['Air Programs']

['Mobile Emission Sources']

12/22/2025

...

§86.1101-87 Applicability.

(a) The provisions of this subpart are applicable for 1987 and later model year gasoline-fueled and diesel heavy-duty engines and heavy-duty vehicles. These vehicles include light-duty trucks rated in excess of 6,000 pounds gross vehicle weight.

(b) References in this subpart to engine families and emission control systems shall be deemed to apply to durability groups and test groups as applicable for manufacturers certifying new light-duty trucks and Otto-cycle complete heavy-duty vehicles under the provisions of subpart S of this part.

[65 FR 59957, Oct. 6, 2000]

§86.1102-87 Definitions.

(a) The definitions in this section apply to this subpart.

(b) As used in this subpart, all terms not defined herein have the meaning given them in the Act.

Compliance level means the deteriorated pollutant emissions level at the 60th percentile point for a population of heavy-duty engines or heavy-duty vehicles subject to Production Compliance Audit testing pursuant to the requirements of this subpart. A compliance level for a population can only be determined for a pollutant for which an upper limit has been established in this subpart.

Configuration means a subdivision, if any, of a heavy-duty engine family for which a separate projected sales figure is listed in the manufacturer's Application for Certification and which can be described on the basis of emission control system, governed speed, injector size, engine calibration, or other parameters which may be designated by the Administrator, or a subclassification of light-duty truck engine family emission control system combination on the basis of engine code, inertia weight class, transmission type and gear ratios, rear axle ratio, or other parameters which may be designated by the Administrator.

NCP means a nonconformance penalty as described in section 206(g) of the Clean Air Act and in this subpart.

PCA means Production Compliance Audit as described in §86.1106-87 of this subpart.

Round has the meaning given in 40 CFR 1065.1001.

Subclass means a classification of heavy-duty engines of heavy-duty vehicles based on such factors as gross vehicle weight rating, fuel usage (gasoline-, diesel-, and methanol-fueled), vehicle usage, engine horsepower or additional criteria that the Administrator shall apply. Subclasses include, but are not limited to:

(i) Light-duty gasoline-fueled Otto cycle trucks (6,001-8,500 lb. GVW)

(ii) Light-duty methanol-fueled Otto cycle trucks (6,001-8,500 lb. GVW)

(iii) Light-duty petroleum-fueled diesel trucks (6,001-8,500 lb. GVW)

(iv) Light-duty methanol-fueled diesel trucks (6,001-8,500 lb. GVW)

(v) Light heavy-duty gasoline-fueled Otto cycle engines (for use in vehicles of 8,501-14,000 lb. GVW)

(vi) Light heavy-duty methanol-fueled Otto cycle engines (for use in vehicles of 8,501-14,000 lb. GVW)

(vii) Heavy heavy-duty gasoline-fueled Otto cycle engines (for use in vehicles of 14,001 lb and above GVW)

(viii) Heavy heavy-duty methanol-fueled Otto cycle engines (for use in vehicles of 14,001 lb. and above GVW)

(ix) Light heavy-duty petroleum-fueled diesel engines (see §86.085-2(a)(1))

(x) Light heavy-duty methanol-fueled diesel engines (see §86.085-2(a)(1))

(xi) Medium heavy-duty petroleum-fueled diesel engines (see §86.085-2(a)(2))

(xii) Medium heavy-duty methanol-fueled diesel engines (see §86.085-2(a)(2))

(xiii) Heavy heavy-duty petroleum-fueled diesel engines (see §86.085-2(a)(3))

(xiv) Heavy heavy-duty methanol-fueled diesel engines (see §86.085-2(a)(3))

(xv) Petroleum-fueled Urban Bus engines (see §86.091-2)

(xvi) Methanol-fueled Urban Bus engines (see §86.091-2).

For NCP purposes, all optionally certified engines and/or vehicles (engines certified in accordance with §86.087-10(a)(3) and vehicles certified in accordance with §86.085-1(b)) shall be considered part of, and included in the FRAC calculation of, the subclass for which they are optionally certified.

Test Sample means a group of heavy-duty engines or heavy-duty vehicles of the same configuration which have been selected for emission testing.

Upper limit means the emission level for a specific pollutant above which a certificate of conformity may not be issued or may be suspended or revoked.

[50 FR 35388, Aug. 30, 1985, as amended at 55 FR 46628, Nov. 5, 1990; 79 FR 23703, Apr. 28, 2014]

§86.1103-2016 Criteria for availability of nonconformance penalties.

(a) General. This section describes the three criteria EPA will use to use to evaluate whether NCPs are appropriate under the Clean Air Act for a given pollutant and a given subclass of heavy-duty engines and heavy-duty vehicles. Together, these criteria evaluate the likelihood that a manufacturer will be technologically unable to meet a standard on time. Note that since the first two of these criteria are intended to address the question of whether a given standard creates the possibility for this to occur, they are evaluated before the third criterion that addresses the likelihood that the possibility will actually happen.

(b) Criteria. We will establish NCPs for a given pollutant and subclass when we find that each of the following criteria is met:

(1) There is a new or revised emission standard is more stringent than the previous standard for the pollutant, or an existing standard for that pollutant has become more difficult to achieve because of a new or revised standard. When evaluating this criterion, EPA will consider a new or revised standard to be “new” or “revised” until the point at which all manufacturers already producing U.S.-directed engines or vehicles within the subclass have achieved full compliance with the standard. For purposes of this criterion, EPA will generally not consider compliance using banked emission credits to be “full compliance”.

(2) Substantial work is required to meet the standard for which the NCP is offered, as evaluated from the point at which the standard was adopted or revised (or the point at which the standard became more difficult meet because another standard was adopted or revised). Substantial work, as used in this paragraph (b)(2), means the application of technology not previously used in an engine or vehicle class or subclass, or the significant modification of existing technology or design parameters, needed to bring the vehicle or engine into compliance with either the more stringent new or revised standard or an existing standard which becomes more difficult to achieve because of a new or revised standard. Note that where this criterion is evaluated after any of the work has been completed, the criterion would be interpreted as whether or not substantial work was required to meet the standard.

(3) There is or is likely to be a technological laggard for the subclass. Note that a technological laggard is a manufacturer that is unable to meet the standard for one or more products within the subclass for technological reasons.

(c) Evaluation. (1) We will generally evaluate these criteria in sequence. Where we find that the first criterion has not been met, we will not consider the other two criteria. Where we find that the first criterion has been met but not the second, we will not consider the third criterion. We may announce our findings separately or simultaneously.

(2) We may consider any available information in making our findings.

(3) Where we are uncertain whether the first and/or second criteria have been met, we may presume that they have been met and make our decision based solely on whether or not the third criterion has been met.

(4) Where we find that a manufacturer will fail to meet a standard but are uncertain whether the failure is a technological failure, we may presume that the manufacturer is a technological laggard.

[81 FR 73980, Oct. 25, 2016]

§86.1104-2016 Determination of upper limits.

EPA shall set a separate upper limit for each phase of NCPs and for each service class.

(a) Except as provided in paragraphs (b), (c) and (d) of this section, the upper limit shall be set as follows:

(1) The upper limit applicable to a pollutant emission standard for a subclass of heavy-duty engines or heavy-duty vehicles for which an NCP is established in accordance with §86.1103-87, shall be the previous pollutant emission standard for that subclass.

(2) If a manufacturer participates in any of the emissions averaging, trading, or banking programs, and carries over certification of an engine family from the prior model year, the upper limit for that engine family shall be the family emission limit of the prior model year, unless the family emission limit is less than the upper limit determined in paragraph (a)(1) of this section.

(b) If no previous standard existed for the pollutant under paragraph (a) of this section, the upper limit will be developed by EPA during rulemaking.

(c) EPA may set the upper limit during rulemaking at a level below the level specified in paragraph (a) of this section if we determine that a lower level is achievable by all engines or vehicles in that subclass.

(d) EPA may set the upper limit at a level above the level specified in paragraph (a) of this section if we determine that such level will not be achievable by all engines or vehicles in that subclass.

