['Air Programs']

['Hazardous Air Pollutants']

02/27/2022

...

Table 1 to Subpart MMMM of Part 63 - Operating Limits if Using the Emission Rate With Add-On Controls Option

If you are required to comply with operating limits by §63.3892(c), you must comply with the applicable operating limits in the following table:

| For the following device . . . | You must meet the following operating limit . . . | And you must demonstrate continuous compliance with the operating limit by . . . |

|---|---|---|

| 1. Thermal oxidizer | a. The average combustion temperature in any 3-hour period must not fall below the combustion temperature limit established according to §63.3967(a) | i. Collecting the combustion temperature data according to §63.3968(c); ii. Reducing the data to 3-hour block averages; and iii. Maintaining the 3-hour average combustion temperature at or above the temperature limit. |

| 2. Catalytic oxidizer | a. The average temperature measured just before the catalyst bed in any 3-hour period must not fall below the limit established according to §63.3967(b) (for magnet wire coating machines, temperature can be monitored before or after the catalyst bed); and either | i. Collecting the temperature data according to §63.3968(c); ii. Reducing the data to 3-hour block averages; and iii. Maintaining the 3-hour average temperature before (or for magnet wire coating machines after) the catalyst bed at or above the temperature limit. |

| b. Ensure that the average temperature difference across the catalyst bed in any 3-hour period does not fall below the temperature difference limit established according to §63.3967(b) (2); or | i. Collecting the temperature data according to §63.3968(c); ii. Reducing the data to 3-hour block averages; and iii. Maintaining the 3-hour average temperature difference at or above the temperature difference limit. | |

| c. Develop and implement an inspection and maintenance plan according to §63.3967(b)(4) or for magnet wire coating machines according to section 3.0 of appendix A to this subpart | i. Maintaining and up-to-date inspection and maintenance plan, records of annual catalyst activity checks, records of monthly inspections of the oxidizer system, and records of the annual internal inspections of the catalyst bed. If a problem is discovered during a monthly or annual inspection required by §63.3967(b)(4) or for magnet wire coating machines by section 3.0 of appendix A to this subpart, you must take corrective action as soon as practicable consistent with the manufacturer's recommendations. | |

| 3. Regenerative carbon adsorber | a. The total regeneration desorbing gas (e.g., steam or nitrogen) mass flow for each carbon bed regeneration cycle must not fall below the total regeneration desorbing gas mass flow limit established according to §63.3967(c); and | i. Measuring the total regeneration desorbing gas (e.g., steam or nitrogen) mass flow for each regeneration cycle according to §63.3968(d); and ii. Maintaining the total regeneration desorbing gas mass flow at or above the mass flow limit. |

| b. The temperature of the carbon bed, after completing each regeneration and any cooling cycle, must not exceed the carbon bed temperature limit established according to §63.3967(c) | i. Measuring the temperature of the carbon bed after completing each regeneration and any cooling cycle according to §63.3968(d); and ii. Operating the carbon beds such that each carbon bed is not returned to service until completing each regeneration and any cooling cycle until the recorded temperature of the carbon bed is at or below the temperature limit. | |

| 4. Condenser | a. The average condenser outlet (product side) gas temperature in any 3-hour period must not exceed the temperature limit established according to §63.3967(d) | i. Collecting the condenser outlet (product side) gas temperature according to §63.3968(e); ii. Reducing the data to 3-hour block averages; and iii. Maintaining the 3-hour average gas temperature at the outlet at or below the temperature limit. |

| 5. Concentrators, including zeolite wheels and rotary carbon adsorbers | a. The average gas temperature of the desorption concentrate stream in any 3-hour period must not fall below the limit established according to §63.3967(e); and | i. Collecting the temperature data according to 63.3968(f); ii. Reducing the data to 3-hour block averages; and iii. Maintaining the 3-hour average temperature at or above the temperature limit. |

| b. The average pressure drop of the dilute stream across the concentrator in any 3-hour period must not fall below the limit established according to §63.3967(e) | i. Collecting the pressure drop data according to 63.3968(f); ii. Reducing the pressure drop data to 3-hour block averages; and iii. Maintaining the 3-hour average pressure drop at or above the pressure drop limit. | |

| 6. Emission capture system that is a PTE according to §63.3965(a) | a. The direction of the air flow at all times must be into the enclosure; and either | i. Collecting the direction of air flow, and either the facial velocity of air through all natural draft openings according to §63.3968(b)(1) or the pressure drop across the enclosure according to §63.3968(g)(2); and ii. Maintaining the facial velocity of air flow through all natural draft openings or the pressure drop at or above the facial velocity limit or pressure drop limit, and maintaining the direction of air flow into the enclosure at all times. |

| b. The average facial velocity of air through all natural draft openings in the enclosure must be at least 200 feet per minutes; or | i. See items 6.a.i and 6.a.ii. | |

| c. The pressure drop across the enclosure must be at least 0.007 inch H2O, as established in Method 204 of appendix M to 40 CFR part 51 | i. See items 6.a.i and 6.a.ii. | |

| 7. Emission capture system that is not a PTE according to §63.3965(a) | a. The average gas volumetric flow rate or duct static pressure in each duct between a capture device and add-on control device inlet in any 3-hour period must not fall below the average volumetric flow rate or duct static pressure limit established for that capture device according to §63.3967(f) | i. Collecting the gas volumetric flow rate or duct static pressure for each capture device according to §63.3968(g); ii. Reducing the data to 3-hour block averages; and iii. Maintaining the 3-hour average gas volumetric flow rate or duct static pressure for each capture device at or above the gas volumetric flow rate or duct static pressure limited. |

