['Industrial Hygiene', 'Air Programs']

['Mobile Emission Sources', 'Hearing Conservation and Noise']

04/02/2025

...

Authority: Secs. 6, 10, 11, 13, Pub. L. 92-574, 86 Stat. 1234 (42 U.S.C. 4905, 4909, 4910, 4912).

Subpart A - General Provisions

§205.1 General applicability.

The provisions of this subpart are applicable to all products for which regulations have been published under this part and which are manufactured after the effective date of such regulations.

§205.2 Definitions.

(a) As used in this subpart, all terms not defined herein shall have the meaning given them in the Act.

(1) Act means the Noise Control Act of 1972 (Pub. L. 92-574, 86 Stat. 1234).

(2) Administrator means the Administrator of the Environmental Protection Agency or his authorized representative.

(3) Agency means the United States Environmental Protection Agency.

(4) Export exemption means an exemption from the prohibitions of section 10(a) (1), (2), (3), and (4) of the Act, granted by statute under section 10(b)(2) of the Act for the purpose of exporting regulated products.

(5) National security exemption means an exemption from the prohibitions of section 10(a) (1), (2), (3), and (5) of the Act, which may be granted under section 10(b)(1) of the Act for the purpose of national security.

(6) [Reserved]

(7) Sound Level means 20 times the logarithm to base 10 of the ratio of pressure of a sound to the reference pressure. The reference pressure is 20 micropascals (20 micronewtons per square meter). NOTE: Unless otherwise explicitly stated, it is to be understood that the sound pressure is the effective (rms) sound pressure, per American National Standards Institute, Inc., 1430 Broadway, New York, New York 10018.

(8) Sound Pressure Level means in decibels, 20 times the logarithm to the base 10 of the ratio of a sound pressure to the reference sound pressure of 20 micropascals (20 micronewtons per square meter). In the absence of any modifier, the level is understood to be that of a root-mean-square pressure. The unit of any sound level is the decibel, having the unit symbol dB.

(9) dB(A) means the standard abbreviation for A-weighted sound levels in decibels.

(10) Highway means the streets, roads, and public ways in any State.

(11) Fast Meter Response means that the fast dynamic response of the sound level meter shall be used. The fast dynamic response shall comply with the meter dynamic characteristics in paragraph 5.3 of the American National Standard Specification for Sound Level Meters, ANSI SI.4-1971. This publication is available from the American National Standards Institute, Inc., 1430 Broadway, New York, New York 10018.

(12) Person means an individual, corporation, partnership, or association, and except as provided in sections 11(e) and 12(a) of the Act includes any officer, employee, department, agency or instrumentality of the United States, a State or any political subdivision of a State.

(13) Reasonable assistance means providing timely and unobstructed access to test products or products and records required by this part, and opportunity for copying such records or testing such test products.

(14) Ultimate purchaser means the first person who in good faith purchases a product for purposes other than resale.

(15) New product means (i) a product the equitable or legal title of which has never been transferred to an ultimate purchaser, or (ii) a product which is imported or offered for importation into the United States and which is manufactured after the effective date of a regulation under section 6 or 8 which would have been applicable to such product had it been manufactured in the United States.

(16) Manufacturer means any person engaged in the manufacturing or assembling of new products, or the importing of new products for resale, or who acts for and is controlled by any such person in connection with the distribution of such products.

(17) Commerce means trade, traffic, commerce, or transportation:

(i) Between a place in a State and any place outside thereof, or

(ii) Which affects trade, traffic, commerce, or transportation described in paragraph (a)(17)(i) of this section.

(18) Distribute in commerce means sell in, offer for sale in, or introduce or deliver for introduction into, commerce.

(19) State includes the District of Columbia, the Commonwealth of Puerto Rico, the Virgin Islands, American Samoa, Guam, and the Trust Territory of the Pacific Islands.

(20) Federal Agency means an executive agency (as defined in section 105 of title 5, United States Code) and includes the United States Postal Service.

(21) Environmental noise means the intensity, duration, and the character of sounds from all sources.

(22) Warranty means the warranty required by section 6(c)(1) of the Act.

(23) Tampering means those acts prohibited by section 10(a)(2) of the Act.

(24) Maintenance instructions or instructions means those instructions for maintenance, use, and repair, which the Administrator is authorized to require pursuant to section 6(c)(1) of the Act.

(25) Type I Sound Level Meter means a sound level meter which meets the Type I requirements of ANSI SI.4-1972 specification for sound level meters. This publication is available from the American National Standards Institute, Inc., 1430 Broadway, New York, New York 10018.

(26) Testing exemption means an exemption from the prohibitions of section 10(a) (1), (2), (3), and (5) of the Act, which may be granted under section 10(b)(1) of the Act for the purpose of research, investigations, studies, demonstrations, or training, but not including national security.

(27) Product means any transportation equipment for which regulations have been promulgated under this part and includes “test product.”

(28) Test product means any product that is required to be tested pursuant to this part.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61457, Dec. 5, 1977]

§205.3 Number and gender.

As used in this part, words in the singular shall be deemed to import the plural, and words in the masculine gender shall be deemed to import the feminine and vice versa, as the case may require.

§205.4 Inspection and monitoring.

(a) Any inspection or monitoring activities conducted under this section shall be for the purpose of determining (1) whether test products are being selected and prepared for testing in accordance with the provisions of these regulations, (2) whether test product testing is being conducted in accordance with these regulations, and (3) whether products being produced for distribution into commerce comply with these regulations.

(b) The Director, Noise Enforcement Division, may request that a manufacturer subject to this part admit an EPA Enforcement Officer during operating hours to any of the following:

(1) Any facility or site where any product to be distributed into commerce is manufactured, assembled, or stored;

(2) Any facility or site where any tests conducted pursuant to this part or any procedures or activities connected with such tests are or were performed; and

(3) Any facility or site where any test product is present.

(c)(1) An EPA Enforcement Officer, once admitted to a facility or site, will not be authorized to do more than:

(i) To inspect and monitor test product manufacture and assembly, selection, storage, preconditioning, noise emission testing, and maintenance, and to verify correlation or calibration of test equipment;

(ii) To inspect products prior to their distribution in commerce:

(iii) To inspect and photograph any part or aspect of any such product and any component used in the assembly thereof that are reasonably related to the purpose of his entry.

(iv) [Reserved]

(v) To obtain from those in charge of the facility or site such reasonable assistance as he may request to enable him to carry out any proper function listed in this section.

(2) [Reserved]

(3) The provisions of this section apply whether the facility or site is owned or controlled by the manufacturer or by one who acts for the manufacturer.

(d) For purposes of this section:

(1) An “EPA Enforcement Officer” is an employee of the EPA Office of Enforcement who displays upon arrival at a facility or site the credentials identifying him as such an employee and a letter signed by the Director, Noise Enforcement Division designating him to make the inspection.

(2) Where test product storage areas or facilities are concerned, “operating hours” shall mean all times during which personnel other than custodial personnel are at work in the vicinity of the area or facility and have access to it.

(3) Where facilities or areas other than those covered by paragraph (d)(2) of this section are concerned, “operating hours” shall mean all times during which product manufacture or assembly is in operation or all times during which product testing and maintenance is taking place and/or production or compilation of records is taking place, or any other procedure or activity related to selective enforcement audit testing or product manufacture or assembly being carried out in a facility.

(e) The manufacturer shall admit to a facility or site an EPA Enforcement Officer who presents a warrant authorizing entry. In the absence of such warrant, entry to any facility or site under this section will be only upon the consent of the manufacturer.

(1) It is not a violation of this regulation or the Act for any person to refuse entry without a warrant.

(2) The Administrator or his designee may proceed ex parte to obtain a warrant whether or not the manufacturer has refused entry.

[41 FR 15544, Apr. 13, 1976, as amended at 43 FR 27990, June 28, 1978; 47 FR 57713, Dec. 28, 1982]

§205.5 Exemptions.

§205.5-1 Testing exemption.

(a) A new product intended to be used solely for research, investigations, studies, demonstrations or training, and so labeled or marked on the outside of the container and on the product itself, shall be exempt from the prohibitions of section 10(a)(1), (2), (3), and (5) of the Act.

