...

(a) Before July 9, 2021, for each existing source for which construction or reconstruction commenced on or before September 19, 2019, you must be in compliance with the emission limits and operating limits in this subpart at all times, except during periods of SSM. On and after July 9, 2021, for each such source you must be in compliance with the emission limits and operating limits in this subpart at all times. For new and reconstructed sources for which construction or reconstruction commenced after September 19, 2019, you must be in compliance with the emission limits and operating limits in this subpart at all times, starting July 9, 2020, or immediately upon startup, whichever is later.

(b) For affected sources as of September 19, 2019, before July 9, 2021, you must always operate and maintain your affected source, including all air pollution control and monitoring equipment you use for purposes of complying with this subpart, according to the provisions in §63.6(e)(1)(i). On and after July 9, 2021, for such sources and on July 9, 2020, or immediately upon startup, whichever is later, for new or reconstructed affected sources, you must always operate and maintain your affected source, including associated air pollution control equipment and monitoring equipment, in a manner consistent with safety and good air pollution control practices for minimizing emissions. The general duty to minimize emissions does not require the owner or operator to make any further efforts to reduce emissions if levels required by the applicable standard have been achieved. Determination of whether a source is operating in compliance with operation and maintenance requirements will be based on information available to the Administrator which may include, but is not limited to, monitoring results, review of operation and maintenance procedures, review of operation and maintenance records, and inspection of the source.

(c) You must conduct each performance test required by §63.3360 according to the requirements in §63.3360(e)(2) and under the conditions in this section unless you obtain a waiver of the performance test according to the provisions in §63.7(h).

(1) Representative coating operation operating conditions. You must conduct the performance test under representative operating conditions for the coating operation. Operations during periods of startup, shutdown, and nonoperation do not constitute representative conditions. You may not conduct performance tests during periods of malfunction. You must record the process information that is necessary to document operating conditions during the test and explain why the conditions represent normal operation. Upon request, you shall make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

(2) Representative emission capture system and add-on control device operating conditions. You must conduct the performance test when the emission capture system and add-on control device are operating at a representative flow rate, and the add-on control device is operating at a representative inlet concentration. Representative conditions exclude periods of startup and shutdown. You may not conduct performance tests during periods of malfunction. You must record information that is necessary to document emission capture system and add-on control device operating conditions during the test and explain why the conditions represent normal operation.

(d) Table 2 to this subpart specifies the provisions of subpart A of this part that apply if you are subject to subpart JJJJ.

[85 FR 41296, July 9, 2020]

(a) A summary of monitoring you must do follows:

| If you operate a web coating line, and have the following: | Then you must: |

|---|---|

| (1) Intermittently-controlled work stations | Record parameters related to possible exhaust flow bypass of control device and to coating use (§63.3350(c)). |

| (2) Solvent recovery unit | Operate continuous emission monitoring system and perform quarterly audits or determine volatile matter recovered and conduct a liquid-liquid material balance (§63.3350(d)). |

| (3) Control Device | Operate continuous parameter monitoring system (§63.3350(e)). |

| (4) Capture system | Monitor capture system operating parameter (§63.3350(f)). |

(b) Following the date on which the initial or periodic performance test of a control device is completed to demonstrate continuing compliance with the standards, you must monitor and inspect each capture system and each control device used to comply with §63.3320. You must install and operate the monitoring equipment as specified in paragraphs (c) and (f) of this section.

(c) Bypass and coating use monitoring. If you own or operate web coating lines with intermittently-controlled work stations, you must monitor bypasses of the control device and the mass of each coating material applied at the work station during any such bypass. If using a control device for complying with the requirements of this subpart, you must demonstrate that any coating material applied on a never-controlled work station or an intermittently-controlled work station operated in bypass mode is allowed in your compliance demonstration according to §63.3370(o) and (p). The bypass monitoring must be conducted using at least one of the procedures in paragraphs (c)(1) through (4) of this section for each work station and associated dryer.

(1) Flow control position indicator. Install, calibrate, maintain, and operate according to the manufacturer's specifications a flow control position indicator that provides a record indicating whether the exhaust stream from the dryer was directed to the control device or was diverted from the control device. The time and flow control position must be recorded at least once per hour as well as every time the flow direction is changed. A flow control position indicator must be installed at the entrance to any bypass line that could divert the exhaust stream away from the control device to the atmosphere.

