['Air Programs']

['Greenhouse Gases']

05/22/2023

...

You must calculate and report the annual process CO2 emissions from each soda ash manufacturing line using the procedures specified in paragraph (a) or (b) of this section.

(a) For each soda ash manufacturing line that meets the conditions specified in §98.33(b)(4)(ii) or (b)(4)(iii), you must calculate and report under this subpart the combined process and combustion CO2 emissions by operating and maintaining a CEMS to measure CO2 emissions according to the Tier 4 Calculation Methodology specified in §98.33(a)(4) and all associated requirements for Tier 4 in subpart C of this part (General Stationary Fuel Combustion Sources).

(b) For each soda ash manufacturing line that is not subject to the requirements in paragraph (a) of this section, calculate and report the process CO2 emissions from the soda ash manufacturing line by using the procedure in either paragraphs (b)(1), (b)(2), or (b)(3) of this section; and the combustion CO2 emissions using the procedure in paragraph (b)(4) of this section.

(1) Calculate and report under this subpart the combined process and combustion CO2 emissions by operating and maintaining a CEMS to measure CO2 emissions according to the Tier 4 Calculation Methodology specified in §98.33(a)(4) and all associated requirements for Tier 4 in subpart C of this part (General Stationary Fuel Combustion Sources).

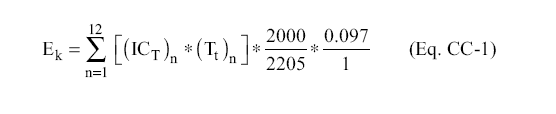

(2) Use either Equation CC–1 or Equation CC–2 of this section to calculate annual CO2 process emissions from each manufacturing line that calcines trona to produce soda ash:

Where: Ek = Annual CO2 process emissions for each manufacturing line, k (metric tons).

ICT)n = Inorganic carbon content (percent by weight, expressed as a decimal fraction) in trona input, from the carbon analysis results for month n. This represents the ratio of trona to trona ore.

(ICsa)n = Inorganic carbon content (percent by weight, expressed as a decimal fraction) in soda ash output, from the carbon analysis results for month n. This represents the purity of the soda ash produced.

(Tt)n = Mass of trona input in month n (tons).

(Tsa)n = Mass of soda ash output in month n (tons).

2000/2205 = Conversion factor to convert tons to metric tons.

0.097/1 = Ratio of ton of CO2 emitted for each ton of trona.

0.138/1 = Ratio of ton of CO2 emitted for each ton of soda ash produced.

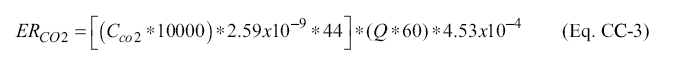

(b)(3) Site-specific emission factor method. Use Equations CC–3, CC–4, and CC–5 of this section to determine annual CO2 process emissions from manufacturing lines that use the liquid alkaline feedstock process to produce soda ash. You must conduct an annual performance test and measure CO2 emissions and flow rates at all process vents from the mine water stripper/ evaporator for each manufacturing line and calculate CO2 emissions as described in paragraphs (b)(3)(i) through (b)(3)(iv) of this section.

(i) During the performance test, you must measure the process vent flow from each process vent during the test and calculate the average rate for the test period in metric tons per hour.

(ii) Using the test data, you must calculate the hourly CO2 emission rate using Equation CC–3 of this section:

Where:

ERCO2 = CO2 mass emission rate (metric tons/hour).

CCO2 = Hourly CO2 concentration (percent CO2) as determined by §98.294(c).

10000 = Parts per million per percent

2.59 x 10- 9 = Conversion factor (poundsmole/dscf/ppm).

44 = Pounds per pound-mole of carbon dioxide.

Q = Stack gas volumetric flow rate per minute (dscfm).

60 = Minutes per hour

4.53 × 10 -4 = Conversion factor (metric tons/ pound)

(iii) Using the test data, you must calculate a CO2 emission factor for the process using Equation CC–4 of this section:

Where:

EFCO2 = CO2 emission factor (metric tons CO2/metric ton of process vent flow from mine water stripper/evaporator).

ERCO2 = CO2 mass emission rate (metric tons/hour).

Vt = Process vent flow rate from mine water stripper/evaporator during annual performance test (pounds/hour).

4.53 × 10-4 = Conversion factor (metric tons/pound)

(iv) You must calculate annual CO2 process emissions from each manufacturing linline using Equation CC–5 of this section:

Where:

Ek = Annual CO2 process emissions for each manufacturing line, k (metric tons).

EFCO2 = CO2 emission factor (metric tons CO2/metric ton of process vent flow from mine water stripper/evaporator).

Va = Annual process vent flow rate from mine water stripper/evaporator (thousand pounds/hour).

H = Annual operating hours for the each manufacturing line.

0.453 = Conversion factor (metric tons/thousand pounds).

(4) Calculate and report under subpart C of this part (General Stationary Fuel Combustion Sources) the combustion CO2, CH4, and N2O emissions in the soda ash manufacturing line according to the applicable requirements in subpart C.

[74 FR 56468 Oct. 30, 2009]

['Air Programs']

['Greenhouse Gases']

UPGRADE TO CONTINUE READING

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2026 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.