(b) No request for a testing exemption is required.

(c) For purposes of section 11(d) of the Act, any testing exemption shall be void ab initio with respect to each new product, originally intended for research, investigations, studies, demonstrations, or training, but distributed in commerce for other uses.

[47 FR 57713, Dec. 28, 1982]

§205.5-2 National security exemptions.

(a) A new product which is produced to conform with specifications developed by a national security agency, and so labeled or marked on the outside of the container and on the product itself, shall be exempt from the prohibitions of section 10(a)(1), (2), (3), and (5) of the Act.

(b) No request for a national security exemption is required.

(c) For purposes of section 11(d) of the Act, any national security exemption shall be void ab initio with respect to each new product, originally intended to be produced to conform with specifications developed by a national security agency, but distributed in commerce for other uses.

(d) Any manufacturer or person subject to the liabilities of section 11(a) with respect to any product originally intended for a national security agency, but distributed in commerce for use in any State, may be excluded from the application of section 11(a) with respect to such product based upon a showing that such manufacturer:

(1) Had no knowledge of such product being distributed in commerce for use in any state; and

(2) Made reasonable effort to ensure that such products would not be distributed in commerce for use in any State. Such reasonable efforts would include investigation, prior dealings, contract provisions, etc.

[47 FR 57714, Dec. 28, 1982]

§205.5-3 Export exemptions.

(a) A new product intended solely for export, and so labeled or marked on the outside of the container and on the product itself, shall be exempt from the prohibitions of section 10(a), (1), (2), (3), and (4) of the Act.

(b) No request for an export exemption is required.

(c) For purposes of section 11(d) of the Noise Control Act, the Administrator may consider any export exemption under section 10(b)(2) as void ab initio with respect to each new product intended solely for export which is distributed in commerce for use in any State.

(d) In deciding whether to institute proceedings against a manufacturer pursuant to section 11(d)(1) of the Act with respect to any product originally intended solely for export but distributed in commerce for use in any state, the Administrator will consider:

(1) Whether the manufacturer had knowledge that such product would be distributed in commerce for use in any state; and

(2) Whether the manufacturer made reasonable efforts to ensure that such product would not be distributed in commerce for use in any state. Such reasonable efforts would include consideration of prior dealings with any person which resulted in introduction into commerce of a product manufactured for export only, investigation of prior instances known to the manufacturer of introduction into commerce of a product manufactured for export only, and contract provisions which minimize the probability of introduction into commerce of a product manufactured for export only.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61457, Dec. 5, 1977. Redesignated at 47 FR 57714, Dec. 28, 1982]

Subpart B - Medium and Heavy Trucks

§205.50 Applicability.

(a) Except as otherwise provided for in these regulations the provisions of this subpart apply to any vehicle which has a gross vehicle weight rating (GVWR) in excess of 10,000 pounds, which is capable of transportation of property on a highway or street and which meets the definition of the term “new product” in the Act.

(b) The provisions of the subpart do not apply to highway, city, and school buses or to special purpose equipment which may be located on or operated from vehicles. Tests performed on vehicles containing such equipment may be carried out with the special purpose equipment in nonoperating condition. For purposes of this regulation special purpose equipment includes, but is not limited to, construction equipment, snow plows, garbage compactors and refrigeration equipment.

§205.51 Definitions.

(a) As used in this subpart, all terms not defined herein shall have the meaning given them in the Act or in other subparts of this part.

(1) Acceptable Quality Level means the maximum percentage of failing vehicles that for purposes of sampling inspection, can be considered satisfactory as a process average.

(2) Acceptance of a batch means that the number of noncomplying vehicles in the batch sample is less than or equal to the acceptance number as determined by the appropriate sampling plan.

(3) Batch means the collection of vehicles of the same category, configuration or subgroup thereof as designated by the Administrator in a test request, from which a batch sample is to be drawn, and inspected to determine conformance with the acceptability criteria.

(4) Batch size means the number as designated by the Administrator in the test request of vehicles of the same category or configuration in a batch.

(5) Batch sample means the collection of vehicles of the same category, configuration or subgroup thereof which are drawn from a batch and from which test samples are drawn.

(6) Batch sample size means the number of vehicles of the same category or configuration in a batch sample.

(7) Cab over axle or cab over engine means the cab which contains the operator/passenger compartment is directly above the engine and front axle and the entire cab can be tilted forward to permit access to the engine compartment.

(8) Category means a group of vehicle configurations which are identical in all material aspects with respect to the parameters listed in §205.55-2.

(9) Configuration means the basic classification unit of a manufacturer's product line and is comprised of all vehicle designs, models or series which are identical in material aspects with respect to the parameters listed in §205.55-3.

(10) Acceptance of a Batch sequence means that the number of rejected batches in the sequence is less than or equal to the acceptance number as determined by the appropriate sampling plan.

(11) Rejection of a Batch sequence means that the number of rejected batches in a sequence is equal to or greater than the rejection number as determined by the appropriate sampling plan.

(12) Capable of Transportation of Property on a street or highway means that the vehicle:

(i) Is self propelled and is capable of transporting any material or fixed apparatus, or is capable of drawing a trailer or semi-trailer;

(ii) Is capable of maintaining a cruising speed of at least 25 mph over level, paved surface;

(iii) Is equipped or can readily be equipped with features customarily associated with practical street or highway use, such features including but not being limited to: A reverse gear and a differential, fifth wheel, cargo platform or cargo enclosure, and

(iv) Does not exhibit features which render its use on a street or highway impractical, or highly unlikely, such features including, but not being limited to, tracked road means, an inordinate size or features ordinarily associated with combat or tactical vehicles.

(13) Exhaust System means the system comprised of a combination of components which provides for enclosed flow of exhaust gas from engine exhaust port to the atmosphere.

(14) Gross Combination Weight Rating (GCWR) means the value specified by the manufacturer as the loaded weight of a combination vehicle.

(15) Gross Vehicle Weight Rating (GVWR) means the value specified by the manufacturer as the loaded weight of a single vehicle.

(16) Inspection Criteria means the rejection and acceptance numbers associated with a particular sampling plan.

(17) Model year means the manufacturer's annual production period which includes January 1 of such calendar year: Provided, that if the manufacturer has no annual production period, the term “model year” shall mean the calendar year.

(18) Noise Control System includes any vehicle part, component or system the primary purpose of which is to control or cause the reduction of noise emitted from a vehicle.

(19) Noise emission test means a test conducted pursuant to the measurement methodology specified in this subpart.

(20) [Reserved]

(21) Rejection of a batch means the number of noncomplying vehicles in the batch sample is greater than or equal to the rejection number as determined by the appropriate sampling plan.

(22) Shift means the regular production work period for one group of workers.

(23) Test sample means the collection of vehicles from the same category, configuration or subgroup thereof which is drawn from the batch sample and which will receive noise emissions tests.

(24) Failing vehicle means that the measured emissions of the vehicle, when measured in accordance with the applicable procedure, exceeds the applicable standard.

(25) Acceptance of a vehicle means that the measured emissions of the vehicle when measured in accordance with the applicable procedure, conforms to the applicable standard.

(26) Tampering means those acts prohibited by section 10(a)(2) of the Act.

(27) Test sample size means the number of vehicles of the same category or configuration in a test sample.

(28) Test vehicle means a vehicle selected and used to demonstrate compliance with the applicable noise emission standards.

(29) Vehicle means any motor vehicle, machine or tractor, which is propelled by mechanical power and capable of transportation of property on a street or highway and which has a gross vehicle weight rating in excess of 10,000 pounds and a partially or fully enclosed operator's compartment.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61456, 61458, Dec. 5, 1977; 47 FR 57714, Dec. 28, 1982]

§205.52 Vehicle noise emission standards.

(a) Low Speed Noise Emission Standard. Vehicles which are manufactured after the following effective dates shall be designed, built and equipped so that they will not produce sound emissions in excess of the levels indicated.

| Effective date | Level |

|---|---|

| (i) January 1, 1979 | 83 dBA. |

| (ii) January 1, 1988 | 80 dBA. |

(b) The standards set forth in paragraph (a) of this section refer to the sound emissions as measured in accordance with the procedures prescribed in §205.54-1,2.

