['Air Programs']

['Air Quality']

11/20/2023

...

§60.50a Applicability and delegation of authority.

(a) The affected facility to which this subpart applies is each municipal waste combustor unit with a municipal waste combustor unit capacity greater than 225 megagrams per day (250 tons per day) of municipal solid waste for which construction, modification, or reconstruction is commenced as specified in paragraphs (a)(1) and (a)(2) of this section.

(1) Construction is commenced after December 20, 1989 and on or before September 20, 1994.

(2) Modification or reconstruction is commenced after December 20, 1989 and on or before June 19, 1996.

(b) [Reserved]

(c) Any unit combusting a single-item waste stream of tires is not subject to this subpart if the owner or operator of the unit:

(1) Notifies the Administrator of an exemption claim; and

(2) Provides data documenting that the unit qualifies for this exemption.

(d) Any cofired combustor, as defined under §60.51a, located at a plant that meets the capacity specifications in paragraph (a) of this section is not subject to this subpart if the owner or operator of the cofired combustor:

(1) Notifies the Administrator of an exemption claim;

(2) Provides a copy of the federally enforceable permit (specified in the definition of cofired combustor in this section); and

(3) Keeps a record on a calendar quarter basis of the weight of municipal solid waste combusted at the cofired combustor and the weight of all other fuels combusted at the cofired combustor.

(e) Any cofired combustor that is subject to a federally enforceable permit limiting the operation of the combustor to no more than 225 megagrams per day (250 tons per day) of municipal solid waste is not subject to this subpart.

(f) Physical or operational changes made to an existing municipal waste combustor unit primarily for the purpose of complying with emission guidelines under subpart Cb are not considered a modification or reconstruction and do not result in an existing municipal waste combustor unit becoming subject to this subpart.

(g) A qualifying small power production facility, as defined in section 3(17)(C) of the Federal Power Act (16 U.S.C. 796(17)(C)), that burns homogeneous waste (such as automotive tires orused oil, but not including refuse-derived fuel) for the production of electric energy is not subject to this subpart if the owner or operator of the facility notifies the Administrator of an exemption claim and provides data documenting that the facility qualifies for this exemption.

(h) A qualifying cogeneration facility, as defined in section 3(18)(B) of the Federal Power Act (16 U.S.C. 796(18)(B)), that burns homogeneous waste (such as automotive tires or used oil, but not including refuse-derived fuel) for the production of electric energy and steam or forms of useful energy (such as heat) that are used for industrial, commercial, heating, or cooling purposes, is not subject to this subpart if the owner or operator of the facility notifies the Administrator of an exemption claim and provides data documenting that the facility qualifies for this exemption.

(i) Any unit required to have a permit under section 3005 of the Solid Waste Disposal Act is not subject to this subpart.

(j) Any materials recovery facility (including primary or secondary smelters) that combusts waste for the primary purpose of recovering metals is not subject to this subpart.

(k) Pyrolysis/combustion units that are an integrated part of a plastics/rubber recycling unit (as defined in §60.51a) are not subject to this subpart if the owner or operator of the plastics/rubber recycling unit keeps records of: the weight of plastics, rubber, and/or rubber tires processed on a calendar quarter basis; the weight of chemical plant feedstocks and petroleum refinery feedstocks produced and marketed on a calendar quarter basis; and the name and address of the purchaser of the feedstocks. The combustion of gasoline, diesel fuel, jet fuel, fuel oils, residual oil, refinery gas, petroleum coke, liquified petroleum gas, propane, or butane produced by chemical plants or petroleum refineries that use feedstocks produced by plastics/rubber recycling units are not subject to this subpart.

(l) The following authorities shall be retained by the Administrator and not transferred to a State:

None.

(m) This subpart shall become effective on August 12, 1991.

[56 FR 5507, Feb. 11, 1991, as amended at 60 FR 65384, Dec. 19, 1995]

§60.51a Definitions.

ASME means the American Society of Mechanical Engineers.

Batch MWC means an MWC unit designed such that it cannot combust MSW continuously 24 hours per day because the design does not allow waste to be fed to the unit or ash to be removed while combustion is occurring.

Bubbling fluidized bed combustor means a fluidized bed combustor in which the majority of the bed material remains in a fluidized state in the primary combustion zone.

Calendar quarter means a consecutive 3-month period (nonoverlapping) beginning on January 1, April 1, July 1, and October 1.

Chief facility operator means the person in direct charge and control of the operation of an MWC and who is responsible for daily on-site supervision, technical direction, management, and overall performance of the facility.

Circulating fluidized bed combustor means a fluidized bed combustor in which the majority of the fluidized bed material is carried out of the primary combustion zone and is transported back to the primary zone through a recirculation loop.

Clean wood means untreated wood or untreated wood products including clean untreated lumber, tree stumps (whole or chipped), and tree limbs (whole or chipped). Clean wood does not include yard waste, which is defined elsewhere in this section, or construction, renovation, and demolition wastes (which includes but is not limited to railroad ties and telephone poles), which are exempt from the definition of municipal solid waste in this section.

Cofired combustor means a unit combusting municipal solid waste with nonmunicipal solid waste fuel (e.g., coal, industrial process waste) and subject to a federally enforceable permit limiting the unit to combusting a fuel feed stream, 30 percent or less of the weight of which is comprised, in aggregate, of municipal solid waste as measured on a calendar quarter basis.

Continuous emission monitoring system or CEMS means a monitoring system for continuously measuring the emissions of a pollutant from an affected facility.

Continuous monitoring system means the total equipment used to sample and condition (if applicable), to analyze, and to provide a permanent record of emissions or process parameters.

Dioxin/furan means total tetra- through octachlorinated dibenzo-p-dioxins and dibenzofurans.

Federally-enforceable means all limitations and conditions that are enforceable by the Administrator including the requirements of 40 CFR parts 60 and 61, requirements within any applicable State implementation plan, and any permit requirements established under 40 CFR 52.21 or under 40 CFR 51.18 and 40 CFR 51.24.

Four-hour block average or 4-hour block average means the average of all hourly emission rates when the affected facility is operating and combusting MSW measured over 4-hour periods of time from 12 midnight to 4 a.m., 4 a.m. to 8 a.m., 8 a.m. to 12 noon, 12 noon to 4 p.m., 4 p.m. to 8 p.m., and 8 p.m. to 12 midnight.