[81 FR 73981, Oct. 25, 2016]

§86.1105-87 Emission standards for which nonconformance penalties are available.

(a)-(b) [Reserved]

(c) Effective in the 1991 model year, NCPs will be available for the following additional emission standards:

(1) [Reserved]

(2) Petroleum-fueled diesel heavy-duty engine oxides of nitrogen standard of 5.0 grams per brake horsepower-hour.

(i) For petroleum-fueled light heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $830.

(2) COC90: $946.

(3) MC50: $1,167 per gram per brake horsepower-hour.

(4) F: 1.2.

(B) The following factor shall be used to calculate the engineering and development component of the NCP in accordance with §86.1113-87(h): 0.12.

(ii) For petroleum-fueled medium heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $905.

(2) COC90: $1,453.

(3) MC50: $1,417 per gram per brake horsepower-hour.

(4) F: 1.2.

(B) The following factor shall be used to calculate the engineering and development component of the NCP in accordance with §86.1113-87(h): 0.11.

(iii) For petroleum-fueled heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $930.

(2) COC90: $1,590.

(3) MC50: $2,250 per gram per brake horsepower-hour.

(4) F: 1.2.

(B) The following factor shall be used to calculate the engineering and development component of the NCP in accordance with §86.1113-87(h): 0.11.

(3) Petroleum-fueled diesel light-duty trucks (between 6,001 and 14,000 lbs GVW) particulate matter emission standard of 0.13 grams per vehicle mile.

(i) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(A) COC50: $711.

(B) COC90: $1,396.

(C) MC50: $2,960 per gram per brake horsepower-hour.

(D) F: 1.2.

(ii) The following factor shall be used to calculate the engineering and development component of the NCP in accordance with §86.1113-87(h): 0.01.

(d) Effective in the 1993 model year, NCPs will be available for the following additional emission standard:

(1) Petroleum-fueled diesel bus engine (as defined in §86.093-2) particulate emission standard of 0.10 grams per brake horsepower-hour.

(i) The following values shall be used to calculate an NCP for the standard set forth in §86.093-11(a)(1)(v)(A) in accordance with §86.1113-87(a):

(A) COC50: $4,020.

(B) COC90: $4,535.

(C) MC50: $22,971 per gram per brake horsepower-hour.

(D) F: 1.2.

(E) UL: 0.25 grams per brake horsepower-hour.

(ii) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.093-11(a)(1)(v)(A) in accordance with §86.1113-87(h): 0.02.

(2) [Reserved]

(e) The values of COC50, COC90, and MC50 in paragraphs (a) and (b) of this section are expressed in December 1984 dollars. The values of COC50, COC90, and MC50 in paragraphs (c) and (d) of this section are expressed in December 1989 dollars. The values of COC50, COC90, and MC50 in paragraph (f) of this section are expressed in December 1991 dollars. The values of COC50, COC90, and MC50 in paragraphs (g) and (h) of this section are expressed in December 1994 dollars. The values of COC50, COC90, and MC50 in paragraph (i) of this section are expressed in December 2001 dollars. These values shall be adjusted for inflation to dollars as of January of the calendar year preceding the model year in which the NCP is first available by using the change in the overall Consumer Price Index, and rounded to the nearest whole dollar.

(f) Effective in the 1994 model year, NCPs will be available for the following emission standards:

(1) Petroleum-fueled urban bus engine (as defined in §86.091-2) particulate emission standard of 0.07 grams per brake horsepower-hour.

(i) The following values shall be used to calculate an NCP for the standard set forth in §86.094-11(a)(1)(v)(A) in accordance with §86.1113-87(a):

(A) COC50: $3292.

(B) COC90: $10,014.

(C) MC50: $109,733.

(D) F: 1.2.

(ii) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.094-11(a)(1)(v)(A) in accordance with §86.1113-87(h): 0.38.

(2) Petroleum-fueled diesel heavy-duty engine particulate matter emission standard of 0.10 grams per brake horsepower-hour.

(i) For petroleum-fueled light heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $772.

(2) COC90: $1,325.

(3) MC50: $8,178 per gram per brake horsepower-hour.

(4) F: 1.2.

(B) The following factor shall be used to calculate the engineering and development component of the NCP in accordance with §86.1113-87(h): 0.081.

(ii) For petroleum-fueled medium heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $1,276.

(2) COC90: $3,298.

(3) MC50: $15,370 per gram per brake horsepower-hour.

(4) F: 1.2.

(B) The following factor shall be used to calculate the engineering and development component of the NCP in accordance with §86.1113-87(h): 0.098.

(iii) For petroleum-fueled heavy heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $2,105.

(2) COC90: $6,978.

(3) MC50: $30,070 per gram per brake horsepower-hour.

(4) F: 1.2.

(B) The following factor shall be used to calculate the engineering and development component of the NCP in accordance with §86.1113-87(h): 0.083.

(g) Effective in the 1996 model year, NCPs will be available for the following emission standard:

(1) Light-duty truck 3 diesel-fueled vehicle at full useful life (as defined in §86.094-2) particulate matter emission standard of 0.10 g/mi.

(i) The following values shall be used to calculate an NCP for the standard set forth in §86.094-9(a)(1)(ii) in accordance with §86.1113-87(a):

(A) COC50: $441.

(B) COC90: $1,471.

(C) MC50: $14,700 per gram per mile.

(D) F: 1.2.

(ii) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.094-9(a)(1)(ii) in accordance with §86.1113-87(h): 0.093.

(2) Light-duty truck 3 diesel-fueled vehicle at full useful life (as defined in §86.094-2) oxides of nitrogen emission standard of 0.98 g/mi.

(i) The following values shall be used to calculate an NCP for the standard set forth in §86.094-9(a)(1)(ii) in accordance with §86.1113-87(a):

(A) COC50: $654.

(B) COC90: $779.

(C) MC50: $908 per gram per mile.

(D) F: 1.2.

(ii) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.094-9(a)(1)(ii) in accordance with §86.1113-87(h): 0.082.

(3) 1996 Urban Bus (as defined in §86.094-2) particulate matter emission standard of 0.05 g/BHp-hr.

(i) The following values shall be used to calculate an NCP for the standard set forth in §86.094-9(a)(1)(ii) in accordance with §86.1113-87(a):

(A) COC50: $576.

(B) COC90: $6,569.

(C) MC50: $28,800 per gram per brake horsepower-hour.

(D) F: 1.2.

(ii) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.094-9(a)(1)(ii) in accordance with §86.1113-87(h): 0.500.

(h) Effective in the 1998 model year, NCPs will be available for the following emission standard:

(1) Petroleum-fueled diesel heavy-duty engine oxides of nitrogen standard of 4.0 grams per brake horsepower-hour.

(i) For petroleum-fueled light heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $833.

(2) COC90: $1,513.

(3) MC50: $833 per gram per brake horsepower-hour.

(4) F: 1.2.

(B) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.094-9(a)(1)(ii) in accordance with §86.1113-87(h): 0.039.

(ii) For petroleum-fueled medium heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $444.

(2) COC90: $1,368.

(3) MC50: $444 per gram per brake horsepower-hour.

(4) F: 1.2.

(B) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.094-9(a)(1)(ii) in accordance with §86.1113-87(h): 0.043.

(iii) For petroleum-fueled heavy heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $1,086.

(2) COC90: $2,540.

(3) MC50: $1,086 per gram per brake horsepower-hour

(4) F: 1.2.

(B) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.094-9(a)(1)(ii) in accordance with §86.1113-87(h): 0.039.

(2) [Reserved]

(i) Effective in the 2004 model year, NCPs will be available for the following emission standard:

(1) Diesel heavy-duty engine non-methane hydrocarbon plus oxides of nitrogen standard of 2.4 grams per brake horsepower-hour (or alternatively, 2.5 grams per brake horsepower-hour with a limit on non-methane hydrocarbon emissions of 0.5 grams per brake horsepower-hour), in §86.004-11(a)(1)(i).

(i) For light heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $1,240.

(2) COC90: $2,710.

(3) MC50: $2,000 per gram per brake horsepower-hour.

