['Air Programs']

['Mobile Emission Sources']

07/23/2024

...

Section 86.110-94 includes text that specifies requirements that differ from §86.110-90. Where a paragraph in §86.110-90 is identical and applicable to §86.110-94, this may be indicated by specifying the corresponding paragraph and the statement “[Reserved]. For guidance see §86.110-90.” Where a corresponding paragraph of §86.110-90 is not applicable, this is indicated by the statement “[Reserved].”

(a) General. The exhaust gas sampling system described in this paragraph is designed to measure the true mass of both gaseous and particulate emissions in the exhaust of either diesel-cycle or Otto-cycle light-duty vehicles and light-duty trucks. This system utilizes the CVS concept (described in §86.109) of measuring mass emissions. The mass of gaseous emissions is determined from the sample concentration and total flow over the test period. The mass of particulate emissions is determined from a proportional mass sample collected on a filter and from the total flow over the test period. General requirements are as follows:

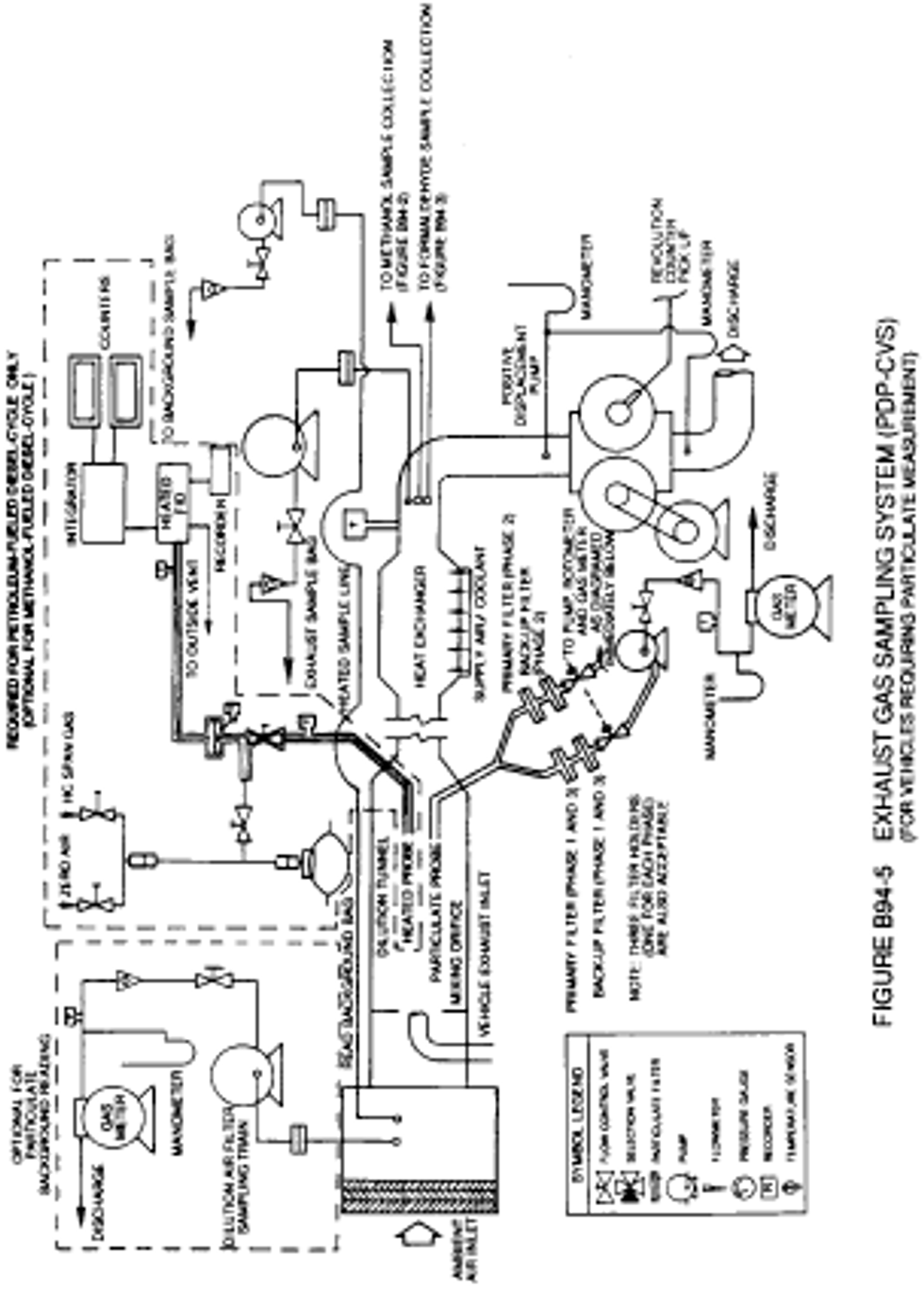

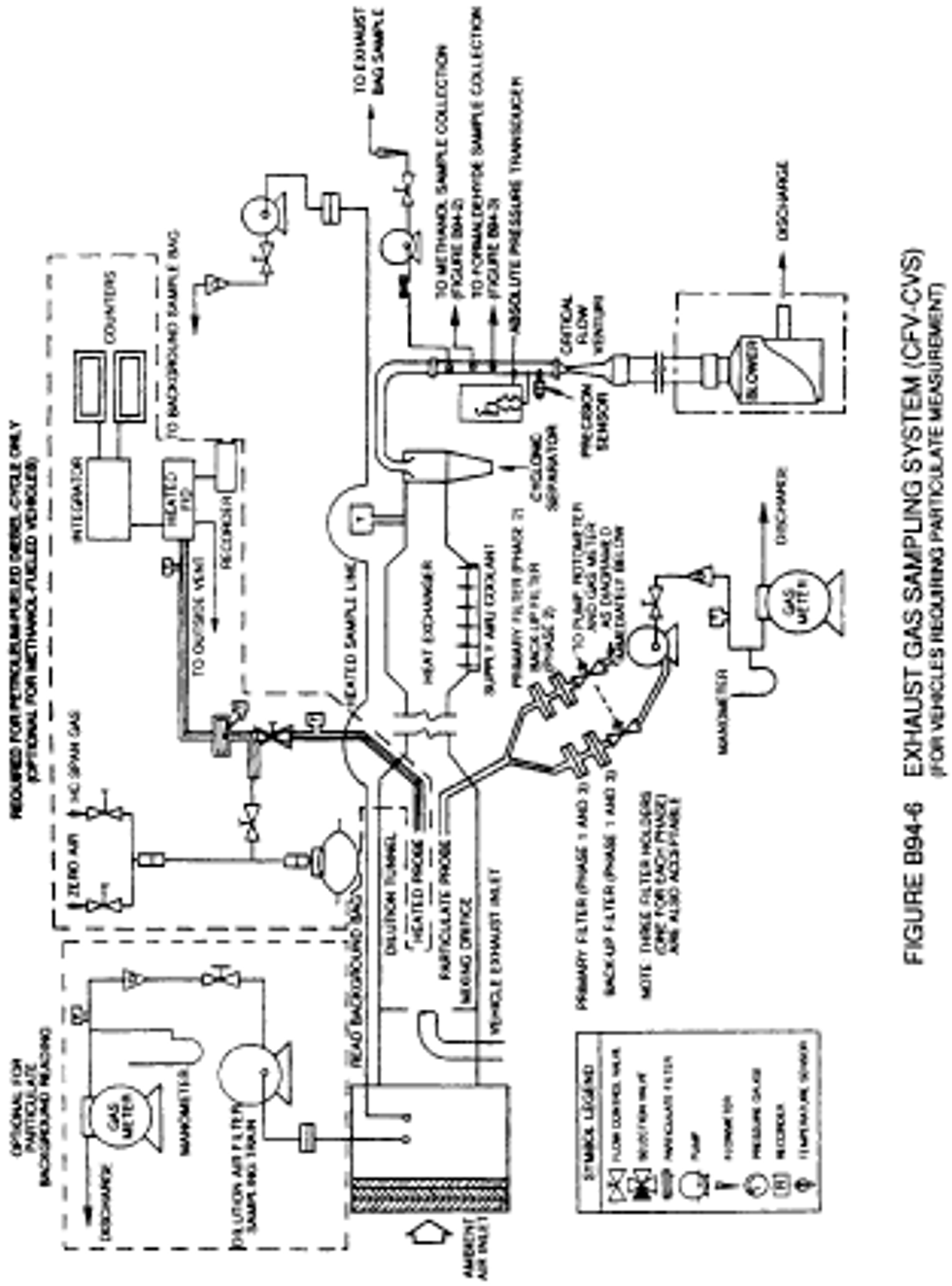

(1) This sampling system requires the use of a PDP-CVS, CFV-CVS (or a CFV-EFC-CVS), sample system with heat exchanger connected to a dilution tunnel. The heat exchanger is not required for the CFV-CVS or EFC-CFV-CVS if electronic flow controllers are used to maintain proportionality for the particulate sample. Figure B94-5 is a schematic drawing of the PDP system. Figure B94-6 is a schematic drawing of the CFV-CVS system. (Methanol-fueled Otto-cycle vehicles may be tested using this test equipment, without measuring particulate emissions.)