Table 2 to Subpart MMMM of Part 63 - Applicability of General Provisions to Subpart MMMM of Part 63

You must comply with the applicable General Provisions requirements according to the following table:

| Citation | Subject | Applicable to subpart MMMM | Explanation |

|---|---|---|---|

| §63.1(a)(1)-(14) | General Applicability | Yes | |

| §63.1(b)(1)-(3) | Initial Applicability Determination | Yes | Applicability to subpart MMMM is also specified in §63.3881. |

| §63.1(c)(1) | Applicability After Standard Established | Yes | |

| §63.1(c)(2)-(3) | Applicability of Permit Program for Area Sources | No | Area sources are not subject to subpart MMMM. |

| §63.1(c)(4)-(5) | Extensions and Notifications | Yes | |

| §63.1(c)(6) | Reclassification | Yes | |

| §63.1(e) | Applicability of Permit Program Before Relevant Standard is Set | Yes | |

| §63.2 | Definitions | Yes | Additional definitions are specified in §63.3981. |

| §63.1(a)-(c) | Units and Abbreviations | Yes | |

| §63.4(a)(1)-(5) | Prohibited Activities | Yes | |

| §63.4(b)-(c) | Circumvention/Severability | Yes | |

| §63.5(a) | Construction/Reconstruction | Yes | |

| §63.5(b)(1)-(6) | Requirements for Existing Newly Constructed, and Reconstructed Sources | Yes | |

| §63.5(d) | Application for Approval of Construction/Reconstruction | Yes | |

| §63.5(e) | Approval of Construction/Reconstruction | Yes | |

| §63.5(f) | Approval of Construction/Reconstruction Based on Prior State Review | Yes | |

| §63.6(a) | Compliance With Standards and Maintenance Requirements—Applicability | Yes | |

| §63.6(b)(1)-(7) | Compliance Dates for New and Reconstructed Sources | Yes | Section 63.3883 specifies the compliance dates. |

| §63.6(c)(1)-(5) | Compliance Dates for Existing Sources | Yes | Section 63.3883 specifies the compliance dates. |

| §63.6(e)(1)-(2) | Operation and Maintenance | Yes before January 5, 2021. No on and after January 5, 2021 | See §63.3900(b) for general duty requirement. |

| §63.6(e)(3) | SSMP | Yes before January 5, 2021. No on and after January 5, 2021 | |

| §63.6(f)(1) | Compliance Except During SSM | Yes before January 5, 2021. No on and after January 5, 2021 | |

| §63.6(f)(2)-(3) | Methods for Determining Compliance. | Yes | |

| §63.6(g)(1)-(3) | Use of an Alternative Standard | Yes | |

| §63.6(h) | Compliance With Opacity/Visible Emission Standards | No | Subpart MMMM does not establish opacity standards and does not require continuous opacity monitoring systems (COMS). |

| §63.6(i)(1)-(16) | Extension of Compliance | Yes | |

| §63.6(j) | Presidential Compliance Exemption | Yes | |

| §63.7(a)(1) | Performance Test Requirements—Applicability | Yes | Applies to all affected sources. Additional requirements for performance testing are specified in §§63.3964, 63.3965, and 63.3966. |

| §63.7(a)(2) | Performance Test Requirements—Dates | Yes | Applies only to performance tests for capture system and control device efficiency at sources using these to comply with the standard. Section 63.3960 specifies the schedule for performance test requirements that are earlier than those specified in §63.7(a)(2). |

| §63.7(a)(3)-(4) | Performance Tests Required By the Administrator, Force Majeure | Yes | |

| §63.7(b)-(d) | Performance Test Requirements—Notification, Quality Assurance, Facilities Necessary for Safe Testing, Conditions During Test | Yes | Applies only to performance tests for capture system and add-on control device efficiency at sources using these to comply with the standard. |

| §63.7(e)(1) | Conduct of Performance Tests | Yes before January 5, 2021. No on and after January 5, 2021 | See §§63.3964. |

| §63.7(e)(2)-(4) | Conduct of Performance Tests | Yes | |

| §63.7(f) | Performance Test Requirements—Use of Alternative Test Method | Yes | Applies to all test methods except those used to determine capture system efficiency. |

