['General Packaging Requirements - Hazmat']

['Cylinders - Hazmat']

07/16/2025

...

DEPARTMENT OF TRANSPORTATION

Pipeline and Hazardous Materials Safety Administration

49 CFR Part 180

[Docket No. PHMSA-2017-0083 (HM-219B)]

RIN 2137-AF30

Hazardous Materials: Response to an Industry Petition To Reduce Regulatory Burden for Cylinder Requalification Requirements

AGENCY: Pipeline and Hazardous Materials Safety Administration (PHMSA), Department of Transportation (DOT).

ACTION: Notice of proposed rulemaking (NPRM).

SUMMARY: PHMSA is proposing to revise requirements on the requalification period for certain DOT 4-series specification cylinders in non-corrosive gas service in response to a petition for rulemaking submitted by the National Propane Gas Association. This rulemaking proposes regulatory relief and a reduction in the requalification-related costs for propane marketers, distributors, and others in non-corrosive gas service.

DATES: Comments must be received by October 7, 2019. To the extent possible, PHMSA will consider late-filed comments as a final rule is developed.

ADDRESSES: You may submit comments identified by the Docket Number PHMSA-2017-0083 (HM-219B) by any of the following methods:

- Federal eRulemaking Portal: http://www.regulations.gov. Follow the instructions for submitting comments.

- Fax: 1-202-493-2251.

- Mail: Docket Management System; U.S. Department of Transportation, West Building, Ground Floor, Room W12-140, Routing Symbol M-30, 1200 New Jersey Avenue SE, Washington, DC 20590.

- Hand Delivery: To the Docket Management System; Room W12-140 on the ground floor of the West Building, 1200 New Jersey Avenue SE, Washington, DC 20590, between 9 a.m. and 5 p.m., Monday through Friday, except Federal holidays.

Instructions: All submissions must include the agency name and Docket Number (PHMSA-2017-0083) or RIN (2137-AF30) for this rulemaking at the beginning of the comment. To avoid duplication, please use only one of these four methods. All comments received will be posted without change to the Federal Docket Management System (FDMS) and will include any personal information you provide.

Docket: For access to the dockets to read background documents or comments received, go to http://www.regulations.gov or DOT's Docket Operations Office (see ADDRESSES).

Privacy Act: In accordance with 5 U.S.C. 553(c), DOT solicits comments from the public to better inform its rulemaking process. DOT posts these comments, without edit, including any personal information the commenter provides, to http://www.regulations.gov, as described in the system of records notice (DOT/ALL-14 FDMS), which can be reviewed at http://www.dot.gov/privacy.

FOR FURTHER INFORMATION CONTACT: Shelby Geller, Standards and Rulemaking Division, (202) 366-8553, Pipeline and Hazardous Materials Safety Administration, U.S. Department of Transportation, 1200 New Jersey Avenue SE, Washington, DC 20590-0001.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Background

A. History

B. Petition P-1696

C. Statement of Enforcement Discretion

II. Overview

III. Regulatory Analyses and Notices

A. Statutory/Legal Authority for This Rulemaking

B. Executive Order 12866 and DOT Regulatory Policies and Procedures

C. Executive Order 13771

D. Executive Order 13132

E. Executive Order 13175

F. Regulatory Flexibility Act, Executive Order 13272, and DOT Policies and Procedures

G. Paperwork Reduction Act

H. Regulation Identifier Number (RIN)

I. Unfunded Mandates Reform Act

J. Environmental Assessment

K. Privacy Act

L. Executive Order 13609 and International Trade Analysis

M. National Technology Transfer and Advancement Act

N. Executive Order 13211

List of Subjects

I. Background

A. History

On January 30, 2015, PHMSA published a notice of proposed rulemaking (NPRM) titled “Hazardous Materials: Adoption of Special Permits (MAP-21) (RRR)” [Docket No. PHMSA-2013-0042 (HM-233F); 80 FR 5339]. The HM-233F NPRM proposed to adopt provisions contained in 98 widely-used or longstanding special permits with an established safety record. Following a 60-day comment period, PHMSA published a final rule on January 21, 2016, that adopted the provisions of 96 of these special permits [81 FR 3635]. The HM-233F final rule became effective on February 22, 2016.

The HM-233F final rule amended §180.209(e), which details conditions for allowing the requalification period to be longer for DOT 4-series specification cylinders in certain hazardous material service. Prior to publication of the final rule, §180.209(e) authorized DOT 4B, 4BW, 4BA, or 4E cylinders used exclusively for a specified list of hazardous materials (non-corrosive gases) to be requalified by volumetric expansion every 12 years, instead of every 5 years. Alternatively, these cylinders were authorized to be requalified by the proof pressure test method every 7 years after the first 12-year period. A proof pressure test is a pressurization test without the determination of a cylinder's expansion, and a volumetric expansion test determines the total and permanent expansion of a cylinder at a given pressure and is conducted by either water jacket or direct expansion test, both of which are conducted with water (see §180.203).

In the HM-233F NPRM, PHMSA proposed to adopt the provisions of special permit 12084, which was issued to Honeywell International, Inc.1 This special permit authorized the requalification of DOT 4B, 4BA, or 4BW cylinders in accordance with §180.209(e) for 11 additional non-corrosive gases. PHMSA identified this special permit as suitable for adoption into the regulations. In the HM-233F NPRM, PHMSA proposed to revise §180.209(e) by replacing the list of specific hazardous materials with broader applicability to non-corrosive gases commercially free from corroding components.

1 https://www.phmsa.dot.gov/approvals-and-permits/hazmat/file-serve/offer/SP12084.pdf/offerserver/SP12084.

PHMSA also proposed to amend the requalification periods of authorized cylinders for both the volumetric expansion and proof pressure tests in §180.209(e). Specifically, PHMSA proposed to standardize the requalification period to 10 years for both the volumetric expansion test (previously a 12-year period) and the proof pressure test (previously a 7-year period after an initial 12-year period). While this proposed change was not discussed in the preamble of the HM-233F NPRM, PHMSA did propose amended regulatory text. PHMSA received no adverse comments to any of the proposed changes to §180.209(e)—the adoption of special permit 12084 and 10-year requalification period—and therefore adopted the language as proposed in the final rule. While the effective date of the final rule was February 22, 2016, PHMSA allowed for delayed compliance to begin on January 23, 2017.

B. Petition P-1696

On January 13, 2017, the National Propane Gas Association (NPGA) submitted a petition to PHMSA and the Office of the Secretary of Transportation (OST) titled “Petition for Rulemaking and Emergency Stay Cylinder Requalification Requirements” [PHMSA-2017-0019 (P-1696) 2 ]. NPGA requested that PHMSA revise the initial timeframe before requalification, revise the requalification period for both the volumetric expansion and proof pressure tests in §180.209(e) to those authorized prior to the HM-233F final rule, and update the table in §180.209(a) accordingly. NPGA also requested a Statement of Enforcement Discretion while the rulemaking action was pending.

2 See P-1696: https://www.regulations.gov/docket?D=PHMSA-2017-0019.

In the petition, NPGA advised PHMSA and OST that the HM-233F rulemaking created potential impacts and unanticipated costs. Specifically, NPGA asserted that the regulatory change to the requalification period created confusion in the propane industry because it was unclear whether those cylinders manufactured or requalified by the volumetric expansion test within the last 10 to 12 years had to be immediately requalified, since prior to the final rule they would not have required requalification until the 12-year date. Furthermore, NPGA stated that the requirement to test cylinders following manufacture or volumetric expansion testing more frequently (i.e., every 10 years instead of every 12 years) would increase qualification and training costs. NPGA explained that current industry practice 3 is to mark newly manufactured cylinders, eligible for requalification in accordance with §180.209(e), with a 12-year requalification mark. Even though this marking is not required by the Hazardous Materials Regulations (HMR; 49 CFR parts 171-180), industry would have to train employees to ignore those markings. Additional training would be required on the revised requalification periods for both volumetric expansion and proof pressure testing.

3 This is voluntary industry practice and not required by the HMR.

On March 2, 2017, PHMSA met with NPGA representatives to: (1) Better understand NPGA's concerns; (2) identify existing industry practice and request data to assess the impact of the revised cylinder requalification periods; and (3) evaluate the merits of a rulemaking and Statement of Enforcement Discretion. During this meeting, NPGA reiterated their petition, in that the change in requalification intervals would impose unanticipated industry costs. Furthermore, NPGA conveyed that a majority of their associate members requalify certain DOT 4-series specification cylinders by volumetric expansion testing. Following these discussions, PHMSA accepted NPGA's petition for rulemaking.

