['Air Programs']

['Air Quality']

11/20/2023

...

§60.390 Applicability and designation of affected facility.

(a) The provisions of this subpart apply to the following affected facilities in an automobile or light-duty truck assembly plant: each prime coat operation, each guide coat operation, and each topcoat operation.

(b) Exempted from the provisions of this subpart are operations used to coat plastic body components or all-plastic automobile or light-duty truck bodies on separate coating lines. The attachment of plastic body parts to a metal body before the body is coated does not cause the metal body coating operation to be exempted.

(c) The provisions of this subpart apply to any affected facility identified in paragraph (a) of this section that begins construction, reconstruction, or modification after October 5, 1979, and on or before May 18, 2022.

[88 FR 29999, May 9, 2023]

§60.391 Definitions.

(a) All terms used in this subpart that are not defined below have the meaning given to them in the Act and in subpart A of this part.

Applied coating solids means the volume of dried or cured coating solids which is deposited and remains on the surface of the automobile or light-duty truck body.

Automobile means a motor vehicle capable of carrying no more than 12 passengers.

Automobile and light-duty truck body means the exterior surface of an automobile or light-duty truck including hoods, fenders, cargo boxes, doors, and grill opening panels.

Bake oven means a device that uses heat to dry or cure coatings.

Electrodeposition (EDP) means a method of applying a prime coat by which the automobile or light-duty truck body is submerged in a tank filled with coating material and an electrical field is used to effect the deposition of the coating material on the body.

Electrostatic spray application means a spray application method that uses an electrical potential to increase the transfer efficiency of the coating solids. Electrostatic spray application can be used for prime coat, guide coat, or topcoat operations.

Flash-off area means the structure on automobile and light-duty truck assembly lines between the coating application system (dip tank or spray booth) and the bake oven. Flash-off area also means the structure between spray booths in a wet-on-wet coating process in which some of the solvent evaporates before the next spray booth; the flash off area may be ambient temperature or heated to accelerate evaporation.

Guide coat operation means the guide coat spray booth, flash-off area and bake oven(s) which are used to apply and dry or cure a surface coating between the prime coat and topcoat operation on the components of automobile and light-duty truck bodies.

Light-duty truck means any motor vehicle rated at 3,850 kilograms gross vehicle weight or less, designed mainly to transport property.

Plastic body means an automobile or light-duty truck body constructed of synthetic organic material.

Plastic body component means any component of an automobile or light-duty truck exterior surface constructed of synthetic organic material.

Prime coat operation means the prime coat spray booth or dip tank, flash-off area, and bake oven(s) which are used to apply and dry or cure the initial coating on components of automobile or light-duty truck bodies.

Purge or line purge means the coating material expelled from the spray system when clearing it.

Solids Turnover Ratio (R T) means the ratio of total volume of coating solids that is added to the EDP system in a calendar month divided by the total volume design capacity of the EDP system.

Solvent-borne means a coating which contains five percent or less water by weight in its volatile fraction.

Spray application means a method of applying coatings by atomizing the coating material and directing the atomized material toward the part to be coated. Spray applications can be used for prime coat, guide coat, and topcoat operations.

Spray booth means a structure housing automatic or manual spray application equipment where prime coat, guide coat, or topcoat is applied to components of automobile or light-duty truck bodies.

Surface coating operation means any prime coat, guide coat, or topcoat operation on an automobile or light-duty truck surface coating line.

Topcoat operation means the topcoat spray booth, flash-off area, and bake oven(s) which are used to apply and dry or cure the final coating(s) on components of automobile and light-duty truck bodies.

Transfer efficiency means the ratio of the amount of coating solids transferred onto the surface of a part or product to the total amount of coating solids used.

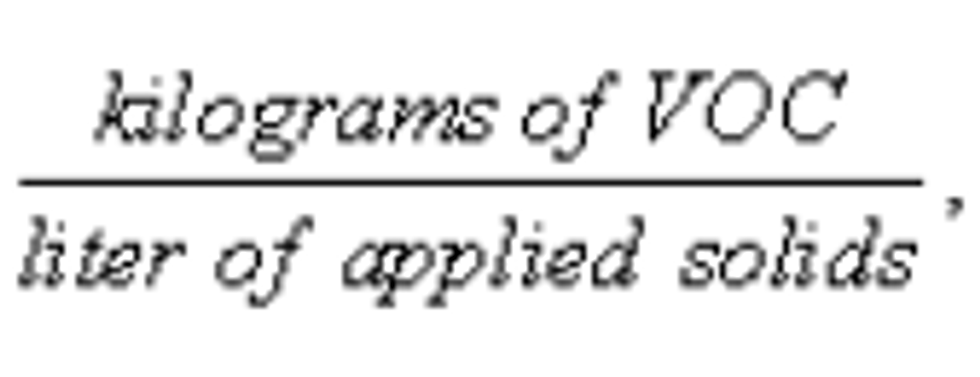

VOC content means all volatile organic compounds that are in a coating expressed as kilograms of VOC per liter of coating solids.

Volume Design Capacity of EDP System (LE) means the total liquid volume that is contained in the EDP system (tank, pumps, recirculating lines, filters, etc.) at its designed liquid operating level.

Waterborne or water reducible means a coating which contains more than five weight percent water in its volatile fraction.

(b) The nomenclature used in this subpart has the following meanings:

Caj = concentration of VOC (as carbon) in the effluent gas flowing through stack (j) leaving the control device (parts per million by volume),

Cbi = concentration of VOC (as carbon) in the effluent gas flowing through stack (i) entering the control device (parts per million by volume),

Cfk = concentration of VOC (as carbon) in the effluent gas flowing through exhaust stack (k) not entering the control device (parts per million by volume),

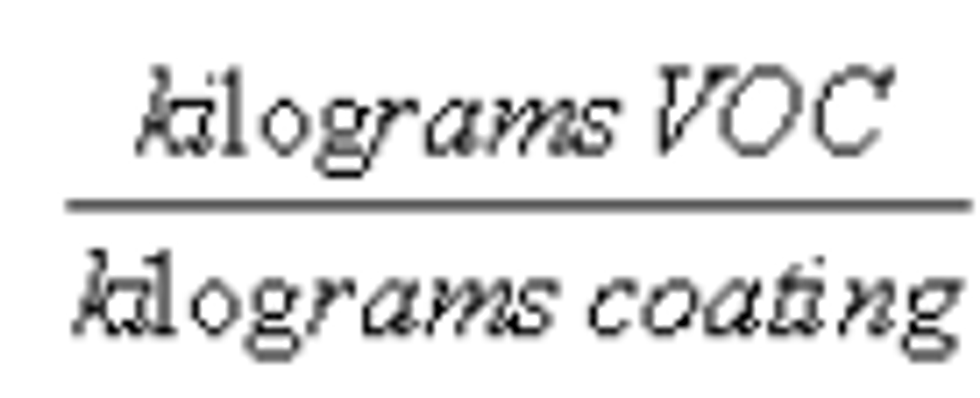

Dci = density of each coating (i) as received (kilograms per liter),

Ddj = density of each type VOC dilution solvent (j) added to the coatings, as received (kilograms per liter),

Dr = density of VOC recovered from an affected facility (kilograms per liter),

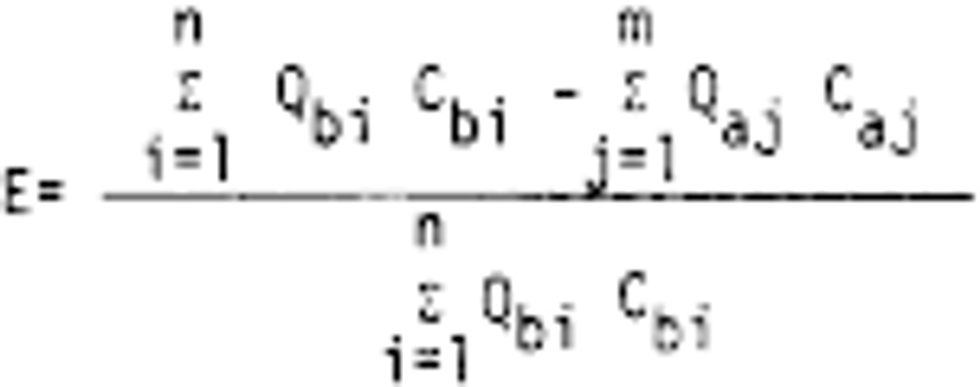

E = VOC destruction or removal efficiency of the control device,

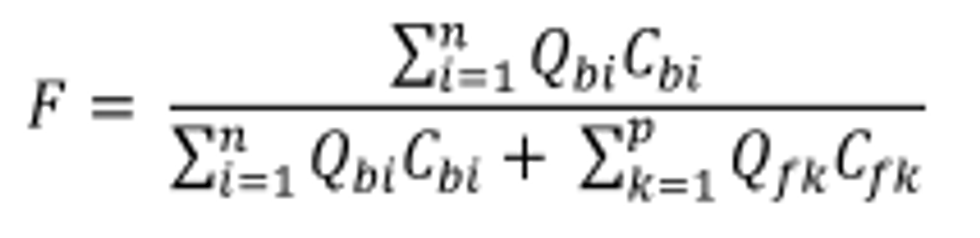

F = fraction of total VOC which is emitted by an affected facility that enters the control device,

