooring a marine tank vessel and loading liquids from shore.

Primary fuel means the fuel that provides the principal heat input to the device. To be considered primary, the fuel must be able to sustain operation of the device without the addition of other fuels.

Process heater means a device that transfers heat liberated by burning fuel to fluids contained in tubes, including all fluids except water that are heated to produce steam.

Recovery device means an individual unit of equipment, including, but not limited to, a carbon adsorber, condenser/refrigeration unit, or absorber that is capable of and used for the purpose of removing vapors and recovering liquids or chemicals.

Routine loading means, with respect to the VMT source, marine tank vessel loading operations that occur as part of normal facility operation over a loading berth when no loading berths are inoperable due to maintenance.

Secondary fuel means any fuel other than the primary fuel. The secondary fuel provides supplementary heat in addition to the heat provided by the primary fuel and is generally fired through a burner other than the primary burner.

Source(s) means any location where at least one dock or loading berth is bulk loading onto marine tank vessels, except offshore drilling platforms and lightering operations.

Source(s) with emissions less than 10 and 25 tons means major source(s) having aggregate actual HAP emissions from marine tank vessel loading operations at all loading berths as follows:

(1) Prior to the compliance date, of less than 9.1 Mg (10 tons) of each individual HAP calculated on a 24-month annual average basis after September 19, 1997 and less than 22.7 Mg (25 tons) of all HAP combined calculated on a 24-month annual average basis after September 19, 1997, as determined by emission estimation in §63.565(l) of this subpart; and

(2) After the compliance date, of less than 9.1 Mg (10 tons) of each individual HAP calculated annually after September 20, 1999 and less than 22.7 Mg (25 tons) of all HAP combined calculated annually after September 20, 1999, as determined by emission estimation in §63.565(l) of this subpart.

Source(s) with emissions of 10 or 25 tons means major source(s) having aggregate actual HAP emissions from marine tank vessels loading operations at all loading berths as follows:

(1) Prior to the compliance date, emissions of 9.1 Mg (10 tons) or more of each individual HAP calculated on a 24-month annual average basis after September 19, 1997 or of 22.7 Mg (25 tons) or more of all HAP combined calculated on a 24-month annual average basis after September 19, 1997, as determined by emission estimation in §63.565(l); or

(2) After the compliance date, emissions of 9.1 Mg (10 tons) or more of each individual HAP calculated annually after September 20, 1999 or of 22.7 Mg (25 tons) or more of all HAP combined calculated annually after September 20, 1999, as determined by emission estimation in §63.565(l).

Source(s) with throughput less than 10 M barrels and 200 M barrels means source(s) having aggregate loading from marine tank vessel loading operations at all loading berths as follows:

(1) Prior to the compliance date, of less than 1.6 billion liters (10 million (M) barrels) of gasoline on a 24-month annual average basis and of less than 32 billion liters (200 M barrels) of crude oil on a 24-month annual average basis after September 19, 1996; and

(2) After the compliance date, of less than 1.6 billion liters (10 M barrels) of gasoline annually and of less than 32 billion liters (200 M barrels) of crude oil annually after September 21, 1998.

Source(s) with throughput of 10 M barrels or 200 M barrels means source(s) having aggregate loading from marine tank vessel loading operations at all loading berths as follows:

(1) Prior to the compliance date, of 1.6 billion liters (10 M barrels) or more of gasoline on a 24-month annual average basis or of 32 billion liters (200 M barrels) or more of crude oil on a 24-month annual average basis after September 19, 1996; or

(2) After the compliance date, of 1.6 billion liters (10 M barrels) or more of gasoline annually or of 32 billion liters (200 M barrels) or more of crude oil annually after September 21, 1998.

Terminal means all loading berths at any land or sea based structure(s) that loads liquids in bulk onto marine tank vessels.

Twenty-four-month (24-month) annual average basis means annual HAP emissions, with respect to MACT standards, or annual loading throughput, with respect to RACT standards, from marine tank vessel loading operations averaged over a 24-month period.

Valdez Marine Terminal (VMT) source means the major source that is permitted under the Trans-Alaska Pipeline Authorization Act (TAPAA) (43 U.S.C. §1651 et seq.). The source is located in Valdez, Alaska in Prince William Sound.

Vapor balancing system means a vapor collection system or piping system that is designed to collect organic HAP vapors displaced from marine tank vessels during marine tank vessel loading operations and that is designed to route the collected organic HAP vapors to the storage vessel from which the liquid being loaded originated or to compress collected organic HAP vapors and commingle with the raw feed of a process unit.

Vapor collection system means any equipment located at the source, i.e., at the terminal, that is not open to the atmosphere, that is composed of piping, connections, and flow inducing devices, and that is used for containing and transporting vapors displaced during the loading of marine tank vessels to a control device or for vapor balancing. This does not include the vapor collection system that is part of any marine vessel vapor collection manifold system.

Vapor-tight marine vessel means a marine tank vessel that has demonstrated within the preceding 12 months to have no leaks. A marine tank vessel loaded at less than atmospheric pressure is assumed to be vapor tight for the purpose of this standard.

Volatile organic compounds or VOC is as defined in 40 CFR 51.100(s) of this chapter.

[60 FR 48399, Sept. 19, 1995, as amended at 76 FR 22596, Apr. 21, 2011]

§63.562 Standards.

(a) The emissions limitations in paragraphs (b), (c), and (d) of this section apply during marine tank vessel loading operations.

(b) MACT standards, except for the VMT source - (1)(i) Vapor collection system of the terminal. The owner or operator of a new source with emissions less than 10 and 25 tons and an existing or new source with emissions of 10 or 25 tons shall equip each terminal with a vapor collection system that is designed to collect HAP vapors displaced from marine tank vessels during marine tank vessel loading operations and to prevent HAP vapors collected at one loading berth from passing through another loading berth to the atmosphere, except for those commodities exempted under §63.560(d).

