['Air Programs']

['Hazardous Air Pollutants']

02/27/2022

...

§63.860 Applicability and designation of affected source.

(a) The requirements of this subpart apply to the owner or operator of each kraft, soda, sulfite, or stand-alone semichemical pulp mill that is a major source of hazardous air pollutants (HAP) emissions as defined in §63.2.

(b) Affected sources. The requirements of this subpart apply to each new or existing affected source listed in paragraphs (b)(1) through (7) of this section:

(1) Each existing chemical recovery system (as defined in §63.861) located at a kraft or soda pulp mill.

(2) Each new nondirect contact evaporator (NDCE) recovery furnace and associated smelt dissolving tank(s) located at a kraft or soda pulp mill.

(3) Each new direct contact evaporator (DCE) recovery furnace system (as defined in §63.861) and associated smelt dissolving tank(s) located at a kraft or soda pulp mill.

(4) Each new lime kiln located at a kraft or soda pulp mill.

(5) Each new or existing sulfite combustion unit located at a sulfite pulp mill, except such existing units at Cosmo Specialty Fibers' Cosmopolis, Washington facility (Emission Unit no. AP-10).

(6) Each new or existing semichemical combustion unit located at a stand-alone semichemical pulp mill.

(7) The requirements of the alternative standard in §63.862(d) apply to the hog fuel dryer at Cosmo Specialty Fibers' Cosmopolis, Washington facility (Emission Unit no. HD-14).

(c) The requirements of the General Provisions in subpart A of this part that apply to the owner or operator subject to the requirements of this subpart are identified in Table 1 to this subpart.

(d) At all times, the owner or operator must operate and maintain any affected source, including associated air pollution control equipment and monitoring equipment, in a manner consistent with safety and good air pollution control practices for minimizing emissions. The general duty to minimize emissions does not require the owner or operator to make any further efforts to reduce emissions if levels required by the applicable standard have been achieved. Determination of whether a source is operating in compliance with operation and maintenance requirements will be based on information available to the Administrator which may include, but is not limited to, monitoring results, review of operation and maintenance procedures, review of operation and maintenance records, and inspection of the source.

[66 FR 3193, Jan. 12, 2001, as amended at 68 FR 7713, Feb. 18, 2003; 82 FR 47347, Oct. 11, 2017]

§63.861 Definitions.

All terms used in this subpart are defined in the Clean Air Act, in subpart A of this part, or in this section. For the purposes of this subpart, if the same term is defined in subpart A or any other subpart of this part and in this section, it must have the meaning given in this section.

Bag leak detection system means an instrument that is capable of monitoring PM loadings in the exhaust of a fabric filter in order to detect bag failures. A bag leak detection system includes, but is not limited to, an instrument that operates on triboelectric, light scattering, light transmittance, or other principle to monitor relative PM loadings.

Black liquor means spent cooking liquor that has been separated from the pulp produced by the kraft, soda, or semichemical pulping process.

Black liquor oxidation (BLO) system means the vessels used to oxidize the black liquor, with air or oxygen, and the associated storage tank(s).

Black liquor solids (BLS) means the dry weight of the solids in the black liquor that enters the recovery furnace or semichemical combustion unit.

Black liquor solids firing rate means the rate at which black liquor solids are fed to the recovery furnace or the semichemical combustion unit.

Chemical recovery combustion source means any source in the chemical recovery area of a kraft, soda, sulfite or stand-alone semichemical pulp mill that is an NDCE recovery furnace, a DCE recovery furnace system, a smelt dissolving tank, a lime kiln, a sulfite combustion unit, or a semichemical combustion unit.

Chemical recovery system means all existing DCE and NDCE recovery furnaces, smelt dissolving tanks, and lime kilns at a kraft or soda pulp mill. Each existing recovery furnace, smelt dissolving tank, or lime kiln is considered a process unit within a chemical recovery system.

Direct contact evaporator (DCE) recovery furnace means a kraft or soda recovery furnace equipped with a direct contact evaporator that concentrates strong black liquor by direct contact between the hot recovery furnace exhaust gases and the strong black liquor.

Direct contact evaporator (DCE) recovery furnace system means a direct contact evaporator recovery furnace and any black liquor oxidation system, if present, at the pulp mill.

Dry electrostatic precipitator (ESP) system means an electrostatic precipitator with a dry bottom (i.e., no black liquor, water, or other fluid is used in the ESP bottom) and a dry particulate matter return system (i.e., no black liquor, water, or other fluid is used to transport the collected PM to the mix tank).

Fabric filter means an air pollution control device used to capture PM by filtering a gas stream through filter media; also known as a baghouse.

Hazardous air pollutants (HAP) metals means the sum of all emissions of antimony, arsenic, beryllium, cadmium, chromium, cobalt, lead, manganese, mercury, nickel, and selenium as measured by EPA Method 29 (40 CFR part 60, appendix A-8).

Hog fuel dryer means the equipment that combusts fine particles of wood waste (hog fuel) in a fluidized bed and directs the heated exhaust stream to a rotary dryer containing wet hog fuel to be dried prior to combustion in the hog fuel boiler at Cosmo Specialty Fibers' Cosmopolis, Washington facility. The hog fuel dryer at Cosmo Specialty Fibers' Cosmopolis, Washington facility is Emission Unit no. HD-14.

Kraft pulp mill means any stationary source that produces pulp from wood by cooking (digesting) wood chips in a solution of sodium hydroxide and sodium sulfide. The recovery process used to regenerate cooking chemicals is also considered part of the kraft pulp mill.

Kraft recovery furnace means a recovery furnace that is used to burn black liquor produced by the kraft pulping process, as well as any recovery furnace that burns black liquor produced from both the kraft and semichemical pulping processes, and includes the direct contact evaporator, if applicable.

Lime kiln means the combustion unit (e.g., rotary lime kiln or fluidized-bed calciner) used at a kraft or soda pulp mill to calcine lime mud, which consists primarily of calcium carbonate, into quicklime, which is calcium oxide (CaO).

Lime production rate means the rate at which dry lime, measured as CaO, is produced in the lime kiln.

Method detection limit means the minimum concentration of an analyte that can be determined with 99 percent confidence that the true value is greater than zero.

Modification means, for the purposes of §63.862(a)(1)(ii)(D)(1), any physical change (excluding any routine part replacement or maintenance) or operational change that is made to the air pollution control device that could result in an increase in PM emissions.

Nondetect data means, for the purposes of this subpart, any value that is below the method detection limit.

Nondirect contact evaporator (NDCE) recovery furnace means a kraft or soda recovery furnace that burns black liquor that has been concentrated by indirect contact with steam.

No-load fan amperage means, for purposes of this subpart, the amperage pulled by the fan motor when the fan is operating under no-load, specifically the amperage value the motor would use if the fan belt was removed or the coupling to a direct drive fan was disconnected.

Particulate matter (PM) means total filterable particulate matter as measured by EPA Method 5 (40 CFR part 60, appendix A-3), EPA Method 17 (§63.865(b)(1)) (40 CFR part 60, appendix A-6), or EPA Method 29 (40 CFR part 60, appendix A-8).

Process unit means an existing DCE or NDCE recovery furnace, smelt dissolving tank, or lime kiln in a chemical recovery system at a kraft or soda mill.

Recovery furnace means an enclosed combustion device where concentrated black liquor produced by the kraft or soda pulping process is burned to recover pulping chemicals and produce steam.

Regenerative thermal oxidizer (RTO) means a thermal oxidizer that transfers heat from the exhaust gas stream to the inlet gas stream by passing the exhaust stream through a bed of ceramic stoneware or other heat-absorbing medium before releasing it to the atmosphere, then reversing the gas flow so the inlet gas stream passes through the heated bed, raising the temperature of the inlet stream close to or at its ignition temperature.

Semichemical combustion unit means any equipment used to combust or pyrolyze black liquor at stand-alone semichemical pulp mills for the purpose of chemical recovery.

Similar process units means all existing DCE and NDCE recovery furnaces, smelt dissolving tanks, or lime kilns at a kraft or soda pulp mill.

Smelt dissolving tank (SDT) means a vessel used for dissolving the smelt collected from a kraft or soda recovery furnace.

Soda pulp mill means any stationary source that produces pulp from wood by cooking (digesting) wood chips in a sodium hydroxide solution. The recovery process used to regenerate cooking chemicals is also considered part of the soda pulp mill.

Soda recovery furnace means a recovery furnace used to burn black liquor produced by the soda pulping process and includes the direct contact evaporator, if applicable.

Stand-alone semichemical pulp mill means any stationary source that produces pulp from wood by partially digesting wood chips in a chemical solution followed by mechanical defibrating (grinding), and has an onsite chemical recovery process that is not integrated with a kraft pulp mill.

Sulfite combustion unit means a combustion device, such as a recovery furnace or fluidized-bed reactor, where spent liquor from the sulfite pulping process (i.e., red liquor) is burned to recover pulping chemicals.

Sulfite pulp mill means any stationary source that produces pulp from wood by cooking (digesting) wood chips in a solution of sulfurous acid and bisulfite ions. The recovery process used to regenerate cooking chemicals is also considered part of the sulfite pulp mill.

