['Air Programs']

['Air Emissions']

03/16/2023

...

§1054.300 Applicability.

This subpart specifies requirements for engine manufacturers to test their production engines for exhaust emissions to ensure that the engines are being produced as described in the application for certification. The production-line verification described in 40 CFR part 1060, subpart D, applies for equipment and components for evaporative emissions.

§1054.301 When must I test my production-line engines?

(a) If you produce engines that are subject to the requirements of this part, you must test them as described in this subpart, except as follows:

(1) Small-volume engine manufacturers may omit testing under this subpart.

(2) We may exempt small-volume emission families from routine testing under this subpart. Submit your request for approval as described in §1054.210. In your request, describe your basis for projecting a production volume below 5,000 units. We will approve your request if we agree that you have made good-faith estimates of your production volumes. You must promptly notify us if your actual production exceeds 5,000 units during the model year. If you exceed the production limit or if there is evidence of a nonconformity, we may require you to test production-line engines under this subpart, or under 40 CFR part 1068, subpart E, even if we have approved an exemption under this paragraph (a)(2).

(b) We may suspend or revoke your certificate of conformity for certain engine families if your production-line engines do not meet the requirements of this part or you do not fulfill your obligations under this subpart (see §§1054.325 and 1054.340).

(c) Other regulatory provisions authorize us to suspend, revoke, or void your certificate of conformity, or order recalls for engine families, without regard to whether they have passed these production-line testing requirements. The requirements of this subpart do not affect our ability to do selective enforcement audits, as described in 40 CFR part 1068. Individual engines in families that pass these production-line testing requirements must also conform to all applicable regulations of this part and 40 CFR part 1068.

(d) You may use alternate programs for testing production-line engines in the following circumstances:

(1) You may use analyzers and sampling systems that meet the field-testing requirements of 40 CFR part 1065, subpart J, but not the otherwise applicable requirements in 40 CFR part 1065 for laboratory testing, to demonstrate compliance with emission standards if you double the minimum sampling rate specified in §1054.310(b). Use measured test results to determine whether engines comply with applicable standards without applying a measurement allowance. This alternate program does not require prior approval but we may disallow use of this option where we determine that use of field-grade equipment would prevent you from being able to demonstrate that your engines are being produced to conform to the specifications in your application for certification.

(2) You may ask to use another alternate program for testing production-line engines. In your request, you must show us that the alternate program gives equal assurance that your products meet the requirements of this part. We may waive some or all of this subpart's requirements if we approve your alternate approach. For example, in certain circumstances you may be able to give us equal assurance that your products meet the requirements of this part by using less rigorous measurement methods if you offset that by increasing the number of test engines.

(e) If you certify an engine family with carryover emission data, as described in §1054.235(d), and these equivalent engine families consistently pass the production-line testing requirements over the preceding two-year period, you may ask for a reduced testing rate for further production-line testing for that family. The minimum testing rate is one engine per engine family. If we reduce your testing rate, we may limit our approval to any number of model years. In determining whether to approve your request, we may consider the number of engines that have failed the emission tests.

(f) We may ask you to make a reasonable number of production-line engines available for a reasonable time so we can test or inspect them for compliance with the requirements of this part.

[86 FR 34521, Jun. 29, 2021]

§1054.305 How must I prepare and test my production-line engines?

This section describes how to prepare and test production-line engines. You must assemble the test engine in a way that represents the assembly procedures for other engines in the engine family. You must ask us to approve any deviations from your normal assembly procedures for other production engines in the engine family.

(a) Test procedures. Test your production-line engines using the applicable testing procedures in subpart F of this part to show you meet the emission standards in subpart B of this part.

(b) Modifying a test engine. Once an engine is selected for testing (see §1054.310), you may adjust, repair, prepare, or modify it or check its emissions only if one of the following is true:

(1) You document the need for doing so in your procedures for assembling and inspecting all your production engines and make the action routine for all the engines in the engine family.

(2) This subpart otherwise specifically allows your action.

(3) We approve your action in advance.

