['Air Programs']

['Air Emissions']

10/12/2023

...

§1090.1500 Overview.

(a) A retailer or WPC must comply with the labeling requirements in §§1090.1510 and 1090.1515, as applicable, and the refueling hardware requirements in §§1090.1550 through 1090.1565, as applicable.

(b) An alternative label design to those specified in this subpart may be used if the design is approved by EPA prior to use and meets all the following requirements:

(1) The alternative label must be similar in substance and appearance to the EPA-required label.

(2) The alternative label must contain the same informational elements as the EPA-required label.

(3) The alternative label must be submitted as specified in §1090.10.

[85 FR 78469, Dec. 4, 2020]

§1090.1510 E15 labeling provisions.

Any retailer or WPC dispensing E15 must apply a label to the fuel dispenser as follows:

(a) Position the label to clearly identify which control the consumer will use to select E15. If the dispenser is set up to dispense E15 without the consumer taking action to select the fuel, position the label on a vertical surface in a prominent place, approximately at eye level.

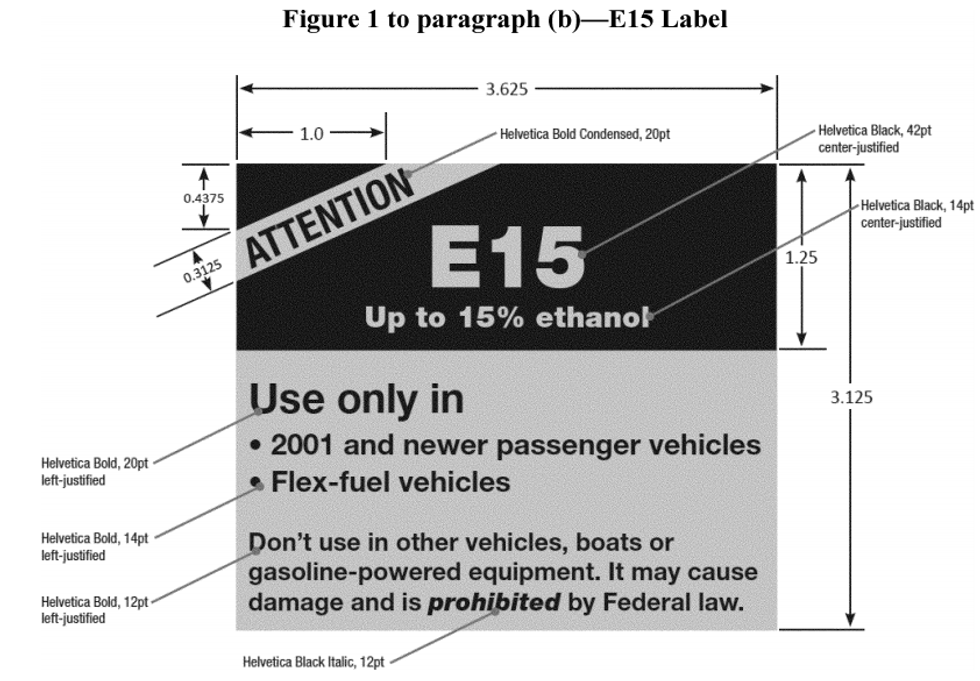

(b) Figure 1 of this paragraph shows the required content and formatting. Use black letters on an orange background for the lower portion and the diagonal “Attention” field and use orange letters on a black background for the rest of the upper portion. Font size is shown in Figure 1. Set vertical position and line spacing as appropriate for each field. Dimensions are nominal values.

[85 FR 78469, Dec. 4, 2020]

§1090.1515 Diesel sulfur labeling provisions.

A retailer or WPC dispensing heating oil, 500 ppm LM diesel fuel, or ECA marine fuel must apply labels to fuel dispensers as follows:

(a) Labels must be in a prominent location where the consumer will select or dispense either the corresponding fuel or heating oil. The label content must be in block letters of no less than 24-point bold type, printed in a color contrasting with the background.