Total hydrocarbons (THC) means the sum of organic compounds measured as carbon using EPA Method 25A (40 CFR part 60, appendix A-7).

[66 FR 3193, Jan. 12, 2001, as amended at 66 FR 16408, Mar. 26, 2001; 68 FR 7713, Feb. 18, 2003; 82 FR 47347, Oct. 11, 2017; 85 FR 70493, Nov. 5, 2020]

§63.862 Standards.

(a) Standards for HAP metals: existing sources. (1) Each owner or operator of an existing kraft or soda pulp mill must comply with the requirements of either paragraph (a)(1)(i) or (ii) of this section.

(i) Each owner or operator of a kraft or soda pulp mill must comply with the PM emissions limits in paragraphs (a)(1)(i)(A) through (C) of this section.

(A) The owner or operator of each existing kraft or soda recovery furnace must ensure that the concentration of PM in the exhaust gases discharged to the atmosphere is less than or equal to 0.10 gram per dry standard cubic meter (g/dscm) (0.044 grain per dry standard cubic foot (gr/dscf)) corrected to 8 percent oxygen.

(B) The owner or operator of each existing kraft or soda smelt dissolving tank must ensure that the concentration of PM in the exhaust gases discharged to the atmosphere is less than or equal to 0.10 kilogram per megagram (kg/Mg) (0.20 pound per ton (lb/ton)) of black liquor solids fired.

(C) The owner or operator of each existing kraft or soda lime kiln must ensure that the concentration of PM in the exhaust gases discharged to the atmosphere is less than or equal to 0.15 g/dscm (0.064 gr/dscf) corrected to 10 percent oxygen.

(ii) As an alternative to meeting the requirements of §63.862(a)(1)(i), each owner or operator of a kraft or soda pulp mill may establish PM emissions limits for each existing kraft or soda recovery furnace, smelt dissolving tank, and lime kiln that operates 6,300 hours per year or more by:

(A) Establishing an overall PM emission limit for each existing process unit in the chemical recovery system at the kraft or soda pulp mill using the methods in §63.865(a)(1) and (2).

(B) The emissions limits for each kraft recovery furnace, smelt dissolving tank, and lime kiln that are used to establish the overall PM limit in paragraph (a)(1)(ii)(A) of this section must not be less stringent than the emissions limitations required by §60.282 of part 60 of this chapter for any kraft recovery furnace, smelt dissolving tank, or lime kiln that is subject to the requirements of §60.282.

(C) Each owner or operator of an existing kraft or soda recovery furnace, smelt dissolving tank, or lime kiln must ensure that the PM emissions discharged to the atmosphere from each of these sources are less than or equal to the applicable PM emissions limits, established using the methods in §63.865(a)(1), that are used to establish the overall PM emissions limits in paragraph (a)(1)(ii)(A) of this section.

(D) Each owner or operator of an existing kraft or soda recovery furnace, smelt dissolving tank, or lime kiln must reestablish the emissions limits determined in paragraph (a)(1)(ii)(A) of this section if either of the actions in paragraphs (a)(1)(ii)(D)(1) and (2) of this section are taken:

(1) The air pollution control system for any existing kraft or soda recovery furnace, smelt dissolving tank, or lime kiln for which an emission limit was established in paragraph (a)(1)(ii)(A) of this section is modified (as defined in §63.861) or replaced; or

(2) Any kraft or soda recovery furnace, smelt dissolving tank, or lime kiln for which an emission limit was established in paragraph (a)(1)(ii)(A) of this section is shut down for more than 60 consecutive days.

(iii) Each owner or operator of an existing kraft or soda recovery furnace, smelt dissolving tank, or lime kiln that operates less than 6,300 hours per year must comply with the applicable PM emissions limits for that process unit provided in paragraph (a)(1)(i) of this section.

(2) Except as specified in paragraph (d) of this section, the owner or operator of each existing sulfite combustion unit must ensure that the concentration of PM in the exhaust gases discharged to the atmosphere is less than or equal to 0.092 g/dscm (0.040 gr/dscf) corrected to 8 percent oxygen.

(b) Standards for HAP metals: new sources. (1) The owner or operator of any new kraft or soda recovery furnace must ensure that the concentration of PM in the exhaust gases discharged to the atmosphere is less than or equal to 0.034 g/dscm (0.015 gr/dscf) corrected to 8 percent oxygen.

(2) The owner or operator of any new kraft or soda smelt dissolving tank must ensure that the concentration of PM in the exhaust gases discharged to the atmosphere is less than or equal to 0.06 kg/Mg (0.12 lb/ton) of black liquor solids fired.

(3) The owner or operator of any new kraft or soda lime kiln must ensure that the concentration of PM in the exhaust gases discharged to the atmosphere is less than or equal to 0.023 g/dscm (0.010 gr/dscf) corrected to 10 percent oxygen.

(4) The owner or operator of any new sulfite combustion unit must ensure that the concentration of PM in the exhaust gases discharged to the atmosphere is less than or equal to 0.046 g/dscm (O.020 gr/dscf) corrected to 8 percent oxygen.

(c) Standards for gaseous organic HAP. (1) The owner or operator of any new recovery furnace at a kraft or soda pulp mill must ensure that the concentration of gaseous organic HAP, as measured by methanol, discharged to the atmosphere is no greater than 0.012 kg/Mg (0.025 lb/ton) of black liquor solids fired.

(2) The owner or operator of each existing or new semichemical combustion unit must ensure that:

(i) The concentration of gaseous organic HAP, as measured by total hydrocarbons reported as carbon, discharged to the atmosphere is less than or equal to 1.49 kg/Mg (2.97 lb/ton) of black liquor solids fired; or

(ii) The gaseous organic HAP emissions, as measured by total hydrocarbons reported as carbon, are reduced by at least 90 percent prior to discharge of the gases to the atmosphere.

(d) Alternative standard. As an alternative to meeting the requirements of paragraph (a)(2) of this section, the owner or operator of the existing hog fuel dryer at Cosmo Specialty Fibers' Cosmopolis, Washington facility (Emission Unit no. HD-14) must ensure that the mass of PM in the exhaust gases discharged to the atmosphere from the hog fuel dryer is less than or equal to 4.535 kilograms per hour (kg/hr) (10.0 pounds per hour (lb/hr)).

[66 FR 3193, Jan. 12, 2001, as amended at 68 FR 7713, Feb. 18, 2003; 68 FR 67954, Dec. 5, 2003; 82 FR 47347, Oct. 11, 2017]

§63.863 Compliance dates.

(a) The owner or operator of an existing affected source or process unit must comply with the requirements in this subpart no later than March 13, 2004, except as noted in paragraph (c) of this section.

(b) The owner or operator of a new affected source that has an initial startup date after March 13, 2001 must comply with the requirements in this subpart immediately upon startup of the affected source, except as specified in §63.6(b).

(c) The owner or operator of an existing source or process unit must comply with the revised requirements published on October 11, 2017 no later than October 11, 2019, with the exception of the following:

(1) The first of the 5-year periodic performance tests must be conducted by October 13, 2020, and thereafter within 5 years following the previous performance test; and

(2) The date to submit performance test data through the CEDRI is within 60 days after the date of completing each performance test.

[66 FR 3193, Jan. 12, 2001, as amended at 66 FR 16408, Mar. 26, 2001; 66 FR 37593, July 19, 2001; 68 FR 46108, Aug. 5, 2003; 82 FR 47347, Oct. 11, 2017]

§63.864 Monitoring requirements.

(a)-(c) [Reserved]

(d) Continuous opacity monitoring system (COMS). The owner or operator of each affected kraft or soda recovery furnace or lime kiln equipped with an ESP must install, calibrate, maintain, and operate a COMS in accordance with Performance Specification 1 (PS-1) in appendix B to 40 CFR part 60 and the provisions in §§63.6(h) and 63.8 and paragraphs (d)(3) and (4) of this section.

(1)-(2) [Reserved]

(3) As specified in §63.8(c)(4)(i), each COMS must complete a minimum of one cycle of sampling and analyzing for each successive 10-second period and one cycle of data recording for each successive 6-minute period.

(4) As specified in §63.8(g)(2), each 6-minute COMS data average must be calculated as the average of 36 or more data points, equally spaced over each 6-minute period.

(e) Continuous parameter monitoring system (CPMS). For each CPMS required in this section, the owner or operator of each affected source or process unit must meet the requirements in paragraphs (e)(1) through (14) of this section.

(1) For any kraft or soda recovery furnace or lime kiln using an ESP emission control device, the owner or operator must maintain proper operation of the ESP's automatic voltage control (AVC).

(2) For any kraft or soda recovery furnace or lime kiln using an ESP followed by a wet scrubber, the owner or operator must follow the parameter monitoring requirements specified in paragraphs (e)(1) and (10) of this section. The opacity monitoring system specified in paragraph (d) of this section is not required for combination ESP/wet scrubber control device systems.

