...

(a) New and reconstructed affected sources. For a new or reconstructed affected source, you must meet the requirements of paragraphs (a)(1) through (4) of this section.

(1) All emission capture systems, add-on control devices, and CPMS must be installed and operating no later than the applicable compliance date specified in §63.4283. Except for solvent recovery systems for which you conduct liquid-liquid material balances according to §63.4341(e)(5) or (f)(5), you must conduct a performance test of each capture system and add-on control device according to the procedures in §§63.4360, 63.4361, and 63.4362, and establish the operating limits required by §63.4292, within 180 days of the applicable compliance date specified in §63.4283. For a solvent recovery system for which you conduct liquid-liquid material balances according to §63.4341(e)(5) or (f)(5), you must initiate the first material balance no later than the applicable compliance date specified in §63.4283.

(2) You must develop and begin implementing the work practice plan required by §63.4293 no later than the compliance date specified in §63.4283.

(3) You must complete the compliance demonstration for the initial compliance period according to the requirements of §63.4341. The initial compliance period begins on the applicable compliance date specified in §63.4283 and ends on the last day of the 12th full month after the compliance date, or the date you conduct the performance tests of the emission capture systems and add-on control devices, or initiate the first liquid-liquid material balance for a solvent recovery system, whichever is later. The initial compliance demonstration includes the results of emission capture system and add-on control device performance tests conducted according to §§63.4360, 63.4361, and 63.4362; results of liquid-liquid material balances conducted according to §63.4341(e)(5) or (f)(5); calculations according to §63.4341 and supporting documentation showing that during the initial compliance period the organic HAP emission rate was equal to or less than the applicable emission limit in Table 1 to this subpart; the operating limits established during the performance tests and the results of the continuous parameter monitoring required by §63.4364; and documentation of whether you developed and implemented the work practice plan required by §63.4293.

(4) You do not need to comply with the operating limits for the emission capture system and add-on control device required by §63.4292 until after you have completed the performance tests specified in paragraph (a)(1) of this section. Instead, you must maintain a log detailing the operation and maintenance of the emission capture system, add-on control device, and continuous parameter monitors during the period between the compliance date and the performance test. You must begin complying with the operating limits for your affected source on the date you complete the performance tests specified in paragraph (a)(1) of this section. This requirement does not apply to solvent recovery systems for which you conduct liquid-liquid material balances according to the requirements of §63.4341(e)(5) or (f)(5).

(b) Existing sources. For an existing affected source, you must meet the requirements of paragraphs (b)(1) through (3) of this section.

(1) All emission capture systems, add-on control devices, and CPMS must be installed and operating no later than the applicable compliance date specified in §63.4283. Except for solvent recovery systems for which you conduct liquid-liquid material balances according to §63.4341(e)(5) or (f)(5), you must conduct a performance test of each capture system and add-on control device according to the procedures in §§63.4360, 63.4361, and 63.4362, and establish the operating limits required by §63.4292, within 180 days of the compliance date specified in §63.4283. For a solvent recovery system for which you conduct liquid-liquid material balances according to §63.4341(e)(5) or (f)(5), you must initiate the first material balance no later than the compliance date specified in §63.4283.

(2) You must develop and begin implementing the work practice plan required by §63.4293 no later than the compliance date specified in §63.4283.

(3) You must complete the compliance demonstration for the initial compliance period according to the requirements of §63.4341. The initial compliance period begins on the applicable compliance date specified in §63.4283 and ends on the last day of the 12th full month after the compliance date. The initial compliance demonstration includes the results of emission capture system and add-on control device performance tests conducted according to §§63.4360, 63.4361, and 63.4362; results of liquid-liquid material balances conducted according to §63.4341(e)(5) or (f)(5); calculations according to §63.4341 and supporting documentation showing that during the initial compliance period the organic HAP emission rate was equal to or less than the applicable emission limit in Table 1 to this subpart; the operating limits established during the performance tests and the results of the continuous parameter monitoring required by §63.4364; and documentation of whether you developed and implemented the work practice plan required by §63.4293.