(4) F: 1.3.

(5) UL: 4.5 grams per brake horsepower-hour; notwithstanding §86.1104-91.

(B) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.004-11(a)(1)(i) in accordance with §86.1113-87(h): 0.403.

(ii) For medium heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $2,740.

(2) COC90: $4,930.

(3) MC50: $1,400 per gram per brake horsepower-hour.

(4) F: 1.3.

(5) UL: 4.5 grams per brake horsepower-hour; notwithstanding §86.1104-91.

(B) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.004-11(a)(1)(i) in accordance with §86.1113-87(h): 0.197.

(iii) For heavy heavy-duty diesel engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC50: $6,810.

(2) COC90: $12,210.

(3) MC50: $5,600 per gram per brake horsepower-hour.

(4) F: 1.3.

(5) UL: 6.0 grams per brake horsepower-hour; notwithstanding §86.1104-91.

(B) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.004-11(a)(1)(i) in accordance with §86.1113-87(h): 0.090.

(iv) For diesel urban bus engines:

(A) The following values shall be used to calculate an NCP in accordance with §86.1113-87(a):

(1) COC 50: $3,930.

(2) COC90: $6,660.

(3) MC50: $3,800 per gram per brake horsepower-hour.

(4) F: 1.3.

(5) UL: 4.5 grams per brake horsepower-hour; notwithstanding §86.1104-91.

(B) The following factor shall be used to calculate the engineering and development component of the NCP for the standard set forth in §86.004-11(a)(1)(i) in accordance with §86.1113-87(h): 0.155.

(2) [Reserved]

[50 FR 53466, Dec. 31, 1985, as amended at 52 FR 47870, Dec. 16, 1987; 53 FR 43878, Oct. 31, 1988; 56 FR 64712, Dec. 12, 1991; 58 FR 15802, Mar. 24, 1993; 58 FR 68540, Dec. 28, 1993; 60 FR 33925, June 29, 1995; 61 FR 6949, 6953, Feb. 23, 1996; 67 FR 51477, Aug. 8, 2002; 69 FR 18803, Apr. 9, 2004; 77 FR 4687, Jan. 31, 2012; 77 FR 54402, Sept. 5, 2012; 79 FR 23703, Apr. 28, 2014; 81 FR 73981, Oct. 25, 2016]

§86.1106-87 Production compliance auditing.

For a model year in which upper limits for heavy-duty engine or heavy-duty vehicle emission standards for one or more exhaust pollutants are specified in §86.1105-87, a manufacturer may elect to conduct a Production Compliance Audit (PCA) for each engine or vehicle configuration satisfying the following conditions:

(a) Certification test results, pursuant to §86.082-23, exceed the emission standard for a particular pollutant but do not exceed the upper limit established for that pollutant. In thatevent, the manufacturer will be offered a qualified certificate of conformity allowing for the introduction into commerce of the specified engine family, Provided, That:

(1) The manufacturer must agree to conduct a PCA of those engines or vehicles;

(2) PCA testing must be conducted on the same configurations that exceeded the standard in certification. In lieu of that requirement, the Administrator may approve testing of a greater or lesser number of configurations provided the manufacturer agrees to pay the NCP determined from the CL of each tested configuration for that configuration and for other non-tested configurations that have similar emission characteristics. If an acceptable showing of similar emission characteristics is not made, the highest CL of the configurations tested will apply to all non-tested configurations exceeding the standard.

(3) The selection of engines or vehicles for PCA testing must be initiated no later than five (5) days after the start of assembly-line production of the specified engine or vehicle configuration, unless that period is extended by the Administrator;

(4) The manufacturer must agree:

(i) To pay the NCP amount calculated as a result of PCA testing on each engine or vehicle, unless the manufacturer successfully challenges the Administrator's determination of the compliance level or penalty calculation or both under §86.1115-87(c);

(ii) To recall any engines or vehicles introduced into commerce, without invoking the procedural requirements of section 207(c) of the Clean Air Act, if the compliance level for the engine or vehicle configuration of (a)(2) exceeds the upper limit as determined by the PCA;

(5) If the compliance level determined in the PCA is below the emission standard, no NCP will be offered, and all appropriate qualifications will be removed from the qualified certificate of conformity.

(b) An engine or vehicle configuration fails a Selective Enforcement Audit (SEA) under subpart K of 40 CFR part 86 with respect to the standard for a particular pollutant but does not fail with respect to the upper limit established for that pollutant, and no NCP has been previously assessed for that configuration, Provided, That:

(1) The manufacturer must submit a written report to the Administrator within five (5) days after failure to pass the audit containing the following:

(i) A statement that the manufacturer does not intend, at that time, to make any engine and/or emission control system design changes that may remedy the nonconformity; and

(ii) A request from the manufacturer to conduct the PCA, including the date the testing will begin;

(2) Failure to submit the report within five (5) days after the SEA failure will result in the forfeiture of the NCP option, unless a satisfactory justification for the delay is provided to the Administrator;

(3) The selection of any required engines or vehicles for PCA testing must be initiated no later than ten (10) days after the SEA failure unless extended by the Administrator; otherwise, the manufacturer may forfeit the option to elect an NCP;

(4) PCA testing must be conducted on the same configuration that failed the SEA;

(5) Test results from the SEA, together with any additional test results required during the PCA, will be used in establishing a compliance level for the configuration pursuant to §86.1112-87(a); and

(6) The manufacturer, upon approval by the Administrator to conduct a PCA on a failed SEA engine or vehicle configuration, must agree:

(i) To pay the NCP amount calculated as a result of PCA testing on each engine or vehicle introduced into commerce after the tenth day of the SEA failure, unless the manufacturer successfully challenges the Administrator's determination of the compliance level or penalty calculation or both under §86.1115-87(c);

(ii) To recall any engines or vehicles introduced into commerce after the tenth day of the SEA failure, without invoking the procedural requirements of section 207(c) of the Clean Air Act, if the compliance level of the engine or vehicle configuration exceeds the upper limit as determined by the PCA.

(c) An engine or vehicle configuration, for which an NCP has been previously assessed for a particular pollutant, either passes an SEA with respect to the particular pollutant standard, fails an SEA with respect to the particular pollutant standard but not the previous compliance level, or fails an SEA with respect to the previous compliance level but not the associated upper limit, Provided, That:

(1) The manufacturer must submit a written statement to the Administrator within five (5) days of the conclusion of the SEA requesting a PCA, including the date the PCA testing will begin; otherwise, the manufacturer forfeits the option to establish a new compliance level;

(2) The selection of any required engines or vehicles for PCA testing must be initiated no later than ten (10) days after the conclusion of the SEA unless the period is extended by the Administrator; otherwise, the manufacturer forfeits the option to establish a new compliance level;

(3) PCA testing must be conducted on the same configuration tested during the SEA, and all conditions in the SEA test order must apply to the PCA;

(4) Test results for the SEA, together with any additional test results required during the PCA, will be used in establishing a new compliance level for the configuration pursuant to §86.1112-87(a);

(5) The manufacturer must agree:

(i) To pay the NCP amount calculated as a result of PCA testing on each engine or vehicle introduced into commerce after the tenth day of the conclusion of the SEA, unless the manufacturer successfully challenges the Administrator's determination of the compliance level or penalty calculation or both under §86.1115-87(c);

(ii) To recall any engines or vehicles introduced into commerce after the tenth day after the conclusion of the SEA, without invoking the procedural requirements of section 207(c) of the Clean Air Act, if the engine or vehicle configuration exceeds the upper limit as determined by the PCA;

(6) A previously assessed NCP will be terminated and no NCP will be established as a result of the new PCA if the compliance level is determined to be below the applicable emission standards.