C. Statement of Enforcement Discretion

On March 17, 2017, PHMSA issued a Statement of Enforcement Discretion stating that it will not take enforcement action against a person who requalifies DOT 4-series specification cylinders using volumetric expansion testing pursuant to a 12-year requalification period while it reviews NPGA's petition for rulemaking.4 This Statement of Enforcement Discretion specified that until further action, DOT 4-series specification cylinders requalified by volumetric expansion in accordance with §180.209(e) may have a 10- or 12-year requalification period without any enforcement action taken.

4 Pipeline and Hazardous Materials Safety Administration's Notice Regarding the Requalification Period for Department of Transportation (DOT) Specification Cylinders, issued May 17, 2017, available at: https://www.regulations.gov/document?D=PHMSA-2017-0083-0001.

II. Overview

PHMSA has reviewed NPGA's petition for rulemaking and agrees that it merits a rulemaking to consider revising the §180.209(e) requalification period, as accepting the petition is expected to reduce regulatory burden and industry cost. PHMSA does not anticipate that this revision poses any increased safety risk, as historically these cylinders were authorized to be requalified on a 12-year cycle for volumetric expansion testing and on a 7-year cycle (after an initial 12-year period) for proof pressure testing with no known incidents attributable to the requalification timeframe. It should be noted that in accordance with §180.205(c), even if a cylinder is due for requalification, it may be used until emptied, as long as it was filled prior to the requalification due date. Once emptied and placed into transportation, it must be requalified in accordance with the appropriate test method before being refilled.

In this NPRM, PHMSA is proposing to return the initial and subsequent requalification periods to 12 years for volumetric expansion tests, as proposed in the NPGA petition and authorized prior to HM-233F. PHMSA is proposing to also return the initial requalification period for proof pressure testing to 12 years, but maintain the 10-year period for subsequent proof pressure requalification testing as adopted in HM-233F final rule. The proof pressure test requalification period of 10 years was not proposed in NPGA's petition for rulemaking (proposed as 7 years). We acknowledge that the proposed 10-year requalification period will likely result in one-time industry training costs; however, the allowance to requalify a cylinder by proof pressure test every 10-years, instead of every 7 years, after the initial 12-year requalification period, may outweigh the costs of training because of less frequent cylinder requalification. Thus, PHMSA believes that this could allow for the greatest regulatory relief. PHMSA invites comments on the potential for costs or savings that may result from maintaining a 10-year requalification period following the initial 12-year requalification period for proof pressure testing instead of returning to the 7-year cycle, after the initial 12-year period (as proposed by the NPGA in its petition and reflective of the requalification period prior to publication of the HM-233F final rule).

Additionally, PHMSA is proposing to revise the title of §180.209(e) to more appropriately reflect the regulatory provisions in this paragraph. PHMSA is also proposing to revise the table in §180.209(a) to properly reflect the baseline requalification period and the alternate requalification period allowances for various DOT specification cylinders. The baseline for DOT 4B, 4BA, 4BW, and 4E cylinder requalification is 5-years, but in accordance with the proposed language of §180.209(e), these cylinders may be requalified every 10 or 12 years, under the specified conditions and dependent on the type of pressure test performed. In addition, PHMSA proposes to add a “7” to the §180.209(a) table for DOT 4B, 4BA, or 4BW cylinders, as they are authorized for requalification every 7 or 12 years, instead of 5 years, when used as a fire extinguisher in accordance with §180.209(j). There is no substantive change in adding “7” to the table as this is a conforming amendment for consistency between the table in paragraph (a) and the provisions in paragraph (j), which was inadvertently deleted in the HM-233F final rule.

PHMSA is also proposing to amend the table in §180.209(a) to remove any reference to paragraph (e) for DOT 3A, 3AA, 3AL, 3AX, 3AAX, 3B, 3BN, and 4AA480 cylinders. Section 180.209(e) does not authorize requalification of these cylinder types. Therefore, this NPRM adjusts for any requalification period that is not currently authorized.

Further, PHMSA is proposing to make editorial corrections to the table for consistency. We propose to: Delete “DOT” preceding 3, 3A, 3AA, 3AL, 3AX, 3AAX, and 4E cylinders because the other entries do not have a similar qualifier; specify “service pressure” in the “Minimum test pressure (psig)” column for DOT 4D, 4DA, and 4DS cylinders to match other entries; and remove a duplicative citation of §180.209 for DOT 3AL cylinders to be consistent with the other requalification period references.

III. Regulatory Analyses and Notices

A. Statutory/Legal Authority for This Rulemaking

This rulemaking is published under the authority of Federal Hazardous Materials Transportation Law (Federal hazmat law; 49 U.S.C. 5101 et seq.), which authorizes the Secretary of Transportation to “prescribe regulations for the safe transportation, including security, of hazardous materials in intrastate, interstate, and foreign commerce.” The Secretary's authority is delegated to PHMSA at 49 CFR 1.97. This rulemaking proposes to amend the requalification periods for certain DOT 4-series specification cylinders under relief provided in §180.209(e) and to revise the requalification table in §180.209(a) accordingly.

B. Executive Order 12866 and DOT Regulatory Policies and Procedures

This rulemaking is considered a nonsignificant regulatory action under section 3(f) of Executive Order 12866 (“Regulatory Planning and Review”) and was not reviewed by the Office of Management and Budget (OMB). This rulemaking is also considered a nonsignificant rulemaking under the DOT's Policies and Procedures for Rulemakings [DOT Order 2100.6; December 20, 2018].

Executive Order 12866 (“Regulatory Planning and Review”) 5 requires agencies to regulate in the “most cost-effective manner,” to make a “reasoned determination that the benefits of the intended regulation justify its costs,” and to develop regulations that “impose the least burden on society.”

5 See 58 FR 51735, October 4, 1993 for Executive Order 12866

Additionally, Executive Order 12866 requires agencies to provide a meaningful opportunity for public participation, which also reinforces requirements for notice and comment under the Administrative Procedure Act (APA).6 Therefore, PHMSA solicits comment on the revised requalification periods for DOT 4-series specification cylinders as proposed in §180.209(e). PHMSA also seeks comment on the preliminary cost and cost savings analyses, including industry costs or cost savings due to the revised requalification periods for volumetric expansion and proof pressure testing.

6 See 5 U.S.C. 553.

Overall, this rulemaking maintains the continued safe transportation of hazardous materials while producing a net cost savings. PHMSA's findings are summarized here and described in further detail in the following 13 sections, which together comprise our preliminary analysis for this NPRM:

1. Summary of preliminary findings

2. Description of the need for the regulatory action

3. Definition of the baseline and rulemaking scenarios

4. The time horizon of analysis

5. Description of the type and number of affected cylinders

6. Description of the type and number of affected entities

7. Analysis of requalification cost savings

8. Analysis of training costs and cost savings

9. Analysis of total net cost savings

10. Evaluation of non-quantified and non-monetized impacts

11. Characterization of additional uncertainty in impacts, including estimated costs, cost savings, and net cost savings

12. Supplemental analysis regarding the number of affected cylinders

13. Supplemental analysis regarding possible effects on proof pressure-tested cylinders

Summary of Preliminary Findings

PHMSA's preliminary analysis finds that the proposed changes would result in total net cost savings of approximately $142.4 million over 10 years, or $20.3 million annualized, when discounted at 7 percent.

These cost savings are almost entirely based on two effects. The first effect is avoiding the immediate, accelerated requalification of approximately 5 million DOT 4-series specification cylinders that would otherwise be required if the proposed changes of this rulemaking are not adopted. The second effect is an anticipated reduction in the number of cylinders in need of requalification in any given year. The avoidance of accelerated requalification occurs in year one, and the “enduring” effect of reducing the number of cylinders in need of requalification occurs in subsequent years (years 2-10). Our primary analysis focuses on cost savings to entities that requalify cylinders by volumetric expansion testing. However, this NPRM also proposes to retain the 10-year requalification period for the proof pressure test adopted under the HM-233F final rule, so we assume cylinder marketers require some training to ensure knowledge of the revised requalification timeframes for proof pressure testing. This NPRM would also relieve cylinder manufacturers of training to ensure that voluntary stamping practices align with the initial requalification timeframe, resulting in training-related cost savings for cylinder manufacturers. On net, we estimate training cost savings at approximately $0.2 million. We add the two types of requalification cost savings to the net cost savings related to training to determine the total net cost savings. See Exhibit 1.

| Number of Cylinders Affected in Year 1 | 5 million. |

| Annual Number of Cylinders Affected in Years 2-10 | 500,000. |

| Requalification Cost Savings in Year 1 | $86.1 million. |

| Requalification Cost Savings per Cylinder (weighted average) | $17.22. |

| Training Net Cost Savings in Year 1 | $0.2 million. |

| Requalification Cost Savings in Years 2-10 (7%) | $56.1 million. |

| Total Net Cost Savings (7%) | $142.4 million. |

7 Due to rounding, these estimates and findings may differ slightly from those expressed elsewhere in this analysis. Net cost savings is defined as cost savings minus costs, but in Exhibit 1, it is presented equivalently as the sum of (net) cost savings. Year-one effects are undiscounted. Effects related to years two through ten are discounted at 7%. Total effects, covering the 10-year time period of analysis, include an undiscounted, year-one value, which is added to values discounted at 7% for years two through ten.