Large municipal waste combustor plant means a municipal waste combustor plant with a municipal waste combustor aggregate plant capacity for affected facilities that is greater than 225 megagrams per day (250 tons per day) of municipal solid waste.

Mass burn refractory municipal waste combustor means a field-erected combustor that combusts municipal solid waste in a refractory wall furnace. Unless otherwise specified, this includes combustors with a cylindrical rotary refractory wall furnace.

Mass burn rotary waterwall municipal waste combustor means a field-erected combustor that combusts municipal solid waste in a cylindrical rotary waterwall furnace.

Mass burn waterwall municipal waste combustor means a field-erected combustor that combusts municipal solid waste in a waterwall furnace.

Maximum demonstrated municipal waste combustor unit load means the highest 4-hour arithmetic average municipal waste combustor unit load achieved during four consecutive hours during the most recent dioxin/furan performance test demonstrating compliance with the applicable limit for municipal waste combustor organics specified under §60.53a.

Maximum demonstrated particulate matter control device temperature means the highest 4-hour arithmetic average flue gas temperature measured at the particulate matter control device inlet during four consecutive hours during the most recent dioxin/furan performance test demonstrating compliance with the applicable limit for municipal waste combustor organics specified under §60.53a.

Modification or modified municipal waste combustor unit means a municipal waste combustor unit to which changes have been made if the cumulative cost of the changes, over the life of the unit, exceed 50 percent of the original cost of construction and installation of the unit (not including the cost of any land purchased in connection with such construction or installation) updated to current costs; or any physical change in the municipal waste combustor unit or change in the method of operation of the municipal waste combustor unit increases the amount of any air pollutant emitted by the unit for which standards have been established under section 129 or section 111. Increases in the amount of any air pollutant emitted by the municipal waste combustor unit are determined at 100-percent physical load capability and downstream of all air pollution control devices, with no consideration given for load restrictions based on permits or other nonphysical operational restrictions.

Modular excess air MWC means a combustor that combusts MSW and that is not field-erected and has multiple combustion chambers, all of which are designed to operate at conditions with combustion air amounts in excess of theoretical air requirements.

Modular starved air MWC means a combustor that combusts MSW and that is not field-erected and has multiple combustion chambers in which the primary combustion chamber is designed to operate at substoichiometric conditions.

Municipal solid waste or municipal-type solid waste or MSW means household, commercial/retail, and/or institutional waste. Household waste includes material discarded by single and multiple residential dwellings, hotels, motels, and other similar permanent or temporary housing establishments or facilities. Commercial/retail waste includes material discarded by stores, offices, restaurants, warehouses, nonmanufacturing activities at industrial facilities, and other similar establishments or facilities. Institutional waste includes material discarded by schools, nonmedical waste discarded by hospitals, material discarded by nonmanufacturing activities at prisons and government facilities, and material discarded by other similar establishments or facilities. Household, commercial/retail, and institutional waste does not include used oil; sewage sludge; wood pallets; construction, renovation, and demolition wastes (which includes but is not limited to railroad ties and telephone poles); clean wood; industrial process or manufacturing wastes; medical waste; or motor vehicles (including motor vehicle parts or vehicle fluff). Household, commercial/retail, and institutional wastes include:

(1) Yard waste;

(2) Refuse-derived fuel; and

(3) Motor vehicle maintenance materials limited to vehicle batteries and tires except as specified in §60.50a(c).

Municipal waste combustor, MWC, or municipal waste combustor unit: (1) Means any setting or equipment that combusts solid, liquid, or gasified MSW including, but not limited to, field-erected incinerators (with or without heat recovery), modular incinerators (starved-air or excess-air), boilers (i.e., steam-generating units), furnaces (whether suspension-fired, grate-fired, mass-fired, air curtain incinerators, or fluidized bed-fired), and pyrolysis/combustion units. Municipal waste combustors do not include pyrolysis/combustion units located at plastics/ rubber recycling units (as specified in §60.50a(k) of this section). Municipal waste combustors do not include internal combustion engines, gas turbines, or other combustion devices that combust landfill gases collected by landfill gas collection systems.

(2) The boundaries of an MWC are defined as follows. The MWC unit includes, but is not limited to, the MSW fuel feed system, grate system, flue gas system, bottom ash system, and the combustor water system. The MWC boundary starts at the MSW pit or hopper and extends through:

(i) The combustor flue gas system, which ends immediately following the heat recovery equipment or, if there is no heat recovery equipment, immediately following the combustion chamber;

(ii) The combustor bottom ash system, which ends at the truck loading station or similar ash handling equipment that transfer the ash to final disposal, including all ash handling systems that are connected to the bottom ash handling system; and

(iii) The combustor water system, which starts at the feed water pump and ends at the piping exiting the steam drum or superheater.

(3) The MWC unit does not include air pollution control equipment, the stack, water treatment equipment, or the turbine generator set.

Municipal waste combustor plant means one or more MWC units at the same location for which construction, modification, or reconstruction is commenced after December 20, 1989 and on or before September 20, 1994.

Municipal waste combustor plant capacity means the aggregate MWC unit capacity of all MWC units at an MWC plant for which construction, modification, or reconstruction of the units commenced after December 20, 1989 and on or before September 20, 1994. Any MWC units for which construction, modification, or reconstruction is commenced on or before December 20, 1989 or after September 20, 1994 are not included for determining applicability under this subpart.

Municipal waste combustor unit capacity means the maximum design charging rate of an MWC unit expressed in megagrams per day (tons per day) of MSW combusted, calculated according to the procedures under §60.58a(j). Municipal waste combustor unit capacity is calculated using a design heating value of 10,500 kilojoules per kilogram (4,500 British thermal units per pound) for MSW. The calculational procedures under §60.58a(j) include procedures for determining MWC unit capacity for continuous and batch feed MWC's.

Municipal waste combustor unit load means the steam load of the MWC unit measured as specified in §60.58a(h)(6).

MWC acid gases means all acid gases emitted in the exhaust gases from MWC units including, but not limited to, sulfur dioxide and hydrogen chloride gases.

MWC metals means metals and metal compounds emitted in the exhaust gases from MWC units.