G = volume weighted average mass of VOC per volume of applied solids (kilograms per liter),

Lci = volume of each coating (i) consumed, as received (liters),

Lcil = Volume of each coating (i) consumed by each application method (l), as received (liters),

Ldj = volume of each type VOC dilution solvent (j) added to the coatings, as received (liters),

Lr = volume of VOC recovered from an affected facility (liters),

Ls = volume of solids in coatings consumed (liters),

LE = the total volume of the EDP system (liters),

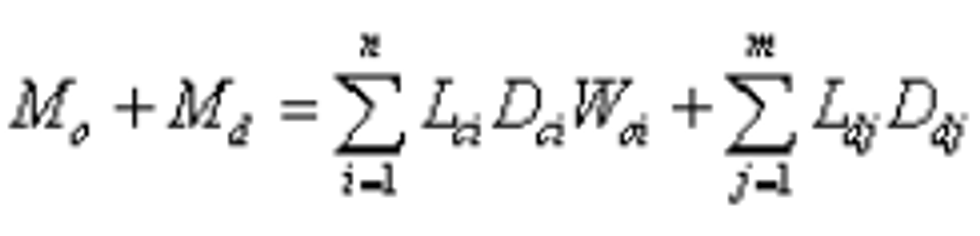

Md = total mass of VOC in dilution solvent (kilograms),

M0 = total mass of VOC in coatings as received (kilograms),

Mr = total mass of VOC recovered from an affected facility (kilograms),

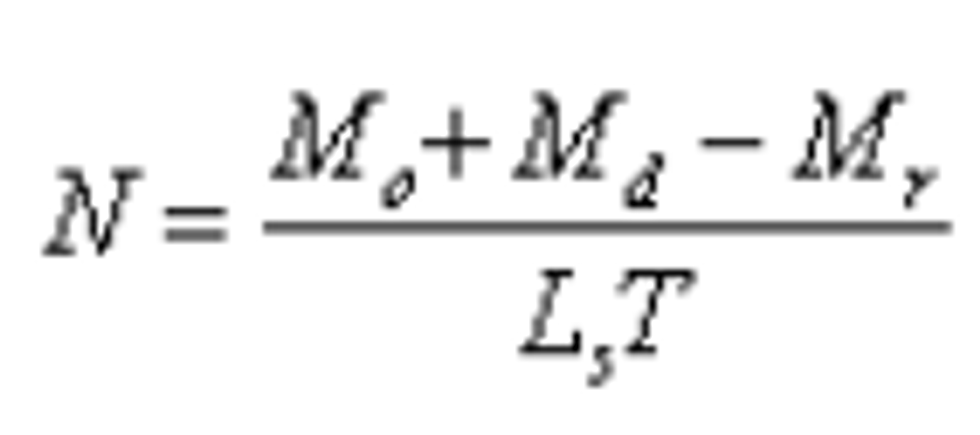

N = volume weighted average mass of VOC per volume of applied coating solids after the control device

Qaj = volumetric flow rate of the effluent gas flowing through stack (j) leaving the control device (dry standard cubic meters per hour),

Qbi = volumetric flow rate of the effluent gas flowing through stack (i) entering the control device (dry standard cubic meters per hour),

Qfk = volumetric flow rate of the effluent gas flowing through exhaust stack (k) not entering the control device (dry standard cubic meters per hour),

T = overall transfer efficiency,

Tl = transfer efficiency for application method (l),

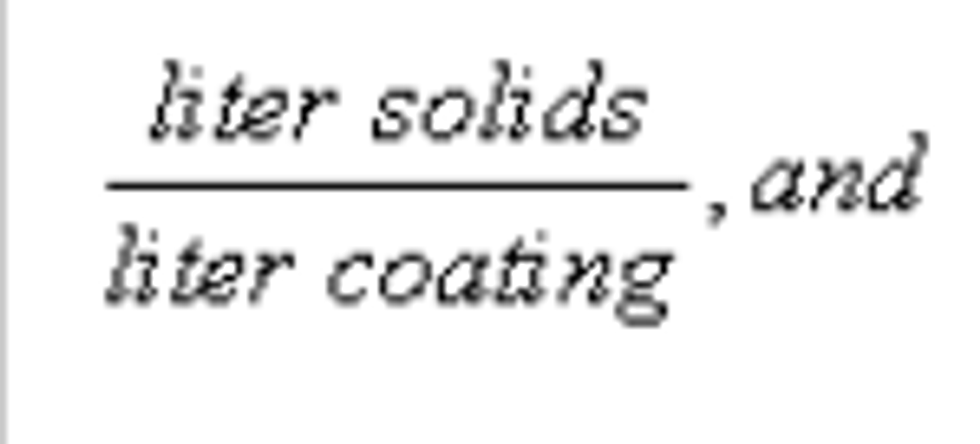

Vsi = proportion of solids by volume in each coating (i) as received

Woi = proportion of VOC by weight in each coating (i), as received

[45 FR 85415, Dec. 24, 1980, as amended at 59 FR 51386, Oct. 11, 1994; 65 FR 61760, Oct. 17, 2000; 88 FR 30000, May 9, 2023]

§60.392 Standards for volatile organic compounds.

On and after the date on which the initial performance test required by §60.8 is completed, no owner or operator subject to the provisions of this subpart shall discharge or cause the discharge into the atmosphere from any affected facility VOC emissions in excess of the limitations listed in paragraphs (a)(1) and (2) of this section. The emission limitations listed in paragraphs (a)(1) and (2) shall apply at all times, including periods of startup, shutdown and malfunction. As provided in §60.11(f), this provision supersedes the exemptions for periods of startup, shutdown and malfunction in the general provisions in subpart A of this part.

(a) Prime Coat Operation. (1) For each EDP prime coat operation:

(i) 0.17 kilogram of VOC per liter of applied coating solids when RT is 0.16 or greater.

(ii) 0.17 × 350 (0.160−R T) kg of VOC per liter of applied coating solids when RT is greater than or equal to 0.040 and less than 0.160.

(iii) When RT is less than 0.040, there is no emission limit.

(2) For each nonelectrodeposition prime coat operation: 0.17 kilogram of VOC per liter of applied coating solids.

(b) 1.40 kilograms of VOC per liter of applied coating solids from each guide coat operation.

(c) 1.47 kilograms of VOC per liter of applied coating solids from each topcoat operation.

[45 FR 85415, Dec. 24, 1980, as amended at 59 FR 51386, Oct. 11, 1994; 88 FR 30000, May 9, 2023]

§60.393 Performance test and compliance provisions.

(a) Section 60.8 (d) and (f) do not apply to the performance test procedures required by this section.

(b) The owner or operator of an affected facility shall conduct an initial performance test in accordance with §60.8(a) and thereafter for each calendar month for each affected facility according to the procedures in this section.

(c) The owner or operator shall use the following procedures for determining the monthly volume weighted average mass of VOC emitted per volume of applied coating solids.

(1) The owner or operator shall use the following procedures for each affected facility which does not use a capture system and a control device to comply with the applicable emission limit specified under §60.392.

(i) Calculate the volume weighted average mass of VOC per volume of applied coating solids for each calendar month for each affected facility. The owner or operator shall determine the composition of the coatings by formulation data supplied by the manufacturer of the coating or from data determined by an analysis of each coating, as received, by Method 24. The Administrator may require the owner or operator who uses formulation data supplied by the manufacturer of the coating to determine data used in the calculation of the VOC content of coatings by Method 24 or an equivalent or alternative method. The owner or operator shall determine from company records on a monthly basis the volume of coating consumed, as received, and the mass of solvent used for thinning purposes. The volume weighted average of the total mass of VOC per volume of coating solids used each calendar month will be determined by the following procedures.