[68 FR 32189, May 29, 2003, as amended at 84 FR 9627, Mar. 15, 2019]

(a) You may use the emission rate with add-on controls option for any individual web coating/printing operation, for any group of web coating/printing operations in the affected source, or for all of the web coating/printing operations in the affected source. You may include both controlled and uncontrolled web coating/printing operations in a group for which you use this option. You must use either the compliant material option, the emission rate without add-on controls option, the organic HAP overall control efficiency option, or the oxidizer outlet organic HAP concentration option for any web coating/printing operation in the affected source for which you do not use the emission rate with add-on controls option. To demonstrate initial compliance, any web coating/printing operation for which you use the emission rate with add-on controls option must meet the applicable emission limitations in Table 1 to this subpart, and in §§63.4292 and 63.4293. You must meet all the requirements of paragraphs (a), (c), (d), and (e) of this section. When calculating the organic HAP emission rate according to this section, do not include any coating, printing, thinning, or cleaning materials applied on web coating/printing operations for which you use the compliant material option, the emission rate without add-on controls option, the organic HAP overall control efficiency option, or the oxidizer outlet organic HAP concentration option. You do not need to redetermine the mass of organic HAP in coating, printing, thinning, or cleaning materials that have been reclaimed onsite and reused in the web coating/printing operation(s) for which you use the emission rate with add-on control option.

(b) You may use the emission rate with add-on controls option for any individual dyeing/finishing operation, for any group of dyeing/finishing operations in the affected source, or for all of the dyeing/finishing operations in the affected source. You may include both controlled and uncontrolled dyeing/finishing operations in a group for which you use this option. You must use either the compliant material option or the emission rate without add-on controls option for any dyeing/finishing operation in the affected source for which you do not use the emission rate with add-on controls option. You may not use the emission rate with add-on controls option for any dyeing/finishing operation in a dyeing/finishing affected source for which you use the equivalent emission rate option. To demonstrate initial compliance, any dyeing/finishing operation for which you use the emission rate with add-on controls option must meet the applicable emission limitations in Table 1 to this subpart, and in §§63.4292 and 63.4293. You must meet all the requirements of paragraphs (b), (c), (d), and (f) this section. When calculating the organic HAP emission rate according to this section, do not include any dyeing or finishing materials applied on dyeing/finishing operations for which you use the compliant material option or the emission rate without add-on controls option. You do not need to redetermine the mass of organic HAP in dyeing or finishing materials that have been reclaimed onsite and reused in the dyeing/finishing operation(s) for which you use the emission rate with add-on controls option.

(c) Compliance with operating limits. Except as provided in §63.4340(a)(4), and except for solvent recovery systems for which you conduct liquid-liquid material balances according to §63.4341(e)(5) or (f)(5), you must establish and demonstrate continuous compliance during the initial compliance period with the operating limits required by §63.4292, using the procedures specified in §§63.4363 and 63.4364.

(d) Compliance with work practice requirements. You must develop, implement, and document your implementation of the work practice plan required by §63.4293 during the initial compliance period as specified in §63.4312.

(e) Compliance with web coating/printing emission limits. You must follow the procedures in paragraphs (e)(1) through (8) of this section to demonstrate compliance with the applicable web coating/printing emission limit in Table 1 to this subpart.

(1) Determine the mass fraction of organic HAP, the mass fraction of solids, and mass of materials. Follow the procedures specified in §63.4331(a)(1), (2), and (3) to determine the mass fraction of organic HAP for each coating, printing, thinning, and cleaning material applied during the compliance period; the mass fraction of solids for each coating and printing material applied during the compliance period; and mass of each coating, printing, thinning, and cleaning material applied during the compliance period.

(2) Calculate the mass of organic HAP emissions before add-on controls. Using Equation 1 of §63.4331, calculate the mass of organic HAP emissions before add-on controls from all coating, printing, thinning, and cleaning materials applied during the compliance period minus the organic HAP in certain waste materials in the web coating/printing operation or group of web coating/printing operations for which you use the emission rate with add-on controls.

(3) Calculate the organic HAP emissions reductions for each controlled web coating/printing operation. Determine the mass of organic HAP emissions reduced for each controlled web coating/printing operation during the compliance period. The emissions reductions determination quantifies the total organic HAP emissions that pass through the emission capture system and are destroyed or removed by the add-on control device. Use the procedures in paragraph (e)(4) of this section to calculate the mass of organic HAP emissions reductions for each controlled web coating/printing operation using an emission capture system and add-on control device other than a solvent recovery system for which you conduct liquid-liquid material balances. For each controlled web coating/printing operation using a solvent recovery system for which you conduct a liquid-liquid material balance, use the procedures in paragraph (e)(5) of this section to calculate the organic HAP emissions reductions.

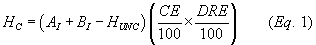

(4) Calculate the organic HAP emission reduction for each controlled web coating/printing operation not using liquid-liquid material balance. For each controlled web coating/printing operation using an emission capture system and add-on control device other than a solvent recovery system for which you conduct liquid-liquid material balances, calculate the organic HAP emissions reductions using Equation 1 of this section. The equation applies the emission capture system efficiency and add-on control device efficiency to the mass of organic HAP contained in the coating, printing, thinning, and cleaning materials applied in the web coating/printing operation served by the emission capture system and add-on control device during the compliance period. For any period of time a deviation specified in §63.4342(c) or (d) occurs in the controlled web coating/printing operation, then you must assume zero efficiency for the emission capture system and add-on control device. Equation 1 of this section treats the coating, printing, thinning, and cleaning materials applied during such a deviation as if they were used on an uncontrolled web coating/printing operation for the time period of the deviation.