(2) Car-seal or lock-and-key valve closures. Secure any bypass line valve in the closed position with a car-seal or a lock-and-key type configuration. A visual inspection of the seal or closure mechanism must be performed at least once every month to ensure that the valve or damper is maintained in the closed position, and the exhaust stream is not diverted through the bypass line.

(3) Valve closure continuous monitoring. Ensure that any bypass line valve or damper is in the closed position through continuous monitoring of valve position when the emission source is in operation and is using a control device for compliance with the requirements of this subpart. The monitoring system must be inspected at least once every month to verify that the monitor will indicate valve position.

(4) Automatic shutdown system. Use an automatic shutdown system in which the web coating line is stopped when flow is diverted away from the control device to any bypass line when the control device is in operation. The automatic system must be inspected at least once every month to verify that it will detect diversions of flow and would shut down operations in the event of such a diversion.

(d) Solvent recovery unit. If you own or operate a solvent recovery unit to comply with §63.3320, you must meet the requirements in either paragraph (d)(1) or (2) of this section depending on how control efficiency is determined.

(1) Continuous emission monitoring system (CEMS). If you are demonstrating compliance with the emission standards in §63.3320 through continuous emission monitoring of a control device, you must install, calibrate, operate, and maintain the CEMS according to paragraphs (d)(1)(i) through (iii) of this section.

(i) Measure the total organic volatile matter mass flow rate at both the control device inlet and the outlet such that the reduction efficiency can be determined. Each continuous emission monitor must comply with performance specification 6, 8, or 9 of 40 CFR part 60, appendix B, as appropriate.

(ii) You must follow the quality assurance procedures in procedure 1, appendix F of 40 CFR part 60. In conducting the quarterly audits of the monitors as required by procedure 1, appendix F, you must use compounds representative of the gaseous emission stream being controlled.

(iii) You must have valid data from at least 90 percent of the hours during which the process is operated.

(2) Liquid-liquid material balance. If you are demonstrating compliance with the emission standards in §63.3320 through liquid-liquid material balance, you must install, calibrate, maintain, and operate according to the manufacturer's specifications a device that indicates the cumulative amount of volatile matter recovered by the solvent recovery device on a monthly basis. The device must be certified by the manufacturer to be accurate to within ±2.0 percent by mass.

(e) Continuous parameter monitoring system (CPMS). If you are using a control device to comply with the emission standards in §63.3320, you must install, operate, and maintain each CPMS specified in paragraphs (e)(10) and (11) and (f) of this section according to the requirements in paragraphs (e)(1) through (9) of this section. You must install, operate, and maintain each CPMS specified in paragraph (c) of this section according to paragraphs (e)(5) through (8) of this section.

(1) Each CPMS must complete a minimum of one cycle of operation for each successive 15-minute period. You must have a minimum of four equally spaced successive cycles of CPMS operation to have a valid hour of data.

(2) You must have valid data from at least 90 percent of the hours when the process operated.

(3) You must determine the hourly average of all recorded readings according to paragraphs (e)(3)(i) and (ii) of this section.

(i) To calculate a valid hourly value, you must have at least three of four equally spaced data values from that hour from a continuous monitoring system (CMS) that is not out-of-control.

(ii) Provided all of the readings recorded in accordance with paragraph (e)(3) of this section clearly demonstrate continuous compliance with the standard that applies to you, then you are not required to determine the hourly average of all recorded readings.

(4) You must determine the block 3-hour average of all recorded readings for each operating period. To calculate the average for each 3-hour averaging period, you must have at least two of three of the hourly averages for that period using only average values that are based on valid data (i.e., not from out-of-control periods).

(5) Except for temperature sensors, you must develop a quality control program that must contain, at a minimum, a written protocol that describes the procedures for each of the operations in §63.3350(e)(5)(i) through (vi). The owner or operator shall keep these written procedures on record for the life of the affected source or until the affected source is no longer subject to the provisions of this part, to be made available for inspection, upon request, by the Administrator. If the performance evaluation plan is revised, the owner or operator shall keep previous (i.e., superseded) versions of the performance evaluation plan on record to be made available for inspection, upon request, by the Administrator, for a period of 5 years after each revision to the plan. For temperature sensors, you must follow the requirements in §63.3350(e)(10).