MWC organics means organic compounds emitted in the exhaust gases from MWC units and includes total tetra- through octa-chlorinated dibenzo-p-dioxins and dibenzofurans.

Particulate matter means total particulate matter emitted from MWC units as measured by Method 5 (see §60.58a).

Plastics/rubber recycling unit means an integrated processing unit where plastics, rubber, and/or rubber tires are the only feed materials (incidental contaminants may be included in the feed materials) and they are processed into a chemical plant feedstock or petroleum refinery feedstock, where the feedstock is marketed to and used by a chemical plant or petroleum refinery as input feedstock. The combined weight of the chemical plant feedstock and petroleum refinery feedstock produced by the plastics/rubber recycling unit on a calendar quarter basis shall be more than 70 percent of the combined weight of the plastics, rubber, and rubber tires processed by the plastics/rubber recycling unit on a calendar quarter basis. The plastics, rubber, and/or rubber tire feed materials to the plastics/rubber recycling unit may originate from the separation or diversion of plastics, rubber, or rubber tires from MSW or industrial solid waste, and may include manufacturing scraps, trimmings, and off-specification plastics, rubber, and rubber tire discards. The plastics, rubber, and rubber tire feed materials to the plastics/rubber recycling unit may contain incidental contaminants (e.g., paper labels on plastic bottles, metal rings on plastic bottle caps, etc.).

Potential hydrogen chloride emission rate means the hydrogen chloride emission rate that would occur from combustion of MSW in the absence of any hydrogen chloride emissions control.

Potential sulfur dioxide emission rate means the sulfur dioxide emission rate that would occur from combustion of MSW in the absence of any sulfur dioxide emissions control.

Pulverized coal/refuse-derived fuel mixed fuel-fired combustor or pulverized coal/RDF mixed fuel-fired combustor means a combustor that fires coal and RDF simultaneously, in which pulverized coal is introduced into an air stream that carries the coal to the combustion chamber of the unit where it is fired in suspension. This includes both conventional pulverized coal and micropulverized coal.

Pyrolysis/combustion unit means a unit that produces gases, liquids, or solids through the heating of MSW, and the gases, liquids, or solids produced are combusted and emissions vented to the atmosphere.

Reconstruction means rebuilding an MWC unit for which the cumulative costs of the construction over the life of the unit exceed 50 percent of the original cost of construction and installation of the unit (not including any cost of land purchased in connection with such construction or installation) updated to current costs (current dollars).

Refractory unit or refractory wall furnace means a combustion unit having no energy recovery (e.g., via a waterwall) in the furnace (i.e., radiant heat transfer section) of the combustor.

Refuse-derived fuel or RDF means a type of MSW produced by processing MSW through shredding and size classification.

This includes all classes of RDF including low density fluff RDF through densified RDF and RDF fuel pellets.

RDF stoker means a steam generating unit that combusts RDF in a semi-suspension firing mode using air-fed distributors.

Same location means the same or contiguous property that is under common ownership or control, including properties that are separated only by a street, road, highway, or other public right-of-way. Common ownership or control includes properties that are owned, leased, or operated by the same entity, parent entity, subsidiary, subdivision, or any combination thereof, including any municipality or other governmental unit, or any quasigovernmental authority (e.g., a public utility district or regional waste disposal authority).

Shift supervisor means the person in direct charge and control of the operation of an MWC and who is responsible for on-site supervision, technical direction, management, and overall performance of the facility during an assigned shift.

Spreader stoker coal/refuse-derived fuel mixed fuel-fired combustor or spreader stoker coal/RDF mixed fuel-fired combustor means a combustor that fires coal and refuse-derived fuel simultaneously, in which coal is introduced to the combustion zone by a mechanism that throws the fuel onto a grate from above. Combustion takes place both in suspension and on the grate.

Standard conditions means a temperature of 20°C (68°F) and a pressure of 101.3 kilopascals (29.92 inches of mercury).

Twenty-four hour daily average or 24-hour daily average means the arithmetic or geometric mean (as specified in §60.58a (e), (g), or (h) as applicable) of all hourly emission rates when the affected facility is operating and firing MSW measured over a 24-hour period between 12 midnight and the following midnight.

Untreated lumber means wood or wood products that have been cut or shaped and include wet, air-dried, and kiln-dried wood products. Untreated lumber does not include wood products that have been painted, pigment-stained, or “pressure-treated.” Pressure-treating compounds include, but are not limited to, chromate copper arsenate, pentachlorophenol, and creosote.

Waterwall furnace means a combustion unit having energy (heat) recovery in the furnace (i.e., radiant heat transfer section) of the combustor.

Yard waste means grass, grass clippings, bushes, shrubs, and clippings from bushes and shrubs that are generated by residential, commercial/retail, institutional, and/or industrial sources as part of maintenance activities associated with yards or other private or public lands. Yard waste does not include construction, renovation, and demolition wastes, which are exempt from the definition of MSW in this section. Yard waste does not include clean wood, which is exempt from the definition of MSW in this section.

[56 FR 5507, Feb. 11, 1991, as amended at 60 FR 65384, Dec. 19, 1995; 65 FR 61753, Oct. 17, 2000]

§60.52a Standard for municipal waste combustor metals.

(a) On and after the date on which the initial compliance test is completed or is required to be completed under §60.8, no owner or operator of an affected facility located within a large MWC plant shall cause to be discharged into the atmosphere from that affected facility any gases that contain particulate matter in excess of 34 milligrams per dry standard cubic meter (0.015 grains per dry standard cubic foot), corrected to 7 percent oxygen (dry basis).

(b) On and after the date on which the initial compliance test is completed or is required to be completed under §60.8, no owner or operator of an affected facility subject to the particulate matter emission limit under paragraph (a) of this section shall cause to be discharged into the atmosphere from that affected facility any gases that exhibit greater than 10 percent opacity (6-minute average).

(c) [Reserved]

§60.53a Standard for municipal waste combustor organics.

(a) [Reserved]

(b) On and after the date on which the initial compliance test is completed or is required to be completed under §60.8, no owner or operator of an affected facility located within a large MWC plant shall cause to be discharged into the atmosphere from that affected facility any gases that contain dioxin/furan emissions that exceed 30 nanograms per dry standard cubic meter (12 grains per billion dry standard cubic feet), corrected to 7 percent oxygen (dry basis).