| §63.7(g)-(h) | Performance Test Requirements—Data Analysis, Recordkeeping, Reporting, Waiver of Test | Yes | Applies only to performance tests for capture system and add-on control device efficiency at sources using these to comply with the standard. |

| §63.8(a)(1)-(3) | Monitoring Requirements—Applicability | Yes | Applies only to monitoring of capture system and add-on control device efficiency at sources using these to comply with the standard. Additional requirements for monitoring are specified in §63.3968. |

| §63.8(a)(4) | Additional Monitoring Requirements | No | Subpart MMMM does not have monitoring requirements for flares. |

| §63.8(b) | Conduct of Monitoring | Yes | |

| §63.8(c)(1) | Continuous Monitoring System (CMS) Operation and Maintenance | Yes before January 5, 2021. No on and after January 5, 2021 | Section 63.3968 specifies the requirements for the operation of CMS for capture systems and add-on control devices at sources using these to comply. |

| §63.8(c)(2)-(3) | CMS Operation and Maintenance | Yes | Applies only to monitoring of capture system and add-on control device efficiency at sources using these to comply with the standard. Additional requirements for CMS operations and maintenance are specified in §63.3968. |

| §63.8(c)(4) | CMS | No | §63.3968 specifies the requirements for the operation of CMS for capture systems and add-on control devices at sources using these to comply. |

| §63.8(c)(5) | COMS | No | Subpart MMMM does not have opacity or visible emission standards. |

| §63.8(c)(6) | CMS Requirements | No | Section 63.3968 specifies the requirements for monitoring systems for capture systems and add-on control devices at sources using these to comply. |

| §63.8(c)(7) | CMS Out-of-Control Periods | Yes | |

| §63.8(c)(8) | CMS Out-of-Control Periods and Reporting | No | §63.3920 requires reporting of CMS out-of-control periods. |

| §63.8(d)-(e) | Quality Control Program and CMS Performance Evaluation | No | Subpart MMMM does not require the use of continuous emissions monitoring systems. |

| §63.8(f)(1)-(5) | Use of an Alternative Monitoring Method | Yes | |

| §63.8(f)(6) | Alternative to Relative Accuracy Test | No | Subpart MMMM does not require the use of continuous emissions monitoring systems. |

| §63.8(g)(1)-(5) | Data Reduction | No | Sections 63.3967 and 63.3968 specify monitoring data reduction. |

| §63.9(a)-(d) | Notification Requirements | Yes | |

| §63.9(e) | Notification of Performance Test | Yes | Applies only to capture system and add-on control device performance tests at sources using these to comply with the standard. |

| §63.9(f) | Notification of Visible Emissions/Opacity Test | No | Subpart MMMM does not have opacity or visible emissions standards. |

| §63.9(g)(1)-(3) | Additional Notifications When Using CMS | No | Subpart MMMM does not require the use of continuous emissions monitoring systems. |

| §63.9(h) | Notification of Compliance Status | Yes | Section 63.3910 specifies the dates for submitting the notification of compliance status. |

| §63.9(i) | Adjustment of Submittal Deadlines | Yes | |

| §63.9(j) | Change in Previous Information | Yes | |

| §63.9(k) | Electronic reporting procedures | Yes | Only as specified in §63.9(j). |

| §63.10(a) | Recordkeeping/Reporting—Applicability and General Information | Yes | |

| §63.10(b)(1) | General Recordkeeping Requirements | Yes | Additional requirements are specified in §§63.3930 and 63.3931. |

| §63.10(b)(2)(i)-(ii) | Recordkeeping of Occurrence and Duration of Startups and Shutdowns and of Failures to Meet Standards | Yes before January 5, 2021. No on and after January 5, 2021 | See §63.3930(j). |

| §63.10(b)(2)(iii) | Recordkeeping Relevant to Maintenance of Air Pollution Control and Monitoring Equipment | Yes | §63.10(b)(2)(iii). |

| §63.10(b)(2)(iv)-(v) | Actions Taken to Minimize Emissions During SSM | Yes before January 5, 2021. No on and after January 5, 2021 | See §63.3930(j) for a record of actions taken to minimize emissions duration a deviation from the standard. |

| §63.10(b)(2)(vi) | Recordkeeping for CMS Malfunctions | Yes before January 5, 2021. No on and after January 5, 2021 | See §63.3930(j) for records of periods of deviation from the standard, including instances where a CMS is inoperative or out-of-control. |

| §63.10(b)(2)(xii) | Records | Yes | |

| §63.10(b)(2)(xiii) | ? | No | Subpart MMMM does not require the use of continuous emissions monitoring systems. |

| §63.10(b)(2)(xiv) | ? | Yes | |

| §63.10(b)(3) | Recordkeeping Requirements for Applicability Determinations | Yes | |

| §63.10(c)(1)-(6) | Additional Recordkeeping Requirements for Sources with CMS | Yes | |