(ii) Ship-to-shore compatibility. The owner or operator of a new source with emissions less than 10 and 25 tons and an existing or new source with emissions of 10 or 25 tons shall limit marine tank vessel loading operations to those vessels that are equipped with vapor collection equipment that is compatible with the terminal's vapor collection system, except for those commodities exempted under §63.560(d).

(iii) Vapor tightness of marine vessels. The owner or operator of a new source with emissions less than 10 and 25 tons and an existing or new source with emissions of 10 or 25 tons shall limit marine tank vessel loading operations to those vessels that are vapor tight and to those vessels that are connected to the vapor collection system, except for those commodities exempted under §63.560(d).

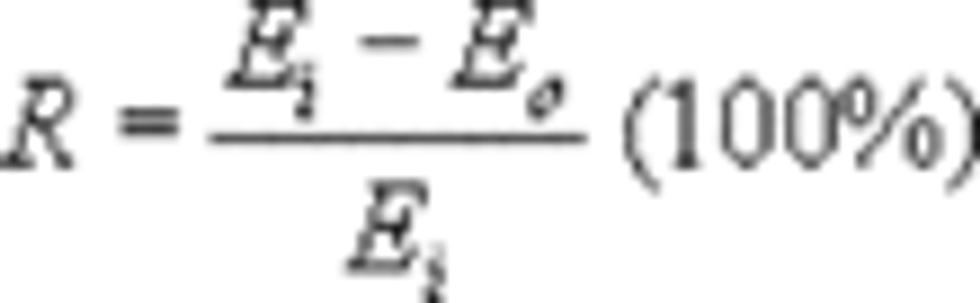

(2) MACT standards for existing sources with emissions of 10 or 25 tons. The owner or operator of an existing source with emissions of 10 or 25 tons, except offshore loading terminals and the VMT source, shall reduce captured HAP emissions from marine tank vessel loading operations by 97 weight-percent, as determined using methods in §63.565 (d) and (l).

(3) MACT standards for new sources. The owner or operator of a new source with emissions less than 10 and 25 tons or a new source with emissions of 10 or 25 tons, except offshore loading terminals and the VMT source, shall reduce HAP emissions from marine tank vessel loading operations by 98 weight-percent, as determined using methods in §63.565 (d) and (l).

(4) MACT standards for new major source offshore loading terminals. The owner or operator of a new major source offshore loading terminal shall reduce HAP emissions from marine tank vessel loading operations by 95 weight-percent, as determined using methods in §63.565 (d) and (l).

(5) Prevention of carbon adsorber emissions during regeneration. The owner or operator of a source subject to paragraph (b)(2), (3), or (4) shall prevent HAP emissions from escaping to the atmosphere from the regeneration of the carbon bed when using a carbon adsorber to control HAP emissions from marine tank vessel loading operations.

(6) Maintenance allowance for loading berths. The owner or operator of a source subject to paragraph (b)(2), (3) or (4), may apply for approval to the Administrator for a maintenance allowance for loading berths based on a percent of annual throughput or annual marine tank vessel loading operation time for commodities not exempted in §63.560(d). The owner or operator shall maintain records for all maintenance performed on the air pollution control equipment. The Administrator will consider the following in approving the maintenance allowance:

(i) The owner or operator expects to be in violation of the emissions standards due to maintenance;

(ii) Due to conditions beyond the reasonable control of the owner or operator, compliance with the emissions standards during maintenance would result in unreasonable economic hardship;

(iii) The economic hardship cannot be justified by the resulting air quality benefit;

(iv) The owner or operator has given due consideration to curtailing marine vessel loading operations during maintenance;

(v) During the maintenance allowance, the owner or operator will endeavor to reduce emissions from other loading berths that are controlled as well as from the loading berth the owner or operator is seeking the maintenance allowance; and

(vi) During the maintenance allowance, the owner or operator will monitor and report emissions from the loading berth to which the maintenance allowance applies.

(c) RACT standards, except the VMT source - (1) Commencement of construction. The owner or operator of a source with throughput of 10 M barrels or 200 M barrels, except the VMT source, with an initial startup date on or before September 21, 1998 shall provide the Agency no later than 2 years after the effective date with proof that it has commenced construction of its vapor collection system and air pollution control device.

(2)(i) Vapor collection system of the terminal. The owner or operator of a source with throughput of 10 M barrels or 200 M barrels shall equip each terminal with a vapor collection system that is designed to collect VOC vapors displaced from marine tank vessels during loading and to prevent VOC vapors collected at one loading berth from passing through another loading berth to the atmosphere, except for those commodities exempted under §63.560(d).

(ii) Ship-to-shore compatibility. The owner or operator of a source with throughput of 10 M barrels or 200 M barrels shall limit marine tank vessel loading operations to those vessels that are equipped with vapor collection equipment that is compatible with the terminal's vapor collection system, except for those commodities exempted under §63.560(d).

(iii) Vapor tightness of marine vessels. The owner or operator of a source with throughput of 10 M barrels or 200 M barrels shall limit marine tank vessel loading operations to those vessels that are vapor-tight and to those vessels that are connected to the vapor collection system, except for those commodities exempted under §63.560(d).

(3) RACT standard for sources with throughput of 10 M or 200 M barrels, except the VMT source. The owner or operator of a source with throughput of 10 M barrels or 200 M barrels, except the VMT source, shall reduce captured VOC emissions from marine tank vessel loading operations by 98 weight-percent when using a combustion device or reduce captured VOC emissions by 95 weight-percent when using a recovery device, as determined using methods in §63.565(d) and (l).

(4) The owner or operator of a source with throughput of 10 M barrels or 200 M barrels, except the VMT source, may meet the requirements of paragraph (c)(3) by reducing gasoline loading emissions to, at most, 1,000 ppmv outlet VOC concentration.

(5) Prevention of carbon adsorber emissions during regeneration. The owner or operator of a source with throughput of 10 M barrels or 200 M barrels shall prevent HAP emissions from escaping to the atmosphere from the regeneration of the carbon bed when using a carbon adsorber to control HAP emissions from marine tank vessel loading operations.

