['Air Programs']

['Air Quality']

06/06/2024

...

§53.20 General provisions.

(a) The test procedures given in this subpart shall be used to test the performance of candidate automated methods against the performance requirement specifications given in table B-1 to subpart B of part 53. A test analyzer representative of the candidate automated method must exhibit performance better than, or not outside, the specified limit or limits for each such performance parameter specified (except range) to satisfy the requirements of this subpart. Except as provided in paragraph (b) of this section, the measurement range of the candidate method must be the standard range specified in table B-1 to subpart B of part 53 to satisfy the requirements of this subpart.

(b) Measurement ranges. For a candidate method having more than one selectable measurement range, one range must be the standard range specified in table B-1 to subpart B of part 53, and a test analyzer representative of the method must pass the tests required by this subpart while operated in that range.

(i) Higher ranges. The tests may be repeated for one or more higher (broader) ranges (i.e., ranges extending to higher concentrations) than the standard range specified in table B-1 to subpart B of part 53, provided that the range does not extend to concentrations more than four times the upper range limit of the standard range specified in table B-1 to subpart B of part 53. For such higher ranges, only the tests for range (calibration), noise at 80% of the upper range limit, and lag, rise and fall time are required to be repeated. For the purpose of testing a higher range, the test procedure of §53.23(e) may be abridged to include only those components needed to test lag, rise and fall time.

(ii) Lower ranges. The tests may be repeated for one or more lower (narrower) ranges (i.e., ones extending to lower concentrations) than the standard range specified in table B-1 to subpart B of part 53. For methods for some pollutants, table B-1 to subpart B of part 53 specifies special performance limit requirements for lower ranges. If special low-range performance limit requirements are not specified in table B-1 to subpart B of part 53, then the performance limit requirements for the standard range apply. For lower ranges for any method, only the tests for range (calibration), noise at 0% of the measurement range, lower detectable limit, (and nitric oxide interference for SO2 UVF methods) are required to be repeated, provided the tests for the standard range shows the applicable limit specifications are met for the other test parameters.

(iii) If the tests are conducted and passed only for the specified standard range, any FRM or FEM determination with respect to the method will be limited to that range. If the tests are passed for both the specified range and one or more higher or lower ranges, any such determination will include the additional higher or lower range(s) as well as the specified standard range. Appropriate test data shall be submitted for each range sought to be included in a FRM or FEM method determination under this paragraph (b).

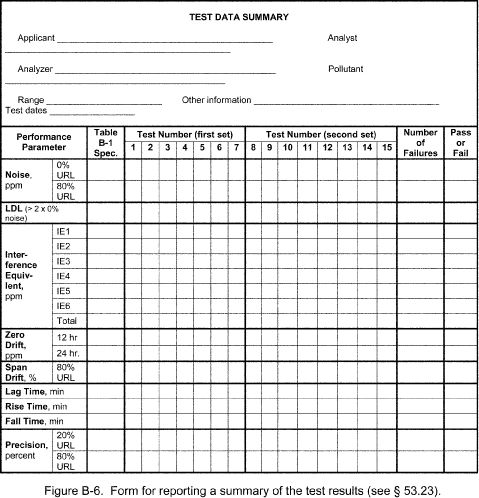

(c) For each performance parameter (except range), the test procedure shall be initially repeated seven (7) times to yield 7 test results. Each result shall be compared with the corresponding performance limit specification in table B-1 to subpart B of part 53; a value higher than or outside the specified limit or limits constitutes a failure. These 7 results for each parameter shall be interpreted as follows:

(1) Zero (0) failures: The candidate method passes the test for the performance parameter.

(2) Three (3) or more failures: The candidate method fails the test for the performance parameter.

(3) One (1) or two (2) failures: Repeat the test procedures for the performance parameter eight (8) additional times yielding a total of fifteen (15) test results. The combined total of 15 test results shall then be interpreted as follows:

(i) One (1) or two (2) failures: The candidate method passes the test for the performance parameter.

(ii) Three (3) or more failures: The candidate method fails the test for the performance parameter.

(d) The tests for zero drift, span drift, lag time, rise time, fall time, and precision shall be carried out in a single integrated procedure conducted at various line voltages and ambient temperatures specified in §53.23(e). A temperature-controlled environmental test chamber large enough to contain the test analyzer is recommended for this test. The tests for noise, lower detectable limit, and interference equivalent shall be conducted at any ambient temperature between 20°C and 30°C, at any normal line voltage between 105 and 125 volts, and shall be conducted such that not more than three (3) test results for each parameter are obtained in any 24-hour period.

(e) If necessary, all measurement response readings to be recorded shall be converted to concentration units or adjusted according to the calibration curve constructed in accordance with §53.21(b).

(f) All recorder chart tracings (or equivalent data plots), records, test data and other documentation obtained from or pertinent to these tests shall be identified, dated, signed by the analyst performing the test, and submitted.

Note to §53.20:

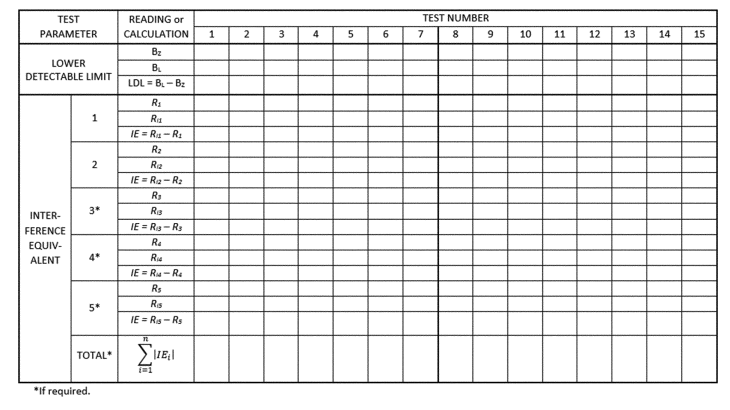

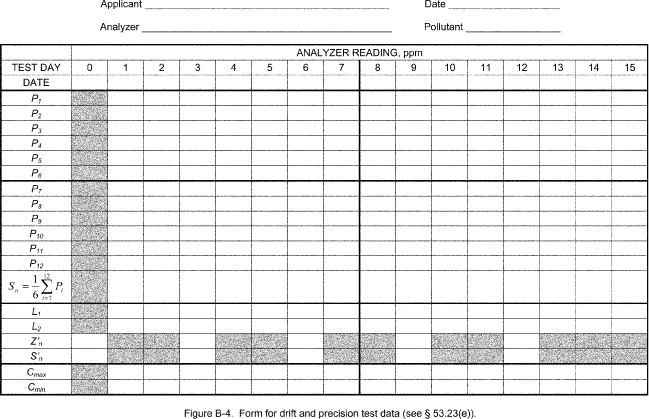

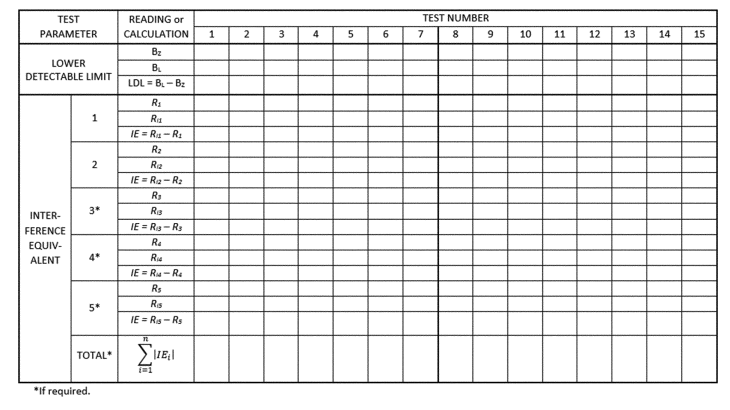

Suggested formats for reporting the test results and calculations are provided in Figures B-2, B-3, B-4, B-5, and B-6 in appendix A to this subpart . Symbols and abbreviations used in this subpart are listed in table B-5 of appendix A to this subpart .

§53.21 Test conditions.

(a) Set-up and start-up of the test analyzer shall be in strict accordance with the operating instructions specified in the manual referred to in §53.4(b)(3). Allow adequate warm-up or stabilization time as indicated in the operating instructions before beginning the tests. The test procedures assume that the test analyzer has a conventional analog measurement signal output that is connected to a suitable strip chart recorder of the servo, null-balance type. This recorder shall have a chart width of at least 25 centimeters, chart speeds up to 10 cm per hour, a response time of 1 second or less, a deadband of not more than 0.25 percent of full scale, and capability either of reading measurements at least 5 percent below zero or of offsetting the zero by at least 5 percent. If the test analyzer does not have an analog signal output, or if a digital or other type of measurement data output is used for the tests, an alternative measurement data recording device (or devices) may be used for recording the test data, provided that the device is reasonably suited to the nature and purposes of the tests, and an analog representation of the analyzer measurements for each test can be plotted or otherwise generated that is reasonably similar to the analog measurement recordings that would be produced by a conventional chart recorder connected to a conventional analog signal output.

(b) Calibration of the test analyzer shall be carried out prior to conducting the tests described in this subpart. The calibration shall be as indicated in the manual referred to in §53.4(b)(3) and as follows: If the chart recorder or alternative data recorder does not have below zero capability, adjust either the controls of the test analyzer or the chart or data recorder to obtain a + 5% offset zero reading on the recorder chart to facilitate observing negative response or drift. If the candidate method is not capable of negative response, the test analyzer (not the data recorder) shall be operated with a similar offset zero. Construct and submit a calibration curve showing a plot of recorder scale readings or other measurement output readings (vertical or y-axis) against pollutant concentrations presented to the analyzer for measurement (horizontal or x-axis). If applicable, a plot of base analog output units (volts, millivolts, milliamps, etc.) against pollutant concentrations shall also be obtained and submitted. All such calibration plots shall consist of at least seven (7) approximately equally spaced, identifiable points, including 0 and 90 ±5 percent of the upper range limit (URL).

(c) Once the test analyzer has been set up and calibrated and the tests started, manual adjustment or normal periodic maintenance is permitted only every 3 days. Automatic adjustments which the test analyzer performs by itself are permitted at any time. The submitted records shall show clearly when any manual adjustment or periodic maintenance was made during the tests and describe the specific operations performed.

(d) If the test analyzer should malfunction during any of the performance tests, the tests for that parameter shall be repeated. A detailed explanation of the malfunction, remedial action taken, and whether recalibration was necessary (along with all pertinent records and charts) shall be submitted. If more than one malfunction occurs, all performance test procedures for all parameters shall be repeated.

(e) Tests for all performance parameters shall be completed on the same test analyzer; however, use of multiple test analyzers to accelerate testing is permissible for testing additional ranges of a multi-range candidate method.

§53.22 Generation of test atmospheres.

(a) Table B-2 to subpart B of part 53 specifies preferred methods for generating test atmospheres and suggested methods of verifying their concentrations. Only one means of establishing the concentration of a test atmosphere is normally required, provided that that means is adequately accurate and credible. If the method of generation can produce accurate, reproducible concentrations, verification is optional. If the method of generation is not reproducible or reasonably quantifiable, then establishment of the concentration by some credible verification method is required.

(b) The test atmosphere delivery system shall be designed and constructed so as not to significantly alter the test atmosphere composition or concentration during the period of the test. The system shall be vented to insure that test atmospheres are presented to the test analyzer at very nearly atmospheric pressure. The delivery system shall be fabricated from borosilicate glass, FEP Teflon, or other material that is inert with regard to the gas or gases to be used.

(c) The output of the test atmosphere generation system shall be sufficiently stable to obtain stable response readings from the test analyzer during the required tests. If a permeation device is used for generation of a test atmosphere, the device, as well as the air passing over it, shall be controlled to 0.1°C.

(d) All diluent air shall be zero air free of contaminants likely to react with the test atmospheres or cause a detectable response on the test analyzer.

(e) The concentration of each test atmosphere used shall be quantitatively established and/or verified before or during each series of tests. Samples for verifying test concentrations shall be collected from the test atmosphere delivery system as close as feasible to the sample intake port of the test analyzer.

(f) The accuracy of all flow measurements used to calculate test atmosphere concentrations shall be documented and referenced to a primary flow rate or volume standard (such as a spirometer, bubble meter, etc.). Any corrections shall be clearly shown. All flow measurements given in volume units shall be standardized to 25°C and 760 mm Hg.

(g) Schematic drawings, photos, descriptions, and other information showing complete procedural details of the test atmosphere generation, verification, and delivery system shall be provided. All pertinent calculations shall be clearly indicated.

§53.23 Test procedures.

(a) Range - (1) Technical definition. The nominal minimum and maximum concentrations that a method is capable of measuring.

Note to §53.23(a)(1):

The nominal range is given as the lower and upper range limits in concentration units, for example, 0-0.5 parts per million (ppm).

(2) Test procedure. Determine and submit a suitable calibration curve, as specified in §53.21(b), showing the test analyzer's measurement response over at least 95 percent of the required or indicated measurement range.