(d) The implementation of a production running change that causes the emission level for a particular pollutant to be either above the emission standard but below the associated upper limit for a vehicle or engine configuration for which an NCP has not been previously assessed, or below the associated upper limit for a vehicle or engine configuration for which an NCP has been previously assessed, regardless of the previous compliance level. In that event, the manufacturer will be offered a qualified certificate of conformity allowing for the introduction into commerce of the engine or vehicle configuration resulting from the running change, Provided, That:

(1) The manufacturer must submit a written report to the Administrator outlining the reason for the running change and the date the manufacturer will begin PCA testing;

(2) The manufacturer must agree:

(i) To pay the NCP amount calculated as a result of PCA testing on each engine or vehicle, unless the manufacturer successfully challenges the Administrator's determination of compliance level or penalty calculation or both under §86.1115-87(c);

(ii) To recall any engines or vehicles introduced into commerce, without invoking the procedural requirements of section 207(c) of the Clean Air Act, if the engine or vehicle configuration exceeds the upper limit as determined by the PCA;

(3) The selection of engines or vehicles for PCA testing must be initiated no later than five (5) days after the start of assembly line production of the engine or vehicle configuration resulting from the running change unless that period is extended by the Administrator; and

(4) If the compliance level is determined to be below the applicable emission standard, a previously assessed NCP will be terminated, an NCP will not be established as a result of the PCA testing, and all qualifications will be removed from the qualified certificate of conformity.

(e) The following requirements are applicable to each PCA under this subpart.

(1) The manufacturer shall make the following documents available to EPA Enforcement Officers upon request;

(i) A properly filed and current application for certification, following the format prescribed by the EPA for the appropriate model year; and

(ii) A copy of the shop manual and dealer service bulletins for the configurations being tested.

(2) Only one mechanic at a time per engine or vehicle shall make authorized checks, adjustments, or repairs, unless a particular check, adjustment, or repair requires a second mechanic as indicated in the shop manual or dealer service bulletins.

(3) A mechanic shall not perform any check, adjustment, or repair without an Enforcement Officer present unless otherwise authorized.

(4) The manufacturer shall utilize only those tools and test equipment utilized by its dealers or those dealers using its engines when performing authorized checks, adjustments, or repairs.

[50 FR 35388, Aug. 30, 1985, as amended at 58 FR 68540, Dec. 28, 1993]

§86.1107-87 Testing by the Administrator.

(a) The Administrator may require that engines or vehicles of a specified configuration be selected in a manner consistent with the requirements of §86.1110-87 and submitted to him at such place as he may designate for the purpose of conducting emission tests in accordance with §86.1111-87 to determine whether engines or vehicles manufactured by the manufacturer conform with the regulations of this subpart.

(b)(1) Whenever the Administrator conducts a test on a test engine or vehicle or the Administrator and manufacturer each conduct a test on the same test engine or vehicle, the results of the Administrator's test will comprise the official data for that engine or vehicle.

(2) Whenever the manufacturer conducts all tests on a test engine or vehicle, the manufacturer's test data will be accepted as the official data, provided that if the Administrator makes a determination based on testing under paragraph (a) of this section that there is a substantial lack of agreement between the manufacturer's test results and the Administrator's test results, no manufacturer's test data from the manufacturer's test facility will be accepted for purposes of this subpart.

(c) If the Administrator determines that testing conducted under paragraph (a) of this section demonstrates a lack of agreement under paragraph (b)(2) of this section, the Administrator shall:

(1) Notify the manufacturer in writing of his determination that the manufacturer's test facility is inappropriate for conducting the tests required by this subpart and the reasons therefore; and

(2) Reinstate any manufacturer's data only upon a showing by the manufacturer that the data acquired under paragraph (a) of this section was erroneous and the manufacturer's data was correct.

(d) The manufacturer may request in writing that the Administrator reconsider his determination in paragraph (b)(2) of this section based on data or information which indicates that changes have been made to the test facility and that these changes have resolved the reasons for disqualification.

§86.1108-87 Maintenance of records.

(a) The manufacturer of any new gasoline-fueled or diesel heavy-duty engine or heavy-duty vehicle subject to any of the provisions of this subpart shall establish, maintain, and retain the following adequately organized and indexed records:

(1) General records. A description of all equipment used to test engines or vehicles in accordance with §86.1111-87, pursuant to PCA testing under this subpart, specifically;

(i) If testing heavy-duty gasoline engines, the equipment requirements specified in 40 CFR part 1065, subparts B and C;

(ii) If testing heavy-duty diesel engines, the equipment requirements specified in 40 CFR part 1065, subparts B and C;

(iii) If testing light-duty gasoline-fueled trucks, the equipment requirements specified in §§86.106 (excluding all references to particulate emission testing) and 86.1506-84 of this part; and

(iv) If testing light-duty diesel trucks, the equipment requirements specified in §86.106 (excluding all references to evaporative emission testing) of this part.

(2) Individual records. These records pertain to each Production Compliance Audit conducted pursuant to this subpart.

(i) The date, time, and location of each test;

(ii) The number of hours of service accumulated on the engine or the number of miles on the vehicle when the test began and ended;

(iii) The names of all supervisory personnel involved in the conduct of the Production Compliance Audit;

(iv) A record and description of any repair performed, giving the date and time of the repair, the reason for it, the person authorizing it, and the names of all personnel involved in the supervision and performance of the repair;

(v) The date when the engine or vehicle was shipped from the assembly plant or associated storage facility and when it was received at the testing facility;

(vi) A complete record of all emission tests performed pursuant to this subpart (except tests performed by EPA directly), including all individual worksheets and/or other documentation relating to each test, or exact copies thereof, specifically -

(A) If testing heavy-duty gasoline engines, the record requirements specified in 40 CFR 1065.695;

(B) If testing heavy-duty diesel engines, the record requirements specified in 40 CFR 1065.695;

(C) If testing light-duty gasoline fueled trucks, the record requirements specified in §§86.142 (excluding all references to diesel vehicles) and 86.1542-84; and

(D) If the testing light-duty diesel trucks, the record requirements specified in §86.142; and

(vii) A brief description of any significant Production Compliance Auditevents commencing with the test engine or vehicle selection process, but not described by any subparagraph under paragraph (a)(2) of this section, including such extraordinary events as engine damage during shipment or vehicle accident.

(3) The manufacturer shall record the test equipment description, pursuant to paragraph (a)(1) of this section, for each test cell that was used to perform emission testing under this subpart.

(b) The manufacturer shall retain all records required to be maintained under this subpart for a period of six (6) years after completion of all testing. Records may be retained as hard copy or reduced to microfilm, punch cards, etc., depending upon the manufacturer's record retention procedure, provided that in every case all the information contained in the hard copy is retained.

[50 FR 35388, Aug. 30, 1985, as amended at 70 FR 40437, July 13, 2005]

§86.1109-87 Entry and access.

(a) To allow the Administrator to determine whether a manufacturer is complying with the provisions of this subpart, EPA Enforcement Officers are authorized to enter any of the following (during operating hours and upon presentation of credentials):

(1) Any facility where any engine or vehicle to be introduced into commerce or any emission related component is manufactured, assembled, or stored;

(2) Any facility where any tests conducted pursuant to a PCA request or any procedures or activities connected with these tests are or were performed;

(3) Any facility where any engine or vehicle which is being tested, was tested, or will be tested is present; and

(4) Any facility where any record or other document relating to any of the above is located.

(b) Upon admission to any facility referred to in paragraph (a) of this section, EPA Enforcement Officers are authorized to perform the following inspection-related activities:

(1) To inspect and monitor any aspects of engine or vehicle manufacture, assembly, storage, testing and other procedures, and the facilities in which these procedures are conducted.

(2) To inspect and monitor any aspect of engine or vehicle test procedures or activities, including, but not limited to, monitoring engine or vehicle selection, preparation, service or mileage accumulation, preconditioning, repairs, emission test cycles, and maintenance; and to verify calibration of test equipment;

(3) To inspect and make copies of any records or documents related to the assembly, storage, selection and testing of an engine or vehicle; and

(4) To inspect and photograph any part or aspect of any engine or vehicle and any component used in the assembly thereof that is reasonably related to the purpose of the entry.

(c) EPA Enforcement Officers are authorized to obtain reasonable assistance without cost from those in charge of a facility to help them perform any function listed in this subpart and are authorized to request the manufacturer conducting the PCA to make arrangement with those in charge of a facility operated for its benefit to furnish reasonable assistance without cost to EPA, whether or not the manufacturer controls the facility.