| §63.10(c)(7)-(8) | Additional Recordkeeping Requirements for Sources with CMS | No | See §63.3930(j) for records of periods of deviation from the standard, including instances where a CMS is inoperative or out-of-control. |

| §63.10(c)(10)-(14) | Additional Recordkeeping Requirements for Sources with CMS | Yes | |

| §63.10(c)(15) | Records Regarding the SSMP | Yes before January 5, 2021. No on and after January 5, 2021 | |

| §63.10(d)(1) | General Reporting Requirements | Yes | Additional requirements are specified in §63.3920. |

| §63.10(d)(2) | Report of Performance Test Results | Yes | Additional requirements are specified in §63.3920(b) and (d). |

| §63.10(d)(3) | Reporting Opacity or Visible Emissions Observations | No | Subpart MMMM does not require opacity or visible emissions observations. |

| §63.10(d)(4) | Progress Reports for Sources With Compliance Extensions | Yes | |

| §63.10(d)(5) | SSM Reports | Yes before January 5, 2021. No on and after January 5, 2021 | See §63.3920 (a)(7) and (c). |

| §63.10(e)(1)-(2) | Additional CMS Reports | No | Subpart MMMM does not require the use of continuous emissions monitoring systems. |

| §63.10(e)(3) | Excess Emissions/CMS Performance Reports | No | Section 63.3920(b) specifies the contents of periodic compliance reports. |

| §63.10(e)(4) | COMS Data Reports | No | Subpart MMMMM does not specify requirements for opacity or COMS. |

| §63.10(f) | Recordkeeping/Reporting Waiver | Yes | |

| §63.11 | Control Device Requirements/Flares | No | Subpart MMMM does not specify use of flares for compliance. |

| §63.12 | State Authority and Delegations | Yes | |

| §63.13 | Addresses | Yes | |

| §63.14 | IBR | Yes | |

| §63.15 | Availability of Information/Confidentiality | Yes |

[85 FR 41145, July 8, 2020; 85 FR 73906, Nov. 19, 2020]

Table 3 to Subpart MMMM of Part 63 - Default Organic HAP Mass Fraction for Solvents and Solvent Blends

You may use the mass fraction values in the following table for solvent blends for which you do not have test data or manufacturer's formulation data and which match either the solvent blend name or the chemical abstract series (CAS) number. If a solvent blend matches both the name and CAS number for an entry, that entry's organic HAP mass fraction must be used for that solvent blend. Otherwise, use the organic HAP mass fraction for the entry matching either the solvent blend name or CAS number, or use the organic HAP mass fraction from table 4 to this subpart if neither the name or CAS number match.

| Solvent/solvent blend | CAS. No. | Average organic HAP mass fraction | Typical organic HAP, percent by mass |

|---|---|---|---|

| 1. Toluene | 108-88-3 | 1.0 | Toluene. |

| 2. Xylene(s) | 1330-20-7 | 1.0 | Xylenes, ethylbenzene. |

| 3. Hexane | 110-54-3 | 0.5 | n-hexane. |

| 4. n-Hexane | 110-54-3 | 1.0 | n-hexane. |

| 5. Ethylbenzene | 100-41-4 | 1.0 | Ethylbenzene. |

| 6. Aliphatic 140 | 0 | None. | |

| 7. Aromatic 100 | 0.02 | 1% xylene, 1% cumene. | |

| 8. Aromatic 150 | 0.09 | Naphthalene. | |

| 9. Aromatic naphtha | 64742-95-6 | 0.02 | 1% xylene, 1% cumene. |

| 10. Aromatic solvent | 64742-94-5 | 0.1 | Naphthalene. |

| 11. Exempt mineral spirits | 8032-32-4 | 0 | None. |

| 12. Ligroines (VM & P) | 8032-32-4 | 0 | None. |

| 13. Lactol spirits | 64742-89-6 | 0.15 | Toluene. |

| 14. Low aromatic white spirit | 64742-82-1 | 0 | None. |

| 15. Mineral spirits | 64742-88-7 | 0.01 | Xylenes. |

| 16. Hydrotreated naphtha | 64742-48-9 | 0 | None. |

| 17. Hydrotreated light distillate | 64742-47-8 | 0.001 | Toluene. |

| 18. Stoddard solvent | 8052-41-3 | 0.01 | Xylenes. |

| 19. Super high-flash naphtha | 64742-95-6 | 0.05 | Xylenes. |

| 20. Varsol ® solvent | 8052-49-3 | 0.01 | 0.5% xylenes, 0.5% ethylbenzene. |

| 21. VM & P naphtha | 64742-89-8 | 0.06 | 3% toluene, 3% xylene. |

| 22. Petroleum distillate mixture | 68477-31-6 | 0.08 | 4% naphthalene, 4% biphenyl. |

Table 4 to Subpart MMMM of Part 63 - Default Organic HAP Mass Fraction for Petroleum Solvent Groups a

You may use the mass fraction values in the following table for solvent blends for which you do not have test data or manufacturer's formulation data.