§60.54a Standard for municipal waste combustor acid gases.

(a)-(b) [Reserved]

(c) On and after the date on which the initial compliance test is completed or is required to be completed under §60.8, no owner or operator of an affected facility located within a large MWC plant shall cause to be discharged into the atmosphere from that affected facility any gases that contain sulfur dioxide in excess of 20 percent of the potential sulfur dioxide emission rate (80 percent reduction by weight or volume) or 30 parts per million by volume, corrected to 7 percent oxygen (dry basis), whichever is less stringent. The averaging time is specified in §60.58a(e).

(d) On and after the date on which the initial compliance test is completed or is required to be completed under §60.8, no owner or operator of an affected facility located within a large MWC plant shall cause to be discharged into the atmosphere from that affected facility any gases that contain hydrogen chloride in excess of 5 percent of the potential hydrogen chloride emission rate (95 percent reduction by weight or volume) or 25 parts per million by volume, corrected to 7 percent oxygen (dry basis), whichever is less stringent.

§60.55a Standard for nitrogen oxides.

On and after the date on which the initial compliance test is completed or is required to be completed under §60.8, no owner or operator of an affected facility located within a large MWC plant shall cause to be discharged into the atmosphere from that affected facility any gases that contain nitrogen oxides in excess of 180 parts per million by volume, corrected to 7 percent oxygen (dry basis). The averaging time is specified under §60.58a(g).

§60.56a Standards for municipal waste combustor operating practices.

(a) On and after the date on which the initial compliance test is completed or is required to be completed under §60.8, no owner or operator of an affected facility located within a large MWC plant shall cause such facility to exceed the carbon monoxide standards shown in table 1.

| MWC technology | Carbon monoxide emission limit (parts per million by volume) 1 |

|---|---|

| 1 Measured at the combustor outlet in conjunction with a measurement of oxygen concentration, corrected to 7 percent oxygen (dry basis). The averaging times are specified in §60.58a(h). | |

| Mass burn waterwall | 100 |

| Mass burn refractory | 100 |

| Mass burn rotary waterwall | 100 |

| Modular starved air | 50 |

| Modular excess air | 50 |

| RDF stoker | 150 |

| Bubbling fluidized bed combustor | 100 |

| Circulating fluidized bed combustor | 100 |

| Pulverized coal/RDF mixed fuel-fired combustor | 150 |

| Spreader stoker coal/RDF mixed fuel-fird combustor | 150 |

(b) No owner or operator of an affected facility located within a large MWC plant shall cause such facility to operate at a load level greater than 110 percent of the maximum demonstrated MWC unit load as defined in §60.51a. The averaging time is specified under §60.58a(h).

(c) No owner or operator of an affected facility located within a large MWC plant shall cause such facility to operate at a temperature, measured at the final particulate matter control device inlet, exceeding 17°Centigrade (30°Fahrenheit) above the maximum demonstrated particulate matter control device temperature as defined in §60.51a. The averaging time is specified under §60.58a(h).

(d) Within 24 months from the date of start-up of an affected facility or before February 11, 1993, whichever is later, each chief facility operator and shift supervisor of an affected facility located within a large MWC plant shall obtain and keep current either a provisional or operator certification in accordance with ASME QRO-1-1994 (incorporated by reference, see §60.17) or an equivalent State-approved certification program.

(e) No owner or operator of an affected facility shall allow such affected facility located at a large MWC plant to operate at any time without a certified shift supervisor, as provided under paragraph (d) of this section, on duty at the affected facility. This requirement shall take effect 24 months after the date of start-up of the affected facility or on and after February 11, 1993, whichever is later.

(f) The owner or operator of an affected facility located within a large MWC plant shall develop and update on a yearly basis a sitespecific operating manual that shall, at a minimum, address the following elements of MWC unit operation:

(1) Summary of the applicable standards under this subpart;

(2) Description of basic combustion theory applicable to an MWC unit;

(3) Procedures for receiving, handling, and feeding MSW;

(4) MWC unit start-up, shutdown, and malfunction procedures;

(5) Procedures for maintaining proper combustion air supply levels;

(6) Procedures for operating the MWC unit within the standards established under this subpart;

(7) Procedures for responding to periodic upset or off-specification conditions;

(8) Procedures for minimizing particulate matter carryover;

(9) [Reserved]

(10) Procedures for handling ash;

(11) Procedures for monitoring MWC unit emissions; and

(12) Reporting and recordkeeping procedures.

(g) The owner or operator of an affected facility located within a large MWC plant shall establish a program for reviewing the operating manual annually with each person who has responsibilities affecting the operation of an affected facility including, but not limited to, chief facility operators, shift supervisors, control room operators, ash handlers, maintenance personnel, and crane/load handlers.

(h) The initial review of the operating manual, as specified under paragraph (g) of this section, shall be conducted prior to assumption of responsibilities affecting MWC unit operation by any person required to undergo training under paragraph (g) of this section. Subsequent reviews of the manual shall be carried out annually by each such person.

(i) The operating manual shall be kept in a readily accessible location for all persons required to undergo training under paragraph (g) of this section. The operating manual and records of training shall be available for inspection by EPA or its delegated enforcement agent upon request.

(j)-(k) [Reserved]

[56 FR 5507, Feb. 11, 1991, as amended at 60 FR 65386, Dec. 19, 1995]

§60.57a [Reserved]

§60.58a Compliance and performance testing.

(a) The standards under this subpart apply at all times, except during periods of start-up, shutdown, or malfunction; provided, however, that the duration of start-up, shutdown, or malfunction shall not exceed 3 hours per occurrence.

(1) The start-up period commences when the affected facility begins the continuous burning of MSW and does not include any warm-up period when the affected facility is combusting only a fossil fuel or other non-MSW fuel and no MSW is being combusted.

(2) Continuous burning is the continuous, semicontinuous, or batch feeding of MSW for purposes of waste disposal, energy production, or providing heat to the combustion system in preparation for waste disposal or energy production. The use of MSW solely to provide thermal protection of grate or hearth during the start-up period shall not be considered to be continuous burning.