Note to §53.23(a)(2):

A single calibration curve for each measurement range for which an FRM or FEM designation is sought will normally suffice.

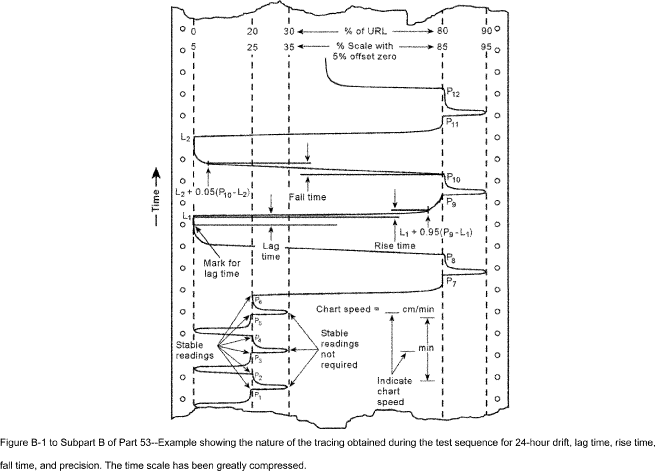

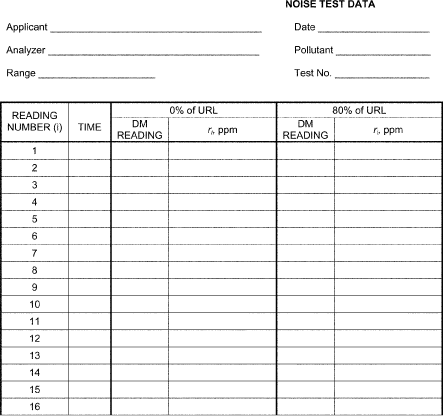

(b) Noise - (1) Technical definition. Spontaneous, short duration deviations in measurements or measurement signal output, about the mean output, that are not caused by input concentration changes. Measurement noise is determined as the standard deviation of a series of measurements of a constant concentration about the mean and is expressed in concentration units.

(2) Test procedure. (i) Allow sufficient time for the test analyzer to warm up and stabilize. Determine measurement noise at each of two fixed concentrations, first using zero air and then a pollutant test gas concentration as indicated below. The noise limit specification in table B-1 to subpart B of part 53 shall apply to both of these tests.

(ii) For an analyzer with an analog signal output, connect an integrating-type digital meter (DM) suitable for the test analyzer's output and accurate to three significant digits, to determine the analyzer's measurement output signal.

Note to §53.23(b)(2):

Use of a chart recorder in addition to the DM is optional.

(iii) Measure zero air with the test analyzer for 60 minutes. During this 60-minute interval, record twenty-five (25) test analyzer concentration measurements or DM readings at 2-minute intervals. (See Figure B-2 in appendix A of this subpart.)

(iv) If applicable, convert each DM test reading to concentration units (ppm) or adjust the test readings (if necessary) by reference to the test analyzer's calibration curve as determined in §53.21(b). Label and record the test measurements or converted DM readings as r1, r2, r3 . . . ri . . . r25.

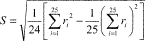

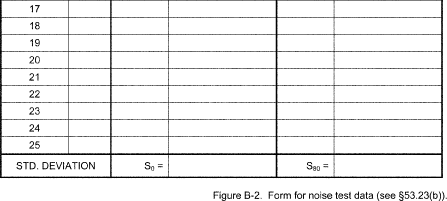

(v) Calculate measurement noise as the standard deviation, S, as follows:

Where i indicates the i-th test measurement or DM reading in ppm.

(vi) Let S at 0 ppm be identified as S0; compare S0 to the noise limit specification given in table B-1 to subpart B of part 53.

(vii) Repeat steps in Paragraphs (b)(2)(iii) through (v) of this section using a pollutant test atmosphere concentration of 80 ±5 percent of the URL instead of zero air, and let S at 80 percent of the URL be identified as S80. Compare S80 to the noise limit specification given in table B-1 to subpart B of part 53.

(viii) Both S0 and S80 must be less than or equal to the table B-1 to subpart B of part 53 noise limit specification to pass the test for the noise parameter.

(c) Lower detectable limit - (1) Technical definition. The minimum pollutant concentration that produces a measurement or measurement output signal of at least twice the noise level.

(2) Test procedure. (i) Allow sufficient time for the test analyzer to warm up and stabilize. Measure zero air and record the stable measurement reading in ppm as BZ. (See Figure B-3 in appendix A of this subpart.)

(ii) Generate and measure a pollutant test concentration equal to the value for the lower detectable limit specified in table B-1 to subpart B of part 53.

Note to §53.23(c)(2):

If necessary, the test concentration may be generated or verified at a higher concentration, then quantitatively and accurately diluted with zero air to the final required test concentration.

(iii) Record the test analyzer's stable measurement reading, in ppm, as BL.

(iv) Determine the lower detectable limit (LDL) test result as LDL = BL− BZ. Compare this LDL value with the noise level, S0, determined in §53.23(b), for the 0 concentration test atmosphere. LDL must be equal to or higher than 2 × S0 to pass this test.

(d) Interference equivalent - (1) Technical definition. Positive or negative measurement response caused by a substance other than the one being measured.

(2) Test procedure. The test analyzer shall be tested for all substances likely to cause a detectable response. The test analyzer shall be challenged, in turn, with each potential interfering agent (interferent) specified in table B-3 to subpart B of part 53. In the event that there are substances likely to cause a significant interference which have not been specified in table B-3 to subpart B of part 53, these substances shall also be tested, in a manner similar to that for the specified interferents, at a concentration substantially higher than that likely to be found in the ambient air. The interference may be either positive or negative, depending on whether the test analyzer's measurement response is increased or decreased by the presence of the interferent. Interference equivalents shall be determined by mixing each interferent, one at a time, with the pollutant at an interferent test concentration not lower than the test concentration specified in table B-3 to subpart B of part 53 (or as otherwise required for unlisted interferents), and comparing the test analyzer's measurement response to the response caused by the pollutant alone. Known gas-phase reactions that might occur between a listed interferent and the pollutant are designated by footnote 3 in table B-3 to subpart B of part 53. In these cases, the interference equivalent shall be determined without mixing with the pollutant.

(i) Allow sufficient time for warm-up and stabilization of the test analyzer.