| Solvent type | Average organic HAP mass fraction | Typical organic HAP, percent by mass |

|---|---|---|

| a Use this table only if the solvent blend does not match any of the solvent blends in Table 3 to this subpart by either solvent blend name or CAS number and you only know whether the blend is aliphatic or aromatic. b Mineral Spirits 135, Mineral Spirits 150 EC, Naphtha, Mixed Hydrocarbon, Aliphatic Hydrocarbon, Aliphatic Naphtha, Naphthol Spirits, Petroleum Spirits, Petroleum Oil, Petroleum Naphtha, Solvent Naphtha, Solvent Blend. c Medium-flash Naphtha, High-flash Naphtha, Aromatic Naphtha, Light Aromatic Naphtha, Light Aromatic Hydrocarbons, Aromatic Hydrocarbons, Light Aromatic Solvent. | ||

| Aliphatic b | 0.03 | 1% Xylene, 1% Toluene, and 1% Ethylbenzene. |

| Aromatic c | 0.06 | 4% Xylene, 1% Toluene, and 1% Ethylbenzene. |

Table 5 to Subpart MMMM of Part 63—List of HAP That Must Be Counted Toward Total Organic HAP Content If Present at 0.1 Percent or More by Mass

| Chemical Name | CAS No. |

| 1,1,2,2-Tetrachloroethane | 79-34-5 |

| 1,1,2-Trichloroethane | 79-00-5 |

| 1,1-Dimethylhydrazine | 57-14-7 |

| 1,2-Dibromo-3-chloropropane | 96-12-8 |

| 1,2-Diphenylhydrazine | 122-66-7 |

| 1,3-Butadiene | 106-99-0 |

| 1,3-Dichloropropene | 542-75-6 |

| 1,4-Dioxane | 123-91-1 |

| 2,4,6-Trichlorophenol | 88-06-2 |

| 2,4/2,6-Dinitrotoluene (mixture) | 25321-14-6 |

| 2,4-Dinitrotoluene | 121-14-2 |

| 2,4-Toluene diamine | 95-80-7 |

| 2-Nitropropane | 79-46-9 |

| 3,3?-Dichlorobenzidine | 91-94-1 |

| 3,3?-Dimethoxybenzidine | 119-90-4 |

| 3,3?-Dimethylbenzidine | 119-93-7 |

| 4,4?-Methylene bis(2-chloroaniline) | 101-14-4 |

| Acetaldehyde | 75-07-0 |

| Acrylamide | 79-06-1 |

| Acrylonitrile | 107-13-1 |

| Allyl chloride | 107-05-1 |

| alpha-Hexachlorocyclohexane (a-HCH) | 319-84-6 |

| Aniline | 62-53-3 |

| Benzene | 71-43-2 |

| Benzidine | 92-87-5 |

| Benzotrichloride | 98-07-7 |

| Benzyl chloride | 100-44-7 |

| beta-Hexachlorocyclohexane (b-HCH) | 319-85-7 |

| Bis(2-ethylhexyl)phthalate | 117-81-7 |

| Bis(chloromethyl)ether | 542-88-1 |

| Bromoform | 75-25-2 |

| Captan | 133-06-2 |

| Carbon tetrachloride | 56-23-5 |

| Chlordane | 57-74-9 |

| Chlorobenzilate | 510-15-6 |

| Chloroform | 67-66-3 |

| Chloroprene | 126-99-8 |

| Cresols (mixed) | 1319-77-3 |

| DDE | 3547-04-4 |

| Dichloroethyl ether | 111-44-4 |

| Dichlorvos | 62-73-7 |

| Epichlorohydrin | 106-89-8 |

| Ethyl acrylate | 140-88-5 |

| Ethylene dibromide | 106-93-4 |

| Ethylene dichloride | 107-06-2 |

| Ethylene oxide | 75-21-8 |

| Ethylene thiourea | 96-45-7 |

| Ethylidene dichloride (1,1-Dichloroethane) | 75-34-3 |

| Formaldehyde | 50-00-0 |

| Heptachlor | 76-44-8 |

| Hexachlorobenzene | 118-74-1 |

| Hexachlorobutadiene | 87-68-3 |

| Hexachloroethane | 67-72-1 |

| Hydrazine | 302-01-2 |

| Isophorone | 78-59-1 |

| Lindane (hexachlorocyclohexane, all isomers) | 58-89-9 |

| m-Cresol | 108-39-4 |

| Methylene chloride | 75-09-2 |

| Naphthalene | 91-20-3 |

| Nitrobenzene | 98-95-3 |

| Nitrosodimethylamine | 62-75-9 |

| o-Cresol | 95-48-7 |

| o-Toluidine | 95-53-4 |

| Parathion | 56-38-2 |

| p-Cresol | 106-44-5 |

| p-Dichlorobenzene | 106-46-7 |

| Pentachloronitrobenzene | 82-68-8 |

| Pentachlorophenol | 87-86-5 |

| Propoxur | 114-26-1 |

| Propylene dichloride | 78-87-5 |

| Propylene oxide | 75-56-9 |

| Quinoline | 91-22-5 |

| Tetrachloroethene | 127-18-4 |

| Toxaphene | 8001-35-2 |

| Trichloroethylene | 79-01-6 |

| Trifluralin | 1582-09-8 |

| Vinyl bromide | 593-60-2 |

| Vinyl chloride | 75-01-4 |

| Vinylidene chloride | 75-35-4 |

[85 FR 41148, July 8, 2020]