(i) Initial and any subsequent calibration of the continuous monitoring system (CMS);

(ii) Determination and adjustment of the calibration drift of the CMS;

(iii) Preventative maintenance of the CMS, including spare parts inventory;

(iv) Data recording, calculations, and reporting;

(v) Accuracy audit procedures, including sampling and analysis methods; and

(vi) Program of corrective action for a malfunctioning CMS.

(6) You must record the results of each inspection, calibration, and validation check of the CPMS.

(7) At all times, you must maintain the monitoring system in proper working order including, but not limited to, maintaining necessary parts for routine repairs of the monitoring equipment.

(8) Except for monitoring malfunctions, associated repairs, or required quality assurance or control activities (including calibration checks or required zero and span adjustments), you must conduct all monitoring at all times that the unit is operating. Data recorded during monitoring malfunctions, associated repairs, out-of-control periods, or required quality assurance or control activities shall not be used for purposes of calculating the emissions concentrations and percent reductions specified in §63.3370. You must use all the valid data collected during all other periods in assessing compliance of the control device and associated control system. A monitoring malfunction is any sudden, infrequent, not reasonably preventable failure of the monitoring system to provide valid data. Monitoring failures that are caused in part by poor maintenance or careless operation are not malfunctions.

(9) Any averaging period for which you do not have valid monitoring data and such data are required constitutes a deviation, and you must notify the Administrator in accordance with §63.3400(c).

(10) Oxidizer. If you are using an oxidizer to comply with the emission standards of this subpart, you must comply with paragraphs (e)(10)(i) through (vi) of this section.

(i) Install, maintain, and operate temperature monitoring equipment according to the manufacturer's specifications.

(ii) For an oxidizer other than a catalytic oxidizer, install, operate, and maintain a temperature monitoring device equipped with a continuous recorder. The device must be capable of monitoring temperature with an accuracy of ±1 percent of the temperature being monitored in degrees Fahrenheit or ±1.8 degrees Fahrenheit, whichever is greater. The temperature sensor must be installed in the combustion chamber at a location in the combustion zone.

(iii) For a catalytic oxidizer, install, operate, and maintain a temperature monitoring device equipped with a continuous recorder. The device must be capable of monitoring temperature with an accuracy of ±1 percent of the temperature being monitored in degrees Fahrenheit or ±1.8 degrees Fahrenheit, whichever is greater. The temperature sensor must be installed in the vent stream at the nearest feasible point to the inlet and outlet of the catalyst bed. Calculate the temperature rise across the catalyst.

(iv) For temperature sensors, you must develop a quality control program that must contain, at a minimum, a written protocol that describes the procedures for verifying that the temperature sensor is operating properly using at least one of the methods in paragraph (e)(10)(iv)(A), (B), (C), (D), (E), or (F) of this section. The owner or operator shall keep these written procedures on record for the life of the affected source or until the affected source is no longer subject to the provisions of this part, to be made available for inspection, upon request, by the Administrator:

(A) Semiannually, compare measured readings to a National Institute of Standards and Technology (NIST) traceable temperature measurement device or simulate a typical operating temperature using a NIST traceable temperature simulation device. When the temperature measurement device method is used, the sensor of the calibrated device must be placed as close as practicable to the process sensor, and both devices must be subjected to the same environmental conditions. The accuracy of the temperature measured must be 2.5 percent of the temperature measured by the NIST traceable device or 5 degrees Fahrenheit whichever is greater.

(B) Annually validate the temperature sensor by following applicable mechanical and electrical validation procedures in the manufacturer owner's manual.

(C) Annually request the temperature sensor manufacturer to certify or re-certify electromotive force (electrical properties) of the thermocouple.

(D) Annually replace the temperature sensor with a new certified temperature sensor in lieu of validation.

(E) Permanently install a redundant temperature sensor as close as practicable to the process temperature sensor. The sensors must yield a reading within 2.5 percent of each other for thermal oxidizers and catalytic oxidizers.

(F) Permanently install a temperature sensor with dual sensors to account for the possibility of failure.

(v) Conduct the validation checks in paragraph (e)(10)(iv)(A), (B), or (C) of this section any time the temperature sensor exceeds the manufacturer's specified maximum operating temperature range or install a new temperature sensor.