Where:

HC = Mass of organic HAP emission reduction for the controlled web coating/printing operation during the compliance period, kg.

AI = Total mass of organic HAP in the coating and printing materials applied in the controlled web coating/printing operation during the compliance period, kg, as calculated in Equation 1A of this section.

BI = Total mass of organic HAP in the thinning and cleaning materials applied in the controlled web coating/printing operation during the compliance period, kg, as calculated in Equation 1B of this section.

HUNC = Total mass of organic HAP in the coating, printing, thinning, and cleaning materials applied during all deviations specified in §63.4342(c) and (d) that occurred during the compliance period in the controlled web coating/printing operation, kg, as calculated in Equation 1C of this section.

CE = Capture efficiency of the emission capture system vented to the add-on control device, percent. Use the test methods and procedures specified in §§63.4360 and 63.4361 to measure and record capture efficiency.

DRE = Organic HAP destruction or removal efficiency of the add-on control device, percent. Use the test methods and procedures in §§63.4360 and 63.4362 to measure and record the organic HAP destruction or removal efficiency.

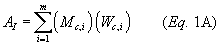

(i) Calculate the total mass of organic HAP in the coating and printing materials applied in the controlled web coating/printing operation(s) during the compliance period, kg, using Equation 1A of this section:

Where:

AI = Total mass of organic HAP in the coating and printing materials applied in the controlled web coating/printing operation(s) during the compliance period, kg.

Mc,i = Mass of coating or printing material, i, applied during the compliance period, kg.

Wc,i = Mass fraction of organic HAP in coating or printing material, i, kg per kg.

m = Number of different coating and printing materials applied during compliance period.

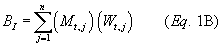

(ii) Calculate the total mass of organic HAP in the thinning and cleaning materials applied in the controlled web coating/printing operation(s) during the compliance period, kg, using Equation 1B of this section:

Where:

BI = Total mass of organic HAP in the thinning and cleaning materials applied in the controlled web coating/printing operation(s) during the compliance period, kg.

Mt,j = Total mass of thinning or cleaning material, j, applied during the compliance period, kg.

Wt,j = Mass fraction of organic HAP in thinning or cleaning material, j, kg per kg.

n = Number of different thinning and cleaning materials applied during the compliance period.

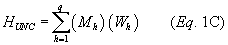

(iii) Calculate the mass of organic HAP in the coating, printing, thinning, and cleaning materials applied in the controlled web coating/printing operation during deviations specified in §63.4342(c) and (d), using Equation 1C of this section.

Where:

HUNC = Total mass of organic HAP in the coating, printing, thinning, and cleaning materials applied during all deviations specified in §63.4342 (c) and (d) that occurred during the compliance period in the controlled web coating/printing operation, kg.

Mh = Total mass of coating, printing, thinning, or cleaning material, h, applied in the controlled web coating/printing operation during deviations, kg.

Wh = Mass fraction of organic HAP in coating, printing, thinning, or cleaning material, h, kg organic HAP per kg material.

q = Number of different coating, printing, thinning, and cleaning materials applied and used.

(5) Calculate the organic HAP emissions reductions for controlled web coating/printing operation using liquid-liquid material balances. For each controlled web coating/printing operation using a solvent recovery system for which you conduct liquid-liquid material balances, calculate the organic HAP emissions reductions by applying the volatile organic matter collection and recovery efficiency to the mass of organic HAP contained in the coating, printing, thinning, and cleaning materials applied in the web coating/printing operation controlled by the solvent recovery system during the compliance period. Perform a liquid-liquid material balance for the compliance period as specified in paragraphs (e)(5)(i) through (v) of this section. Calculate the mass of organic HAP emissions reductions by the solvent recovery system as specified in paragraph (e)(5)(vi) of this section.

(i) For each solvent recovery system, install, calibrate, maintain, and operate according to the manufacturer's specifications, a device that indicates the cumulative amount of volatile organic matter recovered by the solvent recovery system for the compliance period. The device must be initially certified by the manufacturer to be accurate to within ±2.0 percent of the mass of volatile organic matter recovered.

(ii) For each solvent recovery system, determine the mass of volatile organic matter recovered for the compliance period, kg, based on measurement with the device required in paragraph (e)(5)(i) of this section.