(A) Calculate the mass of VOC used in each calendar month for each affected facility by the following equation where “n” is the total number of coatings used and “m” is the total number of VOC solvents used:

[ΣLdjDdj will be zero if no VOC solvent is added to the coatings, as received].

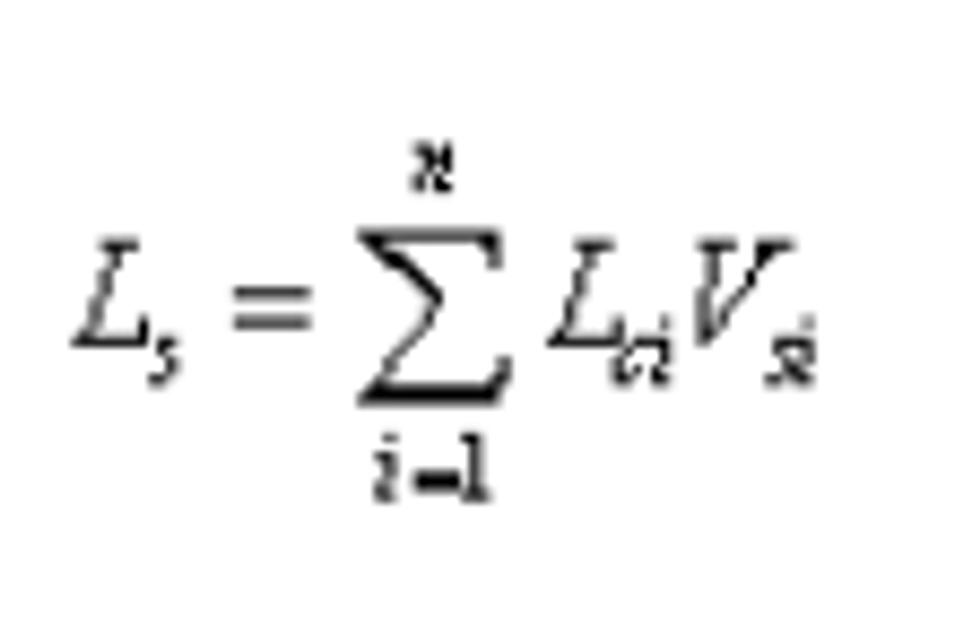

(B) Calculate the total volume of coating solids used in each calendar month for each affected facility by the following equation where “n” is the total number of coatings used:

(C) Select the appropriate transfer efficiency (T) from the following tables for each surface coating operation:

| Application method | Transfer efficiency |

|---|---|

| Air Atomized Spray (waterborne coating) | 0.39 |

| Air Atomized Spray (solvent-borne coating) | 0.50 |

| Manual Electrostatic Spray | 0.75 |

| Automatic Electrostatic Spray | 0.95 |

| Electrodeposition | 1.00 |

The values in the table above represent an overall system efficiency which includes a total capture of purge. If a spray system uses line purging after each vehicle and does not collect any of the purge material, the following table shall be used:

| Application method | Transfer efficiency |

|---|---|

| Air Atomized Spray (waterborne coating) | 0.30 |

| Air Atomized Spray (solvent-borne coating) | 0.40 |

| Manual Electrostatic Spray | 0.62 |

| Automatic Electrostatic Spray | 0.75 |

If the owner or operator can justify to the Administrator's satisfaction that other values for transfer efficiencies are appropriate, the Administrator will approve their use on a case-by-case basis.

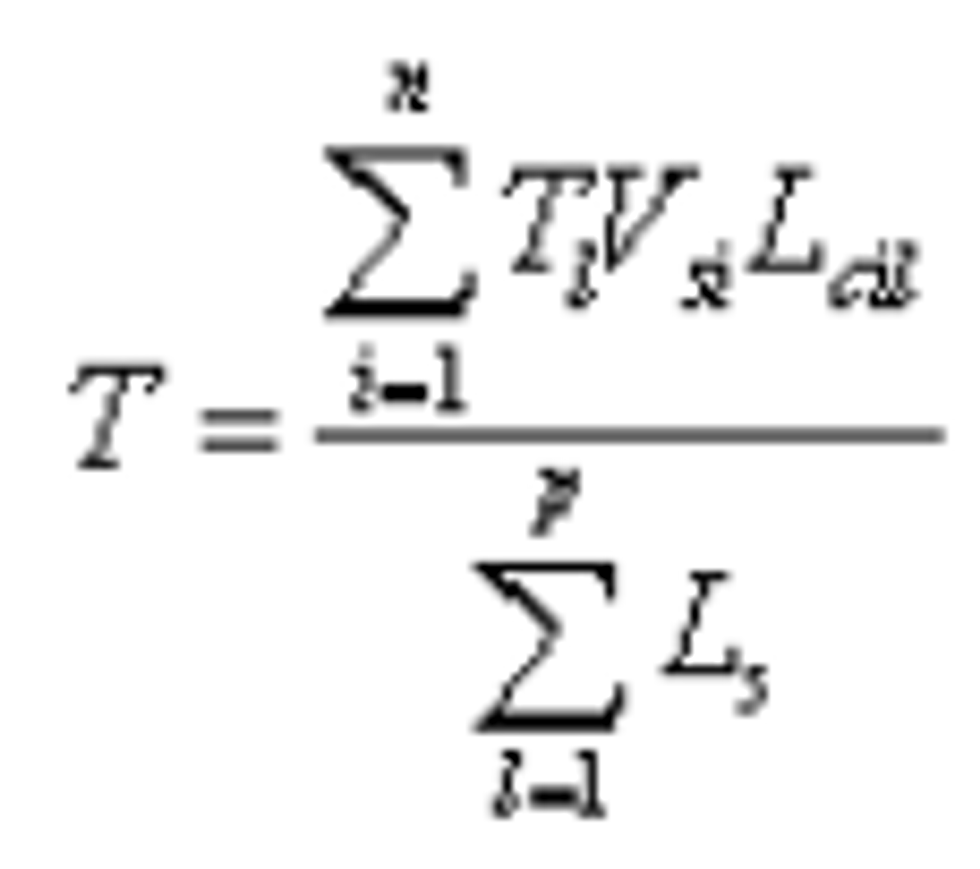

(1) When more than one application method (l) is used on an individual surface coating operation, the owner or operator shall perform an analysis to determine an average transfer efficiency by the following equation where “n” is the total number of coatings used and “p” is the total number of application methods:

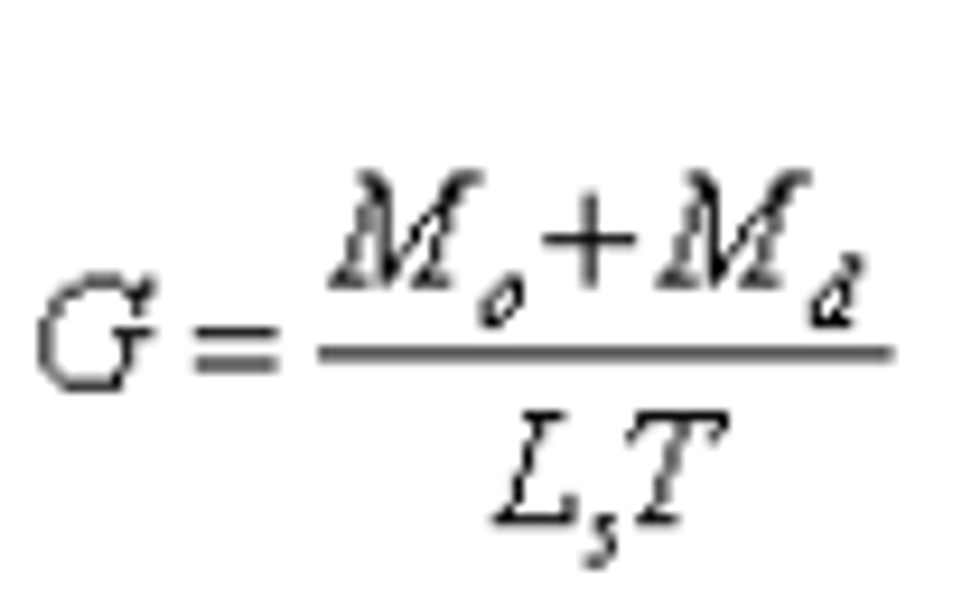

(D) Calculate the volume weighted average mass of VOC per volume of applied coating solids (G) during each calendar month for each affected facility by the following equation:

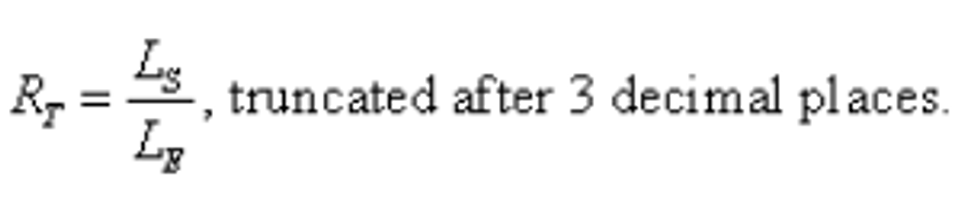

(E) For each EDP prime coat operation, calculate the turnover ratio (RT) by the following equation:

Then calculate or select the appropriate limit according to §60.392(a).