(vi) At least quarterly, inspect temperature sensor components for proper connection and integrity or continuously operate an electronic monitoring system designed to notify personnel if the signal from the temperature sensor is interrupted.

(11) Other types of control devices. If you use a control device other than an oxidizer or wish to monitor an alternative parameter and comply with a different operating limit, you must apply to the Administrator for approval of an alternative monitoring method under §63.8(f).

(f) Capture system monitoring. If you are complying with the emission standards in §63.3320 through the use of a capture system and control device for one or more web coating lines, you must develop a site-specific monitoring plan containing the information specified in paragraphs (f)(1) and (2) of this section for these capture systems. You must monitor the capture system in accordance with paragraph (f)(3) of this section. You must make the monitoring plan available for inspection by the permitting authority upon request.

(1) The monitoring plan must:

(i) Identify the operating parameter to be monitored to ensure that the capture efficiency determined during the initial compliance test is maintained; and

(ii) Explain why this parameter is appropriate for demonstrating ongoing compliance; and

(iii) Identify the specific monitoring procedures.

(2) The monitoring plan must specify the operating parameter value or range of values that demonstrate compliance with the emission standards in §63.3320. The specified operating parameter value or range of values must represent the conditions present when the capture system is being properly operated and maintained.

(3) You must conduct all capture system monitoring in accordance with the plan.

(4) Any deviation from the operating parameter value or range of values which are monitored according to the plan will be considered a deviation from the operating limit.

(5) You must review and update the capture system monitoring plan at least annually.

[85 FR 41297, July 9, 2020]

(a) The performance test methods you must conduct are as follows:

| If you control organic HAP on any individual web coating line or any group of web coating lines to demonstrate compliance with the emission limits in §63.3320 by: | You must: |

|---|---|

| (1) Limiting organic HAP or volatile matter content of coatings | Determine the organic HAP or volatile matter and coating solids content of coating materials according to procedures in paragraphs (c) and (d) of this section. If applicable, determine the mass of volatile matter retained in the coated web or otherwise not emitted to the atmosphere according to paragraph (g) of this section. |

| (2) Using a capture and control system | (i) Initially, conduct a performance test for each capture and control system to determine: The destruction or removal efficiency of each control device other than solvent recovery according to §63.3360(e), and the capture efficiency of each capture system according to §63.3360(f). If applicable, determine the mass of volatile matter retained in the coated web or otherwise not emitted to the atmosphere according to §63.3360(g). |

| (ii) Perform a periodic test once every 5 years for each thermal oxidizer to determine the destruction or removal efficiency according to §63.3360(e). If applicable, determine the mass of volatile matter retained in the coated web or otherwise not emitted to the atmosphere according to §63.3360(g). | |

| (iii) Either perform a periodic test once every 5 years for each catalytic oxidizer to determine the destruction or removal efficiency according to §63.3360(e) OR perform a catalyst activity test annually on each catalytic oxidizer to ensure that the catalyst is performing properly according to §63.3360(e)(3)(ii)(D)(1). If applicable, determine the mass of volatile matter retained in the coated web or otherwise not emitted to the atmosphere according to §63.3360(g). |

(b) Control Device. If you are using a control device to comply with the emission standards in §63.3320, you are not required to conduct a performance test to demonstrate compliance if one or more of the criteria in paragraphs (b)(1) through (3) of this section are met.

(1) The control device is equipped with continuous emission monitoring systems (CEMS) for determining inlet and outlet total organic volatile matter concentration and meeting the requirements of Performance Specification 6, 8, or 9 in Appendix B to 40 CFR Part 60 and capture efficiency has been determined in accordance with the requirements of this subpart such that an overall organic HAP control efficiency can be calculated, and the CEMS are used to demonstrate continuous compliance in accordance with §63.3350; or

(2) You have met the requirements of §63.7(h) (for waiver of performance testing); or

(3) The control device is a solvent recovery system and you comply by means of a monthly liquid-liquid material balance.