(b) The following procedures and test methods shall be used to determine compliance with the emission limits for particulate matter under §60.52a:

(1) Method 1 shall be used to select sampling site and number of traverse points.

(2) Method 3 shall be used for gas analysis.

(3) Method 5 shall be used for determining compliance with the particulate matter emission limit. The minimum sample volume shall be 1.7 cubic meters (60 cubic feet). The probe and filter holder heating systems in the sample train shall be set to provide a gas temperature of 160°±14°Centigrade (320°±25°Fahrenheit). An oxygen or carbon dioxide measurement shall be obtained simultaneously with each Method 5 run.

(4) For each Method 5 run, the emission rate shall be determined using:

(i) Oxygen or carbon dioxide measurements,

(ii) Dry basis F factor, and

(iii) Dry basis emission rate calculation procedures in Method 19.

(5) An owner or operator may request that compliance be determined using carbon dioxide measurements corrected to an equivalent of 7 percent oxygen. The relationship between oxygen and carbon dioxide levels for the affected facility shall be established during the initial compliance test.

(6) The owner or operator of an affected facility shall conduct an initial compliance test for particulate matter and opacity as required under §60.8.

(7) Method 9 shall be used for determining compliance with the opacity limit.

(8) The owner or operator of an affected facility shall install, calibrate, maintain, and operate a continuous opacity monitoring system (COMS) and record the output of the system on a 6-minute average basis.

(9) Following the date the initial compliance test for particulate matter is completed or is required to be completed under §60.8 for an affected facility located within a large MWC plant, the owner or operator shall conduct a performance test for particulate matter on an annual basis (no more than 12 calendar months following the previous compliance test).

(10) [Reserved]

(c) [Reserved]

(d) The following procedures and test methods shall be used to determine compliance with the limits for dioxin/furan emissions under §60.53a:

(1) Method 23 shall be used for determining compliance with the dioxin/furan emission limits. The minimum sample time shall be 4 hours per test run.

(2) The owner or operator of an affected facility shall conduct an initial compliance test for dioxin/furan emissions as required under §60.8.

(3) Following the date of the initial compliance test or the date on which the initial compliance test is required to be completed under §60.8, the owner or operator of an affected facility located within a large MWC plant shall conduct a performance test for dioxin/furan emissions on an annual basis (no more than 12 calendar months following the previous compliance test).

(4) [Reserved]

(5) An owner or operator may request that compliance with the dioxin/furan emissions limit be determined using carbon dioxide measurements corrected to an equivalent of 7 percent oxygen. The relationship between oxygen and carbon dioxide levels for the affected facility shall be established during the initial compliance test.

(e) The following procedures and test methods shall be used for determining compliance with the sulfur dioxide limit under §60.54a:

(1) Method 19, section 5.4, shall be used to determine the daily geometric average percent reduction in the potential sulfur dioxide emission rate.

(2) Method 19, section 4.3, shall be used to determine the daily geometric average sulfur dioxide emission rate.

(3) An owner or operator may request that compliance with the sulfur dioxide emissions limit be determined using carbon dioxide measurements corrected to an equivalent of 7 percent oxygen. The relationship between oxygen and carbon dioxide levels for the affected facility shall be established during the initial compliance test.

(4) The owner or operator of an affected facility shall conduct an initial compliance test for sulfur dioxide as required under §60.8. Compliance with the sulfur dioxide emission limit and percent reduction is determined by using a CEMS to measure sulfur dioxide and calculating a 24-hour daily geometric mean emission rate and daily geometric mean percent reduction using Method 19 sections 4.3 and 5.4, as applicable, except as provided under paragraph (e)(5) of this section.

(5) For batch MWC's or MWC units that do not operate continuously, compliance shall be determined using a daily geometric mean of all hourly average values for the hours during the day that the affected facility is combusting MSW.

(6) The owner or operator of an affected facility shall install, calibrate, maintain, and operate a CEMS for measuring sulfur dioxide emissions discharged to the atmosphere and record the output of the system.

(7) Following the date of the initial compliance test or the date on which the initial compliance test is required to be completed under §60.8, compliance with the sulfur dioxide emission limit or percent reduction shall be determined based on the geometric mean of the hourly arithmetic average emission rates during each 24-hour daily period measured between 12:00 midnight and the following midnight using: CEMS inlet and outlet data, if compliance is based on a percent reduction; or CEMS outlet data only if compliance is based on an emission limit.

(8) At a minimum, valid CEMS data shall be obtained for 75 percent of the hours per day for 75 percent of the days per month the affected facility is operated and combusting MSW.

(9) The 1-hour arithmetic averages required under paragraph (e)(7) of this section shall be expressed in parts per million (dry basis) and used to calculate the 24-hour daily geometric mean emission rates. The 1-hour arithmetic averages shall be calculated using the data points required under §60.13(e)(2). At least two data points shall be used to calculate each 1-hour arithmetic average.

(10) All valid CEMS data shall be used in calculating emission rates and percent reductions even if the minimum CEMS data requirements of paragraph (e)(8) of this section are not met.

(11) The procedures under §60.1 3 shall be followed for installation, evaluation, and operation of the CEMS.

(12) The CEMS shall be operated according to Performance Specifications 1, 2, and 3 (appendix B of part 60).

(13) Quarterly accuracy determinations and daily calibration drift tests shall be performed in accordance with Procedure 1 (appendix F of part 60).

(14) The span value of the CEMS at the inlet to the sulfur dioxide control device is 125 percent of the maximum estimated hourly potential sulfur dioxide emissions of the MWC unit, and the span value of the CEMS at the outlet of the sulfur dioxide control device is 50 percent of the maximum estimated hourly potential sulfur dioxide emissions of the MWC unit.

(15) When sulfur dioxide emissions data are not obtained because of CEMS breakdowns, repairs, calibration checks and zero and span adjustments, emissions data shall be obtained by using other monitoring systems as approved by the Administrator or Method 19 to provide as necessary valid emission data for a minimum of 75 percent of the hours per day for 75 percent of the days per month the unit is operated and combusting MSW.

(16) Not operating a sorbent injection system for the sole purpose of testing in order to demonstrate compliance with the percent reduction standards for MWC acid gases shall not be considered a physical change in the method of operation under 40 CFR 52.21, or under regulations approved pursuant to 40 CFR 51.166 or 40 CFR 51.165 (a) and (b).