(6) Maintenance allowance for loading berths. The owner or operator of a source with throughput of 10 M barrels or 200 M barrels may apply for approval to the Administrator for a maintenance allowance for loading berths based on a percent of annual throughput or annual marine tank vessel loading operation time for commodities not exempted in §63.560(d). The owner or operator shall maintain records for all maintenance performed on the air pollution control equipment. The Administrator will consider the following in approving the maintenance allowance:

(i) The owner or operator expects to be in violation of the emissions standards due to maintenance;

(ii) Due to conditions beyond the reasonable control of the owner or operator, compliance with the emissions standards during maintenance would result in unreasonable economic hardship;

(iii) The economic hardship cannot be justified by the resulting air quality benefit;

(iv) The owner or operator has given due consideration to curtailing marine vessel loading operations during maintenance;

(v) During the maintenance allowance, the owner or operator will endeavor to reduce emissions from other loading berths that are controlled as well as from the loading berth the owner or operator is seeking the maintenance allowance; and

(vi) During the maintenance allowance, the owner or operator will monitor and report emissions from the loading berth to which the maintenance allowance applies.

(d) MACT and RACT standards for the VMT source - (1)(i) Vapor collection system of the terminal. The owner or operator of the VMT source shall equip each terminal subject under paragraph (d)(2) with a vapor collection system that is designed to collect HAP vapors displaced from marine tank vessels during marine tank vessel loading operations and to prevent HAP vapors collected at one loading berth from passing through another loading berth to the atmosphere, except for those commodities exempted under §63.560(d).

(ii) Ship-to-shore compatibility. The owner or operator of the VMT source shall limit marine tank vessel loading operations at berths subject under paragraph (d)(2) of this section to those vessels that are equipped with vapor collection equipment that is compatible with the terminal's vapor collection system, except for those commodities exempted under §63.560(d).

(iii) Vapor tightness of marine vessels. The owner or operator of the VMT source shall limit marine tank vessel loading operations at berths subject under paragraph (d)(2) of this section to those vessels that are vapor-tight and to those vessels that are connected to the vapor collection system, except for those commodities exempted under §63.560(d).

(2) The owner or operator of the VMT source shall reduce captured HAP and VOC emissions by 98 weight-percent, as determined using methods in §63.565(d) and (l) for loading berths subject under this paragraph according to paragraphs (d)(2)(i), (ii), (iii), and (iv):

(i) The owner or operator of the VMT source shall equip at least two loading berths and any additional berths indicated pursuant to paragraph (d)(2)(iii) with a vapor collection system and air pollution control device and shall load marine tank vessels over loading berths equipped with a vapor collection system and control device to the maximum extent practicable. The owner or operator shall equip all loading berths that will be used for routine loading after March 19, 1998 with a vapor collection system and control device if the annual average daily loading rate for all loading berths exceeds the limits in paragraphs (d)(2)(i)(A), (B), and (C) of this section.

(A) For 1995, 1,630,000 barrels per day; and

(B) For 1996, 1,546,000 barrels per day; and

(C) For 1997, 1,445,000 barrels per day.

(ii) Maximum extent practicable means that the total annual average daily loading over all loading berths not equipped with a vapor collection system and control device shall not exceed the totals in paragraphs (d)(2)(ii)(A) and (B):

(A) Loading allowances for marine tank vessel loading operations at loading berths not equipped with control devices. The following maximum annual average daily loading rate for routine loading at loading berths not equipped with control devices in any of the following years shall not exceed:

(1) For 1998, 275,000 barrels per day;

(2) For 1999, 205,000 barrels per day;

(3) For 2000, 118,000 barrels per day;

(4) For 2001, 39,000 barrels per day; and

(5) For 2002 and subsequent years, no marine tank vessel loading operations shall be performed at berths not equipped with a vapor collection system and control device, except as allowed for maintenance under paragraph (B).

(B) Maintenance allowances for loading berths subject under paragraph (d)(2)(i). Beginning in the year 2000, the owner or operator of the VMT source may have a maximum of 40 calendar days per calendar year use of loading berths not equipped with a vapor collection system and control device, in accordance with the limits in paragraph (d)(2)(ii)(B)(a), (b), or (c), to allow for maintenance of loading berths subject to paragraph (d)(2)(i). Beginning in the year 2002, the total annual average daily loading of crude oil over all loading berths not equipped with a vapor collection system and control device shall not exceed the amount stated in paragraph (d)(2)(ii)(B)(b). The 40 days allowed for maintenance shall be converted into a compliance measure of annual average daily loading over the loading berths not equipped with a vapor collection system and control device as follows:

(1) If the total annual average daily volume of crude oil loaded at the facility was greater than or equal to 1,100,000 barrels per day in the prior calendar year, the maintenance allowance shall not exceed an annual average daily loading of 60,000 barrels per day.

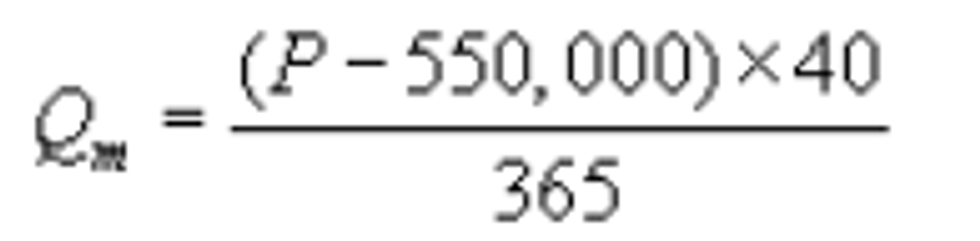

(2) If the total annual average daily volume of crude oil loaded at the facility was less than 1,100,000 barrels per day and greater than or equal to 550,000 barrels per day in the prior calendar year, the maintenance allowance for the calendar year shall not exceed Qm:

Where:

Qm = maintenance allowance, barrels per day

P = prior calendar year's average daily volume of crude oil loaded at the facility, barrels per day.

