['Hazmat: Highway']

['Explosive documents']

07/16/2025

...

Federal Register, July 15, 2014

DEPARTMENT OF TRANSPORTATION

Pipeline and Hazardous Materials Safety Administration

49 CFR Parts 171, 172, 173, and 177

[Docket No. PHMSA-2011-0345 (HM-233D)]

RIN 2137-AE86

Hazardous Materials: Requirements for the Safe Transportation of Bulk Explosives (RRR)

AGENCY: Pipeline and Hazardous Materials Safety Administration (PHMSA), DOT.

ACTION: Notice of proposed rulemaking (NPRM).

SUMMARY: The Pipeline and Hazardous Materials Safety Administration is proposing to amend the Hazardous Materials Regulations by establishing standards for the safe transportation of bulk explosives. This rulemaking would be responsive to two petitions for rulemaking submitted by industry representatives: P-1557 concerning the continued use of renewal applications, and P-1583 concerning the incorporation of an industry standard publication. Further, developing these requirements would provide wider access to the regulatory flexibility currently only offered by special permit and competent authorities.

The requirements of this proposed rule would mirror the majority of provisions contained in nine widely used or longstanding special permits that have established safety records. These proposed revisions are intended to eliminate the need for future renewal requests, thus reducing paperwork burdens and facilitating commerce while maintaining an appropriate level of safety. As proposed, the requirements would authorize the transportation of certain explosives, ammonium nitrates, ammonium nitrate emulsions, and other specific hazardous materials in bulk packagings, which are not otherwise authorized under the regulations. These hazardous materials are used in blasting operations on specialized vehicles, known as multipurpose bulk trucks, which are used as mobile work platforms to create blends of explosives that are unique for each blast site. Finally, this rulemaking addresses the construction of new multipurpose bulk trucks.

DATES: Comments must be submitted by September 15, 2014. To the extent possible, PHMSA will consider late-filed comments as a final rule is developed.

ADDRESSES: You may submit comments by identification of the docket number (PHMSA-2011-0345 (HM-233D)) by any of the following methods:

- Federal eRulemaking Portal: Go to http://www.regulations.gov. Follow the online instructions for submitting comments.

- Fax: 1-202-493-2251.

- Mail: Docket Operations, U.S. Department of Transportation, West Building, Ground Floor, Room W12-140, Routing Symbol M-30, 1200 New Jersey Avenue SE., Washington, DC 20590.

- Hand Delivery: To Docket Operations, Room W12-140 on the ground floor of the West Building, 1200 New Jersey Avenue SE., Washington, DC 20590, between 9 a.m. and 5 p.m., Monday through Friday, except Federal holidays.

Instructions: All submissions must include the agency name and docket number for this notice at the beginning of the comment. All comments received will be posted without change to the Federal Docket Management System (FDMS), including any personal information.

Docket: For access to the dockets to read background documents (including the Regulatory Impact Analysis (RIA)) or comments received, go to http://www.regulations.gov or DOT's Docket Operations Office (see ADDRESSES).

FOR FURTHER INFORMATION CONTACT: Matthew Nickels, Standards and Rulemaking Division, Office of Hazardous Materials Safety, Pipeline and Hazardous Materials Safety Administration, U.S. Department of Transportation, telephone (202) 366-8553, 1200 New Jersey Avenue SE., Washington, DC 20590.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Executive Summary

II. Background

III. Summary Review of Proposed Amendments

IV. Regulatory Analyses and Notices

A. Statutory/Legal Authority for this Rulemaking

B. Executive Order 13610, Executive Order 13563, Executive Order 12866, and DOT Regulatory Policies and Procedures

C. Executive Order 13132

D. Executive Order 13175

E. Regulatory Flexibility Act, Executive Order 13272, and DOT Procedures and Policies

F. Paperwork Reduction Act

G. Regulatory Identifier Number (RIN)

H. Unfunded Mandates Reform Act

I. Environmental Assessment and Finding of No Significant Impact

J. Privacy Act

K. Executive Order 13609 and International Trade Analysis

L. National Technology Transfer and Advancement Act

V. List of Subjects

I. Executive Summary

In this notice of proposed rulemaking (NPRM), the Pipeline and Hazardous Materials Safety Administration (PHMSA) proposes to amend the Hazardous Materials Regulations (HMR) by establishing standards for the safe transportation of bulk explosives. This rulemaking would be responsive to two petitions for rulemaking submitted by industry representatives: P-1557, concerning the continued use of renewal applications, and P-1583, concerning the incorporation of an industry standard publication. Further, developing these requirements would provide wider access to the regulatory flexibility currently offered only by special permit and competent authority approvals. These proposed revisions are intended to eliminate the need for future renewal requests of nine special permits (the transportation of certain explosives, ammonium nitrates, ammonium nitrate emulsions, and other specific hazardous materials in bulk packaging) that have established safety records. The revisions would reduce paperwork burdens and facilitate commerce while maintaining a appropriate level of safety.

This rulemaking specifically proposes to adopt a combination of features, including: incorporating by reference (IBR) the Institute of Makers of Explosives' (IME) Safety Library Publication No. 23 “Recommendations for the Transportation of Explosives, Division 1.5, Ammonium Nitrate Emulsions, Division 5.1, Combustible Liquids, Class 3 and Corrosives, Class 8 in Bulk Packaging” (referred to as SLP-23); requiring fire suppression systems in heat containing compartments (e.g., engine, transmission, etc.) and emergency shut-off/battery disconnect of newly constructed or modified multipurpose bulk trucks (MBTs); and complying with certain National Highway Traffic Safety Administration (NHTSA) requirements. PHMSA believes this NPRM will be of benefit to both the public and the industry, as it will: (1) Eliminate the need for firms to apply individually for the transportation of certain classes of bulk materials in MBTs, (2) provide regulatory flexibility and relief while maintaining an high level of safety, (3) promote safer transportation practices, (4) facilitate commerce, (5) reduce paperwork burdens, (6) protect the public health, welfare, safety, and environment, and (7) eliminate unnecessary regulatory requirements. Finally, with this rulemaking amending the HMR by incorporating IME publication SLP-23, the majority of provisions from nine special permits will be incorporated since those permits were used as the basis to create the SLP-23 document.

This NPRM affects the following entities and proposes the following requirements:

| Affected entities | Proposals |

|---|---|

|

|

|

|

| |

|

The overall costs and benefits of the proposed regulations are dependent on the level of preexisting compliance with the nine special permits and the overall effectiveness of the proposed regulations (e.g., flexibility provided when incorporating portions or whole special permits). Additionally, we believe the net benefits of these proposals will be attractive to the explosives industry as it will allow them to do business in a faster manner, and consequently provide significant cost savings.

The costs associated with the proposed rule are primarily driven by the one-time cost of equipping newly constructed or modified MBTs with fire suppression systems. The other costs associated with this NPRM are estimated to be much smaller. The primary driver for the benefits from this NPRM is the cost savings associated with the incorporation by reference of SLP-23. PHMSA estimates that the positive economic effects of this rulemaking, once finalized and adopted, will be sustained indefinitely. The table below summarizes the calculated costs and benefits associated with this NPRM.1

1For further discussion regarding the individual NPRM provisions, please see Section IV of this document and the regulatory impact assessment available in the public docket for this rulemaking.

| Item | One-time costs | Recurring annual costs | Cost savings per year |

|---|---|---|---|

| Industry Applications for SP | $0 | 0 | $62,700 |

| PHMSA Review of SP Applications | $0 | 0 | 31,464 |

| Tire-Pressure Checks | 0 | 0 | 14,800,000 |

| Fire Extinguishers | 408,750 | 0 | 0 |

| Working Pressure Limit | 450,000 | 0 | 0 |

| Caking | 0 | 0 | 90,000 |

| Periodic Inspections/Tests | 0 | 1,300,000 | 0 |

| Nameplate | 187,500 | 0 | 0 |

| Accident Investigations | 0 | 20,000 | 0 |

| Driver Training | 0 | 9,000 | 0 |

| Maintaining/Updating SLP-23 | 0 | 50,000 | 1,300,000 |

| Reduced Paperwork Burden | 0 | 0 | 3,420 |

| Cost of Fire-Suppression Systems | 9,375,000 | 0 | 0 |

| Total | 10,421,250 | 1,379,000 | 16,287,584 |

Under the NPRM, the one-time costs are approximately $10.4 million; the recurring annual costs are approximately $1.4 million. The net present value of these costs discounted at 3 percent and 7 percent over the 10 years is approximately $22 million and $19 million, respectively. The annualized cost of the rule discounted at 3 percent is $2.2 million and at 7 percent is approximately $1.9 million.

The present values of the $16.3 million in annual cost savings (which represent the major benefits of the proposed rule) discounted at 3 percent and 7 percent over 10 years are approximately $143 million and $122 million, respectively. The annualized benefits at 3 percent are $14.3 million and at 7 percent are $12.2 million.

The annualized net benefits of the proposed rule at 3 percent are approximately $12.1 million ($14.3 million in annualized benefits—$2.2 million in annualized costs) and at 7 percent are approximately $10.3 million ($12.2 million in annualized benefits—$1.9 million in annualized costs). As such, PHMSA has concluded that the aggregate benefits justify the aggregate costs. A summary of the expected annualized costs and benefits is provided in the table below.

| Annualized Benefit (in 2013 $) | $12.2-14.3 million |

| Annualized Cost (in 2013 $) | $1.9-2.2 million |

| Benefit-Cost Ratio. | 6.4-6.5 |

| Annualized Net Benefit | $10.3-12.1 million |

PHMSA requests comments on the analysis underlying these estimates, as well as possible approaches to reduce the costs of this rule while maintaining or increasing the benefits. Additionally, PHMSA seeks comments on possible changes that might improve the rule and increase regulatory flexibility.