(f) The following procedures and test methods shall be used for determining compliance with the hydrogen chloride limits under §60.54a:

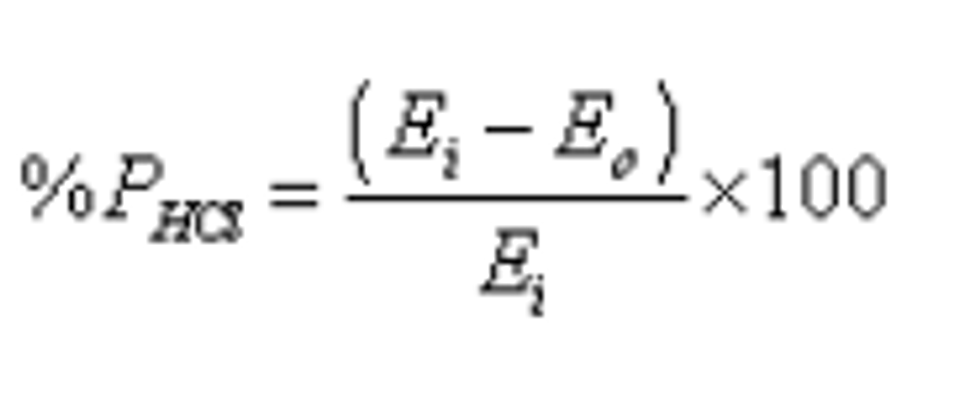

(1) The percentage reduction in the potential hydrogen chloride emissions (%PHCl) is computed using the following formula:

where:

Ei is the potential hydrogen chloride emission rate.

Eo is the hydrogen chloride emission rate measured at the outlet of the acid gas control device.

(2) Method 26 or 26A shall be used for determining the hydrogen chloride emission rate. The minimum sampling time for Method 26 or 26A shall be 1 hour.

(3) An owner or operator may request that compliance with the hydrogen chloride emissions limit be determined using carbon dioxide measurements corrected to an equivalent of 7 percent oxygen. The relationship between oxygen and carbon dioxide levels for the affected facility shall be established during the initial compliance test.

(4) The owner or operator of an affected facility shall conduct an initial compliance test for hydrogen chloride as required under §60.8.

(5) Following the date of the initial compliance test or the date on which the initial compliance test is required under §60.8, the owner or operator of an affected facility located within a large MWC plant shall conduct a performance test for hydrogen chloride on an annual basis (no more than 12 calendar months following the previous compliance test).

(6) [Reserved]

(7) Not operating a sorbent injection system for the sole purpose of testing in order to demonstrate compliance with the percent reduction standards for MWC acid gases shall not be considered a physical change in the method of operation under 40 CFR 52.21, or under regulations approved pursuant to 40 CFR 51.166 or 40 CFR 51.165 (a) and (b).

(g) The following procedures and test methods shall be used to determine compliance with the nitrogen oxides limit under §60.55a:

(1) Method 19, section 4.1, shall be used for determining the daily arithmetic average nitrogen oxides emission rate.

(2) An owner or operator may request that compliance with the nitrogen oxides emissions limit be determined using carbon dioxide measurements corrected to an equivalent of 7 percent oxygen. The relationship between oxygen and carbon dioxide levels for the affected facility shall be established during the initial compliance test.

(3) The owner or operator of an affected facility subject to the nitrogen oxides limit under §60.55a shall conduct an initial compliance test for nitrogen oxides as required under §60.8. Compliance with the nitrogen oxides emission standard shall be determined by using a CEMS for measuring nitrogen oxides and calculating a 24-hour daily arithmetic average emission rate using Method 19, section 4.1, except as specified under paragraph (g)(4) of this section.

(4) For batch MWC's or MWC's that do not operate continuously, compliance shall be determined using a daily arithmetic average of all hourly average values for the hours during the day that the affected facility is combusting MSW.

(5) The owner or operator of an affected facility subject to the nitrogen oxides emissions limit under §60.55a shall install, calibrate, maintain, and operate a CEMS for measuring nitrogen oxides discharged to the atmosphere and record the output of the system.

(6) Following the initial compliance test or the date on which the initial compliance test is required to be completed under §60.8, compliance with the emission limit for nitrogen oxides required under §60.55a shall be determined based on the arithmetic average of the arithmetic average hourly emission rates during each 24-hour daily period measured between 12:00 midnight and the following midnight using CEMS data.

(7) At a minimum valid CEMS data shall be obtained for 75 percent of the hours per day for 75 percent of the days per month the affected facility is operated and combusting MSW.

(8) The 1-hour arithmetic averages required by paragraph (g)(6) of this section shall be expressed in parts per million volume (dry basis) and used to calculate the 24-hour daily arithmetic average emission rates. The 1-hour arithmetic averages shall be calculated using the data points required under §60.13(b). At least two data points shall be used to calculate each 1-hour arithmetic average.

(9) All valid CEMS data must be used in calculating emission rates even if the minimum CEMS data requirements of paragraph (g)(7) of this section are not met.

(10) The procedures under §60.13 shall be followed for installation, evaluation, and operation of the CEMS.

(11) Quarterly accuracy determinations and daily calibration drift tests shall be performed in accordance with Procedure 1 (appendix F of part 60).

(12) When nitrogen oxides emissions data are not obtained because of CEMS breakdowns, repairs, calibration checks, and zero and span adjustments, emission data calculations to determine compliance shall be made using other monitoring systems as approved by the Administrator or Method 19 to provide as necessary valid emission data for a minimum of 75 percent of the hours per day for 75 percent of the days per month the unit is operated and combusting MSW.

(h) The following procedures shall be used for determining compliance with the operating standards under §60.56a:

(1) Compliance with the carbon monoxide emission limits in §60.56a(a) shall be determined using a 4-hour block arithmetic average for all types of affected facilities except mass burn rotary waterwall MWC's, RDF stokers, and spreader stoker/RDF mixed fuel-fired combustors.

(2) For affected mass burn rotary waterwall MWC's, RDF stokers, and spreader stoker/RDF mixed fuel-fired combustors, compliance with the carbon monoxide emission limits in §60.56a(a) shall be determined using a 24-hour daily arithmetic average.