(3) If the total annual average daily volume of crude oil loaded at the facility was less than 550,000 barrels per day in the prior calendar year, there shall be no maintenance allowance.

(iii) If the average daily loading rate for the loading berths not equipped with a vapor collection system and control device is greater than the combined amounts in any year listed in paragraphs (d)(2)(i)(A), (B), and (C) and (d)(2)(ii)(A) and (B), then the owner or operator of the VMT source shall equip all loading berths used for routine loading with a vapor collection system and control device within 2 years of the exceedance except that in an emergency situation the Administrator may, instead of requiring controls, approve an alternative plan to reduce loading over the unequipped berth(s) to a level which will ensure compliance with the applicable limit. Beginning in the year 2002, the owner or operator of the VMT source shall equip all uncontrolled loading berths used for marine tank vessel loading operations beyond the maintenance allowance in paragraph (d)(2)(ii)(B) with a vapor collection system and control device.

(iv) The owner or operator of the VMT source shall develop a program to communicate to relevant facility operations and marine transportation personnel and engage their active and consistent participation in honoring the intent and goal of minimizing loaded volumes over the unequipped berths and maximizing the loaded volumes at the berths equipped with a vapor collection system and control device to prevent exceedance of the load volume limits in paragraphs (d)(2)(ii)(A) and (B). This program is to be presented semi-annually during the first year of compliance and annually thereafter until the use of unequipped berths for routine loading is no longer required.

(e) Operation and maintenance requirements for air pollution control equipment and monitoring equipment for affected sources. At all times, owners or operators of affected sources shall operate and maintain a source, including associated air pollution control equipment, in a manner consistent with safety and good air pollution control practices for minimizing emissions. Determination of whether acceptable operation and maintenance procedures are being used will be based on information available to the Administrator which may include, but is not limited to, monitoring results, review of operation and maintenance procedures, review of operation and maintenance records, and inspection of the source.

(1) The Administrator will determine compliance with design, equipment, work practice, or operational emission standards by evaluating an owner or operator's conformance with operation and maintenance requirements.

(2) The owner or operator of an affected source shall develop a written operation and maintenance plan that describes in detail a program of corrective action for varying (i.e., exceeding baseline parameters) air pollution control equipment and monitoring equipment, based on monitoring requirements in §63.564, used to comply with these emissions standards. The plan shall also identify all routine or otherwise predictable continuous monitoring system (thermocouples, pressure transducers, continuous emissions monitors (CEMS), etc.) variances.

(i) The plan shall specify procedures (preventive maintenance) to be followed to ensure that pollution control equipment and monitoring equipment functions properly and variances of the control equipment and monitoring equipment are minimal.

(ii) The plan shall identify all operating parameters to be monitored and recorded for the air pollution control device as indicators of proper operation and shall establish the frequency at which the parameters will be monitored (see §63.564).

(iii) Owners or operators of affected sources shall incorporate a standardized inspection schedule for each component of the control device used to comply with the emissions standards in §63.562(b), (c), and (d). To satisfy the requirements of this paragraph, the owner or operator may use the inspection schedule recommended by the vendor of the control system or any other technical publication regarding the operation of the control system.

(iv) Owners or operators shall develop and implement a continuous monitoring system (CMS) quality control program. The owner or operator shall develop and submit to the Administrator for approval upon request a site-specific performance evaluation test plan for the CMS performance evaluation required in §63.8(e) of subpart A of this part. Each quality control program shall include, at a minimum, a written protocol that describes procedures for initial and any subsequent calibration of the CMS; determination and adjustment of the calibration drift of the CMS; preventive maintenance of the CMS, including spare parts inventory; data recording, calculations, and reporting; and accuracy audit procedures, including sampling and analysis methods. The owner or operation shall maintain records of the procedures that are part of the quality control program developed and implemented for CMS.

(3) Based on the results of the determination made under paragraph (e)(2), the Administrator may require that an owner or operator of an affected source make changes to the operation and maintenance plan for that source. Revisions may be required if the plan:

(i) Does not address a variance of the air pollution control equipment or monitoring equipment that has occurred that increases emissions;

(ii) Fails to provide for operation during a variance of the air pollution control equipment or the monitoring equipment in a manner consistent with safety and good air pollution control practices; or

(iii) Does not provide adequate procedures for correcting a variance of the air pollution control equipment or monitoring equipment as soon as reasonable.

(4) If the operation and maintenance plan fails to address or inadequately addresses a varianceevent at the time the plan was initially developed, the owner or operator shall revise the operation and maintenance plan within 45 working days after such an event occurs. The revised plan shall include procedures for operating and maintaining the air pollution control equipment or monitoring equipment during similar variance events and a program for corrective action for such events.

(5) The operation and maintenance plan shall be developed by the source's compliance date. The owner or operator shall keep the written operation and maintenance plan on record to be made available for inspection, upon request, by the Administrator for the life of the source. In addition, if the operation and maintenance plan is revised, the owner or operator shall keep previous (i.e., superseded) versions of the plan on record to be made available for inspection upon request by the Administrator for a period of 5 years after each revision to the plan.

(6) To satisfy the requirements of the operation and maintenance plan, the owner or operator may use the source's standard operating procedures (SOP) manual, an Occupational Safety and Health Administration (OSHA) plan, or other existing plans provided the alternative plans meet the requirements of this section and are made available for inspection when requested by the Administrator.

(7) In response to an action to enforce the standards set forth in this subpart, you may assert an affirmative defense to a claim for civil penalties for exceedances of such standards that are caused by a malfunction, as defined in §63.2. Appropriate penalties may be assessed, however, if the respondent fails to meet its burden of proving all the requirements in the affirmative defense. The affirmative defense shall not be available for claims for injunctive relief.