II. Background

Special Permits

The Pipeline and Hazardous Materials Safety Administration (PHMSA) is proposing to amend the Hazardous Materials Regulations (HMR; 49 CFR Parts 171-180) by establishing standards for the safe transportation of bulk explosives. These proposed standards for bulk explosives will mirror the majority of provisions contained in nine widely-used longstanding special permits issued by PHMSA under 49 CFR Part 107, Subpart B (§§107.101 to 107.127). A special permit sets forth alternative requirements (variances) to the requirements in the HMR in a way that achieves a safety level at least equal to the safety level required under the regulations or that is consistent with the public interest. Congress expressly authorized DOT to issue these variances in the Hazardous Materials Transportation Act of 1975 as amended.

The HMR generally are performance oriented regulations, which provide the regulated community with a certain amount of flexibility in meeting safety requirements. Even so, not every transportation situation can be anticipated and built into the regulations. Innovation is the strength of our economy and the hazardous materials community is particularly strong at developing new materials and technologies and innovative ways of moving materials. Special permits enable the hazardous materials industry to quickly, effectively, and safely integrate new products and technologies into production and the transportation stream. Thus, special permits provide a mechanism for testing new technologies, promoting increased transportation efficiency and productivity, and ensuring global competitiveness.

Hazardous materials transported under the terms of a special permit must achieve a level of safety at least equal to the level of safety achieved when transported under the HMR. Implementation of new technologies and operational techniques enhances safety because the authorized operations or activities may achieve a greater level of safety than that currently required under the regulations. Special permits also reduce the volume and complexity of the HMR by addressing unique or infrequent transportation situations that would be difficult to accommodate in regulations intended for use by a wide range of shippers and carriers.

PHMSA conducts ongoing reviews of special permits to identify widely used and longstanding special permits with an established safety record for conversion (fully or in part) into regulations of broader applicability. To obtain a special permit, interested parties must prepare and submit a detailed application that PHMSA reviews extensively. If granted and its use is needed after the expiration date assigned, the person authorized to use the special permit must submit an application to continue their use of it and undergo another extensive PHMSA renewal process. Converting the provisions (fully or in part) of these special permits into regulations reduces paperwork burdens and facilitates commerce while maintaining an acceptable level of safety. Additionally, adoption of special permits as rules of general applicability provides wider access to the benefits and regulatory flexibility of the provisions granted in the special permits. Factors that influence whether a specific special permit is a candidate for regulatory action include: the safety record for hazardous materials transported, or the transport operations conducted, under a special permit; the potential for broad application of a special permit; suitability of provisions in the special permit for incorporation (fully or in part) into the HMR; rulemaking activity in related areas; and agency priorities. Special permits involving packaging used by a large number of persons—such as those issued to many persons with party status or issued to a manufacturer as a “manufacture, mark, and sell”—are potentially among the most suitable types of special permits for adoption into the HMR. Such special permits have broad applicability; moreover, many of them have been in effect for a number of years and have demonstrated safety records.

Further, although we make every effort to stay as true as possible to the conditions prescribed in each special permit when converting it to proposed regulatory text, PHMSA recognizes that sometimes, due to existing regulations or historical interpretations, provisions in a special permit may require revision to convert them into regulations of general applicability. In addition, when converting special permits we often have to modify the language to describe documents and procedures that are authorized under the special permit but not specifically described in it or to modify the language to comply with requirements for proposed regulatory text prescribed by PHMSA, by other agencies in the Department of Transportation (DOT), and potentially by federal agencies outside of DOT.

The special permits addressed in this NPRM have hundreds of party-to status grantees. Party-to status is granted to a person who would like to offer for transport or transport a hazardous material, or perform an operation in association with a hazardous material in the same manner as the original applicant.

This NPRM proposes to incorporate elements of nine special permits (by way of incorporating SLP-23) that authorize multipurpose bulk truck operations not specifically permitted under the HMR. The proposed amendments will eventually eliminate the need for hundreds of current grantees to reapply for renewal of nine special permits every four years and for PHMSA to process those renewal applications. These proposals will also apply to any special permits PHMSA issues during the development of this rulemaking whose provisions are identical in every respect to those described in the rulemakings issued under this docket. To emphasize this, we preface the description of the affected special permits with the wording “include” or “includes” to clarify that additional special permits other than those specifically listed in this NPRM may have elements of them incorporated under these amendments. These special permits were initially issued to members of industry associations or similar organizations. These nine petitions are:

- DOT-SP 4453: Authorizes the transportation in commerce of certain Division 1.5D explosives contained in non-DOT specification bulk, hopper-type tanks. This special permit was issued in 1980 and is utilized by 142 grantees with acceptable safety performance.

- DOT-SP 5206: Authorizes the transportation in commerce of Division 1.5D explosives contained in privately operated bulk hopper-type units. Specific operational controls are specified in lieu of compliance with these two requirements. This special permit has been in effect since 1980 and is utilized by 44 grantees with acceptable safety performance.

- DOT-SP 8453: Authorizes the transportation in commerce of certain Division 1.5D explosives and Division 5.1 materials contained in DOT specification cargo tanks and certain non-DOT specification cargo tanks and portable tanks. This special permit has been in effect since 1980 and is utilized by 64 grantees with acceptable safety performance.

- DOT-SP 8554: Authorizes the transportation in commerce of certain Division 1.5D explosives and/or Division 5.1 oxidizers in the bulk motor vehicles described in the special permit. This special permit has been in effect since 1981 and is utilized by at least 182 grantees with acceptable safety performance.

- DOT-SP 8723: Authorizes the transportation in commerce of certain Division 1.5 explosives and/or Division 5.1 oxidizers, in bulk, in motor vehicles and portable tanks described in the special permit. This special permit has been in effect since 1981 and has been utilized by at least 109 grantees with acceptable safety performance.

- DOT-SP 9623: Authorizes the transportation in commerce of certain Division 1.5D explosives and Division 5.1 oxidizers in a cargo tank with a dromedary compartment (cargo compartments) containing Division 1.1 explosives mounted directly behind the trailer cab subject to the limitations specified in the special permit. This special permit was issued in 1986 and is utilized by 42 grantees with acceptable safety performance.

- DOT-SP 10751: Authorizes the transportation in commerce of certain Division 1.1, 1.4, and 1.5 explosives, Division 5.1 oxidizers, and Class 3 combustible liquids in separate containers mounted on the same vehicle frame structure. This special permit was issued in 1994 and is utilized by 38 grantees with acceptable safety performance.

- DOT-SP 11579: Authorizes the transportation in commerce of certain Division 1.1B, 1.1D, 1.4B, 1.4D, 1.4S, and 1.5D explosives, Division 5.1 oxidizers, Class 8 materials, and Class 3 combustible liquids in separate containers secured on the same vehicle frame structure. This special permit was issued in 1996 and is utilized by 72 grantees with acceptable safety performance.

- DOT-SP 12677: Authorizes the transportation in commerce of certain Division 1.1, 1.4, and 1.5D explosives, Division 5.1 oxidizers, Class 8 corrosive liquids, and Class 3 combustible liquids in separate containers secured on the same vehicle frame structure. This special permit was issued in 2001 and is utilized by 15 grantees with acceptable safety performance.

PHMSA has included discussion of these nine special permits in this NPRM because we have determined these special permits have well established safety records and the regulated industry would benefit from the HMR mirroring the majority of provisions contained in them.2 These proposed revisions are intended to eliminate the need for future renewal requests, thus reducing paperwork burdens and facilitating commerce while maintaining an appropriate level of safety.

2Over the past 10 years, there have been 35 reported transportation incidents in the U.S. involving multipurpose bulk trucks. During this same period, there has never been a death or major injury attributed to the hazardous materials while in transportation when there was compliance with the regulations. While there has been 1 incident that resulted in a fatality in that 10 year period, it involved a vehicular crash and human error, and was not attributed to the transportation of the hazardous materials themselves. Overall most incidents (90 percent) resulted in spillage; fewer incidents resulted in vapor dispersion (3 percent), environmental damage (0.5 percent), fire (0.5 percent), waterway infringement (0.4 percent), and explosion (0.1 percent.) Most of the time, the closures or covers in portable tanks failed, causing leaks. Detailed hazardous materials incident reports for hazardous materials incidents specified in §171.16 may be found at the PHMSA Web site at the following URL: https://hazmatonline.phmsa.dot.gov/IncidentReportsSearch/Search.aspx

Further, developing standards for the transportation of bulk explosives into the HMR eliminates a significant paperwork burden. As a condition of those special permits issued by PHMSA and depending on the provisions of the special permit, a copy of each special permit must be: (1) Maintained at each facility where an operation is conducted or packaging is manufactured under a special permit; (2) maintained at each facility where a package is offered or re-offered for transportation under a special permit; and (3) in some cases, carried aboard each transport vehicle used to transport a hazardous material under a special permit.

Petitions for Rulemaking

Two elements in this proposed rulemaking were presented to PHMSA in petitions for rulemaking. A more detailed description of each is provided below.

Petition No. P-1557

The petition from R&R Trucking, Inc. (P-1557) dated March 23, 2010, asks PHMSA to eliminate the need to operate under the terms and conditions of a special permit for deliveries of certain types of bulk explosives, and develop bulk explosive requirements in the HMR. R&R Trucking states that “the request is limited to Explosives, blasting, type E, 1.5D, UN0332, PG II and Ammonium nitrate emulsion, 5.1, UN3375, PG II, transported on articulated DOT specification cargo tank motor vehicles.” Further, the petition states that “no other hazardous material may be loaded into or carried on the vehicle or any vehicle in a combination of vehicles when transporting either of these materials in the approved bulk packaging.”