(iii) Determine the mass fraction of volatile organic matter for each coating, printing, cleaning, and thinning material applied in the web coating/printing operation controlled by the solvent recovery system during the compliance period, kg volatile organic matter per kg coating, printing, cleaning, and thinning material. You may determine the volatile organic matter mass fraction using Method 24 in appendix A-7 of part 60, ASTM D2369-10 (R2015), “Test Method for Volatile Content of Coatings” (incorporated by reference, see§63.14), or an EPA approved alternative method. Alternatively, you may use information provided by the manufacturer or supplier of the coating or printing material. In the event of any inconsistency between information provided by the manufacturer or supplier and the results of Method 24, ASTM D2369-10 (R2015), or an approved alternative method, the test method results will govern.

(iv) Measure the mass of each coating, printing, thinning, and cleaning material applied in the web coating/printing operation controlled by the solvent recovery system during the compliance period, kg.

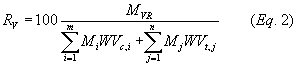

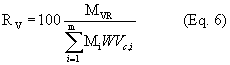

(v) For the compliance period, calculate the solvent recovery system's volatile organic matter collection and recovery efficiency using Equation 2 of this section:

Where:

RV = Volatile organic matter collection and recovery efficiency of the solvent recovery system during the compliance period, percent.

MVR = Mass of volatile organic matter recovered by the solvent recovery system during the compliance period, kg.

Mi = Mass of coating or printing material, i, applied in the web coating/printing operation controlled by the solvent recovery system during the compliance period, kg.

WVc,i = Mass fraction of volatile organic matter for coating or printing material, i, kg volatile organic matter per kg coating or printing material.

Mj = Mass of thinning or cleaning material, j, applied in the web coating/printing operation controlled by the solvent recovery system during the compliance period, kg.

WVt,j = Mass fraction of volatile organic matter for thinning or cleaning material, j, kg volatile organic matter per kg thinning or cleaning material.

m = Number of different coating and printing materials applied in the web coating/printing operation controlled by the solvent recovery system during the compliance period.

n = Number of different thinning and cleaning materials applied in the web coating/printing operation controlled by the solvent recovery system during the compliance period.

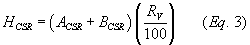

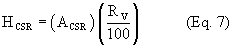

(vi) Calculate the mass of organic HAP emission reductions for the web coating/printing operation controlled by the solvent recovery system during the compliance period using Equation 3 of this section and according to paragraphs (e)(5)(vi)(A) and (B) of this section:

Where:

HCSR = Mass of organic HAP emission reduction for the web coating/printing operation controlled by the solvent recovery system during the compliance period, kg.

ACSR = Total mass of organic HAP in the coating and printing material applied in the web coating/printing operation controlled by the solvent recovery system during the compliance period, kg, calculated using Equation 3A of this section.

BCSR = Total mass of organic HAP in the thinning and cleaning materials applied in the web coating/printing operation controlled by the solvent recovery system during the compliance period, kg, calculated using Equation 3B of this section.

RV = Volatile organic matter collection and recovery efficiency of the solvent recovery system, percent, from Equation 2 of this section.

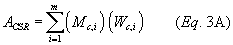

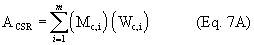

(A) Calculate the total mass of organic HAP in the coating and printing materials applied in the web coating/printing operation(s) controlled by the solvent recovery system during the compliance period, kg, using Equation 3A of this section:

Where:

ACSR = Total mass of organic HAP in the coating and printing materials applied in the web coating/printing operations(s) controlled by the solvent recovery system during the compliance period, kg.

Mc,i = Mass of coating or printing material, i, applied during the compliance period in the web coating/printing operation(s) controlled by the solvent recovery system, kg.

Wc,i = Mass fraction of organic HAP in coating or printing material, i, kg per kg.

m = Number of different coating and printing materials applied during compliance period.

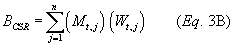

(B) Calculate the total mass of organic HAP in the thinning and cleaning materials applied in the web coating/printing operation(s) controlled by the solvent recovery system during the compliance period, kg, using Equation 3B of this section:

Where:

BCSR = Total mass of organic HAP in the thinning and cleaning materials applied in the web coating/printing operation(s) controlled by the solvent recovery system during the compliance period, kg.

Mt,j = Total mass of thinning or cleaning material, j, applied during the compliance period in the web coating/printing operation(s) controlled by the solvent recovery system, kg.

Wt,j = Mass fraction of organic HAP in thinning or cleaning material, j, kg per kg.

n = Number of different thinning and cleaning materials applied during the compliance period.