(ii) For a candidate method using a prefilter or scrubber device based upon a chemical reaction to derive part of its specificity and which device requires periodic service or maintenance, the test analyzer shall be “conditioned” prior to conducting each interference test series. This requirement includes conditioning for the NO2 converter in chemiluminescence NO/NO2/NOX analyzers and for the ozone scrubber in UV-absorption ozone analyzers. Conditioning is as follows:

(A) Service or perform the indicated maintenance on the scrubber or prefilter device, as if it were due for such maintenance, as directed in the manual referred to in §53.4(b)(3).

(B) Before testing for each potential interferent, allow the test analyzer to sample through the prefilter or scrubber device a test atmosphere containing the interferent at a concentration not lower than the value specified in table B-3 to subpart B of part 53 (or, for unlisted potential interferents, at a concentration substantially higher than likely to be found in ambient air). Sampling shall be at the normal flow rate and shall be continued for 6 continuous hours prior to the interference test series. Conditioning for all applicable interferents prior to any of the interference tests is permissible. Also permissible is simultaneous conditioning with multiple interferents, provided no interferent reactions are likely to occur in the conditioning system.

(iii) Generate three test atmosphere streams as follows:

(A) Test atmosphere P: Pollutant test concentration.

(B) Test atmosphere I: Interferent test concentration.

(C) Test atmosphere Z: Zero air.

(iv) Adjust the individual flow rates and the pollutant or interferent generators for the three test atmospheres as follows:

(A) The flow rates of test atmospheres I and Z shall be equal.

(B) The concentration of the pollutant in test atmosphere P shall be adjusted such that when P is mixed (diluted) with either test atmosphere I or Z, the resulting concentration of pollutant shall be as specified in table B-3 to subpart B of part 53.

(C) The concentration of the interferent in test atmosphere I shall be adjusted such that when I is mixed (diluted) with test atmosphere P, the resulting concentration of interferent shall be not less than the value specified in table B-3 to subpart B of part 53 (or as otherwise required for unlisted potential interferents).

(D) To minimize concentration errors due to flow rate differences between I and Z, it is recommended that, when possible, the flow rate of P be from 10 to 20 times larger than the flow rates of I and Z.

(v) Mix test atmospheres P and Z by passing the total flow of both atmospheres through a (passive) mixing component to insure complete mixing of the gases.

(vi) Sample and measure the mixture of test atmospheres P and Z with the test analyzer. Allow for a stable measurement reading, and record the reading, in concentration units, as R (see Figure B-3).

(vii) Mix test atmospheres P and I by passing the total flow of both atmospheres through a (passive) mixing component to insure complete mixing of the gases.

(viii) Sample and measure this mixture of P and I with the test analyzer. Record the stable measurement reading, in concentration units, as RI.

(ix) Calculate the interference equivalent (IE) test result as:

IE = RI−R.

IE must be within the limits (inclusive) specified in table B-1 to subpart B of part 53 for each interferent tested to pass the interference equivalent test.

(x) Follow steps (iii) through (ix) of this section, in turn, to determine the interference equivalent for each listed interferent as well as for any other potential interferents identified.

(xi) For those potential interferents which cannot be mixed with the pollutant, as indicated by footnote (3) in table B-3 to subpart B of part 53, adjust the concentration of test atmosphere I to the specified value without being mixed or diluted by the pollutant test atmosphere. Determine IE as follows:

(A) Sample and measure test atmosphere Z (zero air). Allow for a stable measurement reading and record the reading, in concentration units, as R.

(B) Sample and measure the interferent test atmosphere I. If the test analyzer is not capable of negative readings, adjust the analyzer (not the recorder) to give an offset zero. Record the stable reading in concentration units as RI, extrapolating the calibration curve, if necessary, to represent negative readings.

(C) Calculate IE = RI− R. IE must be within the limits (inclusive) specified in table B-1 to subpart B of part 53 for each interferent tested to pass the interference equivalent test.

(xii) Sum the absolute value of all the individual interference equivalent test results. This sum must be equal to or less than the total interferent limit given in table B-1 to subpart B of part 53 to pass the test.

(e) Zero drift, span drift, lag time, rise time, fall time, and precision - (1) Technical definitions - (i) Zero drift: The change in measurement response to zero pollutant concentration over 12- and 24-hour periods of continuous unadjusted operation.

(ii) Span drift: The percent change in measurement response to an up-scale pollutant concentration over a 24-hour period of continuous unadjusted operation.

(iii) Lag time: The time interval between a step change in input concentration and the first observable corresponding change in measurement response.

(iv) Rise time: The time interval between initial measurement response and 95 percent of final response after a step increase in input concentration.

(v) Fall time: The time interval between initial measurement response and 95 percent of final response after a step decrease in input concentration.

(vi) Precision: Variation about the mean of repeated measurements of the same pollutant concentration, denoted as the standard deviation expressed as a percentage of the upper range limits. 258

258 NO2 precision in Table B-1 is also changed to percent to agree with the calculation specified in 53.23(e)(10)(vi).

(2) Tests for these performance parameters shall be accomplished over a period of seven (7) or fifteen (15) test days. During this time, the line voltage supplied to the test analyzer and the ambient temperature surrounding the analyzer shall be changed from day to day, as required in paragraph (e)(4) of this section. One test result for each performance parameter shall be obtained each test day, for seven (7) or fifteen (15) test days, as determined from the test results of the first seven days. The tests for each test day are performed in a single integrated procedure.

(3) The 24-hour test day may begin at any clock hour. The first approximately 12 hours of each test day are required for testing 12-hour zero drift. Tests for the other parameters shall be conducted any time during the remaining 12 hours.

(4) Table B-4 to subpart B of part 53 specifies the line voltage and room temperature to be used for each test day. The applicant may elect to specify a wider temperature range (minimum and maximum temperatures) than the range specified in table B-4 to subpart B of part 53 and to conduct these tests over that wider temperature range in lieu of the specified temperature range. If the test results show that all test parameters of this section §53.23(e) are passed over this wider temperature range, a subsequent FRM or FEM designation for the candidate method based in part on this test shall indicate approval for operation of the method over such wider temperature range. The line voltage and temperature shall be changed to the specified values (or to the alternative, wider temperature values, if applicable) at the start of each test day (i.e., at the start of the 12-hour zero test). Initial adjustments (day zero) shall be made at a line voltage of 115 volts (rms) and a room temperature of 25°C.

(5) The tests shall be conducted in blocks consisting of 3 test days each until 7 (or 15, if necessary) test results have been obtained. (The final block may contain fewer than three test days.) Test days need not be contiguous days, but during any idle time between tests or test days, the test analyzer must operate continuously and measurements must be recorded continuously at a low chart speed (or equivalent data recording) and included with the test data. If a test is interrupted by an occurrence other than a malfunction of the test analyzer, only the block during which the interruption occurred shall be repeated.