In support of their petition, R&R Trucking states that:

R&R and other carriers, private and common, have transported these materials in specification cargo tank trailers under the terms and provisions of special permits since the early 1980s. R&R has transported these materials for over ten years without any loss of product during transportation. Annually, R&R handles about 2,150 shipments and travels over two million miles delivering these materials. Under the special permits articulated cargo tank motor vehicles (i.e., similar to tractor trailers) transporting only one material, either explosive 1.5D or oxidized 5.1, are subjected to the same requirements as MBTs transporting all the materials (explosives 1.1D, 1.1B, l.4B, 1.5D and ingredient to manufacture additional explosives) necessary to conduct a blast. The MBT encounters a significantly different transportation challenge due to the off road use, multiple products, and higher than normal center-of-gravity, as compared to the single product articulated cargo tank delivery vehicle.

As for a specific case of why the petition is needed, R&R Trucking states that:

The transport of bulk 1.5D explosives and Ammonium nitrate emulsion, 5.1, in cargo tank trailers under the terms and provisions of the special permits is more restrictive than the transport of packaged 1.lA explosives. This is because of the recent modifications to the special permits addressing issues involving MBTs. The transport vehicles and conditions encountered are different and should be regulated accordingly. The requirements for a dry freight van trailer are different than for a cargo tank trailer or a flat bed trailer. The MBTs are designed for local deliveries, off road use and to mix, blend, manufacture and load explosive materials into blast holes. The articulated cargo tank motor vehicle is designed for a single purpose—to transport one bulk product safely over public highways. The fact that cargo tank trailers have safely transported over public highway bulk Class l.5D emulsion blasting agents for over twenty-five years under the terms and provisions of special permits should be sufficient to justify including requested bulk packaging in the Hazardous Material Regulations.

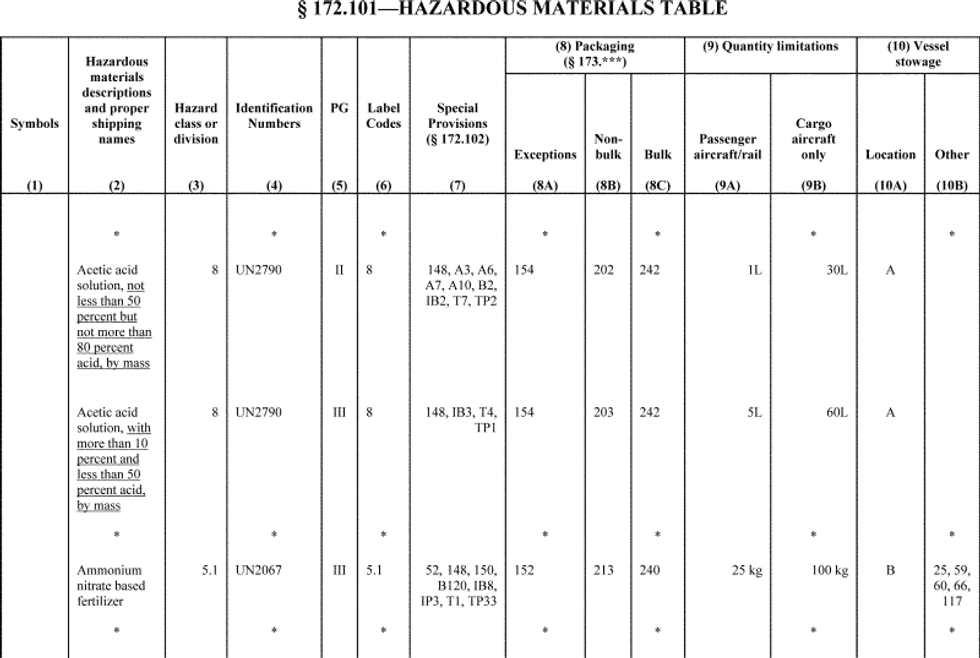

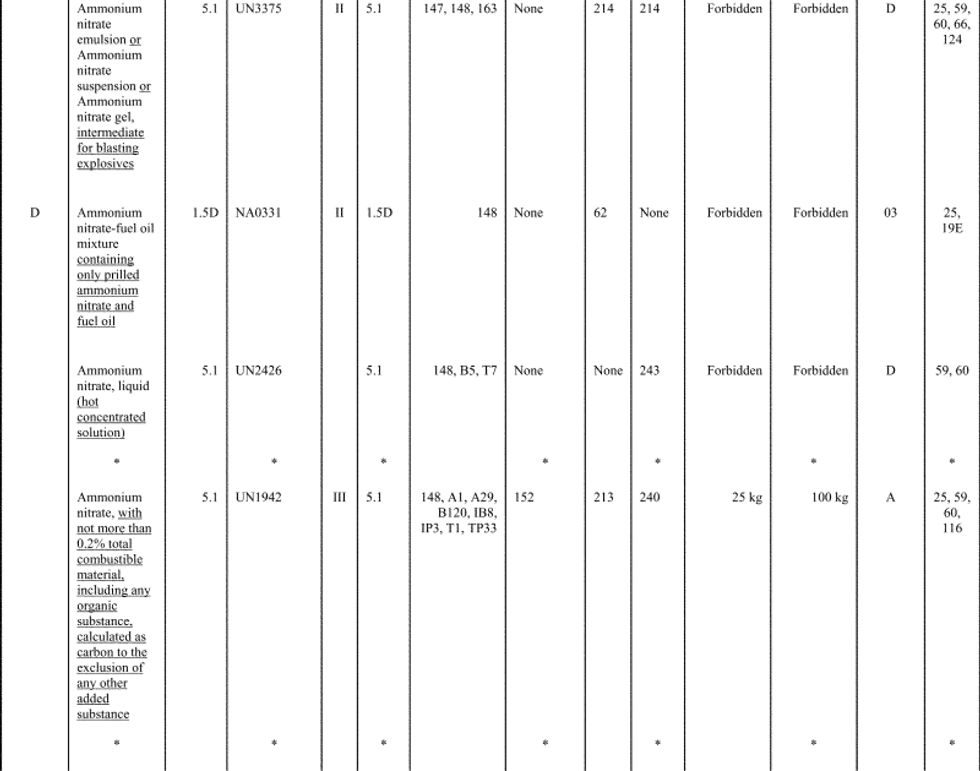

P-1557 requests two regulatory changes, both of them contained in the Hazardous Materials Table (HMT), in 49 CFR 172.101. For “Ammonium nitrate emulsion, 5.1, UN3375”, R&R Trucking petitions us to change:

Column 8—Packaging (173***), Bulk, from “214” to “242”, and to add to Column 7—Special Provisions—Transport restricted to articulated DOT specification cargo tank motor vehicles (road tractor semi trailer). Cargo tank must be constructed of stainless steel. No other hazardous material may be loaded into or carried on the cargo tank motor vehicle or on any vehicle of a combination of vehicles when transporting this material. The product must be approved by the Associate Administrator for transport in bulk packaging.

For “Explosive, blasting, type E, l.5D, UN0332”, R&R Trucking petitions us to change:

Column 8—Packaging (173***), Bulk, from “none” to “242”, and to add to Column 7—Special Provisions—“Transport restricted to articulated DOT specification cargo tank motor vehicles (road tractor semi trailer). Cargo tank must be constructed of stainless steel. No other hazardous material may be loaded into or carried on the cargo tank motor vehicle or on any vehicle of a combination of vehicles when transporting this material. The product must be approved by the Associate Administrator for transport in bulk packaging.

Finally, these two revisions would be permitted for motor vehicle and cargo vessel modes of transportation.

Lastly, R&R Trucking states that “the impact of the proposal should not be substantial. The impact of governing transport of these materials by regulation rather than by special permit should be minimal.”

PHMSA agrees with the petitioner on the merit of establishing requirements for the transportation of bulk explosives in commerce. With the incorporation of IME SLP-23, PHMSA will be establishing all relevant and appropriate requirements set out in the current multipurpose bulk transportation special permits,3 including the special permits R&R Trucking operates under. While we are not incorporating every provision in all nine special permits, we will have established criteria by which to transport these commodities in conformance with the HMR.

3DOT-SP 4453, DOT-SP 5206, DOT-SP 8453, DOT-SP 8554, DOT-SP 8723, DOT-SP 9623, DOT-SP 10751, DOT-SP 11579, and DOT-SP 12677.

Petition No. P-1583

The petition from the Institute of Makers of Explosives (IME) (P-1583) dated May 13, 2011, asks PHMSA to develop bulk explosive requirements in the HMR by incorporating by reference IME Safety Library Publication No. 23, Recommendations for the Transportation of Explosives Division 1.5, Ammonium Nitrate Emulsions Division 5.1, Combustible Liquids Class 3, and Corrosives Class 8 in Bulk Packagings (“SLP-23”). Per IME's petition, IME is a non-profit association founded in 1913 to provide accurate information and comprehensive recommendations concerning the safety and security of commercial explosive materials. IME represents U.S. manufacturers and distributors of commercial explosive materials and oxidizers as well as other companies that provide related services, and the majority of IME members are “small businesses” as determined by the U.S. Small Business Administration.