(i) To establish the affirmative defense in any action to enforce such a limit, the owners or operators of a facility must timely meet the notification requirements of paragraph (e)(7)(ii) of this section, and must prove by a preponderance of evidence that:

(A) The excess emissions were caused by a sudden, infrequent, and unavoidable failure of air pollution control and monitoring equipment, or a process to operate in a normal and usual manner; and could not have been prevented through careful planning, proper design or better operation and maintenance practices; and did not stem from any activity or event that could have been foreseen and avoided, or planned for; and were not part of a recurring pattern indicative of inadequate design, operation, or maintenance;

(B) Repairs were made as expeditiously as possible when the applicable emission limitations were being exceeded. Off-shift and overtime labor were used, to the extent practicable to make these repairs;

(C) The frequency, amount and duration of the excess emissions (including any bypass) were minimized to the maximum extent practicable during periods of such emissions;

(D) If the excess emissions resulted from a bypass of control equipment or a process, then the bypass was unavoidable to prevent loss of life, personal injury, or severe property damage;

(E) All possible steps were taken to minimize the impact of the excess emissions on ambient air quality, the environment, and human health;

(F) All emissions monitoring and control systems were kept in operation if at all possible, consistent with safety and good air pollution control practices;

(G) All of the actions in response to the excess emissions were documented by properly signed, contemporaneous operating logs;

(H) At all times, the affected facility was operated in a manner consistent with good practices for minimizing emissions; and

(I) The owner or operator has prepared a written root cause analysis, the purpose of which is to determine, correct, and eliminate the primary causes of the malfunction and the excess emissions resulting from the malfunction event at issue. The analysis shall also specify, using the best monitoring methods and engineering judgment, the amount of excess emissions that were the result of the malfunction.

(ii) Notification. The owner or operator of the facility experiencing an exceedance of its emission limit(s) during a malfunction shall notify the Administrator by telephone or facsimile (FAX) transmission as soon as possible, but no later than 2 business days after the initial occurrence of the malfunction, if it wishes to avail itself of an affirmative defense to civil penalties for that malfunction. The owner or operator seeking to assert an affirmative defense shall also submit a written report to the Administrator within 45 days of the initial occurrence of the exceedance of the standard in this subpart to demonstrate, with all necessary supporting documentation, that it has met the requirements set forth in paragraph (e)(7)(i) of this section. The owner or operator may seek an extension of this deadline for up to 30 additional days by submitting a written request to the Administrator before the expiration of the 45 day period. Until a request for an extension has been approved by the Administrator, the owner or operator is subject to the requirement to submit such report within 45 days of the initial occurrence of the exceedance.

[60 FR 48399, Sept. 19, 1995, as amended at 68 FR 37350, June 23, 2003; 71 FR 20457, Apr. 20, 2006; 76 FR 22596, Apr. 21, 2011]

§63.563 Compliance and performance testing.

(a) The following procedures shall be used to determine compliance with the emissions limits under §63.562(b)(1), (c)(2), and (d)(1):

(1) Vent stream by-pass requirements for the terminal's vapor collection system. (i) In accordance with §63.562(b)(1)(i), (c)(2)(i), and (d)(1)(i), each valve in the terminal's vapor collection system that would route displaced vapors to the atmosphere, either directly or indirectly, shall be secured closed during marine tank vessel loading operations either by using a car-seal or a lock-and-key type configuration, or the by-pass line from the valve shall be equipped with a flow indicator, except for those valves used for pressure/vacuum relief, analyzers, instrumentation devices, sampling, and venting for maintenance. Marine tank vessel loading operations shall not be performed with open by-pass lines.

(ii) Repairs shall be made to valves, car-seals, or closure mechanisms no later than 15 days after a change in the position of the valve or a break in the car-seal or closure mechanism is detected or no later than prior to the next marine tank vessel loading operation, whichever is later.

(2) Ship-to-shore compatibility of vapor collection systems. Following the date on which the initial performance test is completed, marine tank vessel loading operations must be performed only if the marine tank vessel's vapor collection equipment is compatible to the terminal's vapor collection system; marine tank vessel loading operations must be performed only when the marine tank vessel's vapor collection equipment is connected to the terminal's vapor collection system, as required in §63.562(b)(1)(ii), (c)(2)(ii), and (d)(1)(ii).

(3) Pressure/vacuum settings for the marine tank vessel's vapor collection equipment. During the initial performance test required in paragraph (b)(1) of this section, the owner or operator of an affected source shall demonstrate compliance with operating pressure requirements of 33 CFR 154.814 using the procedures in §63.565(b).

(4) Vapor-tightness requirements of the marine vessel. The owner or operator of an affected source shall use the procedures in paragraph (a)(4)(i), (ii), (iii), or (iv) of this section to ensure that marine tank vessels are vapor tight, as required in §63.562(b)(1)(iii), (c)(2)(iii), and (d)(1)(iii).

(i) Pressure test documentation for determining vapor tightness of the marine vessel. The owner or operator of a marine tank vessel, who loads commodities containing HAP not determined to be exempt under §63.560(d) at an affected source, shall provide a copy of the vapor-tightness pressure test documentation described in §63.567(i) for each marine tank vessel prior to loading. The date of the test listed in the documentation must be within the preceding 12 months, and the test must be conducted in accordance with the procedures in §63.565(c)(1). Following the date on which the initial performance test is completed, the affected source must check vapor-tightness pressure test documentation for marine tank vessels loaded at positive pressure.

(ii) Leak test documentation for determining vapor tightness of the marine vessel. If no documentation of the vapor tightness pressure test as described in paragraph (a)(4)(i) of this section is available, the owner or operator of a marine tank vessel, who loads commodities containing HAP not determined to be exempt under §63.560(d) at an affected source, shall provide the leak test documentation described in §63.567(i) for each marine tank vessel prior to loading. The date of the test listed in the documentation must be within the preceding 12 months, and the test must be conducted in accordance with the procedures in §63.565(c)(2). If the marine tank vessel has failed its most recent vapor-tightness leak test at that terminal, the owner or operator of the non-vapor-tight marine tank vessel shall provide documentation that the leaks detected during the previous vapor-tightness test have been repaired and documented with a successful vapor-tightness leak test described in §63.565(c)(2) conducted during loading. If the owner or operator of the marine tank vessel can document that repair is technically infeasible without cleaning and gas freeing or dry-docking the vessel, the owner or operator of the affected source may load the marine tank vessel. Following the date on which the initial performance test is completed, an affected source must check the vapor-tightness leak test documentation for marine tank vessels loaded at positive pressure.

