...

Except for drying and curing ovens subject to a federally enforceable permit that requires the exclusive use of non-HAP binders, you must conduct a performance test for each drying and curing oven subject to this subpart according to the provisions in paragraphs (a) through (c) of this section:

(a) Initially. You must conduct a performance test to demonstrate initial compliance and to establish operating parameter limits and ranges to be used to demonstrate continuous compliance with the emission standards no later than 180 days after the applicable compliance date specified in §63.2985.

(b) Every 5 years. You must conduct a performance test every 5 years as part of renewing your 40 CFR part 70 operating permit.

(c) To change your OMM plan. You must conduct a performance test according to the requirements specified in §63.2992 to change the limit or range for any operating limit specified in your OMM plan established during a previous compliance test.

[67 FR 17835, Apr. 11, 2002, as amended at 84 FR 6693, Feb. 28, 2019]

(a) You must verify the performance of monitoring equipment as specified in §63.2994 before performing the test.

(b) You must conduct the performance test according to the requirements in §63.7(a) through (d), (e)(2) through (4), and (f) through (h).

(c) You must conduct the performance test under the conditions specified in paragraphs (c)(1) and (2) of this section.

(1) The resin must have the highest specified free-formaldehyde content that will be used.

(2) You must operate at the maximum feasible urea-formaldehyde resin solids application rate (pounds urea-formaldehyde resin solids applied per hour) that will be used.

(d) During the performance test, you must monitor and record the operating parameters that you will use to demonstrate continuous compliance after the test. These parameters are listed in Table 1 to this subpart.

(e) You must conduct performance tests under conditions that are representative of the performance of the affected source. Representative conditions exclude periods of startup and shutdown. You may not conduct performance tests during periods of malfunction. You must record the process information that is necessary to document operating conditions during the test and record an explanation to support that such conditions represent normal operation. Upon request, you must make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

(f) You must conduct three separate test runs for each performance test as specified in §63.7(e)(3), and each test run must last at least 1 hour.

[67 FR 17835, Apr. 11, 2002, as amended at 84 FR 6693, Feb. 28, 2019]

(a) Use EPA Method 1 (40 CFR part 60, appendix A-1) for selecting the sampling port location and the number of sampling ports.

(b) Use EPA Method 2 (40 CFR part 60, appendix A-1) for measuring the volumetric flow rate of the stack gas.

(c) Use EPA Method 3 or 3A (40 CFR part 60, appendix A-2) for measuring oxygen and carbon dioxide concentrations needed to correct formaldehyde concentration measurements to a standard basis.

(d) Use EPA Method 4 (40 CFR part 60, appendix A-3) for measuring the moisture content of the stack gas.

(e) Use EPA Method 316, 318, or 320 (40 CFR part 63, appendix A) for measuring the concentration of formaldehyde.

(f) Use the method contained in appendix A to this subpart or the resin purchase specification and the vendor specification sheet for each resin lot for determining the free-formaldehyde content in the urea-formaldehyde resin.

(g) Use the method in appendix B to this subpart for determining product loss-on-ignition.

[84 FR 6694, Feb. 28, 2019]

(a) Before conducting the performance test, you must take the steps listed in paragraphs (a)(1) through (3) of this section:

(1) Install and calibrate all process equipment, control devices, and monitoring equipment.

(2) Develop and implement a continuous parameter monitoring system (CPMS) quality control program that includes written procedures for CPMS according to §63.8(d)(1) and (2). You must keep these written procedures on record for the life of the affected source or until the affected source is no longer subject to the provisions of this subpart, to be made available for inspection, upon request, by the Administrator. If you revise the performance evaluation plan, you must keep previous (i.e., superseded) versions of the performance evaluation plan on record to be made available for inspection, upon request, by the Administrator, for a period of 5 years after each revision to the plan. You should include the program of corrective action in the plan required under §63.8(d)(2).

(3) Conduct a performance evaluation of the CPMS according to §63.8(e) which specifies the general requirements and requirements for notifications, the site-specific performance evaluation plan, conduct of the performance evaluation, and reporting of performance evaluation results.

(b) If you use a thermal oxidizer, the temperature monitoring device must meet the performance and equipment specifications listed in paragraphs (b)(1) through (3) of this section:

(1) The temperature monitoring device must be installed either at the exit of the combustion zone of each thermal oxidizer, or at the location specified by the manufacturer. The temperature monitoring device must also be installed in a location before any heat recovery or heat exchange equipment, and it must remain in the same location for both the performance test and the continuous monitoring of temperature.

(2) The recorder response range must include zero and 1.5 times the average temperature required in §63.2984(a)(1).

(3) The measurement method or reference method for calibration must be a National Institute of Standards and Technology calibrated reference thermocouple-potentiometer system or an alternate reference subject to the approval of the Administrator.

[67 FR 17835, Apr. 11, 2002, as amended at 84 FR 6694, Feb. 28, 2019]

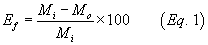

(a) Percent reduction for formaldehyde. To determine compliance with the percent reduction formaldehyde emission standard, use equation 1 of this section as follows:

Where:

Ef = Formaldehyde control efficiency, percent.

Mi = Mass flow rate of formaldehyde entering the control device, kilograms (pounds) per hour.

Mo = Mass flow rate of formaldehyde exiting the control device, kilograms (pounds) per hour.

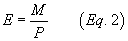

(b) Formaldehyde mass emissions rate. To determine compliance with the kilogram per megagram (pound per ton) formaldehyde emission standard, use equation 2 of this section as follows:

Where:

E = Formaldehyde mass emissions rate, kilograms (pounds) of formaldehyde per megagram (ton) of fiberglass mat produced.

M = Formaldehyde mass emissions rate, kilograms (pounds) per hour.

P = The wet-formed fiberglass mat production rate during the emissions sampling period, including any material trimmed from the final product, megagrams (tons) per hour.

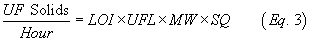

(c) Urea-formaldehyde (UF) resin solids application rate. To determine the UF resin solids application rate, use equation 3 of this section as follows:

Where:

UF solids/hour = UF resin solids application rate (pounds per hour).

LOI = loss on ignition (weight faction), or pound of organic binder per pound of mat.

UFL = UF-to-latex ratio in the binder (mass fraction of UF resin solids in total combined resin solids for UF and latex), or pound of UF solids per pound of total resin solids (UF and latex).

MW = weight of the final mat per square (pounds per roofing square).

SQ = roofing squares produced per hour.