In support of their petition, IME states that:

Approximately 95% of all explosives and blasting agents used in the U.S. are transported in bulk. This transportation is accomplished using two vehicle configurations: Multipurpose bulk trucks (“MBTs”), and articulated vehicles (i.e., cargo tanks). In the many decades that bulk explosives have been widely used, there have been zero deaths or injuries during transportation attributable to the transported materials themselves. Currently, the HMR operates to prohibit the transportation of explosive materials in bulk form. Consequently, these materials have been transported pursuant to special permits since the promulgation of the HMR and the inception of the Special Permits Program. MBT technology was introduced in the late 1970's, and makes possible the transport of millions of pounds of blasting materials in a non-explosive, waterproof form that is mixed to acquire its explosive properties after it is loaded in boreholes at the site of use. MBTs employ technologies that meet strict engineering and design standards. These vehicles serve as a mobile work platform in some of the harshest conditions imaginable. MBTs are capable of going from paved interstate, to unpaved mine roads, to blast sites. Today, the vast majority of bulk high explosives, blasting agents, and oxidizers are transported to work sites by MBTs. We estimate that there are about 1,500 MBTs on highways in any given year. Annually, we estimate these vehicles average 350,000 trips covering tens of millions of miles.

In the petition, IME states that it submitted P-1583 for two reasons:

(1) the long-term, ubiquitous, and safe transport of explosives in bulk form, including the use of MBT technology, warrant expansion of the HMRs to include established requirements of general applicability governing these transportation practices; and (2) the recommendations included in SLP-23 represent industry-wide best practices that, collectively, prescribe a higher standard of safety than the requirements included in the special permits currently used to authorize this transportation.

PHMSA agrees with the petitioners request to develop bulk explosive requirements in the HMR by proposing to incorporate by reference IME SLP-23. A more in-depth review of the SLP-23 (including its recommendations, its differences with the nine special permits, etc.) is discussed in Section III below.

Access to the IME SLP-23 publication discussed in this NPRM is available for public download and review at: http://www.ime.org/. Under the “Publications” tab, click the “Safety Library Publications” link and either order a physical copy or download a free PDF copy via email. Also, a copy of the IME SLP-23 publication has been added to the Docket under “PHMSA-2011-0345” at http://www.regulations.gov. Additionally, access to the petitions referenced in this NPRM can be found at http://www.regulations.gov under Docket Numbers “PHMSA-2010-0101” (P-1557), and “PHMSA-2011-0137” (P-1583), or at DOT's Docket Operations Office (see ADDRESSES).

III. Summary Review of Proposed Amendments

In this NPRM, PHMSA is proposing to revise the HMR by amending the regulations to establish standards for the safe transportation of bulk explosives. These proposals are further described below.

A. Proposed Incorporation of SLP-23 Into the HMR

In 1999, PHMSA requested IME to assist the Agency in preparing a set of standards that would incorporate bulk explosives transportation requirements into the HMR. Between 1999 and early 2001, PHMSA and IME worked cooperatively to prepare an acceptable document. The result of this effort was SLP-23, first published in 2001. At that point in time, PHMSA was considering incorporating the document into the HMR. Unfortunately, the events of September 11th 2001 intervened, and it was determined to be a difficult time to pursue the development of a rule dealing with explosives.

The SLP-23 document itself is structured into four main sections: Section I, Section II, Appendix A, and Appendix B.

- Section I (Standards for Transporting a Single Bulk Hazardous Material for Blasting by Cargo Tank Motor Vehicles) includes parts on: General requirements; modes of transportation; additional provisions; qualifications, maintenance, and repair of packagings; qualifications of individuals certifying non-DOT specification bulk packaging; placarding and marking requirements; and security and safety of the bulk hazardous materials transported.

- Section II (Standards for Cargo Tank Motor Vehicles Capable of Transporting Multiple Hazardous Materials for Blasting in Bulk and Non-Bulk Packaging) includes parts on: Purpose and limitations; hazardous materials covered under Section II; packagings; operational controls; qualifications, maintenance, and repair of packagings; special provisions; and emergency response, reporting, and training requirements.

- Appendix A is comprised of information on the vented pipe test (apparatus and materials, procedure, and test criteria and method of assessing results) including a diagram.

- Appendix B is comprised of information on the qualification, maintenance, and repair for non-DOT specification cargo tanks, for pressure capable sift-proof closed vehicles, and for pressure-capable closed bulk bins (periodic qualification, external visual inspection and testing, internal visual inspection, leakage test, pressure tests, test and inspection markings, repairs, modifications or alterations).

In 2011, IME updated and revised SLP-23 in direct response to concerns expressed by PHMSA regarding bulk transportation of explosives. IME used a team that was comprised of a broad group of experts (including both IME members and non-members) with extensive experience in hazardous materials transportation generally and the bulk transportation of explosives in particular.

The 2011 edition of SLP-23 includes all relevant and appropriate requirements set out in the bulk transportation special permits. In addition, because SLP-23 is a comprehensive standard, the recommendations are broader in scope than the combined special permits and the document succeeds in avoiding certain inconsistencies that inevitably exist between the current special permits. In addition to providing a clear and consolidated framework for the regulation of bulk transportation of explosives, SLP-23 recommends certain practices that exceed the requirements of the current special permits. These recommendations are as follows:

- SLP-23 requires at least two fire extinguishers, each with a rating of at least 4-A:40-B:C to be carried on MBTs.

- SLP-23 incorporates the United Nations (UN) requirement that no closed bulk packaging may have a maximum allowable working pressure exceeding 35 psi. This is a recommendation of the UN and reduces the probability of a deflagration to detonation transition of the cargo.

- SLP-23 provides that materials shall not be allowed to remain in the vehicle for any period of time that might result in caking. In certain environments with certain products, caking occurs relatively easily. This is a situation that is easily preventable, and is not currently addressed in special permits.

- Any non-DOT specification cargo tanks, portable tanks, sift-proof closed vehicles and closed bulk bins must be qualified, inspected, and maintained essentially the same as a DOT-specification bulk container (set out in Appendix B of SLP-23).

- Inspectors conducting inspections of non-DOT non-specification tanks (see above) must meet training qualifications outlined in Appendix B for the MBTs. DOT specification cargo tanks must still be inspected by registered inspectors.

- Each non-DOT non-specification bulk packaging must display a nameplate with a certification that the packaging meets SLP-23 standards and must include additional technical information. The nameplate must be visible for inspection. This helps users stay within the design parameters of the vehicle and inspectors verify compliance with manufacturer specifications.

- SLP-23 addresses security comprehensively. The recommendations specifically address the security of 1.5 and 5.1 materials when in transit, including locking mechanisms for all openings and elimination of any material spillage and/or residue in hoses and other access points. In addition, the recommendations address the safety of process delivery vehicles in general, including: Battery enclosure and disconnect specifications and tire specifications.

- Drivers must meet stringent qualifications and undergo extensive safety training, in addition to the training required to obtain a commercial driver's license with the hazmat endorsement under the Federal Motor Carrier Safety Administration (FMCSA). Furthermore, in addition to meeting the training requirements specified in 49 CFR 172, Subpart H, new drivers must also have a driving record without any preventable accidents in the past year and no moving violations in the previous three years. Drivers must also complete additional classroom training and pass a road test in a vehicle similar to the vehicle the driver will be operating.

In addition to the recommendations above, SLP-23 provides increased clarity compared to the current special permits in the following areas:

- SLP-23 clearly delineates the different transportation risks between single bulk commodities transported by articulated tractor-trailers (cargo tanks), and MBTs. Currently, all the special permits cover both articulated tractor-trailer vehicles carrying one hazmat and MBT straight trucks carrying many.

- All DOT-specification tanks appropriate for transportation of covered materials are clearly identified.

- All standards are consolidated into one document. Further, tanks are required to be marked “IME SLP23.”

Therefore, in this NPRM, PHMSA proposes to incorporate SLP-23 and establish requirements of general applicability governing the transportation of bulk explosive materials. As such, PHMSA proposes to revise the 49 CFR 171.7 table of material incorporated by reference to include SLP-23, and establish a new §173.66 (to be discussed further below) for the bulk explosives requirements.