(iii) Leak test performed during loading using Method 21 for determining vapor tightness of the marine vessel. If no documentation of vapor tightness as described in paragraphs (a)(4)(i) or (ii) of this section is available, the owner or operator of a marine tank vessel, who loads commodities containing HAP not determined to be exempt under §63.560(d) at an affected source, shall perform a leak test of the marine tank vessel during marine tank vessel loading operation using the procedures described in §63.565(c)(2).

(A) If no leak is detected, the owner or operator of a marine tank vessel shall complete the documentation described in §63.567(i) prior to departure of the vessel.

(B) If a leak is detected, the owner or operator of the marine tank vessel shall document the vapor-tightness failure for the marine tank vessel prior to departure of the vessel. The leaking component shall be repaired prior to the next marine tank vessel loading operation at a controlled terminal unless the repair is technically infeasible without cleaning and gas freeing or dry-docking the vessel. If the owner or operator of the vessel provides documentation that repair of such equipment is technically infeasible without cleaning and gas freeing or dry-docking the vessel, the equipment responsible for the leak will be excluded from future Method 21 tests until repairs are effected. A copy of this documentation shall be maintained by the owner or operator of the affected source. Repair of the equipment responsible for the leak shall occur the next time the vessel is cleaned and gas freed or dry-docked. For repairs that are technically feasible without dry-docking the vessel, the owner or operator of the affected source shall not load the vessel again unless the marine tank vessel owner or operator can document that the equipment responsible for the leak has been repaired.

(iv) Negative pressure loading. The owner or operator of an affected source shall ensure that a marine tank vessel is loaded with the product tank below atmospheric pressure (i.e., at negative gauge pressure). The pressure shall be measured between the facility's vapor connection and its manual isolation valve, and the measured pressure must be below atmospheric pressure. Following the date on which the initial performance test is completed, marine tank vessel loading operations for nonvapor-tight vessels must be performed below atmospheric pressure (i.e., at negative gauge pressure) in the product tank.

(b) Compliance determination for affected sources. The following procedures shall be used to determine compliance with the emissions limits under §63.562(b), (c), and (d).

(1) Initial performance test. An initial performance test shall be conducted using the procedures listed in §63.7 of subpart A of this part according to the applicability in Table 1 of §63.560, the procedures listed in this section, and the test methods listed in §63.565. The initial performance test shall be conducted within 180 days after the compliance date for the specific affected source. During this performance test, sources subject to MACT standards under §63.562(b)(2), (3), (4), and (5), and (d)(2) shall determine the reduction of HAP emissions, as VOC, for all combustion or recovery devices other than flares. Performance tests shall be conducted under such conditions as the Administrator specifies to the owner or operator based on representative performance of the affected source for the period being tested. Upon request, the owner or operator shall make available to the Administrator such records as may be necessary to determine the conditions of performance tests. Sources subject to RACT standards under §63.562(c)(3), (4), and (5), and (d)(2) shall determine the reduction of VOC emissions for all combustion or recovery devices other than flares.

(2) Performance test exemptions. An initial performance test required in this section and in §63.565(d) and the continuous monitoring in §63.564(e) is not required in the following cases:

(i) When a boiler or process heater with a design heat input capacity of 44 Megawatts or less is used to comply with §63.562(b)(2), (3), or (4), (c)(3) or (4), or (d)(2) and the vent stream is used as the primary fuel or with the primary fuel;

(ii) When a boiler or process heater with a design heat input capacity of 44 Megawatts or greater is used to comply with §63.562(b)(2), (3), or (4), (c)(3) or (4), or (d)(2); or

(iii) When a boiler subject to 40 CFR part 266, subpart H, “Hazardous Waste Burned in Industrial Furnaces,” that has demonstrated 99.99 percent destruction or recovery efficiency is used to comply with §63.562(b)(2), (3), or (4), (c)(3) or (4), or (d)(2).

(3) Operation and maintenance inspections. If the 3-hour or 3-cycle block average operating parameters in paragraphs (b)(4) through (9) of this section, outside the acceptable operating ranges, are measured and recorded, i.e., variances of the pollution control device or monitoring equipment, the owner or operator of the affected source shall perform an unscheduled inspection of the control device and monitoring equipment and review of the parameter monitoring data. The owner or operator of the affected source shall perform an inspection and review when total parameter variance time for the control device is greater than 10 percent of the operating time for marine tank vessel loading operations on a 30-day, rolling-average basis. The inspection and review shall be conducted within 24 hours after passing the allowable variance time of 10 percent. The inspection checklist from the requirements of §63.562(e)(2)(iii) and the monitoring data from requirements in §§63.562(e)(2)(ii) and 63.564 should be used to identify any maintenance problems that may be associated with the variance. The unscheduled inspection should encompass all components of the control device and monitoring equipment that can be inspected while in operation. If any maintenance problem is identified during the inspection, the owner or operator of the affected source must take corrective action (e.g., adjustments to operating controls, etc.) as soon as practicable. If no immediate maintenance problems are identified from the inspection performed while the equipment is operating, a complete inspection in accordance with §63.562(e)(2) must be conducted prior to the next marine tank vessel loading operation and corrective action (e.g., replacement of defective parts) must be taken as soon as practicable for any maintenance problem identified during the complete inspection.

(4) Combustion device, except flare. During the initial performance test required in paragraph (b)(1) of this section, the owner or operator shall determine the efficiency of and/or the outlet VOC concentration from the combustion device used to comply with §63.562(b)(2), (3), or (4), (c)(3) or (4), and (d)(2) using the test methods in §63.565(d). The owner or operator shall comply with paragraph (b)(4)(i) or (ii) of this section.