(6) During each test block, manual adjustments to the electronics, gas, or reagent flows or periodic maintenance shall not be permitted. Automatic adjustments that the test analyzer performs by itself are permitted at any time.

(7) At least 4 hours prior to the start of the first test day of each test block, the test analyzer may be adjusted and/or serviced according to the periodic maintenance procedures specified in the manual referred to in §53.4(b)(3). If a new block is to immediately follow a previous block, such adjustments or servicing may be done immediately after completion of the day's tests for the last day of the previous block and at the voltage and temperature specified for that day, but only on test days 3, 6, 9, and 12.

Note to §53.23(e)(7):

If necessary, the beginning of the test days succeeding such maintenance or adjustment may be delayed as required to complete the service or adjustment operation.

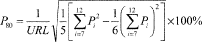

(8) All measurement response readings to be recorded shall be converted to concentration units or adjusted (if necessary) according to the calibration curve. Whenever a test atmosphere is to be measured but a stable reading is not required, the test atmosphere shall be sampled and measured long enough to cause a change in measurement response of at least 10% of full scale. Identify all readings and other pertinent data on the strip chart (or equivalent test data record). (See Figure B-1 to subpart B of part 53 illustrating the pattern of the required readings.)

(9) Test procedure. (i) Arrange to generate pollutant test atmospheres as follows. Test atmospheres A0, A20, and A80 shall be maintained consistent during the tests and reproducible from test day to test day.

|

Test

atmosphere |

Pollutant concentration

(percent) |

|---|---|

| A0 | Zero air. |

| A20 | 20 ±5 of the upper range limit. |

| A30 | 30 ±5 of the upper range limit. |

| A80 | 80 ±5 of the upper range limit. |

| A90 | 90 ±5 of the upper range limit. |

(ii) For steps within paragraphs (e)(9)(xxv) through (e)(9)(xxxi) of this section, a chart speed of at least 10 centimeters per hour (or equivalent resolution for a digital representation) shall be used to clearly show changes in measurement responses. The actual chart speed, chart speed changes, and time checks shall be clearly marked on the chart.

(iii) Test day 0. Allow sufficient time for the test analyzer to warm up and stabilize at a line voltage of 115 volts and a room temperature of 25°C. Adjust the zero baseline to 5 percent of chart (see §53.21(b)mouse right-click in) and recalibrate, if necessary. No further adjustments shall be made to the analyzer until the end of the tests on the third, sixth, ninth, or twelfth test day.

(iv) Measure test atmosphere A0 until a stable measurement reading is obtained and record this reading (in ppm) as Z'n, where n = 0 (see Figure B-4 in appendix A of this subpart).

(v) [Reserved]

(vi) Measure test atmosphere A80. Allow for a stable measurement reading and record it as S'n, where n = 0.

(vii) The above readings for Z'0 and S'0 should be taken at least four (4) hours prior to the beginning of test day 1.

(viii) At the beginning of each test day, adjust the line voltage and room temperature to the values given in table B-4 to subpart B of part 53 (or to the corresponding alternative temperature if a wider temperature range is being tested).

(ix) Measure test atmosphere A0 continuously for at least twelve (12) continuous hours during each test day.

(x) After the 12-hour zero drift test (step ix) is complete, sample test atmosphere A0. A stable reading is not required.

(xi) Measure test atmosphere A20 and record the stable reading (in ppm) as P1. (See Figure B-4 in appendix A.)

(xii) Sample test atmosphere A30; a stable reading is not required.

(xiii) Measure test atmosphere A20 and record the stable reading as P2.

(xiv) Sample test atmosphere A0; a stable reading is not required.

(xv) Measure test atmosphere A20 and record the stable reading as P3.

(xvi) Sample test atmosphere A30; a stable reading is not required.

(xvii) Measure test atmosphere A20 and record the stable reading as P4.

(xviii) Sample test atmosphere A0; a stable reading is not required.

(xix) Measure test atmosphere A20 and record the stable reading as P5.

(xx) Sample test atmosphere A30; a stable reading is not required.

(xxi) Measure test atmosphere A20 and record the stable reading as P6.

(xxii) Measure test atmosphere A80 and record the stable reading as P7.

(xxiii) Sample test atmosphere A90; a stable reading is not required.

(xxiv) Measure test atmosphere A80 and record the stable reading as P8. Increase the chart speed to at least 10 centimeters per hour.

(xxv) Measure test atmosphere A0. Record the stable reading as L1.

(xxvi) Quickly switch the test analyzer to measure test atmosphere A80 and mark the recorder chart to show, or otherwise record, the exact time when the switch occurred.

(xxvii) Measure test atmosphere A80 and record the stable reading as P9.

(xxviii) Sample test atmosphere A90; a stable reading is not required.

(xxix) Measure test atmosphere A80 and record the stable reading as P10.

(xxx) Measure test atmosphere A0 and record the stable reading as L2.

(xxxi) Measure test atmosphere A80 and record the stable reading as P11.

(xxxii) Sample test atmosphere A90; a stable reading is not required.

(xxxiii) Measure test atmosphere A80 and record the stable reading as P12.

(xxxiv) Repeat steps within paragraphs (e)(9)(viii) through (e)(9)(xxxiii) of this section, each test day.

(xxxv) If zero and span adjustments are made after the readings are taken on test days 3, 6, 9, or 12, complete all adjustments; then measure test atmospheres A0 and A80. Allow for a stable reading on each, and record the readings as Z'n and S'n, respectively, where n = the test day number (3, 6, 9, or 12). These readings must be made at least 4 hours prior to the start of the next test day.

(10) Determine the results of each day's tests as follows. Mark the recorder chart to show readings and determinations.

(i) Zero drift. (A) Determine the 12-hour zero drift by examining the strip chart pertaining to the 12-hour continuous zero air test. Determine the minimum (Cmin.) and maximum (Cmax.) measurement readings (in ppm) during this period of 12 consecutive hours, extrapolating the calibration curve to negative concentration units if necessary. Calculate the 12-hour zero drift (12ZD) as 12ZD = Cmax. − Cmin. (See Figure B-5 in appendix A.)

(B) Calculate the 24-hour zero drift (24ZD) for the n-th test day as 24ZDn= Zn− Zn-1, or 24ZDn= Zn− Z'n-1 if zero adjustment was made on the previous test day, where Zn = 1/2(L1 + L2) for L1 and L2 taken on the n-th test day.

(C) Compare 12ZD and 24ZD to the zero drift limit specifications in table B-1 to subpart B of part 53. Both 12ZD and 24ZD must be within the specified limits (inclusive) to pass the test for zero drift.