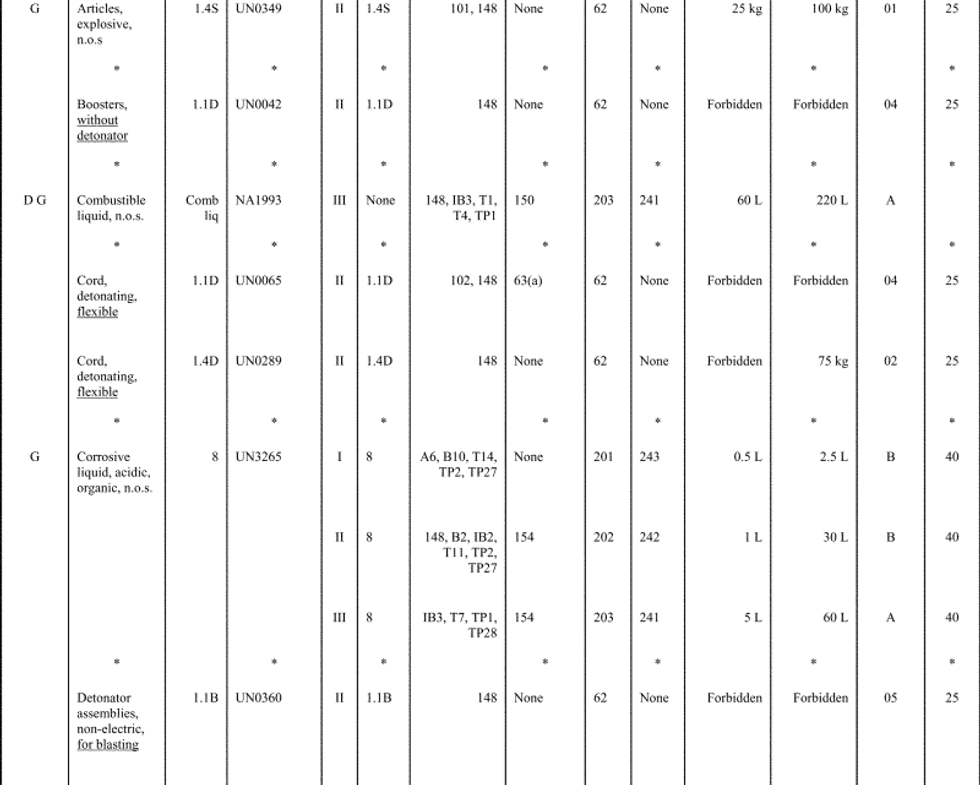

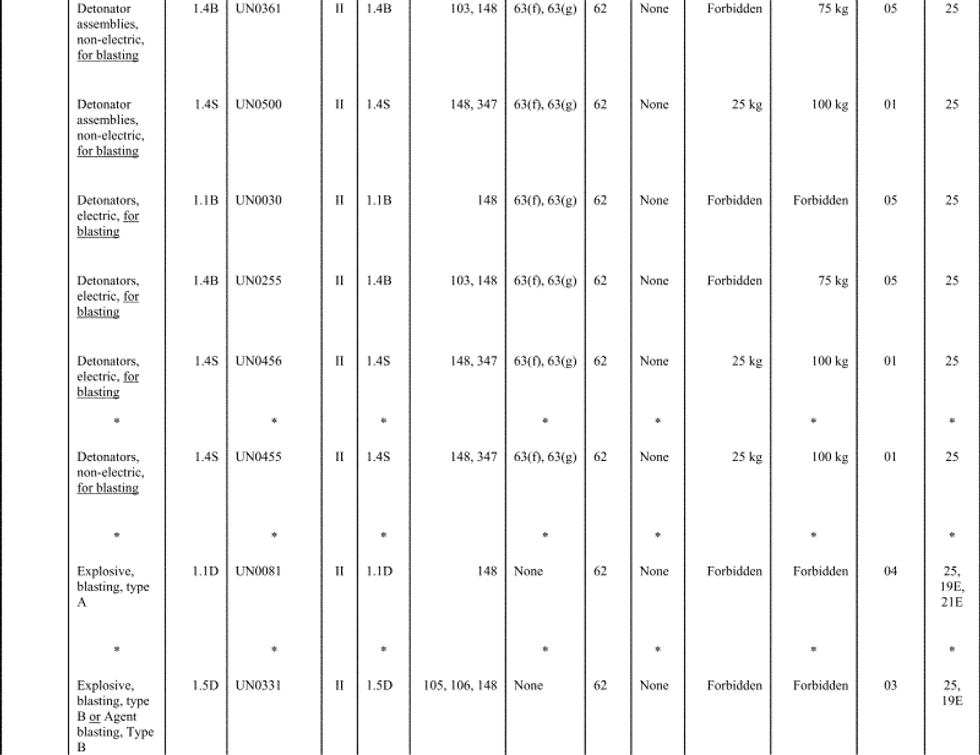

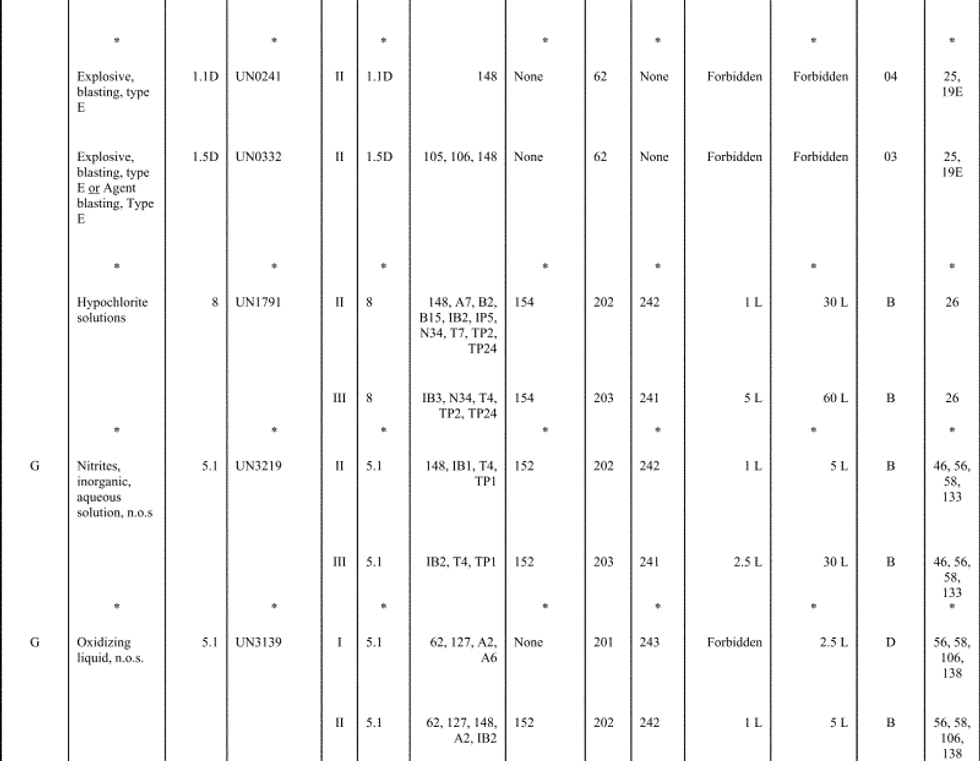

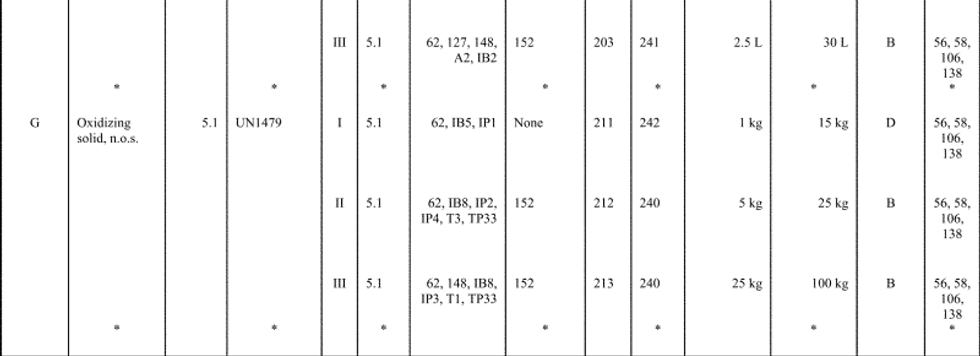

B. Revising the Hazardous Materials Table and Adding Special Provision 148

PHMSA's proposal to incorporate SLP-23 into the HMR and establish requirements of general applicability governing the transportation of bulk explosive materials requires an update to the Hazardous Materials Table (HMT). Currently, the 49 CFR does not include a provision for the transportation in bulk packaging of certain Class 1 and Class 5 hazardous materials that are used in commercial blasting operations. When reviewing the HMT under the bulk packaging section, those types of commodities will have a “None” in Column (8C) meaning bulk packagings are not authorized, except as may be provided by special provisions in Column (7). With the proposed incorporation of SLP-23, the affected hazardous materials require a new special provision 148 added to each entry under Column 7 of the HMT. These HMT entry revisions range from Divisions 1.1B, 1.1D, 1.4B, 1.4D, 1.4S and 1.5D Explosives, Division 5.1 Oxidizers, Class 8 Corrosives, and Combustible liquids.

Special Provision 148 is being proposed in order to allow for the transportation of certain hazardous materials in bulk quantities, or with materials normally not permitted to be transported with such commodities. This Special Provision 148 will direct readers to Section 173.66 in order to comply with the bulk explosives requirements. No other hazardous materials entries will be directed to Section 173.66 and therefore, only certain explosives, oxidizers, etc. will be eligible for bulk explosives transportation.

C. Proposed New Section on the Requirements for MBTs

PHMSA is proposing to add a new section to 49 CFR part 173 (§173.66), which would specify the requirements for MBTs. This includes existing MBTs, future newly constructed MBTs, and future modified MBTs.

In the preamble of the new section, prior to paragraph (a), we propose the requirements for multipurpose bulk trucks as follows. When §172.101 specifies that a Class 1 (explosive) material may be packaged in accordance with this section, only the bulk packagings specified for these materials in IME SLP-23 (IBR, see §171.7 of this subchapter) would be authorized, subject to the requirements of subparts A and B of this part and the special provisions in column 7 of the §172.101 table. Thus, an entity operating a MBT under current conditions, such as a Special Permit, would be subject to operating under the IME SLP-23 document. Additional requirements in paragraphs (a), (b), and (c) apply to: (1) A new multipurpose bulk truck constructed after December 31, 2014, or (2) an old multipurpose bulk truck that requires modifications due to wear and tear (i.e., re-chassis, etc.).

In paragraph (a), we propose additional requirements regarding fire suppression systems for newly constructed and modified MBTs. In addition to complying with the applicable requirements of the HMR (e.g., placarding, shipping papers, etc.) and the applicable requirements in IME Safety Library Publication No. 23 (SLP-23) per §171.7 of the HMR, these vehicles would be required to have a fire suppression system that is an engineered system connected to the engine and transmission compartments. The system would be activated by manual switch or passive means in the event of a fire. Also, all fire extinguishers used as components of the system would be required to meet the requirements of 49 CFR 393.95(a) and the applicable NFPA codes and standards. Further, the fire suppression system's design would be required to be verified and certified by the Design Certifying Engineer (DCE) of the vehicle, and the design would need to be tested through engineering analysis or physical testing to verify the initial design or future modification(s) to the current fire suppression system. The fire suppression system would be required to be visually inspected annually for defects, flaws, damage, etc., to ensure none are present. The system would need to be pneumatically tested every five years to ensure the system is free of debris, leaks, and damage, and to ensure the system will function properly. Finally, the DCE would need to prepare a test report and provide it to the manufacturer of the vehicle and the manufacturer would need to provide a copy to the owner of the vehicle.