(6) Calculate the total mass of coating and printing solids. Determine the total mass of coating and printing solids applied, kg, which is the combined mass of the solids contained in all the coating and printing material applied during the compliance period in the web coating/printing operation(s) for which you use the emission rate with add-on controls option, using Equation 2 of §63.4331.

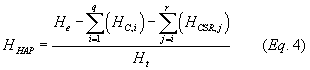

(7) Calculate the organic HAP emission rate with add-on controls for the compliance period. Determine the organic HAP emission rate with add-on controls for the compliance period, kg organic HAP emitted per kg solids applied during the compliance period, using Equation 4 of this section.

Where:

HHAP = Organic HAP emission rate with add-on controls for the compliance period, kg organic HAP emitted per kg solids applied.

He = Total mass of organic HAP emissions before add-on controls from all the coating, printing, thinning, and cleaning materials applied during the compliance period, kg, determined according to paragraph (e)(2) of this section.

HC,i = Total mass of organic HAP emissions reduction for controlled web coating/printing operation, i, not using a liquid-liquid material balance, during the compliance period, kg, from Equation 1 of this section.

HCSR,j = Total mass of organic HAP emissions reduction for web coating/printing operation, j, controlled by a solvent recovery system using a liquid-liquid material balance, during the compliance period, kg, from Equation 3 of this section.

Ht = Total mass of coating and printing solids applied during the compliance period, kg, from Equation 2 of §63.4331.

q = Number of controlled web coating/printing operations not using a liquid-liquid material balance.

r = Number of web coating/printing operations controlled by a solvent recovery system using a liquid-liquid material balance.

(8) Compliance demonstration. To demonstrate initial compliance with the emission limit, the organic HAP emission rate with add-on controls for the compliance period, calculated using Equation 4 of this section, must be less than or equal to the applicable emission limit in Table 1 to this subpart. You must keep all records as required by §§63.4312 and 63.4313. As part of the Notification of Compliance Status required by §63.4310, you must identify the web coating/printing operation(s) for which you used the emission rate with add-on controls option and submit a statement that the web coating/printing operation(s) was (were) in compliance with the emission limitations during the initial compliance period because the organic HAP emission rate was less than or equal to the applicable emission limit in Table 1 to this subpart, and that you achieved the operating limits required by §63.4292 and the work practice standards required by §63.4293.

(f) Compliance with dyeing/finishing emission limits. You must follow the procedures in paragraphs (f)(1) through (8) of this section to demonstrate compliance with the applicable dyeing/finishing emission limit in Table 1 to this subpart.

(1) Determine the mass fraction of organic HAP and mass of materials. Follow the procedures specified in §63.4331(b)(1) and (2) to determine the mass fraction of organic HAP for each dyeing and finishing material applied and mass of each dyeing and finishing material applied during the compliance period.

(2) Calculate the mass of organic HAP emissions before add-on controls. Using Equation 4 of §63.4331, calculate the mass of organic HAP emissions before add-on controls from all dyeing and finishing materials applied during the compliance period minus the organic HAP in certain waste materials and wastewaters in the dyeing/finishing operation or group of dyeing/finishing operations for which you use the emission rate with add-on controls option.

(3) Calculate the organic HAP emissions reductions for each controlled dyeing/finishing operation. Determine the mass of organic HAP emissions reduced for each controlled dyeing/finishing operation during the compliance period. The emissions reductions determination quantifies the total organic HAP emissions that pass through the emission capture system and are destroyed or removed by the add-on control device. Use the procedures in paragraph (f)(4) of this section to calculate the mass of organic HAP emissions reductions for each controlled dyeing/finishing operation using an emission capture system and add-on control device other than a solvent recovery system for which you conduct liquid-liquid material balances. For each controlled dyeing/finishing operation using a solvent recovery system for which you conduct a liquid-liquid material balance, use the procedures in paragraph (f)(5) of this section to calculate the organic HAP emissions reductions.

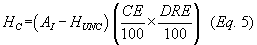

(4) Calculate the organic HAP emission reduction for each controlled dyeing/finishing operation not using liquid-liquid material balance. For each controlled dyeing/finishing operation using an emission capture system and add-on control device other than a solvent recovery system for which you conduct liquid-liquid material balances, calculate the organic HAP emissions reductions using Equation 5 of this section. The equation applies the emission capture system efficiency and add-on control device efficiency to the mass of organic HAP contained in the dyeing and finishing materials applied in the dyeing/finishing operation served by the emission capture system and add-on control device during the compliance period. For any period of time a deviation specified in §63.4342(c) or (d) occurs in the controlled dyeing/finishing operation, then you must assume zero efficiency for the emission capture system and add-on control device. Equation 5 of this section treats the dyeing and finishing materials applied during such a deviation as if they were applied on an uncontrolled dyeing/finishing operation for the time period of the deviation.