Appendix A to Subpart MMMM of Part 63 - Alternative Capture Efficiency and Destruction Efficiency Measurement and Monitoring Procedures for Magnet Wire Coating Operations

1.0 Introduction.

1.1 These alternative procedures for capture efficiency and destruction efficiency measurement and monitoring are intended principally for newer magnet wire coating machines where the control device is internal and integral to the oven so that it is difficult or infeasible to make gas measurements at the inlet to the control device.

1.2 In newer gas fired magnet wire ovens with thermal control (no catalyst), the burner tube serves as the control device (thermal oxidizer) for the process. The combustion of solvents in the burner tube is the principal source of heat for the oven.

1.3 In newer magnet wire ovens with a catalyst there is either a burner tube (gas fired ovens) or a tube filled with electric heating elements (electric heated oven) before the catalyst. A large portion of the solvent is often oxidized before reaching the catalyst. The combustion of solvents in the tube and across the catalyst is the principal source of heat for the oven. The internal catalyst in these ovens cannot be accessed without disassembly of the oven. This disassembly includes removal of the oven insulation. Oven reassembly often requires the installation of new oven insulation.

1.4 Some older magnet wire ovens have external afterburners. A significant portion of the solvent is oxidized within these ovens as well.

1.5 The alternative procedure for destruction efficiency determines the organic carbon content of the volatiles entering the control device based on the quantity of coating used, the carbon content of the volatile portion of the coating and the efficiency of the capture system. The organic carbon content of the control device outlet (oven exhaust for ovens without an external afterburner) is determined using Method 25 or 25A.

1.6 When it is difficult or infeasible to make gas measurements at the inlet to the control device, measuring capture efficiency with a gas-to-gas protocol (see §63.3965(d)) which relies on direct measurement of the captured gas stream will also be difficult or infeasible. In these situations, capture efficiency measurement is more appropriately done with a procedure which does not rely on direct measurement of the captured gas stream.

1.7 Magnet wire ovens are relatively small compared to many other coating ovens. The exhaust rate from an oven is low and varies as the coating use rate and solvent loading rate change from job to job. The air balance in magnet wire ovens is critical to product quality. Magnet wire ovens must be operated under negative pressure to avoid smoke and odor in the workplace, and the exhaust rate must be sufficient to prevent over heating within the oven.

1.8 The liquid and gas measurements needed to determine capture efficiency and control device efficiency using these alternative procedures may be made simultaneously.

1.9 Magnet wire facilities may have many (e.g., 20 to 70 or more) individual coating lines each with its own capture and control system. With approval, representative capture efficiency and control device efficiency testing of one magnet wire coating machine out of a group of identical or very similar magnet wire coating machines may be performed rather than testing every individual magnet wire coating machine. The operating parameters must be established for each tested magnet wire coating machine during each capture efficiency test and each control device efficiency test. The operating parameters established for each tested magnet wire coating machine also serve as the operating parameters for untested or very similar magnet wire coating machines represented by a tested magnet wire coating machine.

2.0 Capture Efficiency.

2.1 If the capture system is a permanent total enclosure as described in §63.3965(a), then its capture efficiency may be assumed to be 100 percent.

2.2 If the capture system is not a permanent total enclosure, then capture efficiency must be determined using the liquid-to-uncaptured-gas protocol using a temporary total enclosure or building enclosure in §63.3965(c), or an alternative capture efficiency protocol (see §63.3965(e)) which does not rely on direct measurement of the captured gas stream.

2.3 As an alternative to establishing and monitoring the capture efficiency operating parameters in §63.3967(f), the monitoring described in either section 2.4 or 2.5, and the monitoring described in sections 2.6 and 2.7 may be used for magnet wire coating machines.

2.4 Each magnet wire oven must be equipped with an interlock mechanism which will stop or prohibit the application of coating either when any exhaust fan for that oven is not operating or when the oven experiences an over limit temperature condition.

2.5 Each magnet wire oven must be equipped with an alarm which will be activated either when any oven exhaust fan is not operating or when the oven experiences an over limit temperature condition.

2.6 If the interlock in 2.4 or the alarm in 2.5 is monitoring for over limit temperature conditions, then the temperature(s) that will trigger the interlock or the alarm must be included in the start-up, shutdown and malfunction plan and the interlock or alarm must be set to be activated when the oven reaches that temperature.