Exhibit 1 shows “year one,” monetized cost savings as well as “enduring” cost savings in years 2-10 based on a reduction in the number of cylinders in need of requalification. Please see the section, “Analysis of total net cost savings,” for additional tabulation of the total net cost savings of the rule, discounted over 10 years.

If one were to present these cost savings on an indefinite or perpetual time horizon, their net present value would be approximately $209.3 million at a 7% discount rate, and their annualized value would be $14.7 million, also at a 7% discount rate.8 Please note, to arrive at this calculation, year-one impacts are undiscounted because these impacts are expected to begin occurring soon after the rulemaking is made effective, if it is made effective. On a perpetual horizon, the year-one savings is $86,338,066 and subsequently, all other years repeat a savings of $8,610,338.

8 The perpetual, annualized cost savings were calculated by discounting the net present value of cost savings ($209,342,894.57) by one year using a 7% discount rate. This is equivalent to multiplying the net present value of cost savings by 0.07. $209,342,894.57 * 0.07 = $14,654,002.62.

Description of the Need for Regulatory Action

NPGA petitioned 9 PHMSA to amend §180.209(e) because the HM-233F final rule was expected to impose a substantial cost burden on industry. Specifically, NPGA reasoned that, due to confusion about the applicability of the HMR, the requirements in the HM-233F final rule would accelerate the requalification of certain DOT 4-series specification cylinders by 2 years, even though the HMR allows a cylinder filled before the end of the requalification period to remain in service until emptied, as long as it is requalified prior to being refilled and offered back into transportation (see §180.205(c)). For example, a cylinder tested by volumetric expansion would need to be requalified every 10 years, rather than every 12 years. This 2-year acceleration would effectively force 3 years of cylinder vintages to be requalified in a single year, and thus would have a potential one-time impact on thousands of propane marketers and millions of cylinders. To avoid this substantial cost burden, PHMSA issued a Statement of Enforcement Discretion on March 17, 2017, and initiated this rulemaking, which proposes to allow affected cylinders to be initially and subsequently requalified over a 12-year period when tested by volumetric expansion.

9 See P-1696: https://www.regulations.gov/docket?D=PHMSA-2017-0019.

NPGA also cited confusion stemming from the industry practice of stamping a propane cylinder at the time of manufacture with an indication that the cylinder must be requalified 12 years after the manufacture date. The HMR do not require this stamp. However, this practice means that under current requirements, retraining would be necessary to educate employees on the 10-year requalification period and to ignore the stamp marking.

Further, PHMSA proposes to retain the 10-year period for proof pressure testing requalification, after the initial requalification test at 12 years. Prior to publication of the HM-233F final rule, the HMR required a 7-year timeframe for subsequent requalification by proof pressure. In its petition, NPGA asked that PHMSA return the proof pressure test requalification periods of paragraph (e) to 7 years. However, PHMSA is proposing to maintain the 10-year requirement on the basis that it may add regulatory relief. PHMSA solicits comments regarding this proposal, especially as it differs from the NPGA petition (P-1696). To address possible cost-saving effects on proof pressure-tested cylinders, PHMSA offers a supplemental analysis in the last section of this analysis. Due to data uncertainties, this supplemental cost savings analysis is separate from and secondary to our primary analysis methods and estimates. PHMSA solicits comments to address these data uncertainties, specifically comments regarding the extent of proof pressure testing.

Definition of the Baseline and Rulemaking Scenarios

This rulemaking is expected to have a variety of effects or impacts, some of which result in cost savings, others in costs. We do not estimate benefits in this analysis because PHMSA anticipates that the proposed changes maintain an equivalent level of safety. This section describes the baseline and rulemaking scenarios, which are the basis for determining whether the proposed rule may result in costs or cost savings.

Absent rulemaking action, the existing Statement of Enforcement Discretion relieves cylinder marketers of the HM-233F requirement to requalify cylinders every 10 years. However, the Statement of Enforcement Discretion does not provide regulatory certainty. Therefore, PHMSA uses the HM-233F or current HMR standards as the baseline, and uses this rulemaking action (HM-219B) as the rulemaking scenario and basis for incremental change.

Thus, in the baseline, requalifications are accelerated by 2 years, resulting in costs; in the rulemaking scenario, these accelerated requalifications are avoided, resulting in cost savings. This effect would occur in year one of impacts. In addition, in subsequent years, the pool of cylinders requiring requalification would be larger in the baseline than in the rulemaking scenario. Thus, if this rulemaking becomes effective, PHMSA is also providing “enduring” cost savings due to fewer cylinders being in need of requalification in the rulemaking versus the baseline scenario. These cost saving effects are the main effects of this proposed rulemaking.

Please note that this analysis focuses on the cost and cost-savings impacts of the 2-year acceleration of requalification by volumetric expansion because there is substantial uncertainty regarding the proportion and number of cylinders that are requalified by proof pressure testing. However, in the last section of this cost-savings analysis, we attempt to address this uncertainty by providing a supplemental analysis illustrating possible cost-savings effects on proof pressure-tested cylinders. In the baseline, proof pressure-tested cylinders must be requalified every 7 years after the initial 12-year period; in the rulemaking scenario, these cylinders can be requalified every 10 years after the initial 12-year period. This may enhance regulatory flexibility, and is a possible mechanism for cost savings. To better address these uncertainties in future analyses, PHMSA solicits comment on the proportion and number of cylinders that are proof pressure-tested versus cylinders tested using other methods. Due to data uncertainties, we limit our discussion of these proof-pressure cost savings to the supplemental analysis—they do not factor into our primary estimates for cost savings.

PHMSA also anticipates another, relatively smaller effect: Cost savings that result from relieving manufacturers of the need to mark cylinders with a revised requalification timeframe. This marking is not an HMR requirement. However, in the baseline scenario, this marking would need to be revised to indicate a 10-year initial requalification timeframe, resulting in costs; in the rulemaking scenario, this marking could continue to indicate a 12-year initial requalification timeframe, resulting in avoided costs or cost savings.

In addition to cost savings, the HM-219B proposal to retain a revised timeframe for subsequent proof pressure requalifications may result in training costs to cylinder marketers. In the baseline, current HMR requirements would necessitate this training and imposition of costs on cylinder marketers. Additionally, the rulemaking scenario will still necessitate this training and imposition of costs, since proof pressure requirements differ from pre-HM-233F conditions.

In summation, this rulemaking may have a variety of cost and cost-savings effects, but the main effects are due to the baseline and rulemaking scenarios for cylinders requalified by volumetric expansion. In the baseline scenario, cylinders must be initially requalified every 10 years. This is the current HMR requirement, as codified in HM-233F. Conversely, in the rulemaking scenario, cylinders tested by volumetric expansion must be requalified every 12 years. This is the change proposed in this rulemaking (HM-219B), which effectively revises the requalification timeframe for volumetric expansion testing back to the standards in place before HM-233F was published. See Exhibit 2.

| Rulemaking provision | Baseline (no action) | HM-219B amendments |

|---|---|---|

| Revise §180.209(e) | HMR remains as made effective in January 2017, and regulatory text remains the same as in HM-233F | PHMSA reverts text in §180.209(e) to its earlier iteration before HM-233F. |

| DOT cylinders must be requalified every 10 years | DOT cylinders must be requalified every 12 years. |

The Time Horizon of Analysis

This analysis assumes that this rulemaking will result in a “one-time” impact occurring in the first year the rulemaking is effective due to accelerated requalifications. After this first year, the rulemaking will also result in a reduction in the number of cylinders requiring requalification in any one year.

