...

(a) A manufacturer must mark every packaging that is represented as manufactured to meet a UN standard with the marks specified in this section. The markings must be durable, legible and placed in a location and of such a size relative to the packaging as to be readily visible, as specified in §178.3(a). Except as otherwise provided in this section, every reusable packaging liable to undergo a reconditioning process which might obliterate the packaging marks must bear the marks specified in paragraphs (a)(1) through (a)(6) and (a)(9) of this section in a permanent form (e.g. embossed) able to withstand the reconditioning process. A marking may be applied in a single line or in multiple lines provided the correct sequence is used. As illustrated by the examples in paragraph (e) of this section, the following information must be presented in the correct sequence. Slash marks should be used to separate this information. A packaging conforming to a UN standard must be marked as follows:

(1) Except as provided in paragraph (e)(1)(ii) of this section, the United Nations symbol as illustrated in paragraph (e)(1)(i) of this section (for embossed metal receptacles, the letters “UN” may be applied in place of the symbol);

(2) A packaging identification code designating the type of packaging, the material of construction and, when appropriate, the category of packaging under §§178.504 through 178.523 of this subpart within the type to which the packaging belongs. The letter “V” must follow the packaging identification code on packagings tested in accordance with §178.601(g)(2); for example, “4GV”. The letter “W” must follow the packaging identification code on packagings when required by an approval under the provisions of §178.601(h) of this part;

(3) A letter identifying the performance standard under which the packaging design type has been successfully tested, as follows:

(i) X—for packagings meeting Packing Group I, II and III tests;

(ii) Y—for packagings meeting Packing Group II and III tests; or

(iii) Z—for packagings only meeting Packing Group III tests;

(4) A designation of the specific gravity or mass for which the packaging design type has been tested, as follows:

(i) For packagings without inner packagings intended to contain liquids, the designation shall be the specific gravity rounded down to the first decimal but may be omitted when the specific gravity does not exceed 1.2; and

(ii) For packagings intended to contain solids or inner packagings, the designation shall be the maximum gross mass in kilograms;

(5)(i) For single and composite packagings intended to contain liquids, the test pressure in kilopascals rounded down to the nearest 10 kPa of the hydrostatic pressure test that the packaging design type has successfully passed;

(ii) For packagings intended to contain solids or inner packagings, the letter “S”;

(6) The last two digits of the year of manufacture. Packagings of types 1H and 3H shall also be marked with the month of manufacture in any appropriate manner; this may be marked on the packaging in a different place from the remainder of the markings;

(7) The state authorizing allocation of the mark. The letters ‘USA’ indicate that the packaging is manufactured and marked in the United States in compliance with the provisions of this subchapter;

(8) The name and address or symbol of the manufacturer or the approval agency certifying compliance with subpart L and subpart M of this part. Symbols, if used must be registered with the Associate Administrator;

(9) For metal or plastic drums or jerricans intended for reuse or reconditioning as single packagings or the outer packagings of a composite packaging, the thickness of the packaging material, expressed in millimeters (rounded to the nearest 0.1 mm), as follows:

(i) Metal drums or jerricans must be marked with the nominal thickness of the metal used in the body. The marked nominal thickness must not exceed the minimum thickness of the steel used by more than the thickness tolerance stated in ISO 3574 (IBR, see §171.7 of this subchapter). (See appendix C of this part.) The unit of measure is not required to be marked. When the nominal thickness of either head of a metal drum is thinner than that of the body, the nominal thickness of the top head, body, and bottom head must be marked (e.g., ‘‘1.0-1.2-1.0’’ or ‘‘0.9-1.0-1.0’’).

(ii) Plastic drums or jerricans must be marked with the minimum thickness of the packaging material. Minimum thicknesses of plastic must be as determined in accordance with §173.28(b)(4). The unit of measure is not required to be marked;

(10) In addition to the markings prescribed in paragraphs (a)(1) through (a)(9) of this section, every new metal drum having a capacity greater than 100 L must bear the marks described in paragraphs (a)(1) through (a)(6), and (a)(9)(i) of this section, in a permanent form, on the bottom. The markings on the top head or side of these packagings need not be permanent, and need not include the thickness mark described in paragraph (a)(9) of this section. This marking indicates a drum’s characteristics at the time it was manufactured, and the information in paragraphs (a)(1) through (a)(6) of this section that is marked on the top head or side must be the same as the information in paragraphs (a)(1) through (a)(6) of this section permanently marked by the original manufacturer on the bottom of the drum; and

(11) Rated capacity of the packaging expressed in liters may be marked.

(b) For a packaging with a removable head, the markings may not be applied only to the removable head.

(c) Marking of reconditioned packagings. (1) If a packaging is reconditioned, it shall be marked by the re-conditioner near the marks required in paragraphs (a)(1) through (6) of this section with the following additional information:

(i) The name of the country in which the reconditioning was performed (in the United States, use the letters ‘‘USA’’);

(ii) The name and address or symbol of the reconditioner. Symbols, if used, must be registered with the Associate Administrator;

(iii) The last two digits of the year of reconditioning;

(iv) The letter ‘‘R’’; and

(v) For every packaging successfully passing a leakproofness test, the additional letter ‘‘L’’.