Where:

HC = Mass of organic HAP emission reduction for the controlled dyeing/finishing operation during the compliance period, kg.

AI = Total mass of organic HAP in the dyeing and finishing materials applied in the controlled dyeing/finishing operation during the compliance period, kg, as calculated in Equation 5A of this section.

HUNC = Total mass of organic HAP in the dyeing and finishing materials applied during all deviations specified in §63.4342(c) and (d) that occurred during the compliance period in the controlled dyeing/finishing operation, kg, as calculated in Equation 5B of this section.

CE = Capture efficiency of the emission capture system vented to the add-on control device, percent. Use the test methods and procedures specified in §§63.4360 and 63.4361 to measure and record capture efficiency.

DRE = Organic HAP destruction or removal efficiency of the add-on control device, percent. Use the test methods and procedures in §§63.4360 and 63.4362 to measure and record the organic HAP destruction or removal efficiency.

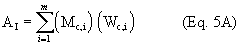

(i) Calculate the total mass of organic HAP in the dyeing and finishing materials applied in the controlled dyeing/finishing operation(s) during the compliance period, kg, using Equation 5A of this section:

Where:

AI = Total mass of organic HAP in the dyeing and finishing materials applied in the controlled dyeing/finishing operations(s) during the compliance period, kg.

Mc,i = Mass of dyeing or finishing material, i, applied during the compliance period, kg.

Wc,i = Mass fraction of organic HAP in dyeing or finishing material, i, kg per kg.

m = Number of different dyeing and finishing materials applied during compliance period.

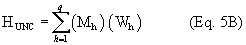

(ii) Calculate the mass of organic HAP in the dyeing and finishing materials applied in the controlled dyeing/finishing operation during deviations specified in §63.4342(c) and (d), using Equation 5B of this section.

Where:

HUNC = Total mass of organic HAP in the dyeing and finishing materials applied during all deviations specified in §63.4342(c) and (d) that occurred during the compliance period in the controlled dyeing/finishing operation, kg.

Mh = Total mass of dyeing and finishing material, h, applied in the controlled dyeing/finishing operation during deviations, kg.

Wh = Mass fraction of organic HAP in dyeing or finishing material, h, kg organic HAP per kg material.

q = Number of different dyeing and finishing materials applied.

(5) Calculate the organic HAP emissions reductions for controlled dyeing/finishing operation using liquid-liquid material balances. For each controlled dyeing/finishing operation using a solvent recovery system for which you conduct liquid-liquid material balances, calculate the organic HAP emissions reductions by applying the volatile organic matter collection and recovery efficiency to the mass of organic HAP contained in the dyeing and finishing materials applied in the dyeing/finishing operation controlled by the solvent recovery system during the compliance period. Perform a liquid-liquid material balance for the compliance period as specified in paragraphs (f)(5)(i) through (v) of this section. Calculate the mass of organic HAP emissions reductions by the solvent recovery system as specified in paragraph (f)(5)(vi) of this section.

(i) For each solvent recovery system, install, calibrate, maintain, and operate according to the manufacturer's specifications, a device that indicates the cumulative amount of volatile organic matter recovered by the solvent recovery system for the compliance period. The device must be initially certified by the manufacturer to be accurate to within ±2.0 percent of the mass of volatile organic matter recovered.

(ii) For each solvent recovery system, determine the mass of volatile organic matter recovered for the compliance period, kg, based on measurement with the device required in paragraph (f)(5)(i) of this section.

(iii) Determine the mass fraction of volatile organic matter for each dyeing and finishing material applied in the dyeing/finishing operation controlled by the solvent recovery system during the compliance period, kg volatile organic matter per kg dyeing and finishing material. You may determine the volatile organic matter mass fraction using information provided by the manufacturer or supplier of the dyeing or finishing material.

(iv) Measure the mass of each dyeing and finishing material applied in the dyeing/finishing operation controlled by the solvent recovery system during the compliance period, kg.

(v) For the compliance period, calculate the solvent recovery system's volatile organic matter collection and recovery efficiency using Equation 6 of this section:

Where:

RV = Volatile organic matter collection and recovery efficiency of the solvent recovery system during the compliance period, percent.

MVR = Mass of volatile organic matter recovered by the solvent recovery system during the compliance period, kg.

Mi = Mass of dyeing or finishing material, i, applied in the dyeing/finishing operation controlled by the solvent recovery system during the compliance period, kg.

WVc,i = Mass fraction of volatile organic matter for dyeing or finishing material, i, kg volatile organic matter per kg dyeing or finishing material.

m = Number of different dyeing and finishing materials applied in the dyeing/finishing operation controlled by the solvent recovery system during the compliance period.