(2) Bag, continuous HFID (required for petroleum-fueled diesel-cycle and optional for methanol-fueled, natural gas-fueled and liquefied petroleum gas-fueled diesel-cycle vehicles), and particulate sampling capabilities as shown in Figure B94-5 (or Figure B94-6) are required to provide both gaseous and particulate emissions sampling capabilities from a single system.

(3) Petroleum-fueled diesel-cycle vehicles require a heated flame ionization detector (HFID) (375°±20°F (191°±11°C)) sample for total hydrocarbon (THC) analysis. The HFID sample must be taken directly from the diluted exhaust stream through a heated probe in the dilution tunnel.

(4) Methanol-fueled vehicles require the use of a heated flame ionization detector (HFID) (235°±15°F (113°±8°C)) for hydrocarbon analysis. With an HFID, the hydrocarbon analysis can be made on the bag sample and the methanol and formaldehyde analyses are performed on the samples collected for these purposes (Figures B94-2 and B94-3).

Note:

For 1990 through 1994 model year methanol-fueled vehicles, methanol and formaldehyde sampling may be omitted provided the bag sample is analyzed using a HFID calibrated with methanol.

(5) For methanol-fueled vehicles, the vehicle tailpipe-to-dilution tunnel connection shall be made by:

(i) A tailpipe to dilution tunnel duct of unrestricted length maintained at a temperature above the dew point of the mixture, but below 250°F (121°C) through heating and cooling as required; or

(ii) Using a short duct (up to 12 feet long) constructed of smooth wall pipe with a minimum of flexible sections maintained at a temperature above the dew point of the mixture, but below 250°F (121°C) prior to the test and during breaks in testing (insulation may remain in place and or heating may occur during the testing provided the maximum temperature is not exceeded); or

(iii) Using smooth wall duct less than five feet long with no required heating. A maximum of two short flexible connectors are allowed under this option; or