(c) Organic HAP content. If you determine compliance with the emission standards in §63.3320 by means other than determining the overall organic HAP control efficiency of a control device, you must determine the organic HAP mass fraction of each coating material “as-purchased” by following one of the procedures in paragraphs (c)(1) through (3) of this section, and determine the organic HAP mass fraction of each coating material “as-applied” by following the procedures in paragraph (c)(4) of this section. If the organic HAP content values are not determined using the procedures in paragraphs (c)(1) through (3) of this section, the owner or operator must submit an alternative test method for determining their values for approval by the Administrator in accordance with §63.7(f). The recovery efficiency of the test method must be determined for all of the target organic HAP and a correction factor, if necessary, must be determined and applied.

(1) Method 311. You may test the coating material in accordance with Method 311 of appendix A of this part. The Method 311 determination may be performed by the manufacturer of the coating material and the results provided to the owner or operator. The organic HAP content must be calculated according to the criteria and procedures in paragraphs (c)(1)(i) through (iii) of this section.

(i) Include each organic HAP determined to be present at greater than or equal to 0.1 mass percent for Occupational Safety and Health Administration (OSHA)-defined carcinogens as specified in section A.6.4 of appendix A to 29 CFR 1910.1200 and greater than or equal to 1.0 mass percent for other organic HAP compounds.

(ii) Express the mass fraction of each organic HAP you include according to paragraph (c)(1)(i) of this section as a value truncated to four places after the decimal point (for example, 0.3791).

(iii) Calculate the total mass fraction of organic HAP in the tested material by summing the counted individual organic HAP mass fractions and truncating the result to three places after the decimal point (for example, 0.763).

(2) Method 24. For coatings, determine the volatile organic content as mass fraction of nonaqueous volatile matter and use it as a substitute for organic HAP using Method 24 of appendix A-7 to 40 CFR part 60. The Method 24 determination may be performed by the manufacturer of the coating and the results provided to you. One of the voluntary consensus standards in paragraphs (c)(2)(i) through (v) of this section may be used as an alternative to using Method 24.

(i) ASTM D1963-85 (Reapproved 1996), (incorporated by reference, see §63.14);

(ii) ASTM D2111-10 (Reapproved 2015), (incorporated by reference, see §63.14);

(iii) ASTM D2369-10 (Reapproved 2015)e, (incorporated by reference, see §63.14);

(iv) ASTM D2697-03 (Reapproved 2014), (incorporated by reference, see §63.14); and

(v) ASTM D6093-97 (Reapproved 2016), (incorporated by reference, see §63.14).

(3) Formulation data. You may use formulation data to determine the organic HAP mass fraction of a coating material. Formulation data may be provided to the owner or operator by the manufacturer of the material. In the event of an inconsistency between Method 311 (appendix A to this part) test data and a facility's formulation data, and the Method 311 test value is higher, the Method 311 data will govern. Formulation data may be used provided that the information represents all organic HAP present at a level equal to or greater than 0.1 percent for OSHA-defined carcinogens as specified in section A.6.4 of appendix A to 29 CFR 1910.1200 and equal to or greater than 1.0 percent for other organic HAP compounds in any raw material used.

(4) As-applied organic HAP mass fraction. If the as-purchased coating material is applied to the web without any solvent or other material added, then the as-applied organic HAP mass fraction is equal to the as-purchased organic HAP mass fraction. Otherwise, the as-applied organic HAP mass fraction must be calculated using Equation 4 of §63.3370.

(d) Volatile organic and coating solids content. If you determine compliance with the emission standards in §63.3320 by means other than determining the overall organic HAP control efficiency of a control device and you choose to use the volatile organic content as a surrogate for the organic HAP content of coatings, you must determine the as-purchased volatile organic content and coating solids content of each coating material applied by following the procedures in paragraph (d)(1) or (2) of this section, and the as-applied volatile organic content and coating solids content of each coating material by following the procedures in paragraph (d)(3) of this section.

(1) Method 24. You may determine the volatile organic and coating solids mass fraction of each coating applied using Method 24 (appendix A-7 to 40 CFR part 60). The Method 24 determination may be performed by the manufacturer of the material and the results provided to you. When using volatile organic compound content as a surrogate for HAP, you may also use ASTM D3960-98, (incorporated by reference, see §63.14) as an alternative to Method 24. If these values cannot be determined using either of these methods, you must submit an alternative technique for determining their values for approval by the Administrator.