In paragraph (b), we propose additional requirements of emergency shut-off/battery disconnect for newly constructed and modified MBTs. For these trucks, the batteries for the chassis would be required to have three easily accessible manual disconnect switches. One manual disconnect switch would be located inside the driver's cab and would not include the ignition, and that the remaining two manual disconnect switches would be located on each side of the vehicle. Further, all three switches would be connected to the positive battery terminal and the line of the switch would be protected from rubbing and abrasion that could cause a short circuit. Finally, the battery disconnect would be required to isolate all manufacturing equipment except critical instrumentation that requires the maintenance of the electrical supply, and that the battery disconnect is tested monthly to ensure proper operation.

In paragraph (c), we propose that for newly constructed and modified MBTs, those trucks would need to be in compliance with the applicable Federal Motor Vehicle Safety Standard (FMVSS) found in 49 CFR part 571. Furthermore, the multipurpose bulk truck manufacturer would need to maintain a certification record ensuring the final manufacturing is in compliance with the FMVSS, per the certification requirements found in 49 CFR Part 567, and these certification records would need to be available to DOT representatives upon request.

By proposing these requirements, PHMSA is echoing the majority of provisions contained in nine widely used or longstanding special permits that have established safety records. These proposed revisions are intended to eliminate the need for future renewal requests, thus reducing paperwork burdens and facilitating commerce while maintaining an appropriate level of safety.

D. Revising the Loading and Unloading Language for Class 1 (Explosive) Materials

In §177.835, we propose to revise paragraph (a) to state that no Class 1 (explosive) materials may be loaded into or on or be unloaded from any motor vehicle with the engine running, except that the engine of a multipurpose bulk truck may be used for the operation of the pumping equipment of the vehicle during loading or unloading.

Furthermore, we propose a new paragraph (d) which discusses multipurpose bulk trucks and specifies that Class 1 (explosive) materials may be packaged in accordance with §173.66 of this subchapter. However, these materials would be permitted to be transported on the same vehicle with Division 5.1 (oxidizing) materials, or Class 8 (corrosive) materials, and/or Combustible Liquid, n.o.s., NA1993 only under the conditions and requirements set forth in SLP-23 (IBR, see §171.7 of this subchapter) and paragraph (g) of this section (177.835).

IV. Regulatory Analyses and Notices

A. Statutory/Legal Authority for This Rulemaking

This NPRM is published under the authority of 49 U.S.C. 5103(b) which authorizes the Secretary to prescribe regulations for the safe transportation, including security, of hazardous material in intrastate, interstate, and foreign commerce. 49 U.S.C. 5117(a) authorizes the Secretary of Transportation to issue a special permit from a regulation prescribed in 5103(b), 5104, 5110, or 5112 of the Federal Hazardous Materials Transportation Law to a person transporting, or causing to be transported, hazardous material in a way that achieves a safety level at least equal to the safety level required under the law, or consistent with the public interest, if a required safety level does not exist. The proposed rule would amend the regulations by incorporating SLP-23 and provisions from certain widely used and longstanding special permits that have established a history of safety and which may, therefore, be converted into the regulations for general use.

B. Executive Order 13610, Executive Order 13563, Executive Order 12866, and DOT Regulatory Policies and Procedures

This proposed rulemaking is not considered a significant regulatory action under Executive Order (E.O.) 12866 (“Regulatory Planning and Review”), as supplemented and reaffirmed by E.O. 13563 (“Improving Regulation and Regulatory Review”), stressing that, to the extent permitted by law, an agency rulemaking action must be based on benefits that justify its costs, impose the least burden, consider cumulative burdens, maximize benefits, use performance objectives, and assess available alternatives, and the Regulatory Policies and Procedures of the Department of Transportation (44 FR 11034). However, due to the specific issues related to the transportation of explosive materials in MBTs, a regulatory impact assessment is available for review in the public docket for this rulemaking (filed under “PHMSA-2011-0345” at http://www.regulations.gov).

Executive Order 13563 is supplemental to and reaffirms the principles, structures, and definitions governing regulatory review that were established in Executive Order 12866 Regulatory Planning and Review of September 30, 1993. Executive Order 13563, issued January 18, 2011, notes that our nation's current regulatory system must not only protect public health, welfare, safety, and our environment but also promote economic growth, innovation, competitiveness, and job creation.4 Further, this executive order urges government agencies to consider regulatory approaches that reduce burdens and maintain flexibility and freedom of choice for the public. In addition, Federal agencies are asked to periodically review existing significant regulations, retrospectively analyze rules that may be outmoded, ineffective, insufficient, or excessively burdensome, and modify, streamline, expand, or repeal regulatory requirements in accordance with what has been learned.

4See http://www.whitehouse.gov/the-press-office/2011/01/18/improving-regulation-and-regulatory-review-executive-order.

Executive Order 13610, issued May 10, 2012, urges agencies to conduct retrospective analyses of existing rules to examine whether they remain justified and whether they should be modified or streamlined in light of changed circumstances, including the rise of new technologies.5

5See http://www.gpo.gov/fdsys/pkg/FR-2012-05-14/pdf/2012-11798.pdf.

By building off of each other, these three Executive Orders require agencies to regulate in the “most cost-effective manner,” to make a “reasoned determination that the benefits of the intended regulation justify its costs,” and to develop regulations that “impose the least burden on society.”

In this notice, PHMSA proposes to amend the HMR to incorporate alternatives this agency has permitted under widely used and longstanding special permits and competent authority approvals with established safety records that we have determined meet the safety criteria for inclusion in the HMR. Incorporation of SLP-23 into the regulations of general applicability will provide shippers and carriers with additional flexibility to comply with established safety requirements, thereby reducing transportation costs and increasing productivity. In addition, the proposed rule will reduce the paperwork burden on industry and this agency resulting from putting an end to the need for renewal applications for special permits. Taken together, the provisions of this proposed rule will promote the continued safe transportation of hazardous materials while reducing transportation costs for the industry and administrative costs for the agency.

PHMSA considered five potential regulatory alternatives.

- Alternative 1: No Action. Under this option, PHMSA would continue existing requirements for Special Permits to transport bulk explosives by taking no action. However, PHMSA believes that there are considerable benefits to taking action provided that a high level of safety is maintained. Furthermore, all costs and benefits are relative to this option.

- Alternative 2: PHMSA Defers to Voluntary Standards. Under this option, PHMSA will defer to voluntary standards developed through organizations or trade associations. PHMSA will likely participate in standard-setting to develop standards that meet safety criteria that are in the interest of the United States. While compliance with voluntary standards is thought to be high by industry participants, firms do not have to comply with them, since they are voluntary. This creates some concern since the non-adoption may mean that those firms may not comply with minimum safety standards.

- Alternative 3: Incorporate Special Permits That Have a Good Safety Record into the HMR. Under this option, PHMSA will incorporate seven of the nine special permits into the HMR. These seven special permits have very good safety records. By incorporating these special permits, PHMSA will need to work through the Federal rulemaking process to modify the HMR in response to technological enhancements and other matters relating to the transportation of the bulk explosives covered under the seven special permits. It may be more advantageous to incorporate standards developed by industry than for PHMSA to develop its own standards and incorporate them into the HMR.

- Alternative 4: Adopt Other National or International Standards. Under this option, PHMSA would adopt other national or international standards, such as those used by Canada, Australia, or the United Nations. These other standards do not conform well to existing U.S. law and to the nine special permits. For example, the U.S. Bridge Law (USBL) provides known standards for bridge construction, by, among other requirements, placing restrictions on the overall size of MBTs in service in the United States. Other standards do not conform to the USBL. Also, these standards are implemented in ways that may not be possible within the regulatory framework in the United States.

- Alternative 5: Incorporate SLP-23 into the HMR with Additional Features. SLP-23 recommends standards for MBT straight trucks that typically transport multiple hazardous materials in support of blasting operations and articulated cargo tanks that carry a single bulk blasting agent or oxidizer. Under this option, PHMSA will incorporate SLP-23 into the HMR with additional features. This rulemaking specifically proposes to adopt a combination of features, including incorporating by reference (IBR) the Institute of Makers of Explosives' (IME) Safety Library Publication No. 23 “Recommendations for the Transportation of Explosives, Division 1.5, Ammonium Nitrate Emulsions, Division 5.1, Combustible Liquids, Class 3 and Corrosives, Class 8 in Bulk Packaging” (referred to as SLP-23), requiring fire suppression systems in heat-containing compartments (e.g., engine, transmission) and emergency shut-off/battery disconnect of newly constructed or modified MBTs, and complying with certain National Highway Traffic Safety Administration (NHTSA) requirements. The NPRM requirements are more comprehensive and have stricter standards than the nine special permits, and it may eliminate some duplicative functions covered by other industry standards. While SLP-23 may need to be re-evaluated and changed to keep pace with technological enhancements and other matters, IME will perform this and publish the revised standards free of charge. SLP-23 was developed with input of IME members, stakeholders, and PHMSA. In addition to incorporating SLP-23, under this option, we would add fire suppressions systems to the vehicles similar to the designs authorized under the Canadian requirements. The fire suppression requirements would strengthen the performance standards, and further accomplish PHMSA's objective of enhancing safety. For all of these reasons, alternative five was PHMSA's chosen alternative for this NPRM.

The proposed rule adopts Alternative 5, “Incorporate SLP-23 into the HMR with Additional Features.” By proposing these requirements, PHMSA will be echoing the majority of provisions contained in nine widely used or longstanding special permits that have established safety records. These proposed revisions are intended to eliminate the need for future renewal requests, thus reducing paperwork burdens and facilitating commerce while maintaining an appropriate level of safety.