(ii) If the volume weighted average mass of VOC per volume of applied coating solids (G), calculated on a calendar month basis, is less than or equal to the applicable emission limit specified in §60.392, the affected facility is in compliance. Each monthly calculation is a performance test for the purpose of this subpart.

(2) The owner or operator shall use the following procedures for each affected facility which uses a capture system and a control device that destroys VOC (e.g., incinerator) to comply with the applicable emission limit specified under §60.392.

(i) Calculate the volume weighted average mass of VOC per volume of applied coating solids (G) during each calendar month for each affected facility as described under §60.393(c)(1)(i).

(A) Determine the fraction of total VOC which is emitted by an affected facility that enters the control device by using the following equation where “n” is the total number of stacks entering the control device and “p” is the total number of stacks not connected to the control device:

(1) In subsequent months, the owner or operator shall use the most recently determined capture fraction for the performance test.

(2) If the owner can justify to the Administrator's satisfaction that another method will give comparable results, the Administrator will approve its use on a case-by-case basis.

(B) Determines the destruction efficiency of the control device using values of the volumetric flow rate of the gas streams and the VOC content (as carbon) of each of the gas streams in and out of the device by the following equation where “n” is the total number of stacks entering the control device and “m” is the total number of stacks leaving the control device:

(1) In subsequent months, the owner or operator shall use the most recently determined VOC destruction efficiency for the performance test.

(C) If an emission control device controls the emissions from more than one affected facility, the owner or operator shall measure the VOC concentration (Cbi) in the effluent gas entering the control device (in parts per million by volume) and the volumetric flow rate (Qbi) of the effluent gas (in dry standard cubic meters per hour) entering the device through each stack. The destruction or removal efficiency determined using these data shall be applied to each affected facility served by the control device.

(iii) If the volume weighted average mass of VOC per volume of applied solids emitted after the control device (N) calculated on a calendar month basis is less than or equal to the applicable emission limit specified in §60.392, the affected facility is in compliance. Each monthly calculation is a performance test for the purposes of this subpart.

(3) The owner or operator shall use the following procedures for each affected facility which uses a capture system and a control device that recovers the VOC (e.g., carbon adsorber) to comply with the applicable emission limit specified under §60.392.

(i) Calculate the mass of VOC (Mo Md) used during each calendar month for each affected facility as described under §60.393(c)(1)(i).

(ii) Calculate the total volume of coating solids (Ls) used in each calendar month for each affected facility as described under §60.393(c)(1)(i).

(iii) Calculate the mass of VOC recovered (Mr) each calendar month for each affected facility by the following equation: Mr = Lr Dr

(iv) Calculate the volume weighted average mass of VOC per volume of applied coating solids emitted after the control device during a calendar month by the following equation:

(v) If the volume weighted average mass of VOC per volume of applied solids emitted after the control device (N) calculated on a calendar month basis is less than or equal to the applicable emission limit specified in §60.392, the affected facility is in compliance. Each monthly calculation is a performance test for the purposes of this subpart.

[45 FR 85415, Dec. 24, 1980, as amended at 59 FR 51387, Oct. 11, 1994; 65 FR 61760, Oct. 17, 2000; 88 FR 30000, May 9, 2023]

§60.394 Monitoring of emissions and operations.

The owner or operator of an affected facility which uses an incinerator to comply with the emission limits specified under §60.392 shall install, calibrate, maintain, and operate temperature measurement devices as prescribed below:

(a) Where thermal incineration is used, a temperature measurement device shall be installed in the firebox. Where catalytic incineration is used, a temperature measurement device shall be installed in the gas stream immediately before and after the catalyst bed.

(b) Each temperature measurement device shall be installed, calibrated, and maintained according to accepted practice and the manufacturer's specifications. The device shall have an accuracy of the greater of ±5 percent of the temperature being measured expressed in degrees Celsius or ±2.5°C.

(c) Each temperature measurement device shall be equipped with a recording device so that a permanent record is produced.

§60.395 Reporting and recordkeeping requirements.

(a) Each owner or operator of an affected facility shall include the data outlined in paragraphs (a)(1) and (2) in the initial compliance report required by §60.8.

(1) The owner or operator shall report the volume weighted average mass of VOC per volume of applied coating solids for each affected facility.

(2) Where compliance is achieved through the use of incineration, the owner or operator shall include the following additional data in the control device initial performance test required by §60.8(a) or subsequent performance tests at which destruction efficiency is determined: the combustion temperature (or the gas temperature upstream and downstream of the catalyst bed), the total mass of VOC per volume of applied coating solids before and after the incinerator, capture efficiency, the destruction efficiency of the incinerator used to attain compliance with the applicable emission limit specified in §60.392 and a description of the method used to establish the fraction of VOC captured and sent to the control device.

(b) Following the initial performance test, the owner or operator of an affected facility shall identify, record, and submit a report to the Administrator every calendar quarter of each instance in which the volume-weighted average of the total mass of VOC's emitted to the atmosphere per volume of applied coating solids (N) is greater than the limit specified under §60.392. If no such instances have occurred during a particular quarter, a report stating this shall be submitted to the Administrator semiannually. Where compliance is achieved through the use of a capture system and control device, the volume-weighted average after the control device should be reported.

(c) Where compliance with §60.392 is achieved through the use of incineration, the owner or operator shall continuously record the incinerator combustion temperature during coating operations for thermal incineration or the gas temperature upstream and downstream of the incinerator catalyst bed during coating operations for catalytic incineration. The owner or operator shall submit a report at the frequency specified in §60.7(c) and paragraph (e) of this section.

(1) For thermal incinerators, every three-hour period shall be reported during which the average temperature measured is more than 28°C less than the average temperature during the most recent control device performance test at which the destruction efficiency was determined as specified under §60.393.

(2) For catalytic incinerators, every three-hour period shall be reported during which the average temperature immediately before the catalyst bed, when the coating system is operational, is more than 28°C less than the average temperature immediately before the catalyst bed during the most recent control device performance test at which destruction efficiency was determined as specified under §60.393. In addition, every three-hour period shall be reported each quarter during which the average temperature difference across the catalyst bed when the coating system is operational is less than 80 percent of the average temperature difference of the device during the most recent control device performance test at which destruction efficiency was determined as specified under §60.393.

(3) For thermal and catalytic incinerators, if no such periods occur, the owner or operator shall submit a negative report.

(d) The owner or operator shall notify the Administrator 30 days in advance of any test by Method 25.

(e) The owner or operator shall submit the reports listed in paragraphs (b) and (c) of this section following the procedures specified in paragraphs (e)(1) through (3) of this section. In addition to the information required in paragraphs (b) and (c) of this section, owners or operators are required to report excess emissions and a monitoring systems performance report and a summary report to the Administrator according to §60.7(c) and (d). Owners or operators are required by §60.7(c) and (d) to report the date, time, cause, and duration of each exceedance of the applicable emission limit specified in §60.392, any malfunction of the air pollution control equipment, and any periods during which the CMS or monitoring device is inoperative. For each failure, the report must include a list of the affected sources or equipment and a description of the method used to estimate the emissions.

(1) Effective date. On and after November 6, 2023, or once the reporting template has been available on the CEDRI website for 1-year, whichever date is later, owners or operators must use the appropriate spreadsheet template on the Compliance and Emissions Data Reporting Interface (CEDRI) website (https://www.epa.gov/electronic-reporting-air-emissions/cedri) for this subpart. The date the reporting template for this subpart becomes available will be listed on the CEDRI website. The report must be submitted by the deadline specified in this subpart, regardless of the method by which the report is submitted. Submit all reports to the EPA via CEDRI, which can be accessed through the EPA's CDX (https://cdx.epa.gov/). The EPA will make all the information submitted through CEDRI available to the public without further notice to the owner or operator. Do not use CEDRI to submit information you claim as CBI. Any information submitted using CEDRI cannot later be claimed CBI. If you claim CBI, submit the report following the procedure described in paragraph (f)(3) of this section. The same file with the CBI omitted must be submitted to CEDRI as described in paragraph (f)(3) of this section.