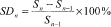

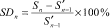

(ii) Span drift.

(A) Calculate the span drift (SD) as:

or if a span adjustment was made on the previous test day,

where

n indicates the n-th test day, and i indicates the i-th measurement reading on the n-th test day.

(B) SD must be within the span drift limits (inclusive) specified in table B-1 to subpart B of part 53 to pass the test for span drift.

(iii) Lag time. Determine, from the strip chart (or alternative test data record), the elapsed time in minutes between the change in test concentration (or mark) made in step (xxvi) and the first observable (two times the noise level) measurement response. This time must be equal to or less than the lag time limit specified in table B-1 to subpart B of part 53 to pass the test for lag time.

(iv) Rise time. Calculate 95 percent of measurement reading P9 and determine, from the recorder chart (or alternative test data record), the elapsed time between the first observable (two times noise level) measurement response and a response equal to 95 percent of the P9 reading. This time must be equal to or less than the rise time limit specified in table B-1 to subpart B of part 53 to pass the test for rise time.

(v) Fall time. Calculate five percent of (P10 − L2) and determine, from the strip chart (or alternative test record), the elapsed time in minutes between the first observable decrease in measurement response following reading P10 and a response equal to L2 + five percent of (P10 − L2). This time must be equal to or less than the fall time limit specification in table B-1 to subpart B of part 53 to pass the test for fall time.

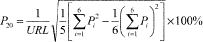

(vi) Precision. Calculate precision (both P20 and P80) for each test day as follows:

(A)

(B)

(C) Both P20 and P80 must be equal to or less than the precision limits specified in table B-1 to subpart B of part 53 to pass the test for precision.

[76 FR 54326, Aug. 31, 2011, as amended at 80 FR 65460, Oct. 26, 2015]

Figure B-1 to Subpart B of Part 53 - Example

Table B-1 to Subpart B of Part 53 - Performance Limit Specifications for Automated Methods

| 1 To convert from parts per million (ppm) to µg/m

3 at 25°C and 760 mm Hg, multiply by M/0.02447, where M is the molecular weight of the gas. Percent means percent of the upper measurement range limit.

2 Tests for interference equivalent and lag time do not need to be repeated for any lower range provided the test for the standard range shows that the lower range specification (if applicable) is met for each of these test parameters. 3 For candidate analyzers having automatic or adaptive time constants or smoothing filters, describe their functional nature, and describe and conduct suitable tests to demonstrate their function aspects and verify that performances for calibration, noise, lag, rise, fall times, and precision are within specifications under all applicable conditions. For candidate analyzers with operator-selectable time constants or smoothing filters, conduct calibration, noise, lag, rise, fall times, and precision tests at the highest and lowest settings that are to be included in the FRM or FEM designation. 4 For nitric oxide interference for the SO 2 ultraviolet fluorescence (UVF) method, interference equivalent is ±0.003 ppm for the lower range. 5 Standard deviation expressed as percent of the URL. | |||||||||

|

Performance

parameter | Units 1 | SO2 | O3 | CO |

NO2 (Std. range) |

Definitions and test

procedures | |||

| Std. range 3 | Lower range 2 3 | Std. range 3 | Lower range 2 3 | Std. range 3 | Lower range 2 3 | ||||

| 1. Range | ppm | 0-0.5 | <0.5 | 0-0.5 | <0.5 | 0-50 | <50 | 0-0.5 | Sec. 53.23(a) |

| 2. Noise | ppm | 0.001 | 0.0005 | 0.0025 | 0.001 | 0.2 | 0.1 | 0.005 | Sec. 53.23(b) |

| 3. Lower detectable limit | ppm | 0.002 | 0.001 | 0.005 | 0.002 | 0.4 | 0.2 | 0.010 | Sec. 53.23(c) |

| 4. Interference equivalent | |||||||||

| Each interferent | ppm | ±0.005 | 4 ±0.005 | ±0.005 | ±0.005 | ±1.0 | ±0.5 | ±0.02 | Sec. 53.23(d) |

| Total, all interferents | ppm | - | - | - | - | - | - | 0.04 | Sec. 53.23(d) |

| 5. Zero drift, 12 and 24 hour | ppm | ±0.004 | ±0.002 | ±0.004 | ±0.002 | ±0.5 | ±0.3 | ±0.02 | Sec. 53.23(e) |

| 6. Span drift, 24 hour | |||||||||

| 20% of upper range limit | Percent | - | - | - | - | - | - | ±20.0 | Sec. 53.23(e) |

| 80% of upper range limit | Percent | ±3.0 | ±3.0 | ±3.0 | ±3.0 | ±2.0 | ±2.0 | ±5.0 | Sec. 53.23(e) |

| 7. Lag time | Minutes | 2 | 2 | 2 | 2 | 2.0 | 2.0 | 20 | Sec. 53.23(e) |

| 8. Rise time | Minutes | 2 | 2 | 2 | 2 | 2.0 | 2.0 | 15 | Sec. 53.23(e) |

| 9. Fall time | Minutes | 2 | 2 | 2 | 2 | 2.0 | 2.0 | 15 | Sec. 53.23(e) |

| 10. Precision | |||||||||

| 20% of upper range limit | - | - | - | - | - | - | Sec. 53.23(e) | ||

| Percent 5 | 2 | 2 | 2 | 2 | 1.0 | 1.0 | 4 | Sec. 53.23(e) | |

| 80% of upper range limit | - | - | - | - | - | - | Sec. 53.23(e) | ||

| Percent 5 | 2 | 2 | 2 | 2 | 1.0 | 1.0 | 6 |

Sec. 53.23(e)

Sec. 53.23(e) | |

[80 FR 65460, Oct. 26, 2015; 89 FR 16383, March 6, 2024]

Table B-2 to Subpart B of Part 53 - Test Atmospheres

| Test gas | Generation | Verification |

|---|---|---|

| 1 Use stainless steel pressure regulator dedicated to the pollutant measured.