(3)-(9) [Reserved]

(10) The owner or operator of each affected kraft or soda recovery furnace, kraft or soda lime kiln, sulfite combustion unit, or kraft or soda smelt dissolving tank equipped with a wet scrubber must install, calibrate, maintain, and operate a CPMS that can be used to determine and record the pressure drop across the scrubber and the scrubbing liquid flow rate at least once every successive 15-minute period using the procedures in §63.8(c), as well as the procedures in paragraphs (e)(10)(i) and (ii) of this section:

(i) A monitoring device used for the continuous measurement of the pressure drop of the gas stream across the scrubber must be certified by the manufacturer to be accurate to within a gage pressure of ±500 pascals (±2 inches of water gage pressure); and

(ii) A monitoring device used for continuous measurement of the scrubbing liquid flow rate must be certified by the manufacturer to be accurate within ±5 percent of the design scrubbing liquid flow rate.

(iii) As an alternative to pressure drop measurement under paragraph (e)(10)(i) of this section, a monitoring device for measurement of fan amperage or fan revolutions per minute (RPM) may be used for smelt dissolving tank dynamic scrubbers that operate at ambient pressure or for low-energy entrainment scrubbers where the fan speed does not vary.

(11) The owner or operator of each affected semichemical combustion unit equipped with an RTO must install, calibrate, maintain, and operate a CPMS that can be used to determine and record the operating temperature of the RTO at least once every successive 15-minute period using the procedures in §63.8(c). The monitor must compute and record the operating temperature at the point of incineration of effluent gases that are emitted using a temperature monitor accurate to within ±1 percent of the temperature being measured.

(12) The owner or operator of the affected hog fuel dryer at Cosmo Specialty Fibers' Cosmopolis, Washington facility (Emission Unit no. HD-14) must meet the requirements in paragraphs (e)(12)(i) through (xi) of this section for each bag leak detection system.

(i) The owner or operator must install, calibrate, maintain, and operate each triboelectric bag leak detection system according to EPA-454/R-98-015, “Fabric Filter Bag Leak Detection Guidance” (incorporated by reference - see §63.14). The owner or operator must install, calibrate, maintain, and operate other types of bag leak detection systems in a manner consistent with the manufacturer's written specifications and recommendations.

(ii) The bag leak detection system must be certified by the manufacturer to be capable of detecting PM emissions at concentrations of 10 milligrams per actual cubic meter (0.0044 grains per actual cubic foot) or less.

(iii) The bag leak detection system sensor must provide an output of relative PM loadings.

(iv) The bag leak detection system must be equipped with a device to continuously record the output signal from the sensor.

(v) The bag leak detection system must be equipped with an audible alarm system that will sound automatically when an increase in relative PM emissions over a preset level is detected. The alarm must be located where it is easily heard by plant operating personnel.

(vi) For positive pressure fabric filter systems, a bag leak detector must be installed in each baghouse compartment or cell.

(vii) For negative pressure or induced air fabric filters, the bag leak detector must be installed downstream of the fabric filter.

(viii) Where multiple detectors are required, the system's instrumentation and alarm may be shared among detectors.

(ix) The baseline output must be established by adjusting the range and the averaging period of the device and establishing the alarm set points and the alarm delay time according to section 5.0 of the “Fabric Filter Bag Leak Detection Guidance” (incorporated by reference - see §63.14).

(x) Following initial adjustment of the system, the sensitivity or range, averaging period, alarm set points, or alarm delay time may not be adjusted except as detailed in the site-specific monitoring plan. In no case may the sensitivity be increased by more than 100 percent or decreased more than 50 percent over a 365-day period unless such adjustment follows a complete fabric filter inspection which demonstrates that the fabric filter is in good operating condition, as defined in section 5.2 of the “Fabric Filter Bag Leak Detection Guidance,” (incorporated by reference - see §63.14). Record each adjustment.

(xi) The owner or operator must record the results of each inspection, calibration, and validation check.

(13) The owner or operator of each affected source or process unit that uses an ESP, wet scrubber, RTO, or fabric filter may monitor alternative control device operating parameters subject to prior written approval by the Administrator. The request for approval must also include the manner in which the parameter operating limit is to be set.

(14) The owner or operator of each affected source or process unit that uses an air pollution control system other than an ESP, wet scrubber, RTO, or fabric filter must provide to the Administrator an alternative monitoring request that includes a description of the control device, test results verifying the performance of the control device, the appropriate operating parameters that will be monitored, how the operating limit is to be set, and the frequency of measuring and recording to establish continuous compliance with the standards. The alternative monitoring request is subject to the Administrator's approval. The owner or operator of the affected source or process unit must install, calibrate, operate, and maintain the monitor(s) in accordance with the alternative monitoring request approved by the Administrator. The owner or operator must include in the information submitted to the Administrator proposed performance specifications and quality assurance procedures for the monitors. The Administrator may request further information and will approve acceptable test methods and procedures. The owner or operator must monitor the parameters as approved by the Administrator using the methods and procedures in the alternative monitoring request.

(f) Data quality assurance. The owner or operator shall keep CMS data quality assurance procedures consistent with the requirements in §63.8(d)(1) and (2) on record for the life of the affected source or until the affected source is no longer subject to the provisions of this part, to be made available for inspection, upon request, by the Administrator. If the performance evaluation plan in §63.8(d)(2) is revised, the owner or operator shall keep previous (i.e., superseded) versions of the performance evaluation plan on record to be made available for inspection, upon request, by the Administrator, for a period of 5 years after each revision to the plan. The program of corrective action should be included in the plan required under §63.8(d)(2).

(g) Gaseous organic HAP. The owner or operator of each affected source or process unit complying with the gaseous organic HAP standard of §63.862(c)(1) through the use of an NDCE recovery furnace equipped with a dry ESP system is not required to conduct any continuous monitoring to demonstrate compliance with the gaseous organic HAP standard.

(h) Monitoring data. As specified in §63.8(g)(5), monitoring data recorded during periods of unavoidable CMS breakdowns, out-of-control periods, repairs, maintenance periods, calibration checks, and zero (low-level) and high level adjustments must not be included in any data average computed under this subpart.

(i) [Reserved]

(j) Determination of operating limits. (1) During the initial or periodic performance test required in §63.865, the owner or operator of any affected source or process unit must establish operating limits for the monitoring parameters in paragraphs (e)(10) through (14) of this section, as appropriate; or

(2) The owner or operator may base operating limits on values recorded during previous performance tests or conduct additional performance tests for the specific purpose of establishing operating limits, provided that data used to establish the operating limits are or have been obtained during testing that used the test methods and procedures required in this subpart. The owner or operator of the affected source or process unit must certify that all control techniques and processes have not been modified subsequent to the testing upon which the data used to establish the operating parameter limits were obtained.

(3) The owner or operator of an affected source or process unit may establish expanded or replacement operating limits for the monitoring parameters listed in paragraphs (e)(10) through (14) of this section and established in paragraph (j)(1) or (2) of this section during subsequent performance tests using the test methods in §63.865.

(4) The owner or operator of the affected source or process unit must continuously monitor each parameter and determine the arithmetic average value of each parameter during each performance test run. Multiple performance tests may be conducted to establish a range of parameter values. Operating outside a previously established parameter limit during a performance test to expand the operating limit range does not constitute a monitoring exceedance. Operating limits must be confirmed or reestablished during performance tests.

(5) New, expanded, or replacement operating limits for the monitoring parameter values listed in paragraphs (e)(10) through (14) of this section should be determined as described in paragraphs (j)(5)(i) and (ii) of this section

(i) The owner or operator of an affected source or process unit that uses a wet scrubber must set minimum operating limits as described in paragraph (j)(5)(i)(A) and (B) of this section.

(A) Set the minimum scrubbing liquid flow rate operating limit as the lowest of the 1-hour average scrubbing liquid flow rate values associated with each test run demonstrating compliance with the applicable emission limit in §63.862.

(B) Set the minimum scrubber pressure drop operating limit as the lowest of the 1-hour average pressure drop values associated with each test run demonstrating compliance with the applicable emission limit in §63.862; or for a smelt dissolving tank dynamic wet scrubber operating at ambient pressure or for low-energy entrainment scrubbers where fan speed does not vary, set the minimum operating limit using one of the methods in paragraph (j)(5)(i)(B)(1) through (3) of this section.

(1) The minimum fan amperage operating limit must be set as the midpoint between the lowest of the 1-hour average fan amperage values associated with each test run demonstrating compliance with the applicable emission limit in §63.862 and the no-load amperage value. The no-load amperage value must be determined using manufacturers specifications, or by performing a no-load test of the fan motor for each smelt dissolving tank scrubber; or

(2) The minimum percent full load amperage (PFLA) to the fan motor must be set as the percent of full load amperage under no-load, plus 10 percent. The PFLA is calculated by dividing the no-load amperage value by the highest of the 1-hour average fan amperage values associated with each test run demonstrating compliance with the applicable emission limit in §63.862 multiplied by 100 and then adding 10 percent. The no-load amperage value must be determined using manufacturers specifications, or by performing a no-load test of the fan motor for each smelt dissolving tank scrubber; or

(3) The minimum RPM must be set as 5 percent lower than the lowest 1-hour average RPM associated with each test run demonstrating compliance with the applicable emission limit.