(c) Every manufacturer of a new motor vehicle subject to the standards prescribed in this paragraph shall, prior to taking any of the actions specified in section 10(a)(1) of the Act, comply with the other provisions of this subpart or Subpart A, as applicable.

(d) In-Use Standard. [Reserved]

(e) Low Noise Emission Product. [Reserved]

(Sec. 6, Pub. L. 92-574, 86 Stat. 1237 (42 U.S.C. 4905, 4906))

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61456, Dec. 5, 1977; 51 FR 852, Jan. 8, 1986]

§205.54 Test procedures.

The procedures described in this and subsequent sections will be the test program to determine the conformity of vehicles with the standards set forth in §205.52 for the purposes of Selective Enforcement Auditing and Testing by the Administrator.

[47 FR 57714, Dec. 28, 1982]

§205.54-1 Low speed sound emission test procedures.

(a) Instrumentation. The following instrumentation shall be used, where applicable.

(1) A sound level meter which meets the Type 1 requirements of ANSI S1.4-1971, Specification for Sound Level Meters, or a sound level meter may be used with a magnetic tape recorder and/or a graphic level recorder or indicating meter, providing the system meets the requirements of §205.54-2.

(2) A sound level calibrator. The calibrator shall produce a sound pressure level, at the microphone diaphragm, that is known to within an accuracy of ±0.5 dB. The calibrator shall be checked annually to verify that its output has not changed.

(3) An engine-speed tachometer which is accurate within ±2 percent of meter reading.

(4) An anemometer or other device for measurement of ambient wind speed accurate within ±10 percent.

(5) A thermometer for measurement of ambient temperature accurate within ±1 C.

(6) A barometer for measurement of ambient pressure accurate within ±1 percent.

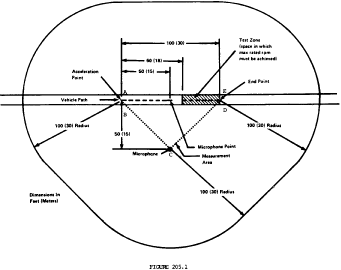

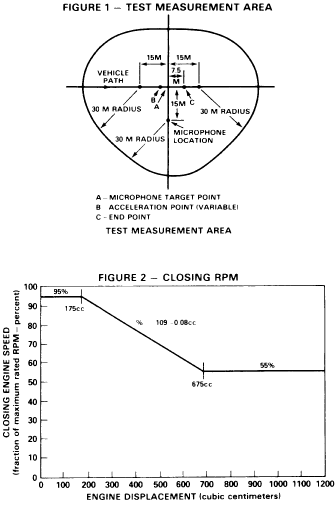

(b)(1) The test site shall be such that the truck radiates sound into a free field over a reflecting plane. This condition may be considered fulfilled if the test site consists of an open space free of large reflecting surfaces, such as parked vehicles, signboards, buildings or hillsides, located within 100 feet (30.4 meters) of either the vehicle path or the microphone.

(2) The microphone shall be located 50 feet ±4 in. (15.2 ±0.1 meter) from the centerline of truck travel and 4 feet ±4 in. (1.2 ±0.1 meters) above the ground plane. The microphone point is defined as the point of intersection of the vehicle path and the normal to the vehicle path drawn from the microphone. The microphone shall be oriented in a fixed position to minimize the deviation from the flattest system response over the frequency range 100 Hz to 10 kHz for a vehicle traversing from the acceleration point through the end zone.

The microphone shall be oriented with respect to the source so that the sound strikes the diaphragm at the angle for which the microphone was calibrated to have the flattest frequency response characteristic over the frequency range 100 Hz to 10 kHz.

(3) An acceleration point shall be established on the vehicle path 50 feet (15 m) before the microphone point.

(4) An end point shall be established on the vehicle path 100 feet (30 m) from the acceleration point and 50 feet (15 m) from the microphone point.

(5) The end zone is the last 40 feet (12 m) of vehicle path prior to the end point.

(6) The measurement area shall be the triangular paved (concrete or sealed asphalt) area formed by the acceleration point, the end point, and the microphone location.

(7) The reference point on the vehicle, to indicate when the vehicle is at any of the points on the vehicle path, shall be the front of the vehicle except as follows:

(i) If the horizontal distance from the front of the vehicle to the exhaust outlet is more than 200 inches (5.1 meters), tests shall be run using both the front and rear of the vehicle as reference points.

(ii) If the engine is located rearward to the center of the chassis, the rear of the vehicle shall be used as the reference point.

(8) The plane containing the vehicle path and the microphone location (plane ABCDE in Figure 1) shall be flat within ±2 inches (.05 meters).

(9) Measurements shall not be made when the road surface is wet, covered with snow, or during precipitation.

(10) Bystanders have an appreciable influence on sound level meter readings when they are in the vicinity of the vehicle or microphone; therefore not more than one person, other than the observer reading the meter, shall be within 50 feet (15.2 meters) of the vehicle path or instrument and the person shall be directly behind the observer reading the meter, on a line through the microphone and observer. To minimize the effect of the observer and the container of the sound level meter electronics on the measurements, cable should be used between the microphone and the sound level meter. No observer shall be located within 1 m in any direction of the microphone location.

(11) The maximum A-weighted fast response sound level observed at the test site immediately before and after the test shall be at least 10 dB below the regulated level.

(12) The road surface within the test site upon which the vehicle travels, and, at a minimum, the measurements area (BCD in figure 205.1) shall be smooth concrete or smooth sealed asphalt, free of extraneous material such as gravel.

(13) Vehicles with diesel engines shall be tested using Number 1D or Number 2D diesel fuel possessing a cetane rating from 42 to 50 inclusive.

(14) Vehicles with gasoline engines shall use the grade of gasoline recommended by the manufacturer for use by the purchaser.

(15) Vehicles equipped with thermo- statically controlled radiator fans may be tested with the fan not operating.

(c) Procedures- (1) Vehicle operation for vehicles with standard transmissions. Full throttle acceleration and closed throttle deceleration tests are to be used. A beginning engine speed and proper gear ratio must be determined for use during measurements. Closed throttle deceleration tests are required only for those vehicles equipped with an engine brake.

(i) Select the highest rear axle and/or transmission gear (“highest gear” is used in the usual sense; it is synonymous to the lowest numerical ratio) and an initial vehicle speed such that at wide-open throttle the vehicle will accelerate from the acceleration point.

(a) Starting at no more than two-thirds (66 percent) of maximum rated or of governed engine speed.

(b) Reaching maximum rated or governed engine speed within the end zone.

(c) Without exceeding 35 mph (56 k/h) before reaching the end point.

(1) Should maximum rated or governed rpm be attained before reaching the end zone, decrease the approach rpm in 100 rpm increments until maximum rated or governed rpm is attained within the end zone.

(2) Should maximum rated or governed rpm not be attained until beyond the end zone, select the next lower gear until maximum rated or governed rpm is attained within the end zone.

(3) Should the lowest gear still result in reaching maximum rated or governed rpm beyond the permissible end zone, unload the vehicle and/or increase the approach rpm in 100 rpm increments until the maximum rated or governed rpm is reached within the end zone.

(ii) For the acceleration test, approach the acceleration point using the engine speed and gear ratio selected in paragraph (c)(1) of this section and at the acceleration point rapidly establish wide-open throttle. The vehicle reference shall be as indicated in paragraph (b)(7) of this section. Acceleration shall continue until maximum rated or governed engine speed is reached.

(iii) Wheel slip which affects maximum sound level must be avoided.

(2) Vehicle operation for vehicles with automatic transmissions. Full throttle acceleration and closed throttle deceleration tests are to be used. Closed throttle deceleration tests are required only for those vehicles equipped with an engine brake.

(i) Select the highest gear axle and/or transmission gear (highest gear is used in the usual sense; it is synonymous to the lowest numerical ratio) in which no up or down shifting will occur under any operational conditions of the vehicle during the test run. Also, select an initial vehicle speed such that at wide-open throttle the vehicle will accelerate from the acceleration point.