(2) System outage. Owner or operators that are required to submit a report electronically through CEDRI in the EPA's CDX, may assert a claim of EPA system outage for failure to timely comply with that reporting requirement. To assert a claim of EPA system outage, owners or operators must meet the requirements outlined in paragraphs (e)(2)(i) through (vii) of this section.

(i) You must have been or will be precluded from accessing CEDRI and submitting a required report within the time prescribed due to an outage of either the EPA's CEDRI or CDX systems.

(ii) The outage must have occurred within the period of time beginning five business days prior to the date that the submission is due.

(iii) The outage may be planned or unplanned.

(iv) You must submit notification to the Administrator in writing as soon as possible following the date you first knew, or through due diligence should have known, that the event may cause or has caused a delay in reporting.

(v) You must provide to the Administrator a written description identifying:

(A) The date(s) and time(s) when CDX or CEDRI was accessed, and the system was unavailable;

(B) A rationale for attributing the delay in reporting beyond the regulatory deadline to EPA system outage;

(C) A description of measures taken or to be taken to minimize the delay in reporting; and

(D) The date by which you propose to report, or if you have already met the reporting requirement at the time of the notification, the date you reported.

(vi) The decision to accept the claim of EPA system outage and allow an extension to the reporting deadline is solely within the discretion of the Administrator.

(vii) In any circumstance, the report must be submitted electronically as soon as possible after the outage is resolved.

(3) Force majeure. Owner or operators that are required to submit a report electronically through CEDRI in the EPA's CDX, may assert a claim of force majeure for failure to timely comply with that reporting requirement. To assert a claim of force majeure, Owner or operators must meet the requirements outlined in paragraphs (e)(1) through (5) of this section.

(i) You may submit a claim if a force majeure event is about to occur, occurs, or has occurred or there are lingering effects from such an event within the period of time beginning five business days prior to the date the submission is due. For the purposes of this section, a force majeure event is defined as an event that will be or has been caused by circumstances beyond the control of the affected facility, its contractors, or any entity controlled by the affected facility that prevents you from complying with the requirement to submit a report electronically within the time period prescribed. Examples of such events are acts of nature (e.g., hurricanes, earthquakes, or floods), acts of war or terrorism, or equipment failure or safety hazard beyond the control of the affected facility (e.g., large scale power outage).

(ii) You must submit notification to the Administrator in writing as soon as possible following the date you first knew, or through due diligence should have known, that the event may cause or has caused a delay in reporting.

(iii) You must provide to the Administrator:

(A) A written description of the force majeure event;

(B) A rationale for attributing the delay in reporting beyond the regulatory deadline to the force majeure event;

(C) A description of measures taken or to be taken to minimize the delay in reporting; and

(D) The date by which you propose to report, or if you have already met the reporting requirement at the time of the notification, the date you reported.

(iv) The decision to accept the claim of force majeure and allow an extension to the reporting deadline is solely within the discretion of the Administrator.

(f) Where compliance is achieved through the use of incineration, the owner or operator shall submit control device performance test results at which destruction efficiency is determined for initial and subsequent performance tests according to paragraph (a) of this section within 60 days of completing each performance test following the procedures specified in paragraphs (f)(1) through (3) of this section.

(1) Data collected using test methods supported by the EPA's Electronic Reporting Tool (ERT) as listed on the EPA's ERT website (https://www.epa.gov/electronic-reporting-air-emissions/electronic-reporting-tool-ert) at the time of the test.

(i) Submit the results of the performance test to the EPA via the CEDRI, which can be accessed through the EPA's Central Data Exchange (CDX) (https://cdx.epa.gov/).

(ii) The data must be submitted in a file format generated using the EPA's ERT. Alternatively, the owner or operator may submit an electronic file consistent with the extensible markup language (XML) schema listed on the EPA's ERT website.

(2) Data collected using test methods that are not supported by the EPA's ERT as listed on the EPA's ERT website at the time of the test.

(i) The results of the performance test must be included as an attachment in the ERT or an alternate electronic file consistent with the XML schema listed on the EPA's ERT website.

(ii) Submit the ERT generated package or alternative file to the EPA via CEDRI.

(3) Confidential business information (CBI). Do not use CEDRI to submit information you claim as CBI. Any information submitted using CEDRI cannot later be claimed CBI. Under CAA section 114(c), emissions data is not entitled to confidential treatment, and the EPA is required to make emissions data available to the public. Thus, emissions data will not be protected as CBI and will be made publicly available. Owners or operators that assert a CBI claim for any information submitted under paragraph (f)(1) or (2) of this section, must submit a complete file, including information claimed to be CBI, to the EPA. The file must be generated using the EPA's ERT or an alternate electronic file consistent with the XML schema listed on the EPA's ERT website. Owners or operators can submit CBI according to one of the two procedures in paragraph (f)(3)(i) or (ii) of this section. All CBI claims must be asserted at the time of submission.

(i) If sending CBI through the postal service, submit the file on a compact disc, flash drive, or other commonly used electronic storage medium and clearly mark the medium as CBI. Owners or operators are required to mail the electronic medium to U.S. EPA/OAQPS/CORE CBI Office, Attention: Automobile and Light Duty Truck Surface Coating Operations Sector Lead, MD C404–02, 4930 Old Page Rd., Durham, NC 27703. The same file with the CBI omitted must be submitted to the EPA via the EPA's CDX as described in paragraphs (f)(1) and (2) of this section.

(ii) The EPA preferred method for CBI submittal is for it to be transmitted electronically using email attachments, File Transfer Protocol (FTP), or other online file sharing services (e.g., Dropbox, OneDrive, Google Drive). Electronic submissions must be transmitted directly to the OAQPS CBI Office at the email address oaqpscbi@epa.gov, Attention: Automobile and Light Duty Truck Surface Coating Operations Sector Lead, and as described above, should be clearly identified as CBI. If assistance is needed with submitting large electronic files that exceed the file size limit for email attachments, and if you do not have your own file sharing service, you may email oaqpscbi@epa.gov to request a file transfer link.

[45 FR 85415, Dec. 24, 1980, as amended at 55 FR 51383, Dec. 13, 1990; 65 FR 61760, Oct. 17, 2000; 88 FR 30000, May 9, 2023]

§60.396 Reference methods and procedures.

(a) The reference methods in appendix A to this part, except as provided in §60.8 shall be used to conduct performance tests.

(1) Method 24 or an equivalent or alternative method approved by the Administrator shall be used for the determination of the data used in the calculation of the VOC content of the coatings used for each affected facility. Manufacturers' formulation data is approved by the Administrator as an alternative method to Method 24. In the event of dispute, Method 24 shall be the referee method.

(2) Method 25 or an equivalent or alternative method approved by the Administrator shall be used for the determination of the VOC concentration in the effluent gas entering and leaving the emission control device for each stack equipped with an emission control device and in the effluent gas leaving each stack not equipped with a control device.

(3) The following methods shall be used to determine the volumetric flow rate in the effluent gas in a stack:

(i) Method 1 for sample and velocity traverses,

(ii) Method 2 for velocity and volumetric flow rate,

(iii) Method 3 for gas analysis, and

(iv) Method 4 for stack gas moisture.

(b) For Method 24, the coating sample must be a 1-liter sample taken in a 1-liter container.

(c) For Method 25, the sampling time for each of three runs must be at least one hour. The minimum sample volume must be 0.003 dscm except that shorter sampling times or smaller volumes, when necessitated by process variables or other factors, may be approved by the Administrator. The Administrator will approve the sampling of representative stacks on a case-by-case basis if the owner or operator can demonstrate to the satisfaction of the Administrator that the testing of representative stacks would yield results comparable to those that would be obtained by testing all stacks.

[45 FR 85415, Dec. 24, 1980, as amended at 65 FR 61760, Oct. 17, 2000]

§60.397 Modifications.

The following physical or operational changes are not, by themselves, considered modifications of existing facilities:

(a) Changes as a result of model year changeovers or switches to larger cars.

(b) Changes in the application of the coatings to increase coating film thickness.

§60.398 Innovative technology waivers.