(ii) [Reserved]

(k) On-going compliance provisions. (1) Following the compliance date, owners or operators of all affected sources or process units are required to implement corrective action if the monitoring exceedances in paragraphs (k)(1)(i) through (vii) of this section occur during times when spent pulping liquor or lime mud is fed (as applicable). Corrective action can include completion of transient startup and shutdown conditions as expediently as possible.

(i) For a new or existing kraft or soda recovery furnace or lime kiln equipped with an ESP, when the average of ten consecutive 6-minute averages result in a measurement greater than 20 percent opacity;

(ii) For a new or existing kraft or soda recovery furnace, kraft or soda smelt dissolving tank, kraft or soda lime kiln, or sulfite combustion unit equipped with a wet scrubber, when any 3-hour average parameter value is below the minimum operating limit established in paragraph (j) of this section, with the exception of pressure drop during periods of startup and shutdown;

(iii) For a new or existing kraft or soda recovery furnace or lime kiln equipped with an ESP followed by a wet scrubber, when any 3-hour average scrubber parameter value is below the minimum operating limit established in paragraph (j) of this section, with the exception of pressure drop during periods of startup and shutdown;

(iv) For a new or existing semichemical combustion unit equipped with an RTO, when any 1-hour average temperature falls below the minimum temperature operating limit established in paragraph (j) of this section;

(v) For the hog fuel dryer at Cosmo Specialty Fibers' Cosmopolis, Washington facility (Emission Unit no. HD-14), when the bag leak detection system alarm sounds;

(vi) For an affected source or process unit equipped with an ESP, wet scrubber, RTO, or fabric filter and monitoring alternative operating parameters established in paragraph (e)(13) of this section, when any 3-hour average value does not meet the operating limit established in paragraph (j) of this section; and

(vii) For an affected source or process unit equipped with an alternative air pollution control system and monitoring operating parameters approved by the Administrator as established in paragraph (e)(14) of this section, when any 3-hour average value does not meet the operating limit established in paragraph (j) of this section.

(2) Following the compliance date, owners or operators of all affected sources or process units are in violation of the standards of §63.862 if the monitoring exceedances in paragraphs (k)(2)(i) through (ix) of this section occur during times when spent pulping liquor or lime mud is fed (as applicable):

(i) For an existing kraft or soda recovery furnace equipped with an ESP, when opacity is greater than 35 percent for 2 percent or more of the operating time within any semiannual period;

(ii) For a new kraft or soda recovery furnace equipped with an ESP, when opacity is greater than 20 percent for 2 percent or more of the operating time within any semiannual period;

(iii) For a new or existing kraft or soda lime kiln equipped with an ESP, when opacity is greater than 20 percent for 3 percent or more of the operating time within any semiannual period;

(iv) For a new or existing kraft or soda recovery furnace, kraft or soda smelt dissolving tank, kraft or soda lime kiln, or sulfite combustion unit equipped with a wet scrubber, when six or more 3-hour average parameter values within any 6-month reporting period are below the minimum operating limits established in paragraph (j) of this section, with the exception of pressure drop during periods of startup and shutdown;

(v) For a new or existing kraft or soda recovery furnace or lime kiln equipped with an ESP followed by a wet scrubber, when six or more 3-hour average scrubber parameter values within any 6-month reporting period are outside the range of values established in paragraph (j) of this section, with the exception of pressure drop during periods of startup and shutdown;

(vi) For a new or existing semichemical combustion unit equipped with an RTO, when any 3-hour average temperature falls below the temperature established in paragraph (j) of this section;

(vii) For the hog fuel dryer at Cosmo Specialty Fibers' Cosmopolis, Washington facility (Emission Unit no. HD-14), when corrective action is not initiated within 1 hour of a bag leak detection system alarm and the alarm is engaged for more than 5 percent of the total operating time in a 6-month block reporting period. In calculating the operating time fraction, if inspection of the fabric filter demonstrates that no corrective action is required, no alarm time is counted; if corrective action is required, each alarm is counted as a minimum of 1 hour; if corrective action is not initiated within 1 hour, the alarm time is counted as the actual amount of time taken to initiate corrective action;

(viii) For an affected source or process unit equipped with an ESP, wet scrubber, RTO, or fabric filter and monitoring alternative operating parameters established in paragraph (e)(13) of this section, when six or more 3-hour average values within any 6-month reporting period do not meet the operating limits established in paragraph (j) of this section; and

(ix) For an affected source or process unit equipped with an alternative air pollution control system and monitoring operating parameters approved by the Administrator as established in paragraph (e)(14) of this section, when six or more 3-hour average values within any 6-month reporting period do not meet the operating limits established in paragraph (j) of this section.

(3) For purposes of determining the number of nonopacity monitoring exceedances, no more than one exceedance will be attributed in any given 24-hour period.

[68 FR 7713, Feb. 18, 2003, as amended at 68 FR 42605, July 18, 2003; 68 FR 67955, Dec. 5, 2003; 71 FR 20458, Apr. 20, 2006; 82 FR 47348, Oct. 11, 2017; 85 FR 70493, Nov. 5, 2020]

§63.865 Performance test requirements and test methods.

The owner or operator of each affected source or process unit subject to the requirements of this subpart is required to conduct an initial performance test and periodic performance tests using the test methods and procedures listed in §63.7 and paragraph (b) of this section. The owner or operator must conduct the first of the periodic performance tests within 3 years of the effective date of the revised standards and thereafter within 5 years following the previous performance test. Performance tests shall be conducted based on representative performance (i.e., performance based on normal operating conditions) of the affected source for the period being tested. Representative conditions exclude periods of startup and shutdown. The owner or operator may not conduct performance tests during periods of malfunction. The owner or operator must record the process information that is necessary to document operating conditions during the test and include in such record an explanation to support that such conditions represent normal operation. Upon request, the owner or operator shall make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

(a) The owner or operator of a process unit seeking to comply with a PM emission limit under §63.862(a)(1)(ii)(A) must use the procedures in paragraphs (a)(1) and (2) of this section:

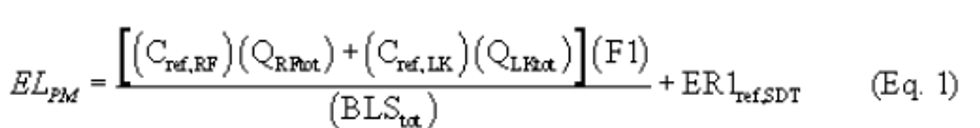

(1) Determine the overall PM emission limit for the chemical recovery system at the mill using Equation 1 of this section as follows:

Where:

ELPM = overall PM emission limit for all existing process units in the chemical recovery system at the kraft or soda pulp mill, kg/Mg (lb/ton) of black liquor solids fired.

Cref, RF = reference concentration of 0.10 g/dscm (0.044 gr/dscf) corrected to 8 percent oxygen for existing kraft or soda recovery furnaces.

QRFtot = sum of the average volumetric gas flow rates measured during the performance test and corrected to 8 percent oxygen for all existing recovery furnaces in the chemical recovery system at the kraft or soda pulp mill, dry standard cubic meters per minute (dscm/min) (dry standard cubic feet per minute (dscf/min)).

Cref,LK = reference concentration of 0.15 g/dscm (0.064 gr/dscf) corrected to 10 percent oxygen for existing kraft or soda lime kilns.

QLKtot = sum of the average volumetric gas flow rates measured during the performance test and corrected to 10 percent oxygen for all existing lime kilns in the chemical recovery system at the kraft or soda pulp mill, dscm/min (dscf/min).

F1 = conversion factor, 1.44 minutes·kilogram/day·gram (min·kg/d·g) (0.206 minutes·pound/day·grain (min·b/d·gr)).

BLStot = sum of the average black liquor solids firing rates of all existing recovery furnaces in the chemical recovery system at the kraft or soda pulp mill measured during the performance test, megagrams per day (Mg/d) (tons per day (ton/d)) of black liquor solids fired.

ER1ref, SDT = reference emission rate of 0.10 kg/Mg (0.20 lb/ton) of black liquor solids fired for existing kraft or soda smelt dissolving tanks.

(2) Establish an emission limit for each kraft or soda recovery furnace, smelt dissolving tank, and lime kiln; and, using these emissions limits, determine the overall PM emission rate for the chemical recovery system at the mill using the procedures in paragraphs (a)(2)(i) through (v) of this section, such that the overall PM emission rate calculated in paragraph (a)(2)(v) of this section is less than or equal to the overall PM emission limit determined in paragraph (a)(1) of this section, as appropriate.

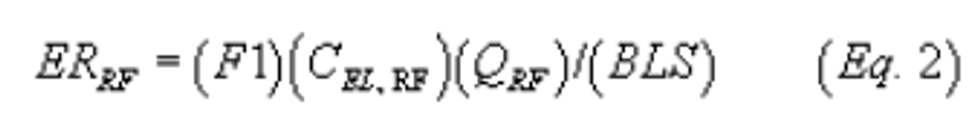

(i) The PM emission rate from each affected recovery furnace must be determined using Equation 2 of this section as follows:

Where:

ERRF = emission rate from each recovery furnace, kg/Mg (lb/ton) of black liquor solids.