(a) Starting at two-thirds (66 percent) of maximum rated or of governed engine speed.

(b) Reaching maximum rated or governed engine speed within the end zone.

(c) Without exceeding 35 mph (56 k/h) before reaching the end point.

(1) Should maximum rated or governed rpm be attained before reaching the end zone, decrease the approach rpm in 100 rpm increments until maximum rated or governed rpm is attained within the end zone.

(2) Should maximum rated or governed rpm not be attained until beyond the end zone, select the next lower gear until maximum rated or governed rpm is attained within the end zone.

(3) Should the lowest gear still result in reaching maximum rated or governed rpm beyond the permissible end zone, unload the vehicle and/or increase the approach rpm in 100 rpm increments until the maximum rated or governed rpm is reached within the end zone, notwithstanding that approach engine speed may now exceed two-thirds of maximum rated or of full load governed engine speed.

(4) Should the maximum rated or governed rpm still be attained before entering the end zone, and the engine rpm during approach cannot be further lowered, begin acceleration at a point 10 feet closer to the beginning of the end zone. The approach rpm to be used is to be that rpm used prior to the moving of the acceleration point 10 feet closer to the beginning of the end zone.

(5) Should the maximum rated or governed rpm still be attained before entering the end zone, repeat the instructions in paragraph (c)(2)(i)(c)(4) of this section until maximum rated or governed rpm is attained within the end zone.

(ii) For the acceleration test, approach the acceleration point using the engine speed and gear ratio selected in paragraph (c)(2)(i) of this section and at the acceleration point rapidly establish wide-open throttle. The vehicle reference shall be as indicated in paragraph (b)(7) of this section. Acceleration shall continue until maximum rated or governed engine speed is reached.

(iii) Wheel slip which affects maximum sound level must be avoided.

(3) Measurements.(i) The meter shall be set for “fast response” and the A-weighted network.

(ii) The meter shall be observed during the period while the vehicle is accelerating or decelerating. The applicable reading shall be the highest sound level obtained for the run. The observer is cautioned to rerun the test if unrelated peaks should occur due to extraneous ambient noises. Readings shall be taken on both sides of the vehicle.

(iii) The sound level associated with a side shall be the average of the first two pass-by measurements for that side, if they are within 2 dB(A) of each other. Average of measurements on each side shall be computed separately. If the first two measurements for a given side differ by more than 2 dB(A), two additional measurements shall be made on each side, and the average of the two highest measurements on each side, within 2 dB(A) of each other, shall be taken as the measured vehicle sound level for that side. The reported vehicle sound level shall be the higher of the two averages.

(d) General requirements.(1) Measurements shall be made only when wind velocity is below 12 mph (19 km/hr).

(2) Proper usage of all test instrumentation is essential to obtain valid measurements. Operating manuals or other literature furnished by the instrument manufacturer shall be referred to for both recommended operation of the instrument and precautions to be observed. Specific items to be adequately considered are:

(i) The effects of ambient weather conditions on the performance of the instruments (for example, temperature, humidity, and barometric pressure).

(ii) Proper signal levels, terminating impedances, and cable lengths on multi-instrument measurement systems.

(iii) Proper acoustical calibration procedure to include the influence of extension cables, etc. Field calibration shall be made immediately before and after each test sequence. Internal calibration means is acceptable for field use, provided that external calibration is accomplished immediately before or after field use.

(3)(i) A complete calibration of the instrumentation and external acoustical calibrator over the entire frequency range of interest shall be performed at least annually and as frequently as necessary during the yearly period to insure compliance with the standards cited in American National Standard S1.4-1971 “Specifications for Sound Level Meters” for a Type 1 instrument over the frequency range 50 Hz-10,000 Hz.

(ii) If calibration devices are utilized which are not independent of ambient pressure (e.g., a piston-phone) corrections must be made for barometric or altimetric changes according to the recommendation of the instrument manufacturer.

(4) The truck shall be brought to a temperature within its normal operating temperature range prior to commencement of testing. During testing appropriate caution shall be taken to maintain the engine temperatures within such normal operating range.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 11836, Mar. 1, 1977; 42 FR 61456, Dec. 5, 1977]

§205.54-2 Sound data acquisition system.

(a) Systems employing tape recorders and graphic level recorders may be established as equivalent to a Type I - ANSI S1.4-1971 sound level meter for use in determining compliance with this regulation by meeting the requirements of this section (§205.54-2(b)). This sound data acquisition system qualification procedure is based primarily on ANSI S6.1-1973.

(1) Performance requirements- (i) System frequency response. It is required that the overall steady-state frequency response of the data acquisition system shall be within the tolerances prescribed in Table 205.1 when measured in accordance with section (2). The tolerances in Table 205.1 are applicable to either flat or A-weighted response. (See paragraph (a)(3)(iii) of this section.)

(ii) Detector response. To ensure that a (true) rms indication is provided, the difference between the level indicated for a 1000 Hz sinusoidal signal equivalent to a sound level of 86 dB (rms) and the level indicated for an octave band of random noise of equal energy as the sinusoidal signal centered at 1000 Hz shall be no greater than 0.5 dB. A true rms voltmeter shall be used to determine equivalence of two input signals.

(iii) Indicating meter. If an indicating meter is used to obtain sound levels or band pressure levels, it must meet the requirements of paragraphs (a)(1)(ii) and (vi)(B) of this section and the following.

| Freq. (hertz) | A-weighted response (Re-1000 Hz, dB) | Tolerance (decibels) | |

|---|---|---|---|

| Plus - | Minus - | ||

| 31.5 | −39.4 | 1.5 | 1.5 |

| 40.0 | −34.6 | 1.5 | 1.5 |

| 50.0 | −30.2 | 1.0 | 1.0 |

| 63.0 | −26.2 | 1.0 | 1.0 |

| 80.0 | −22.5 | 1.0 | 1.0 |

| 100.0 | −19.1 | 1.0 | 1.0 |

| 125.0 | −16.1 | 1.0 | 1.0 |

| 160.0 | −13.4 | 1.0 | 1.0 |

| 200.0 | −10.9 | 1.0 | 1.0 |

| 250.0 | −8.6 | 1.0 | 1.0 |

| 315.0 | −6.6 | 1.0 | 1.0 |

| 400.0 | −4.8 | 1.0 | 1.0 |

| 500.0 | −3.2 | 1.0 | 1.0 |

| 630.0 | −1.9 | 1.0 | 1.0 |

| 800.0 | −.8 | 1.0 | 1.0 |

| 1,000.0 | 0 | 1.0 | 1.0 |

| 1,250.0 | .6 | 1.0 | 1.0 |

| 1,600.0 | 1.0 | 1.0 | 1.0 |

| 2,000.0 | 1.2 | 1.0 | 1.0 |

| 2,500.0 | 1.3 | 1.0 | 1.0 |

| 3,150.0 | 1.2 | 1.0 | 1.0 |

| 4,000.0 | 1.0 | 1.0 | 1.0 |

| 5,000.0 | .5 | 1.5 | 2.0 |

| 6,300.0 | −.1 | 1.5 | 2.0 |

| 8,000.0 | −1.1 | 1.5 | 3.0 |

| 10,000.0 | −2.5 | 2.0 | 4.0 |

| 12,500.0 | −4.3 | 3.0 | 6.0 |

(A) The scale shall be graduated in 1 dB steps.

(B) No scale indication shall be more than 0.2 dB different from the true value of the signal when an input signal equivalent to 86 dB sound level indicates correctly.

(C) Maximum indication for an input signal of 1000 Hz tone burst of 0.2 sec duration shall be within the range of −2 to 0 dB with respect to the steady-state indication for a 1000 Hz tone equivalent to 86 dB sound level.

(iv) Microphone. If microphone is used which has not been provided as a component of a precision sound level meter, it must be determined to meet the microphone characteristics described in IEC Publication 179, Precision Sound Level Meters.

(v) Magnetic tape recorders. No requirements are described in this document pertaining to tape recorders, except for frequency response. Generally, recorders of adequate quality to provide the frequency response performance required will also meet other minimum requirements for distortion, signal-to-noise ratio, etc.