(d) EPA Enforcement Officers are authorized to seek a warrant or court order authorizing the EPA Enforcement Officers to conduct activities related to entry and access as authorized in this section, as appropriate, to execute the functions specified in this section. EPA Enforcement Officers may proceed ex parte to obtain a warrant whether or not the Enforcement Officers first attempted to seek permission of the manufacturer conducting the PCA or the party in charge of the facilities in question to conduct activities related to entry and access as authorized in this section.

(e) A manufacturer that conducts a PCA shall permit EPA Enforcement Officers who present a warrant or court order as described in paragraph (d) of this section to conduct activities related to entry and access as authorized in this section and as described in the warrant or court order. The manufacturer shall cause those in charge of its facility or a facility operated for its benefit to permit EPA Enforcement Officers to conduct activities related to entry and access as authorized in this section pursuant to a warrant or court order whether or not the manufacturer controls the facility. In the absence of such a warrant or court order, EPA Enforcement Officers may conduct activities related to entry and access as authorized in this section only upon the consent of the manufacturer or the party in charge of the facilities in question.

(f) It is not a violation of this part or the Clean Air Act for any person to refuse to permit EPA Enforcement Officers to conduct activities related to entry and access as authorized in this section without a warrant or court order.

(g) A manufacturer is responsible for locating its foreign testing and manufacturing facilities in jurisdictions in which local foreign law does not prohibit EPA Enforcement Officers from conducting the entry and access activities specified in this section. EPA will not attempt to make any inspections which it has been informed that local foreign law prohibits.

(h) For purposes of this section, the following definitions are applicable:

(1) Presentation of Credentials means display of the document designating a person as an EPA Enforcement Officer.

(2) Where engine or vehicle storage areas or facilities are concerned, operating hours means all times during which personnel other than custodial personnel are at work in the vicinity of the area or facility and have access to it.

(3) Where facilities or areas other than those covered by paragraph (h)(2) of this section are concerned, operating hours means all times during which an assembly line is in operation, engine or vehicle assembly is taking place, testing repair, service accumulation, preparation or compilation of records is taking place, or any other procedure or activity related to engine or vehicle manufacture, assembly or testing is being carried out in a facility.

(4) Reasonable assistance includes, but is not limited to, clerical, copying, interpreting and translating services, and making personnel of the facility being inspected available during their working hours on an EPA Enforcement Officer's request to inform the EPA Enforcement Officer of how the facility operates and to answer his or her questions. Any employee whom an EPA Enforcement Officer requests the manufacturer to cause to appear for questioning will be entitled to be accompanied, represented and advised by counsel.

§86.1110-87 Sample selection.

(a) Engines or vehicles comprising a test sample which are required to be tested pursuant to a PCA in accordance with this subpart will be selected at the location and in the manner specified by EPA. If a manufacturer determines that the test engines or vehicles cannot be selected in the manner specified by EPA, an alternative selection procedure may be employed, provided that the manufacturer requests approval of the alternative procedure in advance of the start of test sample selection and that the Administrator approves the procedure.

(b) The manufacturer shall have assembled the test engines or vehicles of the configuration selected for testing using its normal mass production processes for engines or vehicles to be distributed into commerce. In the case of heavy-duty engines, if the test engines are selected at a location where they do not have their operational and emission control systems installed, EPA will specify the manner and location for selection of components to complete assembly of the engines. The manufacturer shall assemble these components onto the test engines using normal assembly and quality control procedures as documented by the manufacturer.

(c) No quality control, testing, or assembly procedures will be used on the completed test engine or vehicle or any portion thereof, including parts and subassemblies, that will not be used during the production and assembly of all other engines or vehicles of that configuration.

(d) The EPA Enforcement Officers may specify that they, rather than the manufacturer, will select the test engines or vehicles.

(e) The order in which test engines or vehicles are selected determines the order in which test results are to be used in applying the PCA testing plan in accordance with §86.1112-87.

(f) The manufacturer shall keep on hand all engines or vehicles comprising the test sample until such time as a compliance level is determined in accordance with §86.1112-87(a) except that the manufacturer may ship any tested engine or vehicle which has not failed in accordance with §86.1112-87(f)(1). However, once the manufacturer ships any test engine or vehicle, it relinquishes the prerogative to conduct retests as provided in §86.1111-87(i).

§86.1111-87 Test procedures for PCA testing.

(a)(1) For heavy-duty engines, the prescribed test procedure for PCA testing is the Federal Test Procedure as described in subparts N, I, and P of this part.

(2) For heavy-duty vehicles, the prescribed test procedure for PCA testing is described in subpart M of this part.

(3) For light-duty trucks, the prescribed test procedure for PCA testing is the Federal Test Procedure as described in subparts B and P of this part.

(4) During the testing of heavy-duty diesel engines, the manufacturer shall decide for each engine, prior to the start of the initial cold cycle, whether the measurement of background particulate is required for the cold and hot cycles to be valid. The manufacturer may choose to have different requirements for the cold and hot cycles. If a manufacturer chooses to require the measurement of background particulate, failure to measure background particulate shall void the test cycle regardless of the test results. If a test cycle is void, the manufacturer shall retest using the same validity requirements of the initial test.

(5) When testing light-duty trucks, the following exceptions to the test procedures in subpart B are applicable:

(i) The manufacturer may use gasoline test fuel meeting the specifications of paragraph (a) of §86.113 for mileage accumulation. Otherwise, the manufacturer may use fuels other than those specified in this section only with advance approval of the Administrator.

(ii) The manufacturer may measure the temperature of the test fuel at other than the approximate midvolume of the fuel tank, as specified in paragraph (a) of §86.131, and may drain the test fuel from other than the lowest point of the fuel tank, as specified in paragraph (b) of §86.131, with the advance approval of the Administrator.

(iii) The manufacturer may perform additional preconditioning on PCA test vehicles other than the preconditioning specified in §86.132 only if the additional preconditioning has been performed on certification test vehicles of the same configuration.

(iv) The manufacturer shall perform the heat build procedure 11 to 34 hours following vehicle preconditioning rather than according to the time period specified in paragraph (a) of §86.133.

(v) The manufacturer may substitute slave tires for the drive wheel tires on the vehicle as specified in paragraph (e) of §86.135, provided that the slave tires are the same size as the drive wheel tires.

(vi) The cold start exhaust emission test described in §86.137 shall follow the heat build procedure described in §86.133 by not more than one hour.

(vii) In performing exhaust sample analysis under §86.140:

(A) When testing diesel vehicles, the manufacturer shall allow a minimum of 20 minutes warm-up for the HC analyzer, and a minimum of 2 hours warm-up for the CO, CO2 and NOX analyzers. [Power is normally left on for infrared and chemiluminescent analyzers. When not in use, the chopper motors of the infrared analyzers are turned off and the phototube high voltage supply to the chemiluminescent analyzers is placed in the standby position.]

(B) The manufacturer shall exercise care to prevent moisture from condensing in the sample collection bags.

(viii) The manufacturer need not comply with §86.142, since the records required therein are provided under other provisions of this subpart.

(ix) In addition to the requirements of subpart B of this part, the manufacturer shall prepare gasoline-fueled vehicles as follows prior to exhaust emission testing:

(A) The manufacturer shall inspect the fuel system to insure the absence of any leaks of liquid or vapor to the atmosphere by applying a pressure of 14.5 ±0.5 inches of water to the fuel system, allowing the pressure to stabilize, and isolating the fuel system from the pressure source. Following isolation of the fuel system, pressure must not drop more than 2.0 inches of water in 5 minutes. If required, the manufacturer shall perform corrective action in accordance with paragraph (d) of this section.

(B) When performing this pressure check, the manufacturer shall exercise care to neither purge nor load the evaporative emission control system.

(C) The manufacturer shall not modify the test vehicle's evaporative emission control system by component addition, deletion, or substitution, except to comply with paragraph (a)(4)(ii) of this section if approved in advance by the Administrator.