Reference 1. O'Keefe, A. E., and Ortaman, G. C. “Primary Standards for Trace Gas Analysis,” Anal. Chem. 38, 760 (1966). Reference 2. Scaringelli, F. P., A. E. . Rosenberg, E*, and Bell, J. P., “Primary Standards for Trace Gas Analysis.” Anal. Chem. 42, 871 (1970). Reference 3. “Tentative Method of Analysis for Ammonia in the Atmosphere (Indophenol Method)”, Health Lab Sciences, vol. 10, No. 2, 115-118, April 1973. Reference 4. 1973 Annual Book of ASTM Standards, American Society for Testing and Materials, 1916 Race St., Philadelphia, PA. Reference 5. Methods for Air Sampling and Analysis, Intersociety Committee, 1972, American Public Health Association, 1015. Reference 6. 40 CFR 50 Appendix F, “Measurement Principle and Calibration Principle for the Measurement of Nitrogen Dioxide in the Atmosphere (Gas Phase Chemiluminescence).” Reference 7. 40 CFR 50 Appendix A-1, “Measurement Principle and Calibration Procedure for the Measurement of Sulfur Dioxide in the Atmosphere (Ultraviolet FIuorscence).” Reference 8. 40 CFR 50 Appendix C, “Measurement Principle and Calibration Procedure for the Measurement of Carbon Monoxide in the Atmosphere (Non-Dispersive Infrared Photometry)”. Reference 9. 40 CFR 50 Appendix D, “Measurement Principle and Calibration Procedure for the Measurement of Ozone in the Atmosphere”. Reference 10. “Standard Test Method for C, through C5 Hydrocarbons in the Atmosphere by Gas Chromatography”, D 2820, 1987 Annual Book of Aston Standards, vol 11.03, American Society for Testing and Materials, 1916 Race St., Philadelphia, PA 19103. | ||

| Ammonia | Permeation device. Similar to system described in references 1 and 2 | Indophenol method, reference 3. |

| Carbon dioxide | Cylinder of zero air or nitrogen containing CO2 as required to obtain the concentration specified in table B-3 | Use NIST-certified standards whenever possible. If NIST standards are not available, obtain 2 standards from independent sources which agree within 2 percent, or obtain one standard and submit it to an independent laboratory for analysis, which must agree within 2 percent of the supplier's nominal analysis. |

| Carbon monoxide | Cylinder of zero air or nitrogen containing CO as required to obtain the concentration specified in table B-3 | Use an FRM CO analyzer as described in reference 8. |

| Ethane | Cylinder of zero air or nitrogen containing ethane as required to obtain the concentration specified in table B-3 | Gas chromatography, ASTM D2820, reference 10. Use NIST-traceable gaseous methane or propane standards for calibration. |

| Ethylene | Cylinder of pre-purified nitrogen containing ethylene as required to obtain the concentration specified in table B-3 | Do. |

| Hydrogen chloride | Cylinder 1 of pre-purified nitrogen containing approximately 100 ppm of gaseous HCl. Dilute with zero air to concentration specified in table B-3 | Collect samples in bubbler containing distilled water and analyze by the mercuric thiocyanate method, ASTM (D612), p. 29, reference 4. |

| Hydrogen sulfide | Permeation device system described in references 1 and 2 | Tentative method of analysis for H2S content of the atmosphere, p. 426, reference 5. |

| Methane | Cylinder of zero air containing methane as required to obtain the concentration specified in table B-3 | Gas chromatography ASTM D2820, reference 10. Use NIST-traceable methane standards for calibration. |

| Nitric oxide | Cylinder 1 of pre-purified nitrogen containing approximately 100 ppm NO. Dilute with zero air to required concentration | Gas phase titration as described in reference 6, section 7.1. |

| Nitrogen dioxide |

1. Gas phase titration as described in reference 6

2. Permeation device, similar to system described in reference 6 |

1. Use an FRM NO2 analyzer calibrated with a gravimetrically calibrated permeation device.

2. Use an FRM NO2 analyzer calibrated by gas-phase titration as described in reference 6. |

| Ozone | Calibrated ozone generator as described in reference 9 | Use an FEM ozone analyzer calibrated as described in reference 9. |

| Sulfur dioxide |

1. Permeation device as described in references 1 and 2

2. Dynamic dilution of a cylinder containing approximately 100 ppm SO2 as described in Reference 7 | Use an SO2 FRM or FEM analyzer as described in reference 7. |

| Water | Pass zero air through distilled water at a fixed known temperature between 20° and 30°C such that the air stream becomes saturated. Dilute with zero air to concentration specified in table B-3 | Measure relative humidity by means of a dew-point indicator, calibrated electrolytic or piezo electric hygrometer, or wet/dry bulb thermometer. |

| Xylene | Cylinder of pre-purified nitrogen containing 100 ppm xylene. Dilute with zero air to concentration specified in table B-3 | Use NIST-certified standards whenever possible. If NIST standards are not available, obtain 2 standards from independent sources which agree within 2 percent, or obtain one standard and submit it to an independent laboratory for analysis, which must agree within 2 percent of the supplier's nominal analysis. |

| Zero air |

1. Ambient air purified by appropriate scrubbers or other devices such that it is free of contaminants likely to cause a detectable response on the analyzer

2. Cylinder of compressed zero air certified by the supplier or an independent laboratory to be free of contaminants likely to cause a detectable response on the analyzer | |

Table B-3 to Subpart B of Part 53 - Interferent Test Concentration, 1 Parts per Million

| Pollutant | Analyzer type 2 | Hydro-chloric acid | Ammonia | Hydrogen sulfide | Sulfur dioxide | Nitrogen dioxide | Nitric oxide | Carbon dioxide | Ethylene | Ozone | M-xylene | Water vapor | Carbon monoxide | Methane | Ethane | Naphthalene |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 Concentrations of interferent listed must be prepared and controlled to ±10 percent of the stated value. | ||||||||||||||||

| 2 Analyzer types not listed will be considered by the Administrator as special cases. | ||||||||||||||||

| 3 Do not mix interferent with the pollutant. | ||||||||||||||||

| 4 Concentration of pollutant used for test. These pollutant concentrations must be prepared to ±10 percent of the stated value. | ||||||||||||||||

| 5 If candidate method utilizes an elevated-temperature scrubber for removal of aromatic hydrocarbons, perform this interference test. | ||||||||||||||||

| 6 If naphthalene test concentration cannot be accurately quantified, remove the scrubber, use a test concentration that causes a full-scale response, reattach the scrubber, and evaluate response for interference. | ||||||||||||||||

| SO 2 | Ultraviolet fluorescence | 5 0.1 | 4 0.14 | 0.5 | 0.5 | 0.5 | 0.2 | 20,000 | 6 0.05 | |||||||

| SO 2 | Flame photometric | 0.01 | 4 0.14 | 750 | 3 20,000 | 50 | ||||||||||

| SO 2 | Gas chromatography | 0.1 | 4 0.14 | 750 | 3 20,000 | 50 | ||||||||||

| SO 2 | Spectrophotometric-wet chemical (pararosanaline) | 0.2 | 0.1 | 0.1 | 4 0.14 | 0.5 | 750 | 0.5 | ||||||||