(vi) Graphic level recorder dynamic response. When using a graphic level recorder, it is necessary to select pen response settings such that the readings obtained are statistically equivalent to those obtained by directly reading a meter which meets the “fast” dynamic requirement of a precision sound level meter indicating meter system for the range of vehicles to be tested. To ensure statistical equivalence, at least 30 comparative observations of real test data shall be made and the average of the absolute value of the differences observed shall be less than 0.5 dB. The settings described in this paragraph likely assure appropriate dynamic response; however, different settings may be selected on the basis of the above requirement.

(A) Use a pen writing speed of nominally 60-100 dB/sec. If adjustable, low frequency response should be limited to about 20 Hz.

(B) Indicated overshoot for a suddenly applied 1000 Hz sinusoidal signal equivalent to 86 dB sound level shall be no more than 1.1 dB and no less than 0.1 dB.

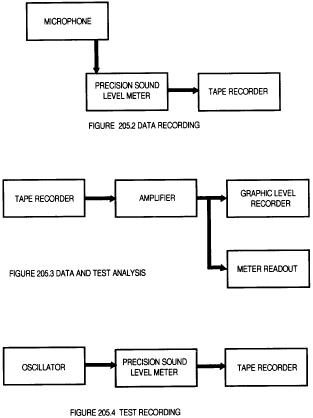

(2) Frequency response qualification procedure.(i) Typical noise measurement and analysis configurations are shown in Figures 205.2 through 205.4. The qualification procedure described herein duplicates these configurations, but with the microphone replaced by an electronic sinewave oscillator. Caution should be exercised when connecting an oscillator to the input of a sound level meter to ensure, perhaps by using a resistive voltage divider network, that the input is not overloaded (see §205.54-2(a)(2)(ii)).

(ii) Calibrate the oscillator to be used by measuring its output relative to the voltage which is equivalent to 86 dB sound level at each of the 27 frequencies listed in Table 205.1 using an electronic voltmeter of known calibration. Record the result in voltage level in dB re voltage corresponding to 86 dB sound level at 1000 Hz. This will describe the frequency response characteristics of the oscillator.

(iii) If a graphic level recorder is to be used, connect it to the oscillator output. If the oscillator and graphic level recorder can be synchronized, slowly sweep the frequency over the range of 31.5 to 12,500 Hz, recording the oscillator output. If they cannot be synchronized, record oscillator output for signals at the 27 frequencies given in Table 205.1. The differences between the combined response thus obtained and the oscillator response obtained previously will describe the frequency response of the graphic level recorder.

(iv) If visual observation of an indicating meter is to be used for obtaining data, the oscillator should be connected to the indicating meter input (such as the microphone input of a sound level meter) and the meter reading observed for a fixed oscillator output voltage setting for signals at the 27 frequencies given in Table 205.1.

(v) To check a tape recorder, connect the instruments as shown in Figure 205.4. Using a 1000 Hz tone, adjust the oscillator output level to obtain a reading 15 dB below maximum record level. If the synchronized oscillator/graphic level recorder system is to be used for analysis, record an oscillator sweep over the range of 31.5 to 12,500 Hz, using an appropriate tape recorder input attenuator setting. Alternatively, tape-record frequency tones at the 27 frequencies given in Table 205.1. Replay the tape recordings using the setup shown in Figure 205.3. Record the data on a graphic level recorder or through visual observation of the indicating meter. Subtract the oscillator frequency response in paragraph (b)(2) of this section from the response obtained through the record-playback sequence to obtain the record/reproduce frequency response of the system except for the microphone.

(vi) To obtain the overall system frequency response, add the manufacturer's microphone calibration data to the response just obtained. This may be the frequency response for the specific microphone to be used, including calibration tolerances. Alternatively, use the manufacturer's “typical” microphone response plus and minus the maximum deviation expected from “typical” including calibration tolerances. Use the microphone response curve which corresponds to the manner in which it is used in the field. It may be required to add a correction to the response curves provided to obtain field response; refer to the manufacturer's manual.

(vii) Adjustment or repair of equipment may be required to obtain response within the requirements of paragraph (a) of this section. After any adjustments, the system shall be requalified according to paragraph (b) of this section.

(3) General comments.(i) Calibrate tape recorders using the brand and type of magnetic tape used for actual data acquisition. Differences in tape can cause an appreciable variation in the recorder/reproduce frequency response characteristics of tape recorder.

(ii) It shall be ensured that the instrumentation used will perform within specifications and applicable tolerances over the temperature, humidity, and other environmental variation ranges which may be encountered in vehicle noise measurement works.

(iii) Qualification tests shall be performed using equipment (including cables) and recording and playback techniques identical with those used while recording vehicle noise. For example, if weighted sound level data are normally recorded use similar weighting and apply the tolerances of Table 205.1 to the weighting curve for comparison with record-playback curves. Precautions should also be taken to ensure that source and load impedances are appropriate to the device being tested. Other data acquisition systems may use any combination of microphones, sound level meters, amplifiers, tape recorders, graphic level recorders, or indicating meters. The same approach to qualifying such a system shall be taken as described in this document for the systems depicted in Figures 205.2, 205.3 and 205.4.

(b) Systems other than those specified in §§205.54-1(a) and 205.54-2(a) may be used for establishing compliance with this regulation. In each case the system must yield sound levels which are equivalent to those produced by a sound level meter Type 1 ANSI S1.4-1971. The manufacturer bears the burden of demonstrating such equivalence.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61456, Dec. 5, 1977; 47 FR 57714, Dec. 28, 1982]

§205.55 Requirements.

§205.55-1 General requirements.

(a) Every new vehicle manufactured for distribution in commerce in the United States which is subject to the standards prescribed in this subpart and not exempted in accordance with §205.5:

(1) Shall be labeled in accordance with the requirements of §205.55-5 of this subpart.

(2) Shall conform to the applicable noise emission standard established in §205.52 of this regulation.

(b) The requirements of paragraph (a) apply to new products which conform to the definition of vehicles in these regulations and at the time such new products are assembled to that state of completeness in which the manufacturer distributes them in commerce.

(c) Subsequent manufacturers of a new product which conforms to the definition of vehicle in these regulations when received by them from a prior manufacturer, need not fulfill the requirements of paragraph (a)(1) where such requirements have already been complied with by a prior manufacturer.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61456, Dec. 5, 1977; 47 FR 57714, Dec. 28, 1982]

§205.55-2 Compliance with standards.

(a)(1) Prior to distribution in commerce of vehicles of a specific configuration, the first manufactures of such vehicles must verify such configurations in accordance with the requirements of this subpart.

(2) [Reserved]

(3) At any time following receipt of notice under this section with respect to a configuration, the Administrator may require that the manufacturer ship test vehicles to the EPA test facility in order for the Administrator to perform the tests required for production verification.

(b) The requirements for purposes of testing by the Administrator and selective enforcement auditing with regard to each vehicle configuration consist of:

(1) Testing in accordance with §205.54 of a vehicle selected in accordance with §205.57-2, and

(2) Compliance of the test vehicle with the applicable standard when tested in accordance with §205.54.

(c)(1) In lieu of testing vehicles of every configuration as described in paragraph (b) of this section, the manufacturer may elect to verify the configuration based on representative testing, the requirements of which consist of:

(i) Grouping configurations into a category where each category will be determined by a separate combination of at least the following parameters (a manufacturer may use more parameters):

(a) Engine type.

(1) Gasoline - two stroke cycle.

(2) Gasoline - four stroke cycle.

(3) Diesel - two stroke cycle.

(4) Diesel - four stroke cycle.

(5) Rotary - wankel.

(6) Turbine.

(7) Other.

(b) Engine manufacturer.

(c) Engine displacement.

(d) Engine configuration (e.g., L-6, V-8, etc.).

(e) Series (i.e., cab design) including but not limited to conventional, cab over engine, and cab forward.