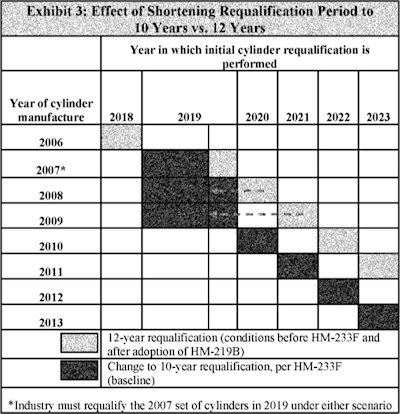

With respect to year-one impacts, we can elaborate further with an example using the baseline and rulemaking scenarios. In the baseline scenario, cylinder marketers need to requalify three different vintages of cylinders in 2019, specifically those cylinders manufactured or requalified in 2007, 2008, and 2009. This is the direct result of the requirement that these cylinders be requalified on a 10-year timeframe instead of a 12-year timeframe. As such, the HM-233F final rule imposed an accelerated requalification for cylinders manufactured or requalified in 2008 and 2009, whereas the cylinders manufactured or requalified in 2007 would need to be requalified in 2019 under either the baseline or rulemaking scenario. In the baseline scenario, 3 years' worth of cylinders need to be requalified in a single year, with the 2008 and 2009 cylinders needing requalification earlier than anticipated. Conversely, in the rulemaking scenario, the 2008 and 2009 cylinders can be requalified in 2020 and 2021, respectively, and the requalification costs that the HM-233F final rule imposed are avoided. To the extent that cylinders are requalified using volumetric expansion, this NPRM proposes a requalification timeframe that would have occurred were the HM-233F final rule never published.

PHMSA's analysis sees this effect as a “one-time” or “year one” impact. In the baseline, it is a one-time cost imposition; in the rulemaking scenario, it is a one-time avoidance of these costs (cost savings). See Exhibit 3.

BILLING CODE 4910-60-P

BILLING CODE 4910-60-C

As evident in Exhibit 3, the baseline scenario (HM 233F; current HMR requirements) primarily affects cylinder requalification in the first year of the rule's effect. Before this first year, there is no difference between the baseline and rulemaking scenario. After this first year of effect (e.g., 2019 onward), the requalification cycle returns to a “normal state,” where only one vintage of cylinders are requalified per year, although the number of cylinders in need of requalification in any given year would be smaller in the rulemaking than in the baseline scenario.

Note that we do not have data on the manufacturing and requalification dates for the affected cylinders—this affects how we chose to model the timing of requalification in Exhibit 3 and the impacts of the baseline and rulemaking scenarios. As evident in Exhibit 3, we assume that each cylinder has a specific manufacturing or requalification year and do not distinguish between the cylinders on a more granular level (e.g., month-to-month). For instance, we do not distinguish between a cylinder from January 2007 and one from June 2007. All 2007 cylinders are assumed to be requalified in 2019, as well as all 2008 and 2009 cylinders in the baseline. We make no further distinction about the timing of the manufacture and requalification of affected cylinders. Further, our analysis does not have a discounting component for avoiding accelerated requalifications because it is assumed to occur in the first year of the rulemaking's implementation, without distinctions between an expenditure made in January 2019 and one in December 2019, for example. For these reasons, the costs of accelerated requalification (or the avoidance of these costs) are undiscounted, one-time or “year one” impacts.

In addition to “year one” impacts, there is potential for “enduring” effects occurring in subsequent years. In subsequent years, the pool of DOT 4-series specification cylinders that need requalification in a given year may be smaller in the rulemaking scenario than in the baseline scenario. In the baseline scenario, this requalification pool represents effectively 1/10th of cylinders in service since these cylinders would need requalification once every 10 years. In the rulemaking scenario, this requalification pool would represent 1/12th of cylinders in service since these cylinders would need requalification once every 12 years. This rulemaking scenario reduction in requalification may result in cost savings. We attempt to quantify and monetize this effect as a cost savings, which in tandem with the avoided accelerated requalification costs, may be substantial. PHMSA solicits comment on the “one-time” and “enduring” effects, and on this analysis in general. We also solicit comment on whether there are additional economic effects that were not foreseen that could be represented in a future, revised analysis.

Description of the Type and Number of Affected Cylinders

According to information provided by NPGA in P-1696, the revisions made in the HM-233F final rule affect nearly 5 million DOT 4-series specification cylinders (e.g., 4B, 4BA, 4BW, and 4E). Furthermore, NPGA estimates that 75 percent of cylinders are 20-lb. cylinders (used primarily for BBQ grills, patio heaters, construction heat, temporary heat, etc.), and the remaining 25 percent comprise a variety of sizes, e.g., 33.5 lb. (forklift cylinders), 100 lb. (exchange cylinders), and the largest size, 420 lb. propane cylinders (residential/commercial heat). Absent any other data describing the population of affected cylinders, PHMSA uses NPGA's assumptions for this analysis.10 See Exhibit 4.

10 NPGA does not provide any supporting documentation or other information describing the basis for these estimates.

| Cylinder service sector | Cylinder size categories | Distribution (%) | Number of cylinders requiring accelerated requalification |

|---|---|---|---|

| Residential | 20 lbs. | 75 | 3,750,000 |

| Commercial | 33-420 lbs. | 25 | 1,250,000 |

| Total | 100 | 5,000,000 |

11 National Propane Gas Association, “RE: Supplement to January 13, 2017 NPGA Petition for Rulemaking and Emergency Stay,” February 13, 2017 [hereinafter NPGA Supplement]: https://www.regulations.gov/document?D=PHMSA-2017-0083-0003.

Exhibit 4 reiterates that, absent this rulemaking, approximately 5 million cylinders would need to be requalified on an accelerated basis. If this rulemaking is adopted, these 5 million cylinders can be requalified on a 12-year timeframe. As explained previously, this would revert volumetric expansion test requalification back to the timing in place before publication of the HM-233F final rule.

This estimate of the number of affected cylinders is also important to the estimation of “enduring” cost savings. After year one, the difference between the annual number of cylinders in need of requalification in the baseline and rulemaking scenarios is an input to our method for the enduring cost savings. Specifically, NPGA's estimate of 5 million represents 2 cylinder vintages that would undergo accelerated requalification. This means an estimated 2.5 million cylinders may need requalification in any one year. As such, over 12 years, 30 million cylinders would need requalification (2.5 * 12). If this same number of cylinders were to be requalified instead over 10 years, as the baseline holds, this would mean 3 million cylinders per year, or an increase of 500,000 cylinders per year. In other words, the baseline scenario would require that 20% more cylinders be requalified each year; in the rulemaking scenario, 20% fewer. This differential is an input to our cost savings method for “enduring” cost savings, which occur after year one.

Based on the accelerated requalifications in year one and the enduring effects thereafter, PHMSA chooses a time period of analysis of 10 years. A different time period of analysis may result in different findings and PHMSA may revise this analysis in the future to reflect different time periods of analysis.

Because PHMSA relies on NPGA assumptions and data, this cost savings analysis includes a supplemental analysis addressing the number of affected cylinders. This is provided in the section, “Supplemental analysis regarding the number of affected cylinders.”

Description of the Type and Number of Affected Entities

This rulemaking affects various entities, specifically cylinder marketers and manufacturers. If this rulemaking is not adopted, cylinder marketers bear the costs of accelerated cylinder requalification; however, if this rulemaking is adopted, cylinder marketers achieve a cost savings because they are relieved of the need to requalify cylinders on an accelerated basis. Moreover, cylinder marketer employees would require training if this rulemaking is adopted as proposed, since proof pressure requirements would be different. Lastly, if adopted, the rulemaking would relieve cylinder manufacturers of changes to voluntary stamping/marking practices, resulting in cost savings (avoided training costs). These training costs and cost savings are detailed in the section, “Analysis of training costs and cost savings.”

To describe the type and number of affected cylinder marketers, PHMSA relies on the North American Industrial Classification System (NAICS),12 specifically sector code 454310 Fuel Dealers.13 This sector is comprised of fuel dealers primarily engaged in retailing heating oil, liquefied petroleum (LP) gas, and other fuels via direct selling to customers. For the purposes of this analysis, we call entities in this sector, “cylinder marketers” or “marketers,” which is used synonymously with “fuel dealers.” There are approximately 8,700 establishments in this sector.14 The employment estimate for this NAICS sector is approximately 74,000, according to U.S. Census data. This estimate of the number of cylinder marketer employees is used as an input in our estimation of this rulemaking's training costs. We detail cost and cost- savings methods and calculations in the sections, “Analysis of requalification cost savings” and “Analysis of training costs and cost savings.”