(a) General Motors Corporation, Wentzville, Missouri, automobile assembly plant. (1) Pursuant to section 111(j) of the Clean Air Act, 42 U.S.C. 7411(j), each topcoat operation at General Motors Corporation automobile assembly plant located in Wentzville, Missouri, shall comply with the following conditions:

(i) The General Motors Corporation shall obtain the necessary permits as required by section 173 of the Clean Air Act, as amended August 1977, to operate the Wentzville assembly plant.

(ii) Commencing on February 4, 1983, and continuing to December 31, 1986, or until the base coat/clear coat topcoat system that can achieve the standard specified in 40 CFR 60.392(c) (Dec. 24, 1980) is demonstrated to the Administrator's satisfaction the General Motors Corporation shall limit the discharge of VOC emissions to the atmosphere from each topcoat operation at the Wentzville, Missouri, assembly plant, to either:

(A) 1.9 kilograms of VOC per liter of applied coating solids from base coat/clear coat topcoats, and 1.47 kilograms of VOC per liter of applied coating solids from all other topcoat coatings; or

(B) 1.47 kilograms of VOC per liter of applied coating solids from all topcoat coatings.

(iii) Commencing on the day after the expiration of the period described in paragraph (a)(1)(ii) of this section, and continuing thereafter, emissions of VOC from each topcoat operations shall not exceed 1.47 kilograms of VOC per liter of applied coating solids as specified in 40 CFR 60.392(c) (Dec. 24, 1980).

(iv) Each topcoat operation shall comply with the provisions of §§60.393, 60.394, 60.395, 60.396, and 60.397. Separate calculations shall be made for base coat/clear coat coatings and all other topcoat coatings when necessary to demonstrate compliance with the emission limits in paragraph (a)(1)(ii)(A) of this section.

(v) A technology development report shall be sent to EPA Region VII, 324 East 11th Street, Kansas City, MO 64106, postmarked before 60 days after the promulgation of this waiver and annually thereafter while this waiver is in effect. The technology development report shall summarize the base coat/clear coat development work including the results of exposure and endurance tests of the various coatings being evaluated. The report shall include an updated schedule of attainment of 40 CFR 60.392(c) (Dec. 24, 1980) based on the most current information.

(2) This waiver shall be a federally promulgated standard of performance. As such, it shall be unlawful for General Motors Corporation to operate a topcoat operation in violation of the requirements established in this waiver. Violation of the terms and conditions of this waiver shall subject the General Motors Corporation to enforcement under section 113 (b) and (c), 42 U.S.C. 7412 (b) and (c), and section 120, 42 U.S.C. 7420, of the Act as well as possible citizen enforcement under section 304 of the Act, 42 U.S.C. 7604.

(b) General Motors Corporation, Detroit, Michigan, Automobile Assembly plant. (1) Pursuant to section 111(j) of the Clean Air Act, 42 U.S.C. 7411(j), each topcoat operation at General Motors Corporation's automobile assembly plant located in Detroit, MI, shall comply with the following conditions:

(i) The General Motors Corporation shall obtain the necessary permits as required by section 173 of the Clean Air Act, as amended August 1977, to operate the Detroit assembly plant.

(ii) Commencing on February 4, 1983, and continuing to December 31, 1986, or until the base coat/clear coat topcoat system that can achieve the standard specified in 40 CFR 60.392(c) (Dec. 24, 1980), is demonstrated to the Administrator's satisfaction, the General Motors Corporation shall limit the discharge of VOC emissions to the atmosphere from each topcoat operation at the Detroit, MI, assembly plant, to either:

(A) 1.9 kilograms of VOC per liter of applied coating solids from base coat/clear coat topcoats, and 1.47 kilograms of VOC per liter of applied coating solids from all other topcoat coatings; or

(B) 1.47 kilograms of VOC per liter of applied coating solids from all topcoat coatings.

(iii) Commencing on the day after the expiration of the period described in paragraph (b)(ii) of this section, and continuing thereafter, emissions of VOC from each topcoat operation shall not exceed 1.47 kilograms of VOC per liter of applied coating solids as specified in 40 CFR 60.392(c) (December 24, 1980).

(iv) Each topcoat operation shall comply with the provisions of §§60.393, 60.394, 60.395, 60.396, and 60.397. Separate calculations shall be made for base coat/clear coat coatings and all other topcoat coatings when necessary to demonstrate compliance with the emission limits in paragraph (b)(1)(ii)(A) of this section.

(v) A technology development report shall be sent to EPA Region V, 230 South Dearborn Street, Chicago, IL 60604, postmarked before 60 days after the promulgation of this waiver and annually thereafter while this waiver is in effect. The technology development report shall summarize the base coat/clear coat development work including the results of exposure and endurance tests of the various coatings being evaluated. The report shall include an updated schedule of attainment of 40 CFR 60.392(c) (Dec. 24, 1980) based on the most current information.

(2) This waiver shall be a federally promulgated standard of performance. As such, it shall be unlawful for General Motors Corporation to operate a topcoat operation in violation of the requirements established in this waiver. Violation of the terms and conditions of this waiver shall subject the General Motors Corporation to enforcement under section 113 (b) and (c), 42 U.S.C. 7412 (b) and (c), and section 120, 42 U.S.C. 7420, of the Act as well as possible citizen enforcement under section 304 of the Act, 42 U.S.C. 7604.

(c) General Motors Corporation, Orion Township, MI, automobile assembly plant. (1) Pursuant to section 111(j) of the Clean Air Act, 42 U.S.C. 7411(j), each topcoat operation at General Motors Corporation automobile assembly plant located in Orion Township, MI, shall comply with the following conditions:

(i) The General Motors Corporation shall obtain the necessary permits as required by section 173 of the Clean Air Act, as amended August 1977, to operate the Orion Township assembly plant.

(ii) Commencing on February 4, 1983, and continuing to December 31, 1986, or until the base coat/clear coat topcoat system that can achieve the standard specified in 40 CFR 60.392(c) (Dec. 24, 1980) is demonstrated to the Administrator's satisfaction, the General Motors Corporation shall limit the discharge of VOC emissions to the atmosphere from each topcoat operation at the Orion Township, MI, assembly plant, to either:

(A) 1.9 kilograms of VOC per liter of applied coating solids from base coat/clear coat topcoats, and 1.47 kilograms of VOC per liter of applied coating solids from all other topcoat coatings; or

(B) 1.47 kilograms of VOC per liter of applied coating solids from all topcoat coatings.

(iii) Commencing on the day after the expiration of the period described in paragraph (c)(l)(ii) of this section and continuing thereafter, emissions of VOC from each topcoat operation shall not exceed 1.47 kilograms of VOC per liter of applied coating solids as specified in 40 CFR 60.392(c) (Dec. 24, 1980).

(iv) Each topcoat operation shall comply with the provisions of §§60.393, 60.394, 60.395, 60.396, and 60.397. Separate calculations shall be made for base coat/clear coat coatings and all other topcoat coatings when necessary to demonstrate compliance with the emission limits in paragraph (c)(l) (ii)(A) of this section.

(v) A technology development report shall be sent to EPA Region V, 230 South Dearborn Street, Chicago, IL 60604, postmarked before 60 days after the promulgation of this waiver and annually thereafter while this waiver is in effect. The technology development report shall summarize the base coat/clear coat development work including the results of exposure and endurance tests of the various coatings being evaluated. The report shall include an updated schedule of attainment of 40 CFR 60.392(c) (December 24, 1980) based on the most current information.

(2) This waiver shall be a federally promulgated standard of performance. As such, it shall be unlawful for General Motors Corporation to operate a topcoat operation in violation of the requirements established in this waiver. Violation of the terms and conditions of this waiver shall subject the General Motors Corporation to enforcement under section 113 (b) and (c), 42 U.S.C. 7412 (b) and (c), and section 120, 42 U.S.C. 7420, of the Act as well as possible citizen enforcement under section 304 of the Act, 42 U.S.C. 7604.

(d) Honda of America Manufacturing, Incorporated (Honda), Marysville, Ohio, automobile assembly plant. (1) Pursuant to section 111(j) of the Clean Air Act, 42 U.S.C. 7411(j), each topcoat operation at Honda's automobile assembly plant located in Marysville, OH, shall comply with the following conditions:

(i) Honda shall obtain the necessary permits as required by section 173 of the Clean Air Act, as amended August 1977, to operate the Marysville assembly plant.