(b) Labels must include the following statements, or equivalent alternative statements approved by EPA:

(1) For dispensing heating oil along with any kind of diesel fuel for any kind of engine, vehicle, or equipment, apply the following label:

Heating Oil

Warning

Federal law prohibits use in highway vehicles or engines, or in nonroad, locomotive, or marine diesel engines.

Its use may damage these diesel engines.

(2) For dispensing 500 ppm LM diesel fuel, apply the following label:

Locomotive and Marine Diesel Fuel (500 ppm Sulfur Maximum)

Warning

Federal law prohibits use in nonroad engines or in highway vehicles or engines.

(3) For dispensing ECA marine fuel, apply the following label:

ECA Marine Fuel (1,000 ppm Sulfur Maximum)

For use in Category 3 (C3) marine vessels only.

Warning

Federal law prohibits use in any engine that is not installed in a C3 marine vessel; use of fuel oil with a sulfur content greater than 1,000 ppm in an ECA is prohibited except as allowed by 40 CFR part 1043.

Note: If a pump dispensing 500 ppm LM diesel fuel is labeled with the “LOW SULFUR LOCOMOTIVE AND MARINE DIESEL FUEL (500 ppm Sulfur Maximum)” label, the retailer or WPC does not need to replace this label.

[85 FR 78469, Dec. 4, 2020]

§1090.1550 Requirements for gasoline dispensing nozzles used with motor vehicles.

The following requirements apply for any nozzle installation used for dispensing gasoline into motor vehicles:

(a) Nozzles must meet the following hardware specifications:

(1) The outside diameter of the terminal end must not be greater than 21.3 mm.

(2) The terminal end must have a straight section of at least 63 mm.

(3) The retaining spring must terminate at least 76 mm from the terminal end.

(b) The dispensing flow rate must not exceed a maximum value of 10 gallons per minute. The flow rate may be controlled through any means in the pump/dispenser system, as long as it does not exceed the specified maximum value.

[85 FR 78469, Dec. 4, 2020; 88 FR 4718, Jan. 24, 2023]

§1090.1555 Requirements for gasoline dispensing nozzles used primarily with marine vessels.

The refueling hardware specifications of this section apply for any nozzle installation used primarily for dispensing gasoline into marine vessels. Note that nozzles meeting these specifications also meet the specifications of §1090.1550(a).

(a) The outside diameter of the terminal end must have a diameter of 20.93 ± 00.43 mm.

(b) The spout must include an aspirator hole for automatic shutoff positioned with a center that is 17.0 ± 01.3 mm from the terminal end of the spout.

(c) The terminal end must have a straight section of at least 63.4 mm with no holes or grooves other than the aspirator hole.

(d) The retaining spring (if applicable) must terminate at least 76 mm from the terminal end.

[85 FR 78469, Dec. 4, 2020]

§1090.1560 Requirements related to dispensing natural gas.

(a) Except for pumps dedicated to heavy-duty vehicles, any pump installation used for dispensing natural gas into motor vehicles must have a nozzle and hose configuration that vents no more than 1.2 grams of natural gas during a complete refueling event for a vehicle that meets the requirements of 40 CFR 86.1813-17(f)(1).

(b) Determine the amount of natural gas vented using calculations based on the geometric shape of the nozzle and hose.

[85 FR 78469, Dec. 4, 2020]

§1090.1565 Requirements related to dispensing liquefied petroleum gas.

(a) Except for pumps dedicated to heavy-duty vehicles, any pump installation used for dispensing liquefied petroleum gas into motor vehicles must have a nozzle that has no greater than 2.0 cm3 dead space from which liquefied petroleum gas will be released when the nozzle disconnects from the vehicle.

(b) Determine the volume of the nozzle cavity using calculations based on the geometric shape of the nozzle, with an assumed flat surface where the nozzle face seals against the vehicle.

[85 FR 78469, Dec. 4, 2020]

[85 FR 78469, Dec. 4, 2020]

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.