F1 = conversion factor, 1.44 min·kg/d·g (0.206 min·/d·gr).

CEL, RF = PM emission limit proposed by owner or operator for the recovery furnace, g/dscm (gr/dscf) corrected to 8 percent oxygen.

QRF = average volumetric gas flow rate from the recovery furnace measured during the performance test and corrected to 8 percent oxygen, dscm/min (dscf/min).

BLS = average black liquor solids firing rate of the recovery furnace measured during the performance test, Mg/d (ton/d) of black liquor solids.

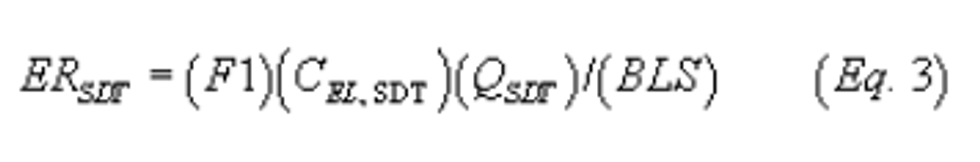

(ii) The PM emission rate from each affected smelt dissolving tank must be determined using Equation 3 of this section as follows:

Where:

ERSDT = emission rate from each SDT, kg/Mg (lb/ton) of black liquor solids fired.

F1 = conversion factor, 1.44 min·kg/dg (0.206 min·lb/d·gr).

CEL, SDT = PM emission limit proposed by owner or operator for the smelt dissolving tank, g/dscm (gr/dscf).

QSDT = average volumetric gas flow rate from the smelt dissolving tank measured during the performance test, dscm/min (dscf/min).

BLS = average black liquor solids firing rate of the associated recovery furnace measured during the performance test, Mg/d (ton/d) of black liquorsolids fired. If more than one SDT is used to dissolve the smelt from a given recovery furnace, then the black liquor solids firing rate of the furnace must be proportioned according to the size of the SDT.

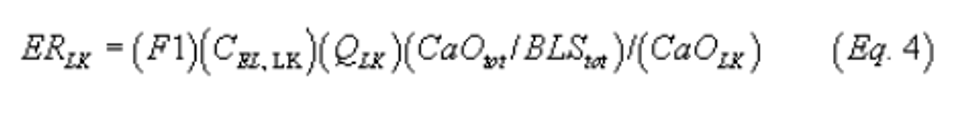

(iii) The PM emission rate from each affected lime kiln must be determined using Equation 4 of this section as follows:

Where:

ERLK = emission rate from each lime kiln, kg/Mg (lb/ton) of black liquor solids.

F1 = conversion factor, 1.44 min·kg/d·g (0.206 min·lb/d·gr).

CEL,LK = PM emission limit proposed by owner or operator for the lime kiln, g/dscm (gr/dscf) corrected to 10 percent oxygen.

QLK = average volumetric gas flow rate from the lime kiln measured during the performance test and corrected to 10 percent oxygen, dscm/min (dscf/min).

CaOLK = lime production rate of the lime kiln, measured as CaO during the performance test, Mg/d (ton/d) of CaO.

CaOtot = sum of the average lime production rates for all existing lime kilns in the chemical recovery system at the mill measured as CaO during the performance test, Mg/d (ton/d).

BLStot = sum of the average black liquor solids firing rates of all recovery furnaces in the chemical recovery system at the mill measured during the performance test, Mg/d (ton/d) of black liquor solids.

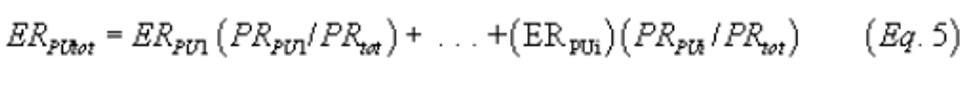

(iv) If more than one similar process unit is operated in the chemical recovery system at the kraft or soda pulp mill, Equation 5 of this section must be used to calculate the overall PM emission rate from all similar process units in the chemical recovery system at the mill and must be used in determining the overall PM emission rate for the chemical recovery system at the mill:

Where:

ERPUtot = overall PM emission rate from all similar process units, kg/Mg (lb/ton) of black liquor solids fired.

ERPU1 = PM emission rate from process unit No. 1, kg/Mg (lb/ton) of black liquor solids fired, calculated using Equation 2, 3, or 4 in paragraphs (a)(2)(i) through (iii) of this section.

PRPU1 = black liquor solids firing rate in Mg/d (ton/d) for process unit No. 1, if process unit is a recovery furnace or SDT. The CaO production rate in Mg/d (ton/d) for process unit No. 1, if process unit is a lime kiln.

PRtot = total black liquor solids firing rate in Mg/d (ton/d) for all recovery furnaces in the chemical recovery system at the kraft or soda pulp mill if the similar process units are recovery furnaces or SDT, or the total CaO production rate in Mg/d (ton/d) for all lime kilns in the chemical recovery system at the mill if the similar process units are lime kilns.

ERPUi = PM emission rate from process unit No. i, kg/Mg (lb/ton) of black liquor solids fired.

PRPUi = black liquor solids firing rate in Mg/d (ton/d) for process unit No. i, if process unit is a recovery furnace or SDT. The CaO production rate in Mg/d (ton/d) for process unit No. i, if process unit is a lime kiln.

i = number of similar process units located in the chemical recovery system at the kraft or soda pulp mill.

(v) The overall PM emission rate for the chemical recovery system at the mill must be determined using Equation 6 of this section as follows:

Where:

ERtot = overall PM emission rate for the chemical recovery system at the mill, kg/Mg (lb/ton) of black liquor solids fired.

ERRFtot = PM emission rate from all kraft or soda recovery furnaces, calculated using Equation 2 or 5 in paragraphs (a)(2)(i) and (iv) of this section, where applicable, kg/Mg (lb/ton) of black liquor solids fired.

ERSDTtot = PM emission rate from all smelt dissolving tanks, calculated using Equation 3 or 5 in paragraphs (a)(2)(ii) and (iv) of this section, where applicable, kg/Mg (lb/ton) of black liquor solids fired.

ERLKtot = PM emission rate from all lime kilns, calculated using Equation 4 or 5 in paragraphs (a)(2)(iii) and (iv) of this section, where applicable, kg/Mg (lb/ton) of black liquor solids fired.

(vi) After the Administrator has approved the PM emissions limits for each kraft or soda recovery furnace, smelt dissolving tank, and lime kiln, the owner or operator complying with an overall PM emission limit established in §63.862(a)(1)(ii) must demonstrate compliance with the HAP metals standard by demonstrating compliance with the approved PM emissions limits for each affected kraft or soda recovery furnace, smelt dissolving tank, and lime kiln, using the test methods and procedures in paragraph (b) of this section.

(b) The owner or operator seeking to determine compliance with §63.862(a), (b), or (d) must use the procedures in paragraphs (b)(1) through (6) of this section.

(1) For purposes of determining the concentration or mass of PM emitted from each kraft or soda recovery furnace, sulfite combustion unit, smelt dissolving tank, lime kiln, or the hog fuel dryer at Cosmo Specialty Fibers' Cosmopolis, Washington facility (Emission Unit no. HD-14), Method 5 in appendix A-3 of 40 CFR part 60 or Method 29 in appendix A-8 of 40 CFR part 60 must be used, except that Method 17 in appendix A-6 of 40 CFR part 60 may be used in lieu of Method 5 or Method 29 if a constant value of 0.009 g/dscm (0.004 gr/dscf) is added to the results of Method 17, and the stack temperature is no greater than 205°C (400°F). For Methods 5, 29, and 17, the sampling time and sample volume for each run must be at least 60 minutes and 0.90 dscm (31.8 dscf), and water must be used as the cleanup solvent instead of acetone in the sample recovery procedure.

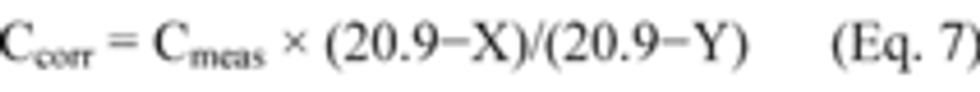

(2) For sources complying with §63.862(a) or (b), the PM concentration must be corrected to the appropriate oxygen concentration using Equation 7 of this section as follows:

Where:

Ccorr = the measured concentration corrected for oxygen, g/dscm (gr/dscf);

Cmeas = the measured concentration uncorrected for oxygen, g/dscm (gr/dscf);

X = the corrected volumetric oxygen concentration (8 percent for kraft or soda recovery furnaces and sulfite combustion units and 10 percent for kraft or soda lime kilns); and

Y = the measured average volumetric oxygen concentration.

(3) Method 3A or 3B in appendix A-2 of 40 CFR part 60 must be used to determine the oxygen concentration. The voluntary consensus standard ANSI/ASME PTC 19.10-1981 - Part 10 (incorporated by reference - see §63.14) may be used as an alternative to using Method 3B. The gas sample must be taken at the same time and at the same traverse points as the particulate sample.