(i) Outlet VOC concentration limit for required percent combustion efficiency. The owner or operator shall establish as an operating parameter the baseline VOC concentration using the procedures described in §63.565(g). Following the date on which the initial performance test is completed, the facility shall be operated with a block average outlet VOC concentration as determined in §63.564(e)(1) no more than 20 percent above the baseline VOC concentration.

(ii) Baseline temperature for required percent combustion efficiency. The owner or operator shall establish as an operating parameter the baseline temperature using the procedures described in §63.565(f). Following the date on which the initial performance test is completed, the facility shall be operated with the block average temperature as determined in §63.564(e)(2) or (3) no more than 28°C (50°F) below the baseline temperature.

(5) Flare. During the initial performance test required in paragraph (b)(1) of this section, the owner or operator shall establish that the flare used to comply with the emissions standards in §63.562(b)(2), (3), or (4), (c)(3) or (4), and (d)(2) is in compliance with the design requirements for flares cited in §63.565(e). Following the date on which the initial determination of compliance is established, the facility shall operate with the presence of a pilot flame in the flare, as determined in §63.564(f).

(6) Carbon adsorber. During the initial performance test required in paragraph (b)(1) of this section, the owner or operator shall determine the efficiency of and/or the outlet VOC concentration from the recovery device used to comply with §63.562(b)(2), (3), (4), and (5), (c)(3), (4), and (5), and (d)(2) using the test methods in §63.565(d). The owner or operator shall comply with paragraph (b)(6)(i) as well as either paragraph (b)(6)(ii) or (iii) of this section. The owner or operator of affected sources complying with paragraph (b)(6)(ii)(B) or (C) of this section shall conduct a performance test once each year.

(i) Compliance determination for carbon bed regeneration. Desorbed hydrocarbons from regeneration of the off-line carbon bed shall be vented to the on-line carbon bed.

(ii) Baseline parameters for required percent recovery efficiency. The owner or operator shall comply with paragraph (b)(6)(ii)(A), (B), or (C) of this section.

(A) Outlet VOC concentration limit for required percent recovery efficiency. The owner or operator shall establish as an operating parameter the baseline VOC concentration using the procedures described in §63.565(g). Following the date on which the initial performance test is completed, the facility shall be operated with a block average outlet VOC concentration as determined in §63.564(g)(1) no more than 20 percent above the baseline VOC concentration.

(B) Carbon adsorbers with vacuum regeneration. The owner or operator shall establish as operating parameters the baseline regeneration time for the vacuum stage of carbon bed regeneration using the procedures described in §63.565(h) and shall establish the baseline vacuum pressure (negative gauge pressure) using the procedures described in §63.565(i). Following the date on which the initial performance test is completed, the facility shall be operated with block average regeneration time of the vacuum stage of carbon bed regeneration as determined in §63.564(g)(2) no more than 20 percent below the baseline regeneration time, and the facility shall be operated with the block average vacuum pressure (negative gauge pressure) as determined in §63.564(g)(2) no more than 20 percent above the baseline vacuum pressure.

(C) Carbon adsorbers with steam regeneration. The owner or operator shall establish as operating parameters the baseline total stream flow using the procedures described in §63.565(j) and a baseline carbon bed temperature after cooling of the bed using the procedures in §63.565(f)(2). Following the date on which the initial performance test is completed, the facility shall be operated with the total stream flow, as determined in §63.564(g)(3), no more than 20 percent below the baseline stream flow and with the carbon bed temperature (measured within 15 minutes after completion of the cooling cycle), as determined in §63.564(g)(3), no more than 10 percent or 5.6°C (10°F) above the baseline carbon bed temperature, whichever is less stringent.

(iii) Outlet VOC concentration of 1,000 ppmv for gasoline loading. Following the date on which the initial performance test is completed, the facility shall operate with a block average outlet VOC concentration as determined in §63.564(g)(1) of no more than 1,200 ppmv VOC.

(7) Condenser/refrigeration unit. During the initial performance test required in paragraph (b)(1) of this section, the owner or operator shall determine the efficiency of and/or the outlet VOC concentration from the recovery device used to comply with §63.562(b)(2), (3), and (4), (c)(3) or (4), and (d)(2) using the test methods in §63.565(d). The owner or operator shall comply with either paragraph (b)(7)(i), (ii), or (iii) of this section.

(i) VOC outlet concentration limit for required percent recovery efficiency. The owner or operator shall establish as an operating parameter the baseline VOC concentration using the procedures described in §63.565(g). Following the date on which the initial performance test is completed, the facility shall be operated with a block average outlet VOC concentration as determined in §63.564(h)(2) no more than 20 percent above the baseline VOC concentration.

(ii) Baseline temperature for required percent recovery efficiency. The owner or operator shall establish as an operating parameter the baseline temperature using the procedures described in §63.565(f). Following the date on which the initial performance test is completed, the facility shall operate with a block average temperature, as determined in §63.564(h)(1), no more than 28°C (50°F) above the baseline temperature.

(iii) Baseline parameters for 1,000 ppmv VOC concentration limit for gasoline loading. The owner or operator shall monitor either the outlet VOC concentration or the outlet temperature of the unit. For sources monitoring temperature, the owner or operator shall establish as an operating parameter the baseline temperature using the procedures described in §63.565(f). Following the date on which the initial performance test is completed, the facility shall operate with a block average outlet VOC concentration, as determined in §63.564(h)(2), of no more than 1,200 ppmv VOC or with a block average temperature, as determined in §63.564(h)(1), no more than 28°C (50°F) above the baseline temperature.

(8) Absorber. During the initial performance test required in paragraph (b)(1) of this section, the owner or operator shall determine the efficiency of the absorber and/or the outlet VOC concentration from the recovery device used to comply with §63.562(b)(2), (3), and (4), (c)(3) and (4), and (d)(2) using the test methods in §63.565(d). The owner or operator shall comply with either paragraph (b)(8)(i) or (ii) of this section.

(i) VOC outlet concentration limit for required percent recovery efficiency. The owner or operator shall establish as an operating parameter the baseline VOC concentration using the procedures described in §63.565(g). Following the date on which the initial performance test is completed, the facility shall be operated with a block average outlet VOC concentration as determined in §63.564(i)(1) no more than 20 percent above the baseline VOC concentration.