(b)(1) The manufacturer shall not adjust, repair, prepare, or modify the engines or vehicles selected for testing and shall not perform any emission tests on engines or vehicles selected for testing pursuant to a PCA request unless the adjustment, repair, preparation, modification, or tests are documented in the manufacturer's engine or vehicle assembly and inspection procedures and are actually performed on all engines or vehicles produced or unless these adjustments or tests are required or permitted under this subpart or are approved in advance by the Administrator.

(2) For 1984 and later model years the Administrator may adjust or cause to be adjusted any engine parameter which the Administrator has determined to be subject to adjustment for certification, Selective Enforcement Audit and Production. Compliance Audit testing in accordance with §86.084-22(e)(1), to any setting within the physically adjustable range of that parameter, as determined by the Administrator in accordance with §86.084-2(e)(3)(ii), prior to the performance of any tests. However, if the idle speed parameter is one which the Administrator has determined to be subject to adjustment, the Administrator shall not adjust it to any setting which causes a lower engine idle speed than would have been possible within the physically adjustable range of the idle speed parameter if the manufacturer had accumulated 125 hours of service on the engine or 4,000 miles on the vehicle under paragraph (c) of this section, all other parameters being identically adjusted for the purpose of the comparison. The manufacturer may be requested to supply information to establish such an alternative minimum idle speed. The Administrator, in making or specifying these adjustments, may consider the effect of the deviation from the manufacturer's recommended setting on emissions performance characteristics as well as the likelihood that similar settings will occur on in-use heavy-duty engines or light-duty trucks. In determining likelihood, the Administrator may consider factors such as, but not limited to, the effect of the adjustment on engine or vehicle performance characteristics and surveillance information from similar in-use engines or vehicles.

(c) Prior to performing emission testing on a PCA test engine, the manufacturer may accumulate on each engine a number of hours of service equal to the greater of 125 hours or the number of hours the manufacturer accumulated during certification on the emission-data engine corresponding to the configuration tested during PCA. Prior to performing emission testing on a PCA test vehicle, the manufacturer may accumulate a number of miles equal to the greater of 4,000 miles or the number of miles the manufacturer accumulated during certification on the emission-data vehicle corresponding to the configuration tested during PCA. Service or mileage accumulation may be performed in any manner the manufacturer desires.

(d) No maintenance shall be performed on test engines or vehicles after selection for testing nor will any test engine or vehicle substitution or replacement be allowed, unless requested of and approved by the Administrator in advance of the performance of any maintenance or engine or vehicle substitution.

(e) The manufacturer shall expeditiously ship test engines or vehicles from the point of selection to the test facility or other location to meet any other requirements of this subpart. If the test facility is not located at or in close proximity to the point of selection, the manufacturer shall assure that test engines or vehicles arrive at the test facility within 24 hours of selection, except that the Administrator may approve more time based upon a request by the manufacturer accompanied by a satisfactory justification.

(f) If an engine or vehicle cannot complete the service or mileage accumulation or emission tests because of engine or vehicle malfunction, the manufacturer may request that the Administrator authorize the repair of the engine or vehicle. If the engine or vehicle cannot be repaired expeditiously, EPA may delete it from the test sequence.

(g)(1) Heavy-duty engine manufacturers with projected sales bound for the United States market for that year of 30,000 or greater, as made in their respective Applications for Certification, shall complete emission testing at their testing facility on a minimum of two engines per 24 hour period, including voided tests.

(2) Heavy-duty engine manufacturers with projected sales bound for the United States market for that year of less than 30,000, as made in their respective Applications for Certification, Shall complete emission testing at one engine per 24 hour period, including voided tests.

(3) Light-duty truck manufacturers shall complete emission testing on a minimum of four vehicles per 24 hour period, including voided tests.

(4) The Administrator may approve a longer period of time for conducting emission tests based upon a request by a manufacturer accompanied by a satisfactory justification.

(h) The manufacturer shall perform test engine or vehicle selection, shipping, preparation, service or mileage accumulation, and testing in such a manner as to insure that the audit is performed in an expeditious manner.

(i) The manufacturer may retest any engines or vehicles tested during a Production Compliance Audit once a compliance level has been established in accordance with §86.1112-87 based on the first test on each engine or vehicle. The Administrator may approve retesting at other times based upon a request by the manufacturer accompanied by a satisfactory justification. The manufacturer may test each engine or vehicle a total of three times. The manufacturer shall test each engine or vehicle the same number of times. The manufacturer may accumulate additional service or mileage before conducting a retest, subject to the provisions of paragraph (c) of this section.

[50 FR 35388, Aug. 30, 1985, as amended at 62 FR 47123, Sept. 5, 1997]

§86.1112-87 Determining the compliance level and reporting of test results.

(a) A manufacturer that has elected to conduct a PCA in accordance with §86.1106-87 may establish the compliance level for a pollutant for any engine or vehicle configuration by using the primary PCA sampling plan or either of two optional reduced PCA sampling plans (the fixed reduced sampling plan or the sequential reduced sampling plan) described below. A manufacturer that uses either of the two optional reduced PCA sampling plans may elect to continue testing and establish a compliance level under the primary PCA sampling plan.

(1) A manufacturer that elects to conduct a PCA for a pollutant using the primary PCA sampling plan shall:

(i) Conduct emission tests on 24 engines or vehicles in accordance with §86.1111-87 for the pollutants for which the PCA was initiated. If the PCA follows an SEA failure, the number of additional tests conducted shall be the difference between 24 and the number of engines or vehicles tested in the SEA. If 24 or more engines or vehicles were tested in the SEA, no additional tests shall be conducted; and

(ii) Rank the final deteriorated test results, as defined by paragraph (e) of this section, obtained for that pollutant in order from the lowest to the highest value. If the PCA follows an SEA failure, all SEA test results for that pollutant shall be included in this ranking.

(iii) The compliance level for that pollutant is the final deteriorated test result in the sequence determined from table 1 of appendix XII of these regulations.

(2) A manufacturer that elects to conduct a PCA for a pollutant using the fixed reduced PCA sampling plan shall:

(i) Select a sample size between 3 and 23 engines or vehicles. If the PCA follows an SEA failure, the sample size selected cannot be less than the number of engines or vehicles tested during the SEA; and

(ii) Conduct emission tests on the selected sample in accordance with §86.1111-87 for the pollutants for which the PCA was initiated.

(iii) The compliance level for the pollutant is the result of the following equation, using the test results obtained in paragraph (a)(2)(ii) of this section and all SEA test results for that pollutant if the PCA follows an SEA failure:

CL = X͞ + Ks

Where:

CL = The compliance level.

X͞= The mean of the final deteriorated test results, as defined by paragraph (e) of this section.

K = A value that depends on the size of the test sample. See table 2 of appendix XII of this part for the value of K that corresponds to the size of the test sample.

s = The sample standard deviation.

Round the compliance level to the same number of significant figures contained in the applicable standard.

(3) A manufacturer that elects to conduct a PCA for a pollutant using the sequential reduced PCA sampling plan shall perform the following:

(i) Select a sample size of 4, 8, 12, 16 or 20 engines or vehicles. If the PCA follows an SEA failure, the sample size selected cannot be less than the number of engines or vehicles tested during the SEA.

(ii) Conduct emission tests on the selected sample in accordance with §86.1111-87 for the pollutants for which the PCA was initiated.

(iii) The compliance level for the pollutant is the result of the following equation, using the test results obtained in (a)(3)(ii) and all SEA test results for that pollutant if the PCA follows an SEA failure:

CL = X͞ + Ks

Where:

CL = The compliance level.

X͞ = The mean of the final deteriorated test results, as defined by paragraph (e) of this section.

K = A value that depends on the size of the test sample. See table 3 of appendix XII of this part for the value of K that corresponds to the size of the test sample.

s = The sample standard deviation.

Round the compliance level to the same number of significant figures contained in the applicable standard.