(ii) Commencing on February 4, 1983, and continuing for 4 years or to December 31, 1986, whichever is sooner, or until the base coat/clear coat topcoat system that can achieve the standard specified in 40 CFR 60.392(c) (Dec. 24, 1980) is demonstrated to the Administrator's satisfaction, Honda shall limit the discharge of VOC emissions to the atmosphere from each topcoat operation at Marysville, OH, assembly plant, to either:

(A) 3.1 kilograms of VOC per liter of applied coating solids from base coat/clear coat topcoats, and 1.47 kilograms of VOC per liter of applied coating solids from all other topcoat coatings; or

(B) 1.47 kilograms of VOC per liter of applied coating solids from all topcoat coatings.

(iii) Commencing on the day after the expiration of the period described in paragraph (d)(1)(ii) of this section and continuing thereafter, emissions of VOC from each topcoat operation shall not exceed 1.47 kilograms of VOC per liter of applied coating solids as specified in 40 CFR 60.392(c) (December 24, 1980).

(iv) Each topcoat operation shall comply with the provisions of §§60.393, 60.394, 60.395, 60.396, and 60.397. Separate calculations shall be made for base coat/clear coat coatings and all other topcoat coatings when necessary to demonstrate compliance with the emission limits in paragraph (d)(1)(ii)(A) of this section.

(v) A technology development report shall be sent to EPA Region V, 230 South Dearborn Street, Chicago, IL 60604, postmarked before 60 days after the promulgation of this waiver and annually thereafter while this waiver is in effect. The technology development report shall summarize the base coat/clear coat development work including the results of exposure and endurance tests of the various coatings being evaluated. The report shall include an updated schedule of attainment of 40 CFR 60.392(c) (Dec. 24, 1980) based on the most current information.

(2) This waiver shall be a federally promulgated standard of performance. As such, it shall be unlawful for Honda to operate a topcoat operation in violation of the requirements established in this waiver. Violation of the terms and conditions of this waiver shall subject Honda to enforcement under section 113(b) and (c), 42 U.S.C. 7412(b) and (c), and section 120, 42 U.S.C. 7420, of the Act as well as possible citizen enforcement under section 304 of the Act, 42 U.S.C. 7604.

(e) Nissan Motor Manufacturing Corporation, U.S.A. (Nissan), Smyrna, TN, light-duty truck assembly plant. (1) Pursuant to section 111(j) of the Clean Air Act, 42 U.S.C. 7411(j), each topcoat operation at Nissan's light-duty truck assembly plant located in Smyrna, Tennessee, shall comply with the following conditions:

(i) Nissan shall obtain the necessary permits as required by section 173 of the Clean Air Act, as amended August 1977, to operate the Smyrna assembly plant.

(ii) Commencing on February 4, 1983, and continuing for 4 years or to December 31, 1986, whichever is sooner, or until the base coat/clear coat topcoat system that can achieve the standard specified in 40 CFR 60.392(c) (Dec. 24, 1980), is demonstrated to the Administrator's satisfaction, Nissan shall limit the discharge of VOC emissions to the atmosphere from each topcoat operation at the Smyrna, TN, assembly plant, to either:

(A) 2.3 kilograms of VOC per liter of applied coating solids from base coat/clear coat topcoats, and 1.47 kilograms of VOC per liter of applied coating solids from all other topcoat coatings; or

(B) 1.47 kilograms of VOC per liter of applied coating solids from all topcoat coatings.

(iii) Commencing on the day after the expiration of the period described in paragraph (e)(1)(ii) of this section and continuing thereafter, emissions of VOC from each topcoat operation shall not exceed 1.47 kilograms of VOC per liter of applied coating solids as specified in 40 CFR 60.392(c) (Dec. 24, 1980).

Each topcoat operation shall comply with the provisions of §§60.393, 60.394, 60.395, 60.396, and 60.397. Separate calculations shall be made for base coat/clear coat coatings and all other topcoat coatings when necessary to demonstrate compliance with the emission limits in paragraph (e)(1)(ii)(A) of this section.

(f) Chrysler Corporation, Sterling Heights, MI, automobile assembly plant. (1) Pursuant to section 111(j) of the Clean Air Act, 42 U.S.C. 7411(j), each topcoat operation at Chrysler Corporation's automobile assembly plant located in Sterling Heights, MI, shall comply with the following conditions:

(i) The Chrysler Corporation shall obtain the necessary permits as required under Parts C and D of the Clean Air Act, as amended August 1977, to operate the Sterling Heights assembly plant.

(ii) Commencing on September 9, 1985, and continuing to December 31, 1986, or until the basecoat/clearcoat (BC/CC) topcoat system that can achieve the standard specified under §60.392(c) of this subpart is demonstrated to the Administrator's satisfaction, whichever is sooner, the Chrysler Corporation shall limit the discharge of VOC emissions to the atmosphere from each topcoat operation at the Sterling Heights, MI assembly plant, to either:

(A) 1.7 kilograms of VOC per liter of applied coating solids from BC/CC topcoats, and 1.47 kilograms of VOC per liter of applied coating solids from all other topcoat coatings; or

(B) 1.47 kilograms of VOC per liter of applied coating solids from all topcoat coatings.

(iii) Commencing on the day after the expiration of the period described in paragraph (f)(1)(ii) and continuing thereafter, emissions of VOC's from each topcoat operation shall not exceed 1.47 kilograms of VOC per liter of applied coating solids as specified under §60.392(c) of this subpart.

(iv) Each topcoat operation shall comply with the provisions of §§60.393, 60.394, 60.395, 60.396, and 60.397. Separate calculations shall be made for BC/CC coatings and all other topcoat coatings when necessary to demonstrate compliance with the emission limits specified under paragraph (f)(1)(ii)(A) of this section.

(v) A technology development report shall be sent to EPA Region V, 230 South Dearborn Street, Chicago, IL 60604, postmarked before 60 days after the promulgation of this waiver and annually thereafter while this waiver is in effect. A copy of this report shall be sent to Director, Emission Standards and Engineering Division, U.S. Environmental Protection Agency, MD-13, Research Triangle Park, NC 27711. The technology development report shall summarize the BC/CC development work including the results of exposure and endurance tests of the various coatings being evaluated. The report shall include an updated schedule of attainment of §60.392(c) of this subpart, based on the most current information.

(2) This waiver shall be a federally promulgated standard of performance. As such, it shall be unlawful for the Chrysler Corporation to operate a topcoat operation in violation of the requirements established in this waiver. Violation of the terms and conditions of this waiver shall subject the Chrysler Corporation to enforcement under sections 113 (b) and (c) of the Act (42 U.S.C. 7412 (b) and (c)) and under section 120 of the Act (42 U.S.C. 7420), as well as possible citizen enforcement under section 304 of the Act (42 U.S.C. 7604).

(3) This waiver shall not be construed to constrain the State of Michigan from imposing upon the Chrysler Corporation any emission reduction requirement at Chrysler's Sterling Heights automobile assembly plant necessary for the maintenance of reasonable further progress or the attainment of the national ambient air quality standard for ozone or the maintenance of the national ambient air quality standard for ozone. Furthermore, this waiver shall not be construed as granting any exemptions from the applicability, enforcement, or other provisions of any other standards that apply or may apply to topcoat operations or any other operations at this automobile assembly plant.

(g) Ford Motor Company, Hapeville, GA, automotive assemply plant. (1) Pursuant to section 111(j) of the Clean Air Act, 42 U.S.C. 7411(j), each topcoat operation at Ford Motor Company's automobile assembly plant located in Hapeville, GA, shall comply with the following conditions:

(i) The Ford Motor Company shall obtain the necessary permits as required under parts C and D of the Clean Air Act, as amended August 1977, to operate the Hapeville assembly plant.

(ii) Commencing on September 9, 1985, and continuing to December 31, 1986, or until the basecoat/clearcoat (BC/CC) topcoat system that can achieve the standard specified under §60.392(c) of this subpart is demonstrated to the Administrator's satisfaction, whichever is sooner, the Ford Motor Company shall limit the discharge of VOC emissions to the atmosphere from each topcoat operation at the Hapeville, GA, assembly plant, to either:

(A) 2.6 kilograms of VOC per liter of applied coating solids from BC/CC topcoats, and 1.47 kilograms of VOC per liter of applied coating solids from all other topcoat coatings; or

(B) 1.47 kilograms of VOC per liter of applied coating solids from all topcoat coatings.

(iii) Commencing on the day after the expiration of the period described in paragraph (g)(1)(ii) and continuing thereafter, emissions of VOC's from each topcoat operation shall not exceed 1.47 kilograms of VOC per liter of applied coating solids as specified under §60.392(c) of this subpart.

