['Air Programs']

['Greenhouse Gases']

05/22/2023

...

(a) For all manure management system components listed in 98.360(b) except digesters, estimate the annual CH4 emissions and sum for all the components to obtain total emissions from the manure management system for all animal types using Equation JJ–1.

Where:

MMSC = Manure management systems component.

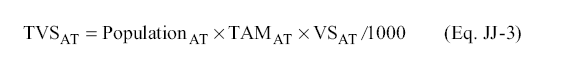

TVSAT = Total volatile solids excreted by animal type, calculated using Equation JJ–3 of this section (kg/day).

VSMMSC = Fraction of the total manure for each animal type that is managed in MMS component MMSC, assumed to be equivalent to the fraction of VS in each MMS component.

VSss = Volatile solids removal through solid separation; if solid separation occurs prior to the MMS component, use a default value from Table JJ–4 of this section; if no solid separation occurs, this value is set to 0.

(B0)AT = Maximum CH4-producing capacity for each animal type, as specified in Table JJ–2 of this section (m3 CH4/kg VS).

MCFMMSC = CH4 conversion factor for the MMS component, as specified in Table JJ–5 of this section (decimal).

Where:

TVSAT = Daily total volatile solids excreted per animal type (kg/day).

PopulationAT = Average annual animal population contributing manure to the manure management system by animal type (head) (see description in §98.363(a)(i) and (ii) below).

TAMAT = Typical animal mass for each animal type, using either default values in Table JJ–2 of this section or farm-specific data (kg/head).

VSAT = Volatile solids excretion rate for each animal type, using default values in Table JJ–2 or JJ–3 of this section (kg VS/day/1000 kg animal mass).

(1) Average annual animal populations for static populations (e.g., dairy cows, breeding swine, layers) must be estimated by performing an animal inventory or review of facility records once each reporting year.

(2) Average annual animal populations for growing populations (meat animals such as beef and veal cattle, market swine, broilers, and turkeys) must be estimated each year using the average number of days each animal is kept at the facility and the number of animals produced annually, and an equation similar or equal to Equation JJ–4 below, adapted from Equation 10.1 in 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Volume 4, Chapter 10.

Where:

PopulationAT = Average annual animal population (by animal type).

Days onsiteAT = Average number of days the animal is kept at the facility, by animal type.

NAPAAT = Number of animals produced annually, by animal type.

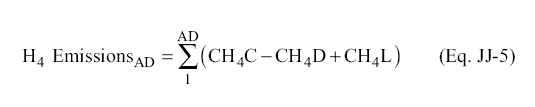

(b) For each digester, calculate the total amount of CH4 emissions, and then sum the emissions from all digesters, as shown in Equation JJ–5 of this section.

Where:

CH4 EmissionsAD = CH4 emissions from anaerobic digestion (metric tons/yr).

AD = Number of anaerobic digesters at the manure management facility.

CH4C = CH4 flow to digester combustion device, calculated using Equation JJ–6 of this section (metric tons CH4/yr).

CH4D = CH4 destruction at digesters, calculated using Equation JJ–11 of this section (metric tons CH4/yr) .

CH4L = Leakage at digesters calculated using Equation JJ–12 of this section (metric tons CH4/yr).

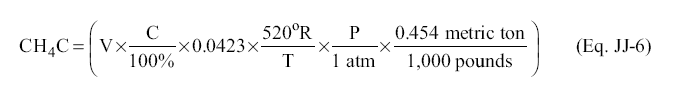

(1) For each digester, calculate the annual CH4 flow to the combustion device (CH4C) using Equation JJ–6 of this section. A fully integrated system that directly reports the quantity of CH4 flow to the digester combustion device requires only summing the results of all monitoring periods for a given year to obtain CH4C.

Where:

CH4C = CH4 flow to digester combustion device (metric tons CH4/yr).

V = Average annual volumetric flow rate, calculated in Equation JJ–7 of this subsection (cubic feet CH4/yr).

C = Average annual CH4 concentration of digester gas, calculated in Equation JJ–8 of this section (%, wet basis).

0.0423 = Density of CH4 lb/scf (at 520 °R or 60 °F and 1 atm).

T = Average annual temperature at which flow is measured, calculated in Equation JJ–9 of this section (°R).

P = Average annual pressure at which flow is measured, calculated in Equation JJ–10 of this section (atm).

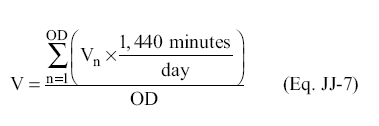

(2) For each digester, calculate the average annual volumetric flow rate, CH4 concentration of digester gas, temperature, and pressure at which flow are measured using Equations JJ–7 through JJ–10 of this section.

Where:

V = Average annual volumetric flow rate (cubic feet CH4/yr).

OD = Operating days, number of days per year that that the digester was operating (days/yr).