(vi) Calculate the mass of organic HAP emission reductions for the dyeing/finishing operation controlled by the solvent recovery system during the compliance period using Equation 7 of this section and according to paragraph (f)(5)(vi)(A) of this section:

Where:

HCSR = Mass of organic HAP emission reduction for the dyeing/finishing operation controlled by the solvent recovery system during the compliance period, kg.

ACSR = Total mass of organic HAP in the dyeing and finishing material applied in the dyeing/finishing operation controlled by the solvent recovery system during the compliance period, kg, calculated using Equation 7A of this section.

RV = Volatile organic matter collection and recovery efficiency of the solvent recovery system, percent, from Equation 6 of this section.

(A) Calculate the total mass of organic HAP in the dyeing and finishing materials applied in the dyeing/finishing operation(s) controlled by the solvent recovery system during the compliance period, kg, using Equation 7A of this section:

Where:

ACSR = Total mass of organic HAP in the dyeing and finishing materials applied in the dyeing/finishing operations(s) controlled by the solvent recovery system during the compliance period, kg.

Mc,i = Mass of dyeing or finishing material, i, applied during the compliance period in the dyeing/finishing operation(s) controlled by the solvent recovery system, kg.

Wc,i = Mass fraction of organic HAP in dyeing or finishing material, i, kg per kg.

m = Number of different dyeing and finishing materials applied during compliance period.

(6) Calculate the total mass of dyeing and finishing materials. Determine the total mass of dyeing and finishing materials applied, kg, which is the combined mass of all the dyeing and finishing materials applied during the compliance period in the dyeing/finishing operation(s) for which you use the emission rate with add-on controls option, using Equation 5 of §63.4331.

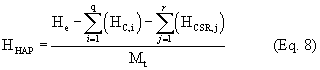

(7) Calculate the organic HAP emission rate with add-on controls for the compliance period. Determine the organic HAP emission rate with add-on controls for the compliance period, kg organic HAP emitted per kg dyeing and finishing materials applied during the compliance period, using Equation 8 of this section.

Where:

HHAP = Organic HAP emission rate with add-on controls for the compliance period, kg organic HAP emitted per kg dyeing and finishing materials applied.

He = Total mass of organic HAP emissions before add-on controls from all the dyeing and finishing materials applied during the compliance period, kg, determined according to paragraph (f)(2) of this section.

HC,i = Total mass of organic HAP emissions reductions for controlled dyeing/finishing operation, i, not using a liquid-liquid material balance, during the compliance period, kg, from Equation 5 of this section.

HCSR,j = Total mass of organic HAP emissions reductions for dyeing/finishing operation, j, controlled by a solvent recovery system using a liquid-liquid material balance, during the compliance period, kg, from Equation 7 of this section.

Mt = Total mass of dyeing and finishing materials applied during the compliance period, kg, from Equation 5 of §63.4331.

q = Number of controlled dyeing/finishing operations not using a liquid-liquid material balance.

r = Number of dyeing/finishing operations controlled by a solvent recovery system using a liquid-liquid material balance.

(8) Compliance demonstration. To demonstrate initial compliance with the emission limit, the organic HAP emission rate with add-on controls for the compliance period, calculated using Equation 8 of this section, must be less than or equal to the applicable emission limit in Table 1 to this subpart. You must keep all records as required by §§63.4312 and 63.4313. As part of the Notification of Compliance Status required by §63.4310, you must identify the dyeing/finishing operation(s) for which you used the emission rate with add-on controls option and submit a statement that the dyeing/finishing operation(s) was (were) in compliance with the emission limitations during the initial compliance period because the organic HAP emission rate was less than or equal to the applicable emission limit in Table 1 to this subpart, and that you achieved the operating limits required by §63.4292 and the work practice standards required by §63.4293.

[68 FR 32189, May 29, 2003, as amended at 84 FR 9627, Mar. 15, 2019]

(a) To demonstrate continuous compliance with the applicable emission limit in Table 1 to this subpart, the organic HAP emission rate for each compliance period, determined according to §63.4341(e) for web coating/printing operations and according to §63.4341(f) for dyeing/finishing operations, must be equal to or less than the applicable emission limit in Table 1 to this subpart. Each month following the initial compliance period described in §63.4340 is a compliance period consisting of that month and the preceding 11 months. You must perform the calculations in §63.4341 on a monthly basis.

(b) If the organic HAP emission rate with add-on controls for any compliance period exceeded the applicable emission limit in Table 1 to this subpart, this is a deviation from the emission limitation for that compliance period and must be reported as specified in §§63.4310(c)(6) and 63.4311(a)(7).