(iv) Each topcoat operation shall comply with the provisions of §§60.393, 60.394, 60.395, 60.396, and 60.397. Separate calculations shall be made for BC/CC coatings and all other topcoat coatings when necessary to demonstrate compliance with the emission limits specified under paragraph (g)(1)(ii)(A) of this section.

(v) A technology development report shall be sent to EPA Region IV, 345 Courtland Street, NE., Atlanta, GA 30365, postmarked before 60 days after the promulgation of this waiver and annually thereafter while this waiver is in effect. A copy of this report shall be sent to Director, Emission Standards and Engineering Division, U.S. Environmental Protection Agency, MD-13, Research Triangle Park, NC 27711. The technology development report shall summarize the BC/CC development work including the results of exposure and endurance tests of the various coatings being evaluated. The report shall include an updated schedule of attainment of §60.392(c) of this subpart, based on the most current information.

(2) This waiver shall be a federally promulgated standard of performance. As such, it shall be unlawful for the Ford Motor Company to operate a topcoat operation in violation of the requirements established in this waiver. Violation of the terms and conditions of this waiver shall subject the Ford Motor Company to enforcement under section 113 (b) and (c) and the Act (42 U.S.C. 7412 (b) and (c)) and under section 120 of the Act (42 U.S.C. 7420), as well as possible citizen enforcement under section 304 of the Act (42 U.S.C. 7604).

(3) This waiver shall not be construed to constrain the State of Georgia from imposing upon the Ford Motor Corporation any emission reduction requirement at Ford's Hapeville automobile assembly plant necessary for the maintenance of reasonable further progress or the attainment of the national ambient air quality standard for ozone or the maintenance of the national ambient air quality standard for ozone. Furthermore, this waiver shall not be construed as granting any exemptions from the applicability, enforcement, or other provisions of any other standards that apply or may apply to topcoat operations or any other operations at this automobile assembly plant.

(h) Ford Motor Company, St. Paul, MN, light-duty truck assembly plant. (1) Pursuant to section 111(j) of the Clean Air Act, 42 U.S.C. 7411(j), each topcoat operation at Ford Motor Company's automobile assembly plant located in St. Paul, MN, shall comply with the following conditions:

(i) The Ford Motor Company shall obtain the necessary permits as required under parts C and D of the Clean Air Act, as amended August 1977, to operate the St. Paul assembly plant.

(ii) Commencing on September 9, 1985, and continuing to December 31, 1986, or until the basecoat/clearcoat (BC/CC) topcoat system that can achieve the standard specified under §60.392(c) of this subpart, is demonstrated to the Administrator's satisfaction, whichever is sooner, the Ford Motor Company shall limit the discharge of VOC emissions to the atmosphere from each topcoat operation at the St. Paul, MN, assembly plant, to either:

(A) 2.0 kilograms of VOC per liter of applied coating solids from BC/CC topcoats, and 1.47 kilograms of VOC per liter of applied coating solids from all other topcoat coatings; or

(B) 1.47 kilograms of VOC per liter of applied coating solids from all topcoat coatings.

(iii) Commencing on the day after the expiration of the period described in paragraph (h)(1)(ii) and continuing thereafter, emissions of VOC's from each topcoat operation shall not exceed 1.47 kilograms of VOC per liter of applied coating solids as specified under §60.392(c) of this subpart.

(iv) Each topcoat operation shall comply with the provisions of §§60.393, 60.394, 60.395, 60.396, and 60.397. Separate calculations shall be made for BC/CC coatings and all other topcoat coatings when necessary to demonstrate compliance with the emission limits specified under paragraph (h)(1)(ii)(A) of this section.

(v) A technology development report shall be sent to EPA Region V, 230 South Dearborn Street, Chicago, IL 60604, postmarked before 60 days after the promulgation of this waiver and annually thereafter while this waiver is in effect. A copy of this report shall be sent to Director, Emission Standards and Engineering Division, U.S. Environmental Protection Agency, MD-13, Research Triangle Park, NC 27711. The technology development report shall summarize the BC/CC development work including the results of exposure and endurance tests of the various coatings being evaluated. The report shall include an updated schedule of attainment of §60.392(c) of this subpart, based on the most current information.

(2) This waiver shall be a federally promulgated standard of performance. As such, it shall be unlawful for the Ford Motor Company to operate a topcoat operation in violation of the requirements established in this waiver. Violation of the terms and conditions of this wavier shall subject the Ford Motor Company to enforcement under section 113 (b) and (c) of the Act (42 U.S.C. 7412 (b) and (c)) and under section 120 of the Act (42 U.S.C. 7420), as well as possible citizen enforcement under section 304 of the Act (42 U.S.C. 7604).

(3) This waiver shall not be construed to constrain the State of Minnesota from imposing upon the Ford Motor Corporation any emission reduction requirements at Ford's St. Paul light-duty truck assembly plant necessary for the maintenance of reasonable further progress or the attainment of the national ambient air quality standard for ozone or the maintenance of the national ambient air quality standard for ozone. Furthermore, this waiver shall not be construed as granting any exemptions from the applicability, enforcement, or other provisions of any other standards that apply or may apply to topcoat operations or any other operations at this light-duty truck assembly plant.

(i) Ford Motor Company, Hazelwood, MO, passenger van assembly plant. (1) Pursuant to section 111(j) of the Clean Air Act, 42 U.S.C. 7411(j), each topcoat operation at Ford Motor Company's passenger van assembly plant located in Hazelwood, MO, shall comply with the following conditions:

(i) The Ford Motor Company shall obtain the necessary permits as required under parts C and D of the Clean Air Act, as amended August 1977, to operate the Hazelwood assembly plant.

(ii) Commencing on September 9, 1985, and continuing to December 31, 1986, or until the basecoat/clearcoat (BC/CC) topcoat system that can achieve the standard specified under §60.392(c) of this subpart is demonstrated to the Administrator's satisfaction, whichever is sooner, the Ford Motor Company shall limit the discharge of VOC emissions to the atmosphere from each topcoat operation at the Hazelwood, MO, assembly plant, to either:

(A) 2.5 kilograms of VOC per liter of applied coating solids from BC/CC topcoats, and 1.47 kilograms of VOC per liter of applied coating solids from all other topcoat coatings; or

(B) 1.47 kilograms of VOC per liter of applied coating solids from all topcoat coatings.

(iii) Commencing on the day after the expiration of the period described in paragraph (i)(1)(ii) and continuing thereafter, emissions of VOC's from each topcoat operation shall not exceed 1.47 kilograms of VOC per liter of applied coating solids as specified under §60.392(c) of this subpart.

(iv) Each topcoat operation shall comply with the provisions of §§60.393, 60.394, 60.395, 60.396, and 60.397. Separate calculations shall be made for BC/CC coatings and all other topcoat coatings when necessary to demonstrate compliance with the emission limits specified under paragraph (i)(1)(ii)(A) of this section.

(v) A technology development report shall be sent to EPA Region VII, 726 Minnesota Avenue, Kansas City, KS 61101, postmarked before 60 days after the promulgation of this waiver and annually thereafter while this waiver is in effect. A copy of this report shall be sent to Director, Emission Standards and Engineering Division, U.S. Environmental Protection Agency, MD-13, Research Triangle Park, NC 27711. The technology development report shall summarize the BC/CC development work including the results of exposure and endurance tests of the various coatings being evaluated. The report shall include an updated schedule of attainment of §60.392(c) of this subpart, based on the most current information.

(2) This waiver shall be a federally promulgated standard of performance. As such, it shall be unlawful for the Ford Motor Company to operate a topcoat operation in violation of the requirements established in this waiver. Violation of the terms and conditions of this waiver shall subject the Ford Motor Company to enforcement under section 113 (b) and (c) of the Act (42 U.S.C. 7412 (b) and (c)) and under section 120 of the Act (42 U.S.C. 7420), as well as possible citizen enforcement under section 304 of the Act (42 U.S.C. 7604).

(3) This waiver shall not be construed to constrain the State of Missouri from imposing upon the Ford Motor Corporation any emission reduction at Ford's Hazelwood passenger van assembly plant necessary for the maintenance of reasonable further progress or the attainment of the national ambient air quality standards for ozone or the maintenance of the national ambient air quality standard for ozone. Furthermore, this waiver shall not be construed as granting any exemptions from the applicability, enforcement, or other provisions of any other standards that apply or may apply to topcoat operations or any other operations at this passenger van assembly plant.

[48 FR 5454, Feb. 4, 1983, as amended at 50 FR 36834, Sept. 9, 1985]

['Air Programs']

['Air Quality']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.