(c) Engine malfunction. If an engine malfunction prevents further emission testing, ask us to approve your decision to either repair the engine or delete it from the test sequence.

(d) Setting adjustable parameters. Before any test, we may require you to adjust any adjustable parameter to any setting within its physically adjustable range.

(1) [Reserved]

(2) We may specify adjustments within the physically adjustable range by considering their effect on emission levels. We may also consider how likely it is that someone will make such an adjustment with in-use equipment.

(3) We may specify an air-fuel ratio within the adjustable range specified in §1054.115(b).

(e) Stabilizing emission levels. Use good engineering judgment to operate your engines before testing such that deterioration factors can be applied appropriately. Determine the stabilization period as follows:

(1) For engine families with a useful life at or below 300 hours, operate the engine for the same number of hours before starting emission measurements that you used for the emission-data engine, within one hour. For example, if the emission-data engine operated for 8 hours before the low-hour emission test, operate the test engines for 7 to 9 hours before starting emission measurements.

(2) For engine families with a useful life above 300 hours, operate each engine for no more than the greater of two periods:

(i) 12 hours.

(ii) The number of hours you operated your emission-data engine for certifying the engine family (see 40 CFR part 1065, subpart E, or the applicable regulations governing how you should prepare your test engine).

(f) Damage during shipment. If shipping an engine to a remote facility for production-line testing makes necessary an adjustment or repair, you must wait until after the initial emission test to do this work. We may waive this requirement if the test would be impossible or unsafe or if it would permanently damage the engine. Report to us, in your written report under §1054.345, all adjustments or repairs you make on test engines before each test.

(g) Retesting after invalid tests. You may retest an engine if you determine an emission test is invalid under subpart F of this part. Explain in your written report reasons for invalidating any test and the emission results from all tests. If we determine that you improperly invalidated a test, we may require you to ask for our approval for future testing before substituting results of the new tests for invalid ones.

§1054.310 How must I select engines for production-line testing?

(a) Test engines from each engine family as described in this section based on test periods, as follows:

(1) For engine families with projected U.S.-directed production volume of at least 1,600, the test periods are defined as follows:

(i) If your annual production period is 120 days or less, the whole model year constitutes a single test period.

(ii) If your annual production period is 121 to 210 days, divide the annual production period evenly into two test periods.

(iii) If your annual production period is 211 to 300 days, divide the annual production period evenly into three test periods.

(iv) If your annual production period is 301 days or longer, divide the annual production period evenly into four test periods. For example, if your annual production period is 392 days (56 weeks), divide the annual production period into four test periods of 98 days (14 weeks).

(2) For engine families with projected U.S.-directed production volume below 1,600, the whole model year constitutes a single test period.

(b) Early in each test period, randomly select and test an engine from the end of the assembly line for each engine family.

(1) In the first test period for newly certified engines, randomly select and test one more engine. Then, calculate the required sample size for the model year as described in paragraph (c) of this section.

(2) In later test periods of the same model year, combine the new test result with all previous testing in the model year. Then, calculate the required sample size for the model year as described in paragraph (c) of this section.

(3) In the first test period for engine families relying on previously submitted test data, combine the new test result with the last test result from the previous model year. Then, calculate the required sample size for the model year as described in paragraph (c) of this section. Use the last test result from the previous model year only for this first calculation. For all subsequent calculations, use only results from the current model year.

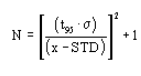

(c) Calculate the required sample size for each engine family. Separately calculate this figure for HC NOX and CO. The required sample size is the greater of these calculated values. Use the following equation:

Where:

N = Required sample size for the model year.

t95 = 95% confidence coefficient, which depends on the number of tests completed, n, as specified in the table in paragraph (c)(1) of this section. It defines 95% confidence intervals for a one-tail distribution.

? = Test sample standard deviation (see paragraph (c)(2) of this section).

x = Mean of emission test results of the sample.

STD = Emission standard (or family emission limit, if applicable).