(iv) After calculating a compliance level in accordance with paragraph (a)(3)(iii) of this section, a manufacturer may elect to increase the sample size by 4 engines or vehicles, or a multiple thereof, up to the maximum, including SEA engines or vehicles if any, of 20. Upon that election, the manufacturer shall add the additional engines or vehicles to the sample and perform paragraphs (a)(3)(ii) and (a)(3)(iii) of this section. This election may be repeated if appropriate. A compliance level determined under this election shall replace a previously determined compliance level.

(b) A fail decision is reached with respect to the upper limit when the compliance level determined in paragraph (a) of this section exceeds the applicable upper limit.

(c) Initial test results are calculated following the Federal Test Procedure specified in §86.1111-87(a).

(d) Final test results are calculated by summing the initial test results derived in paragraph (c) of this section for each test engine or vehicle, dividing by the number of tests conducted on the engine or vehicle, and rounding to the same number of decimal places contained in the applicable standard expressed to one additional significant figure.

(e) Final deteriorated test results. (1) The final deteriorated test results for each heavy-duty engine or light-duty truck tested according to subpart B, I, N, or P of this part are calculated by applying the final test results by the appropriate deterioration factor, derived from the certification process for the engine family control system combination and model year for the selected configuration to which the test engine or vehicle belongs. If the deterioration factor computed during the certification process is multiplicative and it is less than one, that deterioration factor will be one. If the deterioration factor computed during the certification process is additive and it is less than zero, that deterioration factor will be zero.

(2) Round the final deteriorated test results to the same number of significant figures contained in the applicable standard.

(f) A failed engine or vehicle is one whose final deteriorated test results, for one or more of the applicable exhaust pollutants, exceed:

(1) The applicable emission standard, or

(2) The compliance level established in paragraph (b) of this section.

(g) Within five working days after completion of PCA testing of all engines or vehicles, the manufacturer shall submit to the Administrator a report which includes the following information:

(1) The location and description of the manufacturer's emission test facilities which were utilized to conduct testing reported pursuant to this section;

(2) The applicable standards against which the engines or vehicles were tested;

(3) Deterioration factors for the engine family to which the selected configuration belongs;

(4) A description of the engine or vehicle and any emission-related component selection method used;

(5) For each test conducted:

(i) Test engine or vehicle description, including;

(A) Configuration and engine family identification,

(B) Year, make and build date,

(C) Engine or vehicle identification number, and

(D) Number of hours of service accumulated on engine or number of miles on vehicle prior to testing;

(ii) Location where service or mileage accumulation was conducted and description of accumulation procedure and schedule;

(iii) Test number, date, initial test results before and after rounding, final test results and final deteriorated test results for all emission tests, whether valid or invalid, and the reason for invalidation, if applicable;

(iv) A complete description of any modification, repair, preparation, maintenance, and/or testing which was performed on the test engine or vehicle and has not been reported pursuant to any other paragraph of this subpart and will not be performed on all other production engines or vehicles; and

(v) Any other information the Administrator may request relevant to the determination as to whether the new heavy-duty engines or heavy-duty vehicles being manufactured by the manufacturer do in fact conform with the regulations of this subpart; and

(6) The following statement and endorsement:

This report is submitted pursuant to section 206 of the Clean Air Act. This Production Compliance Audit was conducted in complete conformance with all applicable regulations under 40 CFR part 86 et seq. All data and information reported herein is, to the best of

(Company Name)__________'s

knowledge, true and accurate. I am aware of the penalties associated with violations of the Clean Air Act and the regulations thereunder.

(Authorized Company Representative)

[50 FR 35388, Aug. 30, 1985, as amended at 81 FR 73981, Oct. 25, 2016]

§86.1113-87 Calculation and payment of penalty.

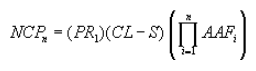

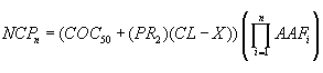

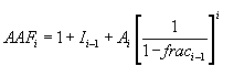

(a) The NCP for each engine or vehicle for which a compliance level has been determined under §86.1112-87 is calculated according to the formula in paragraph (a)(1) or (a)(2) of this section depending on the value of the compliance level. Each formula contains an annual adjustment factor (AAFi) which is defined in paragraph (a)(3) of this section. Other terms in the formulas are defined in paragraph (a)(4) of this section.

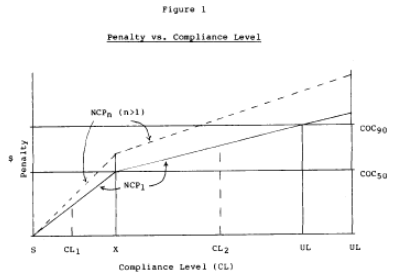

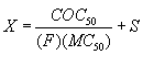

(1) If the compliance level (CL) is greater than the standard and less than or equal to X (e.g., point CL1 in figure 1), then:

where:

PR1 = (F) (MC50)

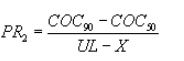

(2) If the compliance level is greater than X and less than or equal to the upper limit as determined by §86.1104-87 (e.g., point CL2 in figure 1), then:

where:

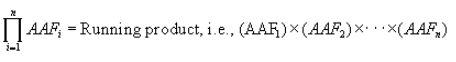

(3) AAFi has the following values:

(i) If fraci−1 = 0, then AAFi = 1 + Ii−1

(ii) If fraci−1 >0, then:

If fraci−1 >0.50, then fraci−1 will be set equal to 0.50.

(iii) AAF1 = 1

(iv) In calculating the NCP for year n, the value fraci−1 for i = n will include actual NCP usage through March 31 of model year n-1 and EPA's estimate of additional usage for the remainder of model year n-1 using manufacturer input. All manufacturers using NCPs must report by subclass actual NCP and non-NCP production numbers through March 31, an estimate of NCP and non-NCP production for the remainder of the model year, and the previous year's actual NCP and non-NCP production to EPA no later than April 30 of the model year. If EPA is unable to obtain similar information from manufacturers not using NCPs, EPA will use projected sales data from the manufacturers' application for certification in computing the total production of the subclass and the fraci−1. The value of fraci−1 will be corrected to reflect actual year-end usage of NCPs and a corrected AAF will be used to establish NCPs in future years. The correction of previous year's AAF will not affect the previous year's penalty.

(4) The terms in the above formulas have the following meanings and values, which may be determined separately for each subclass and pollutant for which an NCP is offered. The production of Federal and California designated engines or vehicles shall be combined for the purpose of this section in calculating the NCP for each engine or vehicle.

NCPn = NCP for year n for each applicable engine or vehicle

CL = Compliance level for year n for applicable engines or vehicles

S = Emission standard

UL = Upper limit as determined by section 86.1104-87, except that, if the upper limit is determined by section §86.1104-87(c), the value of UL in paragraph (a)(2) of this section shall be the prior emission standard for that pollutant.

UL′ = Upper limit as determined by section §86.1104-87(c). This value is not used in the above formulas.

X = Compliance level above the standard at which NCP1 equals COC50

PR1 = Penalty rate when CL ≤X

PR2 = Penalty rate when X <CL ≤applicable upper limit

i = An index representing a year. It represents the same year for both Federal and California designated engines or vehicles of the same production model year.

n = Index representing the number of model years for which the NCP has been available for an engine or vehicle subclass (i.e., n = 1 for the first year that the NCP is available, and so on until n = n for the nth year that the NCP is available). The factor “n” is based on the model year the NCP is first available, as specified in section 86.1105-87 for the engine or vehicle subclass and pollutant for both Federal and California designated engines and vehicles.

COC50 = Estimate of the average total incremental cost to comply with the standard relative to complying with the upper limit.

COC90 = Estimate of the 90th percentile total incremental cost to comply with the standard relative to complying with the upper limit.

MC50 = Estimate of the average marginal cost of compliance (dollars per emission unit) with the standard.

F = Factor used to estimate the 90th percentile marginal cost based on the average marginal cost (the minimum value of F is 1.1, the maximum value of F is 1.3).

AAFi = Annual adjustment factor for year i, fraci-1 = Fraction of engines or vehicles of a subclass using NCPs in previous year (year i-1).