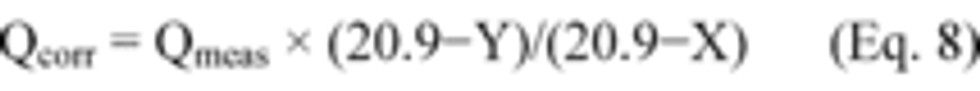

(4) For purposes of complying with §63.862(a)(1)(ii)(A), the volumetric gas flow rate must be corrected to the appropriate oxygen concentration using Equation 8 of this section as follows:

Where:

Qcorr = the measured volumetric gas flow rate corrected for oxygen, dscm/min (dscf/min).

Qmeas = the measured volumetric gas flow rate uncorrected for oxygen, dscm/min (dscf/min).

Y = the measured average volumetric oxygen concentration.

X = the corrected volumetric oxygen concentration (8 percent for kraft or soda recovery furnaces and 10 percent for kraft or soda lime kilns).

(5)(i) For purposes of selecting sampling port location and number of traverse points, Method 1 or 1A in appendix A-1 of 40 CFR part 60 must be used;

(ii) For purposes of determining stack gas velocity and volumetric flow rate, Method 2, 2A, 2C, 2D, or 2F in appendix A-1 of 40 CFR part 60 or Method 2G in appendix A-2 of 40 CFR part 60 must be used;

(iii) For purposes of conducting gas analysis, Method 3, 3A, or 3B in appendix A-2 of 40 CFR part 60 must be used. The voluntary consensus standard ANSI/ASME PTC 19.10-1981 - Part 10 (incorporated by reference - see §63.14) may be used as an alternative to using Method 3B; and

(iv) For purposes of determining moisture content of stack gas, Method 4 in appendix A-3 of 40 CFR part 60 must be used.

(6) Process data measured during the performance test must be used to determine the black liquor solids firing rate on a dry basis and the CaO production rate.

(c) The owner or operator of each affected source or process unit complying with the gaseous organic HAP standard in §63.862(c)(1) must demonstrate compliance according to the provisions in paragraphs (c)(1) and (2) of this section.

(1) The owner or operator complying through the use of an NDCE recovery furnace equipped with a dry ESP system is required to conduct periodic performance testing using Method 308 in appendix A of this part, as well as the methods listed in paragraphs (b)(5)(i) through (iv) of this section to demonstrate compliance with the gaseous organic HAP standard. The requirements and equations in paragraph (c)(2) of this section must be met and utilized, respectively.

(2) The owner or operator complying without using an NDCE recovery furnace equipped with a dry ESP system must use Method 308 in appendix A of this part, as well as the methods listed in paragraphs (b)(5)(i) through (iv) of this section. The sampling time and sample volume for each Method 308 run must be at least 60 minutes and 0.014 dscm (0.50 dscf), respectively.

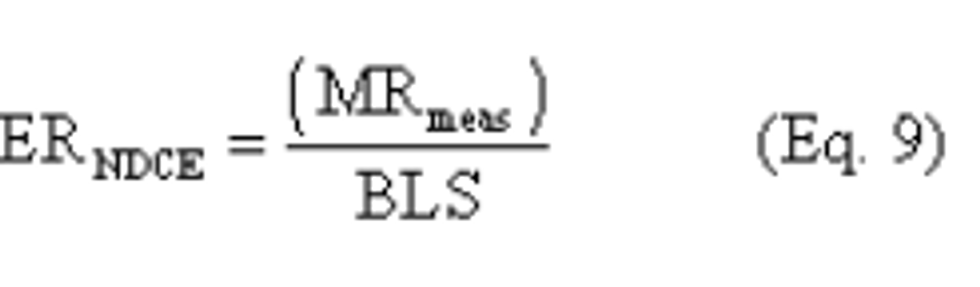

(i) The emission rate from any new NDCE recovery furnace must be determined using Equation 9 of this section as follows:

Where:

ERNDCE = Methanol emission rate from the NDCE recovery furnace, kg/Mg (lb/ton) of black liquor solids fired;

MRmeas = Measured methanol mass emission rate from the NDCE recovery furnace, kg/hr (lb/hr); and

BLS = Average black liquor solids firing rate of the NDCE recovery furnace, megagrams per hour (Mg/hr) (tons per hour (ton/hr)) determined using process data measured during the performance test.

(ii) The emission rate from any new DCE recovery furnace system must be determined using Equation 10 of this section as follows:

Where:

ERDCE = Methanol emission rate from each DCE recovery furnace system, kg/Mg (lb/ton) of black liquor solids fired;

MRmeas,RF = Average measured methanol mass emission rate from each DCE recovery furnace, kg/hr (lb/hr);

MRmeas,BLO = Average measured methanol mass emission rate from the black liquor oxidation system, kg/hr (lb/hr);

BLSRF = Average black liquor solids firing rate for each DCE recovery furnace, Mg/hr (ton/hr) determined using process data measured during the performance test; and

BLSBLO = The average mass rate of black liquor solids treated in the black liquor oxidation system, Mg/hr (ton/hr) determined using process data measured during the performance test.

(d) The owner or operator seeking to determine compliance with the gaseous organic HAP standards in §63.862(c)(2) for semichemical combustion units must use Method 25A in appendix A-7 of 40 CFR part 60, as well as the methods listed in paragraphs (b)(5)(i) through (iv) of this section. The sampling time for each Method 25A run must be at least 60 minutes. The calibration gas for each Method 25A run must be propane.

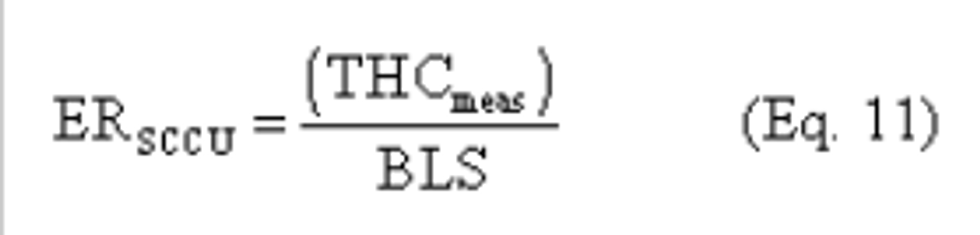

(1) The emission rate from any new or existing semichemical combustion unit must be determined using Equation 11 of this section as follows:

Where:

ERSCCU = THC emission rate reported as carbon from each semichemical combustion unit, kg/Mg (lb/ton) of black liquor solids fired;

THCmeas = Measured THC mass emission rate reported as carbon, kg/hr (lb/hr); and

BLS = Average black liquor solids firing rate, Mg/hr (ton/hr); determined using process data measured during the performance test.

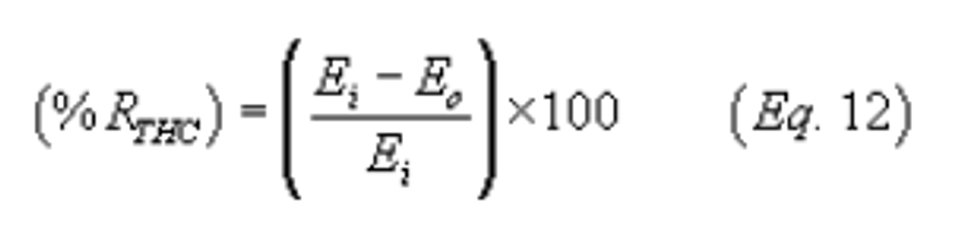

(2) If the owner or operator of the semichemical combustion unit has selected the percentage reduction standards for THC, under §63.862(c)(2)(ii), the percentage reduction in THC emissions is computed using Equation 12 of this section as follows, provided that Ei and Eo are measured simultaneously:

Where:

%RTHC = percentage reduction of total hydrocarbons emissions achieved.

Ei = measured THC mass emission rate at the THC control device inlet, kg/hr (lb/hr).

Eo = measured THC mass emission rate at the THC control device outlet, kg/hr (lb/hr).

[66 FR 3193, Jan. 12, 2001, as amended at 66 FR 37593, July 19, 2001; 68 FR 7716, Feb. 18, 2003; 68 FR 67955, Dec. 5, 2003; 82 FR 47350, Oct. 11, 2017]

§63.866 Recordkeeping requirements.

(a) [Reserved]

(b) The owner or operator of an affected source or process unit must maintain records of any occurrence when corrective action is required under §63.864(k)(1), and when a violation is noted under §63.864(k)(2).

(c) In addition to the general records required by §63.10(b)(2)(iii) and (vi) through (xiv), the owner or operator must maintain records of the information in paragraphs (c)(1) through (8) of this section:

(1) Records of black liquor solids firing rates in units of Mg/d or ton/d for all recovery furnaces and semichemical combustion units;

(2) Records of CaO production rates in units of Mg/d or ton/d for all lime kilns;

(3) Records of parameter monitoring data required under §63.864, including any period when the operating parameter levels were inconsistent with the levels established during the performance test, with a brief explanation of the cause of the monitoring exceedance, the time the monitoring exceedance occurred, the time corrective action was initiated and completed, and the corrective action taken;

(4) Records and documentation of supporting calculations for compliance determinations made under §63.865(a) through (d);

(5) Records of parameter operating limits established for each affected source or process unit;

(6) Records certifying that an NDCE recovery furnace equipped with a dry ESP system is used to comply with the gaseous organic HAP standard in §63.862(c)(1);

(7) For the bag leak detection system on the hog fuel dryer fabric filter at Cosmo Specialty Fibers' Cosmopolis, Washington facility (Emission Unit no. HD-14), records of each alarm, the time of the alarm, the time corrective action was initiated and completed, and a brief description of the cause of the alarm and the corrective action taken; and

(8) Records demonstrating compliance with the requirement in §63.864(e)(1) to maintain proper operation of an ESP's AVC.