(1) Determine the 95% confidence coefficient, t 95, from the following table:

| n | t95 | n | t95 | n | t95 |

|---|---|---|---|---|---|

| 2 | 6.31 | 12 | 1.80 | 22 | 1.72 |

| 3 | 2.92 | 13 | 1.78 | 23 | 1.72 |

| 4 | 2.35 | 14 | 1.77 | 24 | 1.71 |

| 5 | 2.13 | 15 | 1.76 | 25 | 1.71 |

| 6 | 2.02 | 16 | 1.75 | 26 | 1.71 |

| 7 | 1.94 | 17 | 1.75 | 27 | 1.71 |

| 8 | 1.90 | 18 | 1.74 | 28 | 1.70 |

| 9 | 1.86 | 19 | 1.73 | 29 | 1.70 |

| 10 | 1.83 | 20 | 1.73 | 30 | 1.70 |

| 11 | 1.81 | 21 | 1.72 | 31 | 1.65 |

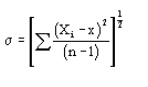

(2) Calculate the standard deviation, ?, for the test sample using the following formula:

Where:

Xi = Emission test result for an individual engine.

n = The number of tests completed in an engine family.

(d) Use final deteriorated test results to calculate the variables in the equations in paragraph (c) of this section (see §1054.315(a)(2)).

(e) After each new test, recalculate the required sample size using the updated mean values, standard deviations, and the appropriate 95-percent confidence coefficient.

(f) Distribute the remaining engine tests evenly throughout the rest of the year. You may need to adjust your schedule for selecting engines if the required sample size changes. If your scheduled quarterly testing for the remainder of the model year is sufficient to meet the calculated sample size, you may wait until the next quarter to do additional testing. Continue to randomly select engines from each engine family.

(g) Continue testing until one of the following things happens:

(1) After completing the minimum number of tests required in paragraph (b) of this section, the number of tests completed in an engine family, n, is greater than the required sample size, N, and the sample mean, x, is less than or equal to the emission standard. For example, if N = 5.1 after the fifth test, the sample-size calculation does not allow you to stop testing.

(2) The engine family does not comply according to §1054.315.

(3) You test 30 engines from the engine family.

(4) You test one percent of your projected annual U.S.-directed production volume for the engine family, rounded to the nearest whole number. Do not count an engine under this paragraph (g)(4) if it fails to meet an applicable emission standard.

(5) You choose to declare that the engine family does not comply with the requirements of this subpart.

(h) If the sample-size calculation allows you to stop testing for one pollutant but not another, you must continue measuring emission levels of all pollutants for any additional tests required under this section. However, you need not continue making the calculations specified in this subpart for the pollutant for which testing is not required. This paragraph (h) does not affect the number of tests required under this section, the required calculations in §1054.315, or the remedial steps required under §1054.320.

(i) You may elect to test more randomly chosen engines than we require under this section. Include these engines in the sample-size calculations.

[86 FR 34521, Jun. 29, 2021]

§1054.315 How do I know when my engine family fails the production-line testing requirements?

This section describes the pass-fail criteria for the production-line testing requirements. We apply these criteria on an emission-family basis. See §1054.320 for the requirements that apply to individual engines that fail a production-line test.

(a) Calculate your test results as follows:

(1) Initial and final test results. Calculate and round the test results for each engine. If you do multiple tests on an engine in a given configuration (without modifying the engine), calculate the initial results for each test, then add all the test results together and divide by the number of tests. Round this final calculated value for the final test results on that engine.

(2) Final deteriorated test results. Apply the deterioration factor for the engine family to the final test results (see §1054.240(c)).

(3) Round deteriorated test results. Round the results to the number of decimal places in the emission standard expressed to one more decimal place.

(b) Construct the following CumSum Equation for each engine family for HC NOX and CO emissions:

Ci = Max [0 or Ci-1 Xi?(STD 0.25 × ?)]

Where:

Ci = The current CumSum statistic.

Ci-1 = The previous CumSum statistic. For the first test, the CumSum statistic is 0 (i.e., C1 = 0).

Xi = The current emission test result for an individual engine.

STD = Emission standard (or family emission limit, if applicable).