Costs To Comply With the NPRM

The costs to comply with the NPRM are the sum of the costs of incorporating SLP-23 into the HMR as estimated for Alternative 5 plus costs for existing and new trucks to meet the additional requirements described in section III above (Proposed New Section on the Requirements for MBTs). Below is an analysis of costs associated with the various provisions under SLP-23 that affect its incorporation into the HMR, followed by an analysis of costs associated with some additional features.

Costs associated with tire-pressure checks. SLP-23 contains a requirement to check tire pressure before the initial trip of the day. This would be part of a routine pre-trip inspection and should not add any costs.

Costs associated with fire extinguishers. SLP-23 requires a minimum of two fire extinguishers rated 4-A:40B:C. Current Federal regulations require a minimum of one fire extinguisher rated 10B:C. IME makes the following estimates:

- Fire extinguishers could be affixed in 8 hours.

- The cost for two fire extinguishers is approximately $250.

- The labor costs for installing the fire extinguishers are estimated at $280.

- The cost associated with the MBT downtime is approximately $560.

- Approximately 25 percent of the MBTs (or 375 of the 1,500 MBTs in service) would need to acquire and affix the extinguishers.

Using IME's data, it's estimated that the cost to equip 375 MBTs with fire extinguishers would be approximately $408,750 ($250 for the fire extinguishers + $280 labor costs + $560 vehicle downtime * 375 MBTs). This is expected to be a one-time cost. There will be annual maintenance costs, but it's believed these costs will be negligible (somewhere between $0 and $5 per MBT over a 10-year period). Each vehicle should already have at least one fire extinguisher on board per DOT regulations. IME's data estimates that the fire extinguisher has a longer life than the MBT; therefore, it's estimated that there would be no annual costs to industry resulting from this requirement.

Costs associated with working pressure limit. SLP-23 limits the maximum allowable working pressure of an MBT cargo tank to 35 psi.6 This measure is intended to help prevent a build-up of pressure in the tank, which could result in a detonation of the contents in a fire. IME data estimates that most MBTs already meet this standard. IME data estimates that at most 10 percent of the MBTs (or 150 MBTs) would need a retrofit. IME data estimates the cost of retrofitting each MBT would be approximately $3,000. The cost to industry to retrofit 150 MBTs would be approximately $450,000. This is a one-time cost.

6This does not have an effect on the capacity of an MBT.

Costs associated with periodic tests and inspections of non-DOT specification cargo tanks. SLP-23 requires that non-DOT-specification cargo tanks be inspected essentially the same way as specification tanks. This requires competence training of inspectors and physical inspections as described in Appendix B of SLP-23. IME data estimates that 75 percent of the MBTs with non-specification tanks are in substantial compliance with SLP-23 in this regard and 25 percent are not. IME data estimates that the annual cost of performing inspections and test for non-compliant vehicles is $3,500 per vehicle. Assuming that 25 percent of MBTs (or 375 vehicles) would need to comply, the annual cost of complying is approximately $1.3 million (375 MBTs not in compliance * $3,500 for inspection and tests per vehicle).

Costs associated with the nameplate. SLP-23 requires a nameplate be affixed to the vehicle describing its design characteristics. According to IME data, virtually all MBTs will need a retrofit, costing an average of about $125 per truck for a total cost of $187,500 ($125 * 1,500 MBTs). This is a one-time cost.

Costs associated with accident investigations. SLP-23 requires companies to provide PHMSA an incident investigation report of all MBT crashes. This report may be an internal investigation because: (1) Some companies are self-insured and (2) some insurance companies will not allow their reports to be released. An independent accident investigation of an MBT crash would be conducted only if PHMSA requests it. IME data estimates that under SLP-23 this would be necessary once a year. An independent accident investigation of an MBT crash costs about $10,000. The annual cost associated with accident investigations could reach $20,000 per year.

Driver training after preventable accidents. SLP-23 requires that drivers involved in preventable accidents (as defined in 49 CFR Section 385.3) while operating an MBT be retrained if the driver remains employed by the motor carrier. The SLP-23 requirement is similar to the requirement in the current applicable SPs, although SLP-23 clarifies that the carrier does not have a responsibility to continue to employ the driver. Driver training costs are variable, depending on the amount of training needed and required by the rule. New driver training is in the vicinity of $3,000 per driver.7 As noted earlier, there are on average approximately three incidents per year under SPs. If the trend continues under SLP-23, the cost of driver training to the industry is expected to be approximately $9,000 per year.

7Data from the Draft Regulatory Flexibility Analysis completed in February 2011 of the Final Rule Minimum Training Requirements for Entry-Level Commercial Motor Vehicle Operators.

Maintaining and updating SLP-23. The cost of standard development is spread amongst many standards that IME makes available to the public. Some standards require more resources than others. IME estimates that annual cost for maintaining and updating SLP-23 is approximately $50,000. IME is prepared to bear the cost of maintaining SLP-23 and updating it at no cost to PHMSA, once it is incorporated into the HMRs. This cost is not included in the total cost to industry, as this not a new cost but an ongoing expenditure that is currently an integral part of industry's management and operation.

Fire suppression system. The cost of equipping an MBT with a fire suppression system is approximately $10,000 to $15,000 per vehicle (or on average $12,500). This is a one-time cost for newly constructed vehicles or trucks undergoing modifications (i.e., re-chassis). Assuming that approximately 750 new vehicles are constructed (per the analysis under Alternative 5), it would on average cost industry approximately $9.4 million ($12,500 average cost of a fire suppression system * 750 new vehicles).

In addition, compliance with the NPRM would involve the cost of inspection of fire suppression systems every 6 months by a qualified and approved facility or person as described in the National Fire Protection Association (NFPA) Standard.8 Should there be any additional costs beyond those included under the incorporation of SLP-23 for the testing of fire suppression systems, the cost is uncertain. PHMSA seeks comment. Finally, there are no additional marginal costs associated with NHTSA requirements in the NPRM.

8The NFPA standard covers all aspects of the design, installation, operation, testing, and maintenance of the systems. The costs associated with this requirement are undetermined at this time. The standards can be purchased from NFPA for under $100.

The following table shows the cost associated with the NPRM.

| Cost items | One-time costs | Recurring annual costs |

|---|---|---|

| Fire Extinguishers | $408,750 | $0 |

| Work Pressure Limit | 450,000 | 0 |

| Periodic Inspections | 0 | 1,300,000 |

| Nameplate | 187,500 | 0 |

| Accident Investigation | 0 | 20,000 |

| Driver Training | 0 | 9,000 |

| Maintaining/Updating SLP-23 | 0 | 50,000 |

| Cost of Fire-Suppression Systems | 9,375,000 | 0 |

| Total | 10,421,250 | 1,379,000 |

The total one-time costs to comply with the requirements in the NPRM are estimated at $10.4 million; the recurring annual costs are estimated at approximately $1.4 million.

Benefits and Cost Savings To Comply With the NPRM

The benefits associated with the NPRM are the sum of the benefits of incorporating SLP-23 into the HMR as estimated for Alternative 5 plus any benefits that may accrue from existing and new trucks meeting the additional requirements. There will be some cost savings associated with reduced paperwork burdens (see Section IV. Regulatory Analyses and Notices, Part F—Paperwork Reduction Act). Below is an analysis of the benefits provided by incorporating SLP-23 into the HMR, along with the cost savings provided to both stakeholders and PHMSA.

Cost savings to industry from no longer having to apply for the nine SPs. According to PHMSA data, from 2005 through 2011 there were 534 requests for SPs submitted.9 There were no requests for new permits; all 534 were party to SPs, modifications, or renewals. This translates to approximately 76 requests for permits per year. According to IME data, the industry spends approximately $825.00 for each renewal, party to, or modification; the cost to industry of applying for new permits is $50,000. Since none of the applications involved new permits, the annual cost to industry would be $62,700 (76 permit applications per year * $825 per renewal, party to, or modification).

9Data file provided by the COR, transmitted via email on June 15, 2012.

Cost savings to PHMSA from no longer having to review and approve applications for the nine SPs. PHMSA spends approximately $414.00 per application.10 The annual total cost to PHMSA for the application and review process is $31,464 [($414.00 per application * 76 (the average number of permits processed per year)].

10Estimate provided by Special Permits and Approvals Division via email on July 17, 2012.

Costs savings to industry associated with not having to check tire pressure before each departure onto the public roads. Currently, the nine special permits may require the tire pressure to be checked multiple times each day. The proposed rule would only require one tire check a day. It is possible that there are multiple times that the MBT is running back and forth to the blast site in a day, therefore, a significant costs savings is accrued with the potential incorporation of SLP-23. For the calculation of costs ensuing from the requirement to check tire pressure (based on information from IME), PHMSA assumed the following:

- There are approximately 1,500 MBTs in service and 500 ACTVs in service.

- Drivers of MBTs earn approximately $35.00 per hour, including overhead.11

11According to the Department of Labor (DOL), Bureau of Labor Statistics (BLS) occupational May 2011 wage statistics for “53-3032 Heavy and Tractor-Trailer Truck Drivers,” the mean hourly wage is $19.15 per hour or $28.72 per hour, including overhead. See: http://www.bls.gov/oes/current/oes533032.htm. The BLS wage estimate is less than that estimated by IME because the BLS estimate includes drivers of all tractor trailers and trucks with a capacity of 26,000 pounds not only MBTs. PHMSA is using IME's wage estimate for this cost analysis as the IME wage estimate relates to MBT drivers considered under this NPRM. PHMSA seeks comments on this estimate. - Drivers perform work-related activities approximately 250 days per year (14-hour days). The 14-hour day consists of driving (which, under current U.S. regulations, is restricted to 11 driving hours during a 14-hour workday), non-driving (such as loading, unloading, performing required tire checks, and doing paperwork), and rest breaks. According to a DOT study, commercial motor vehicle (CMV) drivers spend approximately 66 percent of their workday driving; 23 percent performing non-driving activities; and the remaining 11 percent resting, eating, and sleeping while on duty.12

12Source: The Center for Truck and Bus Safety, Virginia tech Transportation Institute “ The Impact of Driving, Non-Driving Work, and Rest Breaks on Driving Performance in Commercial Motor Vehicle Operations,”May 2011. - A gallon of diesel fuel as of December 2012 is approximately $4.00.13

13See: http://www.eia.gov/petroleum/gasdiesel/ (accessed December 25, 2012). - It costs $560.00 per day to operate an MBT in compliance with SPs.