(2) Formulation data. You may determine the volatile organic content and coating solids content of a coating material based on formulation data and may rely on volatile organic content data provided by the manufacturer of the material. In the event of any inconsistency between the formulation data and the results of Method 24 of appendix A-7 to 40 CFR part 60 and the Method 24 results are higher, the results of Method 24 will govern.

(3) As-applied volatile organic content and coating solids content. If the as-purchased coating material is applied to the web without any solvent or other material added, then the as-applied volatile organic content is equal to the as-purchased volatile content and the as-applied coating solids content is equal to the as-purchased coating solids content. Otherwise, the as-applied volatile organic content must be calculated using Equation 5 to §63.3370(c)(4) and the as-applied coating solids content must be calculated using Equation 6 to §63.3370(d).

(e) Control device efficiency. If you are using an add-on control device other than solvent recovery, such as an oxidizer, to comply with the emission standards in §63.3320, you must conduct a performance test to establish the destruction or removal efficiency of the control device according to the methods and procedures in paragraphs (e)(1) and (2) of this section. During the performance test, you must establish the operating limits required by §63.3321 according to paragraph (e)(3) of this section.

(1) Initial performance test. An initial performance test to establish the destruction or removal efficiency of the control device used to comply with the emission standards in §63.3320 must be conducted such that control device inlet and outlet testing is conducted simultaneously, and the data are reduced in accordance with the test methods and procedures in paragraphs (e)(1)(i) through (ix) of this section. You must conduct three test runs as specified in §63.7(e)(3), and each test run must last at least 1 hour.

(i) Method 1 or 1A of appendix A-1 to 40 CFR part 60 must be used for sample and velocity traverses to determine sampling locations.

(ii) Method 2, 2A, 2C, 2D, or 2F of appendix A-1 to 40 CFR part 60, or Method 2G of appendix A-2 to 40 CFR part 60 must be used to determine gas volumetric flow rate.

(iii) Method 3, 3A, or 3B of appendix A-2 to 40 CFR part 60 must be used for gas analysis to determine dry molecular weight. You may also use as an alternative to Method 3B the manual method for measuring the oxygen, carbon dioxide, and carbon monoxide content of exhaust gas in ANSI/ASME PTC 19.10-1981 Part 10, (incorporated by reference, see §63.14).

(iv) Method 4 of appendix A-3 to 40 CFR part 60 must be used to determine stack gas moisture.

(v) Methods for determining the gas volumetric flow rate, dry molecular weight, and stack gas moisture must be performed, as applicable, during each test run.

(e)(1)(vi) Method 25 or 25A of appendix A-7 to 40 CFR part 60 must be used to determine total gaseous organic matter concentration. Use the same test method for both the inlet and outlet measurements which must be conducted simultaneously. You must submit notice of the intended test method to the Administrator for approval along with notification of the performance test required under § 63.7(b). You must use method 25A if any of the conditions described in paragraphs (e)(1)(vi)(A) through (D) of this section apply to the control device.

(A) The control device is not an oxidizer.

(B) The control device is an oxidizer but an exhaust gas volatile organic matter concentration of 50 ppmv or less is required to comply with the emission standards in §63.3320; or

(C) The control device is an oxidizer but the volatile organic matter concentration at the inlet to the control system and the required level of control are such that they result in exhaust gas volatile organic matter concentrations of 50 ppmv or less; or

(D) The control device is an oxidizer but because of the high efficiency of the control device the anticipated volatile organic matter concentration at the control device exhaust is 50 ppmv or less, regardless of inlet concentration.

(vii) Except as provided in §63.7(e)(3), each performance test must consist of three separate runs with each run conducted for at least 1 hour under the conditions that exist when the affected source is operating under normal operating conditions. For the purpose of determining volatile organic compound concentrations and mass flow rates, the average of the results of all the runs will apply.

(viii) Volatile organic matter mass flow rates must be determined for each run specified in paragraph (e)(1)(vii) of this section using Equation 1:

Where:

Mf = Total organic volatile matter mass flow rate, kilograms (kg)/hour (h).

Qsd = Volumetric flow rate of gases entering or exiting the control device, as determined according to paragraph (e)(1)(ii) of this section, dry standard cubic meters (dscm)/h.

Cc = Concentration of organic compounds as carbon, ppmv.

12.0 = Molecular weight of carbon.