| SO 2 | Electrochemical | 0.2 | 0.1 | 0.1 | 4 0.14 | 0.5 | 0.5 | 0.2 | 0.5 | 3 20,000 | ||||||

| SO 2 | Conductivity | 0.2 | 0.1 | 4 0.14 | 0.5 | 750 | ||||||||||

| SO 2 | Spectrophotometric-gas phase, including DOAS | 4 0.14 | 0.5 | 0.5 | 0.5 | 0.2 | ||||||||||

| O 3 | Ethylene Chemiluminescence | 3 0.1 | 750 | 4 0.08 | 3 20,000 | |||||||||||

| O 3 | NO-chemiluminescence | 3 0.1 | 0.5 | 750 | 4 0.08 | 3 20,000 | ||||||||||

| O 3 | Electrochemical | 3 0.1 | 0.5 | 0.5 | 4 0.08 | 3 20,000 | ||||||||||

| O 3 | Spectrophotometric-wet chemical (potassium iodide) | 3 0.1 | 0.5 | 0.5 | 3 0.5 | 4 0.08 | ||||||||||

| O 3 | Spectrophotometric-gas phase, including ultraviolet absorption and DOAS | 0.5 | 0.5 | 3 0.5 | 4 0.08 | 0.02 | 20,000 | |||||||||

| CO | Non-dispersive Infrared | 750 | 20,000 | 4 10 | ||||||||||||

| CO | Gas chromatography with flame ionization detector | 20,000 | 4 10 | 0.5 | ||||||||||||

| CO | Electrochemical | 0.5 | 0.2 | 20,000 | 4 10 | |||||||||||

| CO | Catalytic combustion-thermal detection | 0.1 | 750 | 0.2 | 20,000 | 4 10 | 5.0 | 0.5 | ||||||||

| CO | IR fluorescence | 750 | 20,000 | 4 10 | 0.5 | |||||||||||

| CO | Mercury replacement-UV photometric | 0.2 | 4 10 | 0.5 | ||||||||||||

| NO 2 | Chemiluminescent | 3 0.1 | 0.5 | 4 0.1 | 0.5 | 20,000 | ||||||||||

| NO 2 | Spectrophotometric-wet chemical (azo-dye reaction) | 0.5 | 4 0.1 | 0.5 | 750 | 0.5 | ||||||||||

| NO 2 | Electrochemical | 0.2 | 3 0.1 | 0.5 | 4 0.1 | 0.5 | 750 | 0.5 | 20,000 | 50 | ||||||

| NO 2 | Spectrophotometric-gas phase | 3 0.1 | 0.5 | 4 0.1 | 0.5 | 0.5 | 20,000 | 50 | ||||||||

[89 FR 16383, March 6, 2024<]

Table B-4 to Subpart B of Part 53 - Line Voltage and Room Temperature Test Conditions

| Test day |

Line

voltage, 1 rms |

Room

temperature, 2°C | Comments |

|---|---|---|---|

| 1 Voltage specified shall be controlled to ±1 volt.

2 Temperatures shall be controlled to ±1°C. | |||

| 0 | 115 | 25 | Initial set-up and adjustments. |

| 1 | 125 | 20 | |

| 2 | 105 | 20 | |

| 3 | 125 | 30 | Adjustments and/or periodic maintenance permitted at end of tests. |

| 4 | 105 | 30 | |

| 5 | 125 | 20 | |

| 6 | 105 | 20 | Adjustments and/or periodic maintenance permitted at end of tests. |

| 7 | 125 | 30 | Examine test results to ascertain if further testing is required. |

| 8 | 105 | 30 | |

| 9 | 125 | 20 | Adjustments and/or periodic maintenance permitted at end of tests. |

| 10 | 105 | 20 | |

| 11 | 125 | 30 | |

| 12 | 105 | 30 | Adjustments and/or periodic maintenance permitted at end of tests. |

| 13 | 125 | 20 | |

| 14 | 105 | 20 | |

| 15 | 125 | 30 | |

Table B-5 to Subpart B of Part 53 - Symbols and Abbreviations

BL - Analyzer reading at the specified LDL test concentration for the LDL test.

BZ - analyzer reading at 0 concentration for the LDL test.

DM - Digital meter.

Cmax - Maximum analyzer reading during the 12ZD test period.

Cmin - Minimum analyzer reading during the 12ZD test period.

i - Subscript indicating the i-th quantity in a series.

IE - Interference equivalent.

L1 - First analyzer zero reading for the 24ZD test.

L2 - Second analyzer zero reading for the 24ZD test.

n - Subscript indicating the test day number.

P - Analyzer reading for the span drift and precision tests.

Pi - The i-th analyzer reading for the span drift and precision tests.

P20 - Precision at 20 percent of URL.

P80 - Precision at 80 percent of URL.

ppb - Parts per billion of pollutant gas (usually in air), by volume.

ppm - Parts per million of pollutant gas (usually in air), by volume.

R - Analyzer reading of pollutant alone for the IE test.

R1 - Analyzer reading with interferent added for the IE test.

ri - the i-th analyzer or DM reading for the noise test.

S - Standard deviation of the noise test readings.

S0 - Noise value (S) measured at 0 concentration.

S80 - Noise value (S) measured at 80 percent of the URL.

Sn - Average of P7 . . . P12 for the n-th test day of the SD test.

S'n - Adjusted span reading on the n-th test day.

SD - Span drift

URL - Upper range limit of the analyzer's measurement range.

Z - Average of L1 and L2 readings for the 24ZD test.

Zn - Average of L1 and L2 readings on the n-th test day for the 24ZD test.

Z'n - Adjusted analyzer zero reading on the n-the test day for the 24ZD test.

ZD - Zero drift.

12ZD - 12-hour zero drift.

24ZD - 24-hour zero drift.

Appendix A to Subpart B of Part 53 - Optional Forms for Reporting Test Results

Figure B–3 to Appendix A to Subpart B of Part 53—Form for Test Data and Calculations for Lower Detectable Limit (LDL) and Interference Equivalent (IE) (see §53.23(c) and (d))

LDL Interference Test Data

Applicant _________________

Analyzer _________________

Date _________________

Pollutant _________________

Figure B–3 to Appendix A to Subpart B of Part 53—Form for Test Data and Calculations for Lower Detectable Limit (LDL) and Interference Equivalent (IE) (see §53.23(c) and (d))

LDL Interference Test Data

Applicant _________________

Analyzer _________________

Date _________________

Pollutant _________________

[89 FR 16385, March 6, 2024]

['Air Programs']

['Air Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.