(iv) By omitting the duct and performing the exhaust gas dilution function at the vehicle tailpipe exit.

(6) For natural gas-fueled and liquefied petroleum gas-fueled diesel vehicles either a heated flame ionization detector (HFID) [375°±20°F (191°±11°C)] or a non-heated flame ionization detector may be used for hydrocarbon analysis.

(7) Since various configurations can produce equivalent results, exact conformance with these drawings is not required. Additional components such as instruments, valves, solenoids, pumps, and switches may be used to provide additional information and coordinate the functions of the component systems.

(8) Other sampling systems may be used if shown to yield equivalent or superior results and if approved in advance by the Administrator.

(b) Component description - petroleum-fueled, natural gas-fueled and liquefied petroleum gas-fueled vehicles. The components necessary for petroleum-fueled, natural gas-fueled and liquefied petroleum gas-fueled vehicle exhaust sampling shall meet the following requirements:

(1) The PDP-CVS, Figure B94-5, shall contain a proportional particulate sampling system, and shall conform to all of the requirements listed for the exhaust gas PDP-CVS (§86.109(b)), with one exception: a flow rate of sufficient volume is required to maintain the diluted exhaust stream, from which the particulate sample flow is taken, at a temperature of 125°F (52°C) or less.

(2) The CFV sample system, Figure B94-6, shall contain a proportional particulate sampling system, and shall conform to all of the requirements listed for the exhaust gas CFV sample system (§86.109(c)), except for the following:

(i) A flow rate of sufficient volume is required to maintain the diluted exhaust stream, from which the particulate sample flow is taken, at a temperature of 125°F (52°C) or less.