(3) The owner or operator of an affected facility shall install, calibrate, maintain, and operate a CEMS for measuring carbon monoxide at the combustor outlet and record the output of the system.

(4) The 4-hour and 24-hour daily arithmetic averages in paragraphs (h) (1) and (2) of this section shall be calculated from 1-hour arithmetic averages expressed in parts per million by volume (dry basis). The 1-hour arithmetic averages shall be calculated using the data points generated by the CEMS. At least two data points shall be used to calculate each 1-hour arithmetic average.

(5) An owner or operator may request that compliance with the carbon monoxide emission limit be determined using carbon dioxide measurements corrected to an equivalent of 7 percent oxygen. The relationship between oxygen and carbon dioxide levels for the affected facility shall be established during the initial compliance test.

(6) The following procedures shall be used to determine compliance with load level requirements under §60.56a(b):

(i) The owner or operator of an affected facility with steam generation capability shall install, calibrate, maintain, and operate a steam flow meter or a feedwater flow meter; measure steam or feedwater flow in kilograms per hour (pounds per hour) on a continuous basis; and record the output of the monitor. Steam or feedwater flow shall be calculated in 4-hour block arithmetic averages.

(ii) The method included in “American Society of Mechanical Engineers Power Test Codes: Test Code for Steam Generating Units, Power Test Code 4.1 - 1964”, Section 4 (incorporated by reference, see §60.17) shall be used for calculating the steam (or feedwater flow) required under paragraph (h)(6)(i) of this section. The recommendations of “American Society of Mechanical Engineers Interim Supplement 19.5 on Instruments and Apparatus: Application, Part II of Fluid Meters, 6th edition (1971),” chapter 4 (incorporated by reference, see §60.17) shall be followed for design, construction, installation, calibration, and use of nozzles and orifices except as specified in (h)(6)(iii) of this section.

(iii) Measurement devices such as flow nozzles and orifices are not required to be recalibrated after they are installed.

(iv) All signal conversion elements associated with steam (or feedwater flow) measurements must be calibrated according to the manufacturer's instructions before each dioxin/furan compliance and performance test, and at least once per year.

(v) The owner or operator of an affected facility without heat recovery shall:

(A) [Reserved]

(7) To determine compliance with the maximum particulate matter control device temperature requirements under §60.56a(c), the owner or operator of an affected facility shall install, calibrate, maintain, and operate a device for measuring temperature of the flue gas stream at the inlet to the final particulate matter control device on a continuous basis and record the output of the device. Temperature shall be calculated in 4-hour block arithmetic averages.

(8) Maximum demonstrated MWC unit load shall be determined during the initial compliance test for dioxins/furans and each subsequent performance test during which compliance with the dioxin/furan emission limit under §60.53a is achieved. Maximum demonstrated MWC unit load shall be the maximum 4-hour arithmetic average load achieved during the most recent test during which compliance with the dioxin/furan limit was achieved.

(9) The maximum demonstrated particulate matter control device temperature shall be determined during the initial compliance test for dioxins/furans and each subsequent performance test during which compliance with the dioxin/furan emission limit under §60.53a is achieved. Maximum demonstrated particulate matter control device temperature shall be the maximum 4-hour arithmetic average temperature achieved at the final particulate matter control device inlet during the most recent test during which compliance with the dioxin/furan limit was achieved.

(10) At a minimum, valid CEMS data for carbon monoxide, steam or feedwater flow, and particulate matter control device inlet temperature shall be obtained 75 percent of the hours per day for 75 percent of the days per month the affected facility is operated and combusting MSW.

(11) All valid data must be used in calculating the parameters specified under paragraph (h) of this section even if the minimum data requirements of paragraph (h)(10) of this section are not met.

(12) Quarterly accuracy determinations and daily calibration drift tests for carbon monoxide CEMS shall be performed in accordance with Procedure 1 (appendix F).

(i) [Reserved]

(j) The following procedures shall be used for calculating MWC unit capacity as defined under §60.51a:

(1) For MWC units capable of combusting MSW continuously for a 24-hour period, MWC unit capacity, in megagrams per day (tons per day) of MSW combusted, shall be calculated based on 24 hours of operation at the maximum design charging rate. The design heating values under paragraph (j)(4) of this section shall be used in calculating the design charging rate.

(2) For batch MWC units, MWC unit capacity, in megagrams per day (tons per day) of MSW combusted, shall be calculated as the maximum design amount of MSW that can be charged per batch multiplied by the maximum number of batches that could be processed in a 24-hour period. The maximum number of batches that could be processed in a 24-hour period is calculated as 24 hours divided by the design number of hours required to process one batch of MSW, and may include fractional batches. 1 The design heating values under paragraph (j)(4) of this section shall be used in calculating the MWC unit capacity in megagrams per day (tons per day) of MSW.

1 For example, if one batch requires 16 hours, then 24/16, or 1.5 batches, could be combusted in a 24-hour period.

(3) [Reserved]

(4) The MWC unit capacity shall be calculated using a design heating value of 10,500 kilojoules per kilogram (4,500 British thermal units per pound) for all MSW.

[56 FR 5507, Feb. 11, 1991, as amended at 60 FR 65387, Dec. 19, 1995; 65 FR 61753, Oct. 17, 2000]

§60.59a Reporting and recordkeeping requirements.

(a) The owner or operator of an affected facility located at an MWC plant with a capacity greater than 225 megagrams per day (250 tons per day) shall provide notification of intent to construct and of planned initial start-up date and the type(s) of fuels that they plan to combust in the affected facility. The MWC unit capacity and MWC plant capacity and supporting capacity calculations shall be provided at the time of the notification of construction.

(b) The owner or operator of an affected facility located within a small or large MWC plant and subject to the standards under §60.52a, §60.53a, §60.54a, §60.55a, §60.56a, or §60.57a shall maintain records of the following information for each affected facility for a period of at least 2 years:

(1) Calendar date.

(2) The emission rates and parameters measured using CEMS as specified under (b)(2) (i) and (ii) of this section:

(i) The following measurements shall be recorded in computer-readable format and on paper:

(A) All 6-minute average opacity levels required under §60.58a(b).