(ii) Identifying the configuration within each category which emits the highest sound pressure level (dBA) based on his best technical judgment and/or emission test data;

(iii) Testing in accordance with §205.54 of a vehicle selected in accordance with §205.57-2 which must be a vehicle of the configuration which is identified pursuant to paragraph (c)(1)(ii) of this section as having the highest sound pressure level (estimated or actual) within the category; and

(iv) Compliance of the test vehicle with applicable standards when tested in accordance with §205.54.

(2) Where the requirements of paragraph (c)(1) are complied with, all those configurations contained within a category are considered represented by the tested vehicle.

(3) Where the manufacturer tests a vehicle configuration which has not been determined as having the highest sound pressure level of a category, but all other requirements of paragraph (c)(1) of this section are complied with all those configurations contained with that category which are determined to have sound pressure levels no greater than the tested vehicle are considered to be represented by the tested vehicle, however, a manufacturer must for purposes of Testing by the Administrator and Selective Enforcement Auditing verify according to the requirements of paragraphs (b)(1) and/or (c)(1) of this section any configurations in the subject category which have a higher sound pressure level than the vehicle configuration tested.

(d) [Reserved]

(e) The manufacturer may, at his option, proceed with any of the following alternatives with respect to any vehicle determined not in compliance with applicable standards.

(1) In the case of representative testing a new test vehicle from another configuration must be selected according to the requirements of paragraph (c) of this section, in order to verify the configurations represented by the non-compliant vehicle.

(2) Modify the test vehicle and demonstrate by testing that it meets applicable standards. The manufacturer must modify all production vehicles of the same configuration in the same manner as the test vehicle before distribution into commerce.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61458, Dec. 5, 1977; 47 FR 57714, Dec. 28, 1982; 48 FR 27040, June 13, 1983]

§205.55-3 Configuration identification.

(a) A separate vehicle configuration shall be determined by each combination of the following parameters:

(1) Exhaust system configuration.(i) Single vertical.

(ii) Dual vertical.

(iii) Single horizontal.

(iv) Dual horizontal.

(2) Air induction system (engine).(i) Natural.

(ii) Turbocharged.

(ii) Drive.

(a) Direct.

(b) Thermostatic.

(iii) Max fan rpm.

(4) Engine manufacturer's horsepower rating.

(5) Cab characteristic.(i) Sleeper.

(ii) Non sleeper.

(6) Category parameters listed in §205.55-2.

§205.55-4 Labeling-compliance.

(a)(1) The manufacturer of any vehicle subject to the provisions of §205.52 shall, at the time of manufacture, affix a permanent, legible label, of the type and in the manner described below, containing the information hereinafter provided, to all such vehicles to be distributed in commerce. The labels shall be affixed in such a manner that they cannot be removed without destroying or defacing them, and shall not be affixed to any equipment which is easily detached from such vehicle.

(2) A label shall be permanently attached, in a readily visible position, in the operator's compartment.

(3) Labels for vehicles not manufactured solely for use outside the United States shall contain the following information lettered in the English language in block letters and numerals, which shall be of a color that contrasts with the background of the label:

(i) The label heading: Vehicle Noise Emission Control Information;

(ii) Full corporate name and trademark of manufacturer;

(iii) Month and year of manufacture;

(iv) The statement:

This Vehicle Conforms to U.S. EPA Regulations for Noise Emission Applicable to Medium and Heavy Trucks.

The following acts or the causing thereof by any person are prohibited by the Noise Control Act of 1972:

(A) The removal or rendering inoperative, other than for purposes of maintenance, repair, or replacement, of any noise control device or element of design (listed in the owner's manual) incorporated into this vehicle in compliance with the Noise Control Act;

(B) The use of this vehicle after such device or element of design has been removed or rendered inoperative.

(b) Labels for vehicles manufactured solely for use outside the United States shall contain the words “For Export Only.”

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61456, 61458, Dec. 5, 1977. Redesignated at 47 FR 57715, Dec. 28, 1982]

§205.55-5 Labeling-exterior. [Reserved]

§205.56 Testing by the Administrator.

(a)(1) The Administrator may require that any vehicles to be tested pursuant to the Act be submitted to him, at such place and time as he may reasonably designate and in such quantity and for such time as he may reasonably require for the purpose of conducting tests in accordance with test procedures described in §205.54 to determine whether such vehicles or a manufacturer's test facility conform to applicable regulations. It is a condition of the requirements under this section that the manner in which the Administrator conducts such tests, the EPA test facility itself, and the test procedures he employs shall be based upon good engineering practice and meet or exceed the requirements of §205.54 of the regulations.

(2) The Administrator may specify that he will conduct such testing at the manufacturer's facility, in which case instrumentation and equipment of the type required by these regulations shall be made available by the manufacturer for test operations. The Administrator may conduct such tests with his own equipment, which shall equal or exceed the performance specifications of the instrumentation or equipment specified by the Administrator in these regulations.

(3) The manufacturer may observe tests conducted by the Administrator pursuant to this section on vehicles produced by such manufacturer and may copy the data accumulated from such tests. The manufacturer may inspect any such vehicles before and after testing by the Administrator.

(b)(1) If, based on tests conducted by the Administrator or other relevant information, the Administrator determines that the test facility does not meet the requirements of §205.54-1 (a) and (b) he will notify the manufacturer in writing of his determination and the reasons therefor.

(2) The manufacturer may at any time within 15 days after receipt of a notice issued under paragraph (b)(1) of this section request a hearing conducted in accordance with 5 U.S.C. 554 on the issue of whether his test facility was in conformance. Such notice will not take effect until 15 days after receipt by the manufacturer, or if a hearing is requested under this paragraph, until adjudication by the hearing examiner.

(3) After any notification issued under paragraph (b)(1) of this section has taken effect, no data thereafter derived from such test facility will be acceptable for purposes of this part.

(4) The manufacturer may request in writing that the Administrator reconsider his determination under paragraph (b)(1) of this section based on data or information which indicates that changes have been made to the test facility and such changes have resolved the reasons for disqualification.

(5) The Administrator will notify the manufacturer of his determination and an explanation of the reasons underlying it with regard to the requalification of the test facility within 10 working days after receipt of the manufacturer's request for reconsideration pursuant to paragraph (b)(4) of this section.

(c)(1) The Administrator will assume all reasonable costs associated with shipment of vehicles to the place designated pursuant to paragraph (a) of this section except with respect to:

(i) [Reserved]

(ii) Testing of a reasonable number of vehicles for purposes of selective enforcement auditing under §205.57 or testing of smaller numbers of vehicles, if the manufacturer has failed to establish that there is a correlation between its test facility and the EPA test facility or the Administrator has reason to believe, and provides the manufacturer a statement of such reasons, that the vehicles to be tested would fail to meet the standard prescribed in this subpart if tested at the EPA test facility, but would meet such standard if tested at the manufacturer's test facility;

(iii) Any testing performed during a period when a notice of nonconfor- mance of the manufacturer's test facility issued pursuant to paragraph (b) of this section is in effect;

(iv) Any testing performed at place other than the manufacturer's facility as a result of the manufacturer's failure to permit the Administrator to conduct or monitor testing as required by this part.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61456, 61459, Dec. 5, 1977; 47 FR 57715, Dec. 28, 1982]

§205.57 Selective enforcement auditing requirements.

§205.57-1 Test request.

(a) The Administrator will request all testing under §205.57 by means of a test request addressed to the manufacturer.

(1) Except as provided in paragraphs (a) (2) and (3) of this section, the Administrator will not issue to a manufacturer during any model year more test requests than a number determined by dividing the total number of vehicles subject to this regulation which the manufacturer projects he will produce during that model year by 25,000 and rounding to the next higher whole number: Except, that the Administrator may issue one additional test request beyond the annual limit to any manufacturer for each time a batch sequence for any category, configuration or subgroup thereof of such manufacturer's production is rejected in accordance with §205.57-7.

(2) Any test request issued against a category, configuration or subgroup thereof which the Administrator has reason to believe does not meet the standards specified in §205.52 will not be counted against the annual limit on test requests described in paragraph (a)(1) of this section. Any such request shall include a statement of the Administrator's reason for such belief.

(3) Any test request under which testing is not completed will not be counted against the annual limit on test requests described in paragraph (a)(1) of this section.