2.7 Once every 6 months, each magnet wire oven must be checked using a smoke stick or equivalent approach to confirm that the oven is operating at negative pressure compared to the surrounding atmosphere.

3.0 Control Device Efficiency.

3.1 Determine the weight fraction carbon content of the volatile portion of each coating, thinner, additive, or cleaning material used during each test run using either the procedure in section 3.2 or 3.3.

3.2 Following the procedures in Method 204F, distill a sample of each coating, thinner, additive, or cleaning material used during each test run to separate the volatile portion. Determine the weight fraction carbon content of each distillate using ASTM Method D5291-02, “Standard Test Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Petroleum Products and Lubricants” (incorporated by reference, see §63.14).

3.3 Analyze each coating, thinner, additive or cleaning material used during each test run using Method 311. For each volatile compound detected in the gas chromatographic analysis of each coating, thinner, additive, or cleaning material calculate the weight fraction of that whole compound in the coating, thinner, additive, or cleaning material. For each volatile compound detected in the gas chromatographic analysis of each coating, thinner, additive, or cleaning material calculate the weight fraction of the carbon in that compound in the coating, thinner, additive, or cleaning material. Calculate the weight fraction carbon content of each coating, thinner, additive, or cleaning material as the ratio of the sum of the carbon weight fractions divided by the sum of the whole compound weight fractions.

3.4 Determine the mass fraction of total volatile hydrocarbon (TVHi) in each coating, thinner, additive, or cleaning material, i, used during each test run using Method 24. The mass fraction of total volatile hydrocarbon equals the weight fraction volatile matter (Wv in Method 24) minus the weight fraction water (Ww in Method 24), if any, present in the coating. The ASTM Method D6053-00, “Standard Test Method for Determination of Volatile Organic Compound (VOC) Content of Electrical Insulating Varnishes” (incorporated by reference, see §63.14), may be used as an alternative to Method 24 for magnet wire enamels. The specimen size for testing magnet wire enamels with ASTM Method D6053-00 must be 2.0 ±0.1 grams.

3.5 Determine the volume (VOLi) or mass (MASSi) of each coating, thinner, additive, or cleaning material, i, used during each test run.

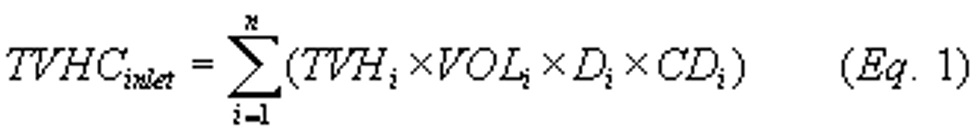

3.6 Calculate the total volatile hydrocarbon input (TVHCinlet) to the control device during each test run, as carbon, using Equation 1:

where:

TVHi = Mass fraction of TVH in coating, thinner, additive, or cleaning material, i, used in the coating operation during the test run.

VOLi = Volume of coating, thinner, additive, or cleaning material, i, used in the coating operation during the test run, liters.

Di = Density of coating, thinner, additive, or cleaning material, i, used in the coating operation during the test run, kg per liter.

CDi = Weight fraction carbon content of the distillate from coating, thinner, additive, or cleaning material, i, used in the coating operation during the test run, percent.

n = Number of coating, thinner, additive, and cleaning materials used in the coating operation during the test run.

3.7 If the mass, MASSi, of each coating, solvent, additive, or cleaning material, i, used during the test run is measured directly then MASSi can be substituted for VOLi × Di in Equation 1 in section 3.6.

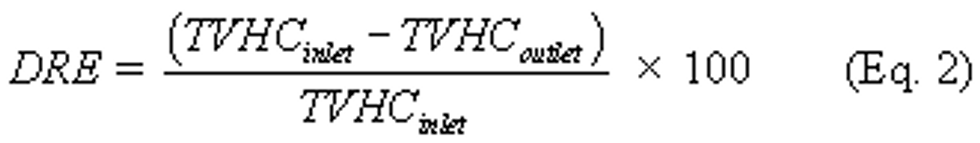

3.8 Determine the TVHC output (TVHCoutlet) from the control device, as carbon, during each test run using the methods in §63.3966(a) and the procedure for determining Mfo in §63.3966(d). TVHCoutlet equals Mfo times the length of the test run in hours.

3.9 Determine the control device efficiency (DRE) for each test run using Equation 2:

3.10 The efficiency of the control device is the average of the three individual test run values determined in section 3.9.

3.11 As an alternative to establishing and monitoring the destruction efficiency operating parameters for catalytic oxidizers in §63.3967(b), the monitoring described in sections 3.12 and 3.13 may be used for magnet wire coating machines equipped with catalytic oxidizers.

3.12 During the performance test, you must monitor and record the temperature either just before or just after the catalyst bed at least once every 15 minutes during each of the three test runs. Use the data collected during the performance test to calculate and record the average temperature either just before or just after the catalyst bed during the performance test. This is the minimum operating limit for your catalytic oxidizer and for the catalytic oxidizers in identical or very similar magnet wire coating machines represented by the tested magnet wire coating machine.