(ii) If a constant volume particulate sample is collected, a heat exchanger is required.

(iii) If a heat exchanger is used, the gas mixture temperature, measured at a point immediately ahead of the critical flow venturi, shall be within ±20°F (11°C) of the designed operating temperature at the start of the test. The gas mixture temperature variation from its value at the start of the test shall be limited to ±20°F (11°C) during the entire test. The temperature measuring system shall have an accuracy and precision of ±2°F (1.1°C).

(iv) The cyclonic separator is optional.

(3) For gasoline-fueled, natural gas-fueled and liquefied petroleum gas-fueled Otto-cycle and petroleum-fueled, natural gas- fueled and liquefied petroleum gas-fueled diesel-cycle vehicles, the transfer of heat from the vehicle exhaust gas shall be minimized between the point where it leaves the vehicle tailpipe(s) and the point where it enters the dilution tunnel airstream. To accomplish this, a short length (not more than 12 feet (365 cm) if uninsulated, or not more than 20 feet (610 cm) if insulated) of smooth stainless steel tubing from the tailpipe to the dilution tunnel is required. This tubing shall have a maximum inside diameter of 4.0 inches (10.2 cm). Short sections of flexible tubing at connection points are allowed.

(4) The vehicle exhaust shall be directed downstream at the point where it is introduced into the dilution tunnel.

(5) The dilution air shall be between 68°F (20°C) and 86°F (30°C) during the test.

(6) The dilution tunnel shall be:

(i) Sized to permit development of turbulent flow (Reynolds No. >>4000) and complete mixing of the exhaust and dilution air between the mixing orifice and each of the two sample probes (i.e., the particulate probe and the heated THC sample probe). It is recommended that uniform mixing be demonstrated by the user.

(ii) At least 8.0 inches (20.3 cm) in diameter.

(iii) Constructed of electrically conductive material which does not react with the exhaust components.

(iv) Grounded.

(7) The temperature of the diluted exhaust stream inside of the dilution tunnel shall be sufficient to prevent water condensation. However, the sample zone dilute exhaust temperature shall not exceed 125°F (52°C) at any time during the test.

(8) The particulate sample probe shall be:

(i) Installed facing upstream at a point where the dilution air and exhaust are well mixed (i.e., near the tunnel centerline, approximately 10 tunnel diameters downstream from the point where the exhaust enters the dilution tunnel).

(ii) Sufficiently distant (radially) from the THC probe (when the THC probe is required) so as to be free from the influence of any wakes or eddies produced by the THC probe.

(iii) 0.5 inch (1.27 cm) minimum inside diameter.

(iv) The distance from the sampling tip to the filter holder shall be at least 5 probe diameters (for filters located inside of the tunnel), but not more than 40.0 inches (102 cm) for filters located outside of the dilution tunnel.

(v) Free from sharp bends.

(vi) Configured so that a clean particulate filter (including back-up filter) can be selected simultaneously with the selection of an empty gaseous emissions bag.

(9) The flow rate through the particulate probe shall be maintained to a constant value within ±5 percent of the set flow rate.

(10) The particulate sample pump shall be located sufficiently distant from the dilution tunnel so that the inlet gas temperature is maintained at a constant temperature (±5.0°F (2.8°C)).

(11) The gas meters or flow instrumentation shall be located sufficiently distant from the tunnel so that the inlet gas temperature remains constant (±5.0°F (2.8°C)).

(12) The THC probe (when the THC probe is required) shall be:

(i) Installed facing upstream at a point where the dilution air and exhaust are well mixed (i.e., approximately 10 tunnel diameters downstream from the point where the exhaust enters the dilution tunnel).

(ii) Sufficiently distant (radially) from the particulate probe so as to be free from the influence of any wakes or eddies produced by the particulate probe.

(iii) Heated and insulated over the entire length to maintain a 375°±20°F (191°±11°C) wall temperature.

(iv) 0.19 in. (0.48 cm) minimum inside diameter.