(c) You must demonstrate continuous compliance with each operating limit required by §63.4292 that applies to you, as specified in Table 2 to this subpart, and you must conduct periodic performance tests as specified in paragraph (c)(3) of this section.

(1) If an operating parameter is out of the allowed range specified in Table 2 to this subpart, this is a deviation from the operating limit that must be reported as specified in §§63.4310(c)(6) and 63.4311(a)(7).

(2) If an operating parameter deviates from the operating limit specified in Table 2 to this subpart, then you must assume that the emission capture system and add-on control device were achieving zero efficiency during the time period of the deviation. For the purposes of completing the compliance calculations specified in §63.4341 (e)(4) and (f)(4), you must treat the regulated materials applied during a deviation on a controlled coating/printing or dyeing/finishing operation as if they were applied on an uncontrolled coating/printing or dyeing/finishing operation for the time period of the deviation, as indicated in Equation 1 of §63.4341 for a web coating/printing operation, and in Equation 5 of §63.4341 for a dyeing/finishing operation.

(3) Except for solvent recovery systems for which you conduct liquid-liquid material balances according to §63.4351(d)(5), within 5 years following the previous performance test, you must conduct according to the procedures in §§63.4360, 63.4361, and 63.4362 a periodic performance test of each capture system and add-on control device used, and you must establish the operating limits required by §63.4292. You must conduct the first periodic performance test and establish the operating limits required by §63.4292 before March 15, 2022, unless you are already required to complete periodic performance tests as a requirement of renewing your facility's operating permit under 40 CFR part 70 or 40 CFR part 71 and have conducted a performance test on or after March 15, 2017. Thereafter you must conduct a performance test no later than 5 years following the previous performance test. Operating limits must be confirmed or reestablished during each performance test.

(d) You must meet the requirements for bypass lines in §63.4364(b) for controlled coating/printing or dyeing/finishing operations for which you do not conduct liquid-liquid material balances. If any bypass line is opened and emissions are diverted to the atmosphere when the web coating/printing or dyeing/finishing operation is running, this is a deviation that must be reported as specified in §§63.4310(c)(6) and 63.4311(a)(7). For the purposes of completing the compliance calculations specified in §63.4341(e)(4), you must treat the coating, printing, thinning, and cleaning materials applied during a deviation on a controlled web coating/printing operation as if they were used on an uncontrolled web coating/printing operation for the time period of the deviation, as indicated in Equation 1 of §63.4341. For the purposes of completing the compliance calculations specified in §63.4341(f)(4), you must treat the dyeing and finishing materials applied during a deviation on a controlled dyeing/finishing operation as if they were used on an uncontrolled dyeing/finishing operation for the time period of the deviation, as indicated in Equation 5 of §63.4341.

(e) You must demonstrate continuous compliance with the work practice standards in §63.4293. If you did not develop a work practice plan, or you did not implement the plan, or you did not keep the records required by §63.4312(j)(8), this is a deviation from the work practice standards that must be reported as specified in §§63.4310(c)(6) and 63.4311(a)(7).

(f) As part of each semiannual compliance report required in §63.4311, you must identify the coating/printing and dyeing/finishing operation(s) for which you use the emission rate with add-on controls option. If there were no deviations from the applicable emission limitations in §§63.4290, 63.4292, and 63.4293, you must submit a statement that, as appropriate, the web coating/printing operations or the dyeing/finishing operations were in compliance with the emission limitations during the reporting period because the organic HAP emission rate for each compliance period was less than or equal to the applicable emission limit in Table 1 to this subpart, and you achieved the operating limits required by §63.4292 and the work practice standards required by §63.4293 during each compliance period.

(g) [Reserved]

(h) Before September 12, 2019, consistent with §§63.6(e) and 63.7(e)(1), deviations that occur during a period of startup, shutdown, or malfunction of the emission capture system, add-on control device, or web coating/printing or dyeing/finishing operation that may affect emission capture or control device efficiency are not violations if you demonstrate to the Administrator's satisfaction that you were operating in accordance with §63.6(e)(1). The Administrator will determine whether deviations that occur during a period of startup, shutdown, or malfunction are violations according to the provisions in §63.6(e). On and after September 12, 2019, as specified in §63.4300(b), at all times, the owner or operator must operate and maintain any affected source, including associated air pollution control equipment and monitoring equipment, in a manner consistent with safety and good air pollution control practices for minimizing emissions, and determination of whether a source is operating in compliance with operation and maintenance requirements will be based on information available to the Administrator.

(i) [Reserved]

(j) You must maintain records as specified in §§63.4312 and 63.4313.

[68 FR 32189, May 29, 2003, as amended at 71 FR 20465, Apr. 20, 2006; 84 FR 9628, Mar. 15, 2019]