(2) When, after reconditioning, the markings required by paragraph (a)(1) through (a)(5) of this section no longer appear on the top head or the side of the metal drum, the reconditioner must apply them in a durable form followed by the markings in paragraph (c)(1) of this section. These markings may identify a different performance capability than that for which the original design type had been tested and marked, but may not identify a greater performance capability. The markings applied in accordance with this paragraph may be different from those which are permanently marked on the bottom of a drum in accordance with paragraph (a)(10) of this section.

(d) Marking of remanufactured packagings. For remanufactured metal drums, if there is no change to the packaging type and no replacement or removal of integral structural components, the required markings need not be permanent (e.g., embossed). Every other remanufactured drum must bear the marks required in paragraphs (a)(1) through (a)(6) of this section in a permanent form (e.g., embossed) on the top head or side. If the metal thickness marking required in paragraph (a)(9)(i) of this section does not appear on the bottom of the drum, or if it is no longer valid, the remanufacturer also must mark this information in permanent form.

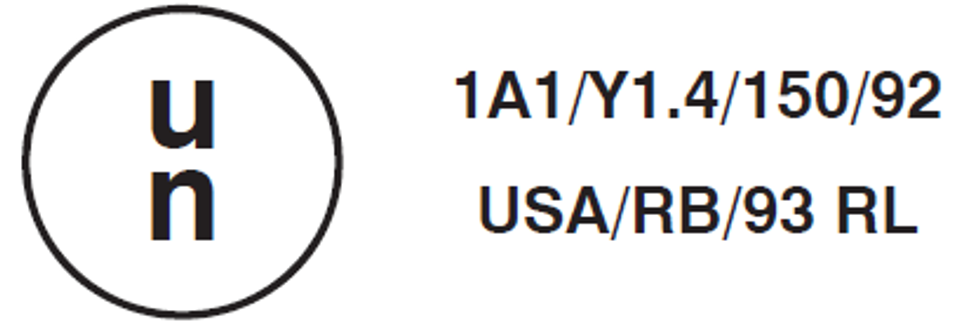

(e) The following are examples of symbols and required markings. (1)(i) The United Nations symbol is:

(ii) The circle that surrounds the letters “u” and “n” may have small breaks provided the following provisions are met:

(A) The total gap space does not exceed 15 percent of the circumference of the circle;

(B) There are no more than four gaps in the circle;

(C) The spacing between gaps is separated by no less than 20 percent of the circumference of the circle (72 degrees); and

(D) The letters “u” and “n” appear exactly as depicted in §178.503(e)(1)(i) with no gaps.

(2) Examples of markings for a new packaging are as follows:

(i) For a fiberboard box designed to contain an inner packaging:

(as in §178.503(a)(1) through (9) of this subpart).

(ii) For a steel drum designed to contain liquids:

(as in §178.503(a)(1) through (10) of this subpart).

(iii) For a steel drum to transport solids or inner packagings:

(as in §178.503(a)(1) through (8) of this subpart).

(3) Examples of markings for reconditioned packagings are as follows:

(as in §178.503(c)(1)).

(f) A manufacturer must mark every UN specification package represented as manufactured to meet the requirements of §178.609 for packaging of infectious substances with the marks specified in this section. The markings must be durable, legible, and must be readily visible, as specified in §178.3(a). An infectious substance packaging that successfully passes the tests conforming to the UN standard must be marked as follows:

(1) The United Nations symbol as illustrated in paragraph (e) of this section.

(2) The code designating the type of packaging and material of construction according to the identification codes for packagings specified in §178.502.

(3) The text “CLASS 6.2”.

(4) The last two digits of the year of manufacture of the packaging.

(5) The country authorizing the allocation of the mark. The letters “USA” indicate the packaging is manufactured and marked in the United States in compliance with the provisions of this subchapter.

(6) The name and address or symbol of the manufacturer or the approval agency certifying compliance with subparts L and M of this part. Symbols, if used, must be registered with the Associate Administrator for Hazardous Materials Safety.

(7) For packagings meeting the requirements of §178.609(i)(3), the letter “U” must be inserted immediately following the marking designating the type of packaging and material required in paragraph (f)(2) of this section.

[Amdt. 178–97, 55 FR 52717, Dec. 21, 1990, as amended at 56 FR 66284, Dec. 20, 1991; Amdt. 178–102, 59 FR 28493, June 2, 1994; Amdt. 178–106, 59 FR 67520, 67521, Dec. 29, 1994; Amdt. 178–107, 60 FR 26806, May 18, 1995; 62 FR 51561, Oct. 1, 1997; 66 FR 45386, Aug. 28, 2001; 67 FR 61016, Sept. 27, 2002; 67 FR 53143, Aug. 14, 2002; 68 FR 75757, Dec. 31, 2003; 75 FR 5395, Feb. 2, 2010; 75 FR 60339, Sept. 30, 2010; 77 FR 60943, Oct. 5, 2012; 78 FR 60755, Oct. 2, 2013]