12 The North American Industry Classification System (NAICS) is the standard used by Federal statistical agencies in classifying business establishments for the purpose of collecting, analyzing, and publishing statistical data related to the U.S. business economy. The classification framework is updated periodically, and most Federal statistical agencies currently report data using the 2012 version of the NAICS. The NAICS version—2012—is not related to the year for which statistical data are being published.

13 https://www.census.gov/cgi-bin/sssd/naics/naicsrch?code=454310&search=2012%20NAICS%20Search.

14 Ibid.

In addition to cylinder marketers, the rulemaking is likely to have an impact on NAICS sector 332420 Metal Tank Manufacturing, 15 which is the sector primarily engaged in cutting, forming, and joining heavy gauge metal to manufacture tanks, vessels, and other containers. For the purposes of this analysis, we call entities in this sector, “cylinder manufacturers,” or “manufacturers” for short. During 2014, this sector included 739 establishments and 36,869 employees.16 It is industry practice—albeit not required by the HMR—that DOT 4-series specification cylinder manufacturers currently place a stamp during manufacture indicating that the cylinder must be requalified 12 years after the manufacture date.17 If this rulemaking is not adopted (baseline), cylinder manufacturers may need to adjust this stamp to reflect the 10-year requirement, and implement any necessary training or manufacturing process changes to do so. This estimate of the number of cylinder manufacturing employees is used as an input in our estimation of this rule's training-related cost savings.

15 https://www.census.gov/cgi-bin/sssd/naics/naicsrch?code=332420&search=2012%20NAICS%20Search.

16 U.S. Census Bureau. “2014 County Business Patterns.” American Fact Finder, April 21, 2016. https://factfinder.census.gov/faces/nav/jsf/pages/searchresults.xhtml?refresh=t.

17 See P-1696, pg. 7: https://www.regulations.gov/docket?D=PHMSA-2017-0019.

See Exhibit 5 for the estimates of the number of establishments and employees on payroll for the NAICS sectors, 454310 Fuel Dealers and 332420 Metal Tank Manufacturing.

| NAICS code | NAICS code sector | Number of establishments | Employees on payroll |

|---|---|---|---|

| Primarily Affected Industry: | |||

| 454310 | Direct Sales Fuel Dealers | 8,677 | 73,555 |

| Other Relevant Industry Stakeholders: | |||

| 332420 | Metal Tank Manufacturing | 739 | 36,869 |

18 U.S. Census Bureau. “2014 County Business Patterns.” American Fact Finder, April 21, 2016. https://factfinder.census.gov/faces/nav/jsf/pages/searchresults.xhtml?refresh=t.

Analysis of Requalification Cost Savings

Assuming the rulemaking takes effect in 2019, adoption of this rulemaking would relieve cylinder marketers of the cost to accelerate the requalification of cylinders manufactured in 2008 and 2009. PHMSA believes it would also provide a reduction in the number of cylinders in need of requalification after year one, on an enduring, year-over-year basis. In this section, we estimate the value of these potentially avoided costs.

In the baseline or HM-233F scenario, changes to §180.209(e) require cylinder marketers to requalify some cylinders on an accelerated basis. Based upon assumptions provided by NPGA, a typical safety inspector can requalify three residential cylinders per hour and two commercial cylinders per hour.19 We estimate the avoided requalification cost by multiplying the number of residential and commercial cylinders requiring requalification, from Exhibit 4, by the amount of time needed to requalify a single cylinder, differentiated by type, and the mean hourly labor rate 20 for a safety inspector in the 454310 Fuel Dealers sector.21 This approach results in estimated costs of $15.26-$23.12 to requalify each residential and commercial cylinder, respectively. Total potentially avoided requalification costs for these cylinders are estimated to be approximately $86 million dollars. See Exhibit 6-1.

19 See NPGA Supplement, Appendix A, for estimates of labor-hours to requalify residential and commercial cylinders: https://www.regulations.gov/document?D=PHMSA-2017-0083-0003.

20 May 2015 National Industry-Specific Occupational Employment and Wage Estimates NAICS 454300—Direct Selling Establishments; available at: https://www.bls.gov/oes/current/naics4_454300.htm.

21 There may be additional costs, aside from labor, particularly to the extent that the temporary increased volume of testing increases wear-and-tear of hydrostatic test equipment and associated maintenance costs.

| Cylinder type | Number of cylinders 22 | Hours to requalify 23 | Labor rate for fuel dealer inspectors 24 | Avoided requalification cost |

|---|---|---|---|---|

| Residential | 3,750,000 | 0.33 | $46.23 | $57,209,625 |

| Commercial | 1,250,000 | 0.50 | 46.23 | 28,893,750 |

| Total | $86,103,375 |

22 See Exhibit 4: Affected Cylinders.

23 See NPGA Supplement: https://www.regulations.gov/document?D=PHMSA-2017-0083-0003.

24 U.S. BLS wage rate is based on 2015 Occupational and Employment Statistics Survey (OES) for NAICS 454310 (https://www.bls.gov/oes/current/naics4_454300.htm). Total labor rate also includes other costs of employee compensation (i.e., benefits) based on BLS' Employer Costs for Employee Compensation Summary, which indicates that private industry labor rates are, overall, comprised of wages/salaries (68.6%) and benefits (30.2%), https://www.bls.gov/news.release/ecec.nr0.htm.

PHMSA interprets this impact as a “one-time” cost savings that is assumed to occur over a one-year period during 2019. We do not distinguish these cost savings on a month-to-month basis because we do not have data relaying the specific manufacturing dates of the affected cylinders. Further, this may not be relevant if requalification dates are uniformly distributed across different months of the year.

There is also cost savings due to enduring, year-over-year effects in which the number of cylinders in need of requalification is expected to be fewer in the rulemaking scenario. With a longer requalification timeframe (12 years vs. 10 years), there are fewer cylinders in need of requalification in a given year. In a previous section regarding the affected number of cylinders, PHMSA estimated that 20% fewer cylinders would be in need of requalification in the rulemaking scenario. Combining this 20% estimate with the cost findings related to year one impacts, we can estimate enduring, year-over-year cost savings. This assumes that input values (e.g., labor rates, time to requalify, breakdown of cylinder types) remain constant over the time period of analysis. For example, labor rates are assumed to be constant; if they were adjusted to reflect inflation, our cost savings estimate would be higher.

Thus, Exhibit 6-1 above provides that the accelerated requalification of 2 cylinder vintages would result in approximately $86 million. We divide that figure in half to represent annual requalification costs and then take 20% of the resulting figure to estimate enduring, year-over-year cost savings.25 This gives approximately $8.6 million in undiscounted, yearly cost savings. Equivalently, if 500,000 extra cylinders need requalification on an on-going basis in the baseline, this amounts to 1/10th of the “glut” created by the accelerated requalification in year one and hence 10% of the estimated costs.26 Exhibit 6-2 below presents these cost savings in years 2-10, as well as the year-one cost savings based on avoidance of accelerated requalification. We present undiscounted (0%) and 3% and 7% discount rates.

25 $86,103,375/2 = $43,051,688. $43,051,688 * 0.2 = $8,610,337.60.

26 $86,103,375 * 0.10 = $8,610,337.5

| Year | Undiscounted (0%) | 3% | 7% |

|---|---|---|---|

| 1 | $86,103,375 | $86,103,375 | $86,103,375 |

| 2 | 8,610,338 | 8,359,551 | 8,047,044 |

| 3 | 8,610,338 | 8,116,069 | 7,520,602 |

| 4 | 8,610,338 | 7,879,679 | 7,028,600 |

| 5 | 8,610,338 | 7,650,173 | 6,568,785 |

| 6 | 8,610,338 | 7,427,353 | 6,139,052 |

| 7 | 8,610,338 | 7,211,022 | 5,737,431 |

| 8 | 8,610,338 | 7,000,992 | 5,362,085 |

| 9 | 8,610,338 | 6,797,080 | 5,011,295 |

| 10 | 8,610,338 | 6,599,107 | 4,683,453 |

| Net Present Value (Total) | 153,144,405 | 142,201,727 | |

| Annualized | 17,953,196 | 20,246,327 | |

Therefore, if this proposed rule is adopted, cylinder marketers in the 454310 Fuel Dealers NAICS sector would be relieved of requalifying approximately 5 million cylinders in year one, which would save them approximately $86 million dollars in costs (undiscounted). Conversely, $86 million in requalification costs would be imposed in year one if this rulemaking is not adopted, which this analysis assumes would sustain HM-233F's requirement for a 10-year requalification timeframe. Moreover, if adopted, cylinder marketers would have 20% fewer cylinders to requalify in each year after year one. This results in cost savings of approximately $8.6 million in years 2-10 (undiscounted).