(b) The test request will be signed by the Assistant Administrator for Enforcement or his designee. The test request will be delivered by an EPA Enforcement Officer to the plant manager or other responsible official as designated by the manufacturer.

(c) The test request will specify the vehicle category, configuration or subgroup thereof selected for testing, the batch from which sampling is to begin, the batch size, the manufacturer's plant or storage facility from which the vehicles must be selected, the time at which a vehicle must be selected. The test request will also provide for situations in which the selected configuration or category is unavailable for testing. The test request may include an alternative category or configuration selected for testing in the event that vehicles of the first specified category or configuration are not available for testing because the vehicles are not being manufactured at the specified plant and/or are not being manufactured during the specified time or not being stored at the specified plant or storage facility.

(d) Any manufacturer shall, upon receipt of the test request, select and test a batch sample of vehicles from two consecutively produced batches of the vehicle category or configurations specified in the test request in accordance with these regulations and the conditions specified in the test request.

(e)(1) Any testing conducted by the manufacturer pursuant to a test request shall be initiated within such period as is specified within the test request: Except, that such initiation may be delayed for increments of 24 hours or one business day where ambient test site weather conditions, or other conditions beyond the control of the manufacturer, in any 24-hour period do not permit testing: Provided, That these conditions for that period are recorded.

(2) The manufacturer shall complete emission testing on a minimum of five vehicles per day unless otherwise provided for by the Administrator or unless ambient test site conditions only permit the testing of a lesser number: Provided, that ambient test site weather conditions for that period are recorded.

(3) The manufacturer will be allowed 24 hours to ship vehicles from a batch sample from the assembly plant to the testing facility if the facility is not located at the plant or in close proximity to the plant: Except, that the Administrator may approve more time based upon a request by the manufacturer accompanied by a satisfactory justification.

(f) The Administrator may issue an order to the manufacturer to cease to distribute into commerce vehicles of a specified category or configuration being manufactured at a particular facility if:

(1) The manufacturer refuses to comply with the provisions of a test request issued by the Administrator pursuant to this section; or

(2) The manufacturer refuses to comply with any of the requirements of this section.

(g) A cease-to-distribute order shall not be issued under paragraph (f) of this section if such refusal is caused by conditions and circumstances outside the control of the manufacturer which renders it impossible to comply with the provisions of a test request or any other requirements of this section. Such conditions and circumstances shall include, but are not limited to, any uncontrollable factors which result in the temporary unavailability of equipment and personnel needed to conduct the required tests, such as equipment break-down or failure or illness of personnel, but shall not include failure of the manufacturer to adequately plan for and provide the equipment and personnel needed to conduct the tests. The manufacturer will bear the burden of establishing the presence of the conditions and circumstances required by this paragraph.

(h) Any such order shall be issued only after a notice and opportunity for a hearing.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61459, Dec. 5, 1977; 43 FR 12326, Mar. 24, 1978]

§205.57-2 Test vehicle sample selection.

(a) Vehicles comprising the batch sample which are required to be tested pursuant to a test request in accordance with this subpart will be selected in the manner specified in the test request from a batch of vehicles of the category or configuration specified in the test request. If the test request specifies that the vehicles comprising the batch sample must be selected randomly, the random selection will be achieved by sequentially numbering all of the vehicles in the batch and then using a table of random numbers to select the number of vehicles as specified in paragraph (c) of this section based on the batch size designated by the Administrator in the test request. An alternative random selection plan may be used by a manufacturer: Provided, That such a plan is approved by the Administrator. If the test request does not specify that test vehicles must be randomly selected, the manufacturer shall select test vehicles consecutively.

(1) Should a situation arise in which the configuration to be tested consists of only vehicles with automatic transmissions, they shall be tested in accordance with §205.54-1(c)(2).

(2) If the configuration to be tested consists of both automatic transmission and standard transmission vehicles, the test vehicle shall be a standard transmission vehicle unless the manufacturer has reason to believe that the automatic transmission vehicle emits a greater sound level.

(b) The Acceptable Quality Level is 10 percent. The appropriate sampling plans associated with the designated AQL are contained in Appendix I, Table II.

(c) The appropriate batch sample size will be determined by reference to Appendix I, Table I and II. A code letter is obtained from Table I based on the batch size designated by the Administrator in a test request. The batch sample size will be obtained from Table II. The batch sample size will be equal to the maximum cumulative sample size for the appropriate code letter obtained from Table I plus an additional 10 percent rounded off to the next highest number.

(d) If the test request specifies that vehicles comprising the batch sample must be selected randomly, individual vehicles comprising the test sample will be randomly selected from the batch sample using the same random selection plan as in paragraph (a) of this section. Test sample size will be determined by entering Table II.

(e) The test vehicle of the category, configuration or subgroup thereof selected for testing shall have been assembled by the manufacturer for distribution in commerce using the manufacturer's normal production process in accordance with §205.55-5(a).

(f) Unless otherwise indicated in the test request, the manufacturer will select the batch sample from the production batch, next scheduled after receipt of the test request, of the category or configuration specified in the test request.

(g) Unless otherwise indicated in the test request, the manufacturer shall select the vehicles designated in the test request for testing.

(h) At their discretion, EPA Enforcement Officers, rather than the manufacturer, may select the vehicles designated in the test request.

(i) The manufacturer will keep on hand all vehicles in the batch sample until such time as the batch is accepted or rejected in accordance with §205.57-6: Except, that vehicles actually tested and found to be in conformance with these regulations need not be kept.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61459, Dec. 5, 1977; 47 FR 57715, Dec. 28, 1982; 48 FR 27039, June 13, 1983]

§205.57-3 Test vehicle preparation.

(a) Prior to the official test, the test vehicle selected in accordance with §205-57-2 shall not be prepared, tested, modified, adjusted, or maintained in any manner unless such adjustments, preparation, modification and/or tests are part of the manufacturer's prescribed manufacturing and inspection procedures, and are documented in the manufacturer's internal vehicle assembly and inspection procedures or unless such adjustments and/or tests are required or permitted under this subpart or are approved in advance by the Administrator. For purposes of this section, prescribed manufacturing and inspection procedures include quality control testing and assembly procedures normally performed by the manufacturer on like products during early production so long as the resulting testing is not biased by the procedure. In the case of imported products the manufacturer may perform adjustments, preparations, modification and/or tests normally performed at the port of entry by the manufacturer to prepare the vehicle for delivery to a dealer or customer.

(b) Equipment or fixtures necessary to conduct the test may be installed on the vehicle: Provided, That such equipment or fixtures shall have no effect on the noise emissions of the vehicle, as determined by measurement methodology.

(c) In the event of vehicle malfunction (i.e., failure to start, misfiring cylinder, etc.) the manufacturer may perform the maintenance that is necessary to enable the vehicle to operate in a normal manner.

(d) No quality control, testing, assembly or selection procedures shall be used on the completed vehicle or any portion thereof, including parts and subassemblies, that will not normally be used during the production and assembly of all other vehicles of the category which will be distributed in commerce, unless such procedures are required or permitted under this subpart.

[47 FR 57715, Dec. 28, 1982; 48 FR 27039, June 13, 1983]

§205.57-4 Testing procedures.

(a) The manufacturer shall conduct one valid test in accordance with the test procedures specified in §205.54 of this subpart for each vehicle selected for testing pursuant to this subpart.

(b) No maintenance will be performed on test vehicles except as provided for by §205.57-3. In the event a vehicle is unable to complete the emission test, the manufacturer may replace the vehicle. Any replacement vehicle will be a production vehicle of the same configuration as the replaced vehicle. It will be randomly selected from the batch sample and will be subject to all the provisions of these regulations.

§205.57-5 Reporting of the test results.

(a) Within 5 working days after completion of testing of all vehicles in a batch sample the manufacturer shall submit to the Administrator a final report which will include the information required by the test request in the format stipulated in the test request in addition to the following:

(1) The name, location, and description of the manufacturer's emission test facilities which meet the specifications of §205.54 and were utilized to conduct testing reported pursuant to this section: Except, that a test facility that has been described in a previous submission under this subpart need not again be described but must be identified as such.