3.13 You must develop and implement an inspection and maintenance plan for your catalytic oxidizer(s). The plan must address, at a minimum, the elements specified in sections 3.14 and 3.15, and the elements specified in either (a) section 3.16 or (b) sections 3.17 and 3.18.

3.14 You must conduct a monthly external inspection of each catalytic oxidizer system, including the burner assembly and fuel supply lines for problems and, as necessary, adjust the equipment to assure proper air-to-fuel mixtures.

3.15 You must conduct an annual internal inspection of each accessible catalyst bed to check for channeling, abrasion, and settling. If problems are found, you must replace the catalyst bed or take corrective action consistent with the manufacturer's recommendations. This provision does not apply to internal catalysts which cannot be accessed without disassembling the magnet wire oven.

3.16 You must take a sample of each catalyst bed and perform an analysis of the catalyst activity (i.e., conversion efficiency) following the manufacturer's or catalyst supplier's recommended procedures. This sampling and analysis must be done within the time period shown in Table 1 below of the most recent of the last catalyst activity test or the last catalyst replacement. For example, if the warranty for the catalyst is 3 years and the catalyst was more recently replaced then the sampling and analysis must be done within the earlier of 26,280 operating hours or 5 calendar years of the last catalyst replacement. If the warranty for the catalyst is 3 years and the catalyst was more recently tested then the sampling and analysis must be done within the earlier of 13,140 operating hours or 3 calendar years of the last catalyst activity test. If problems are found during the catalyst activity test, you must replace the catalyst bed or take corrective action consistent with the manufacturer's recommendations.

| If the catalyst was last (more recently) replaced and the warranty period is . . . | Then the time between catalyst replacement and the next catalyst activity test cannot exceed the earlier of . . . | And the catalyst was more recently tested, then the time between catalyst activity tests cannot exceed the earlier of . . . |

|---|---|---|

| 1 year | 8,760 operating hours or 5 calendar years | 8,760 operating hours or 3 calendar years. |

| 2 years | 15,520 operating hours or 5 calendar years | 8,760 operating hours or 3 calendar years. |

| 3 years | 26,280 operating hours or 5 calendar years | 13,100 operating hours or 3 calendar years. |

| 4 years | 35,040 operating hours or 5 calendar years | 17,520 operating hours or 3 calendar years. |

| 5 or more years | 43,800 operating hours or 5 calendar years | 21,900 operating hours or 3 calendar years. |

3.17 During the performance test, you must determine the average concentration of organic compounds as carbon in the magnet wire oven exhaust stack gases (Cc in Equation 1 in §63.3966(d)) and the destruction efficiency of the catalytic oxidizer, and calculate the operating limit for oven exhaust stack gas concentration as follows. You must identify the highest organic HAP content coating used on this magnet wire coating machine or any identical or very similar magnet wire coating machines to which the same destruction efficiency test results will be applied. Calculate the percent emission reduction necessary to meet the magnet wire coating emission limit when using this coating. Calculate the average concentration of organic compounds as carbon in the magnet wire oven exhaust stack gases that would be equivalent to exactly meeting the magnet wire coating emissions limit when using the highest organic HAP content coating. The maximum operating limit for oven exhaust stack gas concentration equals 90 percent of this calculated concentration.

3.18 For each magnet wire coating machine equipped with a catalytic oxidizer you must perform an annual 10 minute test of the oven exhaust stack gases using EPA Method 25A. This test must be performed under steady state operating conditions similar to those at which the last destruction efficiency test for equipment of that type (either the specific magnet wire coating machine or an identical or very similar magnet wire coating machine) was conducted. If the average exhaust stack gas concentration during the annual test of a magnet wire coating machine equipped with a catalytic oxidizer is greater than the operating limit established in section 3.17 then that is a deviation from the operating limit for that catalytic oxidizer. If problems are found during the annual 10-minute test of the oven exhaust stack gases, you must replace the catalyst bed or take other corrective action consistent with the manufacturer's recommendations.

3.19 If a catalyst bed is replaced and the replacement catalyst is not of like or better kind and quality as the old catalyst, then you must conduct a new performance test to determine destruction efficiency according to §63.3966 and establish new operating limits for that catalytic oxidizer unless destruction efficiency test results and operating limits for an identical or very similar unit (including consideration of the replacement catalyst) are available and approved for use for the catalytic oxidizer with the replacement catalyst.

3.20 If a catalyst bed is replaced and the replacement catalyst is of like or better kind and quality as the old catalyst, then a new performance test to determine destruction efficiency is not required and you may continue to use the previously established operating limits for that catalytic oxidizer.

Source: 69 FR 157, Jan. 2, 2004, unless otherwise noted.

['Air Programs']

['Hazardous Air Pollutants']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2025 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.