Combining these two cost savings effects together, cylinder marketers are expected to save $142.2 million over 10 years, discounted at 7%. On an annual basis, they are expected to save $20.2 million annualized at 7%. We use these figures to calculate total net cost savings later in the document, but first we must account for training-related cost savings, as well as some training-related costs, due to the rulemaking scenario.

Analysis of Training Costs and Cost Savings

This rulemaking may relieve approximately 18,000 cylinder manufacturing employees from needing training. In the baseline scenario, these cylinder manufacturing employees may need to change the way they voluntarily stamp newly-manufactured cylinders, necessitating training; conversely, in the rulemaking scenario, their stamping practices can remain unchanged, avoiding this training and associated costs. The net effect of these training-related impacts is quantified in the section, “Analysis of total net cost savings.”

However, this rulemaking is also likely to result in approximately 36,000 cylinder marketer employees to need training on the proposed changes to proof pressure requalification periods. Specifically, PHMSA is proposing to retain the 10-year requalification timeframe for cylinders that are initially requalified using proof pressure testing. This may provide cylinder marketers regulatory relief by reducing the requalification frequency for proof pressure, but it is also likely to necessitate training because this proposal diverges from the standards in place before the HM-233F final rule. PHMSA seeks comment on this proposal.

Regarding the training of cylinder marketers, their employees need to understand that a 12-year timeframe applies to cylinders initially and subsequently requalified by volumetric expansion testing, and that a 10-year timeframe applies to cylinders requalified by proof pressure testing after an initial 12-year period. In P-1696, NPGA suggests that this training would take two hours per employee and that approximately half of employees would require training. 27 PHMSA believes only the training portion related to proof pressure testing is a relevant change, so we assume this training takes just one hour per employee, and, as stated by NPGA, that half of employees would require training. Thus, we take the number of employees for the 454310 Fuel Dealers sector from Exhibit 5 (73,555) and divide it by 2 to get the number of these employees requiring training (73,555/2 = 36,778, with rounding). We use the hourly labor rate for these 454310 Fuel Dealers employees, as exhibited in Exhibit 6-1 ($46.23), and multiply by 1 training hour to estimate the cost to train each employee ($46.23 * 1 = $46.23). We then multiply $46.23 by the number of 454310 Fuel Dealers employees requiring training to estimate the training cost for these employees ($46.23 * 36,778 = $1,700,247, with rounding).

27 See P-1696: https://www.regulations.gov/docket?D=PHMSA-2017-0019.

As NPGA explains in P-1696, millions of cylinders currently in service show a stamp placed during manufacture, indicating that the cylinder must be requalified 12 years after the manufacture date. Under the baseline scenario, cylinder manufacturers would need to adjust this stamp to indicate a 10-year period. From this vantage, this proposed rulemaking results in training cost savings for cylinder manufacturers, not training costs; in other words, the regulations proposed here ensure that cylinder manufacturers can continue the industry practice of stamping to reflect the 12-year timeframe for initial requalification.

To estimate training cost savings for cylinder manufacturers, PHMSA references NPGA's estimate that training would take two hours per employee and that approximately half of employees would require training.28 Thus, we take the number of employees for the 332420 Metal Tank Manufacturing NAICS sector from Exhibit 5 (36,869) and divide it by 2 to get the number of these employees requiring training (36,869/2 = 18,435, with rounding). We use $52.48 as the hourly labor rate for 332420 Metal Tank Manufacturing employees and multiply by 2 training hours to estimate the cost to train each employee ($52.48 * 2 = $104.96).29 We then multiply $104.96 by the number of 332420 Metal Tank Manufacturing employees requiring training to estimate the training cost savings for these employees ($104.96 * 18,435 = $1,934,938, with rounding).

28 Ibid.

29 U.S. BLS wage rate is based on 2015 Occupational and Employment Statistics Survey (OES) for NAICS 332420. Total labor rate also includes other costs of employee compensation (i.e., benefits) based on BLS' Employer Costs for Employee Compensation Summary; available at: https://www.bls.gov/news.release/ecec.nr0.htm.

Based on these assumptions, input values, and methods, PHMSA estimates net cost savings related to training, totaling approximately $0.2 million dollars (undiscounted). See Exhibit 7. These training costs and cost savings would occur in year one of implementation of the rulemaking and are not discounted. They are not modeled to repeat in subsequent years.

| NAICS Sector | Number of employees 30 | Percent trained | Number of employees trained | Training hour(s) | Labor rate 31 | Total training cost |

|---|---|---|---|---|---|---|

| Fuel Dealers (454310) | 73,555 | 50 | 36,778 | 1 | $46.23 | $1,700,247 |

| Manufacturers (332420) | 36,869 | 50 | 18,435 | 2 | 52.48 | (1,934,938) |

| Total | (234,691) |

30 CB1400A11: Geography Area Series: County Business Patterns 2014 Business Patterns.

31 U.S. BLS wage rate is based on 2015 Occupational and Employment Statistics Survey (OES) for NAICS 454310 and 332420. Total labor rate also includes other costs of employee compensation (i.e., benefits) based on BLS' Employer Costs for Employee Compensation Summary, available at: https://www.bls.gov/news.release/ecec.nr0.htm.

Analysis of Total Net Cost Savings

PHMSA outlined our assumptions, input values, and methods for estimating the expected costs and cost savings of this rulemaking. We now present the total net cost savings as the sum of net cost savings to both 454310 Fuel Dealers and 332420 Manufacturers. See Exhibit 8-1. As such, we estimate total net cost savings at approximately $163.8 million dollars, undiscounted.

| Sector | Cost savings (“avoided accelerated requalification” in year 1) | Cost savings (“enduring” reduction in annual number of needed requalifications) | Training cost savings 32 | Net cost savings |

|---|---|---|---|---|

| Fuel Dealers (454310) | $86,103,375 | $77,493,038 | ($1,700,247) | $161,896,166 |

| Manufacturers (332420) | 0 | 0 | 1,934,938 | 1,934,938 |

| Total | 86,103,375 | 77,493,038 | 234,691 | 163,831,104 |

32 A value in parenthesis indicates a cost, or a “negative cost savings.”

We also discount these savings over the time period of analysis. See Exhibit 8-2. To year one, we add the net cost savings related to training ($234,691) to cost savings related to the avoidance of accelerated requalification ($86,103,375), yielding $86,338,066 in cost savings in year one. The year-one impacts related to both effects are not discounted; they are assumed to occur at present value. However, the “enduring” cost savings are discounted according to the discount rate and the appropriate year in which the savings occurs. As such, we estimate total net cost savings of $142.4 million over 10 years, discounted at 7%, and $20.3 million annualized at 7%. These total figures do not differ much from the results presented in Exhibit 6-2 because training impacts are very small relative to requalification impacts.

| Year | Undiscounted | 3% | 7% |

|---|---|---|---|

| 1 | $86,338,066 | $86,338,066 | $86,338,066 |

| 2 | 8,610,338 | 8,359,551 | 8,047,044 |

| 3 | 8,610,338 | 8,116,069 | 7,520,602 |

| 4 | 8,610,338 | 7,879,679 | 7,028,600 |

| 5 | 8,610,338 | 7,650,173 | 6,568,785 |

| 6 | 8,610,338 | 7,427,353 | 6,139,052 |

| 7 | 8,610,338 | 7,211,022 | 5,737,431 |

| 8 | 8,610,338 | 7,000,992 | 5,362,085 |

| 9 | 8,610,338 | 6,797,080 | 5,011,295 |

| 10 | 8,610,338 | 6,599,107 | 4,683,453 |

| Net Present Value (Total) | $153,379,096 | $142,436,418 | |

| Annualized | $17,980,709 | $20,279,741 | |

Evaluation of Non-Quantified and Non-Monetized Impacts

PHMSA has not estimated quantitatively all the possible cost and cost-savings impacts of this rulemaking. This is due to data availability and uncertainty surrounding the actual impacts of the rulemaking if it is made effective. Ultimately, the actual impacts of the rulemaking may vary from the representation in this analysis; this analysis merely represents our expectations based on the available data and our professional judgment. For these reasons, PHMSA solicits comment on this rulemaking and its analysis as expressed in this NPRM.