(13) It is intended that the THC probe be free from cold spots (i.e., free from spots where the probe wall temperature is less than 355°F). This will be determined by a temperature sensor located on a section of the probe wall outside of the dilution tunnel. The temperature sensor shall be insulated from any heating elements on the probe. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(14) The dilute exhaust gas flowing in the THC sample system shall be:

(i) At 375°F±10°F (191°C±6°C) immediately before the heated filter. This will be determined by a temperature sensor located immediately upstream of the filter. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(ii) At 375°F±10°F (191°C ±6°C) immediately before the HFID. This will be determined by a temperature sensor located at the exit of the heated sample line. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(15) It is intended that the dilute exhaust gas flowing in the THC sample system be between 365°F and 385°F (185°C and 197°C).

(c) Component description - methanol-fueled vehicles. The components necessary for methanol-fueled vehicle exhaust sampling shall meet the following requirements:

(1) The PDP-CVS, Figure B94-5, shall contain a proportional particulate sampling system, and shall conform to all of the requirements listed for the exhaust gas PDP-CVS (§86.109), with one exception: a flow rate of sufficient volume is required to maintain the diluted exhaust stream, from which the particulate sample flow is taken, at a temperature of 125°F (52°C) or less.

(2) The CFV-CVS sample system, Figure B94-6, shall contain a proportional particulate sampling system, and shall conform to all of the requirements listed for the exhaust gas CFV sample system (§86.109), except for the following:

(i) A flow rate of sufficient volume is required to maintain the diluted exhaust stream, from which the particulate sample flow is taken, at a temperature of 125°F (52°C) or less.

(ii) If a constant volume particulate sample is collected, a heat exchanger is required.

(iii) If a heat exchanger is used, the gas mixture temperature, measured at a point immediately ahead of the critical flow venturi, shall be within ±20°F (11°C) of the designed operating temperature at the start of the test. The gas mixture temperature variation from its value at the start of the test shall be limited to ±20°F (11°C) during the entire test. The temperature measuring system shall have an accuracy and precision of ±2°F (1.1°C).

(iv) The cyclonic separator is optional.

(3) The EFC-CFV-CVS sample system shall conform to all of the requirements listed for the exhaust gas EFC sample system (§86.109) with three exceptions:

(i) A flow rate of sufficient volume is required to maintain the diluted exhaust stream, from which the particulate sample flow is taken, at a temperature of 125°F (52°C) or less.

(ii) A proportional particulate sample shall be collected using an electronic flow controller that meets the performance criteria listed in §86.109 for methanol and formaldehyde EFC systems.

(iii) The cyclonic separator is optional.

(4) Losses of methanol due to condensation of water in the duct connecting the vehicle tail pipe to the dilution tunnel must be eliminated. This may be accomplished by:

(i) The use of a duct of unrestricted length maintained at a temperature above the maximum dew point of the exhaust, but below 250°F (121°C), through heating and cooling as required; or

(ii) The use of a short duct (up to 12 feet long) constructed of smooth wall pipe with a minimum of flexible sections maintained at a temperature above the maximum dew point of the exhaust, but below 250°F (121°C), prior to the test and during breaks in testing (insulation may remain in place and/or heating may occur during testing provided maximum temperature is not exceeded); or

(iii) Using smooth wall duct less than five feet long with no required heating. A maximum of two short flexible connectors are allowed under this option; or

(iv) Omitting the duct and performing the exhaust gas dilution function at the vehicle tailpipe exit.

(5) The vehicle exhaust shall be directed downstream at the point where it is introduced into the dilution tunnel.

(6) The dilution air shall be between 68°F (20°C) and 86°F (30°C) during the test (unless the requirements of §86.109-94(b)(4) are also met).

(7) The dilution tunnel shall be:

(i) Sized to permit development of turbulent flow (Reynold's No. >>4000) and complete mixing of the exhaust and dilution air between the mixing orifice and the particulate sample probe. It is recommended that uniform mixing be demonstrated by the user.

(ii) At least 8.0 inches (20.3 cm) in diameter.

(iii) Constructed of electrically conductive material which does not react with the exhaust components.

(iv) Grounded.

(8) The temperature of the diluted exhaust stream inside of the dilution tunnel shall be sufficient to prevent water condensation. However, the sample zone dilute exhaust temperature shall not exceed 125°F (52°C) at any time during the test.

(9) The particulate sample probe shall be:

(i) Installed facing upstream at a point where the dilution air and exhaust are well mixed (i.e., near the tunnel centerline, approximately 10 tunnel diameters downstream from the point where the exhaust enters the dilution tunnel).