(B) All 1 hour average sulfur dioxide emission rates at the inlet and outlet of the acid gas control device if compliance is based on a percent reduction, or at the outlet only if compliance is based on the outlet emission limit, as specified under §60.58a(e).

(C) All 1-hour average nitrogen oxides emission rates as specified under §60.58a(g).

(D) All 1-hour average carbon monoxide emission rates, MWC unit load measurements, and particulate matter control device inlet temperatures as specified under §60.58a(h).

(ii) The following average rates shall be computed and recorded:

(A) All 24-hour daily geometric average percent reductions in sulfur dioxide emissions and all 24-hour daily geometric average sulfur dioxide emission rates as specified under §60.58a(e).

(B) All 24-hour daily arithmetic average nitrogen oxides emission rates as specified under §60.58a(g).

(C) All 4-hour block or 24-hour daily arithmetic average carbon monoxide emission rates, as applicable, as specified under §60.58a(h).

(D) All 4-hour block arithmetic average MWC unit load levels and particulate matter control device inlet temperatures as specified under §60.58a(h).

(3) Identification of the operating days when any of the average emission rates, percent reductions, or operating parameters specified under paragraph (b)(2)(ii) of this section or the opacity level exceeded the applicable limits, with reasons for such exceedances as well as a description of corrective actions taken.

(4) Identification of operating days for which the minimum number of hours of sulfur dioxide or nitrogen oxides emissions or operational data (carbon monoxide emissions, unit load, particulate matter control device temperature) have not been obtained, including reasons for not obtaining sufficient data and a description of corrective actions taken.

(5) Identification of the times when sulfur dioxide or nitrogen oxides emission or operational data (carbon monoxide emissions, unit load, particulate matter control device temperature) have been excluded from the calculation of average emission rates or parameters and the reasons for excluding data.

(6) The results of daily sulfur dioxide, nitrogen oxides, and carbon monoxide CEMS drift tests and accuracy assessments as required under appendix F, Procedure 1.

(7) The results of all annual performance tests conducted to determine compliance with the particulate matter, dioxin/furan and hydrogen chloride limits. For all annual dioxin/furan tests, the maximum demonstrated MWC unit load and maximum demonstrated particulate matter control device temperature shall be recorded along with supporting calculations.

(8)-(15) [Reserved]

(c) Following the initial compliance test as required under §§60.8 and §60.58a, the owner or operator of an affected facility located within a large MWC plant shall submit the initial compliance test data, the performance evaluation of the CEMS using the applicable performance specifications in appendix B, and the maximum demonstrated MWC unit load and maximum demonstrated particulate matter control device temperature established during the dioxin/furan compliance test.

(d) [Reserved]

(e)(1) The owner or operator of an affected facility located within a large MWC plant shall submit annual compliance reports for sulfur dioxide, nitrogen oxide (if applicable), carbon monoxide, load level, and particulate matter control device temperature to the Administrator containing the information recorded under paragraphs (b)(1), (2)(ii), (4), (5), and (6) of this section for each pollutant or parameter. The hourly average values recorded under paragraph (b)(2)(i) of this section are not required to be included in the annual reports. Combustors firing a mixture of medical waste and other MSW shall also provide the information under paragraph (b)(15) of this section, as applicable, in each annual report. The owner or operator of an affected facility must submit reports semiannually once the affected facility is subject to permitting requirements under Title V of the Act.

(2) The owner or operator shall submit a semiannual report for any pollutant or parameter that does not comply with the pollutant or parameter limits specified in this subpart. Such report shall include the information recorded under paragraph (b)(3) of this section. For each of the dates reported, include the sulfur dioxide, nitrogen oxide, carbon monoxide, load level, and particulate matter control device temperature data, as applicable, recorded under paragraphs (b)(2)(ii)(A) through (D) of this section.

(3) Reports shall be postmarked no later than the 30th day following the end of the annual or semiannual period, as applicable.

(f)(1) The owner or operator of an affected facility located within a large MWC plant shall submit annual compliance reports, as applicable, for opacity. The annual report shall list the percent of the affected facility operating time for the reporting period that the opacity CEMS was operating and collecting valid data. Once the unit is subject to permitting requirements under Title V of the Act, the owner or operator of an affected facility must submit these reports semiannually.

(2) The owner or operator shall submit a semiannual report for all periods when the 6-minute average levels exceeded the opacity limit under §60.52a. The semiannual report shall include all information recorded under paragraph (b)(3) of this section which pertains to opacity, and a listing of the 6-minute average opacity levels recorded under paragraph (b)(2)(i)(A) of this section, which exceeded the opacity limit.

(3) Reports shall be postmarked no later than the 30th day following the end of the annual of semiannual period, as applicable.

(g)(1) The owner or operator of an affected facility located within a large MWC plant shall submit reports to the Administrator of all annual performance tests for particulate matter, dioxin/furan, and hydrogen chloride as recorded under paragraph (b)(7) of this section, as applicable, from the affected facility. For each annual dioxin/furan compliance test, the maximum demonstrated MWC unit load and maximum demonstrated particulate matter control device temperature shall be reported. Such reports shall be submitted when available and in no case later than the date of required submittal of the annual report specified under paragraphs (e) and (f) of this section, or within six months of the date the test was conducted, whichever is earlier.

(2) The owner or operator shall submit a report of test results which document any particulate matter, dioxin/furan, and hydrogen chloride levels that were above the applicable pollutant limit. The report shall include a copy of the test report documenting the emission levels and shall include the corrective action taken. Such reports shall be submitted when available and in no case later than the date required for submittal of any semiannual report required in paragraphs (e) or (f) of this section, or within six months of the date the test was conducted, whichever is earlier.

(h) [Reserved]

(i) Records of CEMS data for opacity, sulfur dioxide, nitrogen oxides, and carbon monoxide, load level data, and particulate matter control device temperature data shall be maintained for at least 2 years after date of recordation and be made available for inspection upon request.

(j) Records showing the names of persons who have completed review of the operating manual, including the date of the initial review and all subsequent annual reviews, shall be maintained for at least 2 years after date of review and be made available for inspection upon request.

[56 FR 5507, Feb. 11, 1991, as amended at 60 FR 65387, Dec. 19, 1995; 64 FR 7465, Feb. 12, 1999]

['Air Programs']

['Air Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.