(c) Use final deteriorated test results to calculate the variables in the equation in paragraph (b) of this section (see §1054.315(a)).

(d) After each new test, recalculate the CumSum statistic.

(e) If you test more than the required number of engines, include the results from these additional tests in the CumSum Equation.

(f) After each test, compare the current CumSum statistic, Ci, to the recalculated Action Limit, H, defined as H = 5.0 × ?.

(g) If the CumSum statistic exceeds the Action Limit in two consecutive tests, the engine family fails the production-line testing requirements of this subpart. Tell us within ten working days if this happens. You may request to amend the application for certification to raise the FEL of the entire engine family as described in §1054.225(f).

(h) If you amend the application for certification for an engine family under §1054.225, do not change any previous calculations of sample size or CumSum statistics for the model year.

[86 FR 34521, Jun. 29, 2021]

§1054.320 What happens if one of my production-line engines fails to meet emission standards?

(a) If you have a production-line engine with final deteriorated test results exceeding one or more emission standards (see §1054.315(a)), the certificate of conformity is automatically suspended for that failing engine. You must take the following actions before your certificate of conformity can cover that engine:

(1) Correct the problem and retest the engine to show it complies with all emission standards.

(2) Include the test results and describe the remedy for each engine in the written report required under §1054.345.

(b) You may request to amend the application for certification to raise the FEL of the entire engine family at this point (see §1054.225).

(c) Use test data from a failing engine for the compliance demonstration under §1054.315 as follows:

(1) Use the original, failing test results as described in §1054.315, whether or not you modify the engine or destroy it.

(2) Do not use test results from a modified engine as final test results under §1054.315, unless you change your production process for all engines to match the adjustments you made to the failing engine. If this occurs, count the modified engine as the next engine in the sequence, rather than averaging the results with the testing that occurred before modifying the engine.

[86 FR 34522, Jun. 29, 2021]

§1054.325 What happens if an engine family fails the production-line testing requirements?

(a) We may suspend your certificate of conformity for an engine family if it fails under §1054.315. The suspension may apply to all facilities producing engines from an engine family even if you find noncompliant engines only at one facility.

(b) We will tell you in writing if we suspend your certificate in whole or in part. We will not suspend a certificate until at least 15 days after the engine family fails. The suspension is effective when you receive our notice.

(c) Up to 15 days after we suspend the certificate for an engine family, you may ask for a hearing (see §1054.820). If we agree before a hearing occurs that we used erroneous information in deciding to suspend the certificate, we will reinstate the certificate.

(d) Section 1054.335 specifies steps you must take to remedy the cause of the engine family's production-line failure. All the engines you have produced since the end of the last test period are presumed noncompliant and should be addressed in your proposed remedy. We may require you to apply the remedy to engines produced earlier if we determine that the cause of the failure is likely to have affected the earlier engines.

(e) You may request to amend the application for certification to raise the FEL of the engine family before or after we suspend your certificate as described in §1054.225(f). We will approve your request if the failure is not caused by a defect and it is clear that you used good engineering judgment in establishing the original FEL.

§1054.330 May I sell engines from an engine family with a suspended certificate of conformity?

You may sell engines that you produce after we suspend the engine family's certificate of conformity under §1054.315 only if one of the following occurs:

(a) You test each engine you produce and show it complies with emission standards that apply.

(b) We conditionally reinstate the certificate for the engine family. We may do so if you agree to recall all the affected engines and remedy any noncompliance at no expense to the owner if later testing shows that the engine family still does not comply.

§1054.335 How do I ask EPA to reinstate my suspended certificate?

(a) Send us a written report asking us to reinstate your suspended certificate. In your report, identify the reason for noncompliance, propose a remedy for the engine family, and commit to a date for carrying it out. In your proposed remedy include any quality control measures you propose to keep the problem from happening again.

(b) Give us data from production-line testing that shows the remedied engine family complies with all the emission standards that apply.

§1054.340 When may EPA revoke my certificate under this subpart and how may I sell these engines again?

(a) We may revoke your certificate for an engine family in the following cases:

(1) You do not meet the reporting requirements.