- Time to check the tire pressure is on average approximately 30 minutes per day.14

PHMSA believes this may be an overestimation but has included it in the absence of an alternative value.

14IME estimate.

PHMSA seeks comments on these estimates and assumptions.

Under the above assumptions the cost per year for the tire checks is approximately $4,375 per year ($17.50 driver wage per half hour of work * 250 work days). Vehicles idle during the tire check and consume 1 gallon of fuel per hour. The fuel costs per year are $500 ($2.00 per half gallon * 250 workdays).

Additionally, industry estimates that the time needed to comply with tire checks translates to approximately 0.036 days (0.5 hours/14-hour workday) in lost time. Thus the additional MBT trips required annually cost approximately $5,000 (.036 lost time * 250 workdays * $560 to operate MBT per day). Below is a table demonstrating this entire calculation.

| Average amount of time per day | Labor cost per year per vehicle | Fuel cost per year per vehicle | Vehicle downtime per year | Total per year per vehicle |

|---|---|---|---|---|

| 30 minutes | $4,375 | $500 | $5,000 | 15$9,875 |

15The total cost per day to operate an MBT is equal to $560.00. The $9,875 associated with time lost per year for tire checks represents approximately 7 percent of the total cost of the operation of a vehicle [$9, 875/($560.00 * 250)].

The annual costper vehicle associated with the tire-pressure check requirement is $9,875, which works out to an annual cost to industry from the tire-pressure test requirement of approximately $14.8 million ($9,875 total cost per vehicle per year * 1,500 MBTs).

Costs savings to industry associated with caking. There is a cost savings from the requirements relating to caking. If left sitting for several days, ammonium nitrate (AN), can absorb moisture from the air, allowing it to cake into a solid mass, which is extremely difficult to break up. AN is highly hygroscopic; that is, it readily absorbs water from the atmosphere. AN is also highly water soluble. If AN sits undisturbed in a bulk container long enough, it will absorb water, and the prills will dissolve slightly around the edges. A drop in temperature will then cause the prills to solidify into a solid mass. SLP-23 counteracts this by unloading the transport container. Almost all bulk trucks will have AN prill in them at some point, making them susceptible to caking. Routine maintenance requirements under SLP-23 do not permit caking of the contents of an MBT to occur. SLP-23 specifies that if the interior surfaces of bulk packaging are not smooth and free of obstructions, the bulk packaging is to be inspected and cleaned “to prevent caking and/or drying-out of the bulk hazardous material.” SLP-23 further specifies that bulk hazardous material not be allowed to remain in the bulk packaging for any period of time that could result in caking. SLP-23 recommends that the equipment be cleaned as needed to minimize the accumulation and packing of the bulk hazardous material in the bulk packaging. IME data notes that instances of caking currently occur 5 to 10 times annually and cost about $12,000 to remediate each time caking occurs. There is no additional cost to industry to comply with the requirement in SLP-23 that helps prevent caking. Thus, this preventive requirement represents a savings to industry on average of $90,000 per year (7.5 caking incidents per year * $12,000 per incident for remediation).

Costs savings to the public associated with IBR of SLP-23. In addition, IME will make the standard available at no charge, which represents a cost saving to the public of approximately $1.3 million. Based on IME's experience with standards, we conclude that the total annual costs for the development and maintenance of standards would likely be over $1.3 million ($1 million for staff and equipment + $100,000 for meetings + $50,000 to maintain the standard + $100,000 for videos and posters, etc. + an undetermined licensing fee).

Benefits of fire suppression on new construction and trucks undergoing modifications. The benefits of fire suppression systems are many, including that they stand up under the heavy vibration and shock conditions common to MBTs, are designed to protect human life and property by quickly and efficiently suppressing a fire before it can reach the operator or passenger areas, help to prevent extensive vehicle damage, and curtail the damage that threatens adjacent areas. The system can be water based or chemical based. If a suppressant is water based, it is—without question—environmentally safe. If the suppressants are chemical based, the environment can be remediated.16 There is evidence (noted in a study that examined the effects of fire suppressant agents on art artifacts) that the fire may cause more harm to the environment than the agent used to extinguish it and that the “heat from the fire would help to vaporize the agent.”17 There are too few incident data to estimate and monetize the benefits from a fire suppression system, but given that the cost is in the range of $1,000 to $1,500 per year over the life of a truck, the benefits are likely to justify those low costs. PHMSA seeks comment on this analysis.

16For example, an anaerobic bioremediation product has been specifically manufactured for environmental applications such as remediation of soils and associated groundwater. See: http://www.caruscorporation.com/content.cfm/cap18-me (accessed December 19, 2012).

17See http://www.nfpa.org/∼/media/Files/Research/Research%20Foundation/Research%20Foundation%20reports/Suppression/extinguishentsculturalresourcecollections.pdf, p. 17 (accessed December 19, 2012).

Benefits of NHTSA requirements on new construction and trucks undergoing modifications. NHTSA is the U.S. Government agency responsible for implementing and enforcing the National Traffic and Motor Vehicle Safety Act of 1966, as amended, 49 U.S.C. Chapter 301 (the Vehicle Safety Act), and certain other laws relating to motor vehicle safety. Under that authority, NHTSA issues and enforces Federal motor vehicle safety standards (FMVSS) that apply to motor vehicles and to certain items of motor vehicle equipment. The Vehicle Safety Act requires that motor vehicles and regulated items of motor vehicle equipment manufactured for sale in the United States be certified to comply with all applicable FMVSS. Before offering a motor vehicle or motor vehicle equipment item for sale in the United States, the fabricating manufacturer must: (1) Designate a permanent resident of the United States as its agent for service of process if the fabricating manufacturer is not located in the United States (49 CFR part 551, Subpart D Service of Process on Foreign Manufacturers and Importers) and (2) submit to NHTSA identifying information on itself and on the products it manufactures to the FMVSS, not later than 30 days after the manufacturing process begins (49 CFR part 566 Manufacturer Identification). This requirement is expected to reduce regulatory and administrative burden, without negatively affecting transportation safety. There are likely to be no significant marginal costs or benefits associated with this requirement. PHMSA seeks comment on this analysis.

The following table shows the benefits and cost savings associated with the NPRM.

| Cost savings items | Cost savings per year |

|---|---|

| Industry savings from no longer having to submit SP applications | $62,700 |

| PHMSA savings from SP application review | 31,464 |

| Industry savings from no longer having to do tire checks prior to departures across public roads | 14,800,000 |

| Savings to industry from remediation resulting from caking incidents experienced under current operations under SPs | 90,000 |

| Savings to the public from making SLP-23 available to the public at no-cost, updating and maintaining the publication | 1,300,000 |

| Reduced paperwork burden | 3,420 |

| Total | 16,287,584 |

The annual total cost savings are approximately $16.3 million. The quantified annual benefits of approximately $16.3 million arise mainly from the incorporation of SLP-23 into the HMR. There are other benefits from the other requirements (e.g., from the installation of fire suppression systems and the NHTSA requirements) but these benefits are not quantified.

Summary of Costs, Benefits, and Cost Savings for Adopting the NPRM

Under the NPRM, the one-time costs are approximately $10.4 million; the recurring annual costs are approximately $1.4 million. The net present value of these costs discounted at 3 percent and 7 percent over the 10 years is approximately $22 million and $19 million, respectively. The annualized cost of the rule discounted at 3 percent is $2.2 million and at 7 percent is approximately $1.9 million.

The present value of the $16.3 million in annual cost savings (which represent the major benefits of the proposed rule) discounted at 3 percent and 7 percent over 10 years is approximately $143 million and $122 million, respectively. The annualized benefits at 3 percent are approximately $14.3 million and at 7 percent $12.2 million.

The annualized net benefits of the proposed rule at 3 percent are approximately $12.1 million and at 7 percent approximately $10.3 million.

C. Executive Order 13132

This proposed rule was analyzed in accordance with the principles and criteria contained in Executive Order 13132 (“Federalism”), and the President's memorandum on “Preemption” published in the Federal Register on May 22, 2009 (74 FR 24693). This proposed rule would preempt state, local and Indian tribe requirements but does not propose any regulation that has substantial direct effects on the states, the relationship between the national government and the states, or the distribution of power and responsibilities among the various levels of governments. Therefore, the consultation and funding requirements of Executive Order 13132 do not apply. Federal hazardous material transportation law, 49 U.S.C. 5101-5128, contains an express preemption provision (49 U.S.C 5125(b)) preempting state, local and Indian tribe requirements on certain covered subjects. Covered subjects are:

(1) The designation, description, and classification of hazardous materials;

(2) The packing, repacking, handling, labeling, marking, and placarding of hazardous materials;

(3) The preparation, execution, and use of shipping documents related to hazardous materials and requirements related to the number, contents, and placement of those documents;

(4) The written notification, recording, and reporting of the unintentional release in transportation of hazardous materials; or

(5) The designing, manufacturing, fabricating, inspecting, marking, maintaining, reconditioning, repairing, or testing a package, container or packaging component that is represented, marked, certified, or sold as qualified for use in transporting hazardous material in commerce.