(ii) Sufficiently distant (radially) from the THC probe so as to be free from the influence of any wakes or eddies produced by the THC probe.

(iii) 0.5 inch (1.27 cm) minimum inside diameter.

(iv) The distance from the sampling tip to the filter holder shall be at least five probe diameters (for filters located inside the tunnel), but not more than 40.0 inches (102 cm) for filters located outside of the dilution tunnel.

(v) Free from sharp bends.

(vi) Configured so that a clean particulate filter (including back up filter) can be selected simultaneously with the selection of an empty gaseous emissions bag.

(10) The flow rate through the particulate probe shall be maintained to a constant value within ±5 percent of the set flow rate.

(11) The particulate sample pump shall be located sufficiently distant from the dilution tunnel so that the inlet gas temperature is maintained at a constant temperature (±5.0°F (2.8°C)).

(12) The gas meters or flow instrumentation shall be located sufficiently distant from the tunnel so that the inlet gas temperature remains constant (±5.0°F (2.8°C)).

(13) The hydrocarbon probe shall be:

(i) Installed facing upstream at a point where the dilution air and exhaust are well mixed (i.e., approximately ten tunnel diameters downstream from the point where the exhaust enters the dilution tunnel).

(ii) Sufficiently distant (radially) from the particulate probe so as to be free from the influence of any wakes of eddies produced by the particulate probe.

(iii) Heated and insulated over the entire length to maintain a wall temperature more than 5°F (3°C) above the maximum dew point of the sample, but below 250°F (121°C).

(iv) 0.19 in. (0.48 cm) minimum inside diameter.

(14) It is intended that the THC probe be free from cold spots (i.e., free from cold spots where the probe wall temperature is less than 5°F (3°C) above the maximum dew point of the sample.) This will be determined by a temperature sensor located on a section of the probe wall outside of the dilution tunnel. The temperature sensor shall be insulated from any heating elements on the probe. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(15) The dilute exhaust gas flowing in the hydrocarbon sample system shall be:

(i) At 235°F ±15°F (113°C ±8°C) immediately before the heated filter. This will be determined by a temperature sensor located immediately upstream of the filter. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(ii) At 235° ±15°F (113°C ±8°C) immediately before the HFID. This will be determined by a temperature sensor located at the exit of the heated sample line. The sensor shall have an accuracy and precision of ±2°F (1.1°C).

(16) It is intended that the dilute exhaust gas flowing in the hydrocarbon sample system between 220°F and 250°F (105°C and 121°C).

(17) For methanol-fueled vehicles, bag sampling procedures for the measurement of hydrocarbons as described in §86.109 may be employed.

(d) Filters, particulate sampling. Use fluorocarbon-coated glass fiber filters or fluorocarbon-based (membrane) filters to collect particulate matter, as follows:

(1) Use primary and back-up test filters as follows for particulate measurements:

(i) During each phase of the UDDS, sample dilute exhaust simultaneously with paired primary and back-up test filters.

(ii) Position the back-up filter holder 3 to 4 inches downstream of the primary filter holder.

(iii) Determine the net weight of particulate material collected on each primary test filter and each back-up test filter using the procedure described in §86.139.

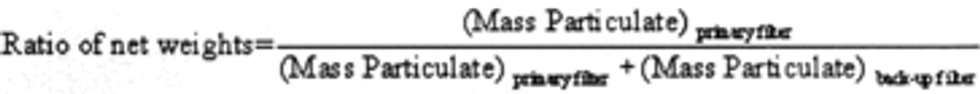

(iv) Determine a ratio of net weights using the following formula:

(v) If the ratio is greater than 0.95, base the particulate emission calculations on the net weight of the primary filter only.

(vi) If the ratio is less than 0.95, base the particulate emission calculations on the combined net weights of the back-up test filter and the primary test filter.

(2) The particulate filter must have a 47 mm diameter (37 mm stain area).

[56 FR 25767, June 5, 1991, as amended at 59 FR 48505, Sept. 21, 1994; 60 FR 34342, June 30, 1995; 79 FR 23692, Apr. 28, 2014]

READ MORESHOW LESS

['Air Programs']

['Mobile Emission Sources']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.