Ai = Usage adjustment factor in year i: Ai = 0.10 for i = 2; Ai = 0.08 for i<2.

Ii = Percentage increase in overall consumer price index in year i.

(5) The values of COC50, COC90, MC50 and F will be determined for each applicable subclass by EPA based on the cost data used by EPA in setting the applicable emission standard. However, where the rulemaking to establish a specific NCP occurs after the rulemaking to establish the standard, EPA may augment the data base used to establish the standard by including the best cost and emission performance data available to EPA during the specific NCP rulemaking.

(6) In calculating the NCP, appropriate values of the following predefined terms should be used: CL, S, UL, F, and Ai. For all other terms, unrounded values of at least five figures beyond the decimal point should be used in calculations leading up to the penalty amount. Any NCP calculated under paragraph (a) of this section will be rounded to the nearest dollar.

(b) The NCP determined in paragraph (a) of this section is assessed against all those engines or vehicles of the nonconforming configuration or engine family produced at all assembly plants and distributed into commerce -

(1) Since the beginning of the model year in the case of a certification failure described by §86.1106-87(a).

(2) Beginning ten days after an SEA failure described by §86.1106-87 (b) or (c).

(3) Following implementation of a production running change described by §86.1106-87(d).

(c) The NCP will continue to be assessed during the model year, until such time, if any, that the configuration or engine family is brought into conformance with applicable emission standards.

(d) A manufacturer may carry over an NCP from a model year to the next model year. There is no limit to the number of years that carryover can continue. The amount of the penalty will increase each year according to paragraph (a) of this section.

(e) The Administrator shall notify the manufacturer in writing of the nonconformance penalty established under paragraph (a) of this section after the completion of the PCA under §86.1112-87.

(f) A manufacturer may request a hearing under 40 CFR part 1068, subpart G, as to whether the compliance level (including a compliance level in excess of the upper limit) was determined properly.

(g)(1) Except as provided in paragraph (g)(2) of this section, the nonconformance penalty or penalties assessed under this subpart must be paid as follows:

(i) By the quarterly due dates, i.e., within 30 days of the end of each calendar quarter (March 31, June 30, September 30 and December 31), or according to such other payment schedule as the Administrator may approve pursuant to a manufacturer's request, for all nonconforming engines or vehicles produced by a manufacturer in accordance with paragraph (b) of this section and distributed into commerce for that quarter.

(ii) The penalty shall be payable to U.S. Environmental Protection Agency, NCP Fund, Motor Vehicle and Engine Compliance Program, P.O. Box 979032 St. Louis, MO 63197-9000. Note on the check and supporting information that this is an NCP payment.

(2) When a manufacturer has requested a hearing under §86.1115-87, it must pay the nonconformance penalty, and any interest, within ten days after the Presiding Officer renders his decision, unless the manufacturer first files a notice of intention to appeal to the Administrator pursuant to §86.1115-87(t)(1), or, if an appeal of the Presiding Officer's decision is taken, within ten days after the Administrator renders his decision, unless the manufacturer first files a petition for judicial review.

(3) A manufacturer making payment under paragraph (g)(1) or (2) of this section shall submit the following information by each quarterly due date to the Designated Compliance Officer (see 40 CFR 1036.801). This information shall be submitted even if a manufacturer has no NCP production in a given quarter.

(i) Corporate identification, identification and quantity of engines or vehicles subject to the NCP, certificate identification (number and date), NCP payment calculations and interest payment calculations, if applicable.

(ii) The following statement and endorsement:

This information is submitted pursuant to section 206 of the Clean Air Act. All information reported herein is, to the best of

_____________________'s

(Company name)

knowledge, true and accurate. I am aware of the penalties associated with violations of the Clean Air Act and the regulations thereunder.

(Authorized Company Representative)

(4) The Administrator may verify the production figures or other documentation submitted under paragraph (g)(3) of this section.

(5)(i) Interest shall be assessed on any nonconformance penalty for which payment has been withheld under §86.113-87(g) (1) or (2). Interest shall be calculated from the due date for the first quarterly NCP payment, as determined under §86.1113-87(g)(1), until either the date on which the Presiding Officer or the Administrator renders the final decision of the Agency under §86.1115-87 or the date when an alternate payment schedule (approved pursuant to §86.1113-87(g)(1)) ends.

(ii) The combined principal plus interest on each quarterly NCP payment withheld pursuant to §86.1113-87(g) (1) or (2) shall be calculated according to the formula:

QNCP(1 + R).25n

where:

QNCP = the quarterly NCP payment

R = the interest rate applicable to that quarter

n = the number of quarters for which the quarterly NCP payment is outstanding.

(iii) The number of quarters for which payment is outstanding for purposes of this paragraph shall be the number of quarterly NCP payment due dates, as determined under §86.1113-87(g)(1), which have elapsed throughout the duration of a hearing request, or alternate payment schedule.

(iv) The interest rate applicable to a quarter for purposes of this paragraph shall be the rate published by the Secretary of the Treasury pursuant to the Debt Collection Act of 1982 and effective on the date on which the NCP payment was originally due.

(6) A manufacturer will be refunded an overpayment, or be permitted to offset an overpayment by withholding a future payment, if approved in advance by the Administrator. The government shall pay no interest on overpayments.

(h) A manufacturer that certifies as a replacement for the nonconforming configuration, a configuration that is in conformance with applicable standards, and that performs a production compliance audit (PCA) in accordance with §86.1112-87(a) that results in a compliance level below the applicable standard, will be eligible to receive a refund of a portion of the engineering and development component of the penalty. The engineering and development component will be determined by multiplying the base penalty amount by the engineering and development factor for the appropriate subclass and pollutant in §86.1105-87. The amount refunded will depend on the model year in which the certification and PCA take place. In cases where payment of penalties have been waived by EPA in accordance with paragraph (g)(1)(iii) of this section, EPA will refund a portion of the engineering and development component. The proportionate refund to be paid by EPA will be based on the proportion of vehicles or engines of the nonconforming configuration for which NCPs were paid to EPA. The refund is calculated as follows:

Rtot = Dn × FE&D × NCP1 × Prodtot

RCal = (ProdCal/Prodtot) × (Rtot)

REPA = Rtot−RCal

Where:

n = index representing the number of model years for which the NCP has been available for an engine or vehicle subclass (i.e., n = 1 for the first year that NCPs are available, . . . , n = n for the n th year the NCPs are available; same as “n” in paragraph (a)(4)).

Dn = discount factor depending on the number of model years (n) for which NCPs were available at the time of certification and PCA of the replacement configuration, and its value is as follows:

D1 = 0.90

D2 = 0.79

D3 = 0.67

D4 = 0.54

D5 = 0.39

D6 = 0.23

D7 = 0.05

Dn = 0.00 for n = 8 or larger

FE&D = the engineering and development factor specified in section 86.1105-87 for the appropriate subclass and pollutant

NCP1 = the penalty for each engine or vehicle during the first (base) year the NCP is available as calculated in paragraph (a)

Prodtot = total number of engines or vehicles produced in the subclass for which NCPs were paid to EPA or to the State of California

ProdCal = number of engines or vehicles in the subclass demonstrated to have been titled, registered or principally used in the State of California and for which NCPs were paid to the State of California under paragraph (g)(1)

Rtot = Total refund due to the manufacturer for the engineering and development component of the NCP

RCal = Refund due to the manufacturer from the State of California for the engineering and development component of the NCP

REPA = Refund due to the manufacturer from EPA for the engineering and development component of the NCP.

[50 FR 35388, Aug. 30, 1985, as amended at 50 FR 53467, Dec. 31, 1985; 53 FR 19134, May 26, 1988; 55 FR 46629, Nov. 5, 1990; 61 FR 51366, Oct. 2, 1996; 77 FR 54402, Sept. 5, 2012; 81 FR 73981, Oct. 25, 2016]

§86.1114-87 Suspension and voiding of certificates of conformity.

(a) The certificate of conformity is suspended with respect to any engine or vehicle failing pursuant to paragraph (f) of §86.1112-87 effective from the time that a fail decision is made for that engine or vehicle.