Vn = Daily average volumetric flow rate for day n, as determined from daily monitoring as specified in §98.364 (acfm).

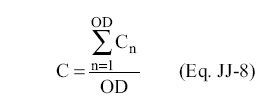

Where:

C = Average annual CH4 concentration of digester gas (%, wet basis).

OD = Operating days, number of days per year that the digester was operating (days/yr).

Cn = Average daily CH4 concentration of digester gas for day n, as determined from daily monitoring as specified in §98.364 (%, wet basis).

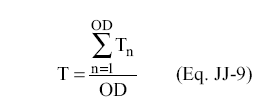

Where:

T = Average annual temperature at which flow is measured (°R).

OD = Operating days, number of days per year that the digester was operating (days/yr).

Tn = Temperature at which flow is measured for day n(°R).

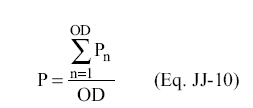

Where:

P = Average annual pressure at which flow is measured (atm).

OD = Operating days, number of days per year that the digester was operating (days/yr).

Pn = Pressure at which flow is measured for day n (atm).

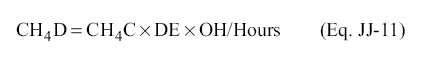

(3) For each digester, calculate the CH4 destruction at the digester combustion device using Equation JJ–11 of this section.

Where:

CH4D = CH4 destruction at digester combustion device (metric tons/yr).

CH4C = Annual quantity of CH4 flow to digester combustion device, as calculated in Equation JJ–6 of this section (metric tons CH4).

DE = CH4 destruction efficiency from flaring or burning in engine (lesser of manufacturer’s specified destruction efficiency and 0.99). If the gas is transported off-site for destruction, use DE = 1.

OH = Number of hours combustion device is functioning in reporting year.

Hours = Hours in reporting year.

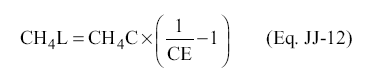

(4) For each digester, calculate the CH4 leakage using Equation JJ–12 of this section.

Where:

CH4L = Leakage at digesters (metric tons/yr).

CH4C = Annual quantity of CH4 flow to digester combustion device, as calculated in Equation JJ–6 of this section (metric tons CH4).

CE = CH4 collection efficiency of anaerobic digester, as specified in Table JJ–6 of this section (decimal).

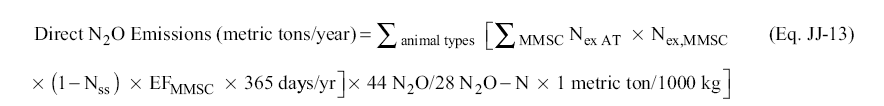

(c) For each MMS component, estimate the annual N2O emissions and sum for all MMS components to obtain total emissions from the manure management system for all animal types using Equation JJ–13 of this section.

Where:

Nex AT = Daily total nitrogen excreted per animal type, calculated using Equation JJ–14 of this section (kg N/day).

Nex,MMSC = Fraction of the total manure for each animal type that is managed in MMS component MMSC, assumed to be equivalent to the fraction of Nex in each MMS component.

Nss = Nitrogen removal through solid separation; if solid separation occurs prior to the MMS component, use a default value from Table JJ–4 of this section; if no solid separation occurs, this value is set to 0.

EFMMSC = Emission factor for MMS component, as specified in Table JJ–7 of this section (kg N2O-N/kg N).

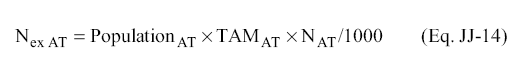

Where:

Nex AT = Total nitrogen excreted per animal type (kg/day).

PopulationAT = Average annual animal population contributing manure to the manure management system by animal type (head) (see description in §98.363(a)(i) and (ii)).

TAMAT = Typical animal mass by animal type, using either default values in Table JJ–2 of this section or farm-specific data (kg/head).

NAT = Nitrogen excretion rate by animal type, using default values in Tables JJ–2 or JJ–3 of this section (kg N/day/1000 kg animal mass).

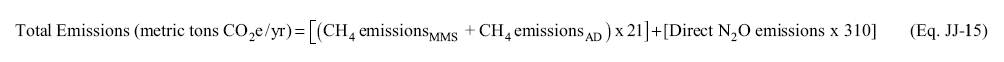

(d) Estimate the annual total facility emissions using Equation JJ–15 of this section.

Where:

CH4 emissionsMMS = From Equation JJ–2 of this section.

CH4 emissionsAD = From Equation JJ–5 of this section.

21 = Global Warming Potential of CH4.

Direct N2O emissions = From Equation JJ–13 of this section.

310 = Global Warming Potential of N2O.

[74 FR 56481 Oct. 30, 2009]

['Air Programs']

['Greenhouse Gases']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.