(d)(1) In theevent that an affected unit fails to meet an applicable standard, including any emission limit in §63.862 or any opacity or CPMS operating limit in §63.864, record the number of failures. For each failure record the date, start time, and duration of each failure.

(2) For each failure to meet an applicable standard, record and retain a list of the affected sources or equipment, and the following information:

(i) For any failure to meet an emission limit in §63.862, record an estimate of the quantity of each regulated pollutant emitted over the emission limit and a description of the method used to estimate the emissions.

(ii) For each failure to meet an operating limit in §63.864, maintain sufficient information to estimate the quantity of each regulated pollutant emitted over the emission limit. This information must be sufficient to provide a reliable emissions estimate if requested by the Administrator.

(3) Record actions taken to minimize emissions in accordance with §63.860(d) and any corrective actions taken to return the affected unit to its normal or usual manner of operation.

[66 FR 3193, Jan. 12, 2001, as amended at 66 FR 16408, Mar. 26, 2001; 68 FR 7718, Feb. 18, 2003; 69 FR 25323, May 6, 2004; 71 FR 20458, Apr. 20, 2006; 82 FR 47351, Oct. 11, 2017]

§63.867 Reporting requirements.

(a) Notifications. (1) The owner or operator of any affected source or process unit must submit the applicable notifications from subpart A of this part, as specified in Table 1 of this subpart.

(2) [Reserved]

(3) In addition to the requirements in subpart A of this part, the owner or operator of the hog fuel dryer at Cosmo Specialty Fibers' Cosmopolis, Washington, facility (Emission Unit no. HD-14) must include analysis and supporting documentation demonstrating conformance with EPA guidance and specifications for bag leak detection systems in §63.864(e)(12) in the Notification of Compliance Status.

(b) Additional reporting requirements for HAP metals standards. (1) Any owner or operator of a group of process units in a chemical recovery system at a mill complying with the PM emissions limits in §63.862(a)(1)(ii) must submit the PM emissions limits determined in §63.865(a) for each affected kraft or soda recovery furnace, smelt dissolving tank, and lime kiln to the Administrator for approval. The emissions limits must be submitted as part of the notification of compliance status required under subpart A of this part.

(2) Any owner or operator of a group of process units in a chemical recovery system at a mill complying with the PM emissions limits in §63.862(a)(1)(ii) must submit the calculations and supporting documentation used in §63.865(a)(1) and (2) to the Administrator as part of the notification of compliance status required under subpart A of this part.

(3) After the Administrator has approved the emissions limits for any process unit, the owner or operator of a process unit must notify the Administrator before any of the actions in paragraphs (b)(3)(i) through (iv) of this section are taken:

(i) The air pollution control system for any process unit is modified or replaced;

(ii) Any kraft or soda recovery furnace, smelt dissolving tank, or lime kiln in a chemical recovery system at a kraft or soda pulp mill complying with the PM emissions limits in §63.862(a)(1)(ii) is shut down for more than 60 consecutive days;

(iii) A continuous monitoring parameter or the value or range of values of a continuous monitoring parameter for any process unit is changed; or

(iv) The black liquor solids firing rate for any kraft or soda recovery furnace during any 24-hour averaging period is increased by more than 10 percent above the level measured during the most recent performance test.

(4) An owner or operator of a group of process units in a chemical recovery system at a mill complying with the PM emissions limits in §63.862(a)(1)(ii) and seeking to perform the actions in paragraph (b)(3)(i) or (ii) of this section must recalculate the overall PM emissions limit for the group of process units and resubmit the documentation required in paragraph (b)(2) of this section to the Administrator. All modified PM emissions limits are subject to approval by the Administrator.

(c) Excess emissions report. The owner or operator must submit semiannual excess emissions reports containing the information specified in paragraphs (c)(1) through (5) of this section. The owner or operator must submit semiannual excess emission reports and summary reports following the procedure specified in paragraph (d)(2) of this section as specified in §63.10(e)(3)(v).

(1) If the total duration of excess emissions or process control system parameter exceedances for the reporting period is less than 1 percent of the total reporting period operating time, and CMS downtime is less than 5 percent of the total reporting period operating time, only the summary report is required to be submitted. This report will be titled “Summary Report - Gaseous and Opacity Excess Emissions and Continuous Monitoring System Performance” and must contain the information specified in paragraphs (c)(1)(i) through (x) of this section.

(i) The company name and address and name of the affected facility.

(ii) Beginning and ending dates of the reporting period.

(iii) An identification of each process unit with the corresponding air pollution control device, being included in the semiannual report, including the pollutants monitored at each process unit, and the total operating time for each process unit.

(iv) An identification of the applicable emission limits, operating parameter limits, and averaging times.

(v) An identification of the monitoring equipment used for each process unit and the corresponding model number.

(vi) Date of the last CMS certification or audit.

(vii) An emission data summary, including the total duration of excess emissions (recorded in minutes for opacity and hours for gases), the duration of excess emissions expressed as a percent of operating time, the number of averaging periods recorded as excess emissions, and reason for the excess emissions (e.g., startup/shutdown, control equipment problems, other known reasons, or other unknown reasons).

(viii) A CMS performance summary, including the total duration of CMS downtime during the reporting period (recorded in minutes for opacity and hours for gases), the total duration of CMS downtime expressed as a percent of the total source operating time during that reporting period, and a breakdown of the total CMS downtime during the reporting period (e.g., monitoring equipment malfunction, non-monitoring equipment malfunction, quality assurance, quality control calibrations, other known causes, or other unknown causes).

(ix) A description of changes to CMS, processes, or controls since last reporting period.

(x) A certification by a certifying official of truth, accuracy and completeness. This will state that, based on information and belief formed after reasonable inquiry, the statements and information in the document are true, accurate, and complete.

(2) [Reserved]

(3) If measured parameters meet any of the conditions specified in §63.864(k)(1) or (2), the owner or operator of the affected source must submit a semiannual report describing the excess emissions that occurred. If the total duration of monitoring exceedances for the reporting period is 1 percent or greater of the total reporting period operating time, or the total CMS downtime for the reporting period is 5 percent or greater of the total reporting period operating time, or any violations according to §63.864(k)(2) occurred, information from both the summary report and the excess emissions and continuous monitoring system performance report must be submitted. This report will be titled “Excess Emissions and Continuous Monitoring System Performance Report” and must contain the information specified in paragraphs (c)(1)(i) through (x) of this section, in addition to the information required in §63.10(c)(5) through (14), as specified in paragraphs (c)(3)(i) through (vi) of this section. Reporting monitoring exceedances does not constitute a violation of the applicable standard unless the violation criteria in §63.864(k)(2) and (3) are reached.

(i) An identification of the date and time identifying each period during which the CMS was inoperative except for zero (low-level) and high-level checks.

(ii) An identification of the date and time identifying each period during which the CMS was out of control, as defined in §63.8(c)(7).

(iii) The specific identification of each period of excess emissions and parameter monitoring exceedances as described in paragraphs (c)(3)(iii)(A) through (E) of this section.

(A) For opacity:

(1) The total number of 6-minute averages in the reporting period (excluding process unit downtime).

(2) [Reserved]

(3) The number of 6-minute averages in the reporting period that exceeded the relevant opacity limit.

(4) The percent of 6-minute averages in the reporting period that exceed the relevant opacity limit.

(5) An identification of each exceedance by start and end time, date, and cause of exceedance (including startup/shutdown, control equipment problems, process problems, other known causes, or other unknown causes).

(B) [Reserved]

(C) For wet scrubber operating parameters:

(1) The operating limits established during the performance test for scrubbing liquid flow rate and pressure drop across the scrubber (or alternatively, fan amperage or RPM if used for smelt dissolving tank scrubbers).

(2) The number of 3-hour wet scrubber parameter averages below the minimum operating limit established during the performance test, if applicable.

(3) An identification of each exceedance by start and end time, date, and cause of exceedance (including startup/shutdown, control equipment problems, process problems, other known causes, or other unknown causes).

(D) For RTO operating temperature:

(1) The operating limit established during the performance test.

(2) The number of 1-hour and 3-hour temperature averages below the minimum operating limit established during the performance test.

(3) An identification of each exceedance by start and end time, date, and cause of exceedance including startup/shutdown, control equipment problems, process problems, other known causes, or other unknown causes).

(E) For alternative parameters established according to §63.864(e)(13) or (14) subject to the requirements of §63.864(k)(1) and (2):

(1) The type of operating parameters monitored for compliance.