To address some of these uncertainties and data limitations, we have identified various non-quantified costs and cost savings that might result from adopting this rulemaking. Our discussion here of non-quantified and non-monetized impacts is not exhaustive. For example, PHMSA can identify the following potential impacts, which are not quantified or monetized in this analysis:

1. Changes in the number of cylinders taken out of service due to accelerated requalification requirements;

2. Changes in the demand for or supply of DOT 4-series cylinders and requalification services; and

3. Changes in the prices faced by propane consumers.

If this rulemaking is not adopted, PHMSA expects there may be changes in the number of cylinders that are taken out of service in the first year of the rule's effect due to failure of a requalification test. The HM-233F final rule accelerated initial requalification requirements, resulting in industry performing triple the number of requalification tests during year one. The increase in the number of requalification tests performed in year one means there could also be an increase in the number of cylinders that are taken out of service as a result of the requalification testing. To the degree that accelerated testing would result in cylinders being removed from service sooner, cylinder marketers would incur costs to acquire more replacement cylinders. PHMSA has not quantified the number of cylinders that might be “prematurely” taken from service and has not monetized the costs of replacing them. This represents a new category of potential costs under the baseline scenario and a new category of potential cost savings for cylinder marketers under the petition scenario. As such, the cost savings of adopting this rulemaking may be understated. Therefore, PHMSA seeks comments and any supporting data on this analysis, including comments and data regarding the potential effect of accelerated requalification on the number of cylinders removed from service and associated costs.

In addition, if this rulemaking is not adopted, PHMSA can anticipate changes in the supply of and demand for DOT 4-series specification cylinders, as well as cylinder requalification services. For instance, accelerated requalification requirements may be expected to result in higher costs for cylinder marketers, disincentivizing cylinder supply in the overall market. Similarly, a temporary increase in the demand for cylinder requalification services could affect the price of these services faced by cylinder marketers. As another example, accelerated requalification requirements may result in increased demand for newly manufactured cylinders to the extent that they are a substitute for requalified cylinders. A temporary increase in the demand for newly manufactured cylinders might result in a temporary increase in economic activity for that sector and could affect the prices for these cylinders and the revenues of cylinder manufacturing companies. PHMSA has not quantified these market dynamics because of their complexity and highly uncertain nature.

Lastly, there is uncertainty about the potential impact on consumers (e.g., propane end-users), so PHMSA has not quantified downstream price impacts. This is also a question of market dynamics. Specifically, the baseline scenario may result in price increases for propane-related goods and services for end-use consumers to the degree that the cylinder manufacturers and marketers are able to pass additional costs onto consumers.

Characterization of Additional Uncertainty in Impacts, Including Estimated Costs, Cost Savings, and Net Cost Savings

The discussion in the previous section characterizes non-quantified and non-monetized impacts of this rulemaking. Other impacts were quantified and/or monetized in this analysis, but PHMSA's estimates remain uncertain. As such, this section characterizes additional uncertainty in the quantitative impacts estimated in this analysis. Note that this discussion is not exhaustive. PHMSA solicits comments on our analysis, including commentary on where our estimates could be improved and findings made more accurate. We note uncertainty in these quantitative areas:

1. Estimate of the number of affected entities and employees;

2. Estimate of the training hours necessitated by the rulemaking;

3. Estimate of the labor hours needed to requalify affected cylinders;

4. Estimate of the number of affected cylinders;

5. Proportion of cylinders initially requalified by proof pressure testing (estimated only in the supplemental analysis); and

6. Number of cylinders initially requalified by proof pressure testing (estimated only in the supplemental analysis).

As outlined, there is uncertainty regarding the estimate of the number of affected entities and, thus, the number of affected employees, per Exhibit 5. This uncertainty arises from the fact that only some establishments in NAICS 454310 Fuel Dealers may sell fuels in DOT 4-series specification cylinders affected by §180.209(e). There may also be propane marketing entities in other NAICS sectors, but current data do not support estimates of the portion of affected establishments in additional sectors. These uncertainties may result in training costs or cost savings being over or underestimated. Since the number of affected entities is not actually used as an input variable to determine training costs or cost savings, we do not explore this variable in a supplemental analysis.

As another example of uncertainty in this analysis, PHMSA is not able to corroborate the NPGA estimate regarding the amount of time required for training. NPGA estimated that each employee would need two hours to be appropriately trained on the revised requalification periods. Since training costs are proportionately small compared to estimated requalification cost savings, we do not explore this uncertainty in a supplemental analysis. To illustrate this point, consider a simple example. Doubling the amount of time for training cylinder marketing employees would double estimated training costs, from approximately $1.7 million to $3.4 million, yet training costs would remain a relatively small proportion of the estimated, year-one requalification cost savings ($3.4 million/$86.1 million = 3.9%). It is unlikely that variance in this input value would alter PHMSA's assessment that this rulemaking provides total net cost savings.

We are also unable to corroborate NPGA's estimate regarding the amount of time required to requalify affected cylinders. To the extent that it takes longer to requalify affected cylinders, requalification costs are understated in the baseline scenario and cost savings are understated in the rulemaking scenario. If less time is required to requalify affected cylinders, the reverse is true: Requalification costs are overstated in the baseline scenario and requalification cost savings are overstated in the rulemaking scenario. However, we believe that NPGA is uniquely positioned to estimate this variable due to the nature of its member representation. For this reason, we do not explore this variable with a supplemental analysis.

Furthermore, PHMSA is not able to corroborate the NPGA estimate for the number of affected cylinders. In this analysis, we rely on NPGA's estimate of approximately 5 million cylinders affected due to accelerated requalification. The number of cylinders affected is a critical input value for the estimation of cylinder requalification costs and cost savings in the baseline and rulemaking scenarios, respectively. Moreover, this specific variable presents uncertainty in that the NPGA estimate may be overestimated. This is because the HMR allow a cylinder, filled before the requalification becomes due, to remain in service until it is emptied.33 As such, filled cylinders may remain in service, and cylinder marketers would not need to remove compliant cylinders from service to meet the 10-year requalification timeframe codified in the HM-233F final rule and presented in this analysis as the baseline scenario. To the extent that fewer cylinders need to be requalified to meet the 10-year timeframe in the baseline scenario, the requalification costs estimated in the baseline scenario and the requalification cost savings in the rulemaking scenario are both overstated. To explore this uncertainty further, we provide a supplemental analysis regarding the number of affected cylinders in the following section.

33 See §180.205(c).

Lastly, PHMSA notes uncertainty regarding the proportion and number of affected cylinders that would be requalified using proof pressure testing versus other methods. Proof pressure testing is an alternative to volumetric expansion testing. Despite proposing to retain the 10-year timeframe for a cylinder initially requalified by proof pressure testing, PHMSA did not include proof pressure-related requalification cost savings in our primary estimates because of the uncertainty surrounding the extent to which proof pressure testing is used to requalify the affected cylinders. If it is costlier to requalify using proof pressure testing than volumetric expansion testing and requalifiers continue to use proof pressure methods, then costs may be understated in the baseline scenario and cost savings may be understated in the rulemaking scenario. To the extent that requalifiers use proof pressure testing and it is less costly to requalify by proof pressure testing, then costs may be overstated in the baseline scenario and cost savings may be overstated in the rulemaking scenario. There also may be little or no difference between the costs of requalifying by volumetric expansion and proof pressure testing. PHMSA solicits comment on the extent of proof pressure testing versus other requalification methods.

Furthermore, our requalification cost savings analysis characterizes the timing of initial requalification in relation to cylinder manufacture. Refer to Exhibit 3. For volumetric expansion testing, the distinction between initial and subsequent requalification tests is not relevant since they would both occur at 12-year intervals; however, for proof pressure testing, the question of whether the cylinder is being initially or subsequently requalified is relevant and would determine the regulatory timeframe that applies (12 or 10 years). Noting this distinction, it may be reasonable to conceive of the cost-savings impacts on proof pressure-tested cylinders as altogether separate and possibly affecting a different, older pool of cylinders. We do not know whether the estimate of affected cylinders that NPGA provided accommodates this distinction. Put another way, uncertainty surrounds the proportion and number of cylinders that would be initially requalified by proof pressure testing versus volumetric expansion testing, as well as the overall number of cylinders that are requalified using proof pressure testing during subsequent requalification tests. These uncertainties are substantial to the point that we refrain from including cost savings related to proof pressure-tested cylinders in our primary estimates.

Nevertheless, we provide a supplemental analysis for the possible cost savings effects on proof pressure-tested cylinders, specifically how this proposed rulemaking would affect different vintages of cylinders that would initially be requalified by proof pressure (at the 12-year mark) and subsequently requalified at the 10-year mark as opposed to the 7-year mark, amounting to a 3-year deferral of these requalification tests and associated costs. This supplemental analysis is found in the section, “Supplemental analysis regarding possible effects on proof pressure-tested cylinders.”