(2) A description of the random vehicle selection method used, referencing any tables of random numbers that were used, name of the person in charge of the random number selection, if the vehicle test request specifies a random vehicle selection.

(3) The following information for each noise emission test conducted,

(i) The completed data sheet required by §205.54 for all noise emission tests including: For each invalid test, the reason for invalidation.

(ii) A complete description of any modification, repair, preparation, maintenance, and/or testing which could affect the noise emissions of the vehicle and which was performed on the test vehicle but will not be performed on all other production vehicles.

(iii) The reason for the replacement where a replacement vehicle was authorized by the Administrator, and, if any, the test results for the replaced vehicles.

(4) A complete description of the sound data acquisition system if other than those specified in §§205.54-1(a) and 205.54-2(a).

(5) The following statement and endorsement:

This report is submitted pursuant to section 6 and section 13 of the Noise Control Act of 1972. To the best of ___(company name) knowledge, all testing for which data are reported herein was conducted in strict conformance with applicable regulations under 40 CFR 205.1et seq., all the data reported herein are a true and accurate representation of such testing and all other information reported herein is true and accurate. I am aware of the penalties associated with violations of the Noise Control Act of 1972 and the regulations thereunder.

(authorized representative)

(b) All information required to be forwarded to the Administrator pursuant to this section shall be addressed to Director, Noise Enforcement Division (EN-387), U.S. Environmental Protection Agency, Washington, DC 20460.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61459, Dec. 5, 1977; 43 FR 12326, Mar. 24, 1978]

§205.57-6 Acceptance and rejection of batches.

(a) The batch from which a batch sample is selected will be accepted or rejected based upon the number of failing vehicles in the batch sample. A sufficient number of test samples will be drawn from the batch sample until the cumulative number of failing vehicles is less than or equal to the acceptance number or greater than or equal to the rejection number appropriate for the cumulative number of vehicles tested. The acceptance and rejection numbers listed in Appendix I, Table II at the appropriate code letter obtained according to §205.57-2 will be used in determining whether the acceptance or rejection of a batch has occurred.

(b) Acceptance or rejection of a batch takes place when the decision that a vehicle is a failing vehicle is made on the last vehicle required to make a decision under paragraph (a) of this section.

§205.57-7 Acceptance and rejection of batch sequence.

(a) The manufacturer will continue to inspect consecutive batches until the batch sequence is accepted or rejected based upon the number of rejected batches. A sufficient number of consecutive batches will be inspected until the cumulative number of rejected batches is less than or equal to the sequence acceptance number of greater than or equal to the sequence rejection number appropriate for the cumulative number of batches inspected. The acceptance and rejection numbers listed in Appendix I, Table III at the appropriate code letter obtained according to §205.57-2 will be used in determining whether the acceptance or rejection of a batch sequence has occurred.

(b) Acceptance or rejection of a batch sequence takes place when the decision that a vehicle is a failiing vehicle is made on the last vehicle required to make a decision under paragraph (a) of this section.

(c) If the batch sequence is accepted, the manufactureer will not be required to perform any additional testing on vehicles from subsequent batches pursuant to the initiating test request.

(d) The Administrator may terminate testing earlier than required in paragraph (b) of this section based on a request by the manufacturer accompanied by voluntary cessation of distribution in commerce, of vehicles from the category, configuration or subgroup in question manufactured at the plant which produced the vehicles under test: Provided, That before reinitiating distribution in commerce of vehicles from such plant of such vehicle category, configuration or subgroup, the manufacturer must take the action described in §205.57-9(a)(1) and (a)(2).

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61460, Dec. 5, 1977]

§205.57-8 Continued testing.

(a) If a batch sequence is rejected in accordance with paragraph (b) of §205.57-7, the Administrator may require that any or all vehicles of that category, configuration of subgroup thereof produced at that plant be tested before distribution in commerce.

(b) The Administrator will notify the manufacturer in writing of his intent to require such continued testing of vehicles pursuant to paragraph (a) of this section.

(c) The manufacturer may request a hearing on the issues of whether the selective enforcement audit was conducted properly; whether the criteria for batch sequence rejection in §204.57-7 have been met; and, the appropriateness or scope of a continued testing order. In the event that a hearing is requested, the hearing shall begin no later than 15 days after the date on which the Administrator received the hearing request. Neither the request for a hearing nor the fact that a hearing is in progress shall affect the reponsibility of the manufacturer to commence and continue testing required by the Administrator pursuant to paragraph (a) of this section.

(d) Any tested vehicle which demonstrated conformance with the applicable standards may be distributed into commerce.

(e) Any knowing distribution into commerce of a vehicle which does not comply with the applicable standards is a prohibited act.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61460, Dec. 5, 1977; 44 FR 54296, Sept. 19, 1979]

§205.57-9 Prohibition on distribution in commerce; manufacturer's remedy.

(a) The Administrator will permit the cessation of continued testing under §205.57-8 once the manufacturer has taken the following actions:

(1) Submit a written report to the Administrator which identifies the reason for the noncompliance of the vehicles, describes the problem and describes the proposed quality control and/or quality assurance remedies to be taken by the manufacturer to correct the problem or follows the requirements for an engineering change. Such requirements include the following:

(i) Any change to a configuration with respect to any of the parameters stated in §205.55-3 shall constitute the addition of a new and separate configuration or category to the manufacturer's product line.

(ii) When a manufacturer introduces a new category or configuration to his product line, he shall proceed in accordance with §205.55-2.

(iii) If the configuration to be added can be grouped within a verified category and the new configuration is estimated to have a lower sound pressure level than a previously verified configuration within the same category, the configuration shall be considered verified.

(2) Demonstrates that the specified vehicle category, configuration or subgroup thereof has passed a retest conducted in accordance with §205.57 and the conditions specified in the initial test request.

(3) The manufacturer may begin testing under paragraph (a)(2) of this section upon submitting such report, and may cease continued testing upon making the demonstration required by paragraph (a)(2) of this section, provided that the Administrator may require resumption of continued testing if he determines that the manufacturer has not satisfied the requirements of paragraphs (a)(1) and (2) of this section.

(b) Any vehicle failing the prescribed noise emission tests conducted pursuant to this Subpart B may not be distributed in commerce until necessary adjustments or repairs have been made and the vehicle passes a retest.

(c) No vehicles of a rejected batch which are still in the hands of the manufacturer may be distributed in commerce unless the manufacturer has demonstrated to the satisfaction of the Administrator that such vehicles do in fact conform to the regulations: Except, that any vehicle that has been tested and does, in fact, conform with these regulations may be distributed in commerce.

[41 FR 15544, Apr. 13, 1976, as amended at 42 FR 61460, Dec. 5, 1977; 47 FR 57715, Dec. 28, 1982]

§205.58 In-use requirements.

§205.58-1 Warranty.

(a) The vehicle manufacturer shall include the owner's manual or in other information supplied to the ulitmate purchaser the following statement:

Noise Emissions Warranty

(Name of vehicle manufacturer) warrants to the first person who purchases this vehicle for purposes other than resale and to each subsequent purchaser that this vehicle as manufactured by (names of vehicle manufacturer), was designed, built and equipped to conform at the time it left (name of vehicle manufacturer)'s control with all applicable U.S. EPA Noise Control Regulations.

This warranty covers this vehicle as designed, built and equipped by (Name of vehicle manufacturer), and is not limited to any particular part, component or system of the vehicle manufactured by (name of vehicle manufacturer). Defects in design, assembly or in any part, component or system of the vehicle as manufactured by (name of vehicle manufacturer), which, at the time it left (name of vehicle manufacturer)'s control, caused noise emissions to exceed Federal standards, are covered by this warranty for the life of the vehicle.

(b) [Reserved]

[41 FR 15544, Apr. 13, 1976, as amended at 47 FR 57715, Dec. 28, 1982; 48 FR 27040, June 13, 1983]

§205.58-2 Tampering.

(a) For each configuration of vehicles covered by this part, the manufacturer shall develop a list of those acts which, in his judgment, might be done to the vehicle in use and which would constitute the removal or rendering inoperative of noise control devices or elements of design of the vehicle.