0.0416 = Conversion factor for molar volume, kg-moles per cubic meter (mol/m3) (@293 Kelvin (K) and 760 millimeters of mercury (mmHg)).

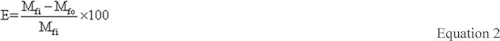

(ix) For each run, emission control device destruction or removal efficiency must be determined using Equation 2:

Where:

E = Organic volatile matter control efficiency of the control device, percent.

Mfi = Organic volatile matter mass flow rate at the inlet to the control device, kg/h.

Mfo = Organic volatile matter mass flow rate at the outlet of the control device, kg/h.

(x) The control device destruction or removal efficiency is determined as the average of the efficiencies determined in the test runs and calculated in Equation 2.

(2) Process information. You must record such process information as may be necessary to determine the conditions in existence at the time of the performance test. Representative conditions exclude periods of startup and shutdown. You may not conduct performance tests during periods of malfunction. You must record the process information that is necessary to document operating conditions during the test and include in such record an explanation to support that such conditions represent normal operation. Upon request, you shall make available to the Administrator such records as may be necessary to determine the conditions of performance tests.

(3) Operating limits. If you are using one or more add-on control device other than a solvent recovery system for which you conduct a liquid-liquid material balance to comply with the emission standards in §63.3320, you must establish the applicable operating limits required by §63.3321. These operating limits apply to each add-on emission control device, and you must establish the operating limits during the performance test required by paragraph (e) of this section according to the requirements in paragraphs (e)(3)(i) and (ii) of this section.

(i) Thermal oxidizer. If your add-on control device is a thermal oxidizer, establish the operating limits according to paragraphs (e)(3)(i)(A) and (B) of this section.

(A) During the performance test, you must monitor and record the combustion temperature at least once every 15 minutes during each of the three test runs. You must monitor the temperature in the firebox of the thermal oxidizer or immediately downstream of the firebox before any substantial heat exchange occurs.

(B) Use the data collected during the performance test to calculate and record the average combustion temperature maintained during the performance test. Maintain the 3-hour average combustion temperature no more than 50 degrees Fahrenheit lower than this average combustion temperature.

(ii) Catalytic oxidizer. If your add-on control device is a catalytic oxidizer, establish the operating limits according to paragraphs (e)(3)(ii)(A) and (B) or paragraphs (e)(3)(ii)(C) and (D) of this section.

(A) During the performance test, you must monitor and record the temperature just before the catalyst bed and the temperature difference across the catalyst bed at least once every 15 minutes during each of the three test runs.

(B) Use the data collected during the performance test to calculate and record the average temperature just before the catalyst bed and the average temperature difference across the catalyst bed maintained during the performance test. Maintain the 3-hour average combustion temperature no more than 50 degrees Fahrenheit lower than this average combustion temperature or maintain the 3-hour average temperature difference across the catalyst bed at no less than 80 percent of this average temperature differential, provided that the minimum temperature is always 50 degrees Fahrenheit above the catalyst's ignition temperature.

(C) As an alternative to monitoring the temperature difference across the catalyst bed, you may monitor the temperature at the inlet to the catalyst bed and implement a site-specific inspection and maintenance plan for your catalytic oxidizer as specified in paragraph (e)(3)(ii)(D) of this section. During the performance test, you must monitor and record the temperature just before the catalyst bed at least once every 15 minutes during each of the three test runs. Use the data collected during the performance test to calculate and record the average temperature just before the catalyst bed during the performance test. Maintain the 3-hour average combustion temperature no more than 50 degrees Fahrenheit lower than this average combustion temperature.

(D) You must develop and implement an inspection and maintenance plan for your catalytic oxidizer(s) for which you elect to monitor according to paragraph (e)(3)(ii)(C) of this section. The plan must address, at a minimum, the elements specified in paragraphs (e)(3)(ii)(D)(1) through (3) of this section.

(1) Annual sampling and analysis of the catalyst activity (i.e., conversion efficiency) following the manufacturer's or catalyst supplier's recommended procedures,

(2) Monthly inspection of the oxidizer system including the burner assembly and fuel supply lines for problems, and

(3) Annual internal and monthly external visual inspection of the catalyst bed to check for channeling, abrasion, and settling. If problems are found, you must take corrective action consistent with the manufacturer's recommendations and conduct a new performance test to determine destruction efficiency in accordance with this section.