See Exhibit 9 for a distillation of the uncertainties discussed in this analysis.

| Variable | Estimate(s) | Source | Description of uncertainty |

|---|---|---|---|

| Number of affected entities | Fuel Dealers: 8,677 Manufacturers: 739 Total: 9,416 | U.S. Census |

|

| Number of affected employees | Fuel Dealers: 36,778 Manufacturers: 18,435 Total: 55,213 | U.S. Census |

|

| Training hours per employee | 1-2 | NPGA |

|

| Percent of affected employees in need of training | 50% | NPGA |

|

| Labor hours to requalify residential and commercial cylinders | Residential: 0.33 hours Commercial: 0.5 hours | NPGA |

|

| Labor rates | Fuel Dealers: $46.23 Manufacturers: $52.48 | U.S. BLS |

|

| Number of affected cylinders | 5,000,000 | NPGA |

|

| Number of cylinders removed from service early | Non-quantified | N/A |

|

| Cost to requalify (market dynamics) | Non-quantified | N/A |

|

| Cost of newly manufactured cylinders (market dynamics) | Non-quantified | N/A |

|

| End-user cylinder prices (market dynamics) | Non-quantified | N/A |

|

| Proportion of proof pressure-tested cylinders | Non-quantified in primary analysis | N/A |

|

| Number of affected proof pressure-tested cylinders | Non-quantified in primary analysis | N/A |

|

Supplemental Analysis Regarding the Number of Affected Cylinders

As previously discussed, PHMSA believes the number of affected cylinders may differ from NPGA's estimate of 5 million affected cylinders. For example, affected cylinders may be fewer than 5 million due to existing allowances in the HMR. Specifically, a cylinder that is filled prior to its requalification date may remain in service until it is emptied. For this reason, the number of cylinders that would need to undergo accelerated requalification in the baseline scenario could be fewer than estimated, and associated costs would be less than estimated. Similarly, the cost savings in the rulemaking scenario would be less than estimated. For example, imagine a cylinder manufactured in 2009; in the baseline scenario, this cylinder would need to be initially requalified in 2019 (10 years later), even though cylinder marketers conventionally expected this cylinder to be requalified in 2021 (12 years later). If that cylinder were filled prior to 2019, but remained in service to the end-user until 2021, this cylinder would not need to be requalified until 2021 despite the regulatory change made in the HM-233F final rule.

Thus, for this cylinder, the baseline and rulemaking scenario are no different. No new cost is imposed in the baseline; no cost savings are achieved by adopting this rulemaking.

Nevertheless, PHMSA does not have data to estimate the number of cylinders that would remain in service under HMR allowances despite the acceleration of their requalification date, and NPGA may have considered this factor when developing its estimate. Even if data were available, this task of differentiating cylinders in this manner would undoubtedly be complicated given differences in service periods. Since we are unable at this time to corroborate NPGA's estimate, PHMSA also considers a scenario where the number of affected cylinders may be greater than estimated in this analysis. This could be the case if NPGA based its estimate on information from its members and there are marketers that are not members of NPGA who requalify cylinders.

In the absence of additional data, PHMSA uses a simple, assumption-based method to present the cost saving variances that would be expected if the number of affected cylinders were 25 percent fewer or 25 percent greater. This gives us a range of requalification cost-savings estimates occurring in year one, and over the 10-year time period of analysis. See Exhibit 10.

| Scenario label(s) | Number of affected cylinders | Proportion of primary estimate | Estimated requalification cost savings (year one) | Total estimated requalification cost savings (years 1-10) |

|---|---|---|---|---|

| High | 6,250,000 | 1.25 | $107,629,219 | $204,495,516 |

| Primary/Middle/NPGA | 5,000,000 | 1.0 | 86,103,375 | 163,596,413 |

| Low | 3,750,000 | 0.75 | 64,577,531 | 122,697,309 |

This simple, straightforward exercise shows that cost savings would be lower if fewer cylinders are affected by the proposed rule due to, for example, the current HMR allowance to keep a cylinder in service past its requalification date. Similarly, if the number of affected cylinders is greater than estimated, cost savings would also be greater. PHMSA solicits comments on this analysis, including the supplemental analysis and our estimate of the number of affected cylinders (5 million) in year one, which is the same as NPGA's. Despite the allowance for in-service cylinders in the HMR and other uncertainties, we continue to use NPGA's estimate because it is the best data available.

Supplemental Analysis Regarding Possible Effects on Proof Pressure-Tested Cylinders

PHMSA focused its cost savings analysis on revising the requalification timeframe for cylinders that are requalified by volumetric expansion. This reflects NPGA's emphasis in its petition for rulemaking (P-1696) and the uncertainty surrounding the extent of impacts on proof pressure-tested cylinders. As discussed in this analysis, PHMSA does not know the proportion or total number of affected cylinders that would be requalified using proof pressure testing, or whether these variables would have any material influence on our cost and cost savings estimates. Similarly, we do not know whether proof pressure-tested cylinders constitute an additional (and possibly older) pool of affected cylinders beyond NPGA's estimate of 5 million cylinders affected in year one. If so, then cost and cost savings estimates may be understated in this analysis. Nevertheless, PHMSA explores the possible effects on proof pressure-tested cylinders in this supplemental analysis. Specifically, we explore the difference between a 7-year timeframe and a 10-year timeframe for cylinder requalification occurring after initial requalification (i.e., “subsequent” or second requalification). By way of the HM-233F final rule, the HMR currently reflect a 10-year timeframe for both initial and subsequent requalification of proof pressure-tested cylinders, whereas the pre-HM-233F standard held that proof pressure-tested cylinders would be initially requalified at the 12-year mark and subsequently requalified on a 7-year timeframe.

In its petition, NPGA appears to recommend that the proof pressure standard for subsequent requalification be reverted to the 7-year timeframe in the HMR prior to HM-233F's publication.34 In contrast, this NPRM proposes to retain the 10-year requalification timeframe since it may add relief. PHMSA solicits comment on this proposal.

34 See P-1696: https://www.regulations.gov/docket?D=PHMSA-2017-0019.

PHMSA believes this proposal would offer additional relief because it would enable cylinder marketers to defer by up to 3 years the subsequent requalification of cylinders that would otherwise be subject to the 7-year requirement. This deferral changes the timing of cash flow obligations for cylinder marketers and presents a potential cost savings.

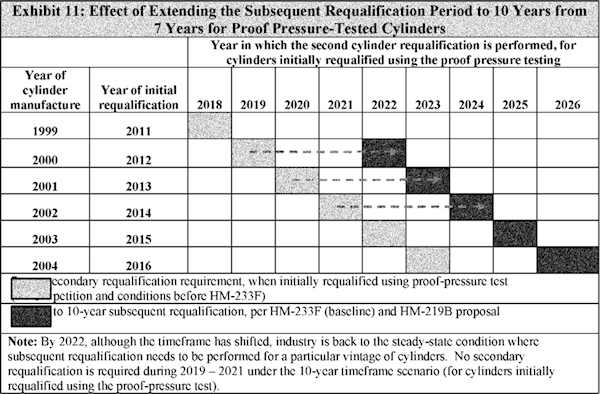

Exhibit 11 illustrates the difference between the 7- and 10-year proof pressure requalification timeframes. Please note, this supplemental analysis relays these abstract scenarios for analysis purposes only; one must refer to the regulatory text of the proposed rule to understand actual regulatory changes and effects.

BILLING CODE 4910-60-P

BILLING CODE 4910-60-C

Exhibit 11 illustrates the effects of the proposal to allow a 3-year deferral of subsequent requalification by proof pressure test. In 2019, under the 7-year requirement, industry would requalify cylinders manufactured in 2000 and initially requalified using proof pressure in 2012; that same set of cylinders would need to be subsequently requalified 7 years later in 2019. In contrast, under the 10-year requirement, industry could defer requalifying those same cylinders until 2022. By 2022, although the timeframe has shifted, industry is back to a more normal condition where subsequent requalification needs to be performed annually.

The potential value of these cost savings is less certain than the cost savings estimates in the primary analysis, because it is not clear what proportion of requalification tests are performed using proof pressure testing (and therefore what number of cylinders would be affected).35 Due to this uncertainty, we do not incorporate proof pressure-related cost savings into our primary analysis and its estimation of requalification cost savings. However, by adopting some assumptions similar to those used in our primary analysis, it is possible to provide an approximate measure of these cost savings.

35 It is also somewhat further complicated by the fact that the provision applies not just to a second requalification, but any requalification that follows a prior requalification performed using the proof-pressure test (third, fourth, etc.).