(2) Your engine family fails to comply with the requirements of this subpart and your proposed remedy to address a suspended certificate under §1054.335 is inadequate to solve the problem or requires you to change the engine's design or emission control system.

(b) To sell engines from an engine family with a revoked certificate of conformity, you must modify the engine family and then show it complies with the requirements of this part.

(1) If we determine your proposed design change may not control emissions for the engine's full useful life, we will tell you within five working days after receiving your report. In this case we will decide whether production-line testing will be enough for us to evaluate the change or whether you need to do more testing.

(2) Unless we require more testing, you may show compliance by testing production-line engines as described in this subpart.

(3) We will issue a new or updated certificate of conformity when you have met these requirements.

§1054.345 What production-line testing records must I send to EPA?

(a) Within 45 days of the end of each test period, send us a report with the following information:

(1) Describe any facility used to test production-line engines and state its location.

(2) State the total U.S.-directed production volume and number of tests for each engine family.

(3) Describe how you randomly selected engines.

(4) Describe each test engine, including the engine family's identification and the engine's model year, build date, model number, identification number, and number of hours of operation before testing.

(5) Identify how you accumulated hours of operation on the engines and describe the procedure and schedule you used.

(6) Provide the test number; the date, time and duration of testing; test procedure; all initial test results; final test results; and final deteriorated test results for all tests. Provide the emission results for all measured pollutants. Include information for both valid and invalid tests and the reason for any invalidation.

(7) Describe completely and justify any nonroutine adjustment, modification, repair, preparation, maintenance, or test for the test engine if you did not report it separately under this subpart. Include the results of any emission measurements, regardless of the procedure or type of engine.

(8) Provide the CumSum analysis required in §1054.315 and the sample-size calculation required in §1054.310 for each engine family.

(9) Report on each failed engine as described in §1054.320.

(10) State the date the test period ended for each engine family.

(b) We may ask you to add information to your written report so we can determine whether your new engines conform with the requirements of this subpart. We may also ask you to send less information.

(c) An authorized representative of your company must sign the following statement:

We submit this report under sections 208 and 213 of the Clean Air Act. Our production-line testing conformed completely with the requirements of 40 CFR part 1054. We have not changed production processes or quality-control procedures for test engines in a way that might affect emission controls. All the information in this report is true and accurate to the best of my knowledge. I know of the penalties for violating the Clean Air Act and the regulations. (Authorized Company Representative)

(d) Send electronic reports of production-line testing to the Designated Compliance Officer using an approved information format. If you want to use a different format, send us a written request with justification for a waiver.

(e) We will send copies of your reports to anyone from the public who asks for them. Section 1054.815 describes how we treat information you consider confidential.

§1054.350 What records must I keep?

(a) Organize and maintain your records as described in this section. We may review your records at any time.

(b) Keep paper or electronic records of your production-line testing for eight years after you complete all the testing required for an engine family in a model year.

(c) Keep a copy of the written reports described in §1054.345.

(d) Keep the following additional records:

(1) A description of all test equipment for each test cell that you can use to test production-line engines.

(2) The names of supervisors involved in each test.

(3) The name of anyone who authorizes adjusting, repairing, preparing, or modifying a test engine and the names of all supervisors who oversee this work.

(4) If you shipped the engine for testing, the date you shipped it, the associated storage or port facility, and the date the engine arrived at the testing facility.

(5) Any records related to your production-line tests that are not in the written report.

(6) A brief description of any significantevents during testing not otherwise described in the written report or in this section.

(7) Any information specified in §1054.345 that you do not include in your written reports.

(e) If we ask, you must give us a more detailed description of projected or actual production figures for an engine family. We may ask you to divide your production figures by maximum engine power, displacement, fuel type, or assembly plant (if you produce engines at more than one plant).

(f) Keep records of the engine identification number for each engine you produce under each certificate of conformity. You may identify these numbers as a range. Give us these records within 30 days if we ask for them.

(g) We may ask you to keep or send other information necessary to implement this subpart.

['Air Programs']

['Air Emissions']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.