(ii) Baseline liquid-to-vapor ratio for required percent recovery efficiency. The owner or operator shall establish as an operating parameter the baseline liquid flow to vapor flow (L/V) ratio using the procedures described in §63.565(k). Following the date on which the initial performance test is completed, the facility shall operate with a block average L/V ratio, as determined in §63.564(i)(2), no more than 20 percent below the baseline L/V ratio.

(9) Alternative control devices. For sources complying with §63.562(b)(2), (3), and (4), (c)(3) and (4), and (d)(2) with the use of a control technology other than the devices discussed in paragraphs (b)(4) through (8) of this section, the owner or operator of an affected source shall provide to the Administrator information describing the design and operation of the air pollution control system, including recommendations for the operating parameter(s) to be monitored to indicate proper operation and maintenance of the air pollution control system. Based on this information, the Administrator shall determine the operating parameter(s) to be established during the performance test. During the initial performance test required in paragraph (b)(1) of this section, the owner or operator shall determine the efficiency of the air pollution control system using the test methods in §63.565(d). The device shall achieve at least the percent destruction efficiency or recovery efficiency required under §63.562(b)(2), (3), and (4), (c)(3) and (4), and (d)(2). The owner or operator shall establish the operating parameter(s) approved by the Administrator. Following the date on which the initial performance test is complete, the facility shall operate either above or below a maximum or minimum operating parameter, as appropriate.

(10) Emission estimation. The owner or operator of a source subject to §63.562(b)(2), (3), and (4) shall use the emission estimation procedures in §63.565(l) to calculate HAP emissions.

(c) Leak detection and repair for vapor collection systems and control devices. The following procedures are required for all sources subject to §63.562(b), (c), or (d).

(1) Annual leak detection and repair for vapor collection systems and control devices. The owner or operator of an affected source shall inspect and monitor all ductwork and piping and connections to vapor collection systems and control devices once each calendar year using Method 21.

(2) Ongoing leak detection and repair for vapor collection systems and control devices. If evidence of a potential leak is found by visual, audible, olfactory, or any other detection method, all ductwork and piping and connections to vapor collection systems and control devices shall be inspected to the extent necessary to positively identify the potential leak and any potential leaks shall be monitored within 5 days by Method 21. Each detection of a leak shall be recorded, and the leak shall be tagged until repaired.

(3) When a leak is detected, a first effort to repair the vapor collection system and control device shall be made within 15 days or prior to the next marine tank vessel loading operation, whichever is later.

[60 FR 48399, Sept. 19, 1995, as amended at 76 FR 22597, Apr. 21, 2011]

§63.564 Monitoring requirements.

(a)(1) The owner or operator of an affected source shall comply with the monitoring requirements in §63.8 of subpart A of this part in accordance with the provisions for applicability of subpart A to this subpart in Table 1 of §63.560 and the monitoring requirements in this section.

(2) Each owner or operator of an affected source shall monitor the parameters specified in this section. All monitoring equipment shall be installed such that representative measurements of emissions or process parameters from the source are obtained. For monitoring equipment purchased from a vendor, verification of the operational status of the monitoring equipment shall include completion of the manufacturer's written specifications or recommendations for installation, operation, and calibration of the system.

(3) Except for system breakdowns, out-of-control periods, repairs, maintenance periods, calibration checks, and zero (low-level) and high-level calibration drift adjustments, all continuous parametric monitoring systems (CPMS) and CEMS shall be in continuous operation while marine tank vessel loading operations are occuring and shall meet minimum frequency of operation requirements. Sources monitoring by use of CEMS and CPMS shall complete a minimum of one cycle of operation (sampling, analyzing, and/or data recording) for each successive 15-minute period.

(4) The owner or operator of a CMS installed in accordance with these emissions standards shall comply with the performance specifications either in performance specification (PS) 8 in 40 CFR part 60, appendix B for CEMS or in §63.7(c)(6) of subpart A of this part for CPMS.

(5) A CEMS is out of control when the measured values (i.e., daily calibrations, multipoint calibrations, and performance audits) exceed the limits specified in either PS 8 or in §63.8(c)(7) of subpart A of this part. The owner or operator of a CEMS that is out of control shall submit all information concerning out of control periods, including start and end dates and hours and descriptions of corrective actions taken, in the excess emissions and continuous monitoring system performance report required in §63.567(e).

(b) Vapor collection system of terminal. Owners or operators of a source complying with §63.563(a)(1) that uses a vapor collection system that contains valves that could divert a vent stream from a control device used to comply with the provisions of this subpart shall comply with paragraph (b)(1), (2), or (3) of this section.

(1) Measure and record the vent stream flowrate of each by-pass line once every 15 minutes. The owner or operator shall install, calibrate, maintain, and operate a flow indicator and data recorder. The flow indicator shall be installed immediately downstream of any valve (i.e., entrance to by-pass line) that could divert the vent stream from the control device to the atmosphere.

(2) Measure the vent stream flowrate of each by-pass line once every 15 minutes. The owner or operator shall install, calibrate, maintain, and operate a flow indicator with either an audio or visual alarm. The flow indicator and alarm shall be installed immediately downstream of any valve (i.e., entrance to by-pass line) that could divert the vent stream from the control device to the atmosphere. The alarm shall be checked every 6 months to demonstrate that it is functioning properly.

(3) Visually inspect the seal or closure mechanism once during each marine tank vessel loading operation and at least once every month to ensure that the valve is maintained in the closed position and that the vent stream is not diverted through the by-pass line; record all times when the car seals have been broken and the valve position has been changed. Each by-pass line valve shall be secured in the closed position with a car-seal or a lock-and-key type configuration.

(c) Pressure/vacuum settings for the marine tank vessel's vapor collection equipment. Owners or operators of a source complying with §63.563(a)(3) shall measure continuously the operating pressure of the marine tank vessel during loading.