(2) The operating limits established during the performance test.

(3) The number of 3-hour parameter averages outside of the operating limits established during the performance test.

(4) An identification of each exceedance by start and end time, date, and cause of exceedance including startup/shutdown, control equipment problems, process problems, other known causes, or other unknown causes).

(iv) The nature and cause of the event (if known).

(v) The corrective action taken or preventative measures adopted.

(vi) The nature of repairs and adjustments to the CMS that was inoperative or out of control.

(4) If a source fails to meet an applicable standard, including any emission limit in §63.862 or any opacity or CPMS operating limit in §63.864, report such events in the semiannual excess emissions report. Report the number of failures to meet an applicable standard. For each instance, report the date, time and duration of each failure. For each failure, the report must include a list of the affected sources or equipment, and for any failure to meet an emission limit under §63.862, provide an estimate of the quantity of each regulated pollutant emitted over the emission limit, and a description of the method used to estimate the emissions.

(5) The owner or operator of an affected source or process unit subject to the requirements of this subpart and subpart S of this part may combine excess emissions and/or summary reports for the mill.

(d) Electronic reporting. (1) Within 60 days after the date of completing each performance test (as defined in §63.2) required by this subpart, the owner or operator must submit the results of the performance test following the procedure specified in either paragraph (d)(1)(i) or (ii) of this section.

(i) For data collected using test methods supported by the EPA's Electronic Reporting Tool (ERT) as listed on the EPA's ERT Web site (https://www.epa.gov/electronic-reporting-air-emissions/electronic-reporting-tool-ert) at the time of the test, the owner or operator must submit the results of the performance test to the EPA via the Compliance and Emissions Data Reporting Interface (CEDRI). (CEDRI can be accessed through the EPA's Central Data Exchange (CDX) (https://cdx.epa.gov/).) Performance test data must be submitted in a file format generated through the use of the EPA's ERT or an alternate electronic file format consistent with the extensible markup language (XML) schema listed on the EPA's ERT Web site. If the owner or operator claims that some of the performance test information being submitted is confidential business information (CBI), the owner or operator must submit a complete file generated through the use of the EPA's ERT or an alternate electronic file consistent with the XML schema listed on the EPA's ERT Web site, including information claimed to be CBI, on a compact disc, flash drive, or other commonly used electronic storage media to the EPA. The electronic media must be clearly marked as CBI and mailed to U.S. EPA/OAPQS/CORE CBI Office, Attention: Group Leader, Measurement Policy Group, MD C404-02, 4930 Old Page Rd., Durham, NC 27703. The same ERT or alternate file with the CBI omitted must be submitted to the EPA via the EPA's CDX as described earlier in this paragraph (d)(1)(i).

(ii) For data collected using test methods that are not supported by the EPA's ERT as listed on the EPA's ERT Web site at the time of the test, the owner or operator must submit the results of the performance test to the Administrator at the appropriate address listed in §63.13 unless the Administrator agrees to or specifies an alternative reporting method.

(2) The owner or operator must submit the notifications required in §63.9(b) and §63.9(h) (including any information specified in §63.867(b)) and semiannual reports to the EPA via the CEDRI. (CEDRI can be accessed through the EPA's CDX (https://cdx.epa.gov).) You must upload an electronic copy of each notification in CEDRI beginning with any notification specified in this paragraph that is required after October 11, 2019. The owner or operator must use the appropriate electronic report in CEDRI for this subpart listed on the CEDRI Web site (https://www.epa.gov/electronic-reporting-air-emissions/compliance-and-emissions-data-reporting-interface-cedri) for semiannual reports. If the reporting form specific to this subpart is not available in CEDRI at the time that the report is due, you must submit the report to the Administrator at all the appropriate addresses listed in §63.13. Once the form has been available in CEDRI for 1 year, you must begin submitting all subsequent reports via CEDRI. The reports must be submitted by the deadlines specified in this subpart, regardless of the method in which the reports are submitted.

(3) If you are required to electronically submit a report through CEDRI in the EPA's CDX, and due to a planned or actual outage of either the EPA's CEDRI or CDX systems within the period of time beginning 5 business days prior to the date that the submission is due, you will be or are precluded from accessing CEDRI or CDX and submitting a required report within the time prescribed, you may assert a claim of EPA system outage for failure to timely comply with the reporting requirement. You must submit notification to the Administrator in writing as soon as possible following the date you first knew, or through due diligence should have known, that the event may cause or caused a delay in reporting. You must provide to the Administrator a written description identifying the date, time and length of the outage; a rationale for attributing the delay in reporting beyond the regulatory deadline to the EPA system outage; describe the measures taken or to be taken to minimize the delay in reporting; and identify a date by which you propose to report, or if you have already met the reporting requirement at the time of the notification, the date you reported. In any circumstance, the report must be submitted electronically as soon as possible after the outage is resolved. The decision to accept the claim of EPA system outage and allow an extension to the reporting deadline is solely within the discretion of the Administrator.

(4) If you are required to electronically submit a report through CEDRI in the EPA's CDX and a force majeure event is about to occur, occurs, or has occurred or there are lingering effects from such an event within the period of time beginning 5 business days prior to the date the submission is due, the owner or operator may assert a claim of force majeure for failure to timely comply with the reporting requirement. For the purposes of this section, a force majeure event is defined as an event that will be or has been caused by circumstances beyond the control of the affected facility, its contractors, or any entity controlled by the affected facility that prevents you from complying with the requirement to submit a report electronically within the time period prescribed. Examples of such events are acts of nature (e.g., hurricanes, earthquakes, or floods), acts of war or terrorism, or equipment failure or safety hazard beyond the control of the affected facility (e.g., large scale power outage). If you intend to assert a claim of force majeure, you must submit notification to the Administrator in writing as soon as possible following the date you first knew, or through due diligence should have known, that the event may cause or caused a delay in reporting. You must provide to the Administrator a written description of the force majeure event and a rationale for attributing the delay in reporting beyond the regulatory deadline to the force majeure event; describe the measures taken or to be taken to minimize the delay in reporting; and identify a date by which you propose to report, or if you have already met the reporting requirement at the time of the notification, the date you reported. In any circumstance, the reporting must occur as soon as possible after the force majeure event occurs. The decision to accept the claim of force majeure and allow an extension to the reporting deadline is solely within the discretion of the Administrator.

[66 FR 3193, Jan. 12, 2001, as amended at 66 FR 16408, Mar. 26, 2001; 68 FR 7718, Feb. 18, 2003; 68 FR 42605, July 18, 2003; 68 FR 46108, Aug. 5, 2003; 69 FR 25323, May 6, 2004; 82 FR 47351, Oct. 11, 2017; 85 FR 70494, Nov. 5, 2020]

§63.868 Delegation of authority.

(a) In delegating implementation and enforcement authority to a State under section 112(d) of the Clean Air Act, the authorities contained in paragraph (b) of this section must be retained by the Administrator and not transferred to a State.

(b) The authorities which will not be delegated to States are listed in paragraphs (b)(1) through (4) of this section:

(1) Approval of alternatives to standards in §63.862 under §63.6(g).

(2) Approval of a major change to test method under §63.7(e)(2)(ii) and (f) and as defined in §63.90.

(3) Approval of a major change to monitoring under §63.8(f) and as defined in §63.90.

(4) Approval of a major change to recordkeeping/reporting under §63.10(f) and as defined in §63.90.

[66 FR 3193, Jan. 12, 2001, as amended at 82 FR 47353, Oct. 11, 2017]

Table 1 to Subpart MM of Part 63 - General Provisions Applicability to Subpart MM

| General provisions reference | Summary of requirements | Applies to subpart MM | Explanation |

|---|---|---|---|

| 63.1(a)(1) | General applicability of the General Provisions | Yes | Additional terms defined in §63.861; when overlap between subparts A and MM of this part, subpart MM takes precedence. |

| 63.1(a)(2)-(14) | General applicability of the General Provisions | Yes | |

| 63.1(b)(1) | Initial applicability determination | No | Subpart MM specifies the applicability in §63.860. |

| 63.1(b)(2) | Title V operating permit - see 40 CFR part 70 | Yes | All major affected sources are required to obtain a title V permit. |

| 63.1(b)(3) | Record of the applicability determination | No | All affected sources are subject to subpart MM according to the applicability definition of subpart MM. |

| 63.1(c)(1) | Applicability of subpart A of this part after a relevant standard has been set | Yes | Subpart MM clarifies the applicability of each paragraph of subpart A of this part to sources subject to subpart MM. |

| 63.1(c)(2) | Title V permit requirement | Yes | All major affected sources are required to obtain a title V permit. There are no area sources in the pulp and paper mill source category. |

| 63.1(c)(3) | [Reserved] | No | |

| 63.1(c)(4) | Requirements for existing source that obtains an extension of compliance | Yes | |

| 63.1(c)(5) | Notification requirements for an area source that increases HAP emissions to major source levels | Yes | |

| 63.1(c)(6) | Reclassification | Yes | |

| 63.1(d) | [Reserved] | No | |

| 63.1(e) | Applicability of permit program before a relevant standard has been set | Yes | |