(4) Control Destruction Efficiency Curve Development. If you are using one or more add-on control devices other than a solvent recovery system for which you conduct a liquid-liquid material balance to comply with the emission standards in §63.3320, you may establish a control destruction efficiency curve for use in estimating emissions that occur during deviations of the 3-hour operating parameters. This curve can be generated using test data or manufacturer's data that specifically documents the level of control at varying temperatures for your control device.

(f) Capture efficiency. If you demonstrate compliance by meeting the requirements of §63.3370(f), (g), (h), (i), (j)(2), (l), (o)(2) or (3), or (q), you must determine capture efficiency using the procedures in paragraph (f)(1), (2), or (3) of this section, as applicable.

(1) You may assume your capture efficiency equals 100 percent if your capture system is a permanent total enclosure (PTE). You must confirm that your capture system is a PTE by demonstrating that it meets the requirements of section 6 of EPA Method 204 of 40 CFR part 51, appendix M, and that all exhaust gases from the enclosure are delivered to a control device.

(2) You may determine capture efficiency according to the protocols for testing with temporary total enclosures that are specified in Methods 204 and 204A through F of 40 CFR part 51, appendix M. You may exclude never-controlled work stations from such capture efficiency determinations.

(3) You may use any capture efficiency protocol and test methods that satisfy the criteria of either the Data Quality Objective or the Lower Confidence Limit approach as described in appendix A of subpart KK of this part. You may exclude never-controlled work stations from such capture efficiency determinations.

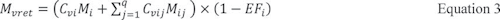

(g) Volatile matter retained in the coated web or otherwise not emitted to the atmosphere. You may choose to take into account the mass of volatile matter retained in the coated web after curing or drying or otherwise not emitted to the atmosphere when determining compliance with the emission standards in §63.3320. If you choose this option, you must develop a site- and product-specific emission factor (EF) and determine the amount of volatile matter retained in the coated web or otherwise not emitted using Equation 3 to §63.3360(g)(1). The EF must be developed by conducting a performance test using an approved EPA test method, or alternative approved by the Administrator by obtaining the average of a three-run test. You may additionally use manufacturer's emissions test data (as long as it replicates the facility's coating formulation and operating conditions), or a mass-balance type approach using a modified Method 24 (including ASTM D5403-93 for radiation-cureable coatings). The EF should equal the proportion of the mass of volatile organics emitted to the mass of volatile organics in the coating materials evaluated. You may use the EF in your compliance calculations only for periods that the work station(s) was (were) used to make the product, or a similar product, corresponding to that produced during the performance test. You must develop a separate EF for each group of different products that you choose to utilize an EF for calculating emissions by conducting a separate performance test for that group of products. You must conduct a periodic performance test to re-establish the EF if there is a change in coating formulation, operating conditions, or other change that could reasonably be expected to increase emissions since the time of the last test that was used to establish the EF.

(1) Calculate the mass of volatile organics retained in the coated web or otherwise not emitted for the month from each group of similar products using Equation 3:

Where:

Mvret = Mass of volatile matter retained in the coated web after curing or drying, or otherwise not emitted to the atmosphere, kg.

Cvi = Volatile organic content of coating material, i, expressed as a mass fraction, kg/kg.

Mi = Mass of as-purchased coating material, i, applied in a month, kg.

q = Number of different materials added to the coating material.

Cvij = Volatile organic content of material, j, added to as-purchased coating material, i, expressed as a mass fraction, kg/kg.

Mij = Mass of material, j, added to as-purchased coating material, i, in a month, kg.

EFi = Volatile organic matter site- and product-specific emission factor (three-run average determined from performance testing, evaluated as proportion of mass volatile organics emitted to mass of volatile organics in the coatings used during the performance test).

(2) [Reserved]

(h) Control devices in series. If you use multiple control devices in series to comply with the emission standards in §63.3320, the performance test must include, at a minimum, the inlet to the first control device in the series, the outlet of the last control device in the series, and all intermediate streams (e.g., gaseous exhaust to the atmosphere or a liquid stream from a recovery device) that are not subsequently treated by any of the control devices in the series.

[85 FR 41298, July 9, 2020